Milwaukee Super Sawzall 6527, Super Sawzall 6527-21, Super Sawzall 6528, Super Sawzall 6537-22, Super Sawzall 6537-75 Operator's Manual

Catalog No.

No de Cat.

Catálogo No.

6527

6527-21

6528

6537-22

6537-75

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

SUPER SAWZALL

®

PASSE-PARTOUT SUPER SAWZALL

SIERRAS SABLE SAWZALL

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

®

®

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operat-

ing a power tool. Distractions can cause you to lose control.

Protect others in the work area from debris such as chips and

sparks. Provide barriers or shields as needed.

ELECTRICAL SAFETY

4. Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adaptor plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should electrically

malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user.

5. Double Insulated tools are equipped with a polarized plug

(one blade is wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates the need for

the three wire grounded power cord and grounded power supply

system.

6. Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded.

7. Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

8. Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

9. When operating a power tool outside, use an outdoor

extension cord marked W-A or W. These cords are rated

for outdoor use and reduce the risk of electric shock.

PERSONAL SAFETY

10. Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in

serious personal injury.

11. Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

12. Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools with the switch on invites accidents.

13. Remove adjusting keys or wrenches before turning on the

tool. A wrench or a key that is left attached to a rotating part of the

tool may result in personal injury.

14. Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

15. Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection must

be used for appropriate conditions.

TOOL USE AND CARE

16. Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to loss of control.

17. Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for which

it is designed.

18. Do not use tool if switch does not turn it on or off. Any tool

that cannot be controlled with the switch is dangerous and must be

repaired.

19. Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventive safety measures reduce the risk of starting the tool

accidentally.

20. Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

21. Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edge are less likely to

bind and are easier to control. Do not use a damaged tool. Tag

damaged tools Do not use until repaired.

22. Check for misalignment or binding of moving parts, break-

age of parts, and any other condition that may affect the

tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

23. Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for

one tool, may become hazardous when used on another tool.

SERVICE

24. Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified per-

sonnel could result in a risk of injury.

25. When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this

manual. Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

page 2

SPECIFIC SAFETY RULES SAWZALLS

1. Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its

own cord. Contact with a live wire will make exposed metal parts of the tool live and shock the operator.

2. Keep hands away from all cutting edges and moving parts.

3. Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a MILWAUKEE service facility for a free

replacement.

4. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

lead from lead-based paint

crystalline silica from bricks and cement and other masonry products, and

arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic

particles.

®

Symbology

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

Volts Alternating Current

1. Handle

2. Trigger

3. Nameplate

4. Blade Clamp

5. Blade

6. Adjustable Pivot Shoe

7. Shoe Release Lever

8. Hex Key (Select Models)

9. Insulating Boot

10. Speed Control Dial

11. Quik-Lok

(Select Models)

®

Cord

FUNCTIONAL DESCRIPTION

3

Catalog

Number

6527

6527-21

6528

6537-22

6537-75

Specifications

Volts

AC Only

120

120

120

120

120

2

Length of

Stroke

1-1/4"

1-1/4"

1-1/4"

1-1/4"

1-1/4"

10

Strokes

per Minute

0-2800

0-2800

0-2800

0-3200

0-3200

1

11

4

5

7

6

9

8

page 3

GROUNDING EXTENSION CORDS

WARNING!

Improperly connecting the grounding wire can

result in the risk of electric shock. Check with a

qualified electrician if you are in doubt as to

whether the outlet is properly grounded. Do not

modify the plug provided with the tool. Never

remove the grounding prong from the plug. Do

not use the tool if the cord or plug is damaged. If

damaged, have it repaired by a MILWAUKEE

service facility before use. If the plug will not fit

the outlet, have a proper outlet installed by a

qualified electrician.

Grounded Tools:

Tools with Three Prong Plugs

Tools marked Grounding Required

have a three wire cord and three

prong grounding plug. The plug must

be connected to a properly grounded

outlet (See Figure A). If the tool should

electrically malfunction or break

down, grounding provides a low resistance path to carry electricity

away from the user, reducing the risk

of electric shock.

The grounding prong in the plug is connected through the green wire

inside the cord to the grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's grounding system and

must never be attached to an electrically live terminal.

Your tool must be plugged into an appropriate outlet, properly installed

and grounded in accordance with all codes and ordinances. The plug

and outlet should look like those in Figure A.

Fig. A

Grounded tools require a three wire extension cord. Double insulated

tools can use either a two or three wire extension cord. As the distance

from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a

serious drop in voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the

total length, be sure each cord contains at least the minimum wire size

required. If you are using one extension cord for more than one tool, add

the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

If you are using an extension cord outdoors, be sure it is marked

with the suffix W-A (W in Canada) to indicate that it is acceptable

for outdoor use.

Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it

repaired by a qualified person before using it.

