Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Cat. No.

No de cat.

Cat. No.

0730-20

CIRCULAR SAW

SCIE CIRCULAIRE

SIERRA CIRCULAR

TO REDUCE THE RISK OF INJURY, USER MUST READ OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER EL MANUAL

DEL OPERADOR.

Page 2

GENERAL SAFETY RULES-FOR ALL BATTERY OPERATED TOOLS

POWER TOOL USE AND CARE

BATTERY TOOL USE AND CARE

WARNING

READ ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in electric shock, fi re and/or

serious injury. The term "power tool" in all of the warnings listed below refers to your

mains-operated (corded) power tool or battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

WORK AREA SAFETY

1. Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2. Do not operate power tools in ex-

plosive atmospheres, such as in the

presence of fl ammable liquids, gases,

or dust. Power tools create sparks which

may ignite the dust or fumes.

3. Keep children and bystanders away

while operating a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

4. Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power tools.

Unmodifi ed plugs and matching outlets

will reduce risk of electric shock.

5. Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

6. Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric

shock.

7. Do not abuse the cord. Never use the

cord for carrying, pulling, or unplugging the power tool. Keep cord away

from heat, oil, sharp edges, or moving parts. Damaged or entangled cords

increase the risk of electric shock.

8. When operating a power tool out-

doors, use an extension cord suitable

for outdoor use. Use of a cord suitable

for outdoor use reduces the risk of electric shock.

PERSONAL SAFETY

9. Stay alert, watch what you are do-

ing and use common sense when

operating a power tool. Do not use

a power tool while you are tired or

under the infl uence of drugs, alcohol

or medication. A moment of inattention

while operating power tools may result

in serious personal injury.

10. Use safety equipment. Always wear

eye protection. Safety equipment such

as dust mask, non-skid safety shoes,

hard hat, or hearing protection used

for appropriate conditions will reduce

personal injuries.

11. Avoid accidental starting. Ensure the

switch is in the off-position before plugging in. Carrying tools with your fi nger on

the switch or plugging in power tools that

have the switch on invites accidents.

12. Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

13. Do not overreach. Keep proper foot-

ing and balance at all times. This

enables better control of the power tool

in unexpected situations.

14. Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery, or long

hair can be caught in moving parts.

15. If devices are provided for the connec-

tion of dust extraction and collection

facilities, ensure these are connected

and properly used. Use of these de-

vices can reduce dust-related hazards.

16. Do not force the power tool. Use the

correct power tool for your application. The correct power tool will do the

job better and safer at the rate for which

it was designed.

17. Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

18. Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools. Such preven-

tive safety measures reduce the risk of

starting the tool accidentally.

19. Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tools or

these instructions to operate power

tools. Power tools are dangerous in the

hands of untrained users.

20. Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect the

power tool's operation. If damaged,

have the power tool repaired before

use. Many accidents are caused by

poorly maintained power tools.

21. Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

22. Use the power tool, accessories and

tool bits etc., in accordance with

these instructions and in the manner

intended for the particular type of

power tool, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

23. Ensure the switch is in the off posi-

tion before inserting battery pack.

Inserting the battery pack into power

tools that have the switch on invites

accidents.

24. Recharge only with the charger speci-

fi ed by the manufacturer. A charger

that is suitable for one type of battery

pack may create a risk of fi re when used

with another battery pack.

25. Use power tools only with specifi cally

designated battery packs. Use of any

other battery packs may create a risk of

injury and fi re.

26. When battery pack is not in use, keep

it away from other metal objects like

paper clips, coins, keys, nails, screws,

or other small metal objects that can

make a connection from one terminal

to another. Shorting the battery terminals

together may cause burns or a fi re.

27. Under abusive conditions, liquid may

be ejected from the battery, avoid

contact. If contact accidentally occurs, fl ush with water. If liquid con-

tacts eyes, additionally seek medical

help. Liquid ejected from the battery

may cause irritation or burns.

SERVICE

28. Have your power tool serviced by a

qualifi ed repair person using only

identical replacement parts. This will

ensure that the safety of the power tool

is maintained.

2 3

Page 3

SPECIFIC SAFETY RULES — CIRCULAR SAWS

1. DANGER!:

Keep hands away from cutting area

and blade. Keep your second hand

on auxiliary handle or motor housing.

If both hands are holding the saw, they

cannot be cut by the blade.

Do not reach underneath the work-

piece. The guard cannot protect you

from the blade below the workpiece.

Adjust the cutting depth to the thick-

ness of the workpiece. Less than a full

tooth of the blade teeth should be visible

below the workpiece.

NEVER hold piece being cut in your

hands or across your leg. Secure the

workpiece to a stable platform. It is

important to support the work properly to

minimize body exposure, blade binding,

or loss of control.

Hold power tool by insulated grip-

ping surfaces when performing an

operation where the cutting tool may

contact hidden wiring or its own cord.

Contact with a “live” wire will also make

exposed metal parts of the tool “live” and

shock the operator.

When ripping always use a rip fence

or straight edge guide. This improves

the accuracy of cut and reduces the

chance of blade binding.

Always use blades with correct size

and shape (diamond versus round) of

arbor holes. Blades that do not match

the mounting hardware of the saw will

run eccentrically, causing loss of control.

Never use damaged or incorrect blade

washers or bolts. The blade washers

and bolts were specially designed for

your saw, for optimum performance and

safety of operation.

2. Causes and Operator Prevention of

KICKBACK:

KICKBACK is a sudden reaction to

a pinched, bound or misaligned saw

blade, causing an uncontrolled saw to

lift up and out of the workpiece toward

the operator.

When the blade is pinched or bound

tightly by the kerf closing down, the

blade stalls and the motor reaction

drives the unit rapidly back toward the

operator.

If the blade becomes twisted or mis-

aligned in the cut, the teeth at the back

edge of the blade can dig into the top

surface of the wood causing the blade

to climb out of the kerf and jump back

toward operator.

KICKBACK is the result of saw misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below:

Maintain a fi rm grip with both hands

on the saw and position your arms to

resist kickback forces. Position your

body to either side of the blade, but not

in line with the blade. Kickback could

cause the saw to jumb backwards, but

kickback forces can be controlled by

the operator, if proper precautions are

taken.

When blade is binding, or when inter-

rupting a cut for any reason, release

the trigger and hold the saw motionless in the material until the blade

comes to a complete stop. Never

attempt to remove the saw from the

work or pull the saw backward while

the blade is in motion or kickback

may occur. Investigate and take cor-

rective actions to eliminate the cause

of blade binding.

When restarting a saw in the work-

piece, center the saw blade in the kerf

and check that saw teeth are not engaged into the material. If saw blade is

binding, it may walk up or kickback from

the workpiece as the saw is restarted.

Support large panels to minimize the

risk of blade pinching and kickback.

Large panels tend to sag under their

own weight. Supports must be placed

under the panel on both sides, near

the line of cut and near the edge of the

panel.

Do not use dull or damaged blade.

Unsharpened or improperly set blades

produce narrow kerf causing excessive

friction, blade binding and kickback.

Blade depth and bevel adjusting lock-

ing levers must be tight and secure

before making cut. If blade adjustment

shifts while cutting, it may cause binding

and kickback.

Use extra caution when making a

"plunge cut" (or pocket cut) into

existing walls or other blind areas.

The protruding blade may cut objects

that can cause kickback.

3. Check lower guard for proper closing

before each use. Do not operate saw

if lower guard does not move freely

and close instantly. Never clamp or

tie the lower guard into the open position. If saw is accidentally dropped,

lower guard may be bent. Raise the

lower guard with the lower guard lever

and make sure it moves freely and does

not touch the blade or any other part, in

all angles and depths of cut.

Check the operation of the lower

guard spring. If the guard and the

spring are not operating properly,

they must be serviced before use.

Lower guard may operate sluggishly due

to damaged parts, gummy deposits, or

a buildup of debris.

Lower guard should be retracted

manually only for special cuts such

as "plunge cuts" ("pocket cuts") and

"compound cuts". Raise lower guard

by lower guard lever and as soon as

blade enters the material, the lower

guard must be released. For all other

sawing, the lower guard should operate

automatically.

Symbology

Volts Direct Current

No Load Revolutions

per Minute (RPM)

Underwriters Laboratories, Inc.,

United States and Canada

Specifi cations

Cat.

No.

0730-20

Volts

DC

28

No Load

RPM

4200

Blade

Size

6-1/2"

Always observe that the lower guard

is covering the blade before placing saw down on bench or fl oor. An

unprotected, coasting blade will cause

the saw to walk backwards, cutting

whatever is in its path. Be aware of the

time it takes for the blade to stop after

switch is released.

4. Maintain labels and nameplates.

These carry important information.

