Cat. No.

No de cat.

2235-20

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

400 AMP CLAMP METER

PINCE AFFICHEUR DE COURANT DE 400 A

MEDIDOR DE PINZA DE 400 A

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S

MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN

COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL

MANUAL DEL OPERADOR.

IMPORTANT SAFETY INSTRUCTIONS

WARNING READ ALL SAFETY WARNINGS AND ALL INSTRUCTIONS.

Failure to follow the warnings and instructions may result in electric shock, fi re and/or serious

injury, as well as instrument damage and/or damage to the equipment being tested.

Save these instructions - This operator’s manual contains important safety and operating

instructions for the MILWAUKEE 400 Amp Clamp Meter. Before using, read this operator’s

manual and all labels on the Clamp Meter.

DANGER

Never make measurement on a circuit in which voltage over 600 volts AC exists. Use only

leads rated 600V or better.

Do not attempt to make measurement in the presence of fl ammable gasses. Otherwise, the

use of the instrument may cause sparking, which can lead to an explosion.

Transformer jaw tips are designed not to short the circuit under test. If equipment under test

has exposed conductive parts, however, extra precaution should be taken to minimize the

possibility of shorting.

Do not hold the meter above hand-stop.

Never attempt to use the instrument if its surface or your hand is wet.

Do not exceed the maximum allowable input of any measuring range.

Only use test leads on unenergized circuits unless absolutely necessary.

Check tool functionality on a known circuit fi rst. Never assume tool is working. Assume circuits

are live until they can be proven de-energized.

Do not ground yourself while measuring. Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators.

Never open the battery cover during a measurement.

The instrument is to be used only in its intended applications or conditions. Otherwise, safety

functions equipped with the instrument doesn’t work, and instrument damage or serious

personal injury may be caused.

To reduce the risk of injury from shock and arc blasts, always wear personal protective

equipment where live conductors are exposed.

WARNING

Never attempt to make measurement if any abnormal conditions, such as broken case and

exposed metal parts are found on the instrument.

Do not rotate the rotary dial while the test leads are being connected.

Verify proper operation on a known source before use or taking action as a result of the indication of the instrument.

Do not install substitute parts or make any modifi cation to the instrument. For repair or re-

calibration, return the tool to a factory Service/Sales Support Branch or authorized service

station.

Do not try to replace the batteries if the surface of the instrument is wet.

Disconnect all the cords and cables from the object under test and power off the instrument

before opening the battery cover for battery replacement.

This tool is designed to be powered by 2-AAA batteries properly inserted into the MILWAUKEE

Clamp Meter. Do not attempt to use with any other voltage or power supply.

Install battery according to polarity (+ and –) diagrams.

Do not leave batteries within the reach of children.

Do not mix new and used batteries. Do not mix brands (or types within brands) of batteries.

Properly dispose of used batteries.

Do not incinerate or dismantle batteries.

Under abusive conditions, liquid may be ejected from the battery, avoid contact. If contact

accidentally occurs, fl ush with water. If liquid contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or burns.

2

CAUTION

Set the rotary dial to an appropriate position before starting measurement.

Firmly insert the test leads.

Disconnect the test leads from the instrument for current measurement.

Do not expose the instrument to the direct sun, high temperature and humidity or dew fall.

Altitude 2000m or less. Appropriate operating temperature is within 14°F and 122°F (-10°C

and 50°C).

This instrument isn’t dust & water proofed. Keep away from dust and water.

Be sure to power off the instrument after use. When the instrument will not be in use for a long

period, place it in storage after removing the batteries.

Use a cloth dipped in water or neutral detergent for cleaning the instrument. Do not use

abrasives or solvents.

Functions

Dial Position Range Resolution Accuracy

Voltage DC 400.0/600V 0.1V/1V ± 1.0%rdg ± 5dgt

Voltage AC 400.0V/600V 0.1V/1V ± 1.2% ± 5dgt (50 to 400Hz)

Current AC 40.00/400.0A 0.01A/0.1A

Resistance 4000 1 ± 1.0%rdg ± 3dgt

Continuity

* These instruments are True-RMS sensing. All voltage and current readings are True-RMS values.

