Page 1

303.5E CR, 304E CR,

305E CR, 305.5E CR

Mini Hydraulic Excavators

303.5E CR 304E CR 305E CR 305.5E CR

Engine

Engine Model Cat

Net Power (ISO 9249) 23.6 kW (31.6 hp) 30 kW (40.2 hp) 30 kW (40.2 hp) 32.9 kW (44.2 hp)

Weights

Operating Weight with Canopy 3508 kg (7,734 lb) 3854 kg (8,497 lb) 4915 kg (10,836 lb) 5270 kg (11,618 lb)

Operating Weight with Cab 3692 kg (8,139 lb) 4009 kg (8,838 lb) 5088 kg (11,217 lb) 5415 kg (11,938 lb)

Operating Specifications

Maximum Dig Depth 3180 mm (10'4") 3430 mm (11'3") 3670 mm (12'1") 3870 mm (12'8")

®

C1.8 Cat® C2.4 Cat® C2.4 Cat® C2.4

Page 2

High

performance

in compact

sizes to

increase your

productivity in

the tightest of

applications.

Contents

Operator Station..................................................4

Performance ........................................................5

Engine ...................................................................5

COMPASS Control Panel ...................................6

Compact Radius, Zero Tail Swing .....................8

Dozer Blade........................................................10

Coupler and Work Tool Options ......................11

Serviceability .....................................................12

Speci cations ....................................................14

Standard Equipment.........................................20

Optional Equipment...........................................21

2

Page 3

The Cat® ESeries Mini Hydraulic Excavators deliver high performance in a compact size to help you work in the tightest

applications. All four models feature a large, integrated counterweight and excellent stability while maintaining a

compact radius design. With the new COMPASS control panel, the ESeries has new standard features like a password

protected security system, Eco mode, adjustable auxiliary ow control, and continuous ow. These new features make

the machines more productive, versatile, and cost effective.