If unreadable or missing, contact a

MILWAUKEE service facility for a free

replacement.

5. WARNING! Some dust created by

power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and

cement and other masonry products,

and

• arsenic and chromium from chemi-

cally-treated lumber.

Your risk from these exposures varies,

depending on how often you do this

type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust

masks that are specially designed to

fi lter out microscopic particles.

Arbor

5/8"

Depth of Cut

At 90°

0 to 2-1/8"

Depth of Cut

at 45°

0 to 1-9/16"

4 5

Page 4

FUNCTIONAL DESCRIPTION

TOOL ASSEMBLY

1. Front handle

2. Lock-off button

3. Trigger

4. Handle

5. Battery pack release buttons

6. Battery pack

7. Shoe

8. Lower guard lever

9. Lower guard

10. Blade bolt

11. Blade fl ange

12. Blade

1

2

12

14

3

11

10

13

15

16

17

4

9

5

6

7

8

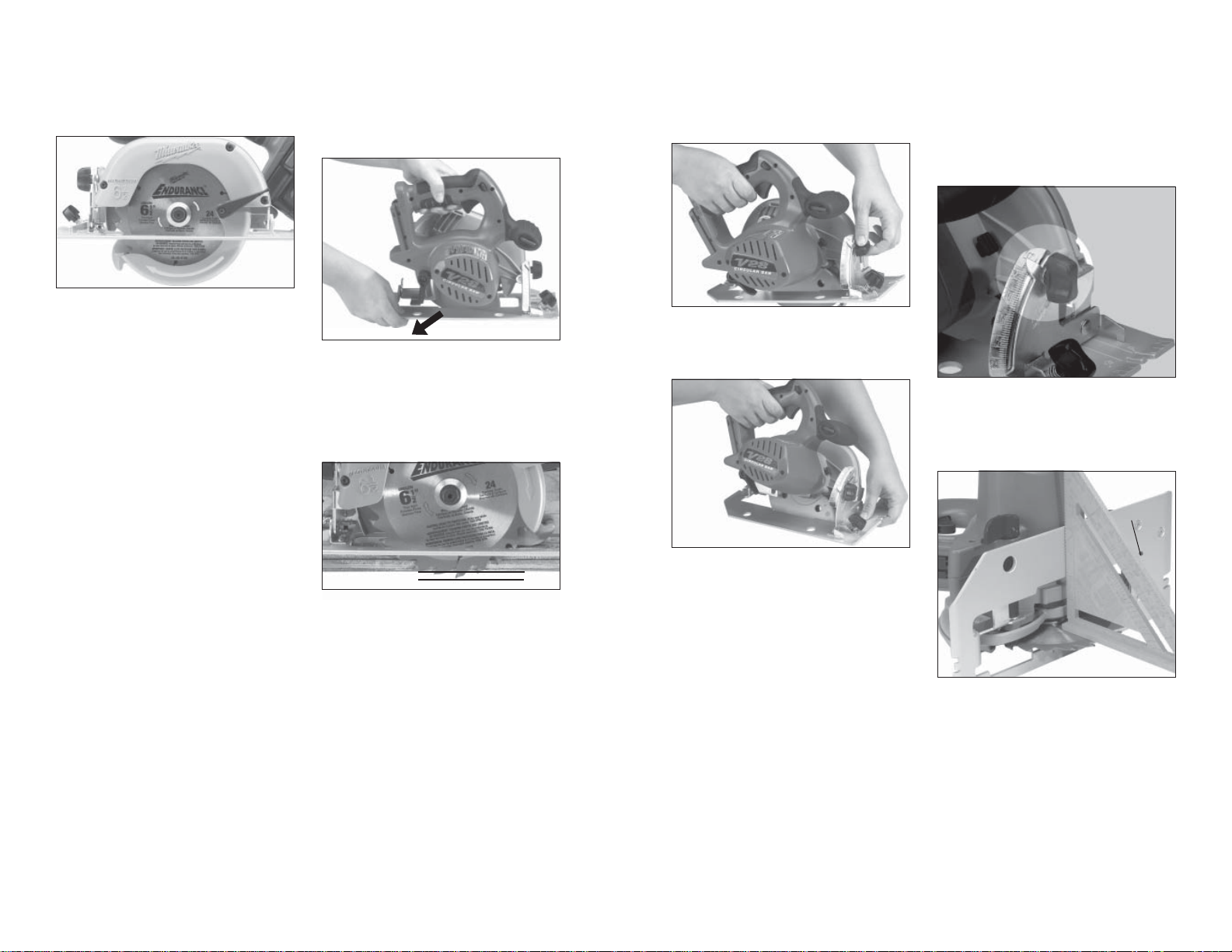

Inserting a

battery pack

Removing Battery Pack from Tool

Push in the release buttons and pull the

battery pack away from the tool.

Inserting Battery Pack into Tool

T o insert the battery pack onto the tool, slide

the pack onto the body of the tool. Make sure

it latches securely into place.

WARNING

Charge only V28™ Lithium-Ion battery

packs on V28 Lithium-Ion chargers.

Other brands of batteries may cause

personal injury or damage.

For specifi c charging instructions,

please read the operator's manual

supplied with your charger.

Fig. 1

Removing a

battery pack

Installing and Removing Blades

1. REMOVE BATTERY P ACK BEFORE INSTALLING OR REMOVING BLADES.

2. Place the saw on a fl at surface with the

blade facing upwards. To remove the

bolt from the spindle, push in the spindle

lock button. While holding in the spindle

lock button, use the wrench provided

with the tool to turn the bolt clockwise

(Fig. 2). Remove the bolt and blade

fl ange.

Fig. 2

3. Slide the lower guard lever up to raise

the lower guard. Remove the blade from

the spindle. Always clean the spindle,

upper guard and lower guard to remove

any dirt and sawdust.

NOTE: Do not remove inner blade

fl ange. Larger diameter of inner fl ange

(Fig. 3) should face the blade.

13. Wrench

18

14. Bevel pointer

15. Bevel adjusting knob

16. Bevel scale

17. Rip fence adjusting knob

18. Depth adjusting lever

19. Upper guard

20. Rip fence slot

21. Sight line

22. Spindle lock button

WARNING

To reduce the risk of injury, always

remove battery pack before changing or removing accessories. Only

19

20

22

6 7

21

use accessories specifi cally recom-

mended for this tool. Others may be

hazardous.

Selecting Blade

Always use sharp blades. Dull blades tend

to overload the tool and increase the chance

of KICKBACK (see "Causes and Operator

Prevention of KICKBACK"). Only use thin

kerf blades with a maximum safe operating

speed greater than the no load RPM marked

on the tool's nameplate. Read the blade

manufacturer's instructions before use. Do

not use any type of abrasive cut-off wheel

or dry diamond cutting blades.

Fig. 3

Inner fl ange

Spindle

Bolt

Outer fl ange

Page 5

4. To install a blade, place the blade on

the spindle with the teeth pointing in

the same direction as the arrow on the

lower guard (Fig. 4). Release the lower

guard lever.

Fig. 4

5. Place the blade fl ange on the spindle

and hand tighten the bolt.

6. While holding in the spindle lock button,

use the wrench to turn the bolt counterclockwise and tighten.

Adjusting Depth

1. Remove battery pack.

2. To adjust the depth of the cut, hold

the saw by the handle and loosen the

depth adjusting lever by pushing it down

toward the shoe (Fig. 5).

Fig. 5

3. Raise or lower the shoe to the desired

position. Markings in 1/4" increments

are located on the inner side of the

upper guard for depth setting. For the

proper depth setting, the blade should

extend no more than 1/8" to 1/4" below

the material being cut (Fig. 6).

Fig. 6

Adjusting Bevel Angle

1. Remove battery pack.

2. To adjust the angle of the cut, hold the

saw by the handle and loosen the bevel

adjusting knob (Fig. 7).

Fig. 7

3. Hold the front of the shoe and rotate the

saw by the handle to the desired angle

as indicated by the markings on the

bevel scale (Fig. 8).

Fig. 8

Adjusting the Blade to Shoe

The shoe has been adjusted at the factory

to a 90 degree setting. Inspect the saw regularly to make sure the blade is 90 degrees

to the shoe.

1. Remove battery pack.

2. Set the bevel pointer to zero (Fig. 9).

Fig. 9

3. T o make sure the blade is 90 degrees to

the shoe, place saw on the blade side

and retract lower guard. Place a square

against the blade and shoe to inspect

the degree setting (Fig. 10).

Fig. 10

Bevel

adjustment

screw

4. Tighten the bevel adjusting knob se-

1/4"

4. Lift the depth adjusting lever up

towards the motor housing to

secure the shoe position.

8 9

curely.

