Milton CAT 320D LRR User Manual

Engine

Engine Model Cat®C6.4 ACERT™

Net Flywheel Power 110 kW 148 hp

Weights

Minimum Operating Weight 21 210 kg 46,755 lb

• Reach boom, R2.5B1 (8 ft 2 in) Stick, 0.47 m3(0.61 yd3)

Bucket, 600 mm (24 in) Double grouser shoes

Maximum Operating Weight 24 990 kg 55,093 lb

• Heavy-duty reach boom, Heavy-duty R2.9B1 (9 ft 6 in)

stick, 1.38 m3(1.80 yd3) Bucket, 600 mm (24 in) Triple

grouser shoes

320D LRR

Hydraulic Excavator

®

®

2

320D LRR Hydraulic Excavator

The D Series incorporates innovations for improved performance and versatility.

The Caterpillar

®

320D LRR excavator provides

all the elements to give you the lowest cost

to own and operate. At the end of the day, it

all comes down to how much work you got

done and how much did it cost you.

Caterpillar and the 320D LRR offer

you the tools to help lower your

owning and operating costs.

Versatility

Caterpillar offers a wide variety of

factory-installed attachments that

enhance performance and job site

management. pg. 12

Work Tools – Attachments

A variety of work tools, including

buckets, couplers, hammers, and shears

are available through Cat®Work Tools.

pg. 11

✔

Hydraulics

The hydraulic system has been designed

to provide reliability and outstanding

controllability. An optional Tool Control

System provides enhanced flexibility.

