Page 1

Cat. No.

No de Cat.

2238-20

2239-20

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

CLAMP METERS

PINCE AFFICHEUR DE COURANT

MEDIDORES DE PINZA

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S

MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN

COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL

MANUAL DEL OPERADOR.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

Hz

WARNING READ ALL SAFETY WARNINGS AND INSTRUCTIONS.

Failure to follow the warnings and instructions may result in electric shock, fi re and/or serious

injury, as well as instrument damage and/or damage to the equipment being tested.

Save these instructions - This operator’s manual contains important safety and operating

instructions for the MILWAUKEE Clamp Meters. Before using, read this operator’s manual,

your battery pack and charger operator’s manual, and all labels on the battery pack, charger

and Clamp Meters.

DANGER

Never make measurement on a circuit in which voltage over 1000V exists. Use only leads

rated 1000V or better.

Do not attempt to make measurement in the presence of fl ammable gasses. Otherwise, the

use of the instrument may cause sparking, which can lead to an explosion.

Transformer jaw tips are designed not to short the circuit under test. If equipment under test

has exposed conductive parts, however, extra precaution should be taken to minimize the

possibility of shorting.

Never attempt to use the instrument if its surface or your hand is wet.

Do not exceed the maximum allowable input of any measuring range.

Only test on unenergized circuits unless absolutely necessary.

Check tool functionality on a known circuit fi rst. Never assume tool is working. Assume circuits

are live until they can be proven de-energized.

Do not ground yourself while measuring. Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators.

Never remove the battery pack during a measurement.

This instrument is to be used only in its intended applications or conditions. Otherwise, the

instrument's safety functions may not work, resulting in serious personal injury and instrument damage.

To reduce the risk of injury from shock and arc blasts, always wear personal protective

equipment where live conductors are exposed.

WARNING

Never attempt to make measurement if any abnormal conditions, such as broken case and

exposed metal parts are found on the instrument.

Do not rotate the Rotary Dial while the test leads are being connected.

Verify proper operation on a known source before use or taking action as a result of the indication of the instrument.

Do not install substitute parts or make any modifi cation to the instrument. For repair or re-

calibration, return the tool to a factory Service/Sales Support Branch or authorized service

station.

Do not try to replace the battery pack if the surface of the instrument is wet.

Disconnect all the cords and cables from the object under test and power off the instrument

before removing or inserting the battery pack.

Recharge only with the charger specifi ed by the manufacturer. A charger that is suitable for one

type of battery pack may create a risk of fi re when used with another battery pack.

Use the meter only with specifi cally designated battery packs. Use of any other battery packs

may create a risk of injury and fi re.

When battery pack is not in use, keep it away from other metal objects like paper clips, coins,

keys, nails, screws, or other small metal objects that can make a connection from one terminal

to another. Shorting the battery terminals together may cause burns or a fi re.

Under abusive conditions, liquid may be ejected from the battery, avoid contact. If contact

accidentally occurs, fl ush with water. If liquid contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or burns.

2

CAUTION

Set the Rotary Dial to an appropriate position before starting measurement.

Firmly insert the test leads.

Disconnect the test leads from the instrument for current measurement.

Do not expose the instrument to the direct sun, high temperature and humidity or dew fall.

Altitude 2000m or less. Appropriate operating temperature is within -10ºC and 50ºC.

This instrument isn’t dust & water proofed. Keep away from dust and water.

Be sure to power off the instrument after use. When the instrument will not be in use for a long

period, place it in storage after removing the battery pack.

Use a damp cloth or neutral detergent for cleaning the instrument. Do not use abrasives or

solvents.

Functions

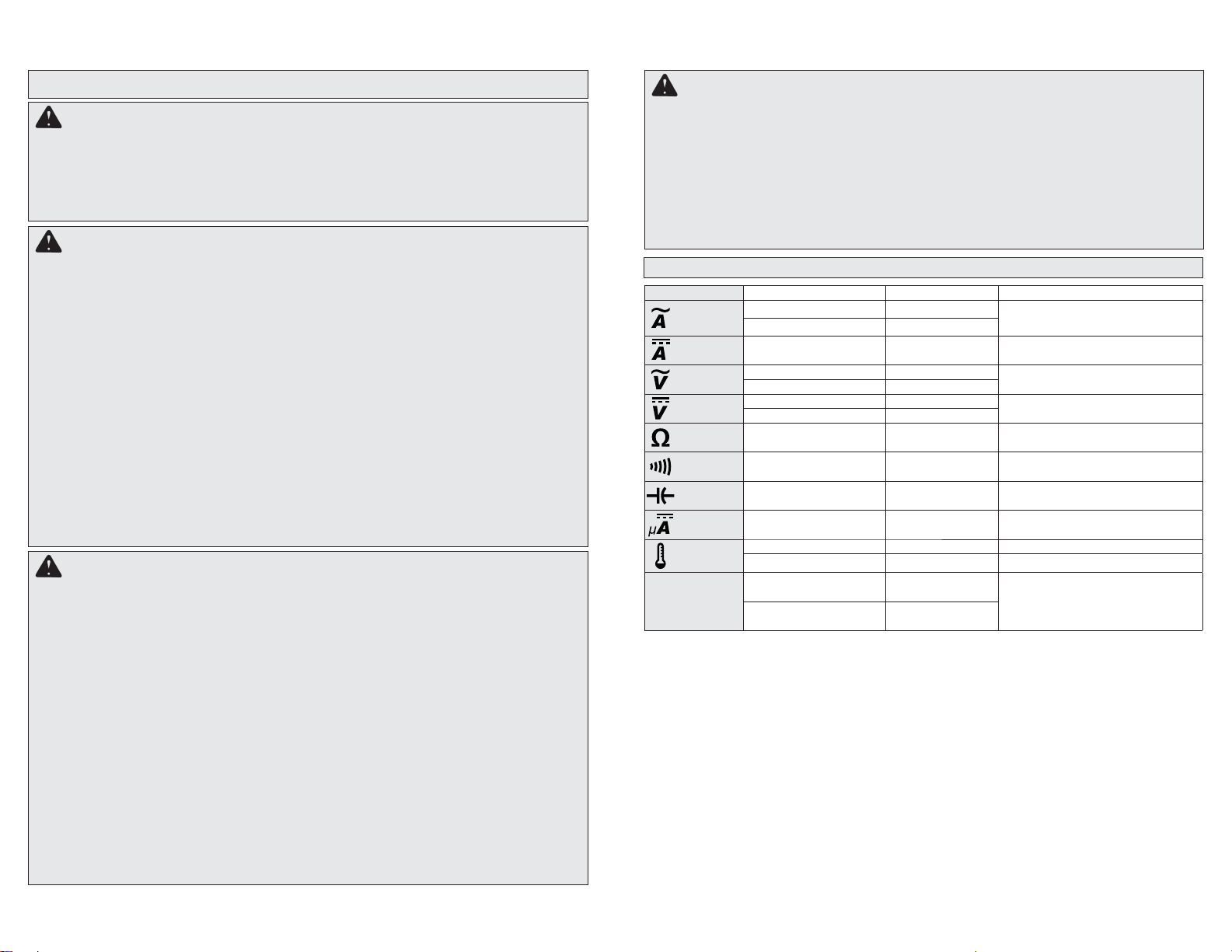

Dial Position Range Resolution Accuracy

Current AC

Current DC 2239-20: 60/600/1000 A 0.01/0.1/1 A ±2%rdg±5dgt

Voltage AC

Voltage DC

Resistance 600 /6000 /60 k/600 k 0.1 /1 /10 /0.1 k ±1%rdg±2dgt

Continuity 600.0 0.1 Buzzer sounds at 30 or less

Capacitance 400F/4000F 0.1F/1F

uA DC 2238-20: 600.0 uA 0.1uA ±1.5%rdg±5dgt

Temperature

Hz Hertz

These instruments are True-RMS sensing. All voltage and current readings are True-RMS values.•

Input impedance: •

Voltage DC: 1MΩ

Voltage AC: 1MΩ

Overload protection: •

Voltage AC / Voltage DC range: 1200V AC RMS

Clamp current range: •

720A AC RMS / DC 10sec (Cat. No. 2238-20 only)

1200A AC RMS / DC 10sec (Cat. No. 2239-20 only)

Inrush (Cat. No. 2239-20 only): integration time less than or equal to 100ms•

2238-20: 60/600 A 0.01/0.1 A

2239-20: 60/600/1000 A 0.01/0.1/1 A

600 V 0.1 V

1000 V 1 V

600 V 0.1 V

1000 V 1 V

2238-20: -40°C - 538°C 0.1°C ±1%±10dgt

2238-20: -40°F - 1000°F 0.1°F ±1%±18dgt

2239-20:

ACA: 600 Hz, 6 kHz

2239-20:

ACV: 600 Hz, 6 kHz, 60 kHz

0.1 Hz, 1Hz

0.1 Hz, 1 Hz, 10 Hz

3

±1.9%rdg ±5dgts, 50Hz/60Hz

±3.0%rdg ±5dgts, 45Hz to 500Hz

* Add 2% at CF>2

±1.2%rdg ±5dgts, 50Hz/60Hz

±1.8%rdg ±5dgts, 45Hz to 500Hz

±1%rdg±2dgt

±2.5%±20dgt

up to 60F

±1%rdg±1dgt

Sensitivity: Amps 5A RMS;

Minimum Herts measurement is 10Hz

Volts - 30V RMS

Page 3

General Specifi cations

Accuracy is specifi ed for 1 year after calibration,

at operating temperatures of 18°C to 28°C (64°F

to 82°F), with relative humidity at 0 % to 85 %.

Maximum voltage between any terminal and

earth ground .... 1000 V

Jaw Opening (maximum conductor size) ....

approx. 1.3” (33 mm)

Temperature ....

