Milwaukee THB High Boy, TLB Low Boy User Manual

Temp-O-Matic Oil Furnaces

THB High Boy

TLB Low Boy

Furnace Manual

KEEP THESE INSTRUCTIONS

WITH FURNACE FOR FUTURE

REFERENCE.

C US

Hazards that will cause severe personal injury,

death or substantial property damage.

Hazards that can cause severe personal injury,

death or substantial property damage.

INSTALLER – Read all instructions before

installing. Read page 2 first. Follow all instructions

in proper order to prevent personal injury or death.

• Consider ducting, fuel supply, venting and

installation when determining furnace location.

• Any claims for damage or shortage in shipment

must be filed immediately against the transportation

company by the consignee.

Do not store or use gasoline or other flammable

liquids or vapors near this furnace or any other

appliance.

Ventilate house while operating furnace for the first

time. Odors may be emitted for a brief period.

Do not alter this furnace in any way. The

manufacturer will not be liable for any damage

resulting from changes made in the field to the

furnace or its components or from improper

installation. Failure to comply could result in severe

personal injury, death or substantial property

damage.

Printed on 100% recycled paper 670-000-005/1010

Hazard definitions

Contents Page

Read this first!............................................................................ 2

1. Prepare furnace location............................................................ 3

2. Prepare furnace and place in position ....................................... 6

3. Connect supply and return ducts...............................................8

4. Venting..................................................................................... 11

5. Connect fuel oil piping ............................................................. 12

6. Wire furnace and burner..........................................................12

7. Start-up....................................................................................16

8. Checkout procedure ................................................................ 16

9. Troubleshooting....................................................................... 18

10. Service and maintenance ........................................................ 19

11. Components and replacement parts........................................ 23

12. Dimensions and ratings ........................................................... 29

13. Owner’s information .................................................................34

Hazards that will or can cause minor personal

injury or property damage.

Special instructions on installation, operation or

maintenance that are important but not related to

personal injury or property damage.

USER – Please read the following. Failure to

comply could result in severe personal injury, death

or substantial property damage.

• This manual is for use only by your qualified

heating installer / service technician.

• Please see the Owner’s information only, on back

page of this manual.

• Have the furnace serviced by a qualified service

technician, at least annually.

This manual must only be used by a qualified

heating installer / service technician. Furnace and

burner must be installed and serviced only by a

qualified heating installer / service technician.

Failure to comply could result in severe personal

injury, death or substantial property damage.

When calling or writing about the furnace – Please

have furnace model number and serial number from

the rating label. You may list the serial number and

model number in the space provided on the

“Installation and service certificate” found on

page 17.

READ THIS FIRST!

Service and maintenance –

1. To avoid electric shock, disconnect electrical supply before

performing maintenance.

2. To avoid severe burns, allow furnace to cool before performing

maintenance.

3. Perform service and maintenance as described in this manual

and the burner manual.

4. Do not attempt to make adjustments to the blower or motor while

the furnace is in operation. Disconnect power to the furnace and

be sure all parts have stopped moving before attempting

adjustments or maintenance.

5. The burner must be set up and adjusted using combustion test

instruments. Visual examination of the flame alone cannot

determine combustion performance.

Operation -

6. Do not use the furnace as a construction heater.

7. Do not operate any furnace if the heat exchanger is damaged,

corroded or pitted. Toxic flue products could enter the air

stream.

8. Do not jumper, attempt to by-pass or override any limit control.

9. Do not block flow of combustion or ventilation air to furnace. Do

not block or obstruct the air openings in the furnace casing.

10. Do not store or use combustible materials, gasoline, or other

flammable liquids or vapors in the furnace area.

11. Do not operate the furnace if the furnace area will be exposed to

air contaminants as described on page 5.

12. Should overheating occur, do not turn off or disconnect electrical

supply to furnace. Instead, shut off the oil supply at a location

external to the appliance, if possible.

13. Do not use this furnace if any part has been under water.

Immediately call a qualified service technician to inspect the

furnace and to replace any part to the furnace, control system or

burner that has been under water.

14. Do not operate furnace if temperature rise through heat

exchanger exceeds 85

Installation –

1. Be sure to level the furnace, using a spirit level on the front and

one side. If the furnace is not level, oil can drip into the

combustion chamber after burner cycling, causing fouling of the

heat exchanger and the burner head.

2. Make sure the legs are in contact with the floor to distribute the

load and prevent the possibility of undue noise or vibration.

.

Failure to adhere to the guidelines below can result in severe personal injury, death or substantial property damage.

o

F.

Apply the following suggestions to prevent unsatisfactory operation of the furnace.

15. Inspect, clean and replace (if necessary) return air filter

regularly.

16. Do not obstruct return air grills or supply air outlets.

17. Supply only #2 fuel oil to the burner. Never attempt to use

gasoline, a mixture of gasoline and oil, waste fuel, refuse or any

other substance in the burner of furnace.

Installation -

18. Do not block flow of combustion or ventilation air to furnace. Do

not block or obstruct the air openings in the furnace casing.

19. Connect furnace only to a functional vent system in good

condition. Place the furnace to allow proper venting, with the

shortest possible venting and minimum number or elbows.

20. Always connect and seal a return air duct to the furnace unless

the furnace is located in a large space, such as an unpartitioned

basement, Route the return air duct to an adjacent room if no

return air manifold is used.

21. Install furnace maintaining minimum clearances for service and

separation from combustible surfaces described in this manual.

If furnace is installed on a combustible floor, you must use the

combustible floor base or provide the minimum clearance from

the furnace to the floor as given in this manual.

22. Install, start-up, service and maintain burner per instructions in

this manual and the burner manual.

23. Verify burner is properly inserted through the combustion

chamber opening.

24. Furnace must be installed so that burner and control system

components are protected from dripping, spraying water or rain

during operation or service.

25. If installing an air conditioning evaporator coil, install the coil

downstream of, or in parallel with, the furnace to prevent

condensation on the furnace heat exchanger. If the coil is in

parallel, provide means to prevent flow of chilled air into the

furnace, including an interlock to prevent simultaneous operation

of heating and air conditioning.

3. Avoid locating return grills in rooms that may contain undesirable

odors.

4. Never locate a return air grill closer than approximately 20 feet

from the furnace.

5. Locate the furnace near the center of the supply and return duct

systems.

6. Always check the size of the ducts on a replacement installation,

particularly if adding air conditioning.

2 670-000-005/1010

THB & TLB Oil Furnaces – Furnace Manual

1 Prepare furnace location

Pre-installation checklist

Verify code compliance

Local, state, provincial, and national codes, laws, regulations

and ordinances

NFPA-31, Installation of Oil-Burning Equipment

National Electrical Code

All local codes and/or regulations take precedence over the

instructions in this manual and should be followed accordingly.

THB & TLB furnaces, their burners and controls met

safe lighting and other performance criteria when

furnace underwent tests specified in Underwriters

Laboratories Standard UL727.

