Minarik Drives MM23xx1C Series Users Manual

An American Control Electronics Brand

MM23xx1C Series

USER MANUAL

MM23001C

MM23001C-Q

MM23011C

MM23011C-Q

MM23101C

MM23111C

MM23201C

MM23211C

MM23401C

MM23411C

Dear Valued Consumer:

Congratulaons on your purchase of the MM23xx1C Series

drive. This User Manual was created for you to get the most out

of your new device and assist with the inial setup. Please visit

www.minarikdrives.com to learn more about our other drives.

Thank you for choosing Minarik Drives!

No part of this document may be reproduced or transmied in any form without wrien permission

from American Control Electronics®. The informaon and technical data in this document are

subject to change without noce. American Control Electronics® makes no warranty of any kind with

respect to this material, including, but not limited to, the implied warranes of its merchantability

and tness for a given purpose. American Control Electronics® assumes no responsibility for any

errors that may appear in this document and makes no commitment to update or to keep current

the informaon in this document.

MM23xx1C Series

Safety First!

SAFETY WARNINGS

Text in gray boxes denote important safety ps or warnings.

Please read these instrucons carefully before performing any of

!

• DO NOT INSTALL, REMOVE, OR REWIRE THIS EQUIPMENT WITH

• Reduce the chance of an electrical fire, shock, or explosion by using

the procedures contained in this manual.

WARNING!

POWER APPLIED. Have a qualified electrical technician install, adjust

and service this equipment. Follow the National Electrical Code

and all other applicable electrical and safety codes, including the

provisions of the Occupational Safety and Health Act (OSHA), when

installing equipment.

proper grounding techniques, over-current protection, thermal

protection, and enclosure. Follow sound maintenance procedures.

It is possible for a drive to run at full speed as a result of a

component failure. Minarik Drives strongly recommends the

!

installaon of a master switch in the main power input to stop

WARNING!

the drive in an emergency.

Circuit potenals are at 115 VAC or 230 VAC above earth ground.

Avoid direct contact with the printed circuit board or with circuit

elements to prevent the risk of serious injury or fatality. Use a

non-metallic screwdriver for adjusng the calibraon trim pots.

Use approved personal protecve equipment and insulated tools

if working on this drive with power applied.

i

MM23xx1C Series

Table of Contents

Section 1. Specifications ..................................................... 1

Section 2. Dimensions ......................................................... 3

Section 3. Installation ....................................................... 10

Heat Sinking ................................................................................10

Mounting ....................................................................................11

Chassis ................................................................................11

Speed Adjust Potentiometer .............................................12

NEMA 1 ...............................................................................13

NEMA 4X .............................................................................14

Wiring .........................................................................................15

Shielding Guidelines.............................................................16

Line Fusing ..........................................................................17

Connections.................................................................................19

Quick-Disconnect Terminal Block ..........................................19

Power Inputs .......................................................................21

Motor ..................................................................................21

Field Output Connections .....................................................22

Speed Adjust Potentiometer .................................................23

Meter (MM230x1C-H models only) .......................................23

Analog Input Signal ..............................................................24

Section 4. Operation ......................................................... 28

Before Applying Power .................................................................28

Select Switches ............................................................................29

Input Voltage Select (SW501) ...............................................29

Armature Voltage Select (SW502) .........................................29

Startup ........................................................................................30

MM23001C, MM23001C-Q, MM23011C, MM23011C-Q..........30

MM23101C, MM23111C, MM23401C, MM23411C .................30

MM23201C and MM23211C ................................................31

Starting and Stopping Methods ....................................................32

ii

Line Starting and Stopping ...................................................32

Dynamic Braking ..................................................................33

Inhibit Terminals ..................................................................35

Decelerating to Minimum Speed ...........................................36

MM23xx1C Series

Section 5. Calibration ....................................................... 37

Minimum Speed (MIN SPD) ..........................................................38

Maximum Speed (MAX SPD) .........................................................38

Torque (TORQUE) .........................................................................39

IR Compensation (IR COMP) .........................................................40

Acceleration (ACCEL) ....................................................................42

Deceleration (DECEL) ...................................................................42

Section 6.Application Notes ............................................... 43

Multiple Fixed Speeds .................................................................. 43

Adjustable Speeds Using Potentiometers In Series .........................44

Independent Adjustable Speeds .................................................... 45