Protect your extension cords from sharp objects, excessive heat

and damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

8.1 - 12

12.1 - 15

15.1 - 20

for Extension Cords*

25'

0 - 5

5.1 - 8

16

16

14

12

10

Extension Cord Length

100'

14

12

10

10

150'

12

10

--

--

--

--

50'

16

16

14

12

10

75'

16

14

12

10

10

200'

12

--

--

--

--

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked Double Insulated do

not require grounding. They have a

special double insulation system

which satisfies OSHA requirements

and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard

Association and the National Electrical Code. Double Insulated tools may

be used in either of the 120 volt outlets shown in Figures B and C.

Fig. B

* Based on limiting the line voltage drop to five

volts at 150% of the rated amperes.

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE USE.

Fig. C

page 4

TOOL ASSEMBLY

WARNING!

To reduce the risk of injury, always unplug

tool before attaching or removing accessories

or making adjustments. Use only specifically

recommended accessories. Others may be

hazardous.

®

Removing and Replacing Quik-Lok

MILWAUKEE's exclusive Quik-Lok

ment or substitution.

Fig. 1

1. To remove the Quik-Lok® Cord, turn the cord nut 1/4 turn to the left

and pull it out.

2. To replace the Quik-Lok

®

push the connector in as far as it will go. Turn the cord nut 1/4 turn

to the right to lock.

Selecting a Blade

Use MILWAUKEE Sawzall

®

Blades for best performance. When select-

ing a blade, choose the right type and length.

Many types of blades are available for a variety of applications: cutting

metal, wood, nail-embedded wood, scroll cutting, roughing-in, and contours.

Many lengths are also available. Choose a length long enough to extend

beyond the shoe and your work throughout the stroke. Do not use

blades less than 3-1/2" long since they won't extend beyond the

shoe throughout the stroke.

For best performance and longest life, see Accessories to select the

best blade for the job.

