Milwaukee LMDVT-3328CNM User Manual

US

WARNINGS

• Hot! Do not touch! The glass and

surfaces of this appliance will be hot

during operation and will retain heat

for a while after shutting off the appliance. Severe burns may result.

• Carefully supervise children in the

same room as appliance.

• If small children are present in the home, it is

recommended that this appliance be fitted with

a screen door or screen panel kit. See

Pages

13 & 14 for ordering information.

WARNING: IF THE INFORMATION IN THIS MANUAL

IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any

other appliance.

CARE AND OPERATION

INSTRUCTIONS

DIRECT VENT MERIT™

LMDV-33/35/40 SERIES

DIRECT-VENT GAS FIREPLACE HEATERS

P/N 875,028M REV. E 02/2008

MODELS

Millivolt Models Electronic Models

LMDVT-3328CNM

LMDVT-3328CPM

LMDVR-3328CNM

LMDVR-3328CPM

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

AVERTISSEMENT: ASSUREZ-VOUS DE BIEN

SUIVRE LES INSTRUCTIONS DONNÉ DANS CETTE

NOTICE POUR RÉDUIRE AU MINIMUM LE RISQUE

D'INCENDIE OU POUR ÉVITER TOUT DOMMAGE

MATÉRIEL, TOUTE BLESSURE OU LA MORT.

LMDV-3530CNM

LMDV-3530CPM

LMDV-4035CNM

LMDV-4035CPM

LMDVT-3328CNE

LMDVR-3328CNE

LMDV-3530CNE

LMDV-4035CNE

WHAT TO DO IF YOU SMELL GAS:

• Do not light any appliance.

• Do not touch any electrical switch; do not

Use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow your gas supplier's

instructions.

• If your gas supplier cannot be reached, call

the fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

OTL Report No. 116-F-31-5

A French manual is available upon request. Order P/N 875,028CF

Ce manuel d’installation est disponible en francais, simplement en

faire la demande. Numéro de la pièce 875,028CF

POUR VOTRE SÉCURITÉ: Ne pas entreposer ni

utiliser d'essence ni d'autre vapeurs ou liquides

inflammables dans le voisinage de cet appareil ou

de tout autre appareil.

POUR VOTRE SÉCURITÉ: Que faire si vous sentez

une odeur de gaz:

• Ne pas tenter d'allumer d'appareil.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones se trouvant dans le batiment où vous vous trouvez.

• Evacuez la piéce, le bâtiment ou la zone.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le service dos incendies.

L'installation et service doit être exécuté par un

qualifié installeur, agence de service ou le fournisseur de gaz.

CONGRATULATIONS!

In selecting this LENNOX Direct-Vent Gas Appliance you have chosen the finest and most

dependable fireplace to be found anywhere. Its a beautiful, prestigious alternative to a

wood burning fireplace. Welcome to a Family of tens of thousands of satisfied LENNOX

Fireplace Owners.

Please carefully read and follow all of the instructions found in this manual. Please pay

special attention to the safety instructions provided in this manual. The Homeowner's

Care and Operation Instructions included here will assure that you have many years of

dependable and enjoyable service from your LENNOX product.

These appliances are designed to operate on natural

gas or propane gas only. The use of other fuels or

combination of fuels will degrade the performance

of this system and may be dangerous.

Millivolt Models - BTU Input

Millivolt models come standard with the manu

ally-modulated gas valve; flame appearance and

heat output can be controlled at the gas valve.

The BTU Input for millivolt models is shown in

Tables 1 & 2:

-

TABLE OF CONTENTS

Introduction ......................................Page 2

General Information ..........................

Gas Controls Access .........................

Operation/Care of Your Appliance .....

Variable Flame Adjustment ................

Maintenance ......................................Page 5

Front Glass Enclosure Panel,

Removal and Installation .................

Install Vermiculite, Volcanic Stone,

Embers & Logs .................................

Burner Flame Appearance & Sooting

Burner Flame Adjustments ................

Millivolt Appliance Checkout .............

Electronic Appliance Checkout ..........

Product Reference Information .........

Warranty ...........................................Page 11

Wiring Diagrams ...............................

Accessory Components ....................

Lighting Instructions – Millivolt ........

Lighting Instructions – Electronic .....

Maintenance Schedule ......................

Troubleshooting Guide – Millivolt

Troubleshooting Guide – Electronic ..

Replacement Parts List .....................

This manual is part of a set of two supporting

this product. Refer to manual 850,029M for

Installation Instructions.

INTRODUCTION

The Fireplace models covered in this manual

are Direct-Vent sealed combustion gas fireplace

heaters designed for residential application.

Direct-Vent appliances operate with the combustion chamber completely isolated from the

indoor environment. All air for combustion is

brought in from the outside and exhaust gases

are vented through the same direct vent, co-axial

(intake/exhaust) vent system.

The Millivolt appliances have a millivolt gas

control valve with piezo ignition system provides

safe, efficient operation. If any optional accessories which require electrical power are being

installed, the electrical power must be provided

at the time of appliance installation.

2

......Page 23

Page 2

Page 3

Page 3

Page 4

Page 6

Page 7

Page 10

Page 10

Page 11

Page 11

Page 11

Page 12

Page 13

Page 18

Page 20

Page 22

Page 23

Page 26

The Electronic appliances have an electronic

intermittent pilot system provides safe, efficient

operation. External electrical power is required

to operate these appliances.

These appliances comply with National Safety

Standards and are tested and listed by OmniTest Laboratories (Report No. 116-F-31-5) to

ANSI ZZ21.88b (in Canada, CSA-2.33b), and

CAN/CGA-2.17-M91 in both USA and Canada,

as vented gas fireplace heaters.

The Installation must conform to local codes

or, in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1/NFPA

54-latest edition, or the Natural Gas and

Propane Installation Code, CSA B149.1-latest

edition. The appliance, when installed, must

be electrically grounded in accordance with

local codes or, in the absence of local codes,

the latest edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22.1 - latest editions.

GENERAL INFORMATION

Note: Installation and repair should be performed by a qualified service person. The

appliance should be inspected annually by a

qualified professional service technician. More

frequent inspections and cleanings may be

required due to excessive lint from carpeting,

bedding material, etc.

It is imperative that the control compartment,

burners and circulating air passage ways of

appliance be kept clean. See Maintenance

instructions on Page 5.

S'assurer que le brùleur et le compartiment des

commandes sont propres. Voir les instructions

d'installation et d'utilisation qui accompagnent

l'appareil.

Provide adequate clearances around air open

ings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front openings of the appliance.

Due to high temperatures the appliance should

be located out of traffic and away from furniture

and draperies. Locate furniture and window

coverings accordingly.

These fireplaces are designed as supplemental

heaters. Therefore, it is advisable to have an alter

nate heat source when installed in a dwelling.