4. To adjust the degree setting, loosen the

bevel adjusting knob. Turn the bevel

adjustment screw in or out until the blade

is at a 90 degree angle with the shoe.

5. Tighten the bevel adjusting knob securely.

Page 6

OPERATION

WARNING

To reduce the risk of injury , keep hands

away from the blade and other moving

parts. Always wear safety goggles or

glasses with side shields. Use only

specifi cally recommended accesso-

ries. Others may be hazardous.

Causes and Operator Prevention of

KICKBACK:

KICKBACK is a sudden reaction to a

pinched, bound or misaligned saw blade,

causing an uncontrolled saw to lift up and out

of the workpiece toward the operator.

When the blade is pinched or bound tightly

by the kerf, or cutting slot, closing down, the

blade stalls and the motor reaction drives the

unit rapidly back toward the operator.

If the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and

jump back toward operator.

KICKBACK is the result of tool misuse and/or

incorrect operating procedures or conditions

and can be avoided by taking proper precautions as given below:

1. Maintain a fi rm grip with both hands

on the saw and position your body

and arm to allow you to resist KICKBACK forces. KICKBACK forces can

be controlled by the operator, if proper

precautions are taken.

2. When blade is binding, or when inter-

rupting a cut for any reason, release

the trigger and hold the saw motionless in the material until the blade

comes to a complete stop. Never

attempt to remove the saw from the

work or pull the saw backward while

the blade is in motion or KICKBACK

may occur. Investigate and take cor-

rective actions to eliminate the cause

of blade binding.

3. When restarting a saw in the work-

piece, center the saw blade in the

kerf, or cut, and check that saw teeth

are not engaged into the material. If

saw blade is binding, it may walk up or

KICKBACK from the workpiece as the

saw is restarted.

4. Support large panels to minimize

the risk of blade pinching and KICKBACK. Large panels tend to sag under

their own weight. Supports must be

placed under the panel on both sides,

near the line of cut and near the edge

of the panel.

5. Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce narrow kerf causing excessive

friction, blade binding and KICKBACK.

6. Blade depth and bevel adjusting lock-

ing levers must be tight and secure

before making cut. If blade adjustment

shifts while cutting, it may cause binding

and KICKBACK.

7. Use extra caution when making a

“Pocket Cut” into existing walls

or other blind areas. The protruding

blade may cut objects that can cause

KICKBACK.

8. Set the depth of cut for no more than

1/8" to 1/4" greater than the thickness

of the stock. The less blade exposed,

the less chance of binding and KICKBACK. Before cutting, be sure depth

and bevel adjustments are tight.

9. Be cautious of pitchy, knotty, wet or

warped stock. These are most likely to

create pinching conditions and possible

KICKBACK. Do not rip warped lumber.

Avoid cutting nails.

10. Use a rip fence or edge guide when

ripping. Guides improve control and

reduce blade binding.

11. Stay alert. Any distraction can cause

twisting or binding. Repetitive cuts may

lull the user into careless movements.

General Operation

Always clamp the workpiece securely on a

saw horse or bench (Fig. 10). See “APPLICATIONS” for the correct way to support your

work in different situations.

Fig. 11

1. Draw a cutting line. Place the front of

the shoe on the edge of the workpiece

without making blade contact. Hold

the handle with one hand and the front

handle with the other (Fig. 12).

Fig. 12

2. Line up the sight line with your cutting

line. Position your arms and body to

resist KICKBACK.

3. T o start the saw, push the lock-of f button

down while pulling the trigger. Allow the

motor to reach full speed before beginning cut.

4. While cutting, keep the shoe fl at against

the workpiece and maintain a firm

grip. Do not force the saw through the

workpiece. Forcing a saw can cause

KICKBACK.

5. If making a partial cut, restarting in

mid-cut or correcting direction, allow

the blade to come to a complete stop.

To resume cutting, center the blade in

the kerf, back the saw away from cutting

edge a few inches, push the lock-off

button down while pulling the trigger and

re-enter the cut slowly.

6. If the saw binds and stalls, maintain

a fi rm grip and release the trigger im-

mediately. Hold the saw motionless in

the workpiece until the blade comes to

a complete stop.

7. After fi nishing a cut, be sure the lower

guard closes and the blade comes to a

complete stop before setting the saw

down.

Electric Brake

The electric brake engages when the trigger is released, causing the blade to stop

and allowing you to proceed with your work.

Generally, the saw blade stops within two

seconds. However, there may be a delay

between the time you release the trigger

and when the brake engages. Occasionally

the brake may miss completely. If the brake

misses frequently, the saw needs servicing

by an authorized MILWAUKEE service facility. The brake is not a substitute for the guard,

and you must always wait for the blade to

stop completely before removing the saw

from the workpiece.

10 11

Page 7

V28™ Lithium-Ion Battery Pack

Unlike other battery pack types, Lithium-Ion

battery packs deliver fade-free power for their

entire run time. The tool will not experience

a slow, gradual loss of power as you work.

To signal to you that the V28 battery pack

is at the end of its run time and needs to be

charged, power to the tool will drop quickly.

When this happens, remove the tool from

the workpiece and charge the battery pack

as needed.

Battery Pack Protection

T o protect itself from damage and extend its

life, the V28 battery pack's intelligent circuit

will turn off the battery pack if its internal

temperature becomes too high. This could

happen in extremely high torque, binding

and stalling situations. The pack must be

placed on the charger to turn it back on.

The charger's light indicator will fl ash red,

indicating that the pack is too hot. Once the

light is continuously red, the pack has cooled

and can be used again.

Cold Weather Operation

The V28 Lithium-Ion battery pack can be

used in temperatures down to -4°F. When

the battery pack is very cold, it may pulse for

the fi rst minute of use to warm itself up. Put

the battery pack on a tool and use the tool in

a light application. After about a minute, the

pack will have warmed itself up and operate

normally.

Troubleshooting

If the blade does not follow a straight line:

• T eeth are dull. This is caused by hitting a

hard object such as a nail or stone, dulling teeth on one side. The blade tends to

cut to the side with the sharpest teeth.

• Shoe is out of line or bent

• Blade is bent

• Rip fence or guide is not being used

If the blade binds, smokes or turns blue

from friction:

• Blade is dull

• Blade is on backwards

• Blade is bent

• Blade is dirty

• Workpiece is not properly supported

• Incorrect blade is being used

APPLICATIONS

Cutting Large Panels

Large panels and long boards sag or bend

if they are not correctly supported. If you

attempt to cut without leveling and properly

supporting the workpiece, the blade will tend

to bind, causing KICKBACK.

Support large panels. Be sure to set the

depth of the cut so that you only cut through

the workpiece, not through the supports.

Fig. 13

Ripping Wood

Ripping is cutting lengthwise with the grain.

Select the proper blade for your job. Use a

rip fence for rips 4" wide or less. T o install the

rip fence, slide the bar through the rip fence

slot in either side of the shoe. The width of

the cut is the distance from the inside of the

blade to the inside edge of the rip fence.

Adjust the rip fence for the desired width, and

lock the setting by tightening the rip fence

adjusting knob.

When ripping widths greater than 4", clamp

or tack 1" lumber to workpiece and use the

inside edge of the shoe as a guide.

WARNING

To reduce the risk of electric shock,

check work area for hidden pipes and

wires before making pocket cuts.

Pocket Cutting

Pocket cuts are made in the middle of the

workpiece when it can not be cut from an

edge. We recommend using a Sawzall

reciprocating saw or jig saw for this type

of cut. However, if you must use a circular

saw to make a pocket cut, USE EXTREME

CAUTION. To maintain control of the saw

during pocket cutting, keep both hands on

the saw.

1. Beginning at a corner, line up the sight

line with your cutting line. Tilt the saw

forward, fi rmly fi xing the front of the shoe

on the workpiece (Fig. 14). The blade

should be just above cutting line, but not

touching it. Raise the lower guard using

the lower guard lever.

Fig. 14

®

Cross-Cutting Wood

Cross-cutting is cutting across the grain.

Select the proper blade for your job. Advance the saw slowly to avoid splintering

the wood.

12 13

Page 8

2. T o start the saw, push the lock-of f button

down while pulling the trigger. Allow the

motor to reach full speed before beginning cut. Using the front of the shoe

as a hinge point, gradually lower the

back end of the saw into the workpiece

(Fig. 15). Release the lower guard lever

and grasp the front handle.

Fig. 15

3. When the shoe rests fl at against work-

piece, advance the saw to the far corner

(Fig. 16). Release the trigger and allow

the blade to come to a complete stop

before removing it from workpiece. Repeat the above steps for each side of the

opening. Use a Sawzall® reciprocating

saw, jig saw or small hand saw to fi nish

the corners if they are not completely

cut through.