* All AC ranges are specifi ed from 0.25% to 100% of range.

Cont Buzzer

0-400.0

0.1

± 1.8%rdg ± 5dgt(50/60Hz)

± 3.0%rdg ± 5dgt(60 to 400Hz)

± 1% ± 5dgt

Beeper sounds at 30 ohms and below.

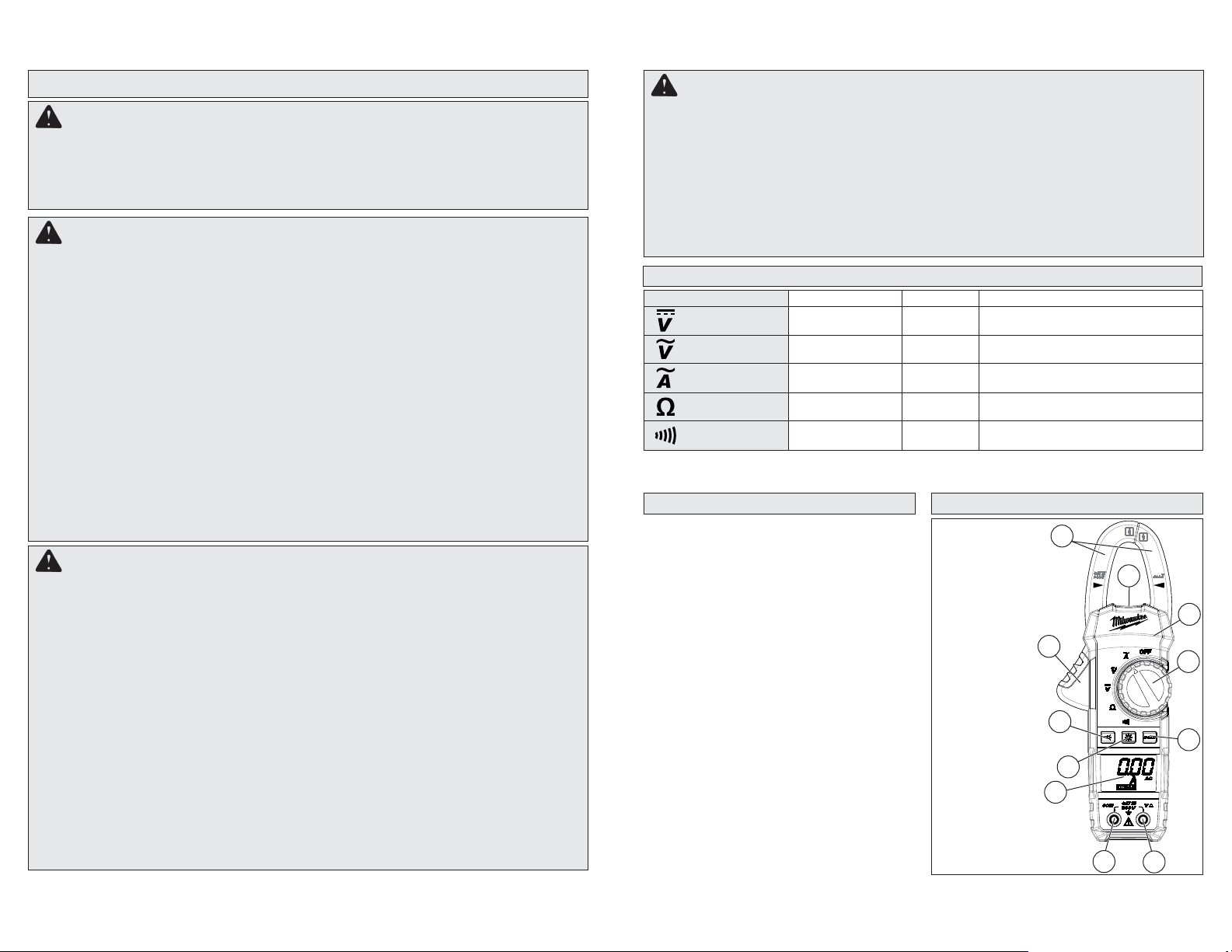

General Specifi cations FUNCTIONAL DESCRIPTION

Accuracy is specifi ed for 1 year after calibration, at

operating temperatures of 64°F to 82°F (18°C to

28°C), with relative humidity at 0 % to 85 %.

