Page 1

SIMPLE. PROVEN. POWERFUL.

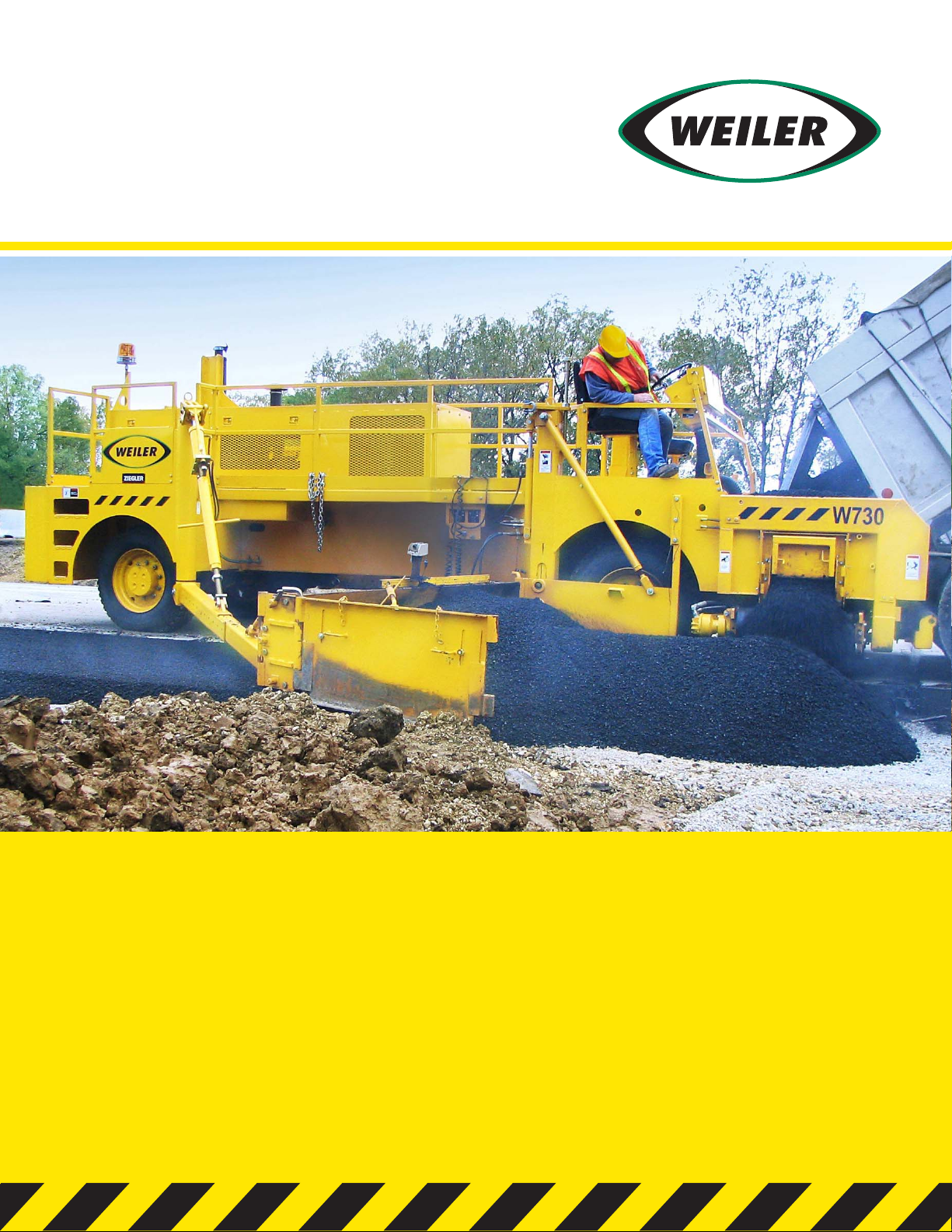

ROAD WIDENER

W730

Page 2

A SIMPLE DESIGN, COMBINED WITH

POWERFUL, PROVEN PERFORMANCE,

HELPS PAVE THE WAY TO SUCCESS.

HIGH-TEMPERATURE-RESISTANT BELT COUPLED WITH A POWERFUL DRIVE ENSURES TOP MATERIAL HANDLING

An independent, variable-speed hydraulic dual end-drive system — complete with two high-torque direct-drive motors — powers the 30-inch wide

conveyor belt at speeds ranging from 0 to 800 fpm. Discharge speed is controlled from the conveyor speed lever on the operator’s console, and

discharge direction is controlled by a switch on the station.

The large-capacity receiving hopper has a 9-foot 4-inch opening with a hydraulic dump lip for cleanout after each truck load to help reduce hand

work. Self-cleaning head, tail, and return pulleys minimize material buildup.

This heavy-duty, self-propelled road widener is designed to handle a variety of widening applications and materials. It is capable of widening from

one to 10 feet with a working depth from 12 inches above grade to 12 inches below grade. With the optional long conveyor and weight kit, it can

widen roads up to 14 feet.