Fig. 16

MAINTENANCE

WARNING

To reduce the risk of personal injury, always unplug the charger and

remove the battery pack from the

charger or tool before performing any

maintenance. Never disassemble the

tool, battery pack or charger. Contact

a MILW AUKEE service facility for ALL

repairs.

Maintaining Tool

Keep your tool, battery pack and charger

in good repair by adopting a regular maintenance program. After six months to one

year, depending on use, return the tool,

battery pack and charger to a MILWAUKEE

service facility for:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

• Electrical inspection (battery pack,

charger, motor)

• T esting to assure proper mechanical and

electrical operation

If the tool does not start or operate at full

power with a fully charged battery pack,

clean the contacts on the battery pack. If

the tool still does not work properly, return

the tool, charger and battery pack to a

MILWAUKEE service facility for repairs.

Maintaining and Storing Battery Pack

V28™ Lithium-Ion battery packs will operate

for many years and/or hundreds of charging

cycles when they are maintained and used

correctly. Refer to your battery pack and

charger operator's manual for proper care

and use.

WARNING

To reduce the risk of personal injury and damage, never immerse your

tool, battery pack or charger in liquid

or allow a liquid to fl ow inside them.

Cleaning

Clean out dust and debris from vents and

electrical contacts by blowing with compressed air. Keep tool handles clean, dry and

free of oil or grease. Use only mild soap and

a damp cloth to clean the tool, battery pack

and charger, keeping away from all electrical contacts. Certain cleaning agents and

solvents are harmful to plastics and other

insulated parts. Some of these include gasoline, turpentine, lacquer thinner, paint thinner ,

chlorinated cleaning solvents, ammonia and

household detergents containing ammonia.

Never use fl ammable or combustible sol-

vents around tools.

WARNING

To reduce the risk of injury or explosion, never burn or incinerate a battery pack even if it is damaged, dead

or completely discharged. When

burned, toxic fumes and materials

are created.

Disposing of Lithium-Ion Battery Packs

Lithium-Ion battery packs are more environmentally friendly than some other types

of power tool battery packs (e.g., nickelcadmium). Always dispose of your battery

pack according to federal, state and local

regulations. Contact a recycling agency in

your area for recycling locations.

Even discharged battery packs contain some

energy. Before disposing, use electrical tape

to cover the terminals to prevent the battery

pack from shorting, which could cause a fi re

or explosion.

14 15

Page 9

RBRC Battery Recycling Seals

The RBRC™ Battery Recycling Seals (see

"Symbology") on your tool battery packs

indicate that MILWAUKEE has arranged

for the recycling of that battery pack with

the Rechargeable Battery Recycling Corporation (RBRC). At the end of your battery

pack's useful life, return the battery pack to a

MILWAUKEE Branch Offi ce/Service Center

or the participating retailer nearest you. For

more information, visit the RBRC web site

at www.rbrc.org.

Repairs

For repairs, return the tool, battery pack and

charger to the nearest authorized service

center.

ACCESSORIES

WARNING

Always remove battery pack before

changing or removing accessories.

Only use accessories specifically

recommended for this tool. Others

may be hazardous.

For a complete listing of accessories refer to

your MILWAUKEE Electric Tool catalog or go

on-line to www.milwaukeetool.com. To obtain

a catalog, contact your local distributor or a

service center.

FIVE YEAR TOOL

LIMITED WARRANTY

Every MILWAUKEE tool is tested before

leaving the factory and is warranted to be

free from defects in material and workmanship. MILWAUKEE will repair or replace (at

MILWAUKEE’s discretion), without charge,

any tool (including battery chargers) which

examination proves to be defective in material or workmanship from fi ve (5) years

after the date of purchase. Return the tool

and a copy of the purchase receipt or other

proof of purchase to a MILW AUKEE Factory

Service/Sales Support Branch location or

MILWAUKEE Authorized Service Station,

freight prepaid and insured. This warranty

does not cover damage from repairs made

or attempted by other than MILW AUKEE authorized personnel, abuse, normal wear and

tear, lack of maintenance, or accidents.

The warranty period for V28 Battery Packs

is two (2) years from the date of purchase.

The warranty period for Ni-Cd battery Packs,

Flashlights, Radios are warranted for one (1)

year from the date of purchase.

THE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN ARE EXCLUSIVE. IN NO EVENT SHALL MILWAUKEE

BE LIABLE FOR ANY INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES,

INCLUDING LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES, OR

CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR IMPLIED FOR MERCHANTABLILITY OR FITNESS FOR P ARTICULAR

USE OR PURPOSE.

This warranty gives you specifi c legal rights.

Y ou may also have other rights that vary from

state to state and province to province. In

those states that do not allow the exclusion of

implied warranties or limitation of incidental

or consequential damages, the above limitations or exclusions may not apply to you.

This warranty applies to the United States,

Canada, and Mexico only.

16 17

RÈGLES GÉNÉRALES DE SÉCURITÉ POUR LES OUTILS ALIMEN-

TÉS PAR BATTERIE

AVERTISSEMENT

LIRE SOIGNEUSEMENT TOUTES LES INSTRUCTIONS

Le non respect des instructions ci-après peut entraîner des chocs électriques, des

incendies et/ou des blessures graves. Le terme «outil électrique» fi gurant dans les

avertissements ci-dessous renvoie à l’outil électrique à alimentation par le réseau

(à cordon) ou par batterie (sans fi l).

CONSERVER CES INSTRUCTIONS

SÉCURITÉ DU LIEU

DE TRAVAIL

1. Maintenir la zone de travail propre et bien

éclairée. Les zones encombrées ou mal

éclairées sont favorables aux accidents.

2. Ne pas utiliser d’outil électrique dans

une atmosphère explosive, telle

qu’en en présence de liquides, de

gaz ou de poussières infl ammables.

Les outils électriques génèrent des

étincelles qui peuvent enfl ammer les

poussières ou les fumées.

3. Tenir les enfants et les personnes

non autorisées à l’écart pendant le

fonctionnement d’un outil électrique.

Un manque d’attention de l’opérateur risque

de lui faire perdre le contrôle de l’outil.

SÉCURITÉ ÉLECTRIQUE

4. La fi che de l’outil électrique doit cor-

respondre à la prise d’alimentation.

Ne jamais modifier la fiche d’une

manière quelconque. Ne pas utiliser

d’adaptateur avec les outils électriques mis à la terre (à la masse).

Des fi ches non modifi ées et des prises

d’alimentation assorties réduisent le

risque de choc électrique.

5. Éviter tout contact corporel avec des

surfaces reliées à la masse ou à la

terre telles que tuyaux, radiateurs,

cuisinières et réfrigérateurs. Un risque

de choc électrique plus élevé existe si le

corps est relié à la masse ou à la terre.

6. Ne pas exposer les outils électriques

à la pluie ou à l’humidité. Le risque de

choc électrique augmente si de l’eau

s’infi ltre dans un outil électrique.

7. Prendre soin du cordon. Ne jamais

utiliser le cordon pour transporter,

tirer ou débrancher l’outil électrique.

Tenir le cordon à l’écart de la chaleur ,

des huiles, des arêtes coupantes ou

des pièces en mouvement. Un cordon

endommagé ou emmêlé présente un

risque accru de choc électrique.

8. Se procurer un cordon d’alimentation

approprié en cas d’utilisation

d’un outil électrique à l’extérieur.

L’utilisation d’un cordon d’alimentation

pour usage extérieur réduit le risque de

choc électrique.

SÉCURITÉ INDIVIDUELLE

9. Être sur ses gardes, être attentif et

faire preuve de bon sens en utilisant

un outil électrique. Ne pas utiliser

un outil électrique en cas de fatigue

ou sous l’influence de drogues,

d’alcool ou de médicaments. Un

instant d’inattention lors de l’utilisation

d’un outil électrique peut entraîner des

blessures graves.

10. Utiliser un équipement de sécurité.

Toujours porter des lunettes de protection. Un équipement de sécurité

comprenant masque anti-poussière,

chaussures de sécurité anti-dérapantes,

casque ou dispositif de protection antibruit peut, dans les circonstances appropriées, réduire le risque de blessure.

11. Éviter tout démarrage accidentel de

l’outil. S’assurer que le commutateur

est en position OFF (Arrêt) avant de

brancher l’outil. Le port de l’outil avec

un doigt sur le commutateur ou son

branchement avec le commutateur en

position ON (Marche) sont favorables

aux accidents.

Page 10

12. Retirer toute clé de réglage avant de

mettre l’outil sous tension. Une clé

laissée attachée sur une pièce mobile

de l’outil électrique peut entraîner des

blessures.

13. Ne pas travailler à bout de bras. Bien

garder un bon équilibre à tout instant.