Maximum voltage between any terminal and

earth ground .... 600 V

Jaw Opening (maximum conductor size) ....

1.0” (25.4 mm)

Temperature ....

Operating: 14°F to 122°F (-10°C to 50°C)

Storage: -40°F to 140°F (-40°C to 60°C)

Temperature Coefficient .... 0.1 x (specified

accuracy)/°C (<18°C or >28°C)

Operating Altitude.... 2,000 meters

Drop Test .... 1 Meter

Battery .... 2 AAA, NEDA 24 A, IEC LR03

Battery Life .... Approx. 20 hours with all lights on,

100 hours without backlight.

Safety Compliances .... EN61010-1,

UL 61010-1, EN61010-031 (Probes),

IEC 61010-2-32 (Clamp Assemblies),

IEC/EN 61010-1 2nd Edition for measurement

Category III, 600 V,

Pollution Degree 2, EMC EN61326-1

Certifi cations .... cULus, CE

1. Current sensing jaws

2. Jaw opening trigger

3. Worklight on/off

4. Backlight button

5. Display

6. COM Terminal input

7. V Terminal input

8. Hold button

9. Rotary dial

10. Hand-stop

11. Worklight LED

3

1

11

2

3

4

5

6

7

10

9

8

Symbology

Read Operator’s Manual

Double Insulation

Risk of Electric Shock

Indicates that this instrument can

clamp on bare conductors when measuring a voltage corresponding to the

applicable measurement category,

which is marked next to this symbol.

Earth (Ground)

Danger, Warning, or Caution

Battery

European Conformity Mark

Underwriters Laboratories, Inc.,

United States and Canada

Canadian Conformity Mark

1

Classifi cation of transient overvolt-

Cat III

ages, based on nominal line voltage

to earth.