Installing and Removing Blades

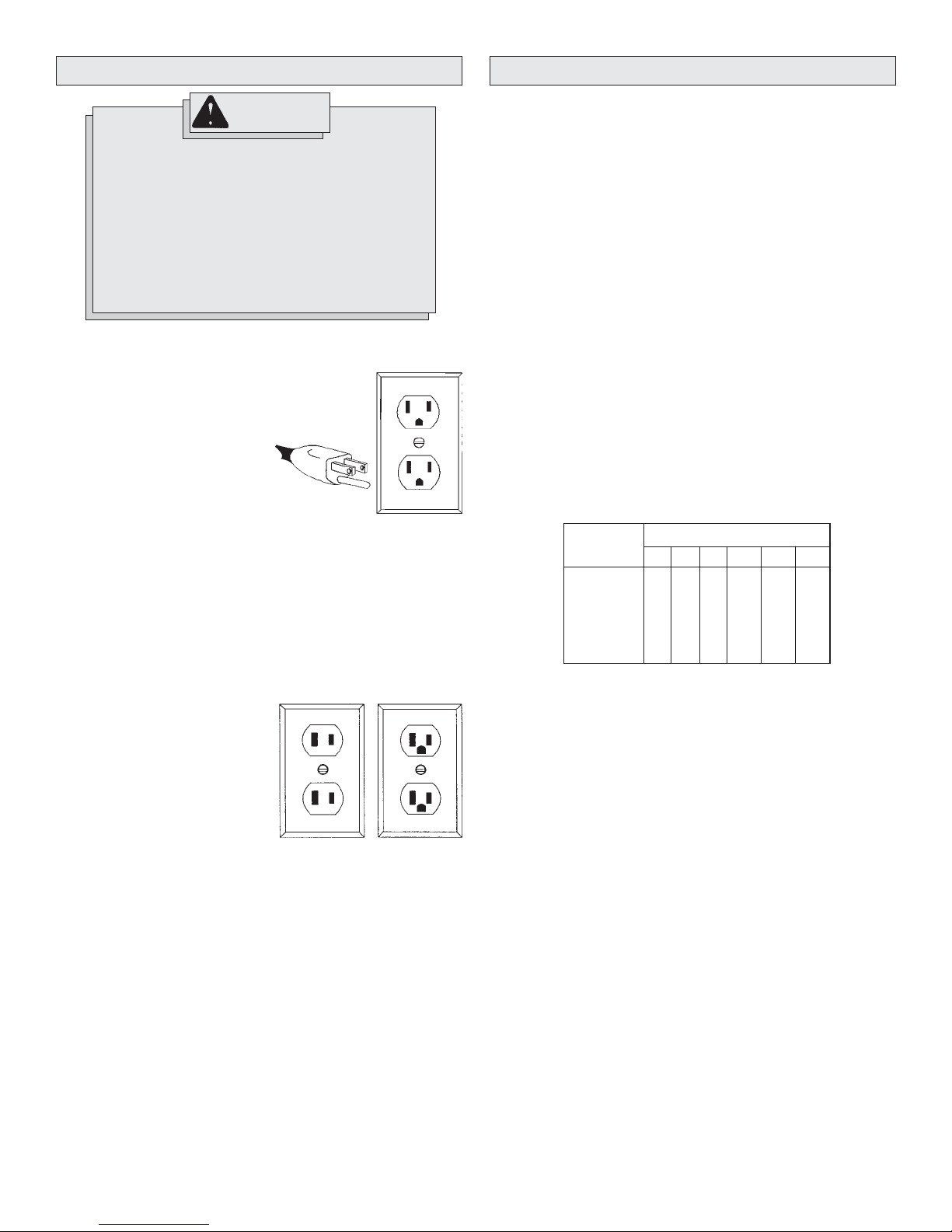

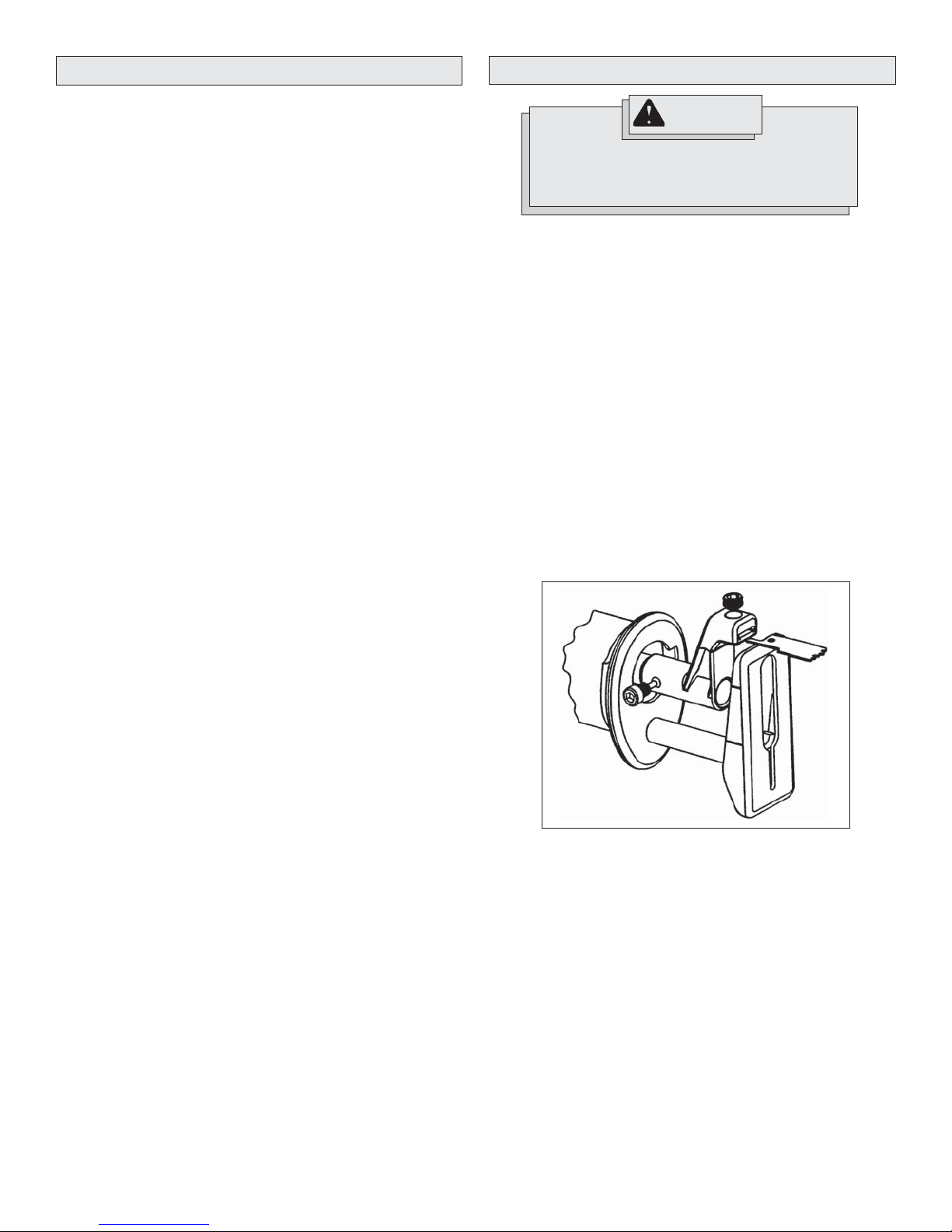

Blade Clamp (Fig. 2) Select Models

Unplug the tool before changing blades. Be sure the spindle and blade

clamp area are clean. Metal chips and sawdust may prevent the blade

clamp screw from clamping securely.

Fig. 2

Cords (Fig. 1) (Select Models)

®

Cords provide instant field replace-

Cord, align the connector keyways and

1. Depending on the job, the blade may be inserted with the teeth

facing upward or downward.

To install a blade, loosen the blade clamp screw, turning it counterclockwise. Insert the blade until the tang butts against the spindle.

NOTE: The blade must be inserted all the way into the spindle so that

the tang on the blade seats firmly in the blade clamp.

Insert the hex key into the blade clamp screw, turning it clockwise.

Tighten securely.

2. To remove a blade, insert hex key into the blade clamp screw and

turn it counterclockwise 1 full turn. Then slide the blade out of the

spindle. Be careful when handling hot blades.