3

Page 4

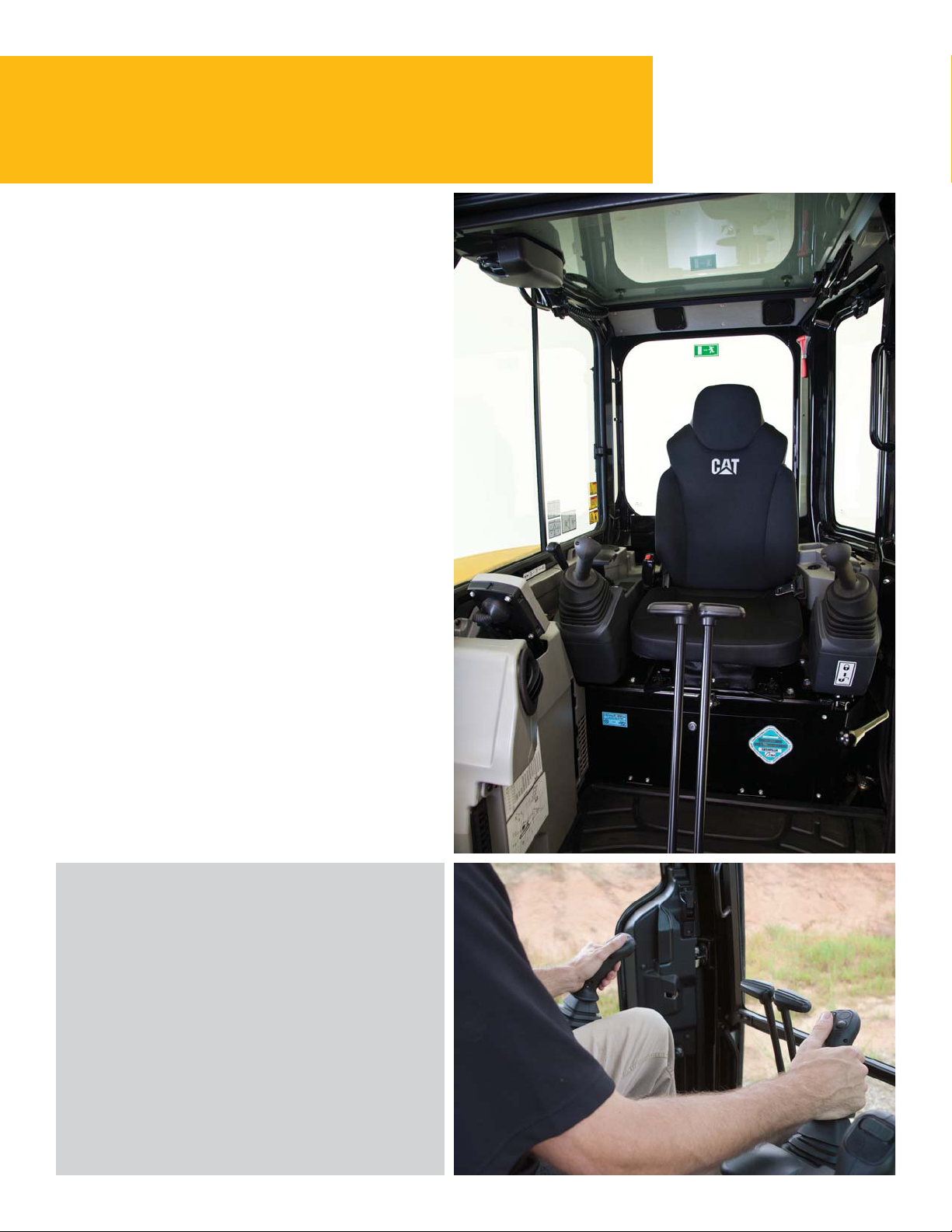

Operator Station

Superior comfort to keep you productive

throughout the work day

Comfortable Working Environment

Spacious and comfortable operator station with excellent

visibility and legroom keeps the operator comfortable

andreduces fatigue. Standard features include:

• Reclining suspension seat with adjustable wrist rests.

• Pilot operated controls on all services including travel levers

and dozer functions.

• A pattern control changer (not available in all regions)

is accessible from the cab to switch between excavator

andbackhoe style controls.

• Ample storage space under the seat that can be locked

foradded security.

Joystick Controls

The boom swing and auxiliary hydraulic functions

are located at your ngertips providing smooth, easy

operation. They also eliminate foot pedals and free up

the oor for more room for the operator’s feet. 100%

pilot controls provide consistent ow and pressure

throughout the life of the machine. This also allows all

controls to be locked out while starting the machine.

4

Page 5

Stability

All four ESeries models feature excellent stability while

maintaining the compact radius design. This increased stability

leads to more productivity and versatility through the use of

heavier work tools and the optional long stick.

Fast, Powerful Digging with Load Sensing Hydraulics

High digging forces and fast cycle times deliver the productivity

that your job demands. Load sensing hydraulics optimize ow for

smooth, powerful performance and increased fuel efciency.

200 Degree Bucket Rotation

Industry leading bucket rotation of over 200 degrees provides

greater material retention during truck loading.

Performance

Powerful digging with precise control

It also allows for easier vertical wall digging without having to

reposition the machine.

Engine

High performance power train provides optimized

engine horsepower and strong performance

Automatic engine idle automatically lowers engine

revolutions when not in use to conserve fuel and lower

environmental noise and emissions.

Automatic Two Speed

With the standard automatic two speed feature, the

machine will automatically balance high speed and

torque travel requirements based on the conditions

to give the operator the optimum speed and control.

The machine can be put in low gear if slower travel

isdesired while in tight conditions.

5

Page 6

COMPASS Control Panel

Complete, Operational, Maintenance, Performance and Security System

The brand new COMPASS control panel on the Cat® ESeries mini

hydraulic excavators was specically designed by Caterpillar for

compact excavators. It adds several new features to the machines

increasing the amount of customer value. All of the following features

are now standard onall ve of the new ESeries models.

