Page 1

Cat. No.

No de cat.

Cat. No.

0719-20

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

SAWZALL

PASSE-PARTOUT SAWZALL

SIERRAS SABLE-SAWZALLS DE

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND

OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET

BIEN COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y

ENTENDER EL MANUAL DEL OPERADOR.

Page 2

GENERAL SAFETY RULES-FOR ALL BATTERY OPERATED TOOLS

WARNING!

READ ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in electric shock, fire

and/or serious injury. The term "power tool" in all of the warnings listed

below refers to your mains-operated (corded) power tool or batteryoperated (cordless) power tool.

SAVE THESE INSTRUCTIONS

WORK AREA SAFETY

1. Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2. Do not operate power tools in ex-

plosive atmospheres, such as in

the presence of flammable liquids, gases, or dust. Power tools

create sparks which may ignite the

dust or fumes.

3. Keep children and bystanders

away while operating a power

tool. Distractions can cause you to

lose control.

ELECTRICAL SAFETY

4. Power tool plugs must match the

outlet. Never modify the plug in

any way. Do not use any adapter

plugs with earthed (grounded)

power tools. Unmodified plugs and

matching outlets will reduce risk of

electric shock.

5. Avoid body contact with earthed

or grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is

earthed or grounded.

6. Do not expose power tools to rain

or wet conditions. Water entering a

power tool will increase the risk of

electric shock.

7. Do not abuse the cord. Never use

the cord for carrying, pulling, or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges, or moving parts. Damaged

or entangled cords increase the risk

of electric shock.

8. When operating a power tool out-

doors, use an extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the

risk of electric shock.

PERSONAL SAFETY

9. Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use a power tool while you

are tired or under the influence

of drugs, alcohol or medication. A

moment of inattention while operating

power tools may result in serious personal injury.

10. Use safety equipment. Always

wear eye protection. Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

11. Avoid accidental starting. Ensure

the switch is in the off-position

before plugging in. Carrying tools

with your finger on the switch or plugging in power tools that have the

switch on invites accidents.

12. Remove any adjusting key or

wrench before turning the power

tool on. A wrench or a key left at-

tached to a rotating part of the power

tool may result in personal injury.

13. Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the

power tool in unexpected situations.

2 3

14. Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away

from moving parts. Loose clothes,

jewellery, or long hair can be caught in

moving parts.

15. If devices are provided for the

connection of dust extraction and

collection facilities, ensure these

are connected and properly used.

Use of these devices can reduce dustrelated hazards.

POWER TOOL USE AND CARE

16. Do not force the power tool. Use

the correct power tool for your

application. The correct power tool

will do the job better and safer at the

rate for which it was designed.

17. Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

18. Disconnect the plug from the

power source and/or the battery

pack from the power tool before

making any adjustments, changing accessories, or storing

power tools. Such preventive safety

measures reduce the risk of starting

the tool accidentally.

19. Store idle power tools out of the

reach of children and do not allow persons unfamiliar with the

power tools or these instructions

to operate power tools. Power

tools are dangerous in the hands of

untrained users.

20. Maintain power tools. Check for

misalignment or binding of moving parts, breakage of parts and

any other condition that may affect the power tool's operation. If

damaged, have the power tool

repaired before use. Many acci-

dents are caused by poorly maintained

power tools.

21. Keep cutting tools sharp and

clean. Properly maintained cutting

tools with sharp cutting edges are less

likely to bind and are easier to control.

22. Use the power tool, accessories

and tool bits etc., in accordance

with these instructions and in the

manner intended for the particular type of power tool, taking into

account the working conditions

and the work to be performed.

Use of the power tool for operations

different from those intended could result in a hazardous situation.

BATTERY TOOL USE AND CARE

23. Ensure the switch is in the off

position before inserting battery

pack. Inserting the battery pack into

power tools that have the switch on

invites accidents.

24. Recharge only with the charger

specified by the manufacturer. A

charger that is suitable for one type of

battery pack may create a risk of fire

when used with another battery pack.

25. Use power tools only with spe-

cifically designated battery packs.

Use of any other battery packs may

create a risk of injury and fire.

26. When battery pack is not in use,

keep it away from other metal

objects like paper clips, coins,

keys, nails, screws, or other

small metal objects that can make

a connection from one terminal

to another. Shorting the battery ter-

minals together may cause burns or a

fire.

27. Under abusive conditions, liquid

may be ejected from the battery,

avoid contact. If contact accidentally occurs, flush with water. If

liquid contacts eyes, additionally

seek medical help. Liquid ejected

from the battery may cause irritation

or burns.

SERVICE

28. Have your power tool serviced by

a qualified repair person using

only identical replacement parts.

This will ensure that the safety of the

power tool is maintained.

Page 3

SPECIFIC SAFETY RULES

Symbology

1. Hold tool by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Contact

with a “live” wire will make exposed metal parts of the tool “live” and shock the operator.

2. Keep hands away from all cutting edges and moving parts.

3. Maintain labels and nameplates. These carry important information. If unreadable

or missing, contact a

4. Use clamps or another practical way to secure and support the workpiece to

a stable platform. Holding the work by hand or against your body leaves it unstable

and may lead to loss of control.

5. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area,

and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

MILWAUKEE

service facility for a free replacement.

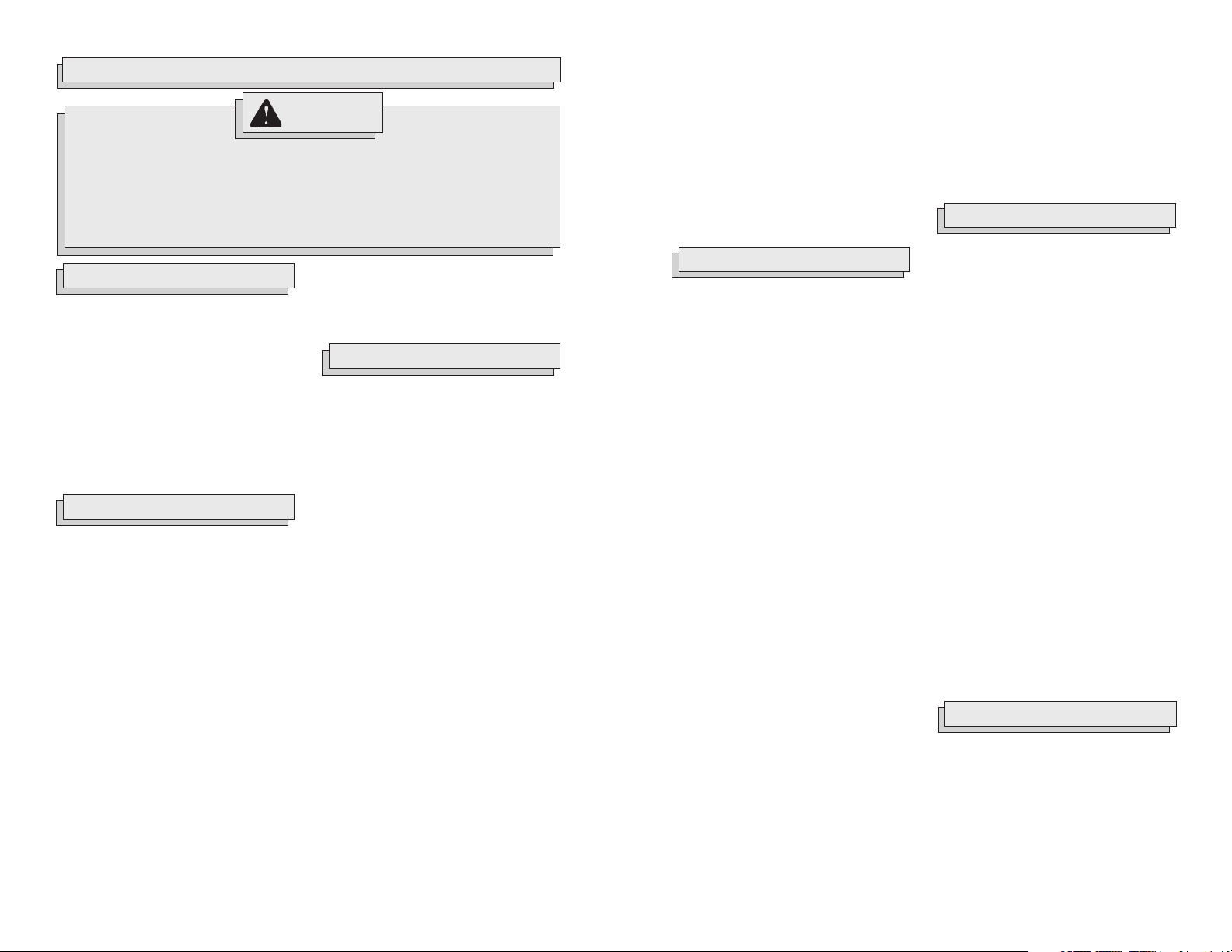

FUNCTIONAL DESCRIPTION

2

5

6

7

1. Handle

2. High/Low/Trigger lock switch

3. Trigger

4. Insulating boot

5. Quik-Lok™ blade clamp

6. Blade

7. Shoe

8. Shoe release lever

9. Battery pack

10. Battery pack release buttons

8

4

3

1

10

9

Volts Direct Current

No Load Strokes per Minute (SPM)

Underwriters Laboratories, Inc.,

United States and Canada

Specifications

No.

Volts

DC

28

Catalog

0719-20

TOOL ASSEMBLY

WARNING!

Charge only

battery packs on

chargers. Other brands of

batteries may cause personal

injury or damage.

For specific charging instructions,

please read the operator's

manual supplied with your charger.