Check location and furnace specifications

Furnace heating capacity

Space is large enough to provide required clearances

Verify the installation will meet the requirements of this manual:

Clearances (page 3)

Combustion/ventilation air openings (page 4)

Supply air duct (page 8)

Return air duct (page 8)

Vent system (page 11)

Fuel oil piping (page 12 plus burner manual)

Electrical connection (page 12)

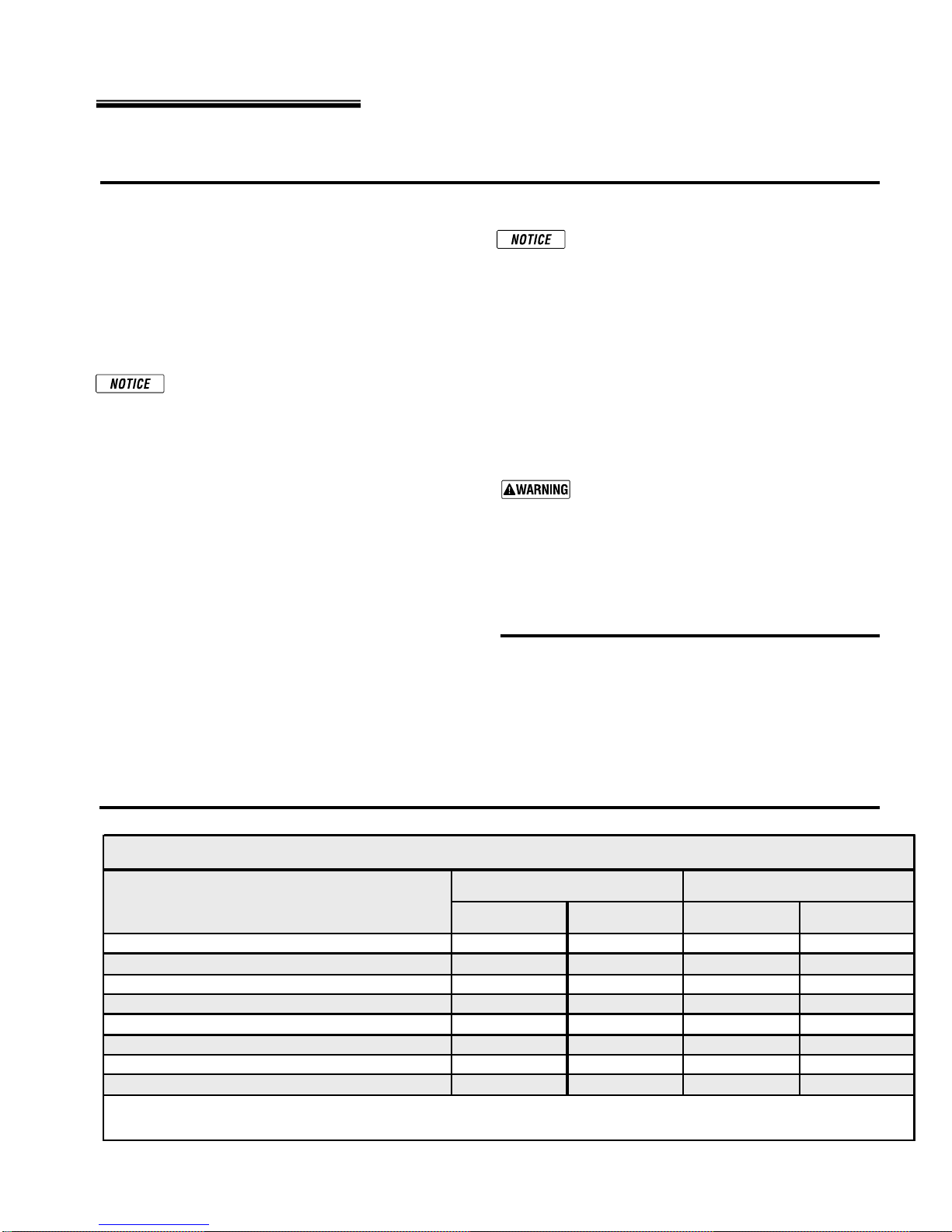

Clearances

Minimum clearance to combustible materials

1. Install the furnac e, ductwork and vent such that no combustible

surface is closer than listed in Table 1.

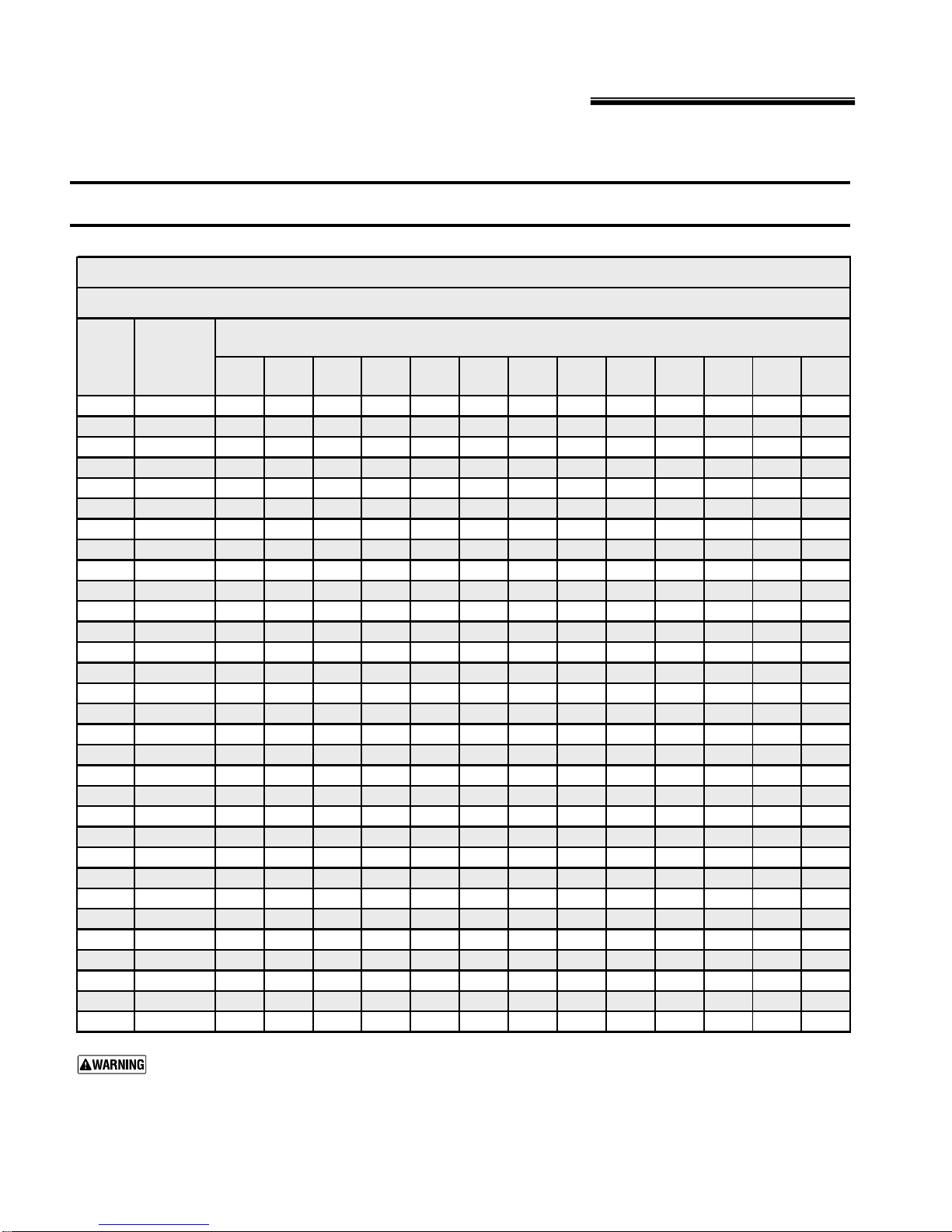

Table 1 Minimum clearances

Minimum clearances from furnace, ductwork and vent

Flue pipe clearances must take precedence over

jacket clearances (listed below).