Input (BTU) MAnnually-Modulated Gas

Valves (millivolt models)

NATURAL GAS

Models Input Rate

(BTU/HR)

LMDVT-3328CNM

LMDVR-3328CNM

LMDV-3530CNM

LMDV-4035CNM

17,500 high

11,700 low

20,000 high

12,800 low

27,000 high

18,500 low

Table 1

Input (BTU) MAnnually-Modulated Gas

Valves (millivolt models)

PROPANE GAS

Models Input Rate

(BTU/HR)

LMDVT-3328CPM

LMDVR-3328CPM

LMDV-3530CPM

LMDV-4035CPM

17,500 high

14,000 low

20,000 high

15,200 low

27,000 high

21,500 low

Table 2

Electronic Models -

Electronic models have a fixed rate gas valve.

The BTU Input for electronic models is shown

Table 3:

in

Input (BTU) - Fixed Rate

(electronic models)

-

-

NATURAL GAS & PROPANE GAS

Models Input Rate

LMDVT-3328CNE

LMDVR-3328CNE

LMDV-3530CNE

LMDV-4035CNM

LMDV-4035CPM

Table 3

(BTU/HR)

17,500

20,000

28,000

Gas Pressure -

Tables 4, 5 and 6 show the appliances' gas

pressure requirements.

Inlet Gas Supply Pressure

(all models)

Fuel # Minimum Maximum

Natural Gas

Propane

5.0" WC

(1.24 kPa)

11.0" WC

(2.74 kPa)

10.5" WC

(2.61 kPa)

13.0" WC

(3.23 kPa)

Table 4

Manifold Gas Supply Pressure

(millivolt models)

Fuel # Low High

Natural

Gas

Propane

(Lo) 2.2" WC

(.55 kPa)

(Lo) 6.3" WC

(1.57 kPa)

(Hi) 3.5" WC

(.87 kPa)

(Hi) 10.0" WC

(2.49 kPa)

Table 5

Manifold Gas Supply Pressure

(electronic models)

Fuel # Fixed

Natural Gas

Propane

3.5" WC

(.87 kPa)

10.0" WC

(2.49 kPa)

Table 6

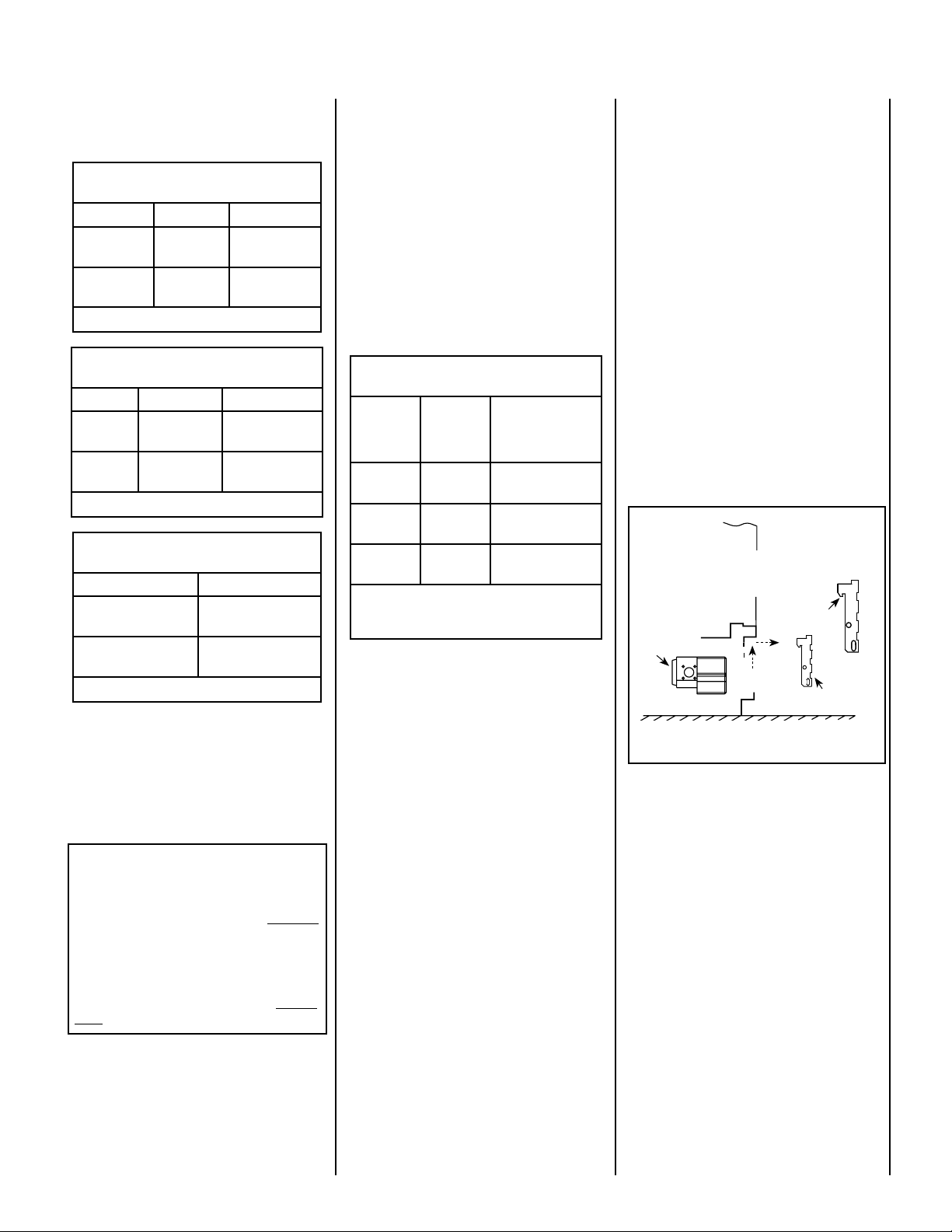

Test gauge connections are provided on the

front of the millivolt gas control valve, identified

IN for the inlet and OUT for the manifold side

(see

Figures 4 or 5 on Page 4). A 1/8" NPT

Test gauge connection is provided at the inlet

and outlet (manifold) ports on the electronic gas

control valve (see

Figure 3 on Page 4).

These appliances must be isolated from the

gas supply piping system (

by closing their

individual manual shut-off valve) during any

pressure testing of the gas supply piping

system at test pressures equal to or

less than

1/2 psig (3.5 kPa).

These appliances and their individual shut-off

must be disconnected from the gas

valves

supply piping system during any pressure

testing of that system at pressures

greater

than 1/2 psig (3.5 kPa).

Orifice Sizes - Sea Level to High Altitude

(All Models): These appliances are tested and

approved for installations at elevations of 0-4500

feet (0-1372 meters) above sea level using the

standard burner orifice sizes (marked with an

"*" in

Table 7).

At the time of installation, it must be determined

if the appliance needs to be derated. Contact

your local gas supplier for deration requirements

for your area.