Ceci permet de mieux préserver la

maîtrise de l’outil électrique dans des

situations imprévues.

14. Porter des vêtements adéquats. Ne

pas porter de vêtements amples

ni de bijoux. Ne pas approcher les

cheveux, vêtements et gants des

pièces en mouvement. Les vêtements

amples, les bijoux ou les cheveux longs

risquent d’être happés par les pièces en

mouvement.

15. Si des dispositifs sont prévus pour

l’extraction et la récupération des

poussières, vérifi er qu’ils sont con-

nectés et utilisés correctement.

L’utilisation de ces dispositifs peut réduire les risques liés aux poussières.

UTILISATION ET ENTRETIEN

DE L’OUTIL ÉLECTRIQUE

16. Ne pas forcer l’outil électrique.

Utiliser l’outil électrique approprié

à l’application considérée. L’outil

électrique adapté au projet considéré

produira de meilleurs résultats, dans

des conditions de sécurité meilleures, à

la vitesse pour laquelle il a été conçu.

17. Ne pas utiliser l’outil électrique si le

commutateur ne le met pas sous ou

hors tension. Tout outil électrique dont

le commutateur de marche-arrêt est inopérant est dangereux et doit être réparé.

18. Débrancher la fiche de la prise

d’alimentation et/ou la batterie de

l’outil électrique avant d’effectuer des

réglages, de changer d’accessoires

ou de ranger l’outil. De telles mesures

de sécurité préventive réduisent le

risque de mettre l’outil en marche accidentellement.

19. Ranger les outils électriques inutili-

sés hors de la portée des enfants et

ne pas laisser des personnes qui

connaissent mal les outils électriques ou ces instructions utiliser

ces outils. Les outils électriques sont

dangereux dans les mains d’utilisateurs

non formés à leur usage.

20. Entretien des outils électriques.

S’assurer de l’absence de tout désalignement ou de grippage des

pièces mobiles, de toute rupture de

pièce ou de toute autre condition

qui pourrait affecter le bon fonctionnement de l’outil électrique. En

cas de dommages, faire réparer l’outil

avant de l’utiliser de nouveau. Les

outils électriques mal entretenus sont à

la source de nombreux accidents.

21. Garder les outils de coupe affûtés et

propres. Les outils de coupe correctement entretenus et bien affûtés risquent

moins de se gripper et sont plus faciles

à manier.

22. Utiliser cet outil électrique, les acces-

soires, les mèches, etc. conformément à ces instructions et de la façon

prévue pour ce type particulier d’outil

électrique, tout en prenant en compte

les conditions de travail et le type de

projet considérés. L’utilisation de cet

outil électrique pour un usage autre que

l’usage prévu peut créer des situations

dangereuses.

UTILISATION ET ENTRETIEN

DE LA BATTERIE

23. S’assurer que le commutateur est en

position OFF (Arrêt) avant d’insérer la

batterie. L’insertion de la batterie dans

un outil électrique dont le commutateur

est en position ON (Marche) est favorable aux accidents.

24. Ne recharger la batterie qu’avec le

chargeur spécifi é par le fabricant.

Un chargeur qui convient à un type de

batterie peut créer un risque d’incendie

s’il est utilisé avec un autre type de batterie.

25. N’utiliser les outils électriques

qu’avec les batteries spécialement

conçues pour eux. L’utilisation de

batteries d’autres marques peut créer

un risque de blessure et d’incendie.

26. Lorsque la batterie est hors service,

la ranger à l’écart d’autres objets métalliques tels que trombones, pièces

de monnaie, clés, clous, vis et autres

petits objets métalliques qui peuvent

établir une connexion d’une borne à

l’autre. Un court-circuit aux bornes de

la batterie peut provoquer des brûlures

ou un incendie.

18 19

27. Du liquide peut être éjecté de la bat-

terie en cas de manutention abusive

; éviter tout contact. En cas de contact accidentel avec les projections,

rincer à l’eau. En cas de contact

avec les yeux, consulter un médecin.

Le liquide s’échappant de la batterie

peut provoquer des irritations ou des

brûlures.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES

1. DANGER:

Garder les mains à l’écart de la zone

de coupe et de la lame. Maintenir

l’autre main sur la poignée auxiliaire

ou sur le carter du moteur. Si les deux

mains tiennent la scie, elles ne peuvent

pas être coupées par la lame.

Ne pas tendre la main vers le dessous

de pièce de travail.Le garant n’offre

aucune protection contre la lame sous

la pièce de travail.

Régler la profondeur de coupe en

fonction de l’épaisseur de la pièce de

travail. Moins d’une dent complète des

dents de la lame doit être visible sous

la pièce de travail.

NE JAMAIS maintenir la pièce dont

la coupe est en cours avec les mains

ou contre la jambe. Fixer la pièce de

travail à une plate-forme stable. Il est

important de supporter correctement

la pièce pour minimiser l’exposition du

corps, le grippage de la lame ou la perte

de contrôle de cette dernière.

Tenir l’outil électrique par les sur-

faces de prise isolées si, au cours

des travaux, l’outil de coupe risque

d’entrer en contact avec des fils

cachés ou avec son propre cordon.

Le contact avec un fi l sous tension met

les parties métalliques exposées de

l’outil sous tension, ce qui infl ige une

secousse électrique à l’opérateur.

ENTRETIEN

28. Faire effectuer l’entretien de l’outil

électrique par un technicien qualifié qui n’utilisera que des pièces

de rechange identiques. La sé-

curité d’utilisation de l’outil en sera

préservée.

Lors du sciage en long, toujours

utiliser un guide longitudinal ou un

guide à bord droit. Ceci améliore la

précision de la coupe et réduit les risque

de grippage de la lame.

Toujours utiliser des lames avec des

trous d’alésage central de la taille

et de la forme (en diamant comparé

aux trous ronds) corrects. Les lames

qui ne correspondent pas à la visserie

de montage de la lame fonctionnent de

façon excentrée, causant une perte de

contrôle.

Ne jamais utiliser des rondelles ou

des vis de lame endommagées ou

incorrectes. Les rondelles et les vis de

la lame sont spécialement conçues pour

la scie, pour des performances et une

sécurité de fonctionnement optimales.

2. Causes des effets de REBOND et leur

prévention par l’opérateur:

Un REBOND est la brusque réaction

d’une lame de scie pincée, coincée ou

mal alignée, provoquant un relèvement

incontrôlé de la lame hors de la pièce

de travail vers l’opérateur.

Lorsque la lame est fermement pincée

ou coincée par la fermeture du trait

de scie, la lame cale et la réaction du

moteur entraîne rapidement l’unité en

arrière vers l’opérateur.

Page 11

Si la lame devient vrillée ou mal alignée

en cours de coupe, les dents du bord arrière de la lame peuvent creuser dans la

surface supérieure du bois, ce qui peut

faire sauter la lame hors du trait de scie

et vers l’opérateur.

Un REBOND est le résultat d’une

mauvaise utilisation de la scie et/ou de

procédures ou de conditions d’utilisation

incorrectes et il peut être évité en

prenant les précautions appropriées

suivantes:

Maintenir une prise ferme des deux

mains sur la scie et positionner les

bras de sorte à résister aux rebonds

éventuels. Se maintenir d’un côté ou

de l’autre de la lame et non pas dans

le prolongement de celle-ci. Un rebond

peut provoquer un saut en arrière de la

lame mais le choc en retour peut être

contrôlé par l’opérateur si les précautions correctes sont prises.

Quand la lame est grippée ou lors

de l’interruption d’une coupe pour

une raison quelconque, relâcher

ladétente et maintenir la scie immobile dans le matériau jusqu’à l’arrêt

total de la lame. Ne jamais tenter de

retirer la lame de la pièce ou de tirer la

lame en arrière lorsque la lame est en

mouvement afi n d’éviter tout rebond.

Rechercher la cause du grippage de la

lame et prendre les actions correctives

pour l’éliminer.

Lors du redémarrage d’une scie dans

la pièce de travail, centrer la lame de

la scie dans le trait et vérifi er que les

dents de la lame ne sont pas engagées dans le matériau. Si la lame de

la scie est grippée, elle peut remonter

ou rebondir de la pièce de travail lors du

redémarrage de la scie.

Supporter les grands panneaux pour

minimiser les risques de pincement

ou de retour de la lame. Les grands

panneaux ont tendance à fl échir sous

leur propre poids. Des supports doivent

être placés des deux côtés sous le panneau, près de la ligne de coupe et près

du bord du panneau.

Ne pas utiliser une lame émoussée ou

endommagée. Des lames émoussés

ou montées incorrectement produisent

un trait de scie fi n provoquant des fric-

tions excessives, des grippages et des

rebonds de lame.