®

Quik-Lok

Blade Clamp (Fig. 3) (Select Models)

Unplug the tool before changing blades. Be sure the spindle and blade

clamp areas are clean. Metal chips and sawdust may prevent the Quik-

®

Lok

blade clamp from clamping securely.

Fig. 3

Collar

Blade

1. Depending on the job, the blade may be inserted with the teeth

facing up or down. To install a blade, twist collar in the direction of

the arrow while inserting the blade into the clamp until the tang butts

against the collar.

2. Release collar and the spring loaded mechanism will clamp the blade

firmly in place.

3. Twist collar in the opposite direction of the arrow to ensure that the

blade is locked into the clamp.

4. Tug on blade to make sure it is securely locked in place.

5. To remove a blade, twist collar in the direction of the arrow while

pulling on the blade. Be careful when handling hot blades.

®

Quik-Lok

Periodically clean dust and debris from the Quik-Lok

Blade Clamp Maintenance

®

blade clamp

with dry compressed air.

If the collar resists twisting, twist the collar back and forth to shake

debris loose.

®

Periodically lubricate Quik-Lok

blade clamp with a dry lubricant

such as graphite.

Hex key

Blade clamp screw

®

Removing broken blades from the Quik-Lok

Blade Clamp

Unplug the tool before removing blades. Broken blades can be removed

by the following methods.

Point the tool downward, twist the collar, and shake the tool up and

down. (DO NOT turn the tool on while your fingers are holding the

blade clamp open). The shank of the broken blade should drop out

of the clamp.

If shaking the tool doesn't work...

In most cases, a corner of the broken blade will extend beyond the

blade clamp. Simply twist the collar and pull the broken blade out of

the clamp by this corner.

If the broken stub doesn't extend far enough to be grabbed by its

corner, use a thin blade with small teeth (such as a metal cutting

blade) to hook the blade that is jammed in the clamp while twisting

the collar and pull it out.

page 5

Adjustable Pivot Shoe (Fig. 4)

The shoe can be adjusted forward or backward to three positions to

take advantage of the unused portion of the blade or for special jobs

requiring low blade clearance.

Fig. 4

1/4 Turn

1. To adjust the shoe, pull the shoe release lever down 1/4 turn and

slide the shoe forward or backward to the desired position.

2. To lock the shoe in position, push the shoe release lever up.

3. After adjusting the shoe, slowly pull the trigger to be sure the blade

always extends beyond the shoe and your work throughout the

stroke.

DO NOT OPERATE SAWZALL WITHOUT SHOE. STRIKING THE SPINDLE

AGAINST WORK MAY DAMAGE THE RECIPROCATING MECHANISM.