Deration - At higher elevations, the amount of

BTU fuel value delivered must be reduced by

either using gas that has been derated by the gas

company or by changing the burner orifice to a

smaller size as regulated by the local authorities

having jurisdiction and by the (USA) National

Fuel Gas Code NFPA 54/ANSI Z223.1 - latest

edition or, in Canada, the CAN1-B149.1 and .2

codes - latest edition.

Burner Orifice Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model

Series

LMDVT-3328

LMDVR-3328

LMDV-3530

LMDV-4035

* Standard size installed at factory

• Part /Cat. Number

Natural

Gas

drill size

(inches)

#45 (.082")

39L66 •

#44 (.086")

60J80 •

#37 (.104")

24M10 •

*

*

*

Propane

Gas

drill size (inches)

1.2 mm (.048")

99K78 •

#55 (.052")

19L52 •

1/16" (.0625")

21L01 •

*

*

*

Table 7

Burn-in Period

During the first few fires of this appliance there

will be some odor due to the curing of the

paint and burning off of lubricants used in the

manufacturing process.

Depending on your use, the burn-in period may

take a few hours or a few days.

KEEP YOUR HOUSE WELL VENTILATED

DURING THE CURING PROCESS. THE ODOR

AND HAZE EMITTED DURING THE CURING

PROCESS CAN BE QUITE NOTICEABLE AND

MAY SET OFF A SMOKE DETECTOR.

If an optional blower is installed, Do not turn it

on during the Burn-In period.

A white film may develop on the glass front

during the first few fires as part of the curing

process. The glass should be kept clean during

the first two weeks of use to prevent the film from

baking on (making it very difficult to remove).

See

Cleaning Glass on Page 5.

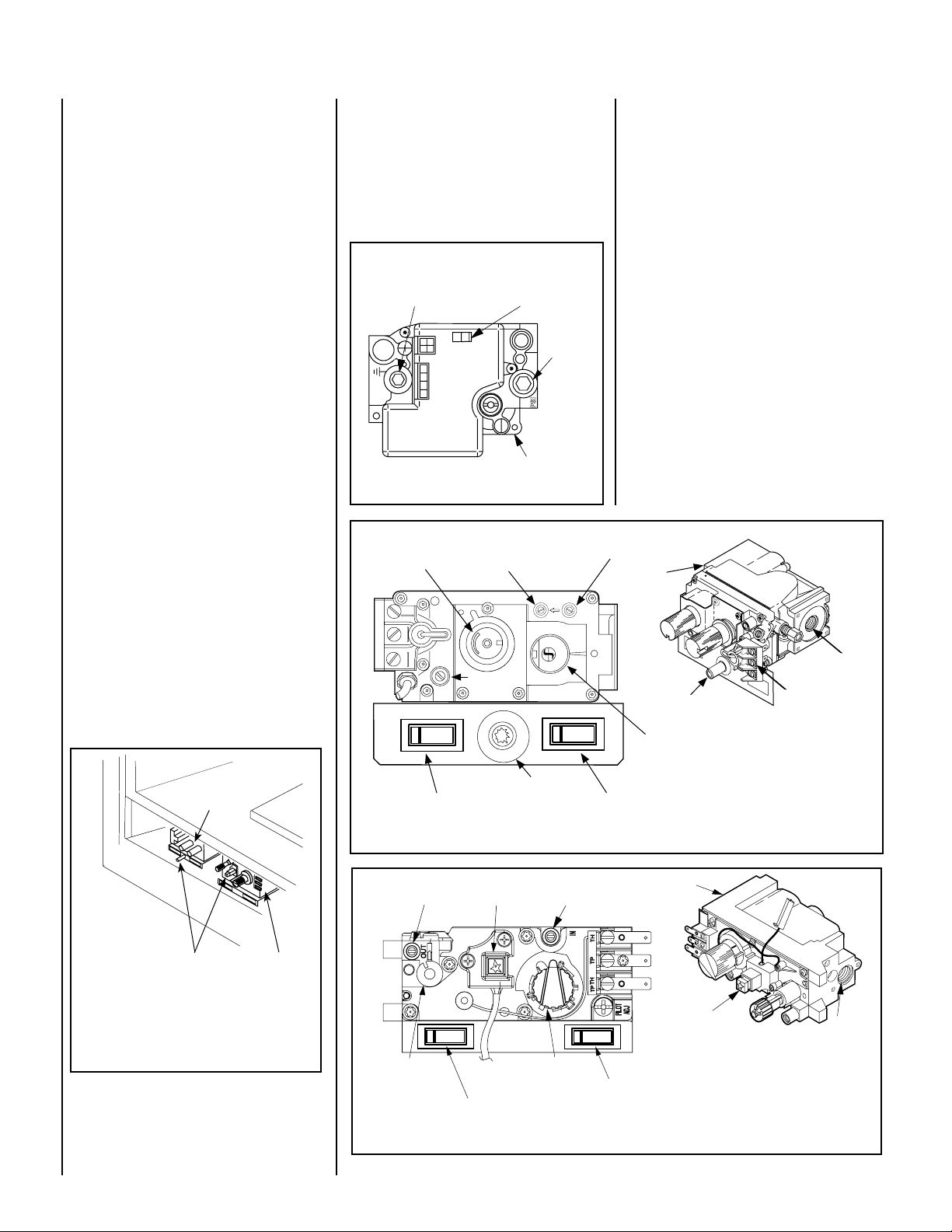

Gas Controls/Control Compartment

Access

The gas controls can be found behind the control

compartment access door.

Removing Control Compartment Door:

Open the door by gently liftint it upward until the

hook catches on boths sides clear the locating

slots. Then pull door out to remove.

On millivolt systems, the piezo igniter, HI/LO

flame adjustment knob, and pilot and main

gas OFF/ON control knob are located below

the glass panel enclosure. The gas valve for

electronic systems is also located below the

glass enclosure panel. See

Figure 1.

Reinstalling Control Compartment Door:

To reinstall, insert the hook catches on each side

of the door into the corresponding slots in the

control compartment opening, then gently push

forward and slide down until it locks in place.

Lift the Lower Control

OPENING CONTROL

COMPARTMENT DOOR

Control Valve

Compartment Door

up and pull out to

remove.

Hook Catch

Out

Up

Lower Control

Compartment Door

Figure 1

OPERATION AND CARE OF YOUR

APPLIANCE

The standard controls for appliance operation are located behind the panel below the

appliance front glass enclosure panel (see

Figure 1). Optional control switches are also

available (see

Remote Control or Wall Thermostat).

Operation of millivolt and electronic gas con

trol systems are different. Before lighting and

operating your appliance determine if you have

a millivolt or electronic appliance. Familiarize

yourself with the gas control valve that your

appliance uses. Refer to

to the gas control valve.