Service accessibility clearances

1. Provide no less than the minimum clearances given in Table 1 to

ensure the furnace can be properly operated, serviced and

maintained.

Always apply whichever clearance is LARGER – combustible

construction or service accessibility.

Flooring and foundation

Flooring

THB & TLB furnaces are approved for installation on combustible

flooring, but must never be installed on carpeting.

Do not install furnace on carpeting even if foundation

is used. Fire can result, causing severe personal

injury, death or substantial property damage.

Foundation

1. Provide a solid brick or minimum 2-inch concrete foundation pad

if any of the following is true:

• The floor can become flooded.

• The furnace mounting area is not level.

Residential garage installations

Take the following special precautions when installing the furnace in

a residential garage. Il the furnace is located in a residential garage:

• Mount the furnace a minimum of 18 inches above the floor

of the garage.

• Locate or protect the furnace so it cannot be damaged by a

moving vehicle.

Servic e acces s ibilit y clearance s are recom m ended

minim um dim ensions to allow ac c es s to furn ace

components (motor, blower, filters, etc.).

Top of plenum t o ce iling 1" 1"

Above warm air duct within 6 fee t of furna ce 1" 1"

Front of furn ace 1 8" (alc ov e) 18" 18" (alc ov e) 18"

Flue pipe (or bar om et ric d. c.) to any surfac e 9" (note 1) 18" 9" (not e 1) 18"

Rea r of furnace 0" 0"

Side of furnace 0" 0"

Warm air plenum t o wall 1" 1"

Combustible floor 0" 0"

Note 1 : Single wall metal vent (or barometric draft control) can be no closer than 9 inches to any combustible surfac e. Apply requirement s of NFPA 31

an d local codes to red uce c l earance using dou bl e-wall vent pi pe and/or pro tectiv e i nsulati on be twee n the flue pi pe or barometric draft control and

combustible surfa ces. Minimum clearance when u sing Type L double-wall vent pipe is 6”.

670-000-005/1010 3

TH B Furnaces TL B Furnac e s

To combust i ble

construction

For serv ice

accessibility

To combustible

construction

For serv ice

accessibility

THB & TLB Oil Furnaces – Furnace Manual

1 Prepare furnace location (continued)

Air for combustion and ventilation

Adequate combustion and ventilation air ensures

proper combustion and reduces risk of severe

personal injury or death from possible flue gas

leakage and carbon monoxide emissions.

Do not install exhaust fan in furnace room.

Consider building construction

Older buildings with single-pane windows, minimal weatherstripping and no vapor barrier often provide enough natural

infiltration and ventilation without dedicated openings.

New construction or remodeled buildings are most often built

tighter. Windows and doors are weather-stripped, vapor barriers

are used and openings in walls are caulked. As a result, such

tight construction is unlikely to allow proper natural air infiltration

and ventilation.

For buildings with tight construction, provide openings directly to

outside or to a ventilated crawl space or attic. Size the openings

to the same specifications as for the furnace location per the

following paragraphs.

Follow state, provincial or local codes when sizing adequate

combustion and ventilation air openings. In absence of codes,

use the following guidelines when furnace is in a confined room

(defined by NFPA 31 as less than 7,200 cubic feet per 1 GPH

input of all appliances in area. A room 8 ft. high x 30.0 ft. x 30.0 ft.

is 7200 cu. ft.).

Provide two permanent openings:

Opening locations

One within 12 inches of ceiling, one within 12 inches of floor.

Minimum height or width dimension of each rectangular opening

should be at least 3 inches.

When inside air is used:

Each opening must freely connect with areas having adequate

infiltration from outside. Each opening should be at least 140 sq.

in. per 1 GPH input (1 sq. in. per 1000 BTU input) of all fuelburning appliances plus requirements for any equipment that can

pull air from room (including clothes dryer and fireplace).

When outside air is used

Connect each opening directly, by way of ducts to the outdoors,

or to crawl or attic space that freely connects with outdoors. Size

per below:

• Throug h outside wall or vertical ducts – at least 35 sq. in. per

1 GPH input (1sq. in. per 4,000 BTU input) of all fuel burning

appliances plus requirements for any equipment that can pull

air from room (including clothes dryer and fireplace).

• Through horizontal ducts – at least 70 sq. in. per 1 GPH

furnace input (1 sq. in. per 2,000 BTU input) of all fuelburning appliances plus requirements for any equipment that

can pull air from room (including clothes dryer and fireplace).

• Where ducts are used, they should have the same crosssectional area as free area of openings to which they

connect. Compensate for louver, grille or screen blockage

when calculating free air openings. Refer to their

manufacturer’s instructions for details. If unknown, use:

• Wood louvers, which provide 20-25 % free air.

• Metal louvers or grilles, which provide 60-75 % free air.

Lock louvers in open position or interlock with equipment to

prove open before furnace operation.

Basement installations

When the furnace is located in an unconfined space, such as an

unpartitioned basement, adequate air should normally be

available without additional opening. An unconfined space is

defined as one having no less than 50 cubic feet room volume

per 1,000 BTU input of all appliances in the space.

If the house is of tight construction, provide air openings to the

basement directly from outside or from a ventilated attic. Size the

openings as described above under “When outside air is used”.

Closet installations – special NOTICE

Openings in closet doors

Provide TWO openings – one within 6 inches of top of closet

door, the other within 6 inches of the bottom of closet door.

EACH opening must be at least 24 inches wide by 12 inches

high.

Advise homeowner that the openings to the

closet must never be obstructed or blocked in any

way. Failure to provide adequate air for

combustion and ventilation could result in severe

personal injury, death or substantial property

damage.

4 670-000-005/1010

THB & TLB Oil Furnaces – Furnace Manual

1 Prepare furnace location (continued)

Air contamination

Please review the following information on potential combustion air

contamination problems.

See Table 2 for products and areas which may cause contaminated

combustion air.

To prevent potential of severe personal injury or

death, check for products or areas listed below

before installing furnace. If any of these

contaminants are found:

• Remove contaminants permanently.

-OR-

• Isolate furnace and provide outside combustion air. See

national, provincial or local codes for further information.