RUN/JOG Switch - Inhibit Connection ............................................46

RUN/JOG Switch - Potentiometer Connection ................................47

Leader-Follower Application .........................................................48

Single Speed Potentiometer Control Of Multiple Drives .................49

Reversing .....................................................................................50

Section 7. Diagnostic LEDs ................................................. 51

Section 8. Troubleshooting ................................................ 52

Before Troubleshooting ................................................................52

Section 9. Block Diagrams ................................................. 55

Section 10. Accessories & Replacement Parts...................... 58

Unconditional Warranty ..................................................... 59

iii

MM23xx1C Series

List of Tables

Table 1 Recommended Line Fuse Sizes ..........................................18

Table 2 Short Circuit Current Ratings ............................................18

Table 3 Field Output Connections .................................................22

Table 3 Minimum Recommended Dynamic Brake Resistor Values ...34

iv

MM23xx1C Series

List of Figures

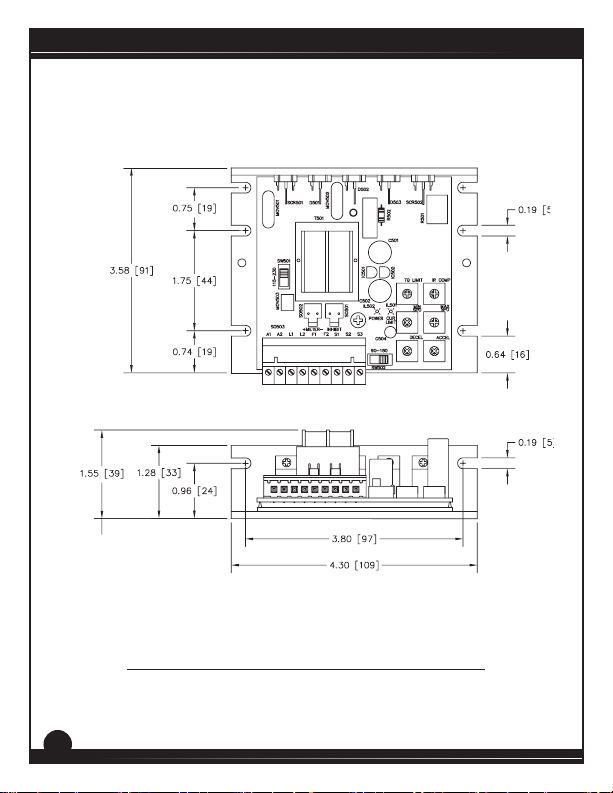

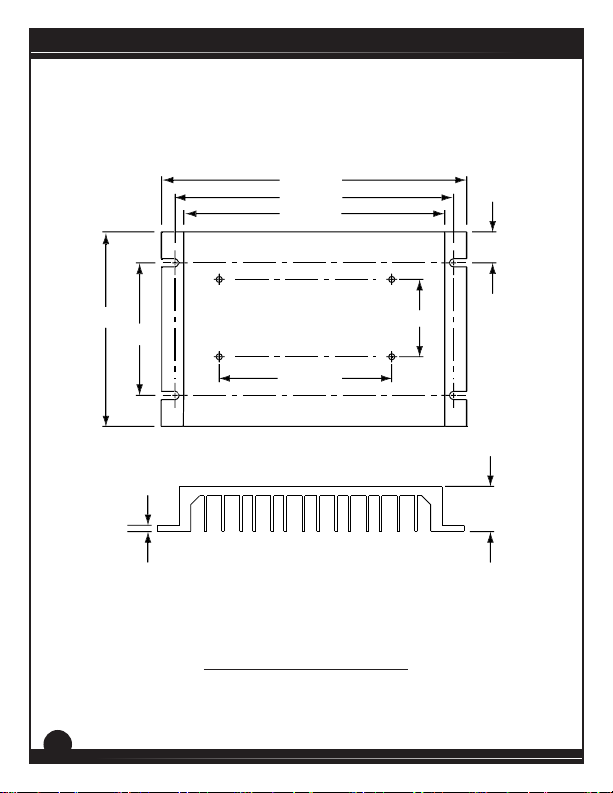

Figure 1 MM23001C and MM23011C Dimensions ............................ 3

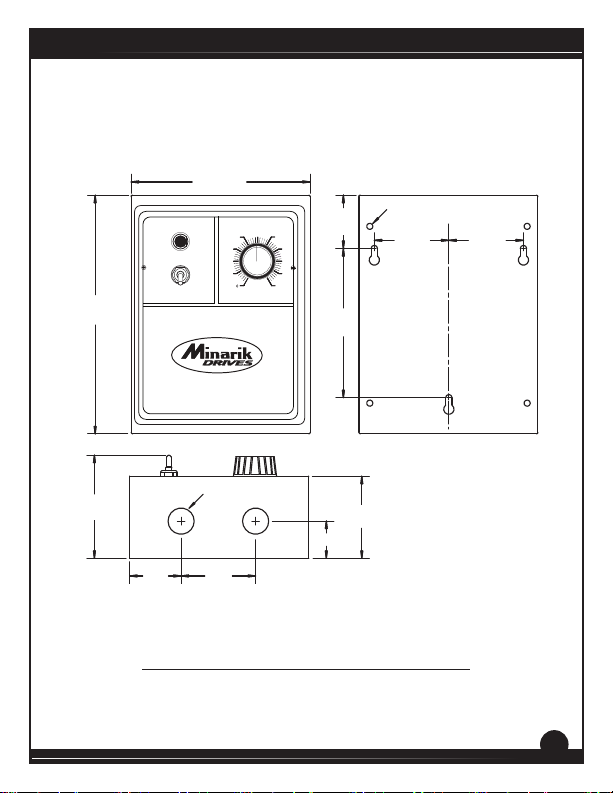

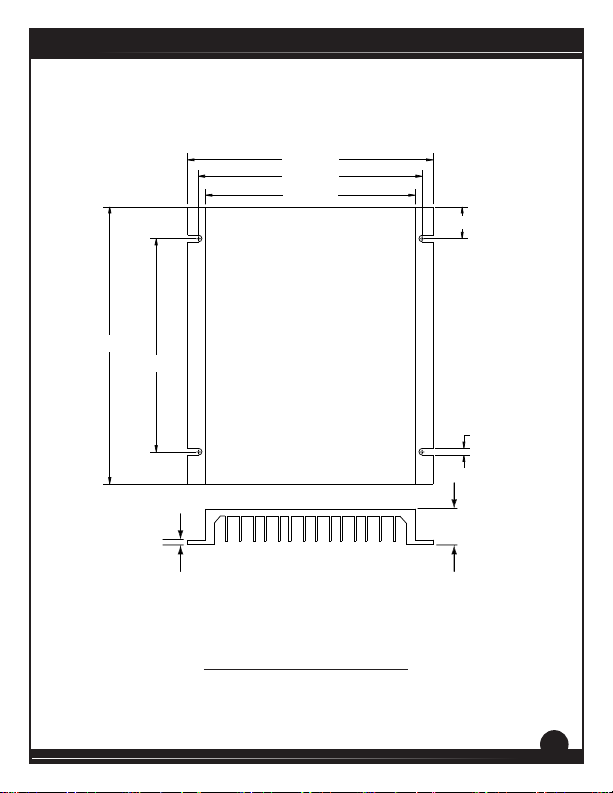