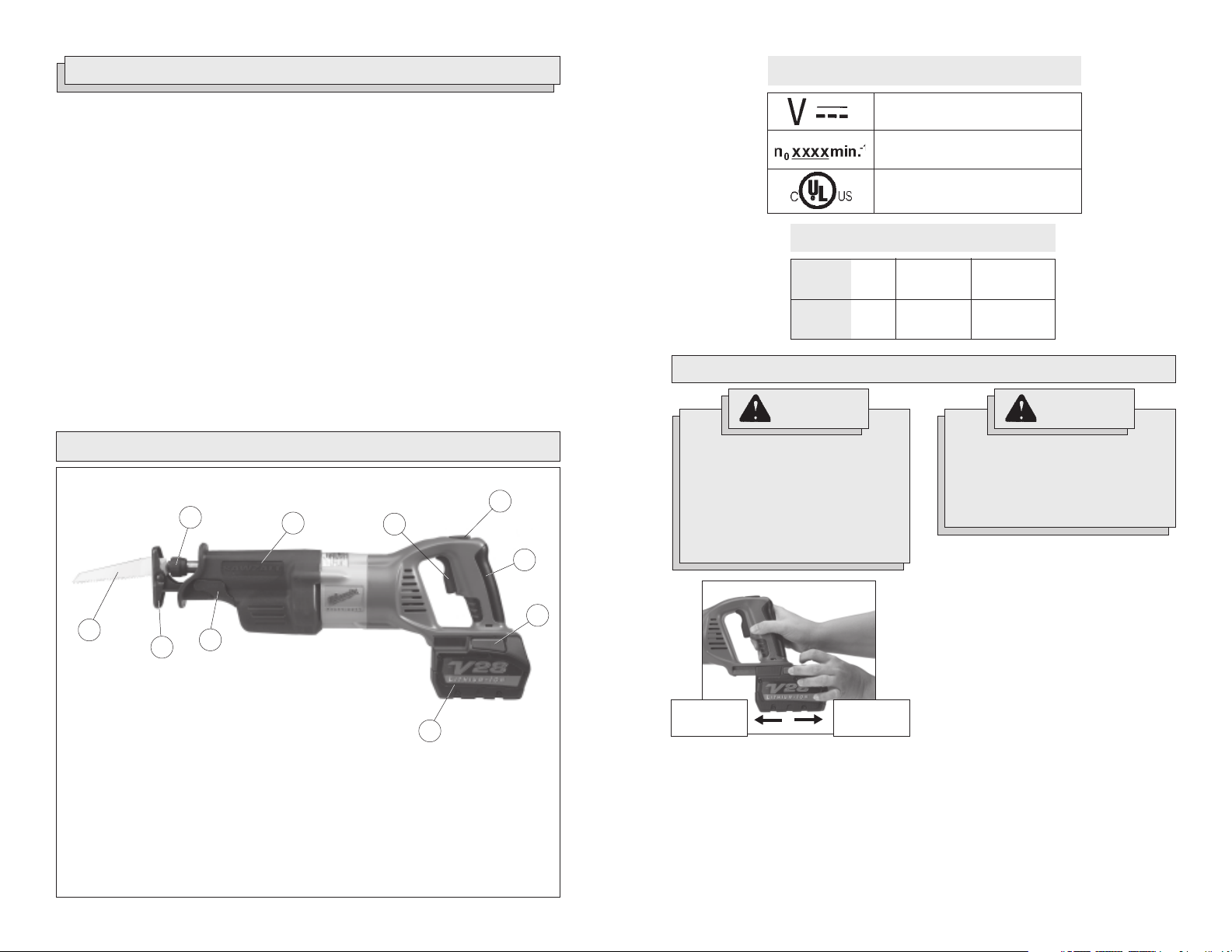

Fig. 1

Inserting a

battery pack

Removing Battery Pack from Tool

Push in the release buttons and pull the

battery pack away from the tool.

Inserting Battery Pack into Tool

To insert the battery pack onto the tool,

slide the pack onto the body of the tool.

Make sure it latches securely into place.

V28

™ Lithium-Ion

V28

Lithium-Ion

Removing a

battery pack

Length of

Stroke

1-1/8"

Strokes

per Minute

Hi 0 - 3000

Lo 0 - 2000

WARNING!

To reduce the risk of injury, always

lock trigger or remove battery

pack before changing or removing

accessories. Only use accessories

specifically recommended for this

tool. Others may be hazardous.

Selecting a Blade

The Quik-Lok® Blade Clamp can be used

with all 1/2" shank universal Sawzall

blades. Use

mance Super Sawzall® blades for best performance. When selecting a blade, choose

the right type and length.

Many types of blades are available for a

variety of applications: cutting metal, wood,

nail-embedded wood, scroll cutting, roughing-in, and contours.

Many lengths are also available. Choose a

length long enough to extend beyond the

shoe and your work throughout the stroke.

Do not use blades less than 3-1/2" long

since they won't extend beyond the

shoe throughout the stroke.

For best performance and longest life, see

“Accessories” to select the best blade for

the job.

MILWAUKEE

®

High Perfor-

4 5

Page 4

Installing and Removing Blades from

the Quik-Lok® Blade Clamp (Fig. 2)

Remove battery pack before changing

blades. Make sure the spindle and blade

clamp areas are clean. Metal chips and

sawdust may prevent the Quik-Lok® Blade

Clamp from clamping securely.

Fig. 2

1. Depending on the job, the blade may

be inserted with the teeth facing up or

down. To install a blade, twist collar in

the direction of the arrow while inserting the blade into the clamp until

the tang butts against the collar.

2. Release collar and the spring loaded

mechanism will clamp the blade firmly

in place.

3. Twist collar in the opposite direction

of the arrow to ensure that the blade

is locked into the clamp.

4. Tug on blade to make sure it is securely locked in place.

5. To remove a blade, twist collar in the

direction of the arrow while pulling on

the blade. Be careful when handling

hot blades.

Quik-Lok® Blade Clamp Maintenance

• Periodically clean dust and debris from

the Quik-Lok® Blade Clamp with dry

compressed air.

• If the collar resists twisting, twist the

collar back and forth to shake debris

loose.

• Periodically lubricate Quik-Lok® Blade

Clamp with a dry lubricant such as

graphite.

Removing broken blades from the

Quik-Lok® Blade Clamp

Broken blades can be removed by the following methods.

• Remove battery pack before removing blades.

• Point the tool downward, twist the

collar, and shake the tool up and down

(DO NOT turn the tool on while your

fingers are holding the blade clamp

open). The shank of the broken blade

should drop out of the clamp.

• If shaking the tool doesn't work...

In most cases, a corner of the broken

blade will extend beyond the blade

clamp. Twist the collar and pull the broken blade out of the clamp by this corner.

• If the broken stub doesn't extend far

enough to be grabbed by its corner,

use a thin blade with small teeth (such

as a metal cutting blade) to hook the

blade that is jammed in the clamp while

twisting the collar and pull it out.

Adjusting the Pivot Shoe (Fig. 3 & 4)

WARNING!

To reduce the risk of injury, be

sure the blade always extends

beyond the shoe and workpiece

throughout the stroke. Blades

may shatter if they impact the

workpiece or shoe (Fig. 4).

The shoe can be adjusted forward or backward to six positions to take advantage of

the unused portion of the blade or for special jobs requiring low blade clearance.

Fig. 3

2. To lock the shoe in position, push the

shoe release lever up.

3. After adjusting the shoe, slowly pull

the trigger to be sure the blade always

extends beyond the shoe and your

workpiece throughout the stroke.

DO NOT OPERATE SAWZALL WITHOUT

SHOE. STRIKING THE SPINDLE AGAINST

WORKPIECE MAY DAMAGE THE RECIPROCATING MECHANISM.

Fig. 4

Stroke

OPERATION

WARNING!

To reduce the risk of injury, keep

hands away from the blade and

other moving parts. Always wear

safety goggles or glasses with

side shields.