Operating: -10°C to 50°C (14°F to 122°F)

Storage: -40°C to 60 °C (-40°F to 140°F)

Temperature Coeffi cient .... 0.1 x (specifi ed

accuracy)/°C (<18°C or >28°C)

Operating Altitude.... 2,000 meters

Drop Test .... 1 meter

Safety Compliances .... EN61010-1,

UL 61010-1, EN61010-031 (Probes),

IEC 61010-2-32 (Clamp Assemblies),

IEC/EN 61010-1 2nd Edition for measurement

Category III, 1000 V, Category IV, 600 V,

Pollution Degree 2, EMC EN61326-1

Certifi cations .... cULus, CE

Voltage: 12 DC Li-Ion, MILWAUKEE Battery

Pack Cat. Nos. 48-11-2401, 48-11-2402

Battery run time: Greater than 12 hrs with all

functions

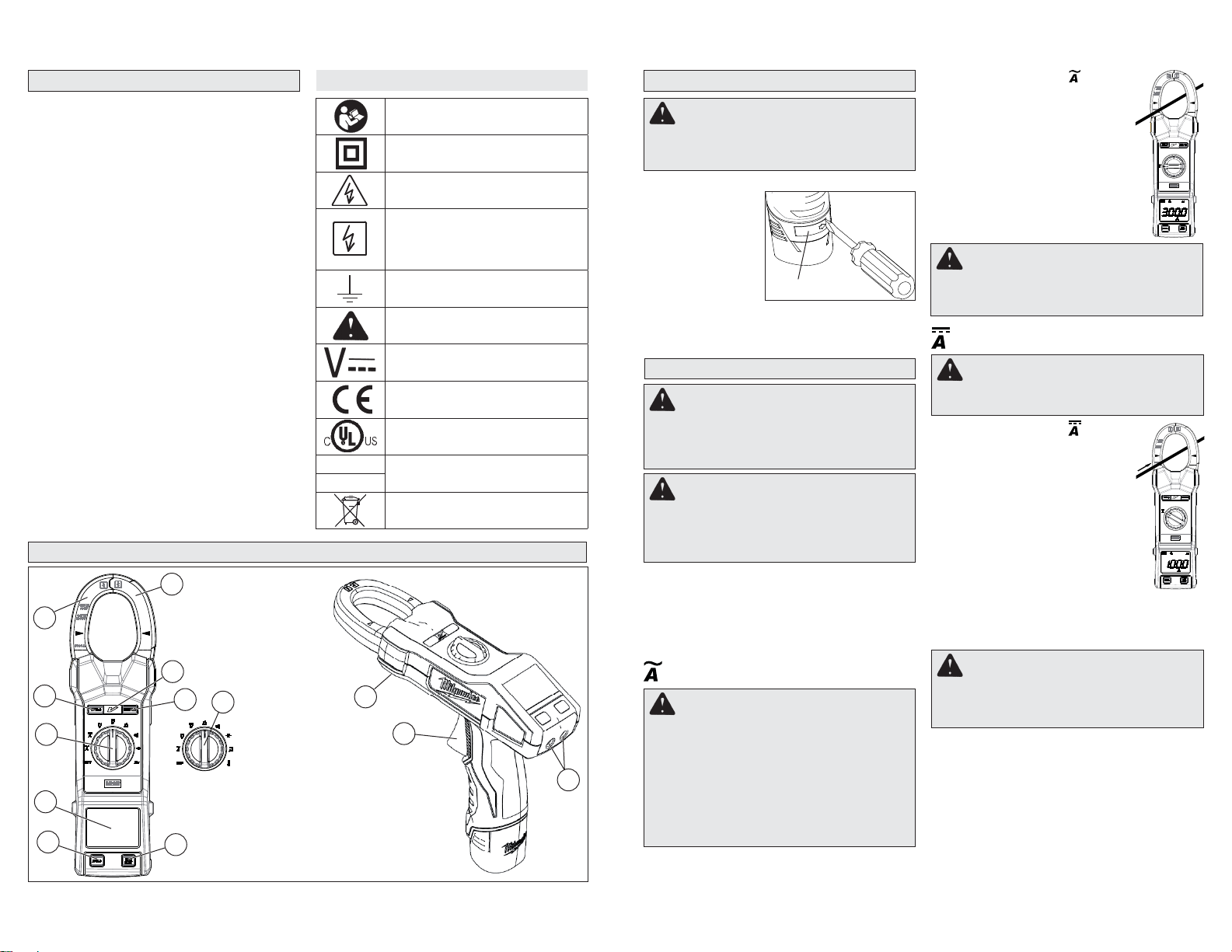

FUNCTIONAL DESCRIPTION

Cat. No.

2239-20

1

4

6

7

8

V

O

2

L

T

A

G

1. Current sensing jaws

E

D

E

2. NCVD sensing area

T

E

C

T

O

R

3. NCVD indicator

4. °F/°C button (2238-20)

Zero button (2239-20)

5. Inrush button (2239-20)

3

5

6. Rotary Dial

7. Display

6

8. Hold button

9. Min/Max button

10. Worklight LED

11. Jaw opening trigger

Cat. No.

2238-20

12. Terminal inputs

9

Cat III

Cat IV

10

Symbology

To reduce the risk of injury, user must

read operator’s manual.

Double insulation

Risk of electric shock

Indicates that this instrument can clamp

on bare conductors when measuring a

voltage corresponding to the applicable

measurement category, which is marked

next to this symbol.

Earth

Danger, Warning, or Caution - Consult

the operators manual for additional

safety information.

Volts Direct Current

European Conformity Mark

Underwriters Laboratories, Inc.,

United States and Canada

Classifi cation of transient overvoltages,

based on nominal line voltage to earth.

Do not dispose of this product as

unsorted municipal waste.

11

12

ASSEMBLY

WARNING Recharge only with the char-

ger specifi ed for the battery. For specifi c charg-

ing instructions, read the operator’s manual

supplied with your charger and battery.

Inserting/Removing the Battery

To remove the bat-

tery, use a fl at screw-

Fig. 1

driver to pry open the

lock latch. Push in the

release buttons and

pull the battery pack

away from the tool.

To insert the battery,

Lock latch

slide the pack into the body of the tool. Make sure

it latches securely into place. Press in the lock latch

to lock the battery in place.

OPERATION

WARNING Always turn the Rotary

Dial to OFF before inserting or removing

probes. Only use accessories specifi cally

recommended for this tool. Others may be

hazardous.

WARNING

Only use MILWAUKEE test leads with the

MILWAUKEE Clamp Meters.

Inspect test leads before each use. Use clamp

meter to run a continuity test.

Before Use

Confi rm the Rotary Dial is set to the correct position,

the instrument is set to the correct measurement

mode, and the Data hold function is disabled. Otherwise, desired measurement cannot be made.

Making a Measurement

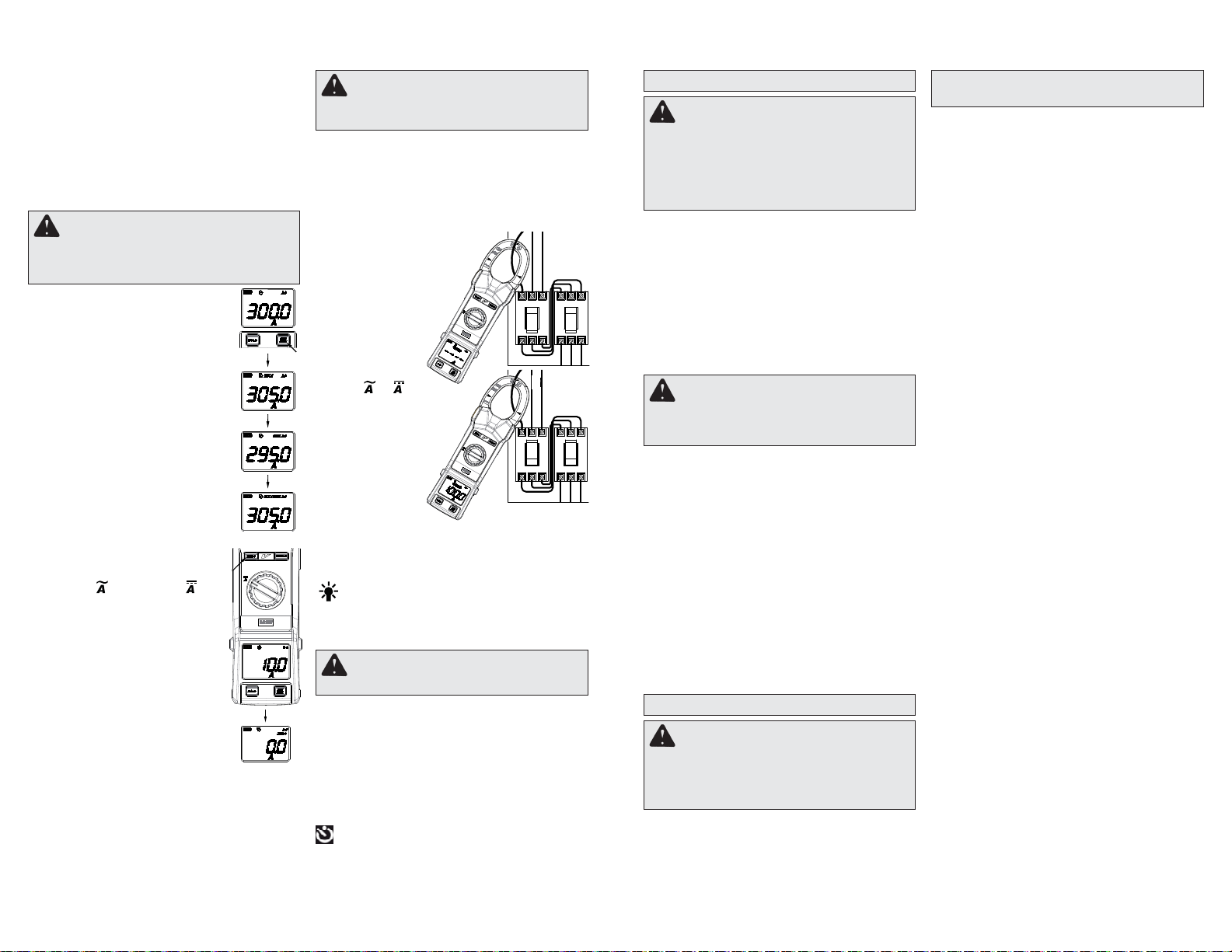

AC Current

DANGER To avoid electrical shock:

Never make measurement on a circuit in

which voltage over 1000V exists. Clamp tips

are designed not to short the circuit under

test. If equipment under test has exposed

conductive parts, however, extra precaution

should be taken to minimize the possibility

of shorting.

Disconnect the test leads from the instrument

for current measurement.

V

O

L

T

A

1. Set the Rotary Dial to position.

G

E

AC mark is displayed.

2. Press the jaw opening trigger to

open the jaws and clamp them

onto the conductor under test. The

reading is displayed.

NOTE: Do not clamp over 2 or more

wires at the same time. Irregular

results will occur.

CAUTION Maximum conductor size

is about 1.3" diameter. During measurement,

keep the jaws fully closed to ensure accurate

measurements.

DC Current (Cat. No. 2239-20 only)

DANGER To avoid electrical shock:

Never make measurement on a circuit in

which voltage over 1000V exists.

V

O

L

T

A

1. Set the Rotary Dial to position.

G

DC mark is displayed.

2. With the jaws closed and without

clamping them around a conductor,

press the ZERO key to zero adjust

the display.

3. Press the jaw opening trigger to

open the jaws and clamp them

around the conductor under test.

NOTE: Do not clamp over 2 or more

wires at the same time. Irregular

results will occur.