Complete – All of the control panel features are standard on all ve

ofthe new ESeries models

Operation – Simple operation of the pattern changer, hydraulic quick

coupler and fuel gauge visibility all at the push of a button

Maintenance – Maintenance intervals, diagnostics and work hours

Performance – Save up to 20% fuel while maintaining optimum

performancelevels

And

Security – Anti theft device with individual user and master

passwords

System – Ergonomically designed control panel

Passcode Protected Security System

A standard anti-theft device now comes on every ESeries compact

excavator. A ve digit alphanumeric password is required to start the

machine when the anti-theft feature is enabled. There is a master

password and up to ve user passwords can be created by the

ownerif desired.

Keep your machine safe on a busy job site by locking it when you

arenotaround

Adjustable Auxiliary Work Tool Flow Control

The ESeries machines now have simple adjustability of the ow

going down the boom and stick to the work tool. Both the standard

main line and optional secondary auxiliary hydraulics can be adjusted

on a scale of 1–15 through afew buttons on the control panel.

Adjust the ow to your different tools with a simple push of a button

6

Page 7

UNLOCK the new features and experience the

value of the exclusive COMPASS control panel

onthe new ESeries compact excavators

Economy Mode

This feature allows your machine to be set in a more economical

power setting with a simple push of a button. While operating in

this mode, the machine will maintain excellent performance levels

while saving up to 20%fuel through a slightly lower engine setting.

Save money with the new ESeries compact excavators

Continuous Flow

Once this feature is enabled through a button on the monitor, the

new ESeries machines can run in continuous ow mode. With the

auxiliary hydraulics on the right hand joystick, just hold the roller

switch at the desired ow rate and direction for 2.5 seconds and

the machine will maintain that ow rate until it is turned off.

Maintain hydraulic ow to your tools at any ow and in any

direction withthe simple push of a button

Pattern Changer

Change the operating pattern between excavator and backhoe

with asimplepress of a button from the comfort of the cab.

Exclusive push button pattern changer is safe and easy

Maintenance and Performance Information

Easily keep track of various maintenance and performance

parameters ofyour machine.

