OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Cat. No. / No de cat.

2236-20, 2237-20

CLAMP METERS

PINCE AFFICHEUR DE COURANT

MEDIDORES DE PINZA

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT An de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

WARNING

WARNING

IMPORTANT

SAFETY

INSTRUCTIONS

READ ALL SAFETY WARNINGS AND INSTRUCTIONS.

Failure to follow the warnings and instructions

may result in electric shock, re and/or serious

injury, as well as instrument damage and/or dam-

age to the equipment being tested.

Save these instructions - This operator’s manual

contains important safety and operating instructions for the MILWAUKEE Clamp Meters. Before

using, read this operator’s manual and all labels

on the Clamp Meters.

DANGER

Never make measurement on a circuit in which

voltage over AC600V exists. Use only leads rated

600V or better.

Do not attempt to make measurement in the pres-

ence of ammable gasses. Otherwise, the use of

the instrument may cause sparking, which can

lead to an explosion.

Transformer jaw tips are designed not to short the cir-

cuit under test. If equipment under test has exposed

conductive parts, however, extra precaution should

be taken to minimize the possibility of shorting.

Never attempt to use the instrument if its surface

or your hand is wet.

Do not exceed the maximum allowable input of

any measuring range.

Only test on unenergized circuits unless abso-

lutely necessary.

Check tool functionality on a known circuit rst.

Never assume tool is working. Assume circuits are

live until they can be proven de-energized.

Do not ground yourself while measuring. Avoid

body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators.

Never open the Battery cover during a measurement.

The instrument is to be used only in its intended

applications or conditions. Otherwise, safety func-

tions equipped with the instrument doesn’t work,

and instrument damage or serious personal injury

may be caused.

To reduce the risk of injury from shock and arc

blasts, always wear personal protective equipment

where live conductors are exposed.

Never attempt to make measurement if any abnormal conditions, such as broken case and exposed

metal parts are found on the instrument.

Do not rotate the Rotary Dial while the test leads

are being connected.

Verify proper operation on a known source before

use or taking action as a result of the indication

of the instrument.

Do not install substitute parts or make any modication to the instrument. For repair or re-calibration, return the tool to a factory Service/Sales

Support Branch or authorized service station.

Do not try to replace the batteries if the surface of

the instrument is wet.

Disconnect all the cords and cables from the object

under test and power off the instrument before

opening the Battery Cover for Battery replacement.

This tool is designed to be powered by 2-AA batter-

ies properly inserted into the MILWAUKEE Clamp

Meters. Do not attempt to use with any other voltage or power supply.

Install battery according to polarity (+ and –) diagrams.

Do not leave batteries within the reach of children.

Do not mix new and used batteries. Do not mix

brands (or types within brands) of batteries.

Properly dispose of used batteries.

Do not incinerate or dismantle batteries.

Under abusive conditions, liquid may be ejected

from the battery, avoid contact. If contact accidentally occurs, ush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

CAUTION

Set the Rotary Dial to an appropriate position

before starting measurement.

Firmly insert the test leads.

Disconnect the test leads from the instrument for

current measurement.

Do not expose the instrument to the direct sun,

high temperature and humidity or dew fall.

Altitude 2000m or less. Appropriate operating

temperature is within -10ºC and 50ºC.

This instrument isn’t dust & water proofed. Keep

away from dust and water.

Be sure to power off the instrument after use. When

the instrument will not be in use for a long period,

place it in storage after removing the batteries.

Use a cloth dipped in water or neutral detergent

for cleaning the instrument. Do not use abrasives

or solvents.

GENERAL SPECIFICATIONS

Cat. No. ...................................... 2236-20, 2237-20

Accuracy is specied for 1 year after calibration, at

operating temperatures of 64°F to 82°F (18°C to

28°C), with relative humidity at 0 % to 85 %.