4. The reading is displayed.

5. Press the ZERO key again to release the ZERO

function.

CAUTION When current fl ows from

the display side to the underside of the meter,

the polarity is positive; fl ow from underside to

display side, the polarity is negative.

D

E

T

E

C

T

O

R

E

D

E

T

E

C

T

O

R

4

5

Page 4

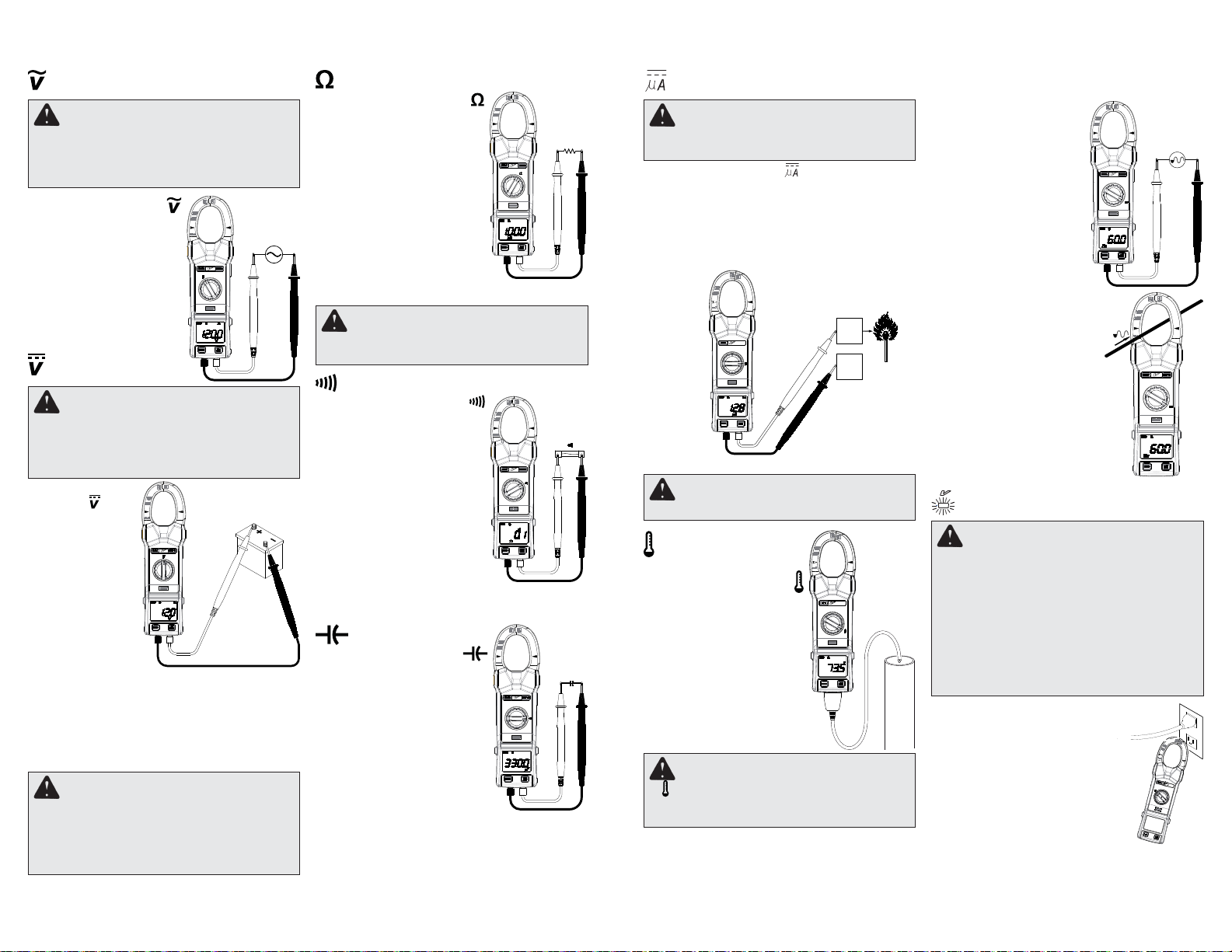

AC Voltage

DANGER To avoid electrical shock:

Never make measurement on a circuit in

which voltage over 1000V exists.

Keep fi ngers away from jaws during mea-

surements.

V

O

L

T

A

G

1. Set the Rotary Dial to

position.

E

D

E

T

E

C

T

O

R

2. Connect the red test lead

to the V terminal and the

black test lead to the COM

terminal.

3. Connect the test leads to

the circuit under test. The

reading is displayed.

DC Voltage

DANGER To avoid electrical shock:

Never make measurement on a circuit in

which voltage over 1000V exists.

Keep fi ngers away from jaws during mea-

surements.

V

O

L

T

1. Set the Rotary

Dial to

tion.

posi-

A

G

E

D

E

T

E

C

T

O

R

2. Connect the red

test lead to the

V terminal and

12V

the black test lead

to the COM terminal.

3. Connect the red

test lead to the

positive (+) side

and black test

leads to the negative (-) side of the circuit under test. The reading

is displayed. A reversed connection is indicated

as a negative value.

Resistance/Continuity/Capacitance

Measurements

DANGER To reduce the risk of

electric shock for Resistance, Continuity, and

Capacitance measurements, never use the

meter on an energized circuit. Make sure a

capacitor is fully discharged before touching

or attempting to make a measurement.

Resistance

1. Set the Rotary Dial to

position.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

2. Connect the red test lead

to the V terminal and the

black test lead to the COM

terminal.

Confi rm “OL” is indicated on

the display, and then shortcircuit the tips of test leads

to make the indication zero.

3. Connect the test leads to

the both ends of the resistor

under test.

4. The reading is displayed.

CAUTION After shorting the test leads,

the displayed value may not be zero due to the

resistance of test leads themselves.

Continuity

1. Set the Rotary Dial to

position.

2. Connect the red test lead

to the V terminal and the

black test lead to the COM

terminal.

Confi rm “OL” is indicated on

the display, and then shortcircuit the tips of test leads

to make the indication zero.

A buzzer will sound.

3. Connect the test leads to the

both ends of the conductor

under test. If the resistance under test is 30

or less, the buzzer will sound.

Capacitance

1. Set the Rotary Dial to

position.

2. Connect the red test lead

to the V terminal and the

black test lead to the COM

terminal.

3. Discharge capacitor.

4. Connect the test leads to the

both ends of the capacitor

under test.

5. The reading is displayed.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

DC Current (Cat. No. 2238-20 only)

DANGER To avoid electrical shock:

Never make measurement on a circuit in

which voltage over 1000V exists.

1. Set the Rotary Dial to

displayed.

position. DC mark is

2. Connect the red test lead to the V terminal and

the black test lead to the COM terminal. Contact

the red test lead to the fl ame sensor probe and

the black test lead to the control module.

3. Turn on the heating unit. The reading is displayed.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

Flame

sensor

probe

Control

Module

WARNING Never connect the

Temperature Probe to an energized circuit.

V

O

L

T

A

G

E

D

E

T

E

Temperature

(Cat. No. 2238-20 only)

1. Set the Rotary Dial to

position.

C

T

O

R

2. Connect the K-type Temperature Probe to the input

terminal. The positive (+)

side of Probe should be

connected to V.

3. Place the probe sensor in

the desired location.

4. The reading is displayed.

CAUTION When the Rotary Dial is set

to , OL should be displayed. If anything else is

displayed, something may be wrong with the

meter. Stop using the meter immediately.

Hz Frequency (Cat. No. 2239-20 only)

1.Set the Dial to Hz position.

2. Voltage: Connect the red

test lead to the V terminal and the black test lead

to the COM terminal.

Connect the test leads to

the circuit under test. The

reading is displayed.

Current: Press the jaw open-

ing trigger to open the jaws

and clamp them onto the

conductor under test. The

reading is displayed.

NOTE: Do not clamp over 2

or more wires at the same

time. Irregular results will

occur.

Non-Contact Voltage Detection (NCVD)

DANGER The LED may not be

displayed due to installation condition of

electrical circuit or equipment. Never touch

the circuit under test to avoid possible danger

even if the LED for NCVD is not displayed.

Check the functionality of LED on a wellknown power supply prior to measurement.

When the LED doesn’t light up, do not make

measurement.

NCVD indication is affected by external voltage, and how the meter is held or placed.

When the meter is on in any

function, the non-contact voltage detector will indicate with a

Red LED on the display when

an electric fi eld exceeding 90V is

detected. Place the edge of the

jaw labeled “Voltage Detector”

near the electric fi eld.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

6

7

Page 5

0N0N

D

R

O

T

E

C

T

E

V

A

G

E

O

T

L

HOLD Function

Data Hold Function - Freezes the value on the

display. Press the “HOLD” button to freeze the

reading. The reading will be held regardless of

subsequent variation in input. HOLD is displayed

with the reading. To exit Data Hold mode, press

the HOLD button again. Hold is not available when

using the Inrush Function.

MIN/MAX Function

CAUTION Make a measurement

and press the MIN/MAX button after an

appropriate range is selected by the autoranging function.

The MIN/MAX recording mode captures the minimum and maximum

input values.

Set the dial to to the desired measurement function. Make a measurement

and press the MIN/MAX button. The

meter will capture the MIN and MAX

readings. Press the MIN/MAX button

to toggle between the captured MIN,

MAX and present readings. MAXMIN

fl ashes when the present reading is

displayed.

To exit and erase stored readings,

press the MIN/MAX button for two

seconds or change the dial.

If MIN/MAX is active, all function buttons are unavailable except HOLD.

ZERO Function

(Cat. No. 2239-20 only)

Press

AC Current / DC Current :

When the LCD doesn’t read

ZERO while the Jaws are closed,

press the ZERO Button to indicate ZERO before starting a

measurement. With the jaws

closed and without clamping

them around a conductor, press

the ZERO key to zero adjust the

display.

The “ZERO” mark appears on

the LCD to indicate the ZERO

Function is activated.

°F / °C (Cat. No. 2238-20 only)

To switch between Fahrenheit or Celsius, press

the °F / °C button.

Press

DANGER To avoid electrical shock:

Never make measurement on a circuit in

which voltage over 1000V exists.

Inrush Function (Cat. No. 2239-20 only)

Inrush current measurement allows for measuring

the sharp peak in current upon motor startups.

Lasting only part of a second, MILWAUKEE's Inrush

function captures and displays the fi rst 100 millisec-

onds of current at motor startup.

Power off the system under test.1.

Press the jaw opening trigger 2.

to open the jaws and clamp

them onto the conductor

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

under test.

NOTE: Do not clamp

over 2 or more wires

at the same time.

0FF 0FF

Irregular results

will occur.

Set the Rotary 3.

Dial to

or

position. AC or DC

mark is displayed.

Press the INRUSH 4.

button.