OPERATION

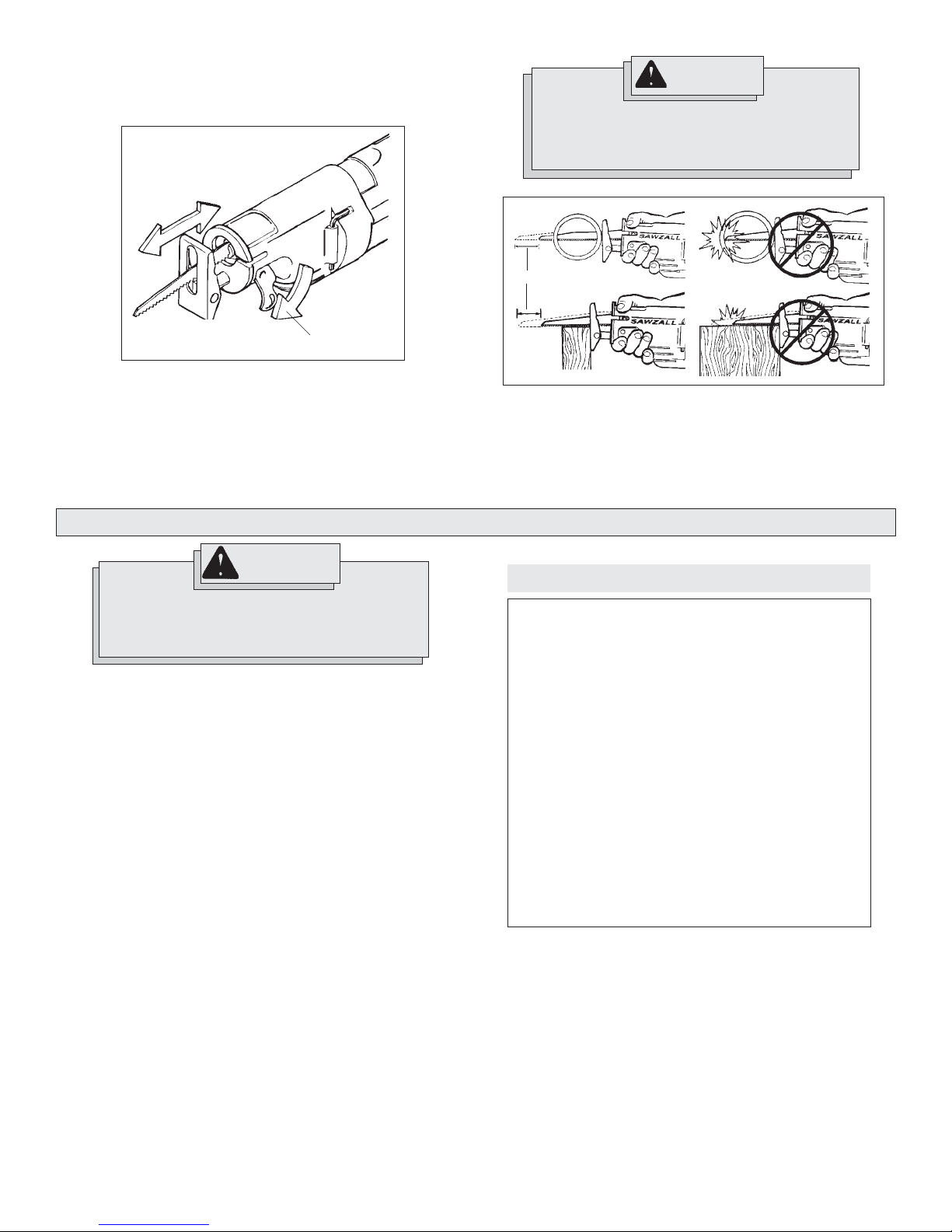

WARNING!

To reduce the risk of injury, be sure the blade

always extends beyond the shoe and work

throughout the stroke. (Fig. 5) Blades may shatter if they impact the work or shoe.

Fig. 5

Stroke

WARNING!

To reduce the risk of injury, wear safety goggles

or glasses with side shields. Unplug the tool

before changing accessories or making adjustments.

Impact Protection System

Select models are equipped with a unique patented gearing system that

provides efficient power transmission and extended life in the most

difficult cutting applications. This durable system will absorb impacts,

blade lock ups, and motor stalls. These models can be used for extreme

cutting applications such as large diameter pipe, thick metal, pallets, and

heavy demolition and renovation work as well as for general purpose

cutting.

Starting, Stopping and Controlling Speed

1. To start the tool, grasp the handle firmly and pull the trigger.

2. To stop the tool, release the trigger. Allow the tool to come to a

complete stop before removing the blade from a partial cut or laying

the tool down.

Selecting the Speed Range

The speed control dial controls the maximum strokes per minute. The

speed will remain variable to the chosen dial setting by use of the trigger

switch. Refer to the chart for recommended dial settings.

Material

Mild Steel

Wood

Nail-Embedded Wood

Stainless Steel

Drywall

Fiberglass

Plastics

Cast Iron

Non-Ferrous

Metals

* These are only suggested settings; the actual optimum

setting may vary depending on line voltage, blade selected

and user preference.

Trigger Speed Control Switch

Super Sawzalls

may be operated at any speed from zero strokes per minute to full

speed. Always start tool before blade contacts the workpiece. To vary

the speed, simply increase or decrease the pressure on the trigger. The

further the trigger is pulled, the greater the speed. To stop the tool,

release the trigger and allow the tool to stop completely before removing

from a partial cut or before laying the tool down.

®

are equipped with a trigger speed control switch. It

Suggested dial settings*

2-3

5

5

1-3

4-5

1-3

1-3

2-3

2-3

page 6

General Cutting

For straight or contour cutting from an edge, line the blade up with your

cutting line. Before the blade contacts the workpiece, grasp the handle

firmly and pull the trigger. Then guide the tool along your cutting line.

Always hold the shoe flat against the workpiece to avoid excessive

vibration.

Cutting Metals

Begin cutting at a slow speed, gradually increasing speed as you cut.

When cutting into metals or hard materials that can not be cut from an

edge, drill a starting hole larger than the widest part of the blade. Extend

blade life by using a solid blade cutting lubricant such as MILWAUKEE

Band Saw Blade Lubricant Catalog Number 49-08-4206.

Plunge Cutting (Fig. 6)

®

Your MILWAUKEE Sawzall

faces that can not be cut from an edge, such as walls or floors. Plunge

cutting may be done two ways depending on how the blade is inserted.

Column A shows how to plunge cut with the teeth of the blade facing

down. Column B shows how to plunge cut with the teeth of the blade

facing up. Do not plunge cut into metal surfaces (see Cutting Metals).

Fig. 6

is ideal for plunge cutting directly into sur-

MAINTENANCE

WARNING!

To reduce the risk of injury, always unplug

your tool before performing any maintenance.

Never disassemble the tool or try to do any

rewiring on the tool's electrical system. Contact

a MILWAUKEE service facility for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular maintenance program. Before use, examine the general condition of your tool. Inspect

guards, switches, tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving parts, improper mounting, broken parts and any other condition that may affect its safe operation. If abnormal noise or vibration occurs, turn the tool off immediately

and have the problem corrected before further use. Do not use a damaged tool. Tag damaged tools DO NOT USE until repaired

(see Repairs).