Figure 2 MM23001C-Q and MM23011C-Q Dimensions ..................... 4

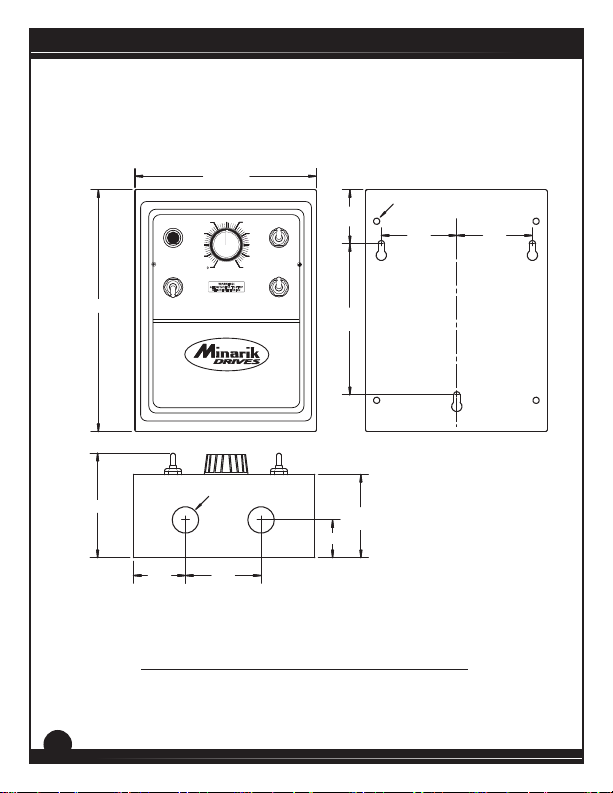

Figure 3 MM23101C and MM23111C Dimensions ............................ 5

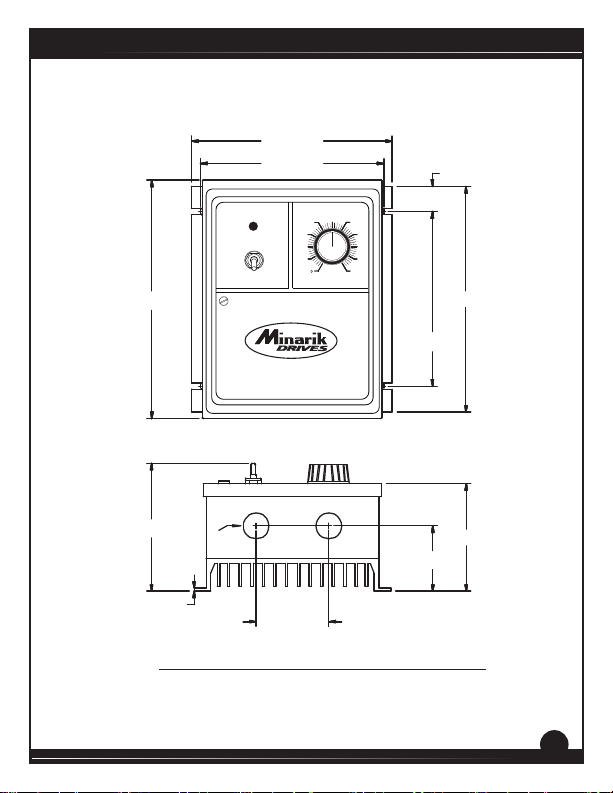

Figure 4 MM23201C and MM23211C Dimensions ............................ 6

Figure 5 MM23401C and MM23411C Dimensions ............................ 7

Figure 6 223-0159 Dimensions ........................................................ 8

Figure 7 223-0174 Dimensions ........................................................ 9

Figure 8 Speed Adjust Potentiometer .............................................12

Figure 9 Quick-Disconnect Terminal Block ......................................20

Figure 10 Analog Input Signal Connections .......................................24

Figure 11 Chassis Drive Connections ................................................ 25

Figure 12 MM23001C-Q and MM23011C-Q Connections ...................26

Figure 13 Cased Drive Connections .................................................. 27

Figure 14 Select Switches ................................................................29

Figure 15 Dynamic Brake Wiring ......................................................34

Figure 16 Inhibit Terminals ..............................................................35

Figure 17 Run/Decelerate to Minimum Speed Switch ........................36

Figure 18 Recommended TORQUE and IR COMP Settings ..................41