Les leviers de verrouillage de la

profondeur de la lame et de réglage

du biseau doivent être serrés et fi xés

avant d’effectuer la coupe. Le grip-

page et le rebond de la lame peuvent

être provoqués par une modifi cation du

réglage de la lame lors de la coupe.

Faire preuve de précaution sup-

plémentaire lors d’une «coupe en

plongée» (ou en alvéole) dans des

murs existants ou d’autres zones

aveugles. La lame protubérante peut

couper des objets qui peuvent provoquer un rebond.

3. Vérifier la fermeture correcte du

garant inférieur avant chaque utilisation. Ne pas utiliser la scie si le garant

inférieur ne se déplace pas librement

et ne se ferme pas instantanément.

Ne jamais fi xer ou attacher le garant

inférieur en position ouverte. Si la scie

tombe accidentellement, le garant inférieur risque d’être tordu. Relever le garant

inférieur avec son levier et s’assurer qu’il

se déplace librement et ne touche pas

la lame ou toute autre pièce, quels que

soient les angles et les profondeurs de

coupe.

Vérifi er le fonctionnement du ressort

du garant inférieur. Si le garant et le

ressort ne fonctionnent pas correctement, les réparer avant utilisation.

Le garant inférieur peut fonctionner

lentement en raison de pièces endommagées, de dépôts gommeux ou

d’accumulation de débris.

Le garant inférieur ne doit être

manuellement rétracté que pour

des coupes spéciales telles que les

«coupes en plongée» («coupes en alvéole») ou les «coupes composées».

Relever le garant inférieur par son

levier du garant et, dès que la lame

pénètre dans le matériau, le garant

inférieur doit être relâché. Pour toutes

les autres coupes, le garant inférieur doit

fonctionner automatiquement.

Toujours s’assurer que le garant

inférieur recouvre la lame avant de

mettre la scie sur un établi ou sur le

sol. Une lame en roue libre non proté-

gée fait progresser la scie en arrière

en coupant tout sur son passage. Être

conscient de la durée nécessaire à la

lame pour s’immobiliser après avoir

relâché la commande.

20 21

4. Maintenir en l’état les étiquettes et les

plaques d’identifi cation. Des informa-

tions importantes y fi gurent. Si elles

sont illisibles ou manquantes, contacter

un centre de services et d’entretien

MILWAUKEE pour un remplacement

gratuit.

5. AVERTISSEMENT! Certaines pous-

sières générées par les activités de

ponçage, de coupe, de rectifi cation, de

perçage et d’autres activités de construction contiennent des substances

considérées être la cause de malformations congénitales et de troubles

de l’appareil reproducteur. Parmi ces

substances fi gurent:

Pictographie

Tension CD seul.

Tours à vide par minute (RPM)

Underwriters Laboratories, Inc.,

États-Unis et Canada

Spécifi cations

No de

cat.

0730-20

Volts

cd

28

RPM

4 200

Taille de la

lame

165 mm

(6-1/2")

Alésage

• le plomb contenu dans les peintures à

base de plomb

• la silice cristalline des briques, du ciment

et d’autres matériaux de maçonnerie,

ainsi que

• l’arsenic et le chrome des sciages traités

chimiquement.

Les risques encourus par l’opérateur

envers ces expositions varient en

fonction de la fréquence de ce type de

travail. Pour réduire l’exposition à ces

substances chimiques, l’opérateur doit :

travailler dans une zone bien ventilée

et porter l’équipement de sécurité approprié, tel qu’un masque anti-poussière

spécialement conçu pour filtrer les

particules microscopiques.

Profondeur de

coupe à 45°

0 à 40 mm

(0 à 1-9/16")

5/8"

Profondeur de

coupe à 90°

0 à 54 mm

(0 à 2-1/8")

Page 12

DESCRIPTION FONCTIONNELLE

MONTAGE DE L’OUTIL

1. Poignée avant

2. Bouton de verrouillage

3. Détente

4. Poignée

5. Boutons d’ouverture de la

batterie

6. Batterie

7. Patin

8. Levier du garant

inférieur

9. Garant inférieur

10. Vis de lame

11. Bride de lame

12. Lame

13. Clé

1

18

14. Indicateur de biseau

15. Molette de réglage du biseau

16. Échelle de biseau

17. Molette de réglage du guide

longitudinal

18. Levier de réglage de la profondeur

19. Garant supérieur

20. Fente du guide longitudinal

21. Ligne de vue

22. Bouton de verrouillage de l’axe

2

12

14

3

4

5

Ne charger que des batteries au

lithium-ion V28™ sur les chargeurs

au lithium-ion V28. Des batteries de

marques différentes peuvent provoquer des blessures ou des dommages.

Pour les instructions de charge spéci-

AVERTISSEMENT

AVERTISSEMENT

Pour éviter les risques de blessure,

toujours retirer la batterie avant de

changer ou de démonter les accessoires. N’utiliser que les accessoires

spécialement conçus pour cet outil.

Les accessoires non recommandés

peuvent présenter des dangers.

fi ques, lire le manuel de l’opérateur

fourni avec le chargeur.

6

Fig. 1

Sélection de la lame

Toujours utiliser des lames affûtées. Des

lames émoussées ont tendance à surcharger l’outil est augmentent les risques de

REBOND (voir «Causes des effets de REBOND et leur prévention par l’opérateur»).

7

8

N’utiliser que des lames à trait fi n avec une

vitesse de fonctionnement maximale en

toute sécurité supérieure à la vitesse de

rotation sans charge indiquée sur la plaque

d’identifi cation de l’outil. Lire les instructions

du fabricant de la lame avant de l’utiliser. Ne

pas utiliser un type quelconque de meule à

tronçonner abrasive ou de lame de coupe

en diamant.

Installation et démontage des lames

1. RETIRER LA BATTERIE AVANT

L’INST ALLA TION OU LE DÉMONT AGE

DES LAMES.

2. Mettre la scie sur une surface plate avec

la lame vers le haut. Pour retirer la vis de

16

17

9

Insertion

d’une batterie

Retrait

d’une batterie

Retrait de la batterie de l’outil

Pousser les boutons d’ouverture vers

l’intérieur et retirer la batterie de l’outil.

Insertion de la batterie dans l’outil

Pour insérer la batterie dans l’outil, la glisser

11

10

13

15

sur le corps de l’outil. S’assurer qu’elle se

loge fermement en place.

l’axe, enfoncer le bouton de verrouillage

de l’axe. Tout en maintenant le bouton

de verrouillage de l’axe enfoncé, utiliser

la clé fournie avec l’outil pour tourner la

19

vis dans le sens horaire (Fig. 2). Retirer

la vis et la bride de la lame.

Fig. 2

20

22

21

22 23

Page 13

3. Faire glisser le levier du garant inférieur

vers le haut pour relever la garant inférieur. Retirer la lame de l’axe. Toujours

nettoyer l’axe, le garant inférieur et le

garant supérieur pour éliminer la saleté

et la sciure.

N.B. : N’enlevez pas la bride intérieure

de lame. Le plus grand diamètre de la

bride intérieure doit appuyer sur la lame

(Fig. 3).

Fig. 3

Pivot

Boulon de lame

Réglage de la profondeur

1. Retirer la batterie.

2. Pour régler la profondeur de coupe,

maintenir la scie par la poignée et

desserrer le levier de réglage de la

profondeur en le poussant vers le bas,

en direction du patin (Fig. 5).

Fig. 5

Réglage de l’angle du biseau

1. Retirer la batterie.

2. Pour régler l’angle de coupe, maintenir

la scie par la poignée et desserrer la

molette de réglage du biseau (Fig. 7).

Fig. 7

Réglage de la lame au patin

Le patin a été réglé en usine à un angle de

90°. Inspecter régulièrement la scie pour

s’assurer que la lame est à 90° du patin.

1. Retirer la batterie.

2. Régler l’indicateur de biseau sur zéro

(Fig. 9).

Fig. 9

Bride

intérieure

4. Pour installer une lame, la placer sur

l’axe avec les dents pointant dans la

même direction que la fl èche sur le ga-

rant inférieur (Fig. 4). Relâcher le levier

du garant inférieur.

Fig. 4

5. Placer la bride de la lame sur l’axe et

serrer la vis à la main.

6. Tout en maintenant le bouton de verrouillage de l’axe enfoncé, utiliser la clé

fournie avec l’outil pour tourner la vis

dans le sens anti-horaire et serrer.

Bride

extérieure

3. Relever ou abaisser le patin à la position

souhaitée. Des repères à incréments

d’6 mm (1/4 pouce) sont situés sur les

côtés intérieurs du garant supérieur

pour le réglage de la profondeur. Pour le

réglage correct de la profondeur, la lame

ne doit pas être déployée de plus d’3 à

6 mm (1/8 à 1/4 pouce) au-dessous du

matériau à couper (Fig. 6).