Reset the maintenance intervals and ensure the machine is

receiving proper care maximizing the life of the machine

7

Page 8

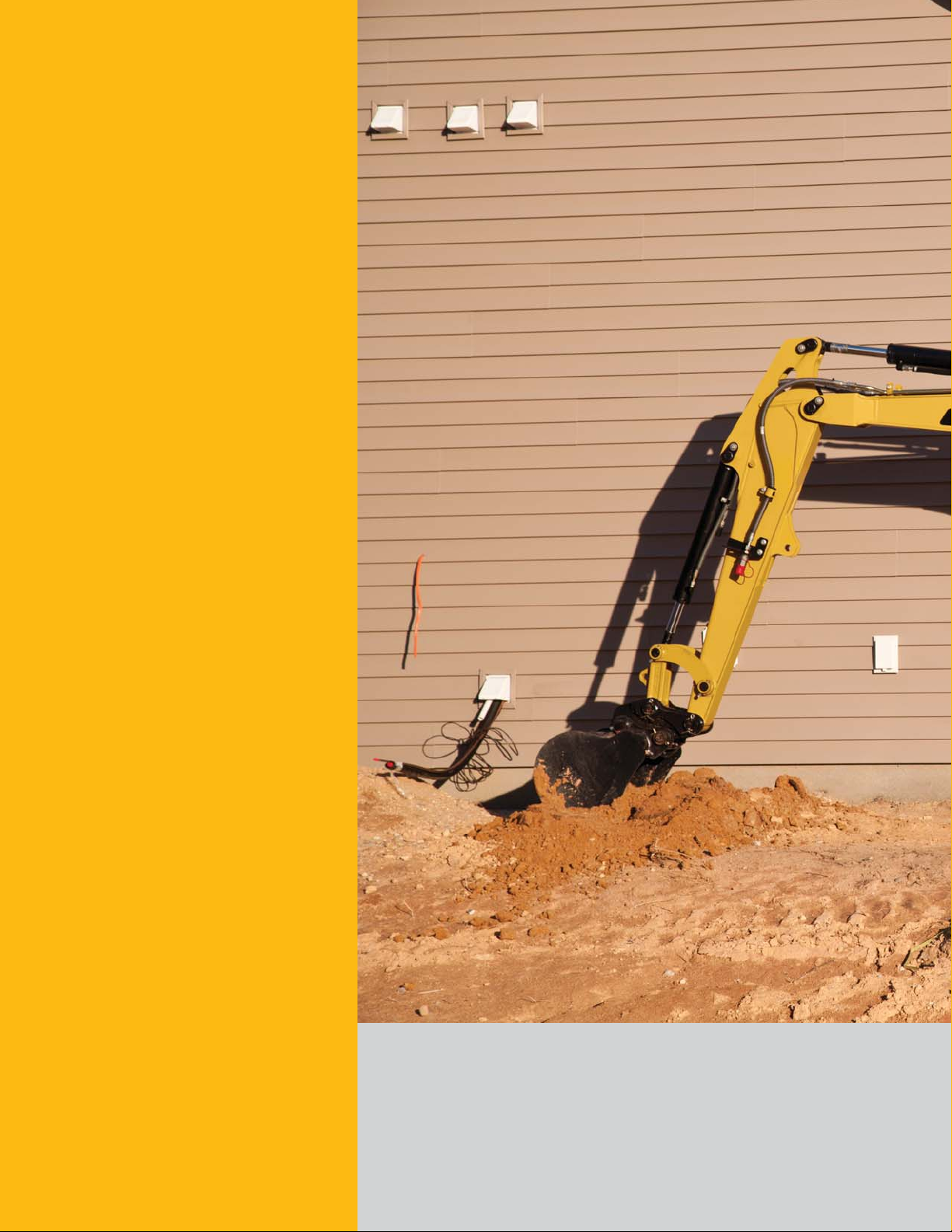

Compact Radius, Zero Tail Swing

Work in the tightest areas

Compact Radius

The compact radius design gives greater machine versatility and the

capability to work within conned areas. This allows the operator to

concentrate on the work being done without having to worry about

damaging the back of the machine or other job site obstacles. On the

305E CR and the 305.5E CR, the upper body stays within 140 mm (5.5 in)

ofthe undercarriage.

Zero Tail Swing

New to the E Series, the 303.5E CR and the 304E CR models feature a zero

tail swing design. On these models, the radius of the upper body stays

entirely within the width of the undercarriage.

8

Page 9

Undercarriage Stability and Durability

Rubber Track – The standard rubber track lets you work on multiple surfaces such as grass, pavement or stone without damaging

thesurface or machine.

Steel Track Option – Optional steel track is available for harsh conditions such as demolition. The extra weight of the steel tracks

generally provides better stability when digging over the side of the machine. (Not available on the 304E CR.)

Rubber Pads – Optional rubber pads can be attached to the steel track to prevent damage to paved surfaces and minimize noise

andvibration during travel with the steel track system. This option provides the maximum overall stability.

9

Page 10

Dozer Blade

Maximize your productivity

Simple Dozer Control with Float Function

The dozer function is pilot controlled from inside

the cab, providing smooth, proportional operation.

The standard oat function is enabled by pushing

the lever fully forward into the detent position.

Cleanup and backlling is easier since the

operator does not have to adjust the blade height

duringtravel.

Excellent Blade Visibility

Visibility to the blade is excellent in any position, allowing the

blade to be positioned behind the operator and away from the

front linkage for better access when back dragging and nishing

intightareas.

Angle Blade Option

Increase machine versatility with the Cat angle dozer blade.

Builtfor strength and durability, the hydraulic angle blade features

a hardened steel wear edge and good protection to cylinders

and hydraulic lines. The angle blade can be positioned straight

ahead or angled up to 25 degrees to the left or right. This reduces

the number of times required to back up and reposition when

backlling so you can nish the job faster. All functions of the blade

are controlled with one joystick using a proportional roller switch

for the angle function.

10

Page 11

Coupler and Work Tool Options

Increased versatility with multiple work tools

Couplers

The E Series is available with a mechanical pin-grabber or

a hydraulic pin-grabber quick coupler option. The coupler

design uses a wedge to keep the tool secure to the coupler,

reducing wear and maintaining a tight t through the life

ofthecoupler.