Under normal conditions, relubrication is not necessary until the motor

brushes need to be replaced. After six months to one year, depending on

use, return your tool to the nearest MILWAUKEE service facility for the

following:

Lubrication

Brush inspection and replacement

Mechanical inspection and cleaning (gears, spindles, bearings,

housing, etc.)

Electrical inspection (switch, cord, armature, etc.)

Testing to assure proper mechanical and electrical operation

WARNING!

To reduce the risk of explosion, electric shock

and property damage, always check the work

area for hidden gas pipes, electrical wires or

water pipes when making blind or plunge cuts.

1. Insert the blade into the tool.

If you inserted the blade with the teeth facing downward, hold the

tool as shown in Column A, resting the edge of the shoe on the

workpiece.

If you inserted the blade with the teeth facing upward, hold the tool

as shown in Column B, resting the edge of the shoe on the workpiece

as shown.

2. With the blade just above the workpiece, pull the trigger. Using the

edge of the shoe as a pivot, lower the blade into the workpiece as

shown.

3. As the blade starts cutting, raise the handle of the tool slowly until

the shoe rests firmly on the workpiece. Then guide the tool along

your cutting line to acquire the desired cut.

NOTE: To make plunge cutting easier, use a heavy gauge blade and

install the blade with the teeth facing upward as shown in Column B.

Cleaning

Clean dust and debris from vents. Keep the tool handles clean, dry and

free of oil or grease. Use only mild soap and a damp cloth to clean your

tool since certain cleaning agents and solvents are harmful to plastics

and other insulated parts. Some of these include: gasoline, turpentine,

lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia

and household detergents containing ammonia. Never use flammable or

combustible solvents around tools.

WARNING!

To reduce the risk of injury, electric shock and

damage to the tool, never immerse your tool in

liquid or allow a liquid to flow inside the tool.

Repairs

If your tool is damaged, return the entire tool to the nearest service

center listed on the back cover of this operators manual.

page 7

WARRANTY

Every MILWAUKEE product is warranted to be free from defects in

material and workmanship. MILWAUKEE will repair or replace any product

which examination proves to be defective in material or workmanship.

Limitations: This warranty does not cover: 1) repairs made or attempted by other than MILWAUKEE or MILWAUKEE Authorized Service

Station personnel; 2) normal wear and tear; 3) abuse; 4) misuse;

5) improper maintenance; 6) continued use after partial failure; 7) tools

that have been modified; or product used with an improper accessory.

Battery Packs are warranted for one (1) year from the date of purchase.

Should a problem develop, return the complete product to any

MILWAUKEE Factory Service Center or MILWAUKEE Authorized Service Station, freight prepaid and insured. If inspection shows the problem is caused by a defect in material or workmanship, all repairs or a

replacement will be made at no charge and the product will be returned,

transportation prepaid. No other warranty, written or verbal, is authorized.

THE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN ARE

EXCLUSIVE. IN NO EVENT SHALL MILWAUKEE BE LIABLE FOR ANY

INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED WHETHER FOR MERCHANTABILITY OR FITNESS FOR PARTICULAR

USE OR PURPOSE.

This warranty gives you specific legal rights. You may also have

other rights that vary from state to state. In those states that do not

allow the exclusion of implied warranties or limitations of incidental or consequential damages, the above limitations or exclusions

may not apply to you.

ACCESSORIES

WARNING!

To reduce the risk of injury, always unplug the

tool before attaching or removing accessories.

Use only specifically recommended accessories. Others may be hazardous.

For a complete listing of accessories refer to your MILWAUKEE Electric

Tool catalog. To obtain a catalog, contact your local distributor or a

service center listed on the back cover of this operators manual.