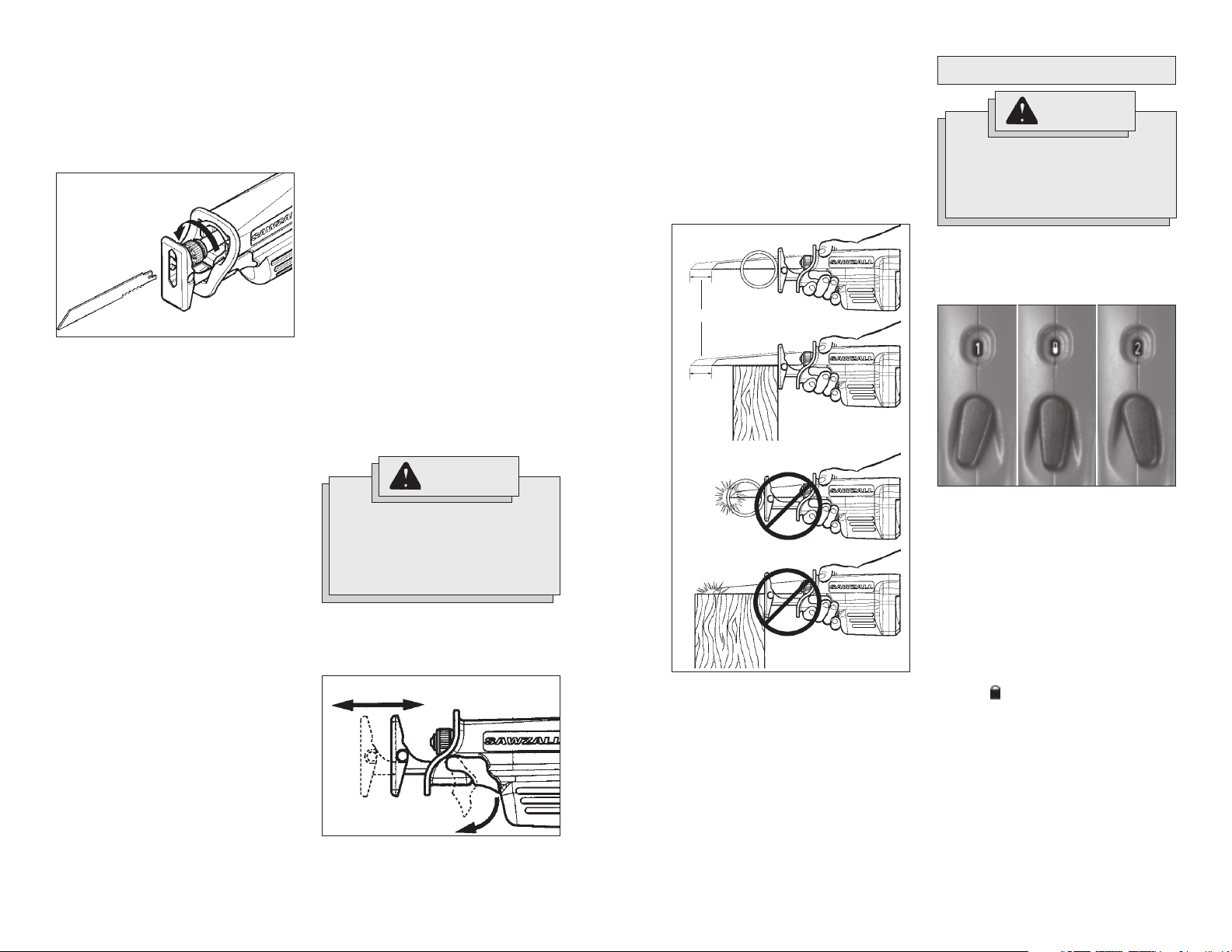

High/Low/Trigger Lock Switch (Fig. 5)

To set the maximum speed or lock the trigger, move the high/low/trigger lock switch

to the following positions (Fig. 5):

Fig. 5

For low speed (Maximum 2000 RPM): Move

the switch to the left." " will be displayed

above the switch. To vary the speed up to

2000 RPM, increase or decrease pressure

on the trigger. Low speed is generally used

for cutting metals.

For high speed (Maximum 3000 RPM): Move

the switch to the right. " " will be displayed above the switch. To vary the

speed up to 3000 RPM, increase or decrease pressure on the trigger.

To lock the trigger: Move the switch to the

center. " " will be displayed above the

switch. The trigger will not work while the

switch is in the locked position. Always lock

the trigger and remove the battery pack before performing maintenance and changing

accessories. Lock the trigger when storing the tool and when the tool is not in use.

1

2

1/4 Turn

1. To adjust the shoe, pull the shoe release lever down 1/4 turn and slide

the shoe forward or backward to the

desired position.

6 7

Page 5

Speed

1. To start the tool, grasp the handle

firmly and pull the trigger.

2. To vary the speed, increase or de-

crease the pressure on the trigger. The

further the trigger is pulled, the greater

the speed. The maximum RPM is determined by the high/low/trigger lock

switch.

3. To stop the tool, release the trigger.

Make sure the blade comes to a complete stop before removing the blade

from a partial cut or laying the tool

down.

Electric Brake

The electric brake engages when the trigger is released, causing the blade to stop

and allowing you to proceed with your

work. Generally, the saw blade stops

within two seconds. However, there may

be a delay between the time you release

the trigger and when the brake engages.

Occasionally the brake may miss completely. If the brake misses frequently, the

saw needs servicing by an authorized

MILWAUKEE

ways wait for the blade to stop completely

before removing the saw from the workpiece.

service facility. You must al-

Battery Pack Protection

To protect itself from damage and extend

its life, the

circuit will turn off the battery pack if its

internal temperature becomes too high. This

could happen in extremely high torque, binding and stalling situations. The pack must

be placed on the charger to turn it back on.

The charger's light indicator will flash red,

indicating that the pack is too hot. Once the

light is continuously red, the pack has

cooled and can be used again.

Cold Weather Operation

The

used in temperatures down to -4°F. When

the battery pack is very cold, it may pulse

for the first minute of use to warm itself

up. Put the battery pack on a tool and use

the tool in a light application. After about a

minute, the pack will have warmed itself

up and operate normally.

General Cutting

For straight or contour cutting from an

edge, line the blade up with your cutting

line. Before the blade contacts the workpiece, grasp the handle firmly and pull the

trigger. Then guide the tool along your cutting

line. Always hold the shoe flat against the

workpiece to avoid excessive vibration.

V28

™battery pack's intelligent

V28

™Lithium-Ion battery pack can be

Plunge Cutting (Fig. 6)Starting, Stopping and Controlling

WARNING!

To reduce the risk of explosion,

electric shock and property damage, always check the work area

for hidden gas pipes, electrical

wires or water pipes when making

blind or plunge cuts.

Your

MILWAUKEE

plunge cutting directly into surfaces that

can not be cut from an edge, such as walls

or floors. Plunge cutting may be done two

ways depending on how the blade is inserted. Column A shows how to plunge

cut with the teeth of the blade facing downward. (When attempting to plunge cut in

this manner, shoe must be moved all the

way out, as shown.) Column B shows how

to plunge cut with the teeth of the blade

facing upward. Do not plunge cut into metal

surfaces (see "Cutting Metals").

Fig. 6

Sawzall® is ideal for

AB

1. Insert the blade into the tool.

If you inserted the blade with the teeth

facing downward, hold the tool as

shown in Column A, resting the edge

of the shoe on the workpiece.

If you inserted the blade with the teeth

facing upward, hold the tool as shown

in Column B, resting the edge of the

shoe on the workpiece as shown.

2. With the blade just above the workpiece, pull the trigger. Using the edge

of the shoe as a pivot, lower the blade

into the workpiece as shown.

3. As the blade starts cutting, raise the

handle of the tool slowly until the shoe

rests firmly on the workpiece. Then

guide the tool along your cutting line to

acquire the desired cut.

NOTE: To make plunge cutting easier, use

a heavy gauge blade and install the blade

with the teeth facing upward as shown in

Column B.

V28™

Lithium-Ion Battery Pack

Unlike other battery pack types, LithiumIon battery packs deliver fade-free power

for their entire run time. The tool will not

experience a slow, gradual loss of power

as you work. To signal to you that the

battery pack is at the end of its run time

and needs to be charged, power to the

tool will drop quickly. When this happens,

remove the tool from the workpiece and

charge the battery pack as needed.

V28

Cutting Metals

Begin cutting at a slow speed, gradually

increasing speed as you cut. When cutting

into metals or hard materials that can not

be cut from an edge, drill a starting hole

larger than the widest part of the blade.

8 9

Page 6

MAINTENANCE

WARNING!

To reduce the risk of personal injury, always unplug the charger

and remove the battery pack from

the charger or tool before performing any maintenance. Never

disassemble the tool, battery pack

or charger. Contact a

service facility for ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger

in good repair by adopting a regular maintenance program. After six months to one

year, depending on use, return the tool,

battery pack and charger to a

service facility for:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning

(gears, spindles, bearings, housing, etc.)

• Electrical inspection (battery pack,

charger, motor)

• Testing to assure proper mechanical

and electrical operation

If the tool does not start or operate at full

power with a fully charged battery pack,

clean the contacts on the battery pack. If

the tool still does not work properly, return

the tool, charger and battery pack to a

MILWAUKEE

Maintaining and Storing Battery Pack

V28™

ate for many years and/or hundreds of

charging cycles when they are maintained

and used correctly. Refer to your battery

pack and charger operator's manual for

proper care and use.

service facility for repairs.

Lithium-Ion battery packs will oper-

MILWAUKEE

MILWAUKEE

WARNING!

WARNING!

To reduce the risk of personal injury and damage, never immerse

your tool, battery pack or charger

in liquid or allow a liquid to flow

inside them.

Cleaning

Clean out dust and debris from vents and

electrical contacts by blowing with compressed air. Keep tool handles clean, dry

and free of oil or grease. Use only mild

soap and a damp cloth to clean the tool,

battery pack and charger, keeping away

from all electrical contacts. Certain cleaning agents and solvents are harmful to plastics and other insulated parts. Some of

these include gasoline, turpentine, lacquer

thinner, paint thinner, chlorinated cleaning

solvents, ammonia and household detergents containing ammonia. Never use flammable or combustible solvents around

tools.

To reduce the risk of injury or

explosion, never burn or incinerate a battery pack even if it is damaged, dead or completely discharged. When burned, toxic

fumes and materials are created.

Disposing of Lithium-Ion Battery Packs

Lithium-Ion battery packs are more environmentally friendly than some other types

of power tool battery packs (e.g., nickelcadmium). Always dispose of your battery

pack according to federal, state and local

regulations. Contact a recycling agency in

your area for recycling locations.

Even discharged battery packs contain

some energy. Before disposing, use electrical tape to cover the terminals to prevent

the battery pack from shorting, which could

cause a fire or explosion.

Repairs

For repairs, return the tool, battery pack

and charger to the nearest authorized service center.

ACCESSORIES

WARNING!

Always remove battery pack

before changing or removing accessories. Only use accessories

specifically recommended for this

tool. Others may be hazardous.

For a complete listing of accessories refer

to your

MILWAUKEE

or go on-line to www.milwaukeetool.com.

To obtain a catalog, contact your local distributor or a service center.

See Pages 34 & 35 for a listing of Super

Sawzall® Blades

10 11

Electric Tool catalog

FIVE YEAR TOOL

LIMITED WARRANTY

Every

MILWAUKEE

leaving the factory and is warranted to be

free from defects in material and workmanship.

replace (at

without charge, any tool (including battery

chargers) which examination proves to be

defective in material or workmanship from

five (5) years after the date of purchase.

