Minarik Drives LVBL SERIES Users Manual

LVBL SERIES

USER MANUAL

LVBL02-24AC/DC

www.minarikdrives.com

Dear Valued Consumer:

Congratulaons on your purchase of the LVBL Series drive.

This User Manual was created for you to get the most out of

your new device and assist with the inial setup. Please visit

www.minarikdrives.com to learn more about our other drives.

Thank you for choosing Minarik Drives!

© 2014 Minarik Drives. All rights reserved.

No part of this document may be reproduced or transmied in any form without wrien permission

from Minarik Drives. The informaon and technical data in this document are subject to change

without noce. Minarik Drives makes no warranty of any kind with respect to this material,

including, but not limited to, the implied warranes of its merchantability and tness for a given

purpose. Minarik Drives assumes no responsibility for any errors that may appear in this document

and makes no commitment to update or to keep current the informaon in this document.

Safety First!

SAFETY WARNINGS

Text in gray boxes denote important safety ps or warnings.

Please read these instrucons carefully before performing any of

!

• DO NOT INSTALL, REMOVE, OR REWIRE THIS EQUIPMENT WITH

• Reduce the chance of an electrical fire, shock, or explosion by using

the procedures contained in this manual.

WARNING!

POWER APPLIED. Have a qualified electrical technician install, adjust

and service this equipment. Follow the National Electrical Code

and all other applicable electrical and safety codes, including the

provisions of the Occupational Safety and Health Act (OSHA), when

installing equipment.

proper grounding techniques, over-current protection, thermal

protection, and enclosure. Follow sound maintenance procedures.

It is possible for a drive to run at full speed as a result of a

component failure. Minarik Drives strongly recommends the

!

installaon of a master switch in the main power input to stop

WARNING!

the drive in an emergency.

LVBL Series

i

LVBL Series

Table of Contents

Section 1. Regenerative Drives ............................................ 1

Section 2. Specifications ..................................................... 2

Section 3. Dimensions ......................................................... 3

Section 4. Installation ......................................................... 4

Mounting ..................................................................................... 4

Speed Adjust Potentiometer .................................................. 5

Wiring .......................................................................................... 6

Shielding Guidelines.............................................................. 7

Line Fusing ........................................................................... 7

Connections.................................................................................. 8

Quick Disconnect Terminal Block ........................................... 8

Power Input .......................................................................... 9

Motor ................................................................................... 9

Motor Hall Effect Sensors ...................................................... 9

Speed Adjust Potentiometer .................................................10

Analog Input Signal ..............................................................10

Direction Switch ..................................................................10

Section 5. Operation ......................................................... 12

Before Applying Power .................................................................12

Select Switches ............................................................................13

Hall Effect Sensor Spacing Select (SW501) .............................13

Startup ........................................................................................14

Starting and Stopping Methods ....................................................15

Line Starting and Stopping ...................................................15

Regenerative Brake to Minimum Speed .................................15

Section 6. Calibration ....................................................... 16

Minimum Speed (MIN SPEED) .......................................................17

Maximum Speed (MAX SPEED) ......................................................17

ii

Section 7.Application Notes ............................................... 18

Multiple Fixed Speeds .................................................................. 18

Adjustable Speeds Using Potentiometers In Series .........................19

Independent Adjustable Speeds .................................................... 20

RUN/JOG Switch...........................................................................21

Leader-Follower Application .........................................................22

Single Speed Potentiometer Control Of Multiple Drives .................23

Section 8. Diagnostic LEDs ................................................. 24

Section 9. Troubleshooting ................................................ 25

Before Troubleshooting ................................................................25

Section 10. Accessories & Replacement Parts...................... 28

Unconditional Warranty ..................................................... 29

LVBL Series

iii

LVBL Series

List of Figures

Figure 1 Four Quadrant Operation .................................................. 1

Figure 2 LVBL02-24AC/DC Dimensions ............................................. 3

Figure 3 Speed Adjust Potentiometer .............................................. 5

Figure 4 Quick Disconnect Terminal Block ........................................ 8

Figure 5 LVBL02-24AC/DC Connections ...........................................11

Figure 6 Hall Effect Sensor Spacing Select Location .........................13

Figure 7 Multiple Fixed Speeds ......................................................18

Figure 8 Adjustable Speeds Using Potentiometers in Series .............19

Figure 9 Independent Adjustable Speeds ........................................20

Figure 10 RUN/JOG Switch ................................................................. 21

Figure 11 Leader-Follower Application .............................................22

Figure 12 Single Speed Potentiometer Control of Multiple Drives ......23

Figure 13 Diagnostic LED Locations .................................................. 24

iv

Section 1. Regenerative Drives

Most non-regenerave,

variable speed, DC drives

control current ow to a

motor in one direcon.

The direcon of current

ow is the same direcon

as the motor rotaon.