Maximum voltage between any

terminal and earth ground ...................... 600 V

Jaw Opening .......................approx. 1.3" (33 mm)

(maximum conductor size)

Temperature

Operating .............14°F to 122°F (-10°C to 50°C)

Storage .............. -40°F to 140°F (-40°C to 60°C)

Temperature Coefcient ...............................0.1 x

Operating Altitude ............................2,000 meters

Drop Test ................................................... 1 Meter

Battery ........................ 2 AA, NEDA 15 A,IEC LR6

Battery Life ..............Approx. 30 Hours all lights on

Safety Compliances .......UL/CSA 61010-1 3rd Ed

UL/CSA 61010-2-032 1st Edition (Clamp Assemblies)

Certications............................................... cULus

2

(specied accuracy)/°C (<18°C or >28°C)

UL/CSA/IEC/EN 61010-031 1st Ed + A1 (Probes)

UL/CSA 61010-2-033 1st Ed (Meters)

Measurement Category III, 600V

Pollution Degree 2, EMC EN61326-1

C

US

FUNCTIONS

Dial Position Range Resolution Accuracy

Voltage DC 60/600V 0.01V/0.1V ±1.0%rdg±3dgt

Voltage AC 0.0 to 600.0V 0.1V

0 to 600.0A

Current AC

Current DC

(2237-20)

Resistance 600Ω/6kΩ 0.1Ω/0.001kΩ ±1.0%rdg±5dgt

Capacitance

Continuity

uA Current

DC uA (2236-20)

Temperature

(2236-20)

Hertz (2237-20)

Hz

* These instruments are True-RMS sensing. All voltage and current readings are True-RMS values.