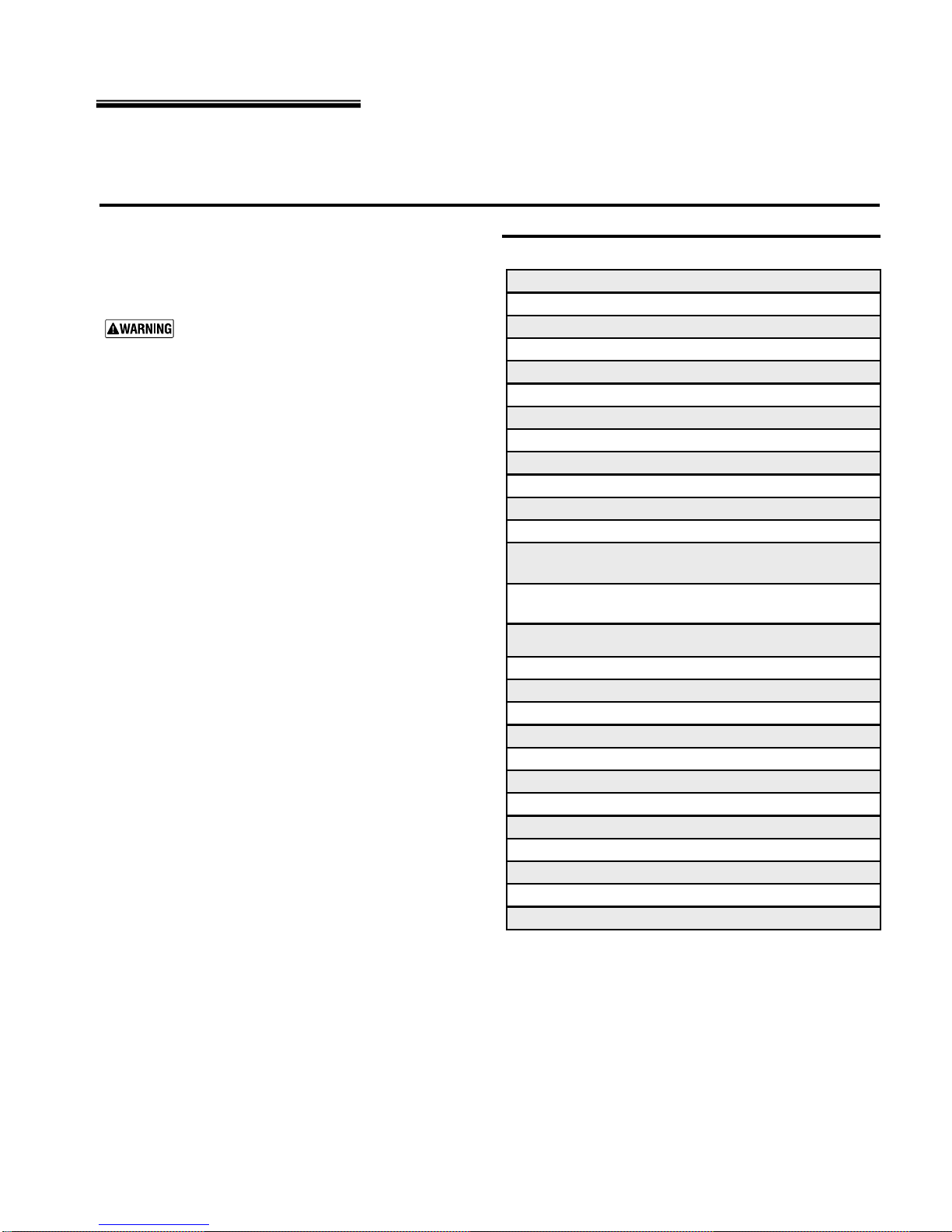

Table 2 Corrosive contaminants and likely locations

Products to avoid

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint varnish remov ers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, a nd cleaning solvents found in

household laundry rooms

Adhesives used to fasten building products and othe r similar

products

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

670-000-005/1010 5

THB & TLB Oil Furnaces – Furnace Manual

2 Prepare furnace and place in position

Inspect & prepare furnace

Remove furnace from carton

Remove the furnace from its shipping carton and inspect thoroughly.

Remove access panels to inspect the furnace interior.

Immediately file a claim with the transportation

company if you discover concealed damage.

Do not install or attempt to operate the furnace if the

heat exchanger, burner or controls have been

damaged. Immediately contact your furnace

supplier. Operating a damaged furnace could result

in severe personal injury, death or substantial

property damage.

Prepare furnace (THB models)

THB furnaces require cutting the return air opening into one side of

the furnace. Carefully cut the opening on the correct side of the

furnace, using the four knockouts on the side as guide.

Prepare burner

Remove the burner from its shipping carton and inspect thoroughly.

Read the burner manual and follow instructions for preparing and

installing the burner.

Install the correct nozzle for the required firing rate, using the burner

manual and the information in Section 12 of this manual. Follow the

burner manual’s instructions for nozzle installation. Verify the correct

settings of electrodes after nozzle and burner oil tube assembly are

in place.

Openings in walls, floor & ceiling

General

Ensure that the finished door opening to the furnace room is large

enough to install and remove the furnace, water heater or any other

appliances in the room.

Before placing furnace in a closet or small room, cut all openings

required in floor, ceiling or walls for ducts and vent. This will simplify

the work and prevent construction dust from entering the furnace

heat exchanger.

Verify that all clearances to combustible construction

and as needed for service accessibility will be met.

The vent must be no closer than 18 inches to any

combustible surface unless using type L double-wall

vent pipe or constructed per the requirements of

NFPA31. Provide ventilated thimble per all

applicable codes where vent pipe passes through

wall or ceiling. Failure to comply could result in

severe personal injury, death or substantial property

damage.

Openings …

Return air duct

You must install a return air duct, sealed to the furnace, even if no

return manifold is used. The only exception is when the furnace is

located in a large unpartitioned room, such as a basement. (A room

whose volume is at least 50 cubic feet per 1,000 BTU/h input of all

appliances in the room is considered large). For large rooms, return

air may be taken directly at the furnace, without a return air duct. No

return air register should be within 20 feet of the furnace.

Cut the required opening for the return air duct in the wall (or floor or

ceiling) of the room before placing the furnace.

Install filter

Install return air filter of the size listed in Section 12.

When installing on combustible flooring, provide supply plenum

size and floor opening as given in Table 3.

(continued)

Verify that the filter will be easily accessible for

removal after the furnace is in place.

Install furnace and burner

Place furnace

Place the furnace in the desired location. Measure clearances and

verify per page 3 of this manual.

Level the furnace using a spirit level on the front and one side.

Inspect combustion chamber

Inspect the combustion chamber. Verify it is in good condition and

correctly in position inside the heat exchanger. The burner opening

in the chamber must align with the burner heat exchanger opening.

The combustion chamber is constructed of ceramic

fiber materials See the WARNING information on

page 20 of this manual. Comply with these

instructions when handling any ceramic fiber or

fiberglass materials. Failure to adhere to these

guidelines could result in severe personal injury or

Insert burner

Following the burner manual instructions, install the burner and its

gasket in the burner opening. Make sure the burner passes through

the opening in the combustion chamber and does not protrude more

than ¼ inch into the chamber.

Secure the burner in place with the three nuts and washers

provided. Wire and pipe fuel to the burner per burner manual and

this manual.

death.

Duct locations and sizing

Verify the size of the supply and return duct system is sufficient for

the application. The pressure drop through the duct system must not

exceed 0.25 inches water column. The total drop through the duct

system and air conditioning condensing coil (if used) must not

exceed 0.5 inches water column.

See suggested duct sizing in this manual. For more detailed sizing

information refer to ACCA Manual D.