Fig. 6

6 mm

(1/4")

4. Relever le levier de réglage de la profondeur vers le haut en direction du

carter du moteur pour fi xer la position

du patin.

3. Maintenir l’avant du patin et faire tourner

la scie par la poignée à l’angle souhaité comme indiqué par les repères de

l’échelle du biseau (Fig. 8).

Fig. 8

4. Serrer fermement la molette de réglage

du biseau.

3. Pour s’assurer que la lame est à 90

degrés du patin, placer la scie sur le

côté de la lame et rétracter le garant

inférieur. Placer une équerre contre la

lame et le patin et vérifi er le réglage de

l’inclinaison (Fig. 10).

Fig. 10

4. Pour régler l’inclinaison, desserrer la

molette de réglage du biseau. Visser

ou dévisser la vis de réglage du biseau

jusqu’à ce que la lame soit à un angle

de 90° du patin.

5. Serrer fermement la molette de réglage

du biseau.

Vis de

réglage du

biseau

24 25

Page 14

MANIEMENT

AVERTISSEMENT

Pour réduire le risque de blessures,

garder les mains à l’écart de la lame

et des autres pièces en mouvement. Toujours porter des lunettes à

coques ou des lunettes de protection

avec écrans latéraux. N’utiliser que

les accessoires spécifi quement re-

commandés. Les accessoires non

recommandés peuvent présenter des

dangers.

Causes des effets de REBOND et leur

prévention par l’opérateur:

Un REBOND est la brusque réaction

d’une lame de scie pincée, coincée ou mal

alignée, provoquant un relèvement incontrôlé de la scie hors de la pièce de travail

vers l’opérateur.

Lorsque la lame est fermement pincée ou

coincée par la fermeture du trait de scie ou

fente de coupe, la lame cale et la réaction du

moteur entraîne rapidement l’unité en arrière

vers l’opérateur.

Si la lame devient vrillée ou mal alignée en

cours de coupe, les dents à l’arrière de la

lame peuvent creuser dans la surface supérieure du bois, ce qui peut faire sauter la lame

hors du trait de scie et vers l’opérateur.

Un REBOND est le résultat d’une mauvaise

utilisation de l’outil et/ou de procédures ou

de conditions d’utilisation incorrectes et il

peut être évité en prenant les précautions

correctes données ci-dessous :

1. Maintenir une prise ferme des deux

mains sur la scie et positionner le

corps et le bras de sorte à résister

aux REBONDS éventuels. Les RE-

BONDS peuvent être contrôlés par

l’opérateur si les précautions correctes

sont prises.

2. Quand la lame est grippée ou lors

de l’interruption d’une coupe pour

une raison quelconque, relâcher la

détente et maintenir la scie immobile dans le matériau jusqu’à arrêt

total de la lame. Ne jamais tenter de

retirer la lame de la pièce de travail

ou tirer la lame en arrière lorsque la

lame est en mouvement afi n d’éviter

tout REBOND. Rechercher la cause

du grippage de la lame et prendre les

actions correctives pour l’éliminer.

3. Lors du redémarrage d’une scie dans

la pièce de travail, centrer la lame

de la scie dans le trait de scie ou la

coupure et vérifi er que les dents de

la lame ne sont pas engagées dans le

matériau. Si la lame de la scie est grip-

pée, elle peut remonter ou REBONDIR

de la pièce de travail lors du redémarrage de la scie.

4. Supporter les grands panneaux pour

minimiser les risques de pincement

ou de REBOND de la lame. Les grands

panneaux ont tendance à fl échir sous

leur propre poids. Des supports doivent

être placés des deux côtés sous le panneau, près de la ligne de coupe et près

du bord du panneau.

5. Ne pas utiliser de lames émoussées

ou endommagées. Des lames émoussés ou montées incorrectement produisent un trait de scie fi n, provoquant des

frictions excessives, des grippages et

des rebonds de lame.

6. Les leviers de verrouillage de la

profondeur de la lame et de réglage

du biseau doivent être serrés et fi xés

avant d’effectuer la coupe. Le grip-

page et le REBOND de la lame peuvent

être provoqués par un glissement du

réglage de la lame lors de la coupe.

7. Faire preuve de précaution sup-

plémentaire lors d’une «coupe en

alvéole» dans des murs existants

ou d’autres zones aveugles. La lame

protubérante peut couper des objets qui

peuvent provoquer un REBOND.

8. Régler la profondeur de coupe au

maximum d’3 à 6 mm (1/8 à 1/4 pouce)

de plus que l’épaisseur du matériau.

Une exposition minimale de la lame

réduit les risques de grippage et de

REBOND. Avant de couper, s’assurer

que les réglages de la profondeur et du

biseau sont bien serrés.

9. Faire attention aux matériaux pois-

seux, noueux, humides ou gauchis.

Ils ont une propension plus importante

à créer des conditions de grippage et

d’éventuels REBONDS. Ne pas couper

du bois gauchi. Éviter de couper des

clous.

10. Lors du sciage longitudinal, utiliser

un guide longitudinal ou un guide

de bordure. Les guides améliorent le

contrôle et réduisent le grippage de la

lame.

11. Rester attentif. Toute distraction peut

provoquer une torsion ou un grippage.

Des coupes répétées peuvent entraîner

l’utilisateur à effectuer des mouvements

imprudents.

Fonctionnement général

Toujours fi xer fermement la pièce de travail

sur un chevalet de sciage ou un établi (Fig.

10). Voir «APPLICATIONS» pour la façon

correcte de supporter la pièce de travail dans

diverses situations.

Fig. 11

1. Tracer une ligne de coupe. Placer

l’avant du patin sur le bord de la pièce de

travail sans toucher la lame. Maintenir la

poignée d’une main et la poignée avant

de l’autre (Fig. 12).

Fig. 12

2. Aligner la ligne de vue avec la ligne de

coupe. Positionner les bras et le corps

pour résister à un REBOND éventuel.

3. Pour mettre la scie en marche, pousser

le bouton de verrouillage vers le bas tout

en appuyant sur la détente. Laisser le

moteur atteindre sa pleine vitesse avant

de commencer à couper.

4. Tout en découpant, maintenir le patin

plat contre la pièce de travail et maintenir une prise ferme. Ne pas forcer la

scie à travers la pièce de travail. Le fait

de forcer une scie peut provoquer un

REBOND.

5. En cas de coupe partielle, de redémarrage à mi-coupe ou de correction de la

direction, attendre l’arrêt complet de la

lame. Centrer la lame dans le trait de

scie, dégager la scie du bord de coupe

de quelques centimètres, appuyer sur

la détente et pénétrer de nouveau lentement dans la fente.

6. Si la lame se grippe ou cale, maintenir

une prise ferme et relâcher immédiatement la détente. Maintenir la scie immobile dans la pièce de travail jusqu’à

ce que la lame s’arrête complètement.

7. Après avoir terminé une coupe, s’assurer

que le garant inférieur se ferme et que

la lame s’arrête complètement avant de

poser la scie.

26 27

Page 15

Frein électrique

Le frein électrique s’enclenche lors du

relâchement de la pression sur la détente,

ce qui a pour effet d’immobiliser la lame et

de permettre à l’opérateur de poursuivre

son travail. La lame de scie s’immobilise

généralement dans les deux secondes qui

suivent. Un délai peut se produire toutefois

entre le relâchement total de la pression

exercée sur la détente et l’enclenchement

du frein. Il se peut qu’occasionnellement le

frein ne s’enclenche pas du tout. En cas de

dysfonctionnement fréquent du frein, faire

réparer la scie par un centre d’entretien

MILWAUKEE agréé. Le frein n’est pas

une alternative au garant etil faut toujours

attendre l’arrêt complet de la lame avant de

retirer la scie de la pièce de travail.

Batterie au lithium-ion V28™

À la différence d’autres types de batterie,

la batterie au lithium-ion fournit une énergie constante pendant toute la durée de

fonctionnement. L’outil ne connaîtra pas

une baisse lente et graduelle de puissance

lors du travail. Pour signaler à l’utilisateur

que la batterie V28 est à la fi n de sa durée

de fonctionnement et requiert une nouvelle

charge, l’alimentation de l’outil chute rapidement. Dans ce cas, retirer l’outil de la

pièce de travail et charger la batterie selon

le besoin.

Protection de la batterie

Pour se protéger contre tout dommage et

prolonger sa durée de vie, le circuit intelligent

de la batterie V28 se ferme automatiquement si sa température interne devient trop

élevée. Ceci peut se produire en cas de

couple extrêmement élevé, de grippage ou

de calage. Placer la batterie sur son chargeur

pour la remettre sous tension. Le témoin

lumineux du chargeur clignote en rouge,

signalant ainsi la surchauffe de la batterie.