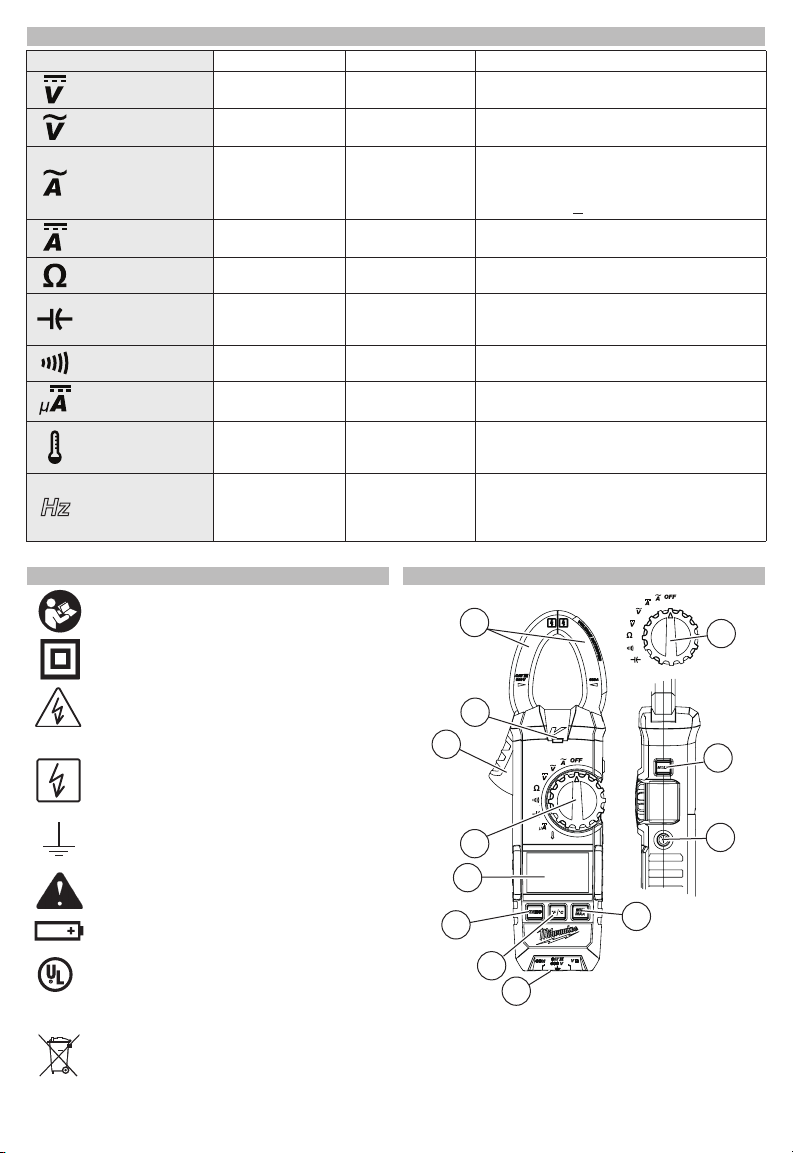

SYMBOLOGY

Peak 1500A

CF=2.5@600A

CF=3.0@500A

0.1A

0-600.0A 0.1A ±1.5%rdg±5dgt

0.01nF - 4000μF

Auto-ranging

Cont Buzzer

0-600.0Ω

0.01nF/0.1nF/

0.001μF/0.01μF/

0.1μF/1μF

0-600.0uA 0.1uA ±1.5%rdg±5dgt

-40C - 400C

-40F - 32.0F

32.1F - 752F

ACA: 40-400Hz,

ACV: 1Hz-10kHz

0.1C

0.1F

0.001/0.01/0.1Hz

0.001/0.01kHz

FUNCTIONAL DESCRIPTION

±1.5%rdg±4dgt (50/60Hz)

±3.5%rdg±5dgt (40~400Hz)

±2.0%rdg±5dgt(50/60Hz)

±3.5%rdg±5dgt(40 ~ 400Hz)

* Add 2% at CF>2

* < 5A, add 3dgt

0.01nF-39.99nF ±2.5%±2nF

40.00nF-1000uF ±2.5%±20dgt

1000uF> ±5%±20dgt

Buzzer sounds at 35Ω ±10Ω or 25Ω or

-40.0F to 20.0F; ±1.5%F ±4F

20.1F to 752F; ±1.5%F ±2F

ACA: 40-400Hz ±0.5%rdg±5dgt

ACV:1Hz-10kHz ±0.5%rdg±5dgt

* Minimum Measurable inputs are: 70

Vrms for VAC or 50 Arms for ACA

less

±1.0%C ±2.0C

Read Operator's Manual

Double insulation

Risk of electric shock

Indicates that this instrument can clamp

on bare conductors when measuring a

voltage corresponding to the applicable

measurement category, which is

marked next to this symbol.

Earth (Ground)

Danger, Warning, or Caution Consult the operator's manual for

additional safety information.

Battery compartment

Do not dispose of this product as

unsorted municipal waste.

UL Listing for Canada and U.S

Cat III

Classication of transient overvoltages,

based on nominal line voltage to earth.

1

Cat. No.

2236-20

2

3

4

5

6

7

8

1. Current sensing jaws

2. NCVD indicator

3. Jaw opening trigger

4. Rotary Dial

5. Display

6. Zero button

3

4

Cat. No.

2237-20

11

10

9

7. °F/°C button (2236-20)

Hz button (2237-20)

8. Terminal inputs

9. Min/Max button

10. Worklight LED

11. Hold button

DANGER

DANGER

ASSEMBLY

WARNING

WARNING

DANGER

To avoid an electrical hazard, turn

nect the test leads before replacing batteries.

Loading/Changing the Batteries

Replace batteries when the Low Battery indicator

is displayed.

1. Turn Rotary Dial to OFF and

disconnect the test leads.

2. Unscrew and remove battery door.

3. Insert two (2) AA batteries,

according to the polarity

marked in the battery compartment

4. Close the battery door and

tighten screw securely.

the Rotary Dial to OFF and discon-

OPERATION

Only use MILWAUKEE test leads

Inspect test leads before each use. Use clamp

meter to run a continuity test.

Conrm the Rotary Dial is set to the correct position, the instrument is set to the correct measurement mode, and the Data hold function is disabled.

Otherwise, desired measurement cannot be made.

The LCD backlight will turn off after about 3 minutes

of inactivity. Push any button or turn the rotary dial

to turn the backlight on.

cuit in which voltage over AC600V exists. Clamp

tips are designed not to short the circuit under

test. If equipment under test has exposed conductive parts, however, extra precaution should

be taken to minimize the possibility of shorting.

Do not use with the Battery Cover removed.