6 670-000-005/1010

THB & TLB Oil Furnaces – Furnace Manual

2 Prepare furnace and place in position

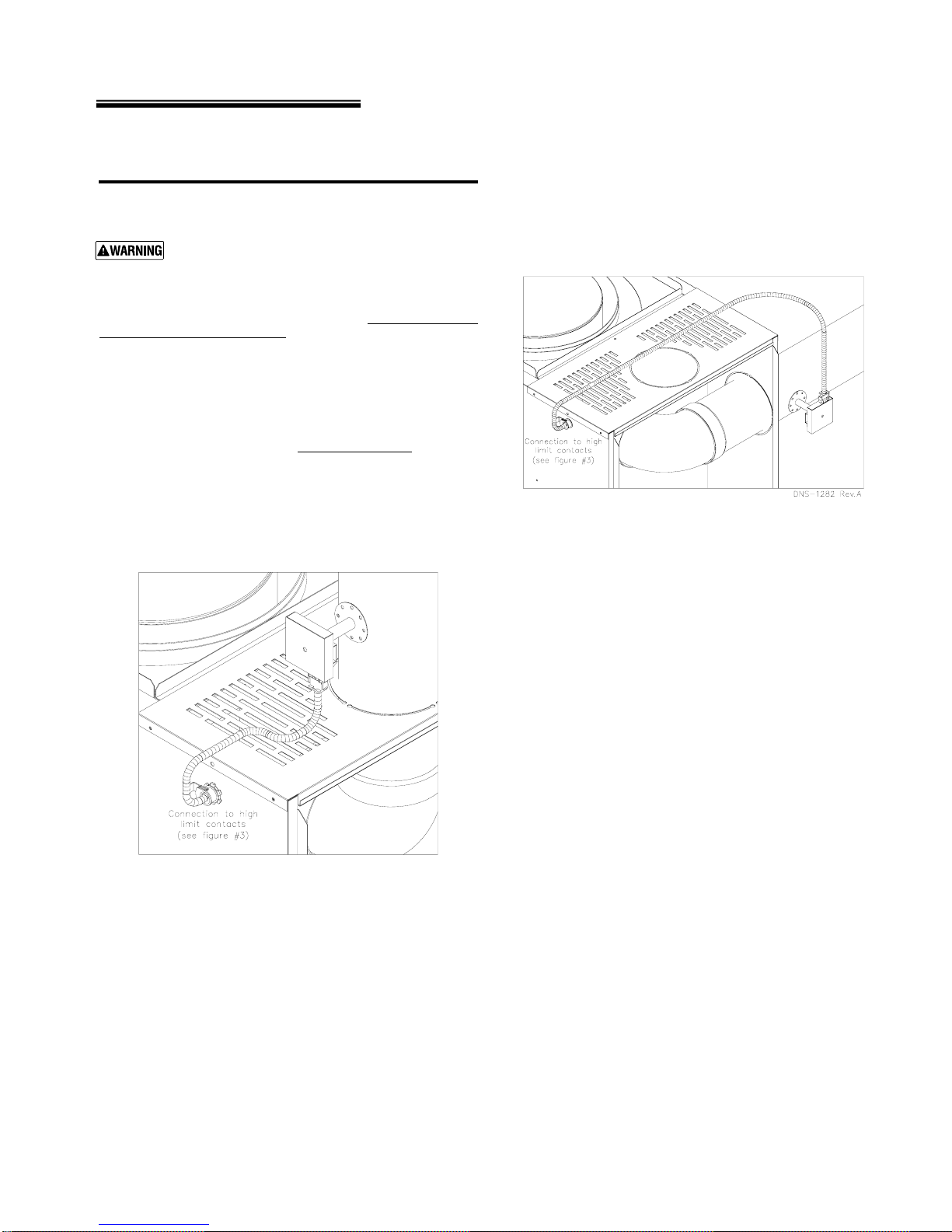

Blocked Vent Shut-Off (BVSO) for chimney venting

(OPTIONAL)

It is imperative that this device be installed by a

qualified agency.

This device is designed to detect the insufficient evacuation of

combustion gases in the event of a vent blockage. In such a case

the thermal switch will shut down the oil burner. The device will then

need to be re-armed MANUALLY.

In the event that the BVSO repetitively shuts down the oil burner, a

qualified technician needs to evaluate the cause of this shut down.

Refer to the figures 3 to 5 at section 6, Wiring Diagrams and detailed

instructions supplied with the BVSO for the installation and wiring

procedures.

It is also essential the the BVSO be maintained annually.

For more details refer to the instructions supplied with the device

itself, as well as the Maintenance Section.

Figure 1

Blocked Vent Shutt-Off device wiring

Installation : Upflow with Vertical exhaust

(Optional)

Figure 2

Blocked Vent Shutt-Off device wiring

Installation : Upflow with Horizontal exhaust

(Optional)

670-000-005/1010 7

THB & TLB Oil Furnaces – Furnace Manual

3 Connect supply and return ducts

Duct sizing

Determine air flow CFM

The temperature rise through the furnace must not exceed 85o F and

should be at least 55

assume a temperature rise of 70

The sensible heat temperature change for cooling would be

approximately 27-30

approximately 18-21

To calculate the sensible heat temperature change (ΔT), you can

use the formula:

ΔT = BTU/h/(1.1 x CFM) Eq. 3-1

To calculate air flow when you know temperature change (ΔT), you

can use:

CFM = BTU/h/(1.1 x ΔT) Eq. 3-2

You can estimate air flow using the following rules of thumb:

Heating: 14 CFM per 1,000 BTU/h output Eq. 3-3

Cooling: 400 CFM per ton air conditioning Eq. 3-4

Determine the required air flow based on whichever is larger –

heating mode or air conditioning mode.

Examples:

1. What would the temperature rise be for a 100,000 BTU/h output

furnace with an air flow rate of 1,200 CFM?

Use Equation 3-1 since you know CFM and BTU/h:

ΔT = 100,000/(1.1 x 1200) = 76

• The temperature rise would be 76

• If the air enters the furnace at 70

furnace at 70

2. What would the air flow be to obtain a 70

120,000 BTU/h output furnace?

Use equation 3-2 since you know ΔT and BTU/h:

CFM = 120,000/(1.1 x 70) = 1,558 CFM

• The air flow would have to be 1,558 CFM to obtain a

temperature rise of 70

3. Estimate the required air flow for a 75,000 BTU/h output furnace

installed with a 2-ton air conditioning evaporator coil.

Heating mode air flow (use Equation 3-3):

CFM = 75 x 14 = 1,050 CFM

Cooling mode air flow (use Equation 3-4):

CFM = 2 x 400 = 800 CFM

• The larger number is 1,050 CFM (heating), so the duct

system should be sized for 1,050 CFM.

• The supply duct would need to be 16" round or a rectangular

equivalent such as 8" x 25" or 12" x 16", using Table 4,

page 9.

4. Estimate the required air flow for the same furnace installed with

a 4-ton air conditioning evaporator coil.

Heating mode air flow is still 1,050 CFM.

Cooling mode air flow (use Equation 3-4):

CFM = 4 x 400 = 1,600 CFM

• The larger number is 1,600 CFM (cooling), so the duct

system should be sized for 1,600 CFM.

• The supply duct would need to be 18" round or a rectangular

equivalent such as 8" x 36" or 12" x 21", using Table 4,

page 9.

o

F for comfort. When calculating air flow,

o

F.

o

F. Actual temperature change will be

o

F due to humidity of the air.

o

F

o

F.

o

o

F + 76o F = 146o F.

o

F.