Return the tool and a copy of the purchase

receipt or other proof of purchase to a

MILWAUKEE

MILWAUKEE

Support Branch location or

Authorized Service Station, freight prepaid

and insured. This warranty does not cover

damage from repairs made or attempted

by other than

personnel, abuse, normal wear and tear,

lack of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are

warranted for one (1) year from the date

of purchase. Note the warranty period for

V28 Battery Packs is two (2) years from

the date of purchase.

THE REPAIR AND REPLACEMENT REMEDIES

DESCRIBED HEREIN ARE EXCLUSIVE. IN NO

EVENT SHALL

FOR ANY INCIDENTAL, SPECIAL, OR

CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES, OR

CONDITIONS, WRITTEN OR ORAL,

EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR

PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal

rights. You may also have other rights that

vary from state to state and province to

province. In those states that do not allow

the exclusion of implied warranties or

limitation of incidental or consequential

damages, the above limitations or

exclusions may not apply to you. This

warranty applies to the United States,

Canada, and Mexico only.

tool is tested before

MILWAUKEE

Factory Service/Sales

will repair or

’s discretion),

MILWAUKEE

MILWAUKEE

MILWAUKEE

authorized

BE LIABLE

Page 7

RÈGLES GÉNÉRALES DE SÉCURITÉ POUR LES OUTILS

ALIMENTÉS PAR BATTERIE

AVERTISSEMENT!

LIRE SOIGNEUSEMENT TOUTES LES INSTRUCTIONS

Le non respect des instructions ci-après peut entraîner des chocs

électriques, des incendies et/ou des blessures graves. Le terme «outil

électrique» figurant dans les avertissements ci-dessous renvoie à l’outil

électrique à alimentation par le réseau (à cordon) ou par batterie (sans fil).

CONSERVER CES INSTRUCTIONS

SÉCURITÉ DU LIEU

DE TRAVAIL

1. Maintenir la zone de travail propre

et bien éclairée. Les zones

encombrées ou mal éclairées sont

favorables aux accidents.

2. Ne pas utiliser d’outil électrique

dans une atmosphère explosive,

telle qu’en en présence de

liquides, de gaz ou de

poussières inflammables. Les

outils électriques génèrent des

étincelles qui peuvent enflammer les

poussières ou les fumées.

3. Tenir les enfants et les

personnes non autorisées à

l’écart pendant le fonctionnement

d’un outil électrique. Un manque

d’attention de l’opérateur risque de lui

faire perdre le contrôle de l’outil.

SÉCURITÉ ÉLECTRIQUE

4. La fiche de l’outil électrique doit

correspondre à la prise

d’alimentation. Ne jamais modifier

la fiche d’une manière

quelconque. Ne pas utiliser

d’adaptateur avec les outils

électriques mis à la terre (à la

masse). Des fiches non modifiées et

des prises d’alimentation assorties

réduisent le risque de choc électrique.

5. Éviter tout contact corporel avec

des surfaces reliées à la masse

ou à la terre telles que tuyaux,

radiateurs, cuisinières et

réfrigérateurs. Un risque de choc

électrique plus élevé existe si le corps

est relié à la masse ou à la terre.

6. Ne pas exposer les outils

électriques à la pluie ou à

l’humidité. Le risque de choc

électrique augmente si de l’eau s’infiltre

dans un outil électrique.

7. Prendre soin du cordon. Ne

jamais utiliser le cordon pour

transporter, tirer ou débrancher

l’outil électrique. Tenir le cordon

à l’écart de la chaleur, des huiles,

des arêtes coupantes ou des

pièces en mouvement. Un cordon

endommagé ou emmêlé présente un

risque accru de choc électrique.

8. Se procurer un cordon

d’alimentation approprié en cas

d’utilisation d’un outil électrique

à l’extérieur. L’utilisation d’un cordon

d’alimentation pour usage extérieur

réduit le risque de choc électrique.

SÉCURITÉ INDIVIDUELLE

9. Être sur ses gardes, être attentif

et faire preuve de bon sens en

utilisant un outil électrique. Ne pas

utiliser un outil électrique en cas

de fatigue ou sous l’influence de

drogues, d’alcool ou de

médicaments. Un instant d’inattention

lors de l’utilisation d’un outil électrique

peut entraîner des blessures graves.

10. Utiliser un équipement de

sécurité. Toujours porter des lunettes de protection. Un

équipement de sécurité comprenant

masque anti-poussière, chaussures

de sécurité anti-dérapantes, casque

ou dispositif de protection anti-bruit

peut, dans les circonstances

appropriées, réduire le risque de

blessure.

12 13

11. Éviter tout démarrage accidentel

de l’outil. S’assurer que le

commutateur est en position OFF

(Arrêt) avant de brancher l’outil.

Le port de l’outil avec un doigt sur le

commutateur ou son branchement

avec le commutateur en position ON

(Marche) sont favorables aux accidents.

12. Retirer toute clé de réglage avant

de mettre l’outil sous tension.

Une clé laissée attachée sur une pièce

mobile de l’outil électrique peut

entraîner des blessures.

13. Ne pas travailler à bout de bras.

Bien garder un bon équilibre à tout

instant. Ceci permet de mieux

préserver la maîtrise de l’outil

électrique dans des situations

imprévues.

14. Porter des vêtements adéquats.

Ne pas porter de vêtements

amples ni de bijoux. Ne pas

approcher les cheveux,

vêtements et gants des pièces

en mouvement. Les vêtements

amples, les bijoux ou les cheveux

longs risquent d’être happés par les

pièces en mouvement.

15. Si des dispositifs sont prévus

pour l’extraction et la

récupération des poussières,

vérifier qu’ils sont connectés et

utilisés correctement. L’utilisation

de ces dispositifs peut réduire les

risques liés aux poussières.

UTILISATION ET ENTRETIEN

DE L’OUTIL ÉLECTRIQUE

16. Ne pas forcer l’outil électrique.

Utiliser l’outil électrique

approprié à l’application

considérée. L’outil électrique adapté

au projet considéré produira de

meilleurs résultats, dans des conditions de sécurité meilleures, à la

vitesse pour laquelle il a été conçu.

17. Ne pas utiliser l’outil électrique si

le commutateur ne le met pas

sous ou hors tension. Tout outil

électrique dont le commutateur de

marche-arrêt est inopérant est

dangereux et doit être réparé.

18. Débrancher la fiche de la prise

d’alimentation et/ou la batterie de

l’outil électrique avant d’effectuer

des réglages, de changer

d’accessoires ou de ranger

l’outil. De telles mesures de sécurité

préventive réduisent le risque de mettre

l’outil en marche accidentellement.

19. Ranger les outils électriques

inutilisés hors de la portée des

enfants et ne pas laisser des

personnes qui connaissent mal

les outils électriques ou ces instructions utiliser ces outils. Les

outils électriques sont dangereux dans

les mains d’utilisateurs non formés à

leur usage.

20. Entretien des outils électriques.

S’assurer de l’absence de tout

désalignement ou de grippage

des pièces mobiles, de toute rupture de pièce ou de toute autre

condition qui pourrait affecter le

bon fonctionnement de l’outil

électrique. En cas de dommages,

faire réparer l’outil avant de

l’utiliser de nouveau. Les outils

électriques mal entretenus sont à la

source de nombreux accidents.

21. Garder les outils de coupe affûtés

et propres. Les outils de coupe

correctement entretenus et bien

affûtés risquent moins de se gripper

et sont plus faciles à manier.

22. Utiliser cet outil électrique, les

accessoires, les mèches, etc.

conformément à ces instructions

et de la façon prévue pour ce type

particulier d’outil électrique, tout

en prenant en compte les conditions de travail et le type de projet

considérés. L’utilisation de cet outil

électrique pour un usage autre que

l’usage prévu peut créer des situations dangereuses.

UTILISATION ET ENTRETIEN

DE LA BATTERIE

23. S’assurer que le commutateur

est en position OFF (Arrêt) avant

d’insérer la batterie. L’insertion de

la batterie dans un outil électrique dont

le commutateur est en position ON

(Marche) est favorable aux accidents.

Page 8

24. Ne recharger la batterie qu’avec

le chargeur spécifié par le

fabricant. Un chargeur qui convient à

un type de batterie peut créer un risque d’incendie s’il est utilisé avec un

autre type de batterie.

25. N’utiliser les outils électriques

qu’avec les batteries

spécialement conçues pour eux.

L’utilisation de batteries d’autres

marques peut créer un risque de

blessure et d’incendie.

26. Lorsque la batterie est hors ser-

vice, la ranger à l’écart d’autres

objets métalliques tels que trombones, pièces de monnaie, clés,

clous, vis et autres petits objets

métalliques qui peuvent établir

une connexion d’une borne à

l’autre. Un court-circuit aux bornes

de la batterie peut provoquer des

brûlures ou un incendie.

27. Du liquide peut être éjecté de la

batterie en cas de manutention

abusive ; éviter tout contact. En

cas de contact accidentel avec les

projections, rincer à l’eau. En cas

de contact avec les yeux, consulter un médecin. Le liquide

s’échappant de la batterie peut

provoquer des irritations ou des

brûlures.

ENTRETIEN

28. Faire effectuer l’entretien de

l’outil électrique par un technicien

qualifié qui n’utilisera que des

pièces de rechange identiques.

La sécurité d’utilisation de l’outil en sera

préservée.

RÈGLES DE SÉCURITÉ

Pictographie

SPÉCIFIQUES

1. Tenir l’outil par les surfaces de

prise isolées si, au cours des

travaux, l’outil de coupe risque

d’entrer en contact avec des fils

cachés ou avec son propre cordon. Le contact avec un fil sous ten-

sion mettra les parties métalliques

exposées de l’outil sous tension, ce qui

infligera une secousse à l’opérateur.

2. Ne pas approcher les mains des

arêtes coupantes et des pièces

en mouvement.