®

Quik-Lok

8' Quik-Lok

Cat. No. 48-76-4008

25' Quik-Lok

Cat. No. 48-76-4025

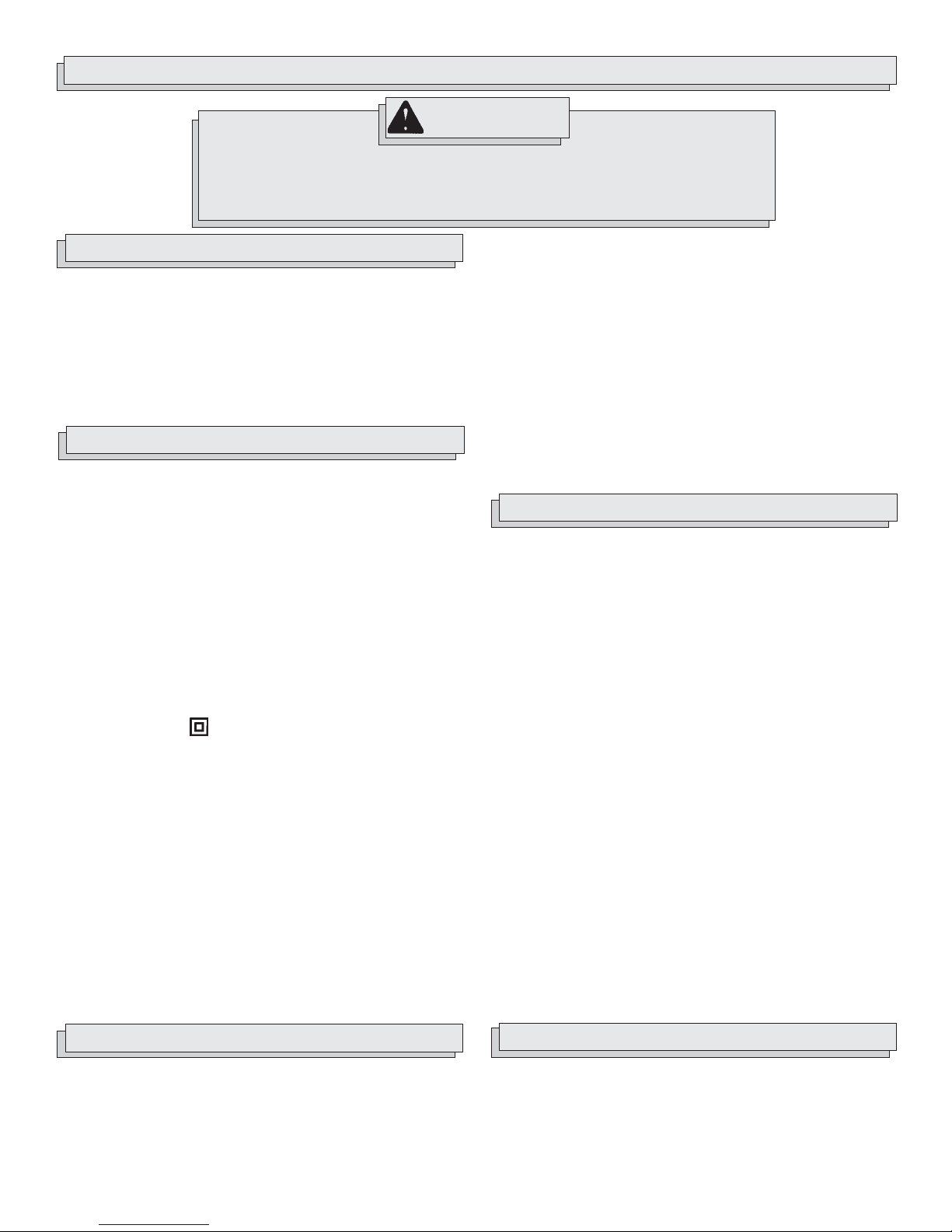

Offset Blade Adapter

Select Models (Fig. 7)

Cat. No. 48-03-2010

An offset blade adapter is available to make flush cuts possible. To

attach, remove blade clamping screw and blade clamp. Place adapter

over spindle, lining up hole in adapter casting with threaded hole in

spindle. Replace screw, attaching adapter to spindle. Blade can then

be secured in adapter blade clamp in the same manner it was secured in

the spindle clamp.

Cord Sets

®

Cord

®

Cord

Fig. 7

Select Models:

Blade Clamp

Cat. No. 42-68-0647

Blade Clamp Screw

Cat. No. 06-83-2960

787 Blades:

Blade Clamp

Cat. No. 42-68-0677

page 8

Blade Clamp Screw

Cat. No. 06-83-2960

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT!

VOUS DEVEZ LIRE ET COMPRENDRE TOUTES LES INSTRUCTIONS.

Le non-respect, même partiel, des instructions ci-après entraîne un risque de choc

électrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS.

AIRE DE TRAVAIL

1. Veillez à ce que laire de travail soit propre et bien éclairée.

Le désordre et le manque de lumière favorisent les accidents.

2. Nutilisez pas doutils électriques dans une atmosphère ex-

plosive, par exemple en présence de liquides, de gaz ou de

poussières inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les poussières ou les vapeurs.

3. Tenez à distance les curieux, les enfants et les visiteurs

pendant que vous travaillez avec un outil électrique. Ils

pourraient vous distraire et vous faire faire une fausse manoeuvre.

Installez des barrières ou des écrans protecteurs si nécessaire.

SÉCURITÉ ÉLECTRIQUE

4. Les outils mis à la terre doivent être branchés dans une

prise de courant correctement installée et mise à la terre

conformément à tous les codes et règlements pertinents.

Ne modifiez jamais la fiche de quelque façon que ce soit,

par exemple en enlevant la broche de mise à la terre.

Nutilisez pas dadaptateur de fiche. Si vous nêtes pas

certain que la prise de courant est correctement mise à la

terre, adressez-vous à un électricien qualifié. En cas de

défaillance ou de défectuosité électrique de loutil, une mise à la

terre offre un trajet de faible résistance à lélectricité qui autrement

risquerait de traverser lutilisateur.