F, it would leave the

o

F rise through a

Always check the size of existing ducts, particularly

if you are adding air conditioning. The air pressure

loss through the cooling evaporator coil reduces

available air flow. If the ducts are too small as well,

the system may not work satisfactorily on either

heating or cooling.

Determine duct dimensions

Table 4, page 9, and Table 5, page 10, provide typical round and

rectangular duct sizes for rectangular and flat oval galvanized ducts.

Do not apply these tables to size ductwork if the total equivalent

length of the duct exceeds approximately 100 feet. For longer

systems or for duct board, fiberglass-lined or flexible duct sizing, use

the ACCA Manual D or the ACCA duct sizing slide rule. These

tables are based on pressure loss of approximately 0.10 inch water

column per 100 feet equivalent length of duct.

Use Table 3 below to size or check sizing of takeoffs to supply

registers or return grills.

Verify the size and type of registers, diffusers and grills from the

manufacturer’s ratings. Do not exceed the recommended flow rate.

The pressure drop allowance for each should not exceed

approximately 0.05 inch water column.

Install a return air filter, sized per specifications on Section 12.

Use only a return air filter mounted to the furnace. Do not add

additional filters unless the duct system is carefully sized to allow for

the additional pressure drop.

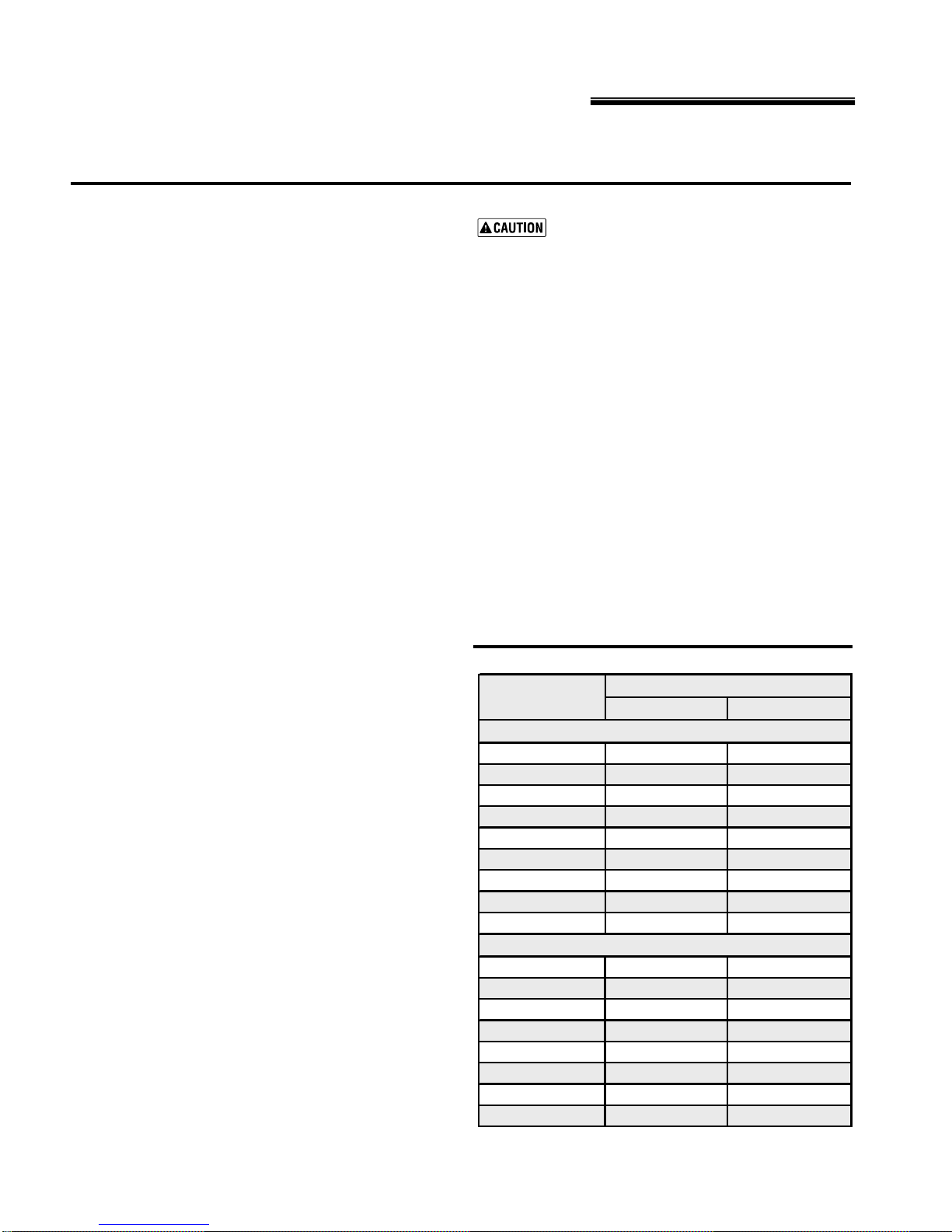

Table 3 Suggested maximum flow to takeoffs

TAKE-OFF SIZE

(Inches)

Sheet metal or ductboard

5 Round 60 45

6 Round 100 75

7 Round 140 110

8 Round 210 160

3 ¼ x 8 Stack 70 55

3 ¼ x 10 Stack 100 75

3 ¼ x 14 Stack 140 110

2 ¼ x 12 Stack 70 55

2 ¼ x 14 Stack 90 70

Flexible duct (keep bends to minimum)

6 Round 55 40

8 Round 120 90

10 Round 200 160

12 Round 320 250

14 Round 480 375

16 Round 660 530

18 Round 880 680

20 Round 1200 900

SUPPLY RETURN

CFM

8 670-000-005/1010

THB & TLB Oil Furnaces – Furnace Manual

3 Connect supply and return ducts (continued)

Duct sizing (continued)