pg. 6

C6.4 with ACERT™ Technology

ACERT™ Technology works at the

point of combustion to optimize engine

performance and provide low exhaust

emissions to meet U.S. EPA Tier 3

emission regulations, with exceptional

performance capabilities and proven

reliability. pg. 5

✔

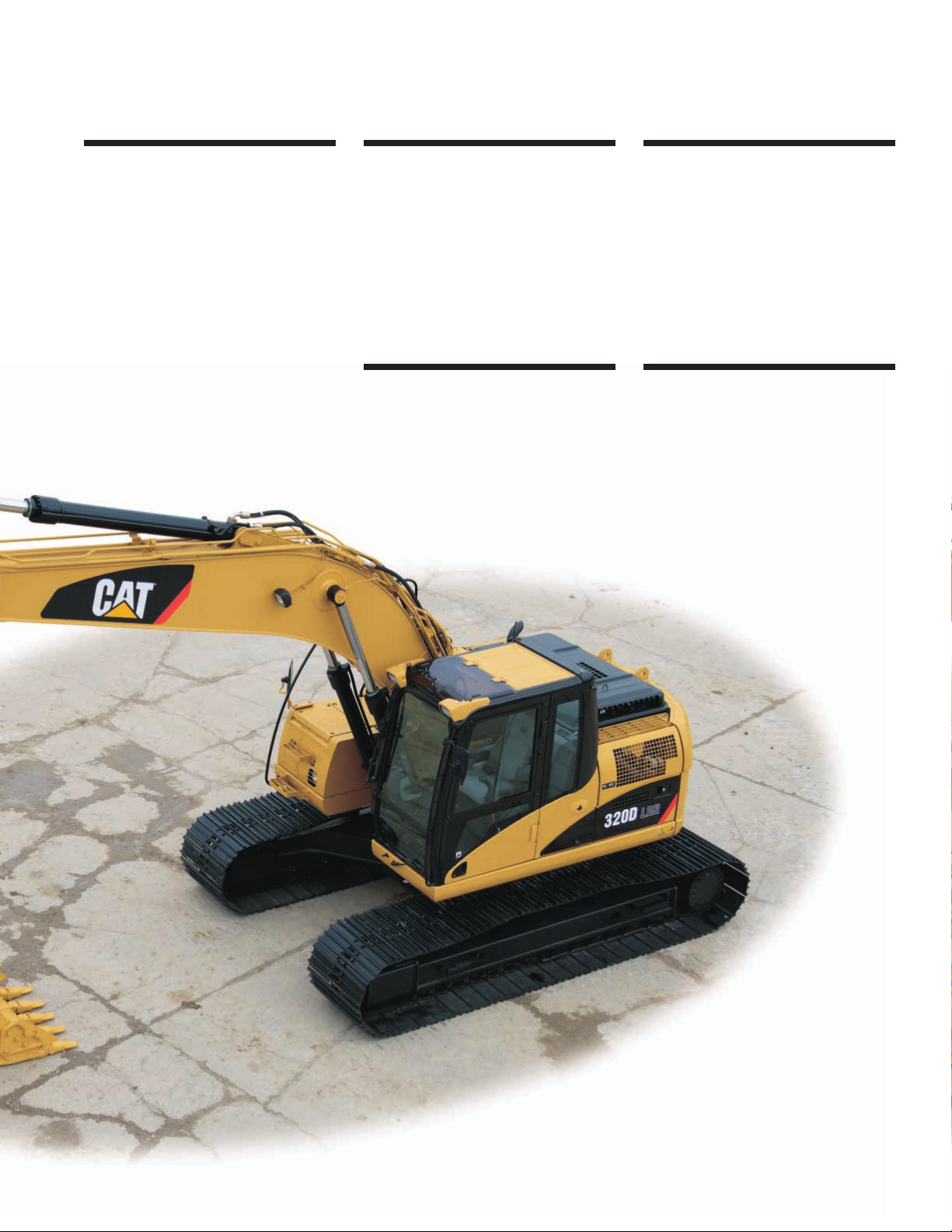

Reduced Radius

The 320D LRR features a reduced tail

swing design that allows it to work well

in space restricted areas, while providing

maximum comfort. pg. 4

✔ New Feature

3

Service and Maintenance

Fast, easy service has been designed in

with extended service intervals, advanced

filtration, convenient filter access and

user-friendly electronic diagnostics for

increased productivity and reduced

maintenance costs. pg. 14

✔

Complete Customer Support

Your Cat®dealer offers a wide range

of services that can be set up under a

customer support agreement when you

purchase your equipment. The dealer will

help you choose a plan that can cover

everything from machine configuration

to eventual replacement. pg. 13

Booms, Sticks and Bucket Linkages

One boom and two sticks are available,

offering a range of configurations suitable

for a wide variety of application

conditions. pg. 10

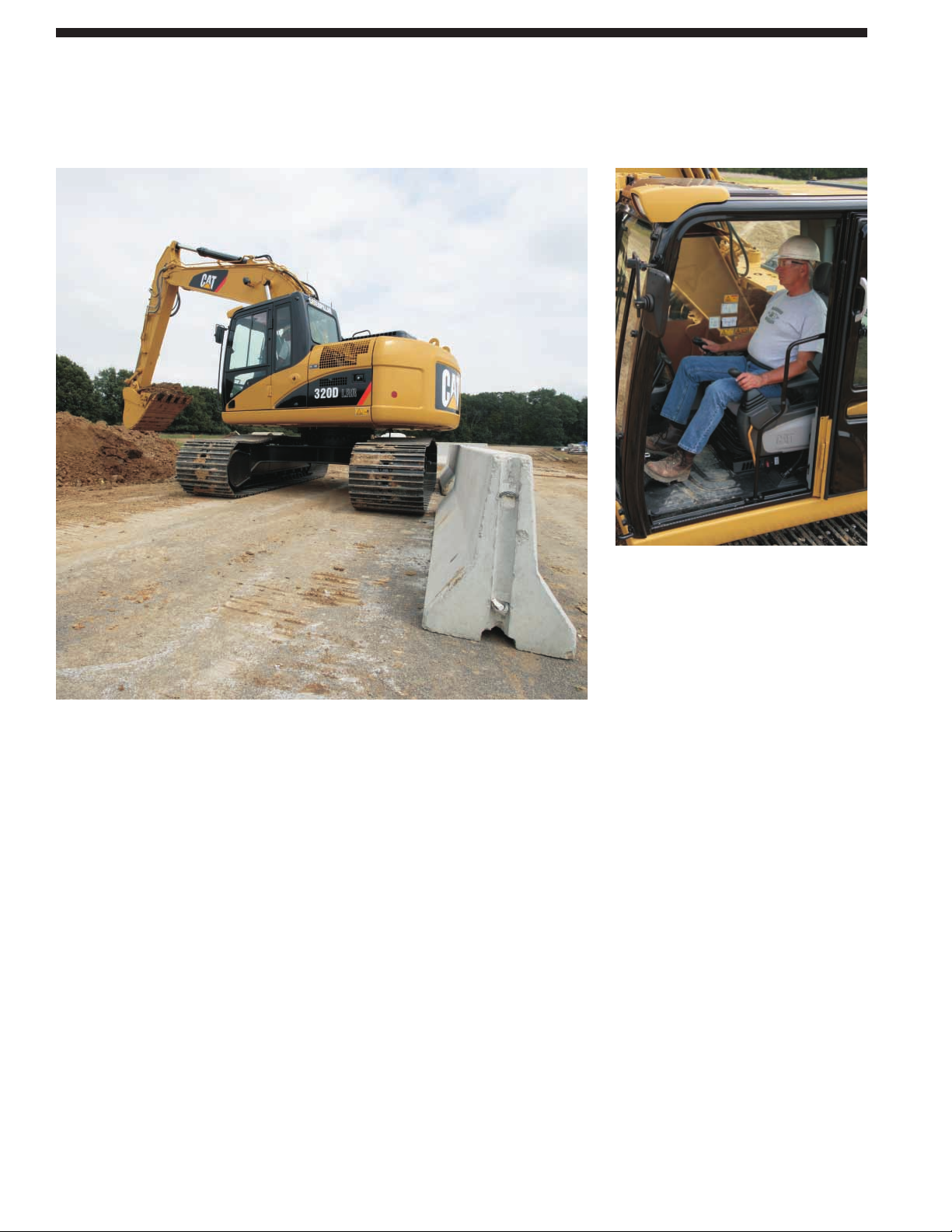

Operator Comfort

Provides maximum space, wider visibility

and easy access to switches. The monitor

is a full-color graphical display that

allows the operator to understand

the machine information easily.

Overall, the new cab provides

a comfortable environment for