5. Les outils à double isolation sont équipés dune fiche

polarisée (une des lames est plus large que lautre), qui ne

peut se brancher que dune seule façon dans une prise

polarisée. Si la fiche nentre pas parfaitement dans la prise,

inversez sa position ; si elle nentre toujours pas bien,

demandez à un électricien qualifié dinstaller une prise de

courant polarisée. Ne modifiez pas la fiche de loutil.

La double isolation élimine le besoin dun cordon dalimentation à

trois fils avec mise à la terre ainsi que dune prise de courant mise à

la terre.

6. Évitez tout contact corporel avec des surfaces mises à la

terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs,

etc.). Le risque de choc électrique est plus grand si votre corps est

en contact avec la terre.

7. Nexposez pas les outils électriques à la pluie ou à leau. La

présence deau dans un outil électrique augmente le risque de choc

électrique.

8. Ne maltraitez pas le cordon. Ne transportez pas loutil par

son cordon et ne débranchez pas la fiche en tirant sur le

cordon. Nexposez pas le cordon à la chaleur, à des huiles, à

des arêtes vives ou à des pièces en mouvement. Remplacez

immédiate-ment un cordon endommagé. Un cordon

endommagé augmente le risque de choc électrique.

9. Lorsque vous utilisez un outil électrique à lextérieur,

employez un prolongateur pour lextérieur marqué « W-A »

ou « W ». Ces cordons sont faits pour être utilisés à lextérieur et

réduisent le risque de choc électrique.

SÉCURITÉ DES PERSONNES

en mouvement. Des vêtements flottants, des bijoux ou des

cheveux longs risquent dêtre happés par des pièces en mouvement.

12. Méfiez-vous dun démarrage accidentel. Avant de brancher

loutil, assurez-vous que son interrupteur est sur ARRÊT. Le

fait de transporter un outil avec le doigt sur la détente ou de brancher

un outil dont linterrupteur est en position MARCHE peut mener tout

droit à un accident.

13. Enlevez les clés de réglage ou de serrage avant de démarrer

loutil. Une clé laissée dans une pièce tournante de loutil peut

provoquer des blessures.

14. Ne vous penchez pas trop en avant. Maintenez un bon appui

et restez en équilibre en tout temps. Un bonne stabilité vous

permet de mieux réagir à une situation inattendue.

15. Utilisez des accessoires de sécurité. Portez toujours des

lunettes ou une visière. Selon les conditions, portez aussi un

masque antipoussière, des bottes de sécurité antidérapantes, un

casque protecteur et/ou un appareil antibruit.

UTILISATION ET ENTRETIEN DES OUTILS

16. Immobilisez le matériau sur une surface stable au moyen

de brides ou de toute autre façon adéquate. Le fait de tenir la

pièce avec la main ou contre votre corps offre une stabilité

insuffisante et peut amener un dérapage de loutil.

17. Ne forcez pas loutil. Utilisez loutil approprié à la tâche. Loutil

correct fonctionne mieux et de façon plus sécuritaire. Respectez

aussi la vitesse de travail qui lui est propre.

18. Nutilisez pas un outil si son interrupteur est bloqué. Un outil

que vous ne pouvez pas commander par son interrupteur est

dangereux et doit être réparé.

19. Débranchez la fiche de loutil avant deffectuer un réglage,

de changer daccessoire ou de ranger loutil. De telles mesures

préventives de sécurité réduisent le risque de démarrage accidentel

de loutil.

20. Rangez les outils hors de la portée des enfants et dautres

personnes inexpérimentées. Les outils sont dangereux dans

les mains dutilisateurs novices.

21. Prenez soin de bien entretenir les outils. Les outils de coupe

doivent être toujours bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger. Nutilisez pas un

outil défectueux. Fixez-y une étiquette marquée « Hors dusage »

jusquà ce quil soit réparé.

22. Soyez attentif à tout désalignement ou coincement des

pièces en mouvement, à tout bris ou à toute autre condition

préjudiciable au bon fonctionnement de loutil. Si vous

constatez quun outil est endommagé, faites-le réparer

avant de vous en servir. De nombreux accidents sont causés par

des outils en mauvais état.

23. Nutilisez que des accessoires que le fabricant recommande

pour votre modèle doutil. Certains accessoires peuvent convenir

à un outil, mais être dangereux avec un autre.

RÉPARATION

10. Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. Nutilisez pas un outil électrique si

vous êtes fatigué ou sous linfluence de drogues, dalcool

ou de médicaments. Un instant dinattention suffit pour entraîner

des blessures graves.

11. Habillez-vous convenablement. Ne portez ni vêtements

flottants ni bijoux. Confinez les cheveux longs. Napprochez

jamais les cheveux, les vêtements ou les gants des pièces

24. La réparation des outils électriques doit être confiée à un

réparateur qualifié. Lentretien ou la réparation dun outil électrique

par un amateur peut avoir des conséquences graves.

25. Pour la réparation dun outil, nemployez que des pièces de

rechange dorigine. Suivez les directives données à la section « Réparation » de ce manuel. Lemploi de pièces non

autorisées ou le non-respect des instructions dentretien peut créer

un risque de choc électrique ou de blessures.

page 9

Loading...

Loading...