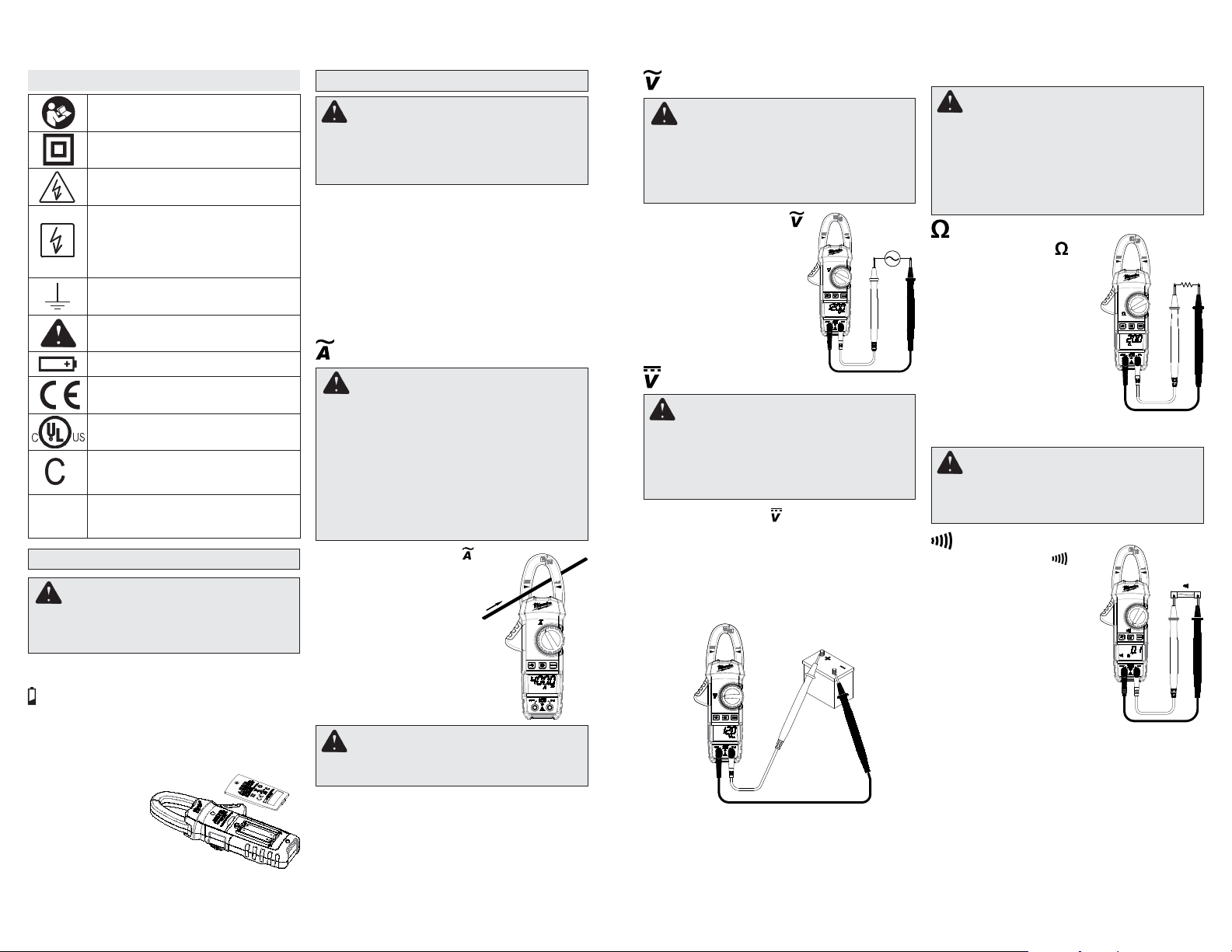

ASSEMBLY

WARNING

To avoid an electrical hazard, turn the rotary

dial to OFF and disconnect the test leads

before replacing batteries.

Changing the Batteries

Replace batteries when the low battery indicator

is displayed.

1. Turn rotary dial to OFF and disconnect the test

leads.

2. Unscrew and remove battery door.

3. Insert two (2) AAA batteries, according to the

polarity marked in

the battery compartment

4. Close the battery

door and tighten

screw securely.

1.5V

1.5V

OPERATION

WARNING

Only use MILWAUKEE test leads with the

MILWAUKEE Clamp Meter.

Inspect test leads before each use. Use Clamp

Meter to run a continuity test.

Before Use

Confi rm the rotary dial is set to the correct position,

the instrument is set to the correct measurement

mode, and the hold function is disabled. Otherwise,

desired measurement cannot be made.

LCD Backlight

The LCD backlight will turn off after about 10 minutes of inactivity. Push the backlight button to turn

the backlight on or off.

Making a Measurement

AC Current

DANGER To avoid electrical shock:

Never make measurement on a circuit in

which voltage over 600 volts AC exists. Clamp

tips are designed not to short the circuit under

test. If equipment under test has exposed

conductive parts, however, extra precaution

should be taken to minimize the possibility

of shorting.

Do not use with the battery cover removed.

Disconnect the test leads from the instrument

for current measurement.