Power on the 5.

system under test.

The reading is 6.

displayed.

Over-fl ow indication

Any time the input exceeds the measuring range

“OL” or “-OL” is displayed.

Worklight LED ON/OFF

To turn the light on and off, pull the trigger.

Sleep Mode

CAUTION The Data Hold readings are

released when the meter enters Sleep Mode.

The clamp meter is automatically powered off in

about 20 min after the last Rotary Dial or button

operation. To reset, rotate the Rotary Dial or pull the

trigger. If the display is still blank when a new Rotary

Dial setting is selected, charge the battery pack.

To disable the sleep function, turn the tool off. Press

and hold the HOLD button and turn on the meter.

After the meter "beeps", release the HOLD button.

The meter will beep again and the clock symbol

will be removed from the display.

The clamp meter does use battery power in sleep

mode. Be sure to switch the tool to OFF to conserve

battery power.

8

MAINTENANCE

FIVE YEAR TOOL

LIMITED WARRANTY

WARNING To reduce the risk of injury,

always unplug the charger and remove the

battery pack from the charger or tool before

performing any maintenance. Never disassemble the tool, battery pack or charger.

Contact a MILWAUKEE service facility for

ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good

repair by adopting a regular maintenance program.

After six months to one year, depending on use,

return the tool, battery pack and charger to a

MILWAUKEE service facility service.

If the tool does not start or operate at full power

with a fully charged battery pack, clean the contacts

on the battery pack. If the tool still does not work

properly, return the tool, charger and battery pack,

to a MILWAUKEE service facility for repairs.

WARNING To reduce the risk of per-

sonal injury and damage, never immerse your

tool, battery pack or charger in liquid or allow

a liquid to fl ow inside them.

Cleaning

Clean dust and debris from charger and tool vents.

Keep tool handles clean, dry and free of oil or grease.

Use only mild soap and a damp cloth to clean the

tool, battery pack and charger since certain cleaning

agents and solvents are harmful to plastics and other

insulated parts. Some of these include gasoline,

turpentine, lacquer thinner, paint thinner, chlorinated

cleaning solvents, ammonia and household detergents containing ammonia. Never use fl ammable or

combustible solvents around tools.

Repairs

For repairs, return the tool, battery pack and charger to the nearest service center listed on the back

cover of this operator's manual.

ACCESSORIES

WARNING Always remove battery

pack before changing or removing accessories. Only use accessories specifically

recommended for this tool. Others may be

hazardous.

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go online to

www.milwaukeetool.com. To obtain a catalog, contact your local distributor or a service center listed

on the back cover of this operator’s manual.

MILWAUKEE Test & Measurement Products (including bare tool, li-ion battery pack(s) and battery charger but excluding alkaline batteries) are warranted

to the original purchaser only to be free from defects

in material and workmanship. Subject to certain

exceptions, MILWAUKEE will repair or replace any

part on this product which, after examination, is determined by MILWAUKEE to be defective in material or

workmanship for a period of fi ve (5) years* after the

date of purchase. Return the Test & Measurement

tool and a copy of proof of purchase to the nearest

Milwaukee Electric Tool Corporation - factory Service

Center. This warranty does not apply to damage that

MILWAUKEE determines to be from repairs made or

attempted by anyone other than MILWAUKEE authorized personnel, misuse, alterations, abuse, normal

wear and tear, lack of maintenance, or accidents.

*The warranty period for the LITHIUM-ION battery

pack that ships with the Test & Measurement tool is

two (2) years from the date of purchase. *Alkaline

battery that ships with Test & Measurement tool is

separately warranted by the battery manufacturer.

*The warranty period for a NON-CONTACT VOLTAGE DETECTOR – 2201 20 is one (1) year from

the date of purchase.

Warranty Registration is not necessary to obtain

the applicable warranty on MILWAUKEE product.

The manufacturing date of the product will be used

to determine the warranty period if no proof of

purchase is provided at the time warranty service

is requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR

AND REPLACEMENT REMEDIES DESCRIBED

HEREIN IS A CONDITION OF THE CONTRACT

FOR THE PURCHASE OF EVERY MIL W AUKEE

PRODUCT. IF YOU DO NOT AGREE TO THIS

CONDITION, YOU SHOULD NOT PURCHASE THE

PRODUCT. IN NO EVENT SHALL MIL W AUKEE

BE LIABLE FOR ANY INCIDENTAL, SPECIAL,

CONSEQUENTIAL OR PUNITIVE DAMAGES, OR

FOR ANY COSTS, ATTORNEY FEES, EXPENSES,

LOSSES OR DELAYS ALLEGED TO BE AS A CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF,

OR DEFECT IN ANY PRODUCT INCLUDING, BUT

NOT LIMITED TO, ANY CLAIMS FOR LOSS OF

PROFITS. THIS WARRANTY IS EXCLUSIVE AND

IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR

IMPLIED. WITHOUT LIMITING THE GENERALITY

OF THE FOREGOING, MILWAUKEE DISCLAIMS

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE OR

PURPOSE, AND ALL OTHER WARRANTIES.

This warranty applies to product sold in the U.S.A.,

Canada and Mexico only.

9

Page 6

RÈGLES IMPORTANTES DE SÉCURITÉ

Hz

AVERTISSEMENT LIRE TOUS LES AVERTISSEMENTS ET TOUTES LES

INSTRUCTIONS.

entraîner une électrocution, un incendie ou des blessures graves, en plus d’endommager la

pince et l’équipement mis à l’essai.

Conserver ces instructions – Ce manuel contient des instructions importantes de sécurité et de

fonctionnement pour la pince affi cheur de courant MILWAUKEE. Avant d’utiliser, lire le présent

manuel d’utilisation, le manuel d’utilisation du bloc-piles et du chargeur, ainsi que toutes les

étiquettes se trouvant sur le bloc-piles, le chargeur et la pince affi cheur de courant.

DANGER Ne jamais prendre une mesure sur un circuit dont la tension est supérieure

à 1 000 V. Utiliser uniquement des fi ls qui résistent à une tension d’au moins 1 000 V.

Ne pas tenter de prendre une mesure en présence de gaz infl ammables. L’utilisation de

l’instrument peut causer des étincelles, ce qui peut entraîner une explosion.

Les extrémités de type « mâchoires » du transformateur sont conçues pour empêcher les

courts-circuits en cours d’essai. Si l’équipement mis à l’essai comporte des pièces conductrices

à découvert, il est nécessaire de prendre des précautions supplémentaires pour minimiser la

possibilité d’un court-circuit.

Ne jamais tenter d’utiliser l’instrument si sa surface est mouillée ou si vos mains le sont.

Ne pas excéder l’alimentation maximale permise de toute plage de mesure.

Effectuer des essais uniquement sur des circuits hors tension, à moins qu’il soit absolument

nécessaire de procéder autrement.

Vérifi er d’abord le fonctionnement de l’outil sur un circuit connu. Ne jamais tenir pour acquis

que l’outil fonctionne. Présumer que les circuits sont sous tension jusqu’à ce qu’il soit confi rmé

qu’ils sont hors tension.

Ne pas mettre l’instrument à la terre au moment de prendre une mesure. Éviter tout contact

avec des surfaces mises à la terre comme des tuyaux, des radiateurs, des cuisinières et des

réfrigérateurs.

Ne jamais retirer le bloc-piles pendant une mesure.

L’instrument doit être utilisé uniquement pour les applications et les conditions pour lesquelles

il a été conçu. Autrement, les fonctions de sécurité de l’instrument failliront et des dommages

à l’outil ainsi que des blessures graves peuvent en découler.

Pour réduire le risque de blessures découlant d’une décharge ou de l’explosion d’un arc électrique, porter de l’équipement de protection individuel au moment de travailler dans un endroit

renfermant des conducteurs sous tension et non protégés.

AVERTISSEMENT Ne jamais tenter de prendre une mesure dans des conditions

anormales par exemple, si le boîtier de l’instrument est cassé et que des pièces métalliques

sont exposées.

Ne pas tourner le cadran rotatif si les fi ls d’essai sont branchés.

S’assurer du bon fonctionnement de l’instrument sur une source d’alimentation connue avant

de l’utiliser ou d’agir en se fondant sur ce qu’il indique.

N’installer aucune pièce de remplacement sur l’instrument et ne le modifi er sous aucun prétexte.

Pour procéder à une réparation ou à un ré étalonnage, confi er l’outil à un bureau d’entretien en

usine ou de soutien des ventes, ou à un poste d’entretien agréé.

Ne pas tenter de remplacer les piles si la surface de l’instrument est mouillée.

Débrancher tous les cordons d’alimentation et les câbles de l’objet mis à l’essai et éteindre

l’instrument avant de retirer ou d’insérer le bloc-piles.

Ne recharger le bloc-piles qu’avec le chargeur spécifi é par le fabricant. Un chargeur qui convient

à un type de bloc-piles peut créer un risque d’incendie s’il est utilisé avec un autre type de

bloc-piles.

N’utiliser les outils électriques qu’avec les bloc-piles recommandés. L’utilisation de tout autre

bloc-piles peut créer un risque de blessures et d’incendie.

Lorsque le bloc-piles n’est pas utilisé, le tenir éloigné des objets en métal tels que les trombones, les pièces de monnaie, les clés, les clous, les vis ou d’autres petits objets métalliques

qui pourraient connecter les bornes. Le court-circuitage des bornes du bloc-piles peut entraîner

des brûlures ou un incendie.

Ne pas suivre l’ensemble des avertissements et des instructions peut

10

Éviter tout contact avec le liquide pouvant être éjecté de la pile en cas de manutention abusive.

En cas de contact accidentel, rincer abondamment avec de l’eau. Si le liquide entre en contact

avec les yeux, consulter un médecin. L’électrolyte qui s’échappe de la pile peut causer des

démangeaisons ou des brûlures.

A TTENTION Régler le cadran à une position appropriée avant de commencer à mesurer.

Insérer fermement les fi ls d’essai.

Débrancher les fi ls d’essai de l’instrument pour obtenir la mesure réelle.

Ne pas exposer directement l’instrument au soleil, à des températures élevées, à l’humidité

ou à la rosée.

Conçu pour une altitude de 2 000 m ou moins. Convient pour des températures de -10°C à 50°C.

Garder l’instrument à l’écart de l’excédent de poussière et d’eau.

S’assurer d’éteindre l’instrument après l’utilisation. Lorsque l’instrument n’est pas utilisé pendant une longue période, l’entreposer après avoir retiré les piles.

Utiliser un chiffon trempé dans l’eau ou du détergent neutre pour nettoyer l’instrument. Ne pas

utiliser de nettoyeurs abrasifs ou de solvants.

Fonctions

Position du cadran Plage Résolution Précision

Courant c.a.

Courant c.c.