Lorsque le témoin émet une lumière rouge

en continu, la batterie s’est refroidie et peut

être utilisée de nouveau.

Fonctionnement par temps froid

Il est possible d’utiliser la batterie au lithiumion V28 à des températures ambiantes allant

jusqu’à -20°C (-4°F). Lorsque la température

de la batterie est très basse, elle peut envoyer des impulsions pendant la première

minute d’utilisation pour se réchauffer. Mettre

la batterie sur un outil et utiliser cet outil sur

une application légère. Au bout d’une minute

d’utilisation, la batterie se sera suffi samment

réchauffée et fonctionnera normalement.

Dépannage

Si la lame ne suit pas une ligne droite:

• Les dents sont émoussées. Ceci résulte

du heurt avec un objet dur tel qu’une

pointe ou une pierre, émoussant les

dents d’un côté. La lame a tendance à

couper du côté ayant les dents les plus

affûtées.

• Le patin n’est pas aligné ou est tordu

• La lame est tordue

• Le guide longitudinal ou le guide ne sont

pas utilisés

Si la lame se grippe, fume ou bleuit en raison

de la friction:

• La lame est émoussée

• La lame est montée à l’envers

• La lame est tordue

• La lame est sale

• La pièce de travail n’est pas correctement supportée

• Une lame incorrecte est utilisée

APPLICATIONS

Coupe de grands panneaux

Les grands panneaux et les longues planches fl échissent ou ploient s’ils ne sont pas

correctement supportés. En cas de coupe

d’une pièce de travail qui n’est ni de niveau

ni supportée, la lame risque de se gripper et

de provoquer des REBONDS.

Supporter les grands panneaux. S’assurer

de régler la profondeur de coupe afi n de ne

couper qu’à travers la pièce de travail et non

pas à travers les supports.

Fig. 13

Sciage de bois longitudinal

Le sciage longitudinal consiste à scier dans

le sens de la longueur avec le grain. Sélectionner la lame correcte pour le travail.

Utiliser un guide longitudinal ou un guide de

bordure pour des sciages en long d’une largeur maximale de 100 mm (4 pouces). Pour

installer le guide longitudinal, faire glisser la

barre par la fente du guide longitudinal sur un

des deux côtés du patin. La largeur de coupe

est la distance de l’intérieur de la lame au

bord intérieur du guide longitudinal. Régler le

guide longitudinal pour la largeur souhaitée

et verrouiller le réglage en serrant la molette

de réglage du guide longitudinal.

Quand les largeurs de sciage longitudinal

sont supérieures à 100 mm (4 pouces),

brider ou clouer une pièce de bois d’25 mm (1

pouce) à la pièce de travail et utiliser le bord

intérieur du patin comme un guide.

Sciage de bois transversal

Le sciage transversal consiste à scier en

travers du grain. Sélectionner la lame correcte pour le travail. Avancer la scie lentement pour éviter l’éclatement du bois.

AVERTISSEMENT

Pour réduire les risques de chocs

électriques, vérifi er la zone de travail

à la recherche de tuyaux et de fi ls

cachés avant d’effectuer des coupes

en alvéole.

Coupe en alvéole

Les coupes en alvéole sont faites au milieu

d’une pièce de travail lorsqu’elle ne peut

pas être découpée à partir d’un bord. Il est

recommandé d’utiliser une scie alternative

®

Sawzall

type de coupe. Toutefois, s’il est nécessaire

d’utiliser une scie circulaire pour effectuer

une coupe en alvéole, FAIRE PREUVE

D’EXTRÊME PRUDENCE. Pour garder le

contrôle de la scie lors de la coupe en alvéole, maintenir les deux mains sur la scie.

1. Commencer à un coin, aligner la ligne

ou une scie sauteuse pour ce

de vue avec la ligne de coupe. Basculer

la scie vers l’avant, en fi xant fermement

l’avant du patin sur la pièce de travail

(Fig. 14). La lame doit être juste audessus de la ligne de coupe, sans la

toucher. Relever le garant inférieur en

utilisant le levier du garant inférieur.

Fig. 14

28 29

Page 16

2. Pour mettre la scie en marche, pousser

le bouton de verrouillage vers le bas tout

en appuyant sur la détente. Attendre

que le moteur atteigne sa pleine vitesse

avant de commencer à couper. En utilisant l’avant du patin comme un point

de charnière, abaisser progressivement l’extrémité arrière de la scie dans

la pièce de travail (Fig. 15). Relâcher

le levier du garant inférieur et saisir la

poignée avant.

Fig. 15

3. Quand le patin repose à plat contre la

pièce de travail, avancer la scie vers

le coin éloigné (Fig. 16). Relâcher la

détente et laisser la lame s’arrêter complètement avant de la retirer de la pièce

de travail. Répéter les étapes ci-dessus

pour chaque côté de l’ouverture. Utiliser

une scie alternative Sawzall

sauteuse ou une petite scie égoïne pour

fi nir les coins s’ils ne sont pas complètement coupés.

Fig. 16

®

, une scie

ENTRETIEN

AVERTISSEMENT

Pour réduire le risque de blessure,

toujours débrancher le chargeur et

retirer la batterie du chargeur ou de

l’outil avant d’effectuer un quelconque

entretien. Ne jamais démonter l’outil,

la batterie ou le chargeur. Contacter

un centre d’entretien MILWAUKEE

pour TOUTES les réparations.

Entretien de l’outil

Maintenir l’outil, la batterie et le chargeur

en bon état en adoptant un calendrier

d’entretien périodique. Après six mois ou un

an, en fonction de l’usage qu’il en est fait,

renvoyer l’outil, la batterie et le chargeur à un

centre d’entretien MILWAUKEE pour:

• Lubrifi cation

• Inspection et replacement du balai

• Inspection et nettoyage des composants

mécaniques (engrenages, axes, roulements, carter, etc.)

• Inspection des composants électriques

(batterie, chargeur et moteur)

• Essai, afin de vérifier le bon fonctionnement des composants mécaniques et électriques de l’outil

Nettoyer les contacts de la batterie s’il est

impossible de mettre l’outil en marche ou si

l’outil ne fonctionne pas à pleine capacité en

dépit d’une batterie complètement chargée.

Si l’outil ne fonctionne toujours pas correctement, renvoyer l’outil, le chargeur et la

batterie à un centre d’entretien MILWAUKEE

pour réparation.

Entretien et remisage de la batterie

La batterie V28™ au lithium-ion fonctionnera

pendant de nombreuses années et/ou des

centaines de cycles de charge si elle est

entretenue et utilisée correctement. Consulter le manuel de l’opérateur du chargeur

et de la batterie pour les conseils d’entretien

et d’usage.

AVERTISSEMENT

Pour réduire le risque de blessure

ou de dommage, ne jamais plonger

l’outil, la batterie ou le chargeur dans

un liquide et ne jamais laisser l’eau

s’y infi ltrer.

Nettoyage

Nettoyer la poussière et les débris des

évents et des contacts électriques à l’air

comprimé. Maintenir les poignées de l’outil

propres, sèches et exemptes de graisse ou

d’huile. N’utiliser que du savon doux et un

chiffon humide pour nettoyer l’outil, la batterie et le chargeur, en évitant les contacts

électriques. Certains produits de nettoyage

ou solvants sont nocifs pour les plastiques

et les pièces isolées, notamment : essence,

essence de térébenthine, diluant pour vernis,

diluant pour peintures, solvant chloré, ammoniaque et détergents ménagers contenant de l’ammoniaque. Ne jamais utiliser de

solvants infl ammables ou combustibles à

proximité d’outils.

AVERTISSEMENT

Afi n de réduire le risque de blessure

ou d’explosion, ne jamais brûler ou

incinérer une batterie même si elle

est endommagée, morte ou complètement déchargée. La combustion d’une batterie libère des fumées

et des substances toxiques dans

l’atmosphère.

Mise au rebut des batteries au

lithium-ion

Les batteries au lithium-ion présentent

moins de risques pour l’environnement

que d’autres types de batterie (nickel-cadmium). Éliminer les batteries conformément

aux règlements fédéraux/nationaux, provinciaux/d’états et locaux. Contacter l’agence

de recyclage locale pour l’adresse des

centres de recyclage locaux.

30 31

Page 17

Les batteries déchargées contiennent du

courant résiduel. Avant de mettre une batterie au rebut, couvrir les bornes de la batterie

avec du ruban isolant afi n d’empêcher un

court-circuit éventuel qui pourrait provoquer

un incendie ou une explosion.