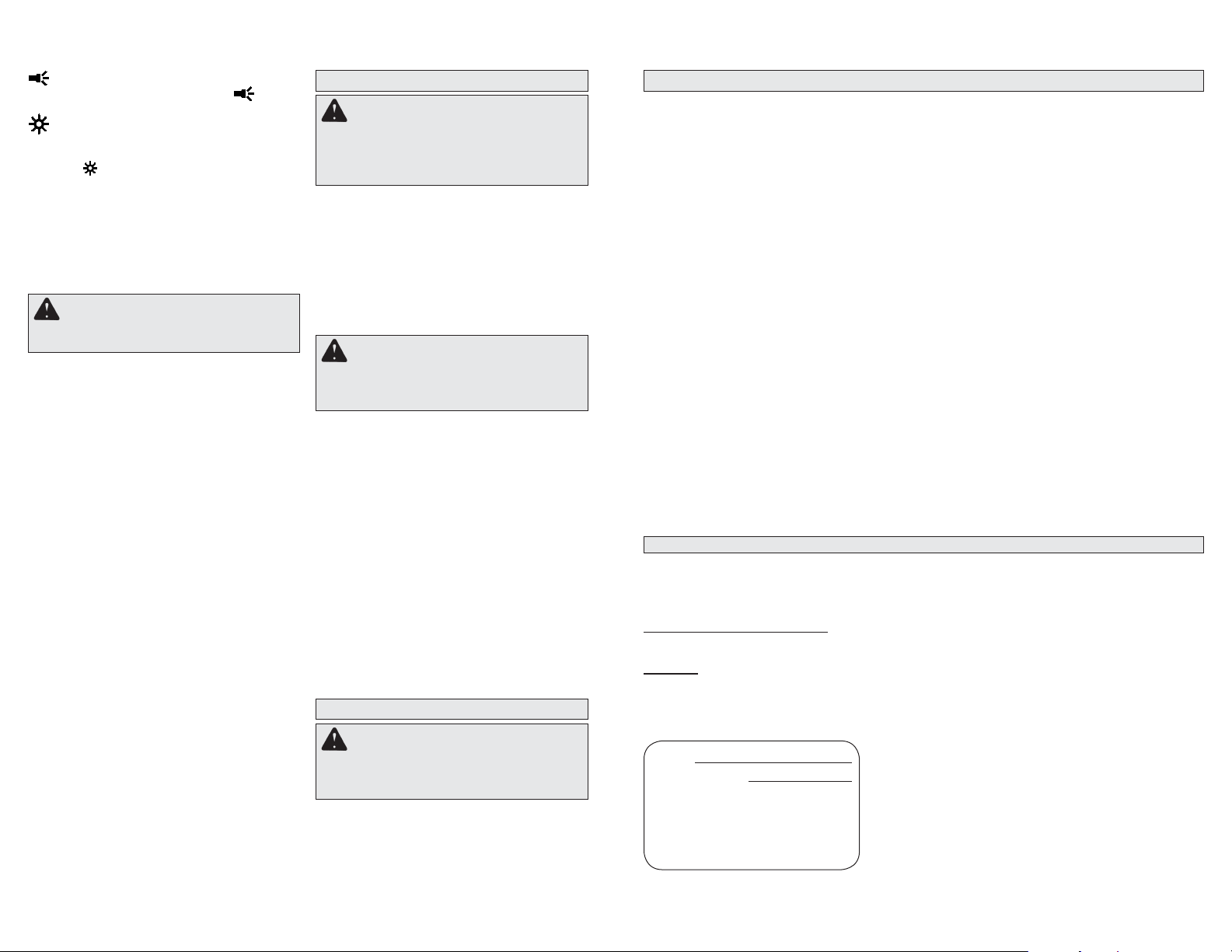

1. Set the rotary dial to

position. AC mark is displayed.

2. Press the jaw opening trigger to open the jaws and

clamp them around the

conductor under test. The

reading is displayed.

NOTE: Do not clamp over 2

or more wires at the same

time. Irregular results will

occur.

200A

CAUTION Maximum conductor size

is 1" diameter. During measurement,

keep the jaws fully closed to ensure accurate

measurements.

AC Voltage

DANGER To avoid electrical shock:

Never make measurement on a circuit in

which voltage over 600 volts AC exists.

Do not use with the battery cover removed.

Keep fi ngers away from jaws during mea-

surements.

1. Set the rotary dial to

position.

2. Connect the red test lead

to the V terminal and the

black test lead to the COM

terminal.

3. Connect the test leads to

the circuit under test. The

reading is displayed.

DC Voltage

DANGER To avoid electrical shock:

Never make measurement on a circuit in

which voltage over 600 volts DC exists.

Do not use with the battery cover removed.

Keep fi ngers away from jaws during mea-

surements.