Tension c.a.

Tension c.c.

Résistancee 600 /6000 /60 k/600 k 0,1 /1 /10 /0,1 k ±1%rdg±2dgt

Continuité 600,0 0,1 L’avertisseur retentit à 30 ou moins

Capacité 400F/4000F 0,1F/1F

Courant c.c.

A

Température

Hz Hertz

Ces instruments permettent la détection de la véritable valeur effi cace. Toutes les lectures de tension et de •

courant constituent des véritables valeurs effi caces.

Impédance d’entrée : •

Tension c.c. : 1 MΩ

Tension c.a. : 1 MΩ

Protection contre les surcharges :•

Tension c.a. ou c.c. : 1 200 V c.a. effi caces

Plage de courant de la pince :•

720 A c.a. ou c.c. effi caces pendant 10 sec (N˚ de Cat. 2238-20 seul.);

1 200 A c.a. ou c.c. effi caces pendant 10 sec (N˚ de Cat. 2239-20 seul.);

Courant d’appel (N˚ de Cat. 2239-20 seul.) : temps d’intégration inférieur ou égal à 100 ms•

2238-20: 60/600 A 0,01/0,1 A

2239-20: 60/600/1000 A 0,01/0,1/1 A

2239-20: 60/600/1000 A 0,01/0,1/1 A ±2%rdg±5dgt

600 V 0,1 V

1000 V 1 V

600 V 0,1 V

1000 V 1 V

2238-20: 600,0 uA 0,1uA ±1,5%rdg±5dgt

2238-20: -40°C - 538°C 0,1°C ±1%±10dgt

2238-20: -40°F - 1000°F 0,1°F ±1%±18dgt

2239-20:

A c.a: 600 Hz, 6 kHz

V c.a: 600 Hz, 6 kHz, 60 kHz

2239-20:

0,1 Hz; 1Hz

0,1 Hz; 1 Hz; 10 Hz

11

±1,9%rdg ±5dgt, 50Hz/60Hz

±3,0%rdg ±5dgt, 45Hz à 500Hz

* additionner 2% at FC>2

±1,2%rdg ±5dgts, 50Hz/60Hz

±1,8%rdg ±5dgts, 45Hz to 500Hz

±1%rdg±2dgt

±2,5%±20dgt

à 60F

±1 % lectures, ±1 chiffre

Sensibilité : 5 A effi caces;

Tension : 30 V effi caces

Mesure minimale de la fréquence : 10 Hz

Page 7

Spécifi cations générales

La précision est garantie pendant un an suivant

l’étalonnage, à des températures de fonctionnement de 18 °C à 28 °C (64 °F à 82 °F) et à une

humidité relative de 0 % à 85 %.

Tension maximale entre les bornes et les

prises de terre .... 1 000 V

Ouverture des mâchoires (taille maximale du

conducteur) .... Environ 33 mm (1,3")

Température .... Fonctionnement : –10 °C à

50 °C (14°F à 122°F)

Entreposage : –40 °C à 60 °C (-40°F à 140°F)

Coeffi cient de température .... 0,1 × (précision

spécifi ée)/°C (< 18°C ou > 28°C)

Altitude d’exploitation .... 2 000 mètres

Épreuve de chute .... 1 mètre

Conformité à la sécurité .... EN61010-1,

UL 61010-1, EN61010-031 (sondes portables),

IEC 61010-2-32 (ensembles de pinces),

e

édition de IEC/EN 61010-1 pour la catégorie

2

de mesure catégorie III, 1 000 V, catégorie IV,

600 V, niveau de pollution 2, EMC EN61326-1

Attestations .... cULus, CE

Tension : 12 V c.c. Li-Ion, MILWAUKEE No de

Cat. 48-11-2401, 48-11-2402

Autonomie des piles : Supérieure à 12 heures

pour toutes les fonctions

Description fonctionnelle

N° de cat.

2239-20

1

4

6

7

8

V

O

1. Mâchoires ampèremétriques

L

2

T

A

G

E

D

2. Zone de détection du

E

T

E

C

T

pouvoir calorifi que

O

R

inférieur sur sec (PCIS)

3. Indicateur de pouvoir calorifi que inférieur sur sec (PCIS)

4. Bouton « °F/°C » (2238-20)

3

Bouton Zéro (2239-20)

5

5. Bouton « Courant d’appel » (2239-20)

6

6. Cadran rotatif

7. Affi cheur

8. Bouton « Hold » (Retenue)

9. Bouton « Min/Max »

N° de cat.

2238-20

10. Lampe de travail DÉL

11. Gâchette d’ouverture des mâchoires

12. Bornes d’entrée

9

12

Cat III

Cat IV

10

Symbologie

Afi n de réduire le risque de blessures,

l'utilisateur doit lire le manuel de

l'utilisateur.

Double isolation

Risque de décharge électrique

Indique que cet instrument peut se fi xer

sur des conducteurs nus au moment de

mesurer une tension correspondant à la

catégorie de mesure applicable, qui est

indiquée à côté de ce symbole.

Prise de terre

Danger, avertissement ou attention l'utilisateur doit lire et bien comprendre

le manuel de l'utilisateur.

Volts courant continu

Marque de conformité aux normes

européennes

Underwriters Laboratories, Inc.,

États-Unis et Canada

Classifi cation des surtensions transi-

toires en fonction de la tension nominale de secteur par rapport à la terre

Ne pas jeter ce produit avec les

ordures ménagères.

11

12

MONTAGE DE L'OUTIL

AVERTISSEMENT Ne recharger la

batterie qu’avec le chargeur spécifi é. Pour

les instructions de charge spécifi ques, lire le

manuel d’utilisation fourni avec le chargeur et

les batteries.

Insertion/ Retrait de la batterie

Pour retirer la pile, util-

Fig. 1

iser un tournevis à tête

plate pour dégager le

loquet. Pousser les boutons d’ouverture vers

l’intérieur et retirer la

batterie de l’outil.

Pour insérer la batterie

Loquet

dans l’outil, la glisser sur le corps de l’outil. S’assurer

qu’elle se loge fermement en place. Appuyer sur le

loquet pour verrouiller la pile en place.

UTILISATION

A VERTISSEMENT Toujours tourner

le cadran rotatif à la position « OFF » (Arrêt)

avant d’insérer ou de retirer les sondes.

L’emploi d’accessoires autres que ceux qui

sont expressément recommandés pour cet

outil peut comporter des risques.

Utiliser uniquement des fils d’essai

MILWAUKEE avec les pinces affi cheur de

courant MILWAUKEE.

Examiner les fi ls d’essai avant chaque utili-

sation. Utiliser la pince pour procéder à une

vérifi cation de continuité.

Avant l’utilisation

S’assurer que le cadran rotatif est réglé à la bonne

position, que l’instrument est réglé au mode de

mesure approprié et que la fonction de retenue

des données est désactivée. Autrement, il sera

impossible de prendre la mesure désirée.

Prendre une mesure

Courant c.a.

DANGER Pour éviter une décharge

électrique : Ne jamais prendre une mesure

sur un circuit dont la tension est supérieure à

1 000 V. Les extrémités de la pince sont conçues

pour ne pas court circuiter l’équipement mis à

l’essai. Toutefois, si cet équipement comporte

des pièces conductrices exposées, il importe de

prendre des précautions supplémentaires afi n

de minimiser les possibilités de court-circuit.

Débrancher les fi ls d’essai de l’instrument

pour mesurer le courant.

1. Régler le cadran rotatif à la position Le symbole « AC » (c.a.)

s’affi che.

2. Appuyer sur la gâchette d’ouverture

des mâchoires pour ouvrir les

mâchoires et les fi xer sur le con-

ducteur mis à l’essai. La lecture

s’affi che.

NOTE : Ne pas pincer deux fi ls ou

plus à la fois. L’utilisateur risque

d’obtenir des résultats inhabituels.

ATTENTION La taille maximale du

conducteur est d’environ 33 mm (1,3") de

diamètre. Au moment de prendre la mesure,

garder les mâchoires complètement fermées

pour plus de précision.

Courant c.c. (N˚ de cat. 2239-20 seul.)

DANGER Pour éviter une décharge

électrique : Ne jamais prendre une mesure

sur un circuit dont la tension est supérieure

à 1 000 V.

1. Régler le cadran rotatif à la position

Le symbole « DC » (c.c.)

s’affi che.

2. En gardant les mâchoires fermées

et sans les fi xer autour d’un con-

ducteur, appuyer sur la touche

ZÉRO pour remettre l’affi cheur à

zéro.

3. Appuyer sur la gâchette d’ouverture

des mâchoires pour ouvrir les

mâchoires et les fi xer sur le con-

ducteur mis à l’essai.

NOTE : Ne pas pincer deux fi ls ou

plus à la fois. L’utilisateur risque d’obtenir des

résultats inhabituels.

4. La lecture s’affi che.

5. Appuyer de nouveau sur la touche ZÉRO pour

quitter la fonction ZÉRO.

ATTENTION Lorsque le courant

circule du côté de l’écran vers le dessous de

la pince, la polarité est positive; lorsque le

courant circule du dessous de la pince vers le

côté de l’écran, la polarité est négative.

13

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

Page 8

Tension c.a.

DANGER Pour éviter une décharge

électrique : Ne jamais prendre une mesure

sur un circuit dont la tension est supérieure

à 1 000 V.

Garder les doigts éloignés des mâchoires

lors de la prise de mesure.

V

O

L

T

1. Régler le cadran à la position

.

A

G

E

D

E

T

E

C

T

O

R

2. Raccorder le fil d’essai

rouge à la borne V et le

fi l d’essai noir à la borne

COM.

3. Raccorder les fi ls d’essai

au circuit mis à l’essai. La

lecture s’affi che.

Tension c.c.

DANGER Pour éviter une décharge

électrique : Ne jamais prendre une mesure

sur un circuit dont la tension est supérieure

à 1 000 V.

Garder ses doigts à l’écart des mâchoires au

moment de prendre les mesures.

1. Régler le cadran à

la position

.

2. Raccorder le fil

d’essai rouge à la

borne V et le fi l

d’essai noir à la

borne COM.

3. Raccorder le fil

d’essai rouge à la

borne positive (+)

et le fi l d’essai noir

à la borne négative (–) du circuit

mis à l’essai. La

lecture s’affi che. Une connexion inversée fera

s’affi cher une valeur négative.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

12V

Mesure de la résistance, de la continuité et de

la capacité

DANGER Pour réduire le risque de

décharge électrique attribuable aux mesures

de la résistance, la continuité et la capacité,

ne jamais utiliser la pince sur un circuit sous

tension. S’assurer que le condensateur est

complètement déchargé avant d’y toucher ou

de tenter de prendre une mesure.