3. Maintenir en l’état les étiquettes

et les plaques d’identification. Des

informations importantes y figurent. Si

elles sont illisibles ou manquantes,

contacter un centre de services et

d’entretien

remplacement gratuit.

4. Utiliser des pinces ou d’autres

moyens appropriés pour fixer et

soutenir la pièce de travail sur une

plate-forme stable. Tenir la pièce à

la main ou contre soi la rend instable et

risque d’entraîner une perte de contrôle.

5. AVERTISSEMENT! Certaines

poussières générées par les activités

de ponçage, de coupe, de rectification,

de perçage et d’autres activités de construction contiennent des substances

considérées être la cause de malformations congénitales et de troubles de

l’appareil reproducteur. Parmi ces substances figurent:

• le plomb contenu dans les peintures à

base de plomb;

• la silice cristalline des briques, du

ciment et d’autres matériaux de

maçonnerie, ainsi que

• l’arsenic et le chrome des sciages

traités chimiquement.

Les risques encourus par l’opérateur

envers ces expositions varient en

fonction de la fréquence de ce type

de travail. Pour réduire l’exposition à

ces substances chimiques, l’opérateur

doit: travailler dans une zone bien

ventilée et porter l’équipement de

sécurité approprié, tel qu’un masque

anti-poussière spécialement conçu

pour filtrer les particules

microscopiques.

MILWAUKEE

pour un

6

1. Poignée

2. Commutateur de blocage de la

détente/Haut/Bas

3. Détente

4. Protection isolante

5. Collier de lame Quik-Lok

6. Lame

7. Patin

8. Levier de libération du patin

9. Batterie

10. Boutons d’ouverture de la batterie

No de

cat.

0719-20

DESCRIPTION FONCTIONNELLE

5

7

8

14 15

Tension CD seul.

Cycles par minute à vide (SPM)

Underwriters Laboratories, Inc.,

États-Unis et Canada

Spécifications

Volts

Longueur de

cd

28

®

course

29 mm

(1-1/8 pouce)

4

Cycles

par minute

Haut 0 - 3 000

Bas 0 - 2 000

2

3

1

10

9

Page 9

MONTAGE DE L’OUTIL

AVERTISSEMENT!

Charger les batteries

lithium-ion uniquement sur les

chargeurs

V28

au lithium-ion. Des

batteries de marques différentes

peuvent provoquer des blessures

ou des dommages.

Pour les instructions de charge

spécifiques, lire le manuel de

l’opérateur fourni avec le

chargeur et la batterie.

Fig. 1

Insertion

d’une batterie

Retrait de la batterie de l’outil

Pousser les boutons d’ouverture vers

l’intérieur et retirer la batterie de l’outil.

Insertion de la batterie dans l’outil

Pour insérer la batterie dans l’outil, la glisser

sur le corps de l’outil. S’assurer qu’elle se

loge fermement en place.

V28

™au

Retrait

d’une batterie

AVERTISSEMENT!

Pour éviter les risques de

blessure, toujours verrouiller la

détente ou retirer la batterie avant

de changer ou de démonter les

accessoires. N’utiliser que les

accessoires spécialement

conçus pour cet outil. Les

accessoires non recommandés

peuvent présenter des dangers.

Sélection d’une lame

Le collier de lame Quik-Lok® peut être utilisé

avec toutes les lames universelles

Sawzall® à tiges d’13 mm (1/2 pouce).

Utiliser les lames de haute performance

2. Relâcher le collier pour que le

mécanisme à ressort vienne

comprimer la lame en la maintenant

Super Sawzall®

MILWAUKEE

pour de

meilleures performances. Lors de la

sélection de la lame, choisir la longueur et

le type de lame corrects.

De nombreux types de lames sont

disponibles pour une variété d’applications:

coupe de métal, de bois, de bois incrusté

de clous, profils en spirale, ébauchage

et contours.

De nombreuses longueurs sont également

disponibles. Choisir une longueur

suffisante pour qu’elle dépasse du

patin et de la pièce à travailler sur

toute la course. Ne pas utiliser de lame

dont la longueur est inférieure à

89 mm (3-1/2 pouces) car elle ne

dépasserait pas le patin sur toute sa

course.

Pour de meilleures performances et une

durée de vie plus longue, voir la section

«Accessoires» pour sélectionner la lame

la mieux adaptée au projet considéré.

Retrait et installation des lames du

collier de lame Quik-Lok® (Fig. 2)

Retirer la batterie avant de changer la lame.

S’assurer que l’axe et le collier de la lame

sont propres. La sciure et les copeaux de

métal peuvent empêcher le collier QuikLok® de bien serrer la lame.

fermement en place.

3. Serrer le collier dans la direction

opposée à la flèche pour que la lame

soit bien verrouillée dans le collier.

4. Appuyer sur la lame pour vérifier qu’elle

est fermement maintenue en position.

5. Pour retirer une lame, tourner le collier

en direction de la flèche tout en tirant

sur la lame. Faire preuve de prudence

lors de la manipulation de lames

chaudes.

Entretien du collier de lame Quik-Lok

• Nettoyer régulièrement les débris et la

poussière du collier de lame Quik-Lok

à l’air comprimé sec.

• S’il faut forcer pour faire tourner le

collier, le faire tourner dans les deux

sens pour dégager les débris.

• Graisser périodiquement le collier de

lame Quik-Lok® avec un lubrifiant sec

tel que du graphite.

Retrait des lames cassées du collier

de lame Quik-Lok

®

Les lames cassées peuvent être retirées

selon les méthodes suivantes.

• Retirer la batterie avant de changer la

lame.

®

®

• Pointer l’outil vers le bas, tourner le

Fig. 2

collier et secouer l’outil vers le haut et

vers le bas (NE PAS mettre l’outil en

marche lorsque les doigts sont en train

de maintenir le collier de lame ouvert).

La tige de la lame cassée doit tomber

du collier.

• Si le fait de secouer l’outil n’est pas

suffisant...

Dans la plupart des cas, un coin de la

lame cassée s’étend au-delà du collier

de la lame. Tourner le collier et tirer sur

1. Selon le travail à effectuer, la lame peut

être insérée avec les dents vers le

haut ou les dents vers le bas. Pour

installer une lame, tourner le collier en

direction de la flèche tout en insérant

la lame dans le collier jusqu’à ce que le

tenon vienne buter contre le collier.

le coin de la lame rompue pour le faire

sortir du collier par ce coin.

• Si le bout brisé ne sort pas

suffisamment pour être saisi par son

coin, utiliser une lame fine à petites

dents (telle qu’une lame de coupe en

métal) pour accrocher la lame coincée

tout en tournant le collier et l’extraire.

16 17

Réglage du patin pivot (Fig. 3 et 4)

AVERTISSEMENT!

Pour réduire les risques de

blessures, s’assurer que la lame

s’étend toujours au-delà du patin

et de la pièce à travailler sur toute

la course. Les lames peuvent se

briser en cas d’impact sur la pièce

à travailler ou le patin (Fig. 4).

Le patin peut être réglé vers l’avant et

l’arrière en six positions permettant de tirer

profit de la portion non utilisée de la lame

pour des travaux spéciaux nécessitant un

faible dégagement de lame.

Fig. 3

1/4 de tour

1. Pour régler le patin, abaisser le levier

de libération du patin d’1/4 de tour et

faire glisser le patin vers l’avant ou

vers l’arrière à la position souhaitée.

2. Pour verrouiller le patin en position, tirer

sur le levier de libération du patin.

3. Après avoir réglé le patin, appuyer

lentement sur la détente pour vérifier

que la lame s’étend toujours au-delà

du patin et de la pièce à travailler sur

toute la course.

Page 10

NE PAS UTILISER L’OUTIL SAWZALL

SANS PATIN. FRAPPER L’AXE DE LA

LAME CONTRE LA PIÈCE À TRAVAILLER

PEUT ENDOMMAGER LE MÉCANISME À

MOUVEMENT ALTERNATIF.

Fig. 4

Course

FONCTIONNEMENT

AVERTISSEMENT!

Pour réduire le risque de

blessures, garder les mains à

l’écart de la lame et des autres

pièces en mouvement. Toujours

porter des lunettes à coques ou

des lunettes de protection avec

écrans latéraux.

Commutateur de blocage de la

détente/Haut/Bas (Fig. 5)

Pour obtenir la vitesse maximale ou

verrouiller la détente, déplacer le

commutateur de blocage de la détente sur

les positions suivantes (Fig. 5):

Fig. 5

Vitesse basse (2 000 tr/mn au maximum):

Déplacer le commutateur vers la gauche.

« » s’affiche au-dessus du commutateur.

1

Pour faire varier la vitesse jusqu’à un régime

maximal de 2 000 tr/mn, augmenter ou

réduire la pression sur la détente. La

vitesse basse est généralement utilisée

pour la coupe du métal.

Vitesse haute (3 000 tr/mn au maximum):

Déplacer le commutateur vers la droite.

« » s’affiche au-dessus du commutateur.

2

Pour faire varier la vitesse jusqu’à un régime

maximal de 3 000 tr/mn, augmenter ou

réduire la pression sur la détente.

Pour verrouiller la détente: Déplacer le

commutateur vers le centre. « » s’affiche

au-dessus du commutateur. La détente ne

fonctionne pas tant que le commutateur

est sur la position verrouillée. Toujours

verrouiller la détente et retirer la batterie

avant d’effectuer l’entretien et de changer

d’accessoires. Verrouiller la détente avant de

ranger l’outil ou lorsque l’outil n’est pas utilisé.

Marche, arrêt et contrôle de la vitesse

1. Pour mettre l’outil en marche, saisir

fermement la poignée et tirer sur la

détente.

2. Pour faire varier la vitesse, augmenter

ou réduire la pression sur la détente.