Disconnect the test leads from the instrument for

current measurement.

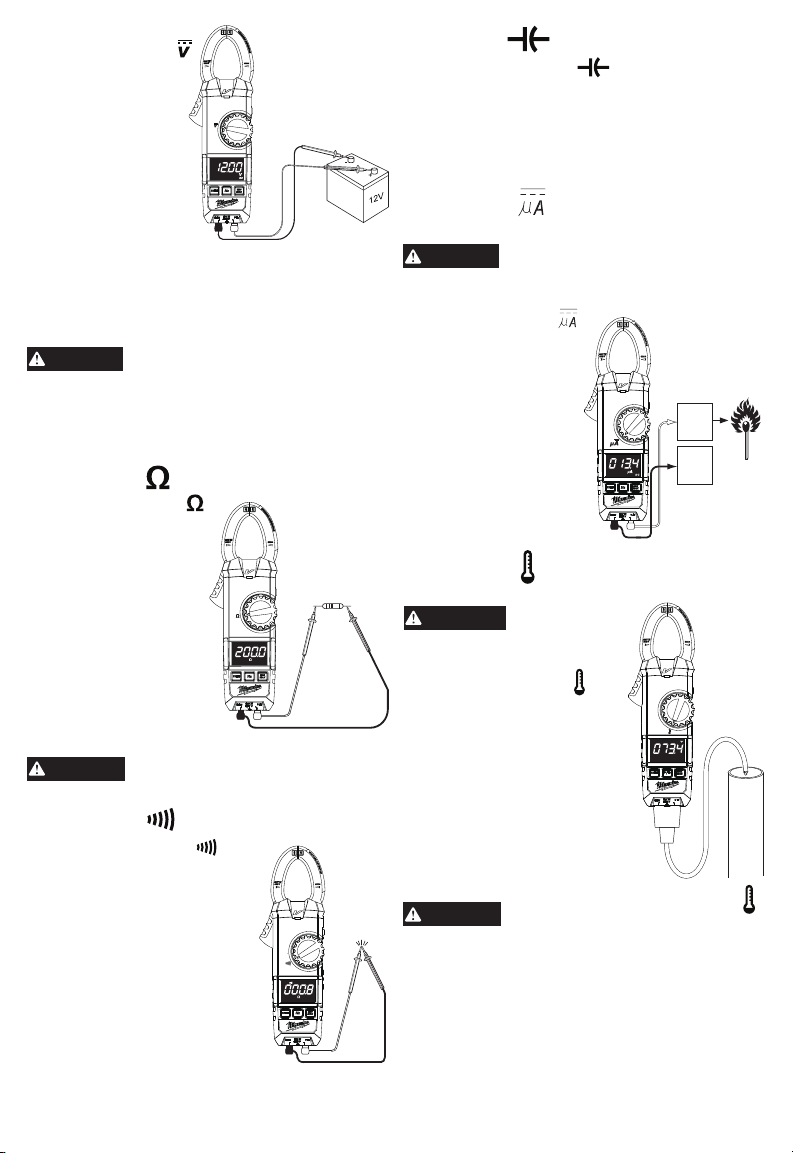

1. Set the Rotary Dial to position.

AC mark is displayed.

2. Press the jaw opening trigger to

open the jaws and clamp them onto

the conductor under test. The reading is displayed.

Cat. No. 2237-20 only: Pressing

the “Hz” Key toggles the reading

between AC Current and Hz.

NOTE: Hz Function requires 50A or

more.

NOTE: Do not clamp over 2 or more

wires at the same time. Irregular

results will occur.

CAUTION

ment, keep the jaws fully closed to ensure accurate measurements.

with the MILWAUKEE Clamp Meters.

Before Use

LCD Backlight

Making a Measurement

AC Current

To avoid electrical shock:

Never make measurement on a cir-

Maximum conductor size is about

1.3" diameter. During measure-

DC Current

(Cat. No. 2237-20 only)

To avoid electrical shock:

circuit in which voltage over AC600V exists.

Do not use with the Battery Cover removed.

1. Set the Rotary Dial to position.

DC mark is displayed.