Page 13 - Remote Wall Switch,

Figure 1 for access

-

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

3

Millivolt Appliances - Appliances with

O

N

O

F

F

P

I

L

O

T

L

O

H

I

OFF

ON

OFF

ON

H

I

L

O

W

H

T

P

T

H

T

P

T

P

I

L

O

T

P

I

L

O

T

O

N

ti

O

F

F

IN

OUT

OFF

ON

OFF

ON

F

F

O

N

I

P

S

I

NO

L

O

R

T

N

O

C

G

I

N

T

I

ER

Millivolt systems will be fitted with the gas

control valve shown in Figures 4 or 5.

Electronic Appliances - Appliances with

electronic systems will be fitted with the

electronic valve shown in

Figure 3.

Millivolt Appliances - To light millivolt appliances refer to the detailed lighting instructions

found on Pages 18 & 19 . Millivolt appliance

lighting instructions may also be found on the

pull out lighting instruction labels attached to

the gas control valve.

Millivolt appliances are fitted with an OFF/ON

Rocker Switch located behind the control

compartment access door, below the appliance front glass enclosure panel (see Figure 2

for location). Once the pilot is lit, the OFF/ON

rocker switch will control the appliance OFF/ON

burner operation. To operate: Toggle the switch

between its ON and OFF positions.

If your millivolt appliance is equipped with an

optional remote switch kit (wall switch, remote

control or wall thermostat) and the pilot is lit,

the appliance main burner may be turned on

and off using the optional switch. When using

an optional remote switch, turn off the standard

OFF/ON switch.

Electronic Appliances -

To light electronic appliances refer to the detailed

lighting instructions found on

Pages 20 & 21

of these instructions. Electronic appliance

lighting instructions may also be found on the

pull out lighting instruction labels attached to

the gas control valve.

Honeywell Electronic Gas Valve

Manifold Pressure

Port

Figure 3

HI/LO Variable

Flame Height

Adjustment

ON/OFF Switch

Inlet

Pressure

Port

Electronic Gas

Control Valve

Manifold Pressure Tap

Inlet Pressure Tap

If your electronic appliance is equipped with an

optional remote wall switch or remote control kit

the appliance main burner may be turned on and

off with the wall switch or remote control.

If your electronic appliance is not equipped

with a wall switch or remote control, the main

burner must be turned off and on with the gas

control switch. Toggle the switch from ON to

OFF to operate the main burner .

Variable Flame Height Adjustment

(Millivolt Appliances only)

1. All Millivolt appliances are equipped with a

variable gas control valve. Flame height for

these models may be adjusted through a

range between fixed low and high settings

while the appliance is in operation. Adjust

the flame height as desired after lighting the

appliance by rotating the variable adjustment

control knob (HI/LO) located on the front of

the valve (refer to

2. During the first initial burns of these appli-

ances, there will be some odor emitted (see

Burn-In Period on Page 3 ).

Gas

Inlet

Figures 4 & 5 ).

Note: To prevent excessive resistance in burner

circuit (which can cause burner operation prob

lems), only one burner control switch should be

wired to valve. Therefore, if an optional control

switch is installed, the standard Off/On switch

and wires should be removed.

SIT Gas Valve

Shown with control

compartment door

removed

Piezo Igniter

Sit and Honeywell Millivolt Gas Valve

Showing Piezo Igniter Location (Each Unit is

Equipped with Only One of these Gas Valves)

Figure 2

4

Honeywell

Gas Valve

-

Pilot Adjustment

Screw

Piezo Igniter

Terminals

TPTH,TP & TH

Gas

Outlet

Main Gas

Control Knob

OFF/PILOT/ON

Piezo Igniter

Optional Burner OFF/ON

Rocker Switch

Figure 4

Optional Blower OFF/ON

Rocker Switch

SIT Millivolt Gas Valve

Gas

Manifold Pressure

Piezo Igniter

Inlet Pressure Tap

Outlet

Tap

Piezo Igniter

Gas

Inlet

HI/LO Variable

Flame Height

Adjustment

Optional Burner OFF/ON

Main Gas

Control Knob

OFF/PILOT/ON

Optional Blower OFF/ON

Rocker Switch

Rocker Switch

Figure 5

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Honeywell Millivolt Gas Valve

3. Keep the lower control compartment clean

by vacuuming or brushing at least twice a

year. More frequent cleaning may be required

due to excessive lint from carpeting, bedding

materials, pet hair, etc. It is very important

that the control compartments, burners

and circulating air passageways of the

appliance are kept clean.

4. Always turn off gas to the pilot (millivolt

appliances) and let the appliance cool down

before cleaning. Before re-lighting, refer

to the lighting instructions in this manual.

Lighting instructions may also be found

on the pull out lighting instruction labels

attached to the gas control valve.

5. Always keep the appliance area clear and

free from combustible materials, gasoline

and other flammable liquids.

6. Remember, Millivolt appliances have a continu-

ous burning pilot flame. Exercise caution when

using products with combustible vapors.

MAINTENANCE

(See Maintenance Schedule,

Refer to the maintenance schedule for maintenance

tasks, procedures, periodicity and by whom they

should be performed. Always verify proper opera

tion of the appliance after servicing.

WARNING

Page 22)

Turn off gas and electrical power

before servicing the appliance.

CAUTION

Wear gloves and safety Glasses

for protection while doing

required maintenance.

IMPORTANT

Always verify proper operation

after servicing.

Before re-lighting the fireplace, refer to the

lighting instructions in this manual. Instruc

tions are also found on pull-out panels

located below the glass door in the control

compartment.

Inspect Venting System

The appliance and venting system should be

thoroughly inspected before initial use and

at least annually by a qualified service techni

cian (inspection should include ensuring that

exhaust or intake passages are unobstructed

and vent components are properly assembled

and not damaged).

If the venting system is disassembled for any

reason, a qualified service technician should

follow vent installation instructions for proper

reassembly and proper sealing of the venting

system components. However, more frequent

periodic inspections and cleanings should be

performed by the homeowner.

Clean Lower Control Compartment

Keep lower control compartment clean by

vacuuming or brushing it out at least twice a

year (also clean the air venturi with a brush or

wire). More frequent cleaning may be required

due to accumulation of lint from carpeting,

bedding materials, pet hair, spider webs, etc. It

is very important that control compartments,

burners, circulating air passageways and air

venturi on the appliance are NOT obstructed

in any way.

Cleaning Glass

(see Front Glass Enclosure Panel, Removal and

Installation on Page 6 )

Note: Clean glass after first two weeks of operation (after Burn-In period is over) and then only

when necessary and when the fireplace is cool.

Wipe surface with clean, dampened, soft cloth.

Follow with dry, soft towel as desired. Take care

not to scratch the glass surface.

The viewing glass should be cleaned periodi

cally to remove any build-up caused from the

following:

IMPORTANT

Do not use abrasive cleaners

on glass. Never clean the glass

when it is hot.