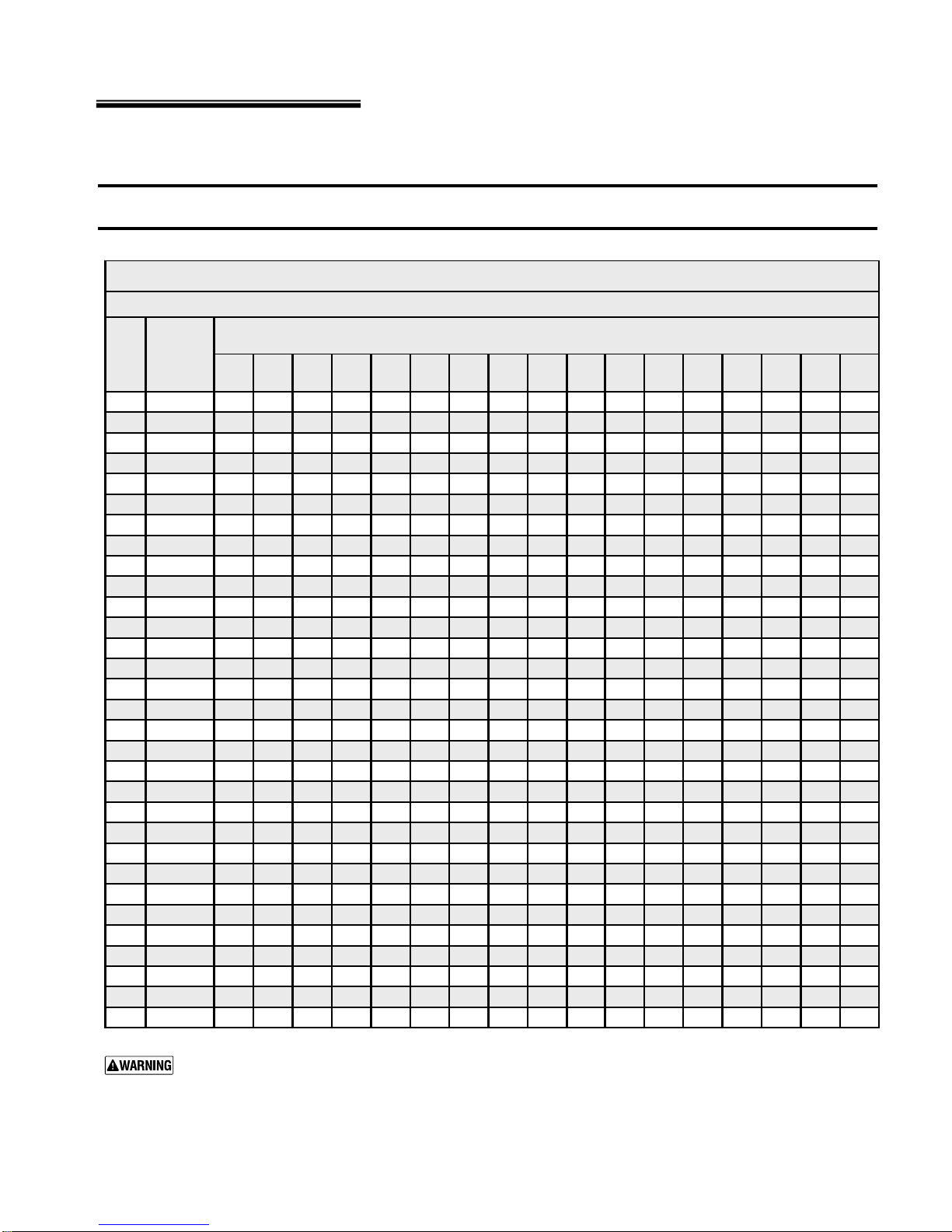

Table 4

Typical duct sizing for systems not over 100 feet equivalent length – round or rectangular galvanized

Typical duct sizing

(For approxim ately 0.10 inch w.c. i n a typical residenti al instal lation of galvani z ed metal duc t)

Round

CFM

duct

diameter4567891012141618202224262830

(inches)xxxxxxxxxxxxxxxxx

45

65

100

150

200

250

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2200

2400

2600

2800

3000

3500

4000

Rectangular duct equival ent sizes

Mini mum wi dt h

4

5

6

7

8

9

9

10

12

12

12

14

14

16

16

16

16

18

18

18

18

18

20

20

20

22

22

22

22

24

26

444-------------6544-------------

865544- - --------1297655544-------141198766544------181310987665544----20151210987665544---2619151311109876655544322318151312119876665555

3828221815131210987766655

46322520171514111098777666

523628231917151311109887766

5841312521191714121110988777

6445342823201815131110998877

72493830252219161412111099887

-5441332724211715131211109988

- 58443529252218161412111010 9 9 8

- 6347383127241916141312111010 9 9

- 685140342925201715141212111010 9

- 725443363027211816141312111110 9

- - 58 45 38 32 28 23 19 17 15 14 13 12 11 10 10

- - 61 48 40 34 29 24 20 17 16 14 13 12 11 11 10

- - 64 51 42 35 31 25 21 18 16 15 14 13 12 11 11

- - 68 53 44 37 32 26 22 19 17 15 14 13 12 12 11

- - - 5948413528232018161514131212

- - - 6452443830252219171615141312

- - - 6956474132272321191716151413

- - - - 61 51 44 34 29 25 22 20 18 17 15 15 14

- - - - 65 54 47 37 30 26 23 21 19 17 16 15 14

-----635442342926232119181716

-----726147393329262321201918

Do not apply this table for duct systems over approximately 100 equivalent feet length. For longer systems or systems using

other duct materials, refer to ACCA Manual D. Incorrectly sizing duct systems can result in unsafe or uncomfortable

operation.

(inches)

for duct heights

(inches)

of :

670-000-005/1010 9

THB & TLB Oil Furnaces – Furnace Manual

3 Connect supply and return ducts (continued)

Duct sizing

Table 5

Typical duct sizing for systems not over 100 feet equivalent length – round or flat oval galvanized

(For approximately 0.10 inch w.c. i n a typical residenti al instal lation of galvani z ed metal duc t)

Round

CFM

45

65

100

150

200

250

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2200

2400

2600

2800

3000

3500

4000

duct

diameter3456789101214161820

(inches)xxxxxxxxxxxxx

Do not apply this table for duct systems over approximately 100 equivalent feet length. For longer systems or systems using

other duct materials, refer to ACCA Manual D. Incorrectly sizing duct systems can result in unsafe or uncomfortable

operation.

(continued)

4

5

6

7

8

9

9

10

12

12

12

14

14

16

16

16

16

18

18

18

18

18

20

20

20

22

22

22

22

24

26

Typical duct sizing

Flat oval duct equi val ent sizes

Mini mum width

65-----------

86----------1187---------161198--------211511108-------26181411109------302016131110------40262016141211-----4932241916141312----5938282219161513----694432252118161513----

-5036292420181614----

-5641322622201815----

- 634535292422191715 - - -

- 694938312623211816 - - -

- 755341332825221917 - - -

- - 58 44 36 30 26 24 20 18 - - -

- - 62 47 38 32 28 25 21 18 17 - -

- - 66 50 41 34 30 26 22 19 18 - -

- - 71 54 43 36 31 28 23 20 18 - -

- - - 57 46 38 33 29 24 21 19 - -

- - - 60 48 40 35 31 25 22 20 - -

- - - 63 50 42 36 32 26 23 21 19 -

- - - 67 53 44 38 33 27 24 21 20 -

- - - 73 58 48 41 36 29 25 23 21 -

----635244393227242221

----685648423429252322

-----6051443630272423

-----6454473832282624

------63544336322826

------71614840353129

(inches)

for duct heights

(inches)

of :

10 670-000-005/1010

THB & TLB Oil Furnaces – Furnace Manual

4 Venting

General venting requirements

Failure to follow all instructions can result in flue gas

spillage and carbon monoxide emissions, causing

severe personal injury or death.

Inspect existing chimney before installing furnace.

Clean chimney thoroughly. Replace or repair

chimney if visual inspection indicates chimney may

be unsuitable for use. Insufficient draft can cause

flue gas leakage and carbon monoxide emissions.

Failure to clean or replace perforated pipe or tile

lining and/or patch mortar and joints can cause

severe personal injury or death.

• THB and TLB furnaces are designed to operate with an over-fire

draft of -0.01" to –0.02" w.c. Proper draft for these oil furnaces

may be achieved using either a conventional chimney (natural

draft) or a power vent (sidewall) system that has been properly

designed for use with oil equipment. Power vent manufacturer’s

instructions must be followed.