Non-regenerave drives

operate in Quadrant I,

and also in Quadrant III if

the drive is reversible (see

Figure 1). Motors must stop

before reversing direcon.

Unless dynamic braking

is used, non regenerave

drives cannot decelerate a

load faster than coasng to a

lower speed.

Regenerative drives operate

in two addional quadrants:

Quadrant II and Quadrant

IV. In these quadrants,

motor torque is in the

opposite direcon of motor rotaon.

This allows regenerave drives to reverse a motor without contractors

or switches, to control an overhauling load, and to decelerate a load

faster than it would to coast to a lower speed.

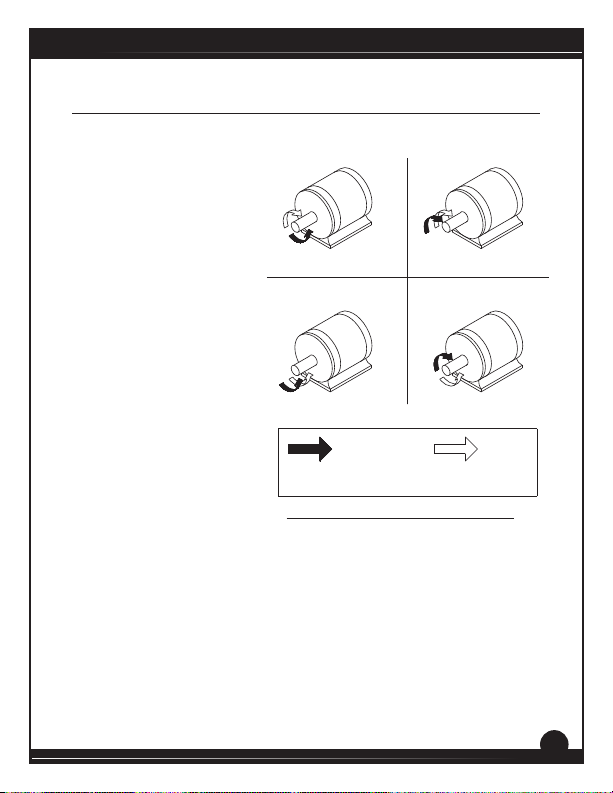

Quadrant II

Quadrant III

MOTOR

ROTATION

NOTE: ARROWS IN SAME DIRECTION = MOTOR ACTION

ARROWS IN OPPOSITE DIRECTION = REGENERATIVE ACTION

Quadrant I

Quadrant IV

Figure 1. Four Quadrant Operaon

LVBL Series

MOTOR

TORQUE

1

LVBL Series

Section 2. Specifications

Connuous

Model

LVBL02-24AC/DC 2 3* 0 - 24 1/100 - 1/44

Armature

Current (ADC)

Peak

Armature

Current (ADC)

Armature

Voltage

Range (VDC) HP Range

* Peak armature current for less than 1 second.

AC Input Voltage 24 - 36 VAC ± 10%, 50/60 Hz, single phase

DC Input Voltage 24 - 48 VDC ± 10%

Armature Voltage Range 0 - 24 VDC

Acceleraon & Deceleraon Time 0.5 seconds

Analog Input Signal Range 0 - 2 VDC (Isolated)

Input Impedance 60K ohms

Form Factor 1.05

Load Regulaon 3% base speed or beer

Speed Range 60:1

Vibraon 0.5G maximum (0 - 50 Hz)

Ambient Temperature Range 0° - 40° C

0.1G maximum (> 50 Hz)

2

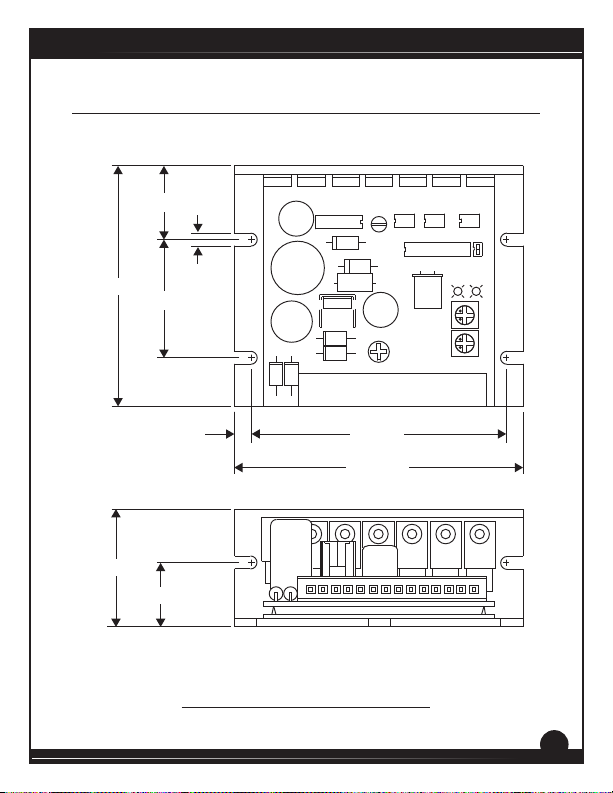

Section 3. Dimensions

LVBL Series

3.58 [91]