• During start-up, it is normal for condensation to form on the inside of the glass (this

condensation and fog will usually disappear

in a few minutes). The moisture can cause

lint, dust and other airborne particles to cling

to the glass surface.

• Initial curing of the high temperature paint

and burning off of lubricants used in the

manufacturing process may result in a film

on the glass.

• A white coating may form on the glass as a

result of impurities and minerals in the fuel.

-

It is recommended that the glass be cleaned

two or three times during each heating season,

depending on the circumstances present. The

following cleaning solutions are approved for use

to clean glass:

• Non-ammonia based household cleaner

• 50%-50% mix of white vinegar & water

• Gas fireplace/stove glass cleaner

Inspect Glass Gasket - Visually inspect the

gasket on the backside of the glass enclosure

panels. The gasket surface must be clean, free

of irregularities and seated firmly.

Clean Logs And Burner

Carefully remove the logs (use care when han

dling the fiber logs, as they become quite fragile

after curing). Vacuum out any foreign matter

(lint, carbon, etc). on the burner. Ensure the

burner ports are “open.” Remove any carbon

deposits from the under side of the logs using

a vacuum cleaner, or a soft bristled brush (i.e.

paint brush). Note: Improper positioning of

logs can create carbon build-up and will alter

the performance of the appliance.Replacing

Logs -

If the logs become damaged by accident or im

proper handling and need replacement, use only

the proper replacement logs from manufacturer

(see

Pages 26 & 27 for ordering information).

Re-Install Embers, Logs and Vermiculite

- Carefully follow placement instructions on

Pages 7 to 9 ). All logs should fit onto corresponding pins and/or log stoppers. This will

ensure a proper flame and safe combustion.

Inspect Wiring

Refer to wiring diagrams on

WARNING

Page 12.

Label all wires prior to discon-

-

nection when servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper operation

after servicing.

Inspect and clean all wire connections. Ensure

that there is no melting or damage. Inspection

should include

• Terminals at the Valve

• OFF/ON Switch

• (Optional Control Switch) Wall Thermostat,

Remote Control or Remote Wall Switch Kit

Inspect Burner Flame Appearance

Ensure that the burner flame appearance

resembles the flame shown in

11 and as described in Flame Appearance and

Sooting on Page 10. The Homeowner must

contact a qualified service technician at once

if any abnormal condition is observed.

Small Area Paint Touch-up

The finish of the appliance is a high-qual

ity powdercoat. Only use factory supplied

powdercoat paint kit for touch-ups. Paint is

available at your local authorized Lennox Hearth

Products dealer, cat. no. 90L74. Never attempt

to paint a hot fireplace.

Do not attempt to repaint the appliance until the

finish is completely cured (see

on

Page 3 ). If the surface later becomes stained

or marred, it may be lightly sanded and touched

up with spray paint.

:

Figures 10 &

Burn-In Period

-

-

-

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

5

Front Glass Enclosure Panel, Removal

and Installation

WARNING

Do not operate appliance with the

glass front removed, cracked or

broken. Replacement of the glass

should be done by a licensed or

qualified service technician.

WARNING

Do not attempt to substitute the

materials used on this door, or

replace cracked or broken glass

with any materials other than

those provided by the appliance

manufacturer.

WARNING

These are direct-vent appliances. They are

designed to operate only when the front glass

enclosure panel is installed. Generally the front

glass enclosure panel should not be removed

except to gain access to the components within

the firebox, and the appliance may only be op

erated without the front glass enclosure panel

in place for very brief periods of time during

appliance checkout and adjustment. Note: The

flame appearance will be diminished while the

front glass enclosure panel is removed.

During this appliance checkout and adjust

ment period, a potential safety hazard exists

- EXERCISE EXTREME CAUTION to prevent

the occurrence of any burn injuries from the

exposed flames or hot surfaces. Also note, that

while the front glass enclosure panel (or any of

the panels) is removed, the flame appearance

will appear to be smaller than normal.

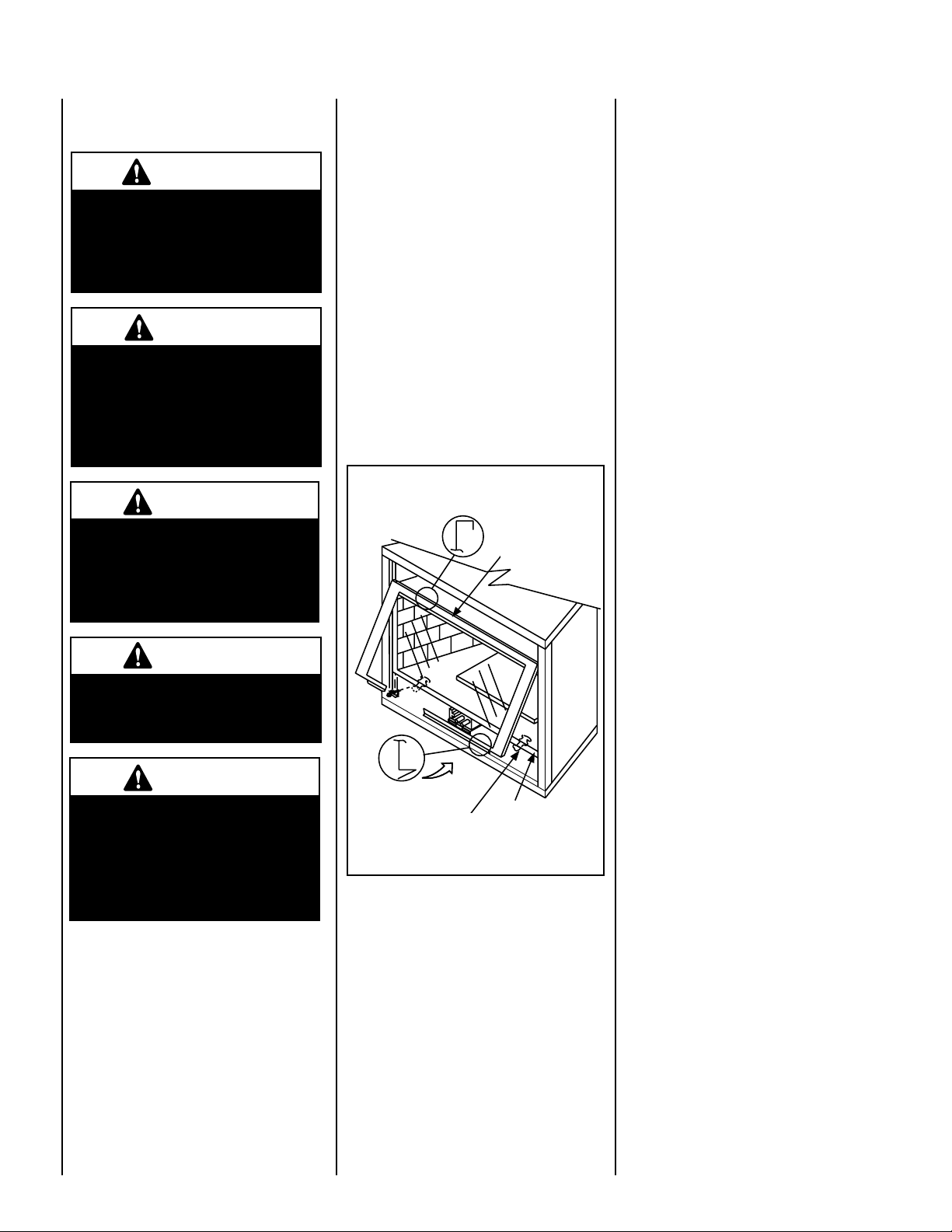

Top Flange on

Glass Door

Removing Glass Enclosure Panels

(see Figure 6)

1. Remove the top louver assembly by pulling

it up and out.