Résistance

1. Régler le cadran à la position .

2. Raccorder le fi l d’essai rouge

à la borne V et le fi l d’essai

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

noir à la borne COM.

S’assurer que l’indication

« OL » s’affi che sur l’écran,

puis court-circuiter le bout

des fi ls d’essais pour obtenir

l’indication « zéro ».

3. Raccorder les fi ls aux deux

extrémités de la résistance

mise à l’essai.

4. La lecture s’affi che.

ATTENTION Après avoir court-

circuité les fi ls d’essai, il est possible que la

valeur affi chée ne soit pas zéro en raison de

la résistance des fi ls d’essai.

Continuité

1. Régler le cadran à la position .

2. Raccorder le fi l d’essai rouge

à la borne V et le fi l d’essai

noir à la borne COM.

S’assurer que l’indication

« OL » s’affi che sur l’écran,

puis court-circuiter le bout

des fi ls d’essais pour

obtenir l’indication « zéro ».

L’avertisseur retentira.

3. Raccorder les fi ls d’essai

aux deux extrémités du

conducteur mis à l’essai. Si

la résistance mise à l’essai

est de 30 ou moins,

l’avertisseur retentira.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

Capacité

1. Régler le cadran à la position .

V

O

L

2. Raccorder le fi l d’essai rouge

à la borne V et le fi l d’essai

noir à la borne COM.

T

A

G

E

D

E

T

E

C

T

O

R

3. Décharger le condensateur.

4. Raccorder les fi ls d’essai aux

deux extrémités du condensateur mis à l’essai.

5. La lecture s’affi che.

Courant c.c. (N˚ de cat. 2238-20 seul.)

DANGER Pour éviter une décharge

électrique : Ne jamais prendre une mesure

sur un circuit dont la tension est supérieure

à 1 000 V.

Régler le cadran à la position .

« DC » (c.c.) s’affi che

.

2. Raccorder le fi l d’essai rouge à la borne A et

le fi l d’essai noir à la borne COM. Raccorder

le fi l d’essai rouge à la sonde du détecteur de

fl ammes et le fi l d’essai noir au module de com-

mande.

3. Mettre en marche l’appareil de chauffage. La

lecture s’affi che.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

Flame

sensor

probe

Control

Module

Le symbole

Température (N˚ de cat. 2238-20 seul.)

AVERTISSEMENT Ne jamais

raccorder une sonde thermique à un circuit

sous tension.

1. Régler le cadran à la position

2. Raccorder la sonde thermique de type K à la borne

.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

d’entrée. La borne positive

(+) de la sonde doit être raccordée à V.

3. Placer le capteur de la sonde

à l’empla-cement désiré.

4. La lecture s’affi che.

ATTENTION Lorsque le cadran

est réglé à la position , « OL » s’affi che.

Si une autre donnée s’affiche, le testeur

ne fonctionne pas correctement. Cesser

immédiatement son utilisation.

Hz Fréquence (N˚ de cat. 2239-20 seul.)

1. Régler le cadran à la position Hz.

2. Tension: Raccorder le fi l

d’essai rouge à la borne

V et le fi l d’essai noir à la

borne COM.

Raccorder les fi ls d’essai

au circuit mis à l’essai. La

lecture s’affi che.

Courant: Appuyer sur la

gâchette d’ouverture des

mâchoires pour ouvrir les

mâchoires et les fi xer sur le

conducteur mis à l’essai. La

lecture s’affi che.

NOTE : Ne pas pincer deux fi ls

ou plus à la fois. L’utilisateur

risque d’obtenir des résultats

inhabituels.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

14

15

Page 9

Fonction de pouvoir calorifi que

0N0N

D

R

O

T

E

C

T

E

V

A

G

E

O

T

L

inférieur sur sec (PCIS)

DANGER Il est possible que la DÉL

ne puisse s’affi cher en raison des conditions

d’installation du circuit électrique ou de

l’équipement. Ne jamais toucher le circuit mis

à l’essai afi n d’éviter tout danger, et ce, même

si la DÉL d’affi chage du pouvoir calorifi que

inférieur (PCIS) n’est pas allumée.

Vérifi er le bon fonctionnement de la DÉL

sur une source d’alimentation bien connue

avant de procéder aux mesures. Si la DÉL ne

s’allume pas, ne prendre aucune mesure.

Les données relatives au PCIS sont modifi ées

par la tension externe ainsi que par la façon

dont l’utilisateur tient ou place la pince.

Lorsque la pince est actionnée,

peu importe à quelle fonction elle

est réglée, le détecteur de tension

sans contact indiquera au moyen

d’une DÉL rouge qui apparaît à

l’écran la présence d’un champ

électrique de plus de 90 V. Placer

le rebord de la mâchoire identifi ée

« Détecteur de tension » près du

champ électrique.

Touche « HOLD » (RETENUE)

Fonction de retenue des données – Bloque la

valeur affi chée à l’écran. Appuyer sur le bouton

« HOLD » (RETENUE) pour bloquer la lecture. La

lecture sera maintenue sans tenir compte de variations subséquentes dans les entrées. L’indication

« HOLD » s’affi che avec la lecture. Pour quitter

le mode « Data Hold » (Retenue des données),

appuyer de nouveau sur le bouton « HOLD ». La

fonction « Hold » (Retenue) n’est pas disponible

au moment d’utiliser la fonction « Inrush » (Courant

d’appel).

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

Fonction « MIN/MAX » (MINIMUM/MAXIMUM)

ATTENTION Prendre une mesure

et appuyer sur le bouton « MIN/MAX »

(minimum/maximum) après avoir sélectionné

la plage appropriée à l’aide de la fonction de

plage automatique.

Le mode d’enregistrement « MIN/MAX »

permet de saisir les valeurs d’entrée

minimales et maximales.

Régler le cadran à la fonction de

mesure désirée. Prendre une mesure

et appuyer sur le bouton « MIN/MAX ».

Le multimètre saisit les lectures maximales et minimales. Appuyer sur le

bouton « MIN/MAX » afin de basculer entre les lectures minimales,

maximales et actuelles. Le bouton

« MIN/MAX » clignote lorsque la lecture actuelle s’affi che.

Pour quitter et effacer les lectures

enregistrées, appuyer sur le bouton

« MIN/MAX » pendant deux secondes

ou modifi er le cadran.

Si le bouton « MIN/MAX » est activé,

aucun bouton fonctionnel n’est disponible, sauf le

bouton « HOLD » (Retenue).

Fonction « ZERO » (ZÉRO)

(N˚ de Cat. 2239-20 seul.)

Courant c.a.

/courant c.c. :

Si l’affi cheur ACL n’affi che pas

ZÉRO lorsque les mâchoires

sont fermées, appuyer sur le

bouton « ZÉRO » pour mettre

l’affichage à ZÉRO avant de

prendre une mesure. En gardant

les mâchoires fermées et sans

les fi xer autour d’un conducteur,

appuyer sur la touche ZÉRO

pour remettre l’affi cheur à zéro.

Le symbole « ZÉRO » apparaît

sur l’affi cheur ACL afi n d’indiquer

que la fonction « ZÉRO » est

activée.

Bouton « °C/°F »

Pour choisir entre l’affi chage en degrés Fahrenheit

ou Celsius, appuyer sur le bouton « °C/°F ».

16

Press

Press

DANGER Pour éviter une décharge

électrique : Ne jamais prendre une mesure

sur un circuit dont la tension effi cace est

supérieure à 1 000 V.

Fonction « Courant d’appel »

(N˚ de Cat. 2239-20 seul.)

La mesure du courant d’appel permet de mesurer

la crête élevée du courant lors du démarrage du

moteur. Durant seulement une fraction de seconde,

la fonction « Courant d’appel » de MILWAUKEE

permet de saisir et d’affi cher les 100 premières

millisecondes du courant lors du démarrage du

moteur.

1. Éteindre le système mis à

l’essai.

2. Appuyer sur la gâchette

d’ouverture des

mâchoires pour ouvrir

les mâchoires et les

fi xer sur le conducteur mis à l’essai.

NOTE : Ne pas

pincer deux fils

ou plus à la fois.

L’utilisateur risque d’obtenir des résultats inhabituels.

3. Régler le cadran rotatif à

la position ou . Le

symbole « AC » (c.a.) ou

« DC » (c.c.) s’affi che.

4. Appuyer sur le bouton

« INRUSH » (Courant

d’appel).

5. Mettre en marche

le système sous

tension.

6. La lecture s’affi che.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

0FF 0FF

Indicateur de dépassement

Chaque fois que les données saisies excèdent la

plage de mesure, les signaux « OL » ou « –OL »

s’affi chent.

DÉL « ON/OFF » (MARCHE/ARRÊT) de la

lampe de travail

Pour allumer et éteindre la lumière, appuyer sur

la gâchette.

Mode veille

A TTENTION

Les données retenues cessent de l’être lorsque la pince passe en mode « veille ».

La pince s’éteint automatiquement environ 20

minutes après que le cadran rotatif ou les boutons

aient été actionnés pour la dernière fois. Pour

réinitialiser, tourner le cadran rotatif ou tirer sur la

gâchette. Si l’affi cheur est toujours vide au moment

de sélectionner un nouveau réglage du cadran

rotatif, charger le bloc-piles.

Pour désactiver le mode veille, éteindre l’outil. Appuyer sur le bouton « HOLD » (Retenue) et le tenir

enfoncé et mettre le multimètre en marche. Lorsque

le multimètre émet un signal sonore, relâcher le

bouton « HOLD » (Retenue). Le multimètre sonnera à nouveau et le symbole « Clock » (Horloge)

sera effacé de l’affi cheur.

La pince utilise les piles même en mode veille.

S’assurer de régler l’interrupteur de l’outil à la position « OFF » (Arrêt) afi n de conserver l’énergie

des piles.

ACCESSOIRES

AVERTISSEMENT Toujours retirer

les piles avant de changer ou de retirer des

accessoires. Utiliser seulement des accessoires conçus spécialement pour cet outil.

L’utilisation d’autres types d’accessoires peut

s’avérer dangereuse.

Pour obtenir une liste complète des accessoires,

consulter le catalogue des outils électriques de

MILWAUKEE ou visiter le site www.milwaukeetool.

com. Pour obtenir un catalogue, communiquer avec

le distributeur local ou un centre de réparations

indiqué au dos du présent manuel d’utilisation.

17

Page 10

ENTRETIEN

AVERTISSEMENT Pour minimiser

les risques de blessures corporelles, débranchez le chargeur et retirez la batterie

du chargeur ou de l’outil avant d’y effectuer

des travaux d’entretien. Ne démontez jamais

l’outil, la batterie ou le chargeur. Pour toute

réparation, consultez un centre de service

MILWAUKEE accrédité.