Figure 19 Multiple Fixed Speeds ......................................................43

Figure 20 Adjustable Speeds Using Potentiometers in Series .............44

Figure 21 Independent Adjustable Speeds ........................................45

Figure 22 RUN/JOG Switch - Inhibit Connection ................................46

Figure 23 RUN/JOG Switch - Potentiometer Connection ....................47

Figure 24 Leader-Follower Application .............................................48

Figure 25 Single Speed Potentiometer Control of Multiple Drives ......49

Figure 26 Reversing Circuit Wiring ...................................................50

Figure 27 Diagnostic LED Locations .................................................. 51

Figure 28 MM23xx1C Series Block Diagram ......................................55

v

MM23xx1C Series

Figure 29 MM23101C, MM23111C, MM23401C, and MM23411C

Figure 30 MM23201C and MM23211C Terminal Block Connections ...57

Terminal Block Connections ..............................................56

vi

Section 1. Specifications

MM23xx1C Series

Model

MM23011C

MM23111C

MM23211C

MM23411C

MM23072A

MM23001C*

MM23101C**

MM23201C**

MM23401C

MM23071A*

Maximum

Armature

Current (ADC)

1.5 1/20 - 1/8 1/10 - 1/4 Chassis

10.0 1/8 - 1 1/4 - 2 Chassis

HP Range

with 90 VDC

Motor

HP Range

with 180 VDC

Motor Enclosure

NEMA 1

NEMA 1

NEMA 4X

Chassis

NEMA 1

NEMA 1

NEMA 4X

Chassis

* Heat sink kit part number 223-0159 must be used when the connuous

current output is over 5 amps.