-

2. Remove the control compartment access

door (see removal instructions on

- Removing Control Compartment Door).

3. Locate the two (2) latches at the top of the

control compartment. To disengage the two

-

latches from the bottom vee-flange of the

glass enclosure panel, reach for the handles

located towards the back of the latches and

pull the handles down toward the front of

the appliance.

4. Swing the bottom of the door out and raise

it slightly to lift the top flange of the door

frame away from the appliance.

Installing Glass Enclosure Panels

(see Figure 6)

Page 3

Handle this glass with extreme

care! Tempered glass is susceptible to damage – do not scratch

or handle roughly while reinstalling the glass door frame.

WARNING

Do not attempt to touch the front

enclosure glass with your hands

while the fireplace is in use.

WARNING

The glass door of this appliance must only be replaced as a

complete unit as provided by the

manufacturer. Do not attempt to

replace broken, cracked or chipped

glass separately.

Glass Door

Bottom Vee-flange

Glass Door

Glass Door Latch

Firebox Floor

Figure 6 - INSTALLING GLASS DOOR

1. Visually inspect the gasket on the backside

of the glass panel. The gasket surface must

be clean, free of irregularities and seated

firmly.

2. Position the glass enclosure panel in front of

the firebox opening at a 45 degree angle and

engage the top flange over the lip at the top

of the firebox opening.

3. Swing the glass enclosure panel down and

back. Ensure the gasket seats evenly as the

panel draws shut. Engage the Vee-flange at

the bottom of the panel with the latches and

close the latches to secure the panel.

4. Reinstall the control compartment door

see installation instructions on

Reinstalling Control Compartment Door).

See Figure 6.

Page 3,

6

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

INSTALL VERMICULITE, VOLCANIC

STONE, GLOWING EMBERS AND LOGS

1. Remove the front glass enclosure panel

(see

Removing Glass Enclosure Panels on

this page).

2.

Carefully remove the old logs, embers

volcanic stone and vermiculite from the

firebox. Handle logs carefully to prevent

breakage.

3.

Install Vermiculite - Place some vermiculite

on the firebox floor around the burner (the

entire bag of vermiculite will NOT be used).

See

Figures 8 & 9. DO NOT PLACE ANY

VERMICULITE ON THE BURNER. Mound

up a portion of the vermiculite in front of the

burner.

4. Install decorative volcanic stone - Sprinkle

the decorative volcanic stone (dark colored)

on top of the vermiculite (light colored) in a

pleasing pattern (see

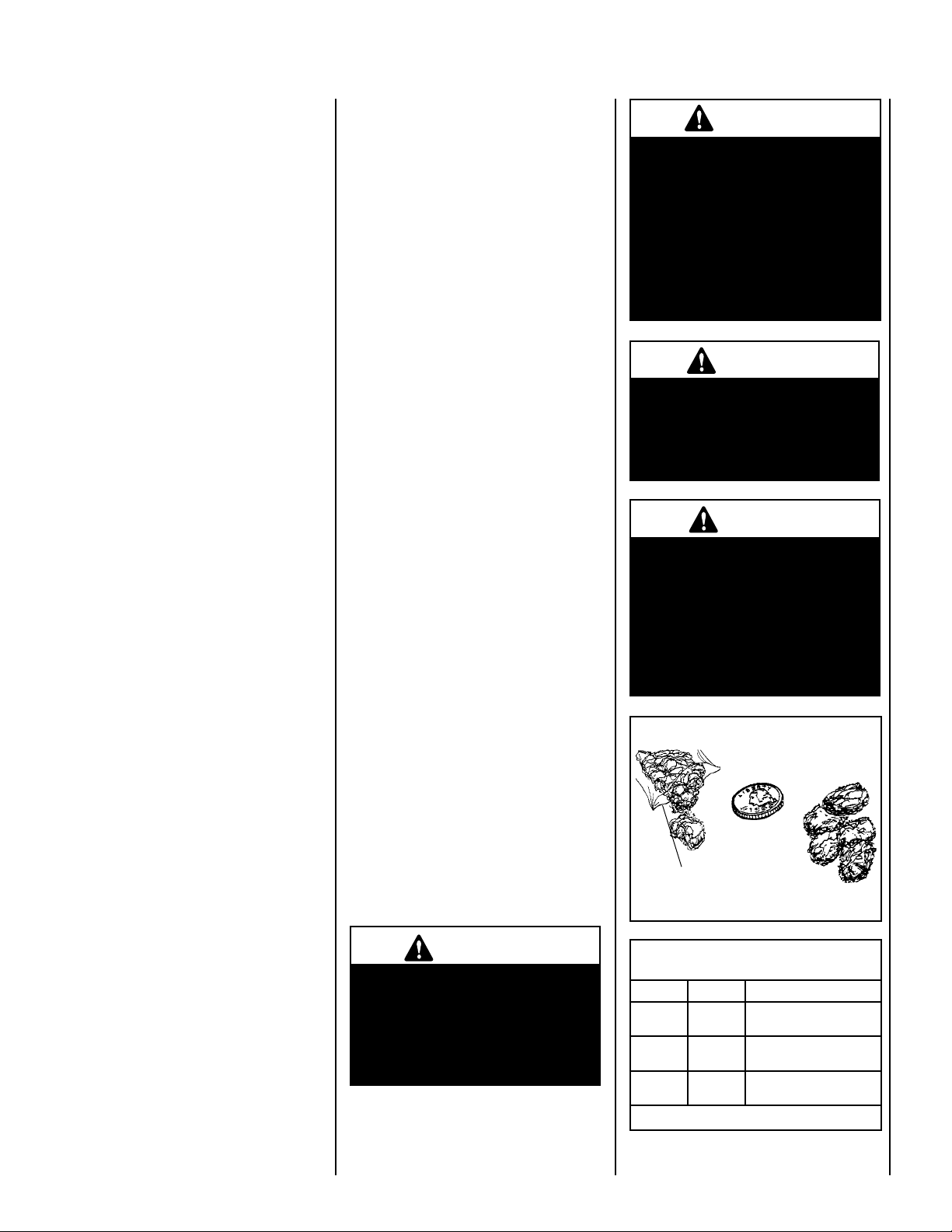

5. Placement of Glowing Embers -

Separate the Embers (rockwool) into pieces

about the size of a quarter (see

Keep the pieces fluffed up, not matted.