La vitesse augmente en fonction de la

pression exercée sur la détente. Le

régime maximal est déterminé par la

position du commutateur high/low

(haut/bas) de verrouillage de la

détente.

3. Pour arrêter l’outil, relâcher la détente.

S’assurer que la lame est

complètement arrêtée avant de la

retirer d’un sciage partiel ou de poser

l’outil.

Frein électrique

Le frein électrique s’enclenche lors du

relâchement de la pression sur la détente,

ce qui a pour effet d’immobiliser la lame et

de permettre à l’opérateur de poursuivre

son travail. La lame de scie s’immobilise

généralement dans les deux secondes qui

suivent. Un délai peut se produire toutefois

entre le relâchement total de la pression

exercée sur la détente et l’enclenchement

du frein. Il se peut qu’occasionnellement le

frein ne s’enclenche pas du tout. En cas

de dysfonctionnement fréquent du frein,

faire réparer la scie par un centre

d’entretien

attendre que la lame s’arrête complètement

avant de retirer la scie de la pièce à

travailler.

Batterie au lithium-ion

À la différence d’autres types de batterie,

la batterie au lithium-ion fournit une énergie

constante pendant toute la durée de

fonctionnement. L’outil ne connaîtra pas

une baisse lente et graduelle de puissance

lors du travail. Pour signaler à l’utilisateur

que la batterie

de fonctionnement et requiert une nouvelle

charge, l’alimentation de l’outil chute

rapidement. Dans ce cas, retirer l’outil de

la pièce de travail et charger la batterie

selon le besoin.

MILWAUKEE

V28

agréé. Toujours

est à la fin de sa durée

V28™

18 19

Protection de la batterie

Pour se protéger contre tout dommage et

prolonger sa durée de vie, le circuit intelligent de la batterie

automatiquement si sa température interne

devient trop élevée. Ceci peut se produire

en cas de couple extrêmement élevé, de

grippage ou de calage. Placer la batterie

sur son chargeur pour la remettre sous

tension. Le témoin lumineux du chargeur

clignote en rouge, signalant ainsi la

surchauffe de la batterie. Lorsque le témoin

émet une lumière rouge en continu, la

batterie s’est refroidie et peut être utilisée

de nouveau.

Fonctionnement par temps froid

Il est possible d’utiliser la batterie au lithiumion

V28™

allant jusqu’à -20°C (-4°F). Lorsque la

température de la batterie est très basse,

elle peut envoyer des impulsions pendant

la première minute d’utilisation pour se

réchauffer. Mettre la batterie sur un outil et

utiliser cet outil sur une application légère.

Au bout d’une minute d’utilisation, la batterie

se sera suffisamment réchauffée et

fonctionnera normalement.

Coupe générale

Pour une coupe droite ou de contour à partir

d’un bord, aligner la lame avec la ligne de

coupe. Avant que la lame n’entre en contact avec la pièce à travailler, saisir

fermement la poignée et tirer sur la détente.

Guider ensuite l’outil le long de la ligne de

coupe. Toujours maintenir le patin plat

contre la pièce à travailler pour éviter les

vibrations excessives.

Coupe de métaux

Commencer à couper à vitesse lente, puis

augmenter la vitesse au fur et à mesure de

la coupe. Lors de la coupe de métaux ou

de matériaux durs ne pouvant pas être

coupés à partir d’un bord, percer un trou

d’abord plus large que la partie la plus large

de la lame.

à des températures ambiantes

V28

™ se ferme

Page 11

Coupe en plongée (Fig. 6)

AVERTISSEMENT!

Pour réduire les risques

d’explosion, de chocs électriques

et de dommages matériels,

toujours vérifier qu’il n’y a pas de

conduites de gaz, de fils

électriques ou de conduites d’eau

cachés dans la zone de travail lors

de procédures de coupe aveugles

ou en plongée.

La scie Sawzall®

pour la coupe en plongée effectué

directement dans les surfaces ne pouvant

pas être coupées à partir d’un bord, telles

que les murs et les planchers. La coupe

en plongée peut être effectuée de deux

façons en fonction de la façon dont la lame

est insérée. La colonne A illustre la coupe

en plongée avec les dents de la lame vers

le bas. (Déployer complètement le patin pour

une coupe de ce type, comme illustré.) La

colonne B illustre la coupe en plongée avec

les dents de la lame vers le haut. Ne pas

couper en plongée dans les surfaces en

métal (voir «Coupe de métaux»).

Fig. 6

MILWAUKEE

est idéale

AB

1. Insérer la lame dans l’outil.

Si la lame est insérée avec les dents

vers le bas, tenir l’outil comme illustré

dans la colonne A, en faisant reposer

le bord du patin sur la pièce à travailler.

Si la lame est insérée avec les dents

vers le haut, tenir l’outil comme illustré

dans la colonne B, en faisant reposer

le bord du patin sur la pièce à travailler

comme illustré.

2. Avec la lame juste au-dessus de la

pièce à travailler, tirer sur la détente.

En utilisant le bord du patin comme un

pivot, abaisser la lame sur la pièce à

travailler comme illustré.

3. Lorsque la lame commence à couper,

relever lentement la poignée de l’outil

jusqu’à ce que le patin repose

fermement sur la pièce à travailler. Puis

guider l’outil le long de la ligne de coupe

pour obtenir la coupe désirée.

REMARQUE: Pour faciliter la coupe en

plongée, utiliser une lame en acier de forte

épaisseur et monter la lame avec les dents

tournées vers le haut comme indiqué à la

Colonne B.

ENTRETIEN

AVERTISSEMENT!

Pour réduire le risque de

blessure, toujours débrancher le

chargeur et retirer la batterie du

chargeur ou de l’outil avant

d’effectuer un quelconque

entretien. Ne jamais démonter

l’outil, la batterie ou le chargeur.

Contacter un centre d’entretien

MILWAUKEE

réparations.

Entretien de l’outil

Maintenir l’outil, la batterie et le chargeur

en bon état en adoptant un calendrier

d’entretien périodique. Après six mois ou

un an, en fonction de l’usage qu’il en est

fait, renvoyer l’outil, la batterie et le

chargeur à un centre d’entretien

MILWAUKEE

• Lubrification

• Inspection et replacement du balai

• Inspection et nettoyage des

composants mécaniques (engrenages,

axes, roulements, carter, etc.)

• Inspection des composants électriques

(batterie, chargeur et moteur)

• Essai, afin de vérifier le bon

fonctionnement des composants

mécaniques et électriques de l’outil

Nettoyer les contacts de la batterie s’il est

impossible de mettre l’outil en marche ou si

l’outil ne fonctionne pas à pleine capacité

en dépit d’une batterie complètement

chargée. Si l’outil ne fonctionne toujours

pas correctement, renvoyer l’outil, le

chargeur et la batterie à un centre

d’entretien

pour TOUTES les

pour:

MILWAUKEE

pour réparation.

AVERTISSEMENT!

Pour réduire le risque de blessure

ou de dommage, ne jamais

plonger l’outil, la batterie ou le

chargeur dans un liquide et ne

jamais laisser l’eau s’y infiltrer.

Nettoyage

Nettoyer la poussière et les débris des

évents et des contacts électriques à l’air

comprimé. Maintenir les poignées de l’outil

propres, sèches et exemptes de graisse

ou d’huile. N’utiliser que du savon doux et

un chiffon humide pour nettoyer l’outil, la

batterie et le chargeur, en évitant les contacts électriques. Certains produits de

nettoyage ou solvants sont nocifs pour les

plastiques et les pièces isolées, notamment :

essence, essence de térébenthine, diluant

pour vernis, diluant pour peintures, solvant

chloré, ammoniaque et détergents

ménagers contenant de l’ammoniaque. Ne

jamais utiliser de solvants inflammables ou

combustibles à proximité d’outils.

Entretien et remisage de la batterie

La batterie

fonctionnera pendant de nombreuses

années et/ou des centaines de cycles de

charge si elle est entretenue et utilisée

correctement. Consulter le manuel de

l’opérateur du chargeur et de la batterie

pour les conseils d’entretien et d’usage.

V28

™ au lithium-ion

20 21

Page 12

AVERTISSEMENT!

Afin de réduire le risque de blessure

ou d’explosion, ne jamais brûler

ou incinérer une batterie même si

elle est endommagée, morte ou

complètement déchargée. La

combustion d’une batterie libère

des fumées et des substances

toxiques dans l’atmosphère.

Mise au rebut des batteries au

lithium-ion

Les batteries au lithium-ion présentent

moins de risques pour l’environnement que

d’autres types de batterie (nickel-cadmium).

Éliminer les batteries conformément

aux règlements fédéraux/nationaux,

provinciaux/d’états et locaux. Contacter

l’agence de recyclage locale pour l’adresse

des centres de recyclage locaux.

Les batteries déchargées contiennent du

courant résiduel. Avant de mettre une batterie

au rebut, couvrir les bornes de la batterie

avec du ruban isolant afin d’empêcher un

court-circuit éventuel qui pourrait

provoquer un incendie ou une explosion.

Réparations

Pour toutes réparations, renvoyer l’outil, la

batterie et le chargeur au centre d’entretien

agréé le plus proche.

ACCESSOIRES

AVERTISSEMENT!

Toujours enlever la batterie

avant de changer ou de retirer un

accessoire. N’utiliser que les

accessoires spécialement

conçus pour cet outil. Les

accessoires non recommandés

peuvent présenter des dangers.

Pour une liste complète des accessoires,

consulter le catalogue des outils

MILWAUKEE

à l’adresse www.milwaukeetool.com.

Pour obtenir un catalogue, contacter le

distributeur local ou un centre d’entretien.

Voir page 34 & 35 pour Lames Super

Sawzall® Bimétalliques.