Entretien de l’outil

Garder l’outil en bon état en suivant un programme

d’entretien régulier. Après un an, il est recommandé de confi er l’outil à un centre de réparations

MILWAUKEE aux fi ns d’étalonnage.

Si l’outil ne démarre pas ou ne fonctionne pas à

pleine puissance alors qu’il est branché sur une

batterie complètement chargée, nettoyez les points

de contact entre la batterie et l’outil. Si l’outil ne

fonctionne toujours pas correctement, renvoyez

l’outil, le chargeur et la batterie à un centre de service MILWAUKEE accrédité, afi nqu’on en effectue

la réparation (voir “Réparations”).

AVERTISSEMENT Pour minimiser

les risques de blessures ou de dommages à

l'outil, n'immergez jamais l'outil, la batterie

ou le chargeur et ne laissez pas de liquide

s'y infi ltrer.

Nettoyage

Débarrassez les évents du chargeur et de l’outil

des débris et de la poussière. Gardez les poignées

de l’outil propres, à sec et exemptes d’huile ou de

graisse. Le nettoyage de l’outil, du chargeur et de

la batterie doit se faire avec un linge humide et un

savon doux. Certains nettoyants tels l’essence, la

térébenthine, lesdiluants à laque ou à peinture, les

solvants chlorés, l’ammoniaque et les détergents

d’usage domestique qui en contiennent pourraient

détériorer le plastique et l’isolation des pièces. Ne

laissez jamais de solvants infl ammables ou com-

bustibles auprès de l’outil.

Réparations

Pour les réparations, retournez outil, batterie et chargeur en entier au centre-service le plus près, selon la

liste apparaissant à la derniè page de ce manuel.

GARANTIE LIMITÉE DE CINQ ANS

Les produits d’essai et de mesure MILWAUKEE (y compris l’outil, les blocs-piles au lithium-ion et le chargeur, mais non les piles alcalines) sont garantis à l’acheteur d’origine être exempts de vice du matériau

et de fabrication. Sous réserve de certaines exceptions, MILWAUKEE réparera ou remplacera toute

pièce de ce produit qui, après examen par MILWAUKEE, s’avère être affectée d’un vice du matériau ou

de fabrication, pendant une période de cinq (5) ans* après la date d’achat. Retourner l’outil d’essai et de

mesure, accompagné d’une copie de la preuve d’achat, au centre de réparations en usine MILWAUKEE

(société d’outils électriques) le plus près. Cette garantie ne couvre pas les dommages que MILWAUKEE

détermine être causés par des réparations ou des tentatives de réparation par quiconque autre que le

personnel agréé par MILWAUKEE, des utilisations incorrectes, des altérations, des utilisations abusives,

une usure normale, une carence d’entretien ou les accidents.

*La période de la garantie du bloc-piles au lithium-ion qui est fourni avec l’outil d’essai et de mesure est

de deux (2) ans à compter de la date d’achat. *La pile alcaline qui est fournie avec l’outil d’essai et de

mesure bénéfi cie d’une garantie distincte accordée par le fabricant de la pile. *La période de la garantie

d’un DÉTECTEUR DE TENSION SANS CONTACT – 2201-20 est d’un (1) an à partir de la date d’achat.

L’enregistrement de la garantie n’est pas nécessaire pour bénéfi cier de la garantie en vigueur sur un produit

MILWAUKEE. La date de fabrication du produit servira à établir la période de garantie si aucune preuve

d’achat n’est fournie lorsqu’une demande de service sous garantie est faite.

L’ACCEPTATION DES RECOURS EXCLUSIFS DE RÉPARATION ET DE REMPLACEMENT DÉCRITS

AUX PRÉSENTES EST UNE CONDITION DU CONTRAT D’ACHAT DE TOUT PRODUIT MILWAUKEE.

SI VOUS N’ACCEPTEZ PAS CETTE CONDITION, VOUS NE DEVEZ PAS ACHETER LE PRODUIT.

EN AUCUN CAS MILWAUKEE NE SAURAIT ÊTRE RESPONSABLE DE TOUT DOMMAGE ACCESSOIRE, SPÉCIAL OU INDIRECT, DE DOMMAGES-INTÉRÊTS PUNITIFS OU DE TOUTE DÉPENSE,

D’HONORAIRES D’AVOCATS, DE FRAIS, DE PERTE OU DE DÉLAIS ACCESSOIRES À TOUT DOMMAGE, DÉFAILLANCE OU DÉFAUT DE TOUT PRODUIT, Y COMPRIS NOTAMMENT LES PERTES

DE PROFIT. CETTE GARANTIE EST EXCLUSIVE ET REMPLACE TOUTE AUTRE GARANTIE OU

CONDITION, ÉCRITE OU VERBALE, EXPRESSE OU IMPLICITE. SANS LIMITER LA GÉNÉRALITÉ

DES DISPOSITIONS PRÉCÉDENTES, MILWAUKEE DÉCLINE TOUTE GARANTIE IMPLICITE DE

QUALITÉ MARCHANDE OU D’ADAPTATION À UNE UTILISATION OU À UNE FIN PARTICULIÈRE ET

TOUT AUTRE GARANTIE.

Cette garantie s’applique aux produits vendus aux États-Unis, au Canada et au Mexique uniquement.

18

INSTRUCCIONES IMPORT ANTES

DE SEGURIDAD

ADVERTENCIA LEA TODAS LAS ADVERTENCIAS Y LAS INSTRUCCIONES

DE SEGURIDAD.

una descarga eléctrica, un incendio y/o lesiones graves, así como daños al instrumento y/o

daños al equipo que se está probando.

Guarde estas instrucciones: Este manual del operador contiene instrucciones importantes

de seguridad y funcionamiento para Medidores de pinza MILWAUKEE. Antes de usarlos, lea

este manual del operador, su manual del operador del paquete de baterías y del cargador, y

todas las etiquetas del paquete de baterías, del cargador y los medidores de pinza.

PELIGRO Nunca efectúe una medición en un circuito que tenga un voltaje superior a

una de 1 000 V. Use únicamente conductores con clasifi cación de 1 000 V o más.

No intente efectuar mediciones cuando haya gases infl amables. De lo contrario, el uso del

instrumento puede provocar chispas, y ocasionar una explosión.

Las puntas de mordazas del transformador están diseñadas para no cortar el circuito que se está

probando. Sin embargo, si el equipo que se está probando tiene piezas conductoras expuestas,

se debe tener precaución adicional para minimizar la posibilidad de hacer cortocircuito.

Nunca intente usar el instrumento si la superfi cie de este, o su mano, están húmedas.

No exceda la entrada máxima permisible de ningún campo de medición.

Realice la comprobación únicamente en circuitos no energizados, a menos que sea

absolutamente necesario.

Primero, pruebe la funcionalidad de la herramienta en un circuito conocido. Nunca suponga

que la herramienta está funcionando. Suponga que los circuitos están activos hasta que pueda

comprobar que están desenergizados.

Durante la medición, no actúe como conector a tierra. Evite el contacto corporal con superfi cies

con puesta a masa o conexión a tierra, como tuberías, radiadores, estufas y refrigeradores.

Nunca retire la batería durante una medición.

El instrumento debe utilizarse únicamente en las aplicaciones o condiciones para las que fue

diseñado. De lo contrario, las funciones de seguridad que están incluidas en el instrumento no

funcionan, y podrían provocar daños al instrumento o lesiones personales graves.

Para disminuir el riesgo de lesión provocada por una descarga y ráfagas de arco, use equipo

de protección personal donde haya conductores con corriente expuestos.

ADVERTENCIA Nunca intente efectuar mediciones si se encuentra ante condiciones

anormales, tales como una caja rota y piezas de metal expuestas en el instrumento.

No gire el selector giratorio en el momento en el que los conductores de prueba se estén

conectando.

Verifi que el funcionamiento adecuado en una fuente conocida antes de usar el instrumento o

tomar alguna medida como resultado de la indicación proporcionada por el instrumento.

No instale piezas sustitutas ni haga modifi caciones en el instrumento. Para su reparación o

recalibración, envíe la herramienta a una sucursal de soporte de servicio/ventas de fábrica o

a un centro de servicio autorizado.

No trate de reemplazar las baterías si la superfi cie del instrumento está húmeda.

Desconecte todos los cables y las conexiones del objeto que se está probando y apague el

instrumento antes de retirar o introducir la batería.

Recargue la batería solamente con el cargador especifi cado por el fabricante. Un cargador apro-

piado para un tipo de batería puede crear riesgo de incendio cuando se usa con otra batería.

Use las herramientas eléctricas solamente con baterías específi camente diseñadas. El uso de

cualquier otro tipo de batería puede crear riesgo de lesiones e incendio.

Cuando no se use la batería manténgala alejada de otros objetos de metal como clips para papel,

monedas, llaves, clavos, tornillos u otros objetos de metal pequeños que puedan realizar una

conexión entre los terminales. Realizar un cortocircuito en los terminales de la batería puede

provocar quemaduras o un incendio.

El incumplimiento de las advertencias e instrucciones, puede provocar

19

Page 11

En condiciones abusivas, puede salir líquido expulsado de la batería; evite el contacto. Si se

Hz

produce un contacto accidental, lávese con agua. Si el líquido entra en contacto con los ojos,

además busque atención médica. El líquido que sale expulsado de la batería puede provocar irritaciones o quemaduras.

PRECAUCIÓN

Confi gure el selector giratorio en una posición adecuada antes de iniciar la medición.

Introduzca fi rmemente los conductores de prueba.

Desconecte los conductores de prueba del instrumento para obtener la medición de corriente.

No exponga el instrumento a la luz solar directa, altas temperaturas, humedad ni rocío.

Para funcionar a una altitud de 2 000 m o menos. La temperatura de funcionamiento adecuada

oscila entre -10 ºC y 50 ºC.

Este instrumento no es a prueba de polvo ni agua. Manténgalo lejos del polvo y el agua.

Asegúrese de apagar el instrumento después de usarlo. Si no se usará el instrumento durante

un tiempo prolongado, retire las baterías antes de guardarlo.

Use un paño humedecido con agua o con detergente neutro para limpiar el instrumento. No

use abrasivos ni solventes.

Funciones

Posición del

selector

Corriente

alterna

Corriente

continua

Voltaje corr.

alt.

Voltaje corr.

cont.

Resistencia 600 /6000 /60 k/600 k 0.1 /1 /10 /0.1 k ±1%rdg±2dgt

Continuidad 600,0 0.,1 El zumbador suena a 30 o menos

Capacitancia 400F/4000F 0,1F/1F

uA Corr. 2238-20: 600,0 uA 0,1uA ±1,5%rdg±5dgt

Temperatura

Hertzios

Hz

Estos instrumentos miden el valor cuadrático medio (root mean square, RMS) exacto. Todas las lecturas de •

voltaje y corriente son valores cuadráticos medios exactos.