the operator. pg. 8

✔

Structures

Caterpillar®design and manufacturing

techniques assure outstanding durability

and service life from these important

components. pg. 7

Reduced Radius. The tail swing of this

machine has been reduced where the

back end of the machine won’t extend

beyond the length of the tracks. The tail

swing is just 2.0 m (6'7") as compared

to the 2.75 m (9'0") on the 320D. When

rotated 90 degrees and working over the

side, just 600 mm (2'0") hangs over the

side. This allows the 320D LRR to work

well in road construction applications

and other space restricted areas.

Stability. The 320D LRR offers a very

stable platform providing great stability

for all applications. When compared

to 320D L, the 320D LRR delivers up

to 6% additional lift over the side with

the heavier counterweight. One of the

main contributors is the additional

counterweight used on the 320D LRR.

This allows for the balance of the machine

to be comparable to a standard machine

with a longer tail swing.

Comfort. The cab of the 320D LRR is the

same full-sized cab with all the amenities

and attachments found on the cab of the

320D L.

4

Reduced Radius

The Caterpillar 320D LRR is designed for high maneuverability in confined spaces.

Cat C6.4. The Cat C6.4 with ACERT™

Technology introduces a series of

evolutionary, incremental improvements

that provide breakthrough engine

technology. The building blocks of

ACERT Technology are fuel delivery,

air management and electronic control.