2. With the jaws closed and without

clamping them around a conductor,

press the ZERO key to zero adjust

the display.

3. Press the jaw opening trigger to

open the jaws and clamp them

around the conductor under test.

The reading is displayed.

NOTE: Do not clamp over 2 or more

wires at the same time. Irregular

results will occur.

4. Set the Rotary Dial to an appropriate position according to current under test.

5. Press the ZERO key again to release the ZERO

function.

CAUTION

meter, the polarity is positive; ow from underside to display side, the polarity is negative.

Never make measurement on a

When current ows from the display side to the underside of the

AC Voltage

To avoid electrical shock:

circuit in which voltage over AC600V exists.

Do not use with the Battery Cover removed.

Keep ngers away from jaws during measure-

ments.

1. Set the Rotary Dial to

tion.

2. Connect the red test lead to

the VΩ terminal and the black

test lead to the COM terminal.

3. Connect the test leads to the

circuit under test. The reading

is displayed.

Cat. No. 2237-20 only: Press-

ing the Hz Key toggles the

reading between AC Voltage

and Hz. NOTE: Hz Function

requires 70V or more.

CAUTION

ronments.

Never make measurement on a

posi-

AC

Readings of frequency may uctuate or be inuenced in noisy envi-

DC Voltage

DANGER

circuit in which voltage over DC600V exists.

Do not use with the Battery Cover removed.

Keep ngers away from jaws during measure-

ments.

To avoid electrical shock:

Never make measurement on a

4

1.

WARNING

Set the Rotary Dial to

position.

2. Connect the red test

lead to the VΩ terminal and the black

test lead to the COM

terminal.

3. Connect the red test

lead to the positive

(+) side and black

test leads to the

negative (-) side

of the circuit under

test. The reading is displayed. A reversed connection is indicated as a negative value.

Resistance/Continuity/Capacitance

Measurements

DANGER

Capacitance measurements, never use the meter

on an energized circuit. Make sure a capacitor is

fully discharged before touching or attempting

to make a measurement.

Do not use with the Battery Cover removed.

To reduce the risk of electric shock

for Resistance, Continuity, and

Resistance

1. Set the Rotary Dial to

position.

2. Connect the red test

lead to the VΩ terminal

and the black test lead

to the COM terminal.

Confirm “OL” is indi-

cated on the display,

and then short-circuit

the tips of test leads

to make the indication

zero.

3. Connect the test leads

to both ends of the

resistor under test.

4. The reading is displayed.

CAUTION

After shorting the test leads, the

displayed value may not be zero

due to the resistance of test leads themselves.

Continuity

1. Set the Rotary Dial to position.

2. Connect the red test lead to the

VΩ terminal and the black test

lead to the COM terminal.

Conrm “OL” is indicated on

the display, and then shortcircuit the tips of test leads to

make the indication zero. A

buzzer will sound.

3. Connect the test leads to both

ends of the conductor under

test. If the resistance under

test is 35 ±10Ω or 25Ω or less,

the buzzer will sound.

Capacitance

1. Set the Rotary Dial to position.

2. Connect the red test lead to the VΩ terminal and

the black test lead to the COM terminal.

3. Discharge capacitor.

4. Connect the test leads to both ends of the capacitor under test.

5. The reading is displayed.

DC Current

(Cat. No. 2236-20 only)

DANGER

circuit in which voltage over AC600V exists.

Do not use with the Battery Cover removed.

1. Set the Rotary Dial to

position. DC mark is

displayed.

2. Connect the red test

lead to the VΩ terminal

and the black test lead

to the COM terminal.

Contact the red test

lead to the ame sensor probe and the black

test lead to the control

module.

3. Turn on the heating

unit. The reading is

displayed.

ture Probe to an energized

circuit.

1. Set the Rotary Dial to

tion.

2. Connect the K-type Temperature Probe to the input

terminal. The positive (+) side

of Probe should be connected

to VΩ.

3. Place the probe sensor in the

desired location.

4. The reading is displayed.

CAUTION

displayed. If anything else is displayed, some-

thing may be wrong with the meter. Stop using

the meter immediately.