1. Set the rotary dial to position.

2. Connect the red test lead to the V terminal and

the black test lead to the COM terminal.

3. Connect the red test lead to the positive (+) side

and black test lead to the negative (-) side of the

circuit under test. The reading is displayed. A

reversed connection is indicated as a negative

value.

12V

Resistance/Continuity Measurements

DANGER

To reduce the risk of electric shock for

Resistance and Continuity measurements,

never use the meter on an energized circuit.

If testing a capacitor, make sure it is fully

discharged before touching or attempting to

make a measurement.

Do not use with the battery cover removed.

Resistance

1. Set the rotary dial to position.

2. Connect the red test lead

to the V terminal and the

black test lead to the COM

terminal.

Confi rm “OL” is indicated on

the display, and then touch

the tips of the test leads together to short circuit them

to confi rm the zero indication.

3. Connect the test leads to

both ends of the resistor

under test. The reading is displayed.

CAUTION

After shorting the test leads, the displayed

value may not be zero due to the resistance

of test leads themselves.

Continuity

1. Set the rotary dial to position.

2. Connect the red test lead

to the V terminal and the

black test lead to the COM

terminal.

Confi rm “OL” is indicated on

the display, and then touch

the tips of the test leads together to short circuit them

to confi rm the zero indica-

tion. A buzzer will sound.

3. Connect the test leads to

both ends of the conductor under test. If the

resistance under test is 30 or less, the buzzer

will sound.

4

5

Worklight LED ON/OFF

To turn the light on and off, press the button.

Display Backlight

When working in dark environments, use the

display backlight. To turn the backlight on and off,

press the button.

HOLD Button

Hold Function - Freezes the value on the display.

Press the HOLD button to freeze the reading. The

reading will be held regardless of subsequent variation in input. HOLD is displayed with the reading. To

exit Hold mode, press the HOLD button again.

CAUTION

The Hold readings are released when the

meter enters Sleep Mode.

Sleep Mode

The Clamp Meter is automatically powered off

about 20 minutes after the last rotary dial or button

operation. To reset, turn the rotary dial or press

any button.

The Clamp Meter uses battery power in sleep

mode. Be sure to switch the tool to OFF to conserve

battery power.

Over-fl ow indication

Any time the input exceeds the measuring range

“OL” or “-OL” is displayed.

MAINTENANCE

WARNING To reduce the risk of injury ,

always remove the batteries from the tool

before performing any maintenance. Never

disassemble the tool. Contact a MILWAUKEE

service facility for ALL repairs.

Maintaining Tool

Keep your tool in good repair by adopting a regular

maintenance program. After one year, it is recommended to return the tool to a MILWAUKEE service

facility for calibration.

If the tool does not start or operate at full power

with fully charged batteries, clean the contacts

on the battery door. If the tool still does not work

properly, return the tool to a MILWAUKEE service

facility for repair.

WARNING To reduce the risk of per-

sonal injury and damage, never immerse

your tool in liquid or allow a liquid to fl ow

inside them.

Cleaning

Clean dust and debris from the tool. Keep tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean the tool

since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some

of these include gasoline, turpentine, lacquer thinner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

For repairs, return the tool to the nearest service

center listed on the back cover of this operator's

manual.

ACCESSORIES

WARNING Always remove accessories

before changing or removing batteries. Only

use accessories specifi cally recommended for

this tool. Others may be hazardous.

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go online

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or service center.

FIVE YEAR TOOL LIMITED WARRANTY

MILWAUKEE T est & Measurement Product (including bare tool, battery pack(s) and battery charger) is warranted to the original

purchaser only to be free from defects in material and workmanship. Subject to certain exceptions, MILWAUKEE will repair

or replace any part on this product which, after examination, is determined by MILWAUKEE to be defective in material or

workmanship for a period of fi ve (5) years* after the date of purchase. Return of the Test & Measurement tool to the nearest

MILWAUKEE Electric Tool Corporation - factory Service Center, freight prepaid and insured is required. A copy of the proof of

purchase should be included with the return product. This warranty does not apply to damage that MILWAUKEE determines

to be from repairs made or attempted by anyone other than MILWAUKEE authorized personnel, misuse, alterations, abuse,

normal wear and tear, lack of maintenance, or accidents.