** Heat sink kit part number 223-0174 must be used when the connuous

current output is over 5 amps.

AC Line Voltage

DC Armature Voltage

with 115 VAC Line Voltage

with 230 VAC Line Voltage

Field Voltage

with 115 VAC Line Voltage

with 230 VAC Line Voltage

Maximum Field Current 1 ADC

Acceleraon Time Range

for 0 - 90 VDC Armature Voltage

for 0 - 180 VDC Armature Voltage

Deceleraon Time Range

for 0 - 90 VDC Armature Voltage

for 0 - 180 VDC Armature Voltage

50 VDC (F1 to L1); 100 VDC (F1 to F2)

100 VDC (F1 to L1); 200 VDC (F1 to F2)

115/230 VAC ± 10%

50/60 Hz, single phase

0 - 90 VDC

0 - 180 VDC

0.5 - 11 seconds

0.5 - 22 seconds

coast to a stop - 13 seconds

coast to a stop - 25 seconds

1

MM23xx1C Series

Deceleraon Time Range

for 0 - 90 VDC Armature Voltage

for 0 - 180 VDC Armature Voltage

Analog Input Range

(signal must be isolated; S1 to S2)

with 115 VAC Line Voltage

with 230 VAC Line Voltage

Input Impedance (S1 to S2) >100K ohms

Form Factor 1.37 at base speed

Load Regulaon 1% base speed or beer

Speed Range 60:1

Vibraon 0.5G maximum (0 - 50 Hz)

Safety Cercaons UL/cUL Listed Equipment, File # E132235

Ambient Temperature Range

Chassis Drive

Cased Drive

UL/cUL Overload Protecon (except -Q models)

CSA Cered Component, File # LR41380

coast to a stop - 13 seconds

coast to a stop - 25 seconds

0.1G maximum (> 50 Hz)

Sux Denions

-H: Basic Drive with Inhibit Style Connector for Meter

-Q: Basic Drive with Power LED and Quick Disconnect

MM2307xA: Basic Drive with Power LED and Vercal Trim Pots

Terminal Block

0 - 1.4 VDC

0 - 2.8 VDC

10°C - 55°C

10°C - 40°C

2

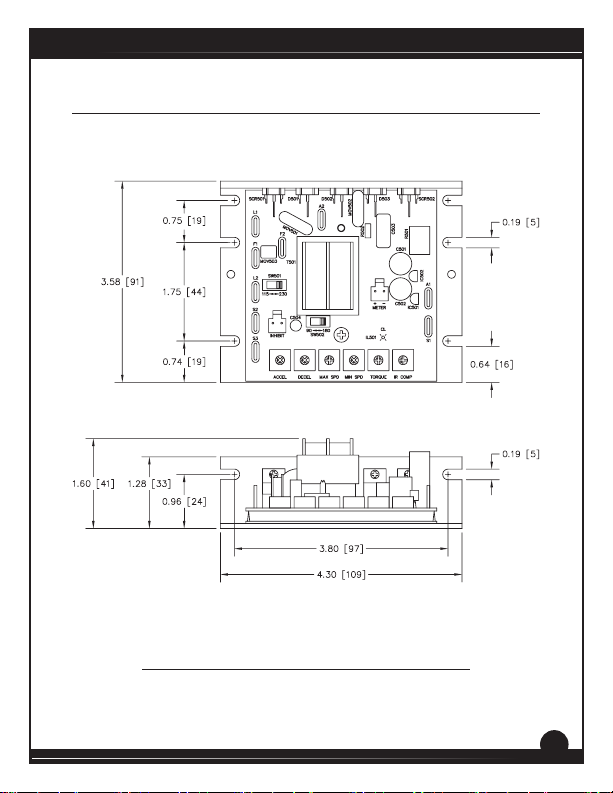

Section 2. Dimensions

MM23xx1C Series

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 1. MM23001C and MM23011C Dimensions

3

MM23xx1C Series

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 2. MM23001C-Q and MM23011C-Q Dimensions

4

MM23xx1C Series

6.00 [125]

Ø 0.19

C

[5] (4)

2.50

[64]

L

2.50

[64]

8.00

[203]

MADE IN U.S.A.