The hydraulic coupler allows the operator to change tools

without leaving the comfort of the cab.

Wide Range of Work Tools

A wide range of Cat Work Tools have been designed

specically for the Cat Mini Hydraulic Excavators to maximize

machine performance. Available work tools include:

• Buckets (heavy duty and heavy duty capacity)

• Tilting, Ditch Cleaning Buckets

• Hydraulic Hammers

• Augers

• Thumbs (not available in all regions)

• Vibratory Compactors

• Shears (boom mounted on 305E CR/305.5E CR only)

• Quick Coupler

Standard Thumb Ready Sticks (optional in Europe)

Machines come standard with stick mounted brackets, ready

to t a hydraulic thumb for even greater machine versatility.

A factory installed bracket and relief valve make hydraulic

thumb installation simple and cost-effective.

Standard Auxiliary Lines and Accumulator

One-way and two-way auxiliary lines (combined function),

including quick connections, are tted as standard equipment

so the machine comes ready to work. A standard accumulator

allows for auxiliary pressure to be released, making connecting

and disconnecting work tools safer and easier.

11

Page 12

Serviceability

Simplied service and maintenance

save you time and money

12

• Easy access to the radiator and oil cooler results in simplied

cleaning and reduced maintenance times.

• S·O·SSM oil sampling valve allows easy sampling of the hydraulic

uid for preventative maintenance.

• 500 hour engine oil and lter change period reduces operating

costs and machine downtime.

Page 13

Easy Service

Convenient service features make maintenance easy, reducing your downtime:

• Lifting side hood allows access to air lter, main implement valve,

1-way/2-way auxiliary ow selector, accumulator, fuel lter and hydraulic

tank. This eliminates the need to lift the cab when maintaining and servicing

the machine.

• Swing open door provides access to major components and service points

including engine oil check and ll, vertically mounted engine oil lter, starter

motor and alternator.

Customer Support You Can Count On

Your Cat dealer is ready to assist you with your purchase decision and

everything after.

• Financing packages are exible to meet your needs.

• Unmatched parts availability keeps you working.

• Make comparisons of machines, with estimates of component life,

preventative maintenance and cost of production.

• Your Cat dealer can evaluate the cost to repair, rebuild and replace

yourmachine.

• For more information on Cat products, dealer services and industry solutions,

visit www.cat.com.

13

Page 14

303.5E CR, 304E CR, 305E CR, 305.5E CR Specifications

Engine Travel System

Engine Model Travel Speed – High 4.6 km/h 2.8 mph

®

303.5E CR Cat

304E CR/305E CR/305.5E CR Cat

Rated Net Power (ISO 9249) 305.5E CR 2.8 km/h 1.7 mph

303.5E CR 23.6 kW 31.6 hp Maximum Traction Force – High Speed

304E CR/305E CR 30 kW 40.2 hp 303.5E CR 16.9 kN 3,799 lb

305.5E CR 32.9 kW 44.2 hp 304E CR 16.8 kN 3,777 lb

Gross Power 305E CR 24.1 kN 5,418 lb

303.5E CR 24.8 kW 33.3 hp 305.5E CR 26.8 kN 6,025 lb

304E CR/305E CR 31.2 kW 41.8 hp Maximum Traction Force – Low Speed

305.5E CR 34.1 kW 45.7 hp 303.5E CR 31 kN 6,969 lb

Bore 87 mm 3.4 in 304E CR 30.8 kN 6,921 lb

Stroke 102.4 mm 4 in 305E CR 45.2 kN 10,161 lb

Displacement 305.5E CR 47.8 kN 10,745 lb

303.5E CR/304E CR 1.8 L 110 in

305E CR/305.5E CR 2.4 L 146 in

Weights*

Operating Weight with Canopy

303.5E CR

304E CR

305E CR 4915 kg 10,836 lb Cooling System

305.5E CR 5270 kg 11,618 lb 303.5E CR/304E CR 5.5 L 1.5 gal

Operating Weight with Cab 305E CR/305.5E CR 10.5 L 2.8 gal

303.5E CR 3692 kg 8,139 lb Engine Oil

304E CR 4009 kg 8,838 lb 303.5E CR/304E CR 7.0 L 1.8 gal

305E CR 5088 kg 11,217 lb 305E CR/305.5E CR 9.5 L 2.5 gal

305.5E CR 5415 kg 11,938 lb Fuel Tank

* Weight includes rubber tracks, bucket, operator, full fuel

andauxiliary lines.