• Use vent material approved by local codes for oil-fired burners.

In their absence, refer to:

• NFPA 31, Installation of Oil-Burning Equipment.

• NFPA211, Standard for Chimneys, Fireplaces, Vents and

Solid Fuel Burning Appliances.

• In Canada, refer to CSA B139, Installation Code for Oil-

Burning Equipment.

• NFPA-211 requires chimney to be lined before being

connected to furnace.

• To prevent downdrafts, extend chimney at least 3 feet above

highest point where it passes through roof and 2 feet higher than

any portion of building within 10 feet. Increase chimney crosssectional area and height at least 4% per 1,000 feet above sea

level.

• Provide minimum clearances from vent (flue) pipe to

combustible material:

• Single-wall vent – 18 inches minimum

• Type "L" double-wall vent – 6 inches minimum

• Provide a chimney no smaller than that listed in Table 6.

Oversized chimneys, outside masonry chimneys

and/or de-rated inputs can result in condensation in

chimney.

Connect venting

Long horizontal vent runs, excessive number of tees

and elbows, or other obstructions restricting

combustion gas flow can result in the possibility of

condensation, flue gas leakage and carbon

monoxide emissions, which can lead to severe

personal injury or death.

1. The horizontal vent must slope upwards, away from the furnace,

a minimum of ¼ inch per foot.

2. Connect full-sized venting when possible. See Table 6.

3. Connection must be made above bottom of chimney to avoid

blockage. Vent pipe must not enter chimney far enough to cause

obstruction. Use thimble or slip joint where vent pipe enters

chimney to allow removal for cleaning.

4. When burner and furnace are properly installed, draft overfire

will be approximately –0.01" to –0.02" w.c. Install barometric

Connect venting (continued)

control in vent, per control manufacturer’s instructions, when

excess draft needs to be relieved or to comply with applicable

codes and regulations. Use draft gauge to adjust proper

opening.

5. An induced draft fan for the chimney may be necessary if:

• Excessive resistance to flow of combustion gases can be

expected.

• Cross-sectional area of chimney is smaller than minimum

recommended.

• Chimney height is less than recommended.

• When using induced draft fan, seal all vent joints and

interlock burner with fan operation.

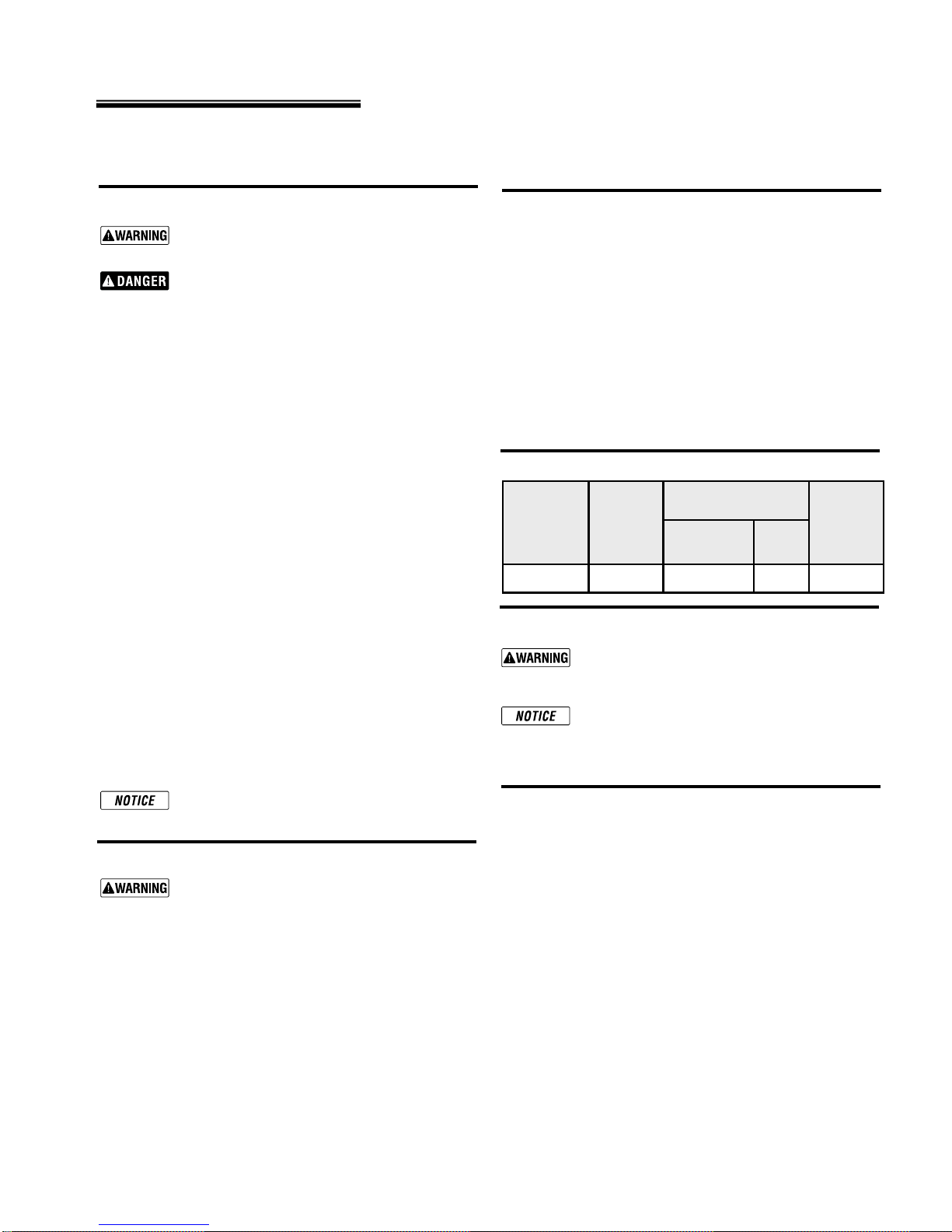

Table 6 Minimum chimney/vent size

Furnace

Model

number

THB/TLB-105 6 “ 6 “ x 6” 6 “ 15’

Minimum

vent

diameter

Minimum chimney

size

Rectangular

(minimum inside

dimensions)

Round

Minimum

Chimney

height

Vent dampers

Do not install a thermal-type vent damper on this

furnace. Failure to comply could result in severe

personal injury, death or substantial property

damage.

If vent damper is required, use only a motorized vent

damper, installed and wired to the furnace following

the vent damper manufacturer’s instructions.

Barometric draft control

Install barometric control in vent, per control manufacturer’s

instructions, when excess draft needs to be relieved or to comply

with applicable codes and regulations. Use draft gauge to adjust

proper opening.

1. Install barometric draft control in vent pipe at least one foot from

the furnace vent connection, preferably in the highest part of the

vent pipe before the vent enters the chimney. If headroom

doesn’t provide enough clearance to locate the control at least

one foot from the vent connection, install an elbow at the furnace

and mount the control in a horizontal pipe at least one foot from

the elbow. Install an elbow after the control to turn vertically.

2. To operate correctly, the barometric draft control must be

located in the same room as the furnace.

3. Ensure the barometric draft control is accessible. Adjust the

damper to obtain the correct overfire draft, as described in this

manual and the burner manual.

670-000-005/1010 11

Loading...

Loading...