South Beloit, IL

SPEED

50

40

30

20

10

POWER

ON

OFF

WARNING: DISCONNECT FROM SUPPLY BEFORE OPENING THIS COVER.

SEPARATE MOTOR OVERCURRENT AND OVERLOAD PROTECTION IN ACCORDANCE WITH

THE CANADIAN ELECTRICAL CODE PART 1 IS PROVIDED BY OTHERS.

1.79

[45]

60

70

80

90

100

5.00

[127]

3.46

[88]

Ø 0.88

[22] (2)

1.25 [32]

1.72

[44]

2.50

[64]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 3. MM23101C and MM23111C Dimensions

2.75

[70]

5

MM23xx1C Series

8.00 [203]

3.46 [88]

6.00 [125]

50

60

40

POWER

ON

OFF

WARNING: DISCONNECT FROM SUPPLY BEFORE OPENING THIS COVER.

SEPARATE MOTOR OVERCURRENT AND OVERLOAD PROTECTION IN ACCORDANCE WITH

THE CANADIAN ELECTRICAL CODE PART 1 IS PROVIDED BY OTHERS.

30

20

10

WARNING!

ALLOW MOTOR TO STOP

BEFORE REVERSING

MADE IN U.S.A.

South Beloit, IL

Ø 0.88

[22] (2)

70

80

90

100

RUN

BRAKE

FORWARD

REVERSE

1.25 [32]

1.79

[45]

5.00

[127]

2.75

[70]

Ø 0.19

[5] (4)

2.50

[64]

C

L

2.50

[64]

1.72

[44]

2.50

[64]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 4. MM23201C and MM23211C Dimensions

6

MM23xx1C Series

6.90 [175]

6.30 [160]

0.87 [22]

POWER

ON

OFF

SPEED

50

60

40

70

30

80

20

90

10

100

8.20 [208]

MADE IN U.S.A.

South Beloit, IL

WARNING: DISCONNECT FROM SUPPLY BEFORE OPENING THIS COVER.

SEPARATE MOTOR OVERCURRENT AND OVERLOAD PROTECTION IN ACCORDANCE WITH

THE CANADIAN ELECTRICAL CODE PART 1 IS PROVIDED BY OTHERS.

4.50 [114]

Ø 0.88

[22] (2)

0.13 [3]

2.50 [64]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 5. MM23401C and MM23411C Dimensions

7.76 [197]

6.00 [152]

3.70 [94]

2.25 [57]

7

]

]

]

MM23xx1C Series

6.90 [ 17 5

6.30 [ 16 0

5.90 [ 150

0.7 [18]

8

4.40 [112]

3.00 [76]

0.125 [3]

1.75 [44]

3.90 [100]

1.00 [26]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 6. 223-0159 Dimensions

6.90 [175]

6.29 [160]

5.90 [150]

7.80 [198]

6.00 [152]

MM23xx1C Series

0.90 [23]

0.19 [5]

0.125 [3]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 7. 223-0174 Dimensions

1.00 [26]

9

MM23xx1C Series

Section 3. Installation

Do not install, rewire, or remove this control with input power

applied. Failure to heed this warning may result in re, explosion,

!

Heat Sinking

Chassis

Models MM23001C and MM23001C-Q require an addional heat sink

when the connuous armature current is above 5 amps. Use heat sink

kit part number 223-0159. All other chassis drives have sucient heat

sinking in their basic conguraon. Use a thermally conducve heat sink

compound (such as Dow Corning® 340 Heat Sink Compound) between

the chassis and the heat sink surface for opmum heat transfer.

NEMA 1

Models MM23101C and MM23201C require an addional heat sink

when the connuous armature current is above 5 amps. Use heat sink

kit part number 223-0174. All other NEMA 1 drives have sucient heat

sinking in their basic conguraon. Use a thermally conducve heat sink

compound (such as Dow Corning® 340 Heat Sink Compound) between

the chassis and the heat sink surface for opmum heat transfer.

NEMA 4X

All NEMA 4X models come with the heat sink already aached.

Therefore, all NEMA 4X drives have sucient heat sinking in their basic

conguraon.

or serious injury. Make sure you read and understand the Safety

WARNING!

Precauons on page i before aempng to install this product.