C1.8 Travel Speed – Low

®

C2.4 303.5E CR/304E CR/305E CR 2.6 km/h 1.6 mph

3508 kg

3854 kg

3

3

7,734 lb

8,497 lb

Ground Pressure

303.5E CR 32.1 kPa 4.7 psi

304E CR

305E CR

305.5E CR 30 kPa 4.4 psi

29.1 kPa

28.2 kPa

Service Refill Capacities

303.5E CR/304E CR 46 L 12.2 gal

305E CR/305.5E CR 63 L

Hydraulic Tank

303.5E CR/304E CR 42.3 L 11.2 gal

305E CR/305.5E CR 68.3 L 18 gal

Hydraulic System

303.5E CR/304E CR 65 L 17.2 gal

305E CR/305.5E CR 78 L 20.6 gal

4.2 psi

4.1 psi

16.6 gal

14

Page 15

Hydraulic System*

Swing System

Pump Flow at 2,400 rpm

303.5E CR/304E CR 87.6 L/min 23.1 gal/min

305E CR 119.3 L/min 31.5 gal/min

305.5E CR 129.6 L/min 34.2 gal/min

Operating Pressure – Equipment 245 bar 3,553 psi

Operating Pressure – Travel 245 bar 3,553 psi

Operating Pressure – Swing

303.5E CR/304E CR 181 bar 2,625 psi

305E CR/305.5E CR 185 bar 2,690 psi

Auxiliary Circuit – Primary (186 bar/2,734 psi)

303.5E CR/304E CR 60 L/min 15.9 gal/min

305E CR/305.5E CR 70 L/min 18.5 gal/min

Auxiliary Circuit – Secondary (174 bar/2,524 psi)

303.5E CR/304E CR 27 L/min 7.1 gal/min

305E CR/305.5E CR 38 L/min 10 gal/min

Digging Force = Stick (standard)

303.5E CR 18.9 kN 4,249 lb

304E CR 21.6 kN 4,856 lb

305E CR 24.7 kN 5,550 lb

305.5E CR 28.9 kN 6,500 lb

Digging Force = Stick (long)

303.5E CR 16.9 kN 3,799 lb

304E CR 19.5 kN 4,384 lb

305E CR 21.3 kN 4,788 lb

305.5E CR 24.8 kN 5,575 lb

Digging Force = Bucket

303.5E CR 33.0 kN 7,419 lb

304E CR 37.8 kN 8,498 lb

305E CR 44.7 kN 10,050 lb

305.5E CR 50.9 kN 11,445 lb

* Load sensing hydraulics with variable displacement piston pump.

Machine Swing Speed 9 rpm

Boom Swing – Left (without stop)

303.5E CR/305E CR/305.5E CR 80°

304E CR 70°

Boom Swing – Left (with stop)

303.5E CR/304E CR 55°

305E CR/305.5E CR 60°

Swing – Right 50°

Blade

Width

303.5E CR 1780 mm 70 in

304E CR 1950 mm 76.8 in

305E CR/305.5E CR 1980 mm 78 in

Height

303.5E CR/304E CR 325 mm 12.8 in

305E CR/305.5E CR 375 mm 14.8 in

Dig Depth

303.5E CR/304E CR 470 mm 18.5 in

305E CR/305.5E CR 540 mm 21.3 in

Lift Height

303.5E CR/304E CR 400 mm 15.7 in

305E CR/305.5E CR 420 mm 16.5 in

15

Page 16

303.5E CR, 304E CR, 305E CR, 305.5E CR Specifications

303.5E CR Dimensions

Standard Stick Long Stick Standard Stick Long Stick

2880 mm 9'6" 3180 mm 10'4"