ACERT Technology optimizes engine

performance while meeting U.S. EPA

Tier 3 emission regulations. With its

proven technology, robust components

and precision manufacturing, you can

count on this engine to power up at start

time and keep working productively all

shift long.

Performance. The 320D LRR, equipped

with the C6.4 engine with ACERT™

Technology, provides 7% more power as

compared to the 3066TA in the 320C LU.

The additional power delivers a speed and

efficiency advantage in high production

applications.

Automatic Engine Speed Control.

The two-stage, one-touch control

maximizes fuel efficiency and

reduces sound levels.

ADEM™ A4 Engine Controller.

The ADEM A4 electronic control module

manages fuel delivery to get the best

performance per liter of fuel used.

The engine management system provides

flexible fuel mapping, allowing the engine

to respond quickly to varying application

needs. It tracks engine and machine

conditions while keeping the engine

operating at peak efficiency.

Electronic Control Module.

The Electronic Control Module (ECM)

works as the “brain” of the engine’s

control system, responding quickly to

operating variables to maximize engine

efficiency. Fully integrated with sensors

in the engine’s fuel, air, coolant, and

exhaust systems, the ECM stores and

relays information on conditions such

as rpm, fuel consumption, and

diagnostic information.

Fuel Delivery. The Cat C6.4 features

electronic controls that govern the fuel

injection system. Multiple injection

fuel delivery involves a high degree

of precision. Precisely shaping the

combustion cycle lowers combustion

chamber temperatures, generating fewer

emissions and optimizing fuel combustion.

This translates into more work output

for your fuel cost.

Cooling System. The cooling fan

is directly driven from the engine.

An electrically controlled viscous clutch

fan is available as an attachment to reduce

fan noise. The optimum fan speed is

calculated based on the target engine

speed, coolant temperature, hydraulic

oil temperature and actual fan speed.

When fan speed is reduced, there’s

more power available for other

functions – and less fuel is burned.

5

C6.4 with ACERT™ Technology

The Cat®C6.4 gives the 320D LRR exceptional power and fuel efficiency, unmatched in the

industry, for consistently high performance in all applications.

Component Layout. To optimize efficiency

of hydraulic performance, the hydraulic

components are located close together,

which reduces friction loss and pressure

drops in the lines.

System Pressure. System pressure has

been increased to 35 000 kPa (5,076 psi),

which attributes to improved performance:

• Increased stick and bucket forces

(up 7% higher than the 320C LU)

to better handle those tight digging

conditions

• More drawbar pull (206 kN –

46,322 lb) to provide more ability

to climb slopes, easier spot turns

and improved travel in poor

underfoot conditions

• More lift capacity, generally over

the front where you are generally

hydraulically limited

Heavy Lift. The 320D LRR features the

addition of a heavy lift, which increases

system pressure to 36 000 kPa (5,220 psi),

giving even more lift capacity over

the front. Heavy Lift is activated by

depressing the soft switch on the right

hand console. As the pressure increases,

the engine speed is reduced, which allows

better control while lifting objects.

Pilot System. The pilot pump is

independent from the main pumps

and controls the front linkage,

swing and travel operations.

Hydraulic Cross Sensing System.

The hydraulic cross sensing system

utilizes each of two hydraulic pumps

to 100 percent of engine power, under

all operating conditions. This improves

productivity with faster implement speeds

and quicker, stronger pivot turns.

Boom and Stick Regeneration Circuit.

Boom and stick regeneration circuit saves

energy during boom-down and stick-in

operation which increases efficiency,

reduces cycle times and pressure loss

for higher productivity, lower operating

costs and increased fuel efficiency.

Auxiliary Hydraulic Valve. The auxiliary

valve is standard on the 320D LRR.

Control Circuits are available as

attachments, allowing for operation of

high and medium pressure tools such as

shears, grapples, hammers, pulverizers,

multi-processors and vibratory plate

compactors.

Hydraulic Cylinder Snubbers.