10

MM23xx1C Series

Mounng

Chassis

• Drive components are sensitive to electrostatic discharge. Avoid

direct contact with the circuit board. Hold the drive by the chassis

or heat sink only.

• Protect the drive from dirt, moisture, and accidental contact.

• Provide sufficient room for access to the terminals and calibration

trim pots.

• Mount the drive away from heat sources. Operate the drive within

the specified ambient operating temperature range.

• Prevent loose connections by avoiding excessive vibration of the

drive.

• Mount the drive with its board in either a horizontal or vertical

plane. Eight 0.19” (5 mm) wide slots in the chassis accept #8 pan

head screws. Fasten either the large base or the narrow flange of

the chassis to the subplate.

• The chassis should be earth grounded. Use a star washer beneath

the head of at least one of the mounting screws to penetrate the

anodized surface and to reach bare metal.

11

MM23xx1C Series

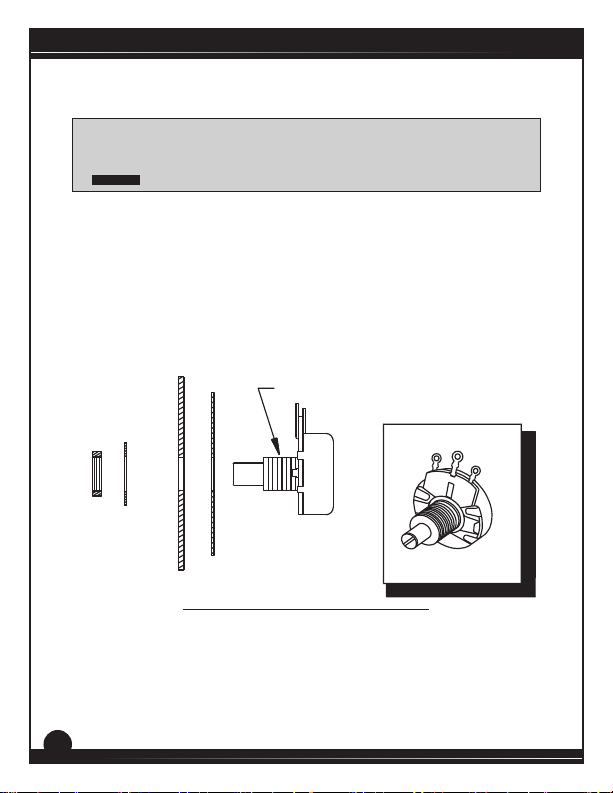

Speed Adjust Potenometer

Be sure that the potenometer tabs do not make contact with the

potenometer’s body. Grounding the input will cause damage to

!

If using a remote potenometer with a chassis drive, mount the speed

adjust potenometer through a 0.38 in. (10 mm) hole with the hardware

provided (Figure 8). Install the circular insulang disk between the panel

and the 10K ohm speed adjust potenometer.

Twist the speed adjust potenometer wire to avoid picking up unwanted

electrical noise. If the speed adjust potenometer wires are longer than

18 in. (46 cm), use shielded cable. Keep the speed adjust potenometer

wires separate from power leads (L1, L2, A1, A2, F1, F2).

NUT

WARNING!

STAR

WASHER

the drive.

MOUNT THROUGH A 0.38 IN. (10 MM) HOLE

SPEED ADJUST

POTENTIOMETER

INSULATING DISK

PANEL

Figure 8. Speed Adjust Potenometer

CW

POT TAB ASSIGNMENTS

WIPER

CCW

12

MM23xx1C Series

Mounng (NEMA 1 Enclosures)

NEMA 1 cased drives come with two 0.88 inch (22 mm) conduit holes

at the boom of the case. The units may be vercally wall mounted or

horizontally bench mounted using the three keyholes on the back of the

case.

1. For access to the keyholes and the terminal strip, remove

the two screws from the front of the case by turning them

counterclockwise. Grasp the front cover and pull it straight out.

2. Install the mounting screws in the three keyholes.

3. Set the POWER switch to the OFF position before applying the

AC line voltage.

4. Install conduit hardware through the conduit holes at the

bottom of the case. Connect external wiring to the terminal

block.

5. Reinstall the front cover. Avoid pinching any wires between the

front cover and the case.

6. Reinstall the two screws on the front cover. Turn the screws

clockwise to tighten.

13

Loading...

Loading...