Distribute these pieces over the surface of

the burner, as shown in

not use more than is necessary. Ensure that

the main burner slots remain uncovered by

the ember material.

Note: This appliance is provided with enough

Glowing Embers for several applications, do

not use all that is in a new bag at one time. For

best glowing effect, replace the ember material

annually.

6. Placement of Logs and Twigs -

All logs that have locating notches or slots to

help ensure that they are properly positioned.

All top logs that rest on lower logs, do so

over notches, indents or pins. Proper twig

placement is critical to prevent sooting. Twigs

should be placed in the gaps between the flame

peaks and should be positioned so they do not

impinge the flames.

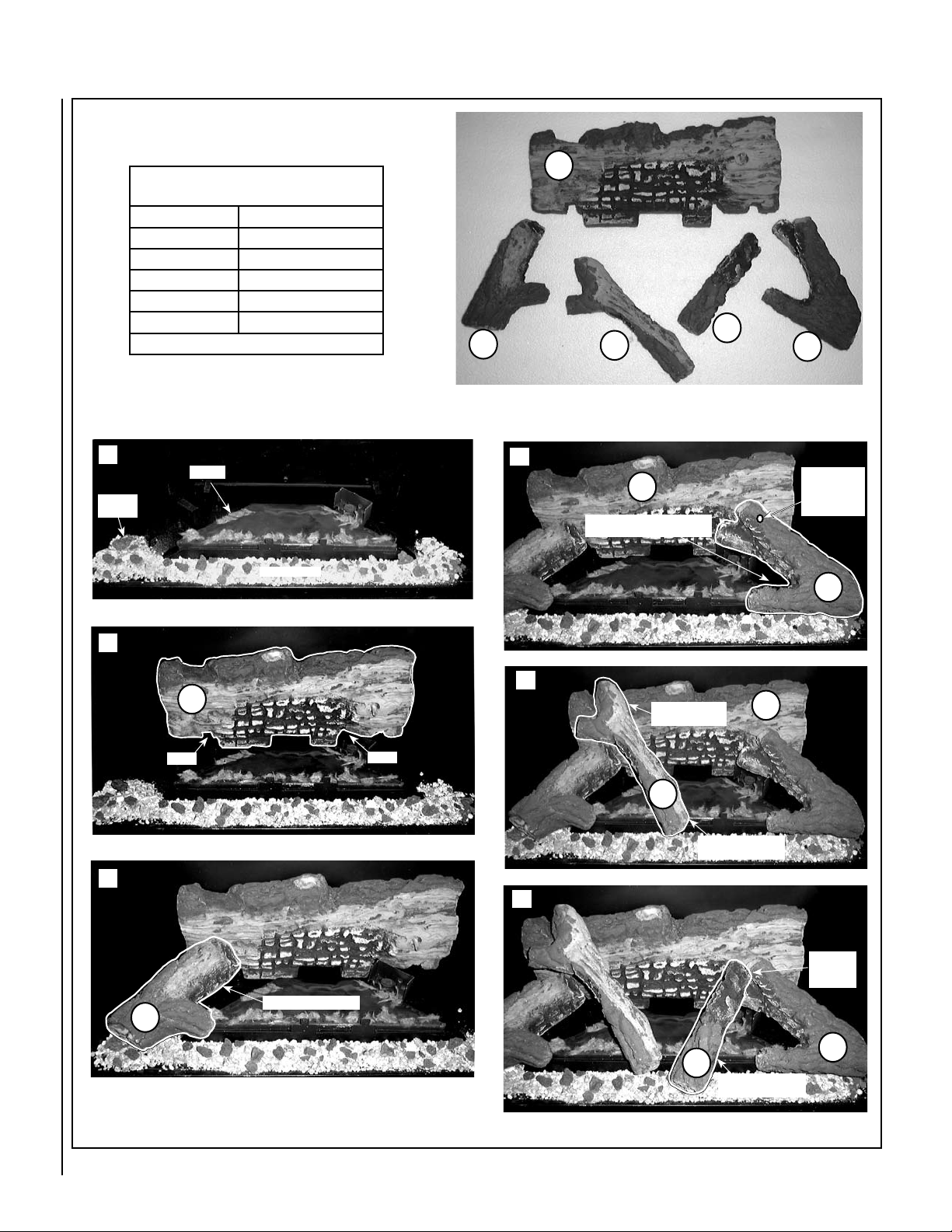

LMDV-3328 & LMDV-3530 - Install as Follows

Figures 8 & 9).

Figure 7).

Figures 8 & 9. Do

1. Place the rear log (A) as shown. Position the

2 notches on the bottom of the log over the

2 corresponding locating brackets against

the back wall of firebox.

2. Place the left log (B) as shown. The notch

on the bottom of the log should fit over the

corresponding locating bracket.

3. Place the right log (E) as shown. The hole

on the back of the log should fit over the

corresponding pin on the rear log (A). Make

sure that the log is positioned so it aligns

to the sides of the gas ports on the corner

of the burner.

4. Place the left center log (C) as shown.

The forked end of the log fits into the cor

responding notch on rear log (A). The slot

on the other end (bottom) of log fits over

the corresponding locating bracket on the

sub-floor.

5. Place the right center log (D) as shown. One

end of the log fits into the corresponding

indent on the right log (E). The slot on

the other end (bottom) of log fits over the

corresponding locating bracket on the subfloor.

LMDV-4035 - Install as Follows

Carefully position the ceramic fiber logs and twigs

over the burner as shown in

should be placed in the order shown and per the

following instructions.

1. Position the center log (C) onto the 2 cor

responding location pins on the burner.

2. Place the rear log (A) as shown. Position the

2 notches on the bottom of the log over the

2 corresponding locating brackets against

the back wall of firebox.

3. Place the left log (B) as shown. The notch

on the bottom of the log should fit over the

corresponding locating bracket.

4. Place the right log (E) as shown. The notch

on the bottom of the log should fit over the

corresponding locating bracket. Make sure

that the log is positioned so it aligns to the

sides of the gas ports on the corner of the

burner.

5. Place the center front log (D) as shown.

The slot in the bottom of the log fits over

the corresponding location bracket on the

sub-floor.

Figure 9. Logs

WARNING

The size and position of the log

set was engineered to give the

appliance a safe, reliable and

attractive flame pattern. Any

attempt to use a different log

set in the fireplace will void

the warranty and will result in

incomplete combustion, sooting, and poor flame quality.