Snubbers are located at the rod-end of

the boom cylinders and both ends of the

stick cylinders to cushion shocks while

reducing sound levels and extending

component life.

6

Hydraulics

Cat®hydraulics deliver power and precise control to keep material moving.

Robust Undercarriage. A solid foundation

built tough to absorb the stresses of

everyday work.

• Rollers and idlers are sealed and

lubricated to extend service life.

• Track links are assembled and sealed

with grease to decrease internal

bushing wear and increase life by

as much as 25%, when compared

to dry seal undercarriages.

• Spring recoil system stroke has been

increased to better relieve excess

track tension, which can occur when

material builds up between the track

and sprocket.

Rugged Structures. Structural components

and the undercarriage are the backbone

of the machines’s durability. Caterpillar

places a lot of emphasis on the machine’s

durability during the designing and

manufacturing of its excavators.

• Up to 95% of the structural welds are

welded by robots, which achieve up

to three times the penetration of a

manual weld and improving overall

durability of the machine.

• The 320D LRR’s main frame utilizes

high-tensile strength steel and a onepiece swing table, which improves

strength and reliability.

• The carbody has a X-shaped, box

section design to resist bending and

twisting forces.

• Track roller frames are press-formed

in a pentagonal shape for additional

strength.

7

Structures

320D LRR is designed to handle the most rugged operating conditions, while providing long

life and value.

8

Caterpillar offers the most intuitive and easy to operate excavators while providing great all

around visibility and exceptional operator comfort.

Operator Comfort

Operator Station. The layout of the interior

has been redesigned to maximize operator

comfort and reduce operator fatigue.

• Frequently used switches have been

relocated for easier access.

• Consoles and armrests have been

redesigned for better comfort and

adjustability.

• More seat options – choose from the

standard mechanical suspension seat,

or the optional air suspension seat with

heater. Both provide excellent comfort.

Standard Cab Equipment. To enhance

operator comfort and productivity, the

cab includes a lighter, drink holder, coat

hook, service meter, literature holder,

magazine rack and storage compartment.

Joystick Control. Joystick controls have

low lever effort and are designed to match

the operator’s natural wrist and arm

position.

Hydraulic Activation Control Lever.

For added safety, this lever must be in the

operate position to activate the machine

control functions.

Automatic Climate Control.

Fully automatic climate control adjusts

temperature and flow, and determines

which air outlet is best in each situation

with a touch of a button.

Cab Exterior. The exterior design uses

thick steel tubing along the bottom

perimeter of the cab, improving the

resistance of fatigue and vibration.

Cab Mounts. The cab shell is attached

to the frame with viscous rubber cab

mounts, which dampen vibrations and

sound levels while enhancing operator

comfort.

Windows. All glass is affixed directly to

the cab for excellent visibility eliminating

window frames.

Wipers. Pillar-mounted wipers increase

the operator’s viewing area and offer

continuous and intermittent modes.

Skylight. An enlarged skylight with

sunshade provides excellent visibility

and ventilation.

Monitor. The monitor is a full color Liquid

Crystal Display that gives you vital

operating and performance information,

alerts in text, all in a simple, east to

navigate format.

Default Display. Three analog gauges,

fuel level, hydraulic oil temperature

and coolant temperature, are displayed

in this area.

Main Menu. Four menu options to

choose from:

Settings – Adjust monitor settings, select

work tool or choose video mode (when

equipped with a camera)

Maintenance – Displays service intervals

and hours accumulated since last serviced.

Performance – Displays machine

performance attributes such as Engine

Speed, Coolant and Hydraulic Oil

Temperature.

Service – Allows access to machine

parameters for service intervals,

diagnostic information and information

related to the machines software.

Event Display. Machine information is

displayed in this area with the icon and

language.

Multi-information Display. This area

is reserved for displaying various

information which is convenient for the

operator. The “CAT” logo is displayed

when no information is available to be

displayed.

9

Loading...

Loading...