WEILER W730 ROAD WIDENER

Page 3

FRONT-WHEEL STEERING

COORDINATED STEERING

CRAB STEERING REAR-WHEEL STEERING

STRIKE-OFF TOOLS ADD VERSATILITY,

EASY STORAGE

By using a specific combination of strike-off tools,

the standard tool package allows for 1- to 10-foot

widening. The strike-off tools, supports, and

hydraulic system are designed for use on either

side of the unit. Tool sections have wedge-type

quick-latch connectors. The strike-off tools fold to

allow tool storage within the basic 10-foot

machine width for transport.

STEERING MODES ENSURE MAXIMUM

MANEUVERABILITY

In addition to the three steering modes on the

W730, the rear-wheel steering axle has a manual

override to allow the fourth steering mode or

minor corrections while operating.

SLIDING CONTROL CONSOLE ENHANCES

OPERATOR EASE OF USE

Operators have convenient right- or left-side

access to all machine controls needed for

paving, and console controls are user-friendly

and ergonomically designed.

SEALED CIRCUIT BREAKERS OFFER

ADDED PROTECTION

The electrical system utilizes sealed connections.

Each circuit is protected and can be reset.

BRAKES

Primary braking is accomplished through the

dynamics of the hydrostatic traction drive.

Foot-actuated hydraulic secondary brakes are

integral to the drive axles. Application of the

spring-applied hydraulic release brake can be

performed by the operator.

STANDARD OSCILLATING PUSH ROLLERS

Two bearing-equipped push rollers mounted on

the 112-inch wide oscillating frame compensate

for minor direction misalignment of truck with

road widener.

REMOTELY LOCATED OIL COOLER INCREASES

COOLING CAPACITY

The hydraulically driven oil cooler is thermostatically

controlled and reversible for radiator clean-out.

The remote location isolates the heat from the

engine cooling system.

STRONG HORSEPOWER HELPS BOOST

PRODUCTIVITY

With its powerful 6-cylinder 174 hp Cat engine, the

W730 delivers the muscle to run longer, harder, and

faster and to keep projects moving.

Page 4

Weight

33,500 lb (15,200 kg)

Opt 40,000 lbs (18,181kg)

Engine 174 hp (130 kW) Cat 3056E ATAAC

Hydraulic Drive

4-wheel hydrostatic drive

Lockable differential

2-speed motors

2-speed gearbox

Steering

4-wheel steer

3 steering modes

Suspension

(4) 385/65Rx22.5

16-ply pneumatic tires

Speeds (max)

Low

High

0 – 180 fpm (0 – 55 m/min) @ 0 – 7.2 mph (0 – 11.6 kph)

0 – 350 fpm (0 – 107 m/min) @ 0 – 14 mph (0 – 22.5 kph)

Conveyor

Belt Width

Shift

30˝ (762 mm)

6˝ (152 mm) either side, opt. 10˝ (254 mm)

Dimensions

Length

Width

Height

Wheel Base

25´8˝ (7.88m) without weight kit

26´9˝ (8.15m) with weight kit

10´ 0˝ (3 m)

9´ 7˝ (2.9 m)

180˝ (4,572 mm)

Working Width

1´ 10˝ (.6 m), 14´ (4.3 m) w/ options

Working Depth

12˝ (305 mm) above and below grade

Turning Radius

14´ (4 m) outside tires

Capacities

Fuel

Hydraulic Oil

62 gal (235 L)

50 gal (189 L)

Strike-off Tools

One 2´ – 3´ (0.6 m – 0.3 m) telescoping

One each 1´, 2´, 3´, 6´ (0.3 m, 0.6 m, 0.9 m, 1.8 m)

Five Star Industries, Inc., is a premier whole product contract manufacturing provider and prototype development resource center.

©2006 Five Star Industries, Inc.

Five Star Industries, Inc.

815 Newbold Drive

P.O. Box 289

Knoxville, IA 50138

Phone: (641) 828-6622 • Fax: (641) 828-6612

www.weilerproducts.com

W730 ROAD WIDENER SPECIFICATIONS

Weiler reserves the right to make changes in engineering, design, and specifications, and to add improvements

at any time without notice or obligation.

OPTIONAL CAB PROTECTS THE OPERATOR

FROM THE ELEMENTS

Operator will be in a climate-controlled environment and still

have excellent visibility.

EQUIPMENT FEATURES

• Optional truck hitch

• Additional operator seat

• Strobe light

• Strike-off washdown system

• 10´ or 12´ rear-mount broom

• 6,500 lb counterweight

• Grade and slope control prep group with standard

or proportional valves

• 14´ paving group (requires 6,500 lb counterweight

and 12´ conveyor)

• 12´ conveyor

• Opposite side mounts and hydraulics

• Opposite side strike-off tools

• Cab

• 9 KW Generator

• Hydraulic push beams

Loading...

Loading...