*The warranty period for the LITHIUM-ION battery pack that ships with Test & Measurement Product is two (2) years from

the date of purchase. *Alkaline battery that ships with Test & Measurement Product is separately warranted by the battery

manufacture.

*The warranty period for a NON-CONTACT VOLTAGE DETECTOR – 2201 20 or Plumb 2-Beam Plumb Laser – 2230 20 is

one (1) year from the date of purchase.

Warranty Registration is not necessary to obtain the applicable warranty on MILWAUKEE product. The manufacturing date

of the product will be used to determine the warranty period if no proof of purchase is provided at the time warranty service

is requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN IS A CONDITION

OF THE CONTRACT FOR THE PURCHASE OF EVERY MILWAUKEE PRODUCT. IF YOU DO NOT AGREE TO THIS

CONDITION, YOU SHOULD NOT PURCHASE THE PRODUCT. IN NO EVENT SHALL MILWAUKEE BE LIABLE FOR ANY

INCIDENTAL, SPECIAL, CONSEQUENTIAL OR PUNITIVE DAMAGES, OR FOR ANY COSTS, A TTORNEY FEES, EXPENSES,

LOSSES OR DELAYS ALLEGED TO BE AS A CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN ANY

PRODUCT INCLUDING, BUT NOT LIMITED TO, ANY CLAIMS FOR LOSS OF PROFITS. SOME STATES DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES,

WRITTEN OR ORAL. TO THE EXTENT PERMITTED BY LAW, MILWAUKEE DISCLAIMS ANY IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMITA TION ANY IMPLIED W ARRANTY OF MERCHANT ABILITY OR FITNESS FOR A P ARTICULAR

USE OR PURPOSE; TO THE EXTENT SUCH DISCLAIMER IS NOT PERMITTED BY LAW, SUCH IMPLIED WARRANTIES

ARE LIMITED TO THE DURA TION OF THE APPLICABLE EXPRESS WARRANTY AS DESCRIBED ABOVE. SOME ST A TES

DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY T O YOU, THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS

WHICH VARY FROM STATE TO STATE.

This warranty applies to product sold in the U.S.A. and Canada only.

LIMITED WARRANTY - MEXICO, CENTRAL AMERICA AND CARIBBEAN

TECHTRONIC INDUSTRIES' warranty is for 5 year since the original purchase date.

This warranty card covers any defect in material and workmanship on this Power Tool.

To make this warranty valid, present this warranty card, sealed/stamped by the distributor or store where you purchased the product, to the

Authorized Service Center (ASC). Or, if this card has not been sealed/stamped, present the original proof of purchase to the ASC.

Call toll-free 1 800 832 1949 to fi nd the nearest ASC, for service, parts, accessories or components.

Procedure to make this warranty valid

Take the product to the ASC, along with the warranty card sealed/stamped by the distributor or store where you purchased the product, and

there any faulty piece or component will be replaced without cost for you. We will cover all freight costs relative with this warranty process.

Exceptions

This warranty is not valid in the following situations:

a) When the product is used in a different manners from the end-user guide or instruction manual.

b) When the conditions of use are not normal.

c) When the product was modifi ed or repaired by people not authorized by TECHTRONIC INDUSTRIES.

Note: If cord set is damaged, it should be replaced by an Authorized Service Center to avoid electric risks.

Model:

Date of Purchase:

Distributor or Store Stamp:

SERVICE AND ATTENTION CENTER

Rafael Buelna No.1.

Col. Tezozomoc Mexico, Azcapotzalco D.F.

Ph. 01 800 832 1949

IMPORTED AND COMMERCIALIZED BY:

TECHTRONIC INDUSTRIES MEXICO, .S.A. DE C.V.

Av. Santa Fe 481 piso 6, Col. Curz Manca.

CP 05349, Cuajimalpa, D.F.

6

7

Loading...

Loading...