Impedancia de entrada: •

Voltaje de corr. cont.: 1 MΩ

Voltaje de corr. alt.: 1 MΩ

Protección contra sobrecargas: •

Rango de voltaje de corr. alt./voltaje de corr. cont.: 1 200 V de corr. alt. RMS

Rango de corriente de la pinza: •

720 A de corr. alt. RMS/corr. cont. 10 s (Cat. No. 2238-20 únicamente)

1 200 A de corr. alt. RMS/corr. cont. 10 s (Cat. No. 2239-20 únicamente)

Corriente de irrupción (Cat. No. 2239-20 únicamente): tiempo de integración menor o igual que 100 ms•

ACV: 600 Hz, 6 kHz, 60 kHz

Rango Resolución Precisión

2238-20: 60/600 A 0,01/0,1 A

2239-20: 60/600/1000 A 0,01/0,1/1 A

2239-20: 60/600/1000 A 0,01/0,1/1 A ±2%rdg±5dgt

600 V 0,1 V

1000 V 1 V

600 V 0,1 V

1000 V 1 V

2238-20: -40°C - 538°C 0,1°C ±1%±10dgt

2238-20: -40°F - 1000°F 0,1°F ±1%±18dgt

2239-20:

ACA: 600 Hz, 6 kHz

2239-20:

0,1 Hz; 1Hz

0,1 Hz; 1 Hz; 10 Hz

±1,9%rdg ±5dgts, 50Hz/60Hz

±3,0%rdg ±5dgts, 45Hz a 500Hz

Agregue 2% a CF>2

*

±1,2%rdg ±5dgts, 50Hz/60Hz

±1,8%rdg ±5dgts, 45Hz a 500Hz

±1%rdg±2dgt

±2,5%±20dgt

a 60F

Sensibilidad: Amperaje 5 A RMS;

La medición mínima en Hertzios es 10 Hz

±1%rdg±1dgt

Voltios: 30 V RMS

Especifi caciones generales

La precisión está especifi cada para 1 año después

de la calibración, a temperaturas de funcionamiento

entre 18 °C y 28 °C (entre 64 °F y 82 °F), con una

humedad relativa entre 0% y 85%.

Voltaje máximo entre cualquier terminal y la

conexión a tierra.... 1 000 V

Abertura de mordazas (tamaño máximo de

conductor) .... Aprox. 33 mm (1,3")

Temperatura ....

Funcionamiento: entre -10 °C y 50 °C (entre

14 °F y 122 °F)

Almacenamiento: entre -40 °C y 60 °C (entre

-40 °F y 140 °F)

Coefi ciente de temperatura .... 0,1 x (precisión

especifi cada)/°C (<18 °C o >28 °C)

Altitud de funcionamiento.... 2 000 metros

Prueba de caída .... 1 metro

Cumplimiento con las normas de seguridad ....

EN61010-1, UL 61010-1, EN61010-031 (sondas), IEC 61010-2-32 (conjunto de pinzas),

IEC/EN 61010-1 2da edición para mediciones

Categoría III, 1000 V, Categoría IV, 600 V, Grado

de contaminación 2, EMC EN61326-1

Certifi caciones .... cULus, CE

Voltaje: 12 corr. cont. Li-Ion, MILWAUKEE Cat.

Nos. 48-11-2401, 48-11-2402

Tiempo de funcionamiento de batería: Más de

12 h con todas las funciones

DESCRIPCIÓN FUNCIONAL

Cat. No.

2239-20

1

4

6

7

8

V

O

2

L

T

A

G

E

1. Mordazas sensoras

D

E

T

E

C

T

O

R

de corriente

2. Área de detección NCVD

3. Indicador NCVD

4. Botón °F/°C (2238-20)

Botón Zero (cero) (2239-20)

3

5. Botón Inrush

5

(Corriente de irrupción) (2239-20)

6

6. Selector giratorio

7. Pantalla

8. Botón Hold (retención)

9. Botón MIN/MAX (mínimo/máximo)

Cat. No.

2238-20

10. Lámpara de trabajo LED

11. Gatillo de abertura de mordazas

12. Entradas de terminales

9

Cat III

Cat IV

10

Simbología

Para reducir el riesgo de lesiones, el

usuario debe leer el manual del operador.

Doble aislamiento

Riesgo de descarga eléctrica

Indica que este instrumento puede fi jarse

en conductores desnudos cuando se mide

un voltaje correspondiente a la categoría

de medición aplicable que está marcada

junto a este símbolo.

Tierra

Peligro, advertencia o precaución Consulte el manual del operador si

necesita más información de seguridad.

Volts Direct Current

Marca de Conformidad Europea

Underwriters Laboratories, Inc.,

Estados Unidos y Canadá

Clasifi cación de sobrevoltajes transito-

rios, basada en el voltaje nominal de

línea a tierra.

No deseche este producto como residuos municipales sin clasifi car.

11

12

20

21

Page 12

ENSAMBLAJE

ADVERTENCIA Recargue la batería

sólo con el cargador especifi cado para ella.

Para instrucciones específi cas sobre cómo

cargar, lea el manual del operador suministrado con su cargador y la batería.

Inserción/Extracción de la batería

Para retirar la batería,

use un destornillador

Fig. 1

de punta plana a fi n de

abrir el pestillo de traba.

Presione los botones

de liberación y jale de

la batería para sacarla

Pestillo de traba

de la herramienta.

Para insertar la batería en la herramienta, deslícela

sobre el cuerpo de la herramienta. Asegúrese de que

se asegura bien en su posición. Presione el pestillo

de traba para asegurar la batería en su lugar.

FUNCIONAMIENTO

ADVERTENCIA Siempre gire el

selector giratorio a la posición OFF (apagado)

antes de introducir o retirar las sondas. Utilice

únicamente accesorios específicamente

recomendados para esta herramienta. El

uso de accesorios no recomendados podría

resultar peligroso.

Use únicamente conductores de prueba

MILWAUKEE con los Medidores de Pinza.

Inspeccione la continuidad de los conductores de prueba antes de cada uso. No use

la herramienta si las lecturas son altas o

ruidosas.

Antes de usarlo

Asegúrese de que el selector giratorio esté

configurado en la posición correcta, que el

instrumento esté confi gurado en el modo correcto

de medición y que la función de retención de

datos esté desactivada. De lo contrario, no puede

efectuarse la medición deseada.

Cómo efectuar una medición

Corr. alt.

PELIGRO Para evitar descargas eléc-

tricas: Nunca efectúe una medición en un circuito que tenga un voltaje superior a una de 1

000 V. Las puntas de la pinza están diseñadas

para no cortar el circuito que se está probando.

Sin embargo, si el equipo que se está probando

tiene piezas conductoras expuestas, se debe

tener precaución adicional para minimizar la

posibilidad de hacer cortocircuito.

PELIGRO Desconecte los conduc-

tores de prueba del instrumento para obtener

la medición de corriente.

1. Confi gure el selector giratorio en la

posición . La marca AC (corr. alt.)

se muestra en la pantalla.

2. Presione el gatillo de abertura de

mordazas para abrir las mordazas

y sujete con ellas el conductor que

se está probando. La lectura se

muestra en la pantalla.

NOTA: No sujete 2 o más cables

al mismo tiempo. Se arrojarán

resultados irregulares.

PRECAUCIÓN El tamaño máximo del

conductor es de, aproximadamente, 33 mm

(1,3") de diámetro. Durante la medición,

mantenga las mordazas completamente

cerradas para asegurar la obtención de

mediciones precisas.

Corr. cont. (Cat. No. 2239-20, únicamente)

PELIGRO Para evitar descargas

eléctricas: Nunca efectúe una medición en

un circuito que tenga un voltaje superior a

una de 1 000 V.

1. Confi gure el selector giratorio en

la posición

cont.) se muestra en la pantalla.

. La marca DC (corr.

2. Con las mordazas cerradas y sin

sujetarlas al conductor, presione

la tecla ZERO (cero) para ajustar

la pantalla.

3. Presione el gatillo de abertura de

mordazas para abrir las mordazas

y sujete con ellas el conductor que

se está probando.

NOTA: No sujete 2 o más cables

al mismo tiempo. Se arrojarán

resultados irregulares.

4. La lectura se muestra en la pantalla.

5. Presione la tecla ZERO (cero) nuevamente para

liberar la función ZERO (cero).

PRECAUCIÓN Cuando la corriente

fl uye desde el lado de la pantalla hacia la parte

inferior del medidor, la polaridad es positiva;

cuando fl uye desde la parte inferior hacia el

lado de la pantalla, la polaridad es negativa.

22

Voltaje corr. alt.

PELIGRO Para evitar descargas

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

eléctricas: Nunca efectúe una medición en

un circuito que tenga un voltaje superior a

una de 1 000 V.

Mantenga los dedos lejos de las mordazas,

cuando efectúe una medición.

V

1. Confi gure el selector gira-

torio en la posición

2. Conecte el conductor de

.

O

L

T

A

G

E

D

E

T

E

C

T

O

R

prueba rojo al terminal V

y el conductor de prueba

negro al terminal COM.

3. Conecte los conductores

de prueba al circuito que

se está probando. La lec-

Resistencia

1. Confi gure el selector giratorio

en la posición .

2. Conecte el conductor de

prueba rojo al terminal V y

el conductor de prueba negro

al terminal COM.

Asegúrese de que se indique

“OL” en la pantalla y, luego,

cortocircuite las puntas de los

conductores de prueba para

que la indicación quede en

cero.

3. Conecte los conductores de

prueba a ambos extremos

del resistor que se está probando.

4. La lectura se muestra en la pantalla.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

tura se muestra en la

pantalla.

PRECAUCIÓN Después de

cortocircuitar los conductores de prueba,

es posible que el valor que se muestra en la

Voltaje corr. cont.

PELIGRO Para evitar descargas

eléctricas: Nunca efectúe una medición en

un circuito que tenga un voltaje superior a

una de 1 000 V.

Mantenga los dedos lejos de las mordazas,

cuando efectúe una medición.

pantalla no sea cero, debido a la resistencia

propia de los conductores de prueba.

Continuidad

1. Confi gure el selector giratorio

en la posición .

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

2. Conecte el conductor de

prueba rojo al terminal V y

el conductor de prueba negro

1. Confi gure el selector giratorio en la posición .

2. Conecte el conduc-

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

tor de prueba rojo

al terminal V y el

conductor de prueba

negro al terminal

COM.

V

O

L

T

A

G

E

D

E

T

E

C

T

O

R

12V

3. Conecte el conductor

de prueba rojo al lado

positivo (+) y los conductores de prueba

negros al lado negativo (-) del circuito que

se está probando. La

lectura se muestra en la pantalla. Una conexión

invertida se indica con un valor negativo.