Electric Tool ou aller en ligne

GARANTIE LIMITÉE DE

L’OUTIL DE CINQ ANS

Tous les outils

avant de quitter l’usine et sont garantis

exempts de vice de matériau ou de

fabrication.

remplacera (à la discrétion de

MILWAUKEE

compris les chargeurs de batterie) dont

l’examen démontre le caractère défectueux

du matériau ou de la fabrication dans les

cinq (5) ans suivant la date d’achat.

Retourner l’outil et une copie de la facture

ou de toute autre preuve d’achat à une

branche Entretien usine/Assistance des

ventes de l’établissement

à un centre d’entretien agréé par

MILWAUKEE

garantie ne couvre pas les dommages

causés par les réparations ou les tentatives

de réparation par quiconque autre que le

personnel agréé par

utilisations abusives, l’usure normale, les

carences d’entretien ou les accidents.

Les batteries, les lampes de poche et les

radios sont garanties pour un (1) an à partir

de la date d’achat. Noter que le période de

garantie pour les batteries

(2) ans à compter de la date d’achat.

LES SOLUTIONS DE RÉPARATION ET DE

REMPLACEMENT DÉCRITES PAR LES

PRÉSENTES SONT EXCLUSIVES.

MILWAUKEE

RESPONSABLE, EN AUCUNE

CIRCONSTANCE, DES DOMMAGES

ACCESSOIRES, SPÉCIAUX OU INDIRECTS,

Y COMPRIS LES MANQUES À GAGNER.

CETTE GARANTIE EST EXCLUSIVE ET

REMPLACE TOUTES LES AUTRES

GARANTIES OU CONDITIONS, ÉCRITES OU

ORALES, EXPRESSES OU TACITES DE

QUALITÉ MARCHANDE OU D’ADAPTATION

À UNE UTILISATION OU UNE FIN

PARTICULIÈRE.

Cette garantie vous donne des droits

particuliers. Vous pouvez aussi bénéficier

d’autres droits variant d’un état à un autre

et d’une province à une autre. Dans les

états qui n’autorisent pas les exclusions

de garantie tacite ou la limitation des

dommages accessoires ou indirects, les

limitations ou exclusions ci-dessus peuvent

ne pas s’appliquer. Cette garantie s’applique

aux États-Unis, au Canada et au Mexique

uniquement.

MILWAUKEE

MILWAUKEE

), sans frais, tout outil (y

, en port payé et assuré. Cette

NE SAURAIT ÊTRE

sont testés

réparera ou

MILWAUKEE

MILWAUKEE

V28

est de deux

ou

, les

REGLAS DE SEGURIDAD GENERALES PARA HERRAMIENTAS

OPERADAS POR BATERÍA

¡ADVERTENCIA!

LEA TODAS LAS INSTRUCCIONES

Si no se siguen todas las siguientes instrucciones se puede provocar una

descarga eléctrica, un incendio y/o lesiones graves. El término “herramienta

eléctrica” en todas las advertencias incluidas más abajo se refiere a su

herramienta operada por conexión (cable) a la red eléctrica o por medio de

una batería (inalámbrica).

GUARDE ESTAS INSTRUCCIONES

SEGURIDAD EN EL ÁREA

DE TRABAJO

1. Mantenga limpia y bien iluminada

el área de trabajo. Las áreas

desordenadas u oscuras contribuyen

a que se produzcan accidentes.

2. No utilice herramientas eléctricas

en atmósferas explosivas, como

en la presencia de líquidos, gases

o polvo inflamables. Las

herramientas eléctricas crean chispas

que pueden incendiar el polvo o las

emanaciones.

3. Mantenga a los niños y otras per-

sonas alejadas mientras utiliza

una herramienta eléctrica. Las

distracciones pueden hacerle perder

el control.

SEGURIDAD ELÉCTRICA

4. Los enchufes de las herramientas

eléctricas deben ser del mismo

tipo que el tomacorrientes. Nunca

realice ningún tipo de

modificación en el enchufe. No

use enchufes adaptadores con

herramientas eléctricas con

conexión a tierra. Se reducirá el

riesgo de descarga eléctrica si no se

modifican los enchufes y los

tomacorrientes son del mismo tipo.

5. Evite el contacto corporal con su-

perficies con conexión a tierra,

como tuberías, radiadores,

estufas y refrigeradores. El riesgo

de descarga eléctrica aumenta si su

cuerpo está conectado a tierra.

22 23

6. No exponga la herramientas

eléctricas a la lluvia o a

condiciones de humedad. El agua

que entra en una herramienta eléctrica

aumenta el riesgo de descarga

eléctrica.

7. No abuse del cable. Nunca use el

cable para transportar la

herramienta eléctrica, tirar de ella

o desenchufarla. Mantenga el

cable alejado del calor, los bordes

afilados o las piezas en

movimiento. Los cables dañados o

enmarañados aumentan el riesgo de

descarga eléctrica.

8. Cuando se utiliza una herramienta

eléctrica en el exterior, use una

extensión que sea apropiada para

uso en el exterior. El uso de un cable

apropiado para el exterior reduce el

riesgo de descarga eléctrica.

SEGURIDAD PERSONAL

9. Manténgase alerta, ponga cuidado

a lo que está haciendo y use el

sentido común cuando utilice una

herramienta eléctrica. No use una

herramienta eléctrica cuando está

cansado o bajo la influencia de

drogas, alcohol o medicinas.

Despistarse un minuto cuando se utiliza

una herramienta eléctrica puede tener

como resultado lesiones personales

graves.

10. Use equipo de seguridad. Lleve

siempre protección ocular. Llevar

equipo de seguridad apropiado para

la situación, como una máscara

antipolvo, zapatos de seguridad

Page 13

antideslizantes casco o protección

auditiva, reducirá las lesiones

personales.

11. Evite los arranques accidentales.

Asegúrese de que el interruptor

esté en la posición de apagado

antes de enchufar la herramienta.

Mover herramientas con el dedo en el

interruptor o enchufar herramientas

con el interruptor en la posición de

encendido contribuye a que se

produzcan accidentes.

12. Quite todas las llaves de ajuste

antes de encender la herramienta.

Una llave que esté acoplada a una

pieza giratoria de la herramienta puede

provocar lesiones personales.

13. No se estire demasiado. Mantenga

los pies bien asentados y el

equilibrio en todo momento. Esto

permite tener mejor control de la

herramienta eléctrica en situaciones

inesperadas.

14. Vístase de manera apropiada. No

lleve ropa suelta ni joyas. Mantenga

el cabello, la ropa y los guantes

lejos de la piezas en movimiento.

La ropa floja, las joyas o el cabello

largo pueden quedar atrapados en las

piezas en movimiento.

15. Si se proporcionan dispositivos

para la conexión de sistemas de

recolección y extracción de polvo,

asegúrese de que estén

conectados y se usen

apropiadamente. El uso de estos

dispositivos puede reducir los peligros

relacionados con el polvo.

USO Y CUIDADO DE LAS

HERRAMIENTAS ELÉCTRICAS

16. No fuerce la herramienta eléctrica.

Use la herramienta eléctrica

correcta para la aplicación. La

herramienta eléctrica correcta

funcionará mejor y de manera más

segura a la velocidad para la que se

diseñó.

17. No use la herramienta eléctrica si

el interruptor no la enciende ni la

apaga. Cualquier herramienta eléctrica

que no se pueda controlar con el

interruptor es peligrosa y se debe

reparar.

18. Desconecte el enchufe de la toma

de alimentación y/o la batería de

la herramienta eléctrica antes de

realizar cualquier ajuste, cambiar

accesorios o almacenar las

herramientas eléctricas. Dichas

medidas preventivas de seguridad

reducen el riesgo de que la herramienta

se prenda accidentalmente.

19. Almacene las herramientas

eléctricas fuera del alcance de los

niños y no permita que personas

no familiarizadas con ellas o estas

instrucciones las utilicen. Las

herramientas eléctricas son peligrosas

en las manos de usuarios no

capacitados.

20. Mantenimiento de las

herramientas eléctricas. Revise

que no haya piezas móviles que

estén desalineadas o que se

atasquen, piezas rotas ni ninguna

otra condición que pueda afectar

el funcionamiento de la

herramienta eléctrica. Si se

encuentran daños, haga que le

reparen la herramienta antes de

usarla. Las herramientas mal

mantenidas son la causa de muchos

accidentes.

21. Mantenga las herramientas de

corte limpias y afiladas. Es menos

probable que se atasquen las

herramientas de corte con filos

afilados que se mantienen de manera

apropiada y también son más fáciles

de controlar.

22. Use la herramienta eléctrica, los

accesorios y las brocas, etc.

siguiendo estas instrucciones y

de la manera para la que dicha

herramienta eléctrica en particular fue diseñada, teniendo en

cuenta las condiciones de trabajo

y la tarea que se va a realizar. El

uso de la herramienta eléctrica para

operaciones diferentes de aquellas

para las que se diseño podría resultar

en una situación peligrosa.

USO Y CUIDADO DE LAS

HERRAMIENTAS CON BATERÍA

23. Asegurarse de que el interruptor

esté en la posición apagada antes de colocar la batería. Colocar la

batería en las herramientas eléctricas

que tienen el interruptor en la posición

de encendido contribuye a que se

produzcan accidentes.

24. Recárguela solamente con el

cargador especificado por el

fabricante. Un cargador que sea

apropiado para un tipo de batería

puede crear riesgo de incendio cuando

se use con otra batería.

25. Use las herramientas eléctricas

solamente con baterías

específicamente diseñadas. El uso

de cualquier otro tipo de batería puede

crear riesgo de lesiones o incendio.

26. Cuando no se use la batería

manténgala alejada de otros

objetos de metal como clips para

papel, monedas, llaves, clavos,

tornillos u otros objetos de metal

pequeños que puedan realizar

una conexión entre los bornes.

Realizar un cortacircuito en los

terminales de la batería puede provocar

quemaduras o un incendio.