To avoid electrical shock:

Never make measurement on a

Flame

sensor

probe

Control

Module

Temperature

(Cat. No. 2236-20 only)

Never connect

the Tempera-

posi-

When the Rotary Dial is set to ,

the room temperature should be

5

Worklight LED ON/OFF

WARNING

WARNING

To turn the light on and off, press the button.

HOLD Key

Data Hold Function - Freezes the value on the display. Press the “HOLD” button to freeze the reading.

The reading will be held regardless of subsequent

variation in input. HOLD is displayed with the reading. To exit Data Hold mode, press the HOLD button

again.

CAUTION

Mode.

The clamp meter is automatically powered off in

about 20 min after the last Rotary Dial or button

operation. To reset, rotate the Rotary Dial to OFF.

If the display is still blank when a new Rotary Dial

setting is selected, replace the batteries.

The sleep mode is disabled when the MIN/MAX

function is selected.

The clamp meter does use battery power in sleep

mode. Be sure to switch the tool to OFF to conserve

battery power.

The Data Hold readings are re-

leased when the meter enters Sleep

Sleep Mode

Non-Contact Voltage Detection (NCVD)

DANGER

cal circuit or equipment. Never touch the circuit

under test to avoid possible danger even if the

LED for NCVD is not displayed.

Check the functionality of LED on a well-known

power supply prior to measurement. When the LED doesn’t

light up, do not make measurement.

NCVD indication is affected by

external voltage, and how the

meter is held or placed.

When the meter is on in any

function, the non-contact voltage detector will indicate with a

Red LED on the display when

an electric eld exceeding 90V is

detected. Place the edge of the

jaw labeled “Voltage Detector”

near the electric eld.

The LED may not be displayed due

to installation condition of electri-

Over-ow indication

Any time the input exceeds the measuring range “OL”

or “-OL” is displayed.

CAUTION

MAX button after an appropriate range is selected by Auto-ranging function. ZERO and Hz

keys are disabled while MIN/MAX Function is

active.

Clamp the jaws around the conductor under test and press the MIN/

The MIN/MAX function can be used

during measurements of AC or DC

current, AC or DC voltage, Temperature (2236-20 only), uA DC (2236-20

only), and Resistance. The MIN/MAX

function does not work in the Capacitance or Continuity measurements.

To measure the minimum or maximum

of the function, set the dial to the appropriate dial position and then press

the MIN/MAX button to capture the

maximum reading. Press the MIN/

MAX button again to capture the

minimum reading.

Press the MIN/MAX button to toggle

between minimum or maximum. The

minimum or maximum reading is

displayed and held until the MIN/MAX is turned off

by holding in the MIN/MAX button for 2 seconds or

changing the Rotary Dial position.

CAUTION

is in use. ZERO function operates only in AC

Current , DC Current and Capacitance .

AC Current / DC Current : When the LCD

doesn’t read ZERO while the

Jaws are closed, press the

ZERO Button to indicate

ZERO before starting a

measurement. In this case,

the “ZERO” mark appears

on the LCD to indicate the

ZERO Function is activated.

Capacitance : Effective

at 40nF Range only. Press

the ZERO Button with the

Test leads opened before

measuring capacitances to

indicate ZERO before starting a measurement.

MIN/MAX Function

Auto-Ranging and MIN/MAX button

are disabled when ZERO function

ZERO Function

MAINTENANCE

To reduce the risk of injury, always

before performing any maintenance. Never disassemble the tool. Contact a MILWAUKEE service

facility for ALL repairs.

Keep your tool in good repair by adopting a regular

maintenance program. After one year, it is recommended to return the tool to a MILWAUKEE service

facility for calibration.

If the tool does not start or operate at full power with

fully charged batteries, clean the contacts on the battery door. If the tool still does not work properly, return

the tool to a MILWAUKEE service facility for repair.

your tool, battery pack or charger in liquid or

allow a liquid to ow inside them.

remove the batteries from the tool

Maintaining Tool

To reduce the risk of personal injury and damage, never immerse

6

Loading...

Loading...