1.75 [44]

1.10 [28]

Q502 Q501 Q504 Q503 Q506 Q505

C501

L501

IC504

D501

0.188 [5]

1.75 [44]

C502

IC503

D502

D503

D505

D504

INPUT

DIR S1 S2 S3 HA HB HC COM +5V PH-A PH-B PH-C1 2

0.25 [6] 3.80 [97]

4.30 [109]

0.96 [24]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Figure 2. LVBL02-24AC/DC Dimensions

IC505 IC506 IC507

IC501

D506

Y501

L502

C503

J501

TRIP POWER

IL502

SW501

120 - 60

IL501

3

LVBL Series

Section 4. Installation

Do not install, rewire, or remove this control with input power

applied. Failure to heed this warning may result in re, explosion,

!

Mounng

• Drive components are sensitive to electrostatic discharge. Avoid

• Protect the drive from dirt, moisture, and accidental contact.

• Provide sufficient room for access to the terminals and calibration

• Mount the drive away from heat sources. Operate the drive within

• Prevent loose connections by avoiding excessive vibration of the

• Mount the drive with its board in either a horizontal or vertical plane.

• The chassis does not need to be earth grounded. If you choose to

or serious injury. Make sure you read and understand the Safety

WARNING!

Precauons on page i before aempng to install this product.

direct contact with the circuit board. Hold the drive by the heat sink

only.

trim pots.

the specified ambient operating temperature range.

drive.

Six 0.19” (5 mm) wide slots in the chassis accept #8 pan head screws.

Fasten either the large base or the narrow flange of the chassis to

the subplate.

ground the chassis, use a star washer beneath the head of at least

one of the mounting screws to penetrate the anodized surface and

to reach bare metal.

4

Speed Adjust Potenometer

Be sure that the potenometer tabs do not make contact with the

!

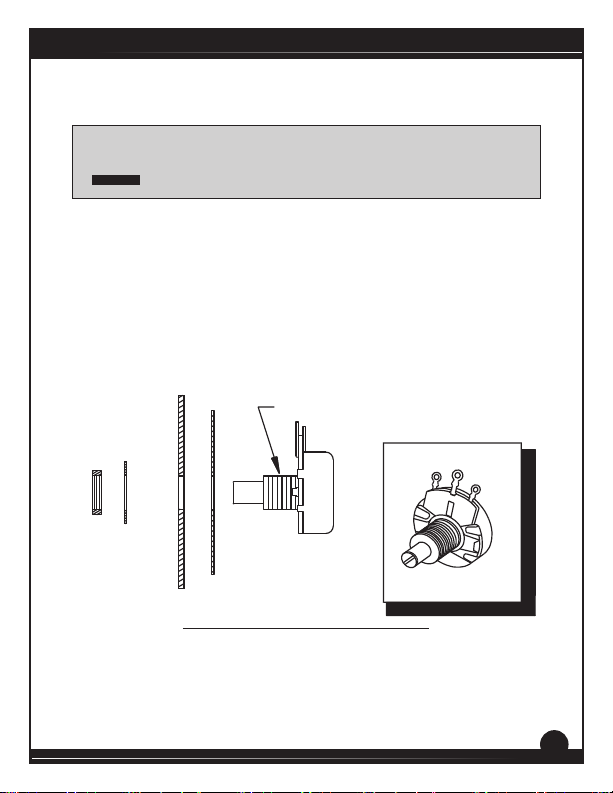

If using a remote potenometer with a chassis drive, mount the speed

adjust potenometer through a 0.38 in. (10 mm) hole with the hardware

provided (Figure 3). Install the circular insulang disk between the panel

and the 10K ohm speed adjust potenometer.

Twist the speed adjust potenometer wire to avoid picking up unwanted

electrical noise. If the speed adjust potenometer wires are longer than

18 in. (46 cm), use shielded cable. Keep the speed adjust potenometer

wires separate from power leads (INPUT 1, INPUT 2, PH A, PH B, PH C).

NUT

potenometer’s body. Grounding the input will cause damage to

WARNING!

the drive.

MOUNT THROUGH A 0.38 IN. (10 MM) HOLE

STAR

WASHER

INSULATING DISK

PANEL

SPEED ADJUST

POTENTIOMETER

CW

POT TAB ASSIGNMENTS

LVBL Series

WIPER

CCW

Figure 3. Speed Adjust Potenometer

5

Loading...

Loading...