-

WARNING

This appliance is not designed

to burn wood. Any attempt to

do so could cause irreparable

damage to appliance and prove

hazardous to your safety.

WARNING

If logs are not installed according

to the log installation instructions, flame impingement and

improper combustion could

-

occur and result in soot and/or

excessive production of carbon

monoxide (CO), a colorless,

odorless, toxic gas.

Glowing Embers

Separate into Quarter

Size (separate) Pieces

Bag of Glowing

Embers (rockwool)

Figure 7

Carefully position the ceramic fiber logs and twigs

over the burner as shown in

should be placed in the order shown and per the

following instructions.

Figure 8. Logs

WARNING

DO NOT attempt to install the logs

until the appliance installation

has been completed, the gas line

connected and tested for leaks

and the initial burner operation

has been checked out.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

REFERENCE

Firebox Accessories/Parts

Cat. No. Model No. Description

88L53 FGE Bag of Glowing Embers

H3696

80L42 FDVS

(1 oz. rockwool)

Vermiculite, Bag (2 liters)

Bag of Decorative

Volcanic Stone

Table 8

7

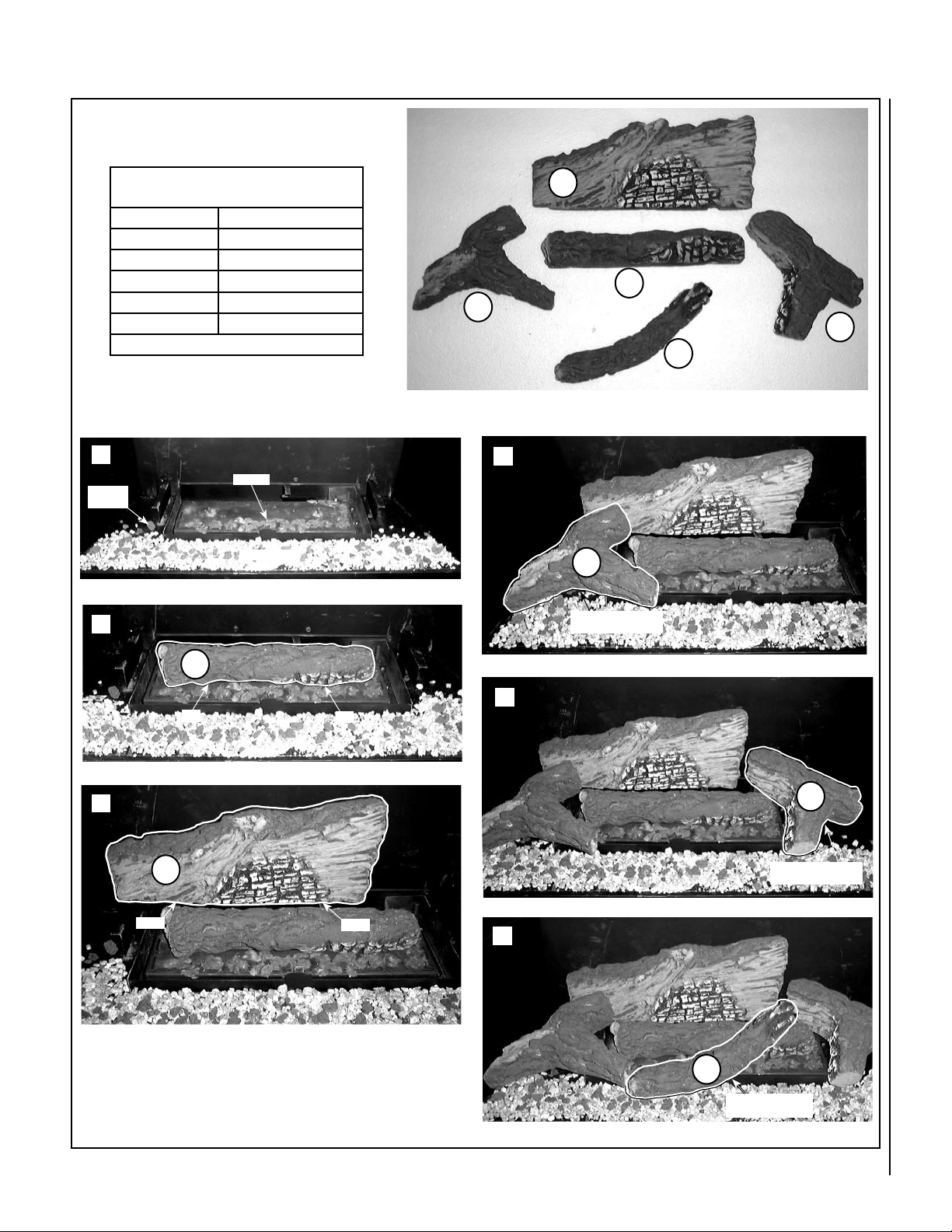

MODEL LMDV-3328 & LMDV-3530

Log Placement Instructions

LOG SET

Catalog Number

* Item

A

B

C

D

E

* Item "letters" above correspond to photos

Install the Embers, Vermiculite, Volcanic Stone and Logs in the order

shown here (1 through 6) and per the instructions on Page 7.

H3366

Description

Log, Rear

Log, Left

Log, Left Center

Log, Right Center

Log, Right

A

D

B

C

E

1

Volcanic

Stone

2

3

DO NOT PLACE EMBERS OVER GAS SLOTS

Embers

Vermiculite

The 2 notches on log bottom rest on locating brackets

A

Notch

Notch

4

Hole on bot-

A

V-Shape area of log (E) should

align to sides of burner ports

tom of log (E)

fits over pin

on log (A).

E

5

Log (C) fits into

indent in Log (A)

A

C

Slot on bottom of Log

(C) fits over bracket

6

Log (D) fits

into indent

on Log (E)

Slot fits over bracket.

B

E

D

Slot on bottom of Log

(D) fits over bracket

Figure 8

8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

MODEL LMDV-4035

Log Placement Instructions

LOG SET

Catalog Number

* Item

A

B

C

D

E

* Item "letters" above correspond to photos

Install the Embers, Vermiculite, Volcanic Stone and Logs in

the order shown here (1 through 6) and per the instructions

on Page 7.

1

Volcanic

Stone

2

DO NOT PLACE EMBERS OVER GAS SLOTS

Place log over pins

H3365

Description

Log, Rear

Log, Left

Log, Center

Log, Center Front

Log, Right

Embers

Vermiculite

A

C

B

E

D

4

B

Notch on log bottom

fits over bracket

3

Figure 9

Notch

C

5

Pin

Pin

E

The 2 notches

A

on log bottom

rest on locating

brackets

Notch

Notch on log bottom

fits over bracket

6

D

Slot on bottom of Log

(D) fits over bracket

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

9

Loading...

Loading...