27. Bajo condiciones abusivas, puede

salir líquido expulsado de la

batería; evitar el contacto. Si se

produce un contacto accidental,

lavar con agua. Si el líquido entra

en contacto con los ojos buscar

ayuda médica adicional. El líquido

que sale despedido de la batería puede

causar irritaciones o quemaduras.

MANTENIMIENTO

28. Haga que un técnico calificado

realice el mantenimiento de la

herramienta eléctrica utilizando

solamente piezas de repuesto

idénticas. Esto asegurará que se

mantiene la seguridad de la herramienta

eléctrica.

24 25

REGLAS DE SEGURIDAD

ESPECÍFICAS

1. Agarre la herramienta por los

asideros aislados cuando realice

una operación en la que la

herramienta de corte pueda

entrar en contacto con cables

ocultos o con su propio cable. El

contacto con un cable “con corriente”

hará que las partes de metal expuesto

de la herramienta pasen la corriente y

produzcan una descarga al operador.

2. Mantenga las manos alejadas de

todos los filos y piezas en

movimiento.

3. Mantenga las etiquetas y las placas

de identificación. Tienen información

importante. Si no se pueden leer o si

faltan, póngase en contacto con un

centro de servicio

obtener un repuesto gratuito.

4. Use abrazaderas u otra manera

práctica de asegurar y sujetar la

pieza en la que se va a trabajar en

una plataforma estable. Sujetar la

pieza con la mano o contra su cuerpo

la deja inestable y puede conducir a la

pérdida de control.

5. ¡ADVERTENCIA! Ciertos polvos

creados al lijar, serrar, esmerilar,

perforar y realizar otras actividades

de construcción contienen productos

químicos que se sabe que causan

cáncer, defectos congénitos u otros

daños al aparato reproductor. Algunos

ejemplos de dichos productos químicos

son:

• plomo de pintura con base de plomo

• sílice cristalino de los ladrillos y

cemento y de otros productos de

mampostería, y

• arsénico y cromo de madera tratada

químicamente.

Su riesgo de exposición varía

dependiendo de la frecuencia con la

que realice este tipo de trabajo. Para

reducir su exposición a estos

productos químicos: trabaje en un área

bien ventilada, y trabaje con equipo de

seguridad aprobado, como aquellas

máscaras antipolvo especialmente

diseñadas para filtrar partículas

microscópicas.

MILWAUKEE

para

Page 14

Simbología

MONTAJE DE LA HERRAMIENTA

Volts corriente directa

Cortes por minuto sin carga (SPM)

Underwriters Laboratories, Inc.,

Estados Unidos y Canadá

Especificaciones

Cat.

No.

0719-20

Volts

cd

28

Longitud

del Corte

29 mm

(1-1/8 pulg.)

Velocidad alta 0 - 3 000

Velocidad baja 0 - 2 000

DESCRIPCIÓN FUNCIONAL

5

6

7

1. Mango

2. Interruptor de velocidad alta/baja/traba del gatillo

3. Gatillo

4. Funda aislante

5. Portaseguetas Quik-Lok

6. Segueta

7. Zapata

8. Palanca de liberación de la zapata

9. Batería

10. Botones de liberación de la batería

8

4

®

26 27

Cortes

por minuto

3

9

¡ADVERTENCIA!

Cargue solamente baterías de

iones de litio

cargadores de iones de litio

Otras marcas de baterías pueden

ocasionar lesiones personales y

daños.

Para obtener instrucciones

específicas de carga, por favor lea

el manual del operador que se

incluye con el cargador.

Fig. 1

2

1

10

Inserción de

una batería

Extracción de la batería de la herramienta

Presione los botones de liberación y jale

de la batería para sacarla de la

herramienta.

Inserción de la batería en la herramienta

Para insertar la batería en la herramienta,

deslícela en el cuerpo de la herramienta.

Asegúrese de que se asegura bien en su

posición.

V28

™ en los

Extracción de

una batería

V28

Al seleccionar una segueta, elija el tipo y la

longitud adecuados.

Hay diferentes tipos de seguetas disponibles

para diversas aplicaciones: corte de metal, de

.

madera, de madera con clavos incrustados, de

rollos de papel, desbastado y contorneo.

Se dispone también de muchas longitudes. Elija

una segueta que sea lo suficientemente larga

para extenderse en todo momento más allá de

la zapata y de la pieza que se desea cortar. No

use seguetas a menos que, como

mínimo, midan 89 mm (3-1/2 pulg.) de

largo ya que no se extenderán más allá

de la zapata durante el corte.

Consulte “Accesorios” para seleccionar la mejor

segueta para la tarea a realizar y así obtener el

mejor rendimiento y la vida útil más larga.

Instalación u extracción de seguetas

del portaseguetas Quik-Lok® (Fig. 2)

Quite la batería antes de cambiar las

seguetas. Asegúrese de que los espacios

que circundan al portaseguetas y al eje

estén limpios. El aserrín y las rebabas de

acero pueden hacer que el portaseguetas

Quik-Lok® no se cierre bien.

Fig. 2

¡ADVERTENCIA!

Para reducir el riesgo de lesiones,

trabe siempre el gatillo o quite la

batería antes de cambiar o quitar

accesorios. Use solamente accesorios específicamente recomendados para esta herramienta. El uso de

otros puede resultar peligroso.

Selección de una segueta

El portaseguetas Quik-Lok® puede usarse con

todas las seguetas Sawzall® universales con

una espiga de 13 mm (1/2 pulg.). Para obtener

el mejor rendimiento, use seguetas de alto

rendimiento Super Sawzall® de

MILWAUKEE

1. Dependiendo de la tarea a realizar, la

segueta se puede introducir con los

dientes hacia arriba o hacia abajo. Para

instalar una segueta, haga girar el

anillo en la dirección de la flecha

mientras introduce la segueta hasta

que la cola de ésta toque fondo en el

anillo.

2. Suelte el anillo. El mecanismo de resorte

de éste sujetará la cuchilla firmemente

en su sitio.

3. Haga girar el anillo en la dirección

.

opuesta a la marcada por la flecha

Page 15

para así asegurarse de que la segueta

ha quedado bien afianzada en el

portaseguetas.

4. Empuje con fuerza de la segueta para

asegurarse de que ha quedado bien

afianzada en su sitio.

5. Para sacar una segueta, jálela mientras

gira el anillo en la dirección de la flecha.

Sea cuidadoso al manipular seguetas

calientes.

Mantenimiento del portaseguetas

Quik-Lok

• De manera periódica limpie el polvo y

• Si el collar se resiste al giro, gírelo de un

• Lubrique periódicamente el

®

los residuos que haya en el

portaseguetas Quik-Lok® con aire

comprimido.

lado a otro para sacudir los residuos.

portaseguetas Quik-Lok® con un

lubricante seco, como por ejemplo

grafito.

Ajuste de la zapata pivotante (Fig. 3 y 4)

¡ADVERTENCIA!

Para reducir el riesgo de lesiones,

asegúrese de que la segueta

siempre se extiende más allá de la

zapata y de la pieza que se desea

cortar. Las seguetas pueden

romperse si golpean la pieza que

se desea cortar o la zapata (Fig. 4).

La zapata puede colocarse en seis

diferentes posiciones hacia delante y hacia

detrás para aprovechar la parte de la

segueta que no está siendo usada o para

trabajos especiales que requieren un

espacio libre reducido para la segueta.

Fig. 3

NO UTILICE EL PORTASEGUETAS SAWZALL

SIN ZAPATA. GOLPEAR EL EJE CONTRA LA

PIEZA PUEDE DAÑAR EL MECANISMO DE

RECIPROCIDAD.

Fig. 4

Corte

FUNCIONAMIENTO

¡ADVERTENCIA!

Para reducir el riesgo de lesiones,

mantenga ambas manos alejadas de

la segueta y de otras piezas móviles.

Lleve siempre lentes de seguridad

con protectores laterales.

Interruptor de velocidad alta/baja/

traba del gatillo (Fig. 5)

Para fijar la velocidad máxima o para trabar el

gatillo, coloque el interruptor de velocidad alta/

baja/traba del gatillo en las siguientes posiciones

(Fig. 5):

Fig. 5

Extracción de seguetas rotas del

portaseguetas Quik-Lok

Las seguetas rotas pueden sacarse

siguiendo los siguientes métodos.

• Quite la batería antes de sacar las

seguetas.

• Apunte la herramienta hacia el suelo,

gire el anillo y sacuda la herramienta

hacia arriba y hacia abajo (NO

encienda la herramienta mientras sus

dedos sostienen el portaseguetas

abierto). La espiga de la segueta rota

deberá entonces desprenderse del

portaseguetas.

• Si el sacudir la herramienta no

funciona...

En la mayoría de los casos, un

fragmento de la segueta rota se

extenderá más allá del portaseguetas.

Haga girar el anillo y saque la segueta

rota jalándola de ese fragmento.

• Si el fragmento roto no es lo

suficientemente largo para asirlo,

utilice una segueta delgada de dientes

pequeños (tal como una segueta para

cortar metal) para enganchar la

segueta que ha quedado atorada en

el portaseguetas y sáquela mientras

hace girar el anillo.

®

1/4 de vuelta

1. Para ajustar la zapata, jale hacia abajo

su palanca de liberación 1/4 de vuelta

y deslice la zapata hacia delante o

hacia detrás a la posición deseada.

2. Para trabar la zapata en su posición,

empuje hacia arriba su palanca de

liberación.

3. Después de ajustar la zapata, tire

lentamente del gatillo para asegurarse

de que la segueta siempre se extiende

más allá de la zapata y de la pieza que

se desea cortar.

28 29

Para la velocidad baja (Máximo 2 000 RPM):

Mueva el interruptor a la izquierda. “ ”

aparecerá sobre el interruptor. Para variar