1

2320 mm 7'8" 2470 mm 8'2"

2

5060 mm 16'8" 5320 mm 17'6"

3

5200 mm 17'1" 5440 mm 17'10"

4

4920 mm 16'2" 5030 mm 16'6"

5

3520 mm 11'6" 3640 mm 11'11"

6

2060 mm 6'9" 2180 mm 7'2"

7

890 mm 2'11" 890 mm 2'11"

8

400 mm 1'4" 400 mm 1'4"

9

10

470 mm 1'7" 470 mm 1'7"

11

12

13

14

15

16

17

18

19

1420 mm 4'8" 1650 mm 5'4"

2500 mm 8'2" 2500 mm 8'2"

565 mm 1'10" 565 mm 1'10"

2220 mm 7'3" 2220 mm 7'3"

4730 mm 15'6" 4790 mm 15'9"

765 mm 2'6" 765 mm 2'6"

670 mm 2'2" 670 mm 2'2"

300 mm 1'0" 300 mm 1'0"

1780 mm 5'10" 1780 mm 5'10"

303.5E CR Lift Capacities at Ground Level*

Lift Point Radius 3000 mm (9'8") 4000 mm (13'1")

Front Side Front Side

Blade Down kg

lb

Blade Up kg

lb

* The above loads are in compliance with hydraulic excavator lift capacity rating standard ISO 10567:2007 and they do not exceed 87% of hydraulic lifting capacity

or75% of tipping capacity. The excavator bucket weight is not included on this chart. Lifting capacities are for standard stick.

1370 740 880 470

2,940 1,590 1,890 1,010

770 680 490 440

1,698 1,499 1,080 970

16

Page 17

304E CR Dimensions

Standard Stick Long Stick Standard Stick Long Stick

3130 mm 10'3" 3430 mm 11'3"

1

2420 mm 8'0" 2560 mm 8'5"

2

5220 mm 17'1" 5470 mm 18'0"

3

5350 mm 17'7" 5590 mm 18'4"

4

4980 mm 16'5" 5070 mm 16'8"

5

3590 mm 11'9" 3690 mm 12'1"

6

2110 mm 6'11" 2220 mm 7'3"

7

975 mm 3'2" 975 mm 3'2"

8

400 mm 1'4" 400 mm 1'4"

9

10

470 mm 1'7" 470 mm 1'7"

11

12

13

14

15

16

17

18

19

1480 mm 4'10" 1770 mm 5'9"

2500 mm 8'2" 2500 mm 8'2"

565 mm 1'10" 565 mm 1'10"

2220 mm 7'3" 2220 mm 7'3"

4820 mm 15'10" 4930 mm 16'2"

735 mm 2'5" 735 mm 2'5"

670 mm 2'2" 670 mm 2'2"

350 mm 1'1" 350 mm 1'1"

1950 mm 6'5" 1950 mm 6'5"

304E CR Lift Capacities at Ground Level*

Lift Point Radius 3000 mm (9'8") 4500 mm (14'9")

Front Side Front Side

Blade Down kg

lb

Blade Up kg

lb

* The above loads are in compliance with hydraulic excavator lift capacity rating standard ISO 10567:2007 and they do not exceed 87% of hydraulic lifting capacity

or75% of tipping capacity. The excavator bucket weight is not included on this chart. Lifting capacities are for standard stick.

1610 920 1040 590

3,549 2,028 2,292 1,301

830 830 530 530

1,830 1,830 1,168 1,168

17

Page 18

303.5E CR, 304E CR, 305E CR, 305.5E CR Specifications

305E CR Dimensions

Standard Stick Long Stick Standard Stick Long Stick

3280 mm 10'9" 3670 mm 12'1"

1

2320 mm 7'7" 2630 mm 8'8"

2

5430 mm 17'10" 5810 mm 19'1"

3

5600 mm 18'5" 5960 mm 19'7"

4

5250 mm 17'3" 5440 mm 17'10"

5

3720 mm 12'2" 3920 mm 12'10"

6

2350 mm 7'8" 2530 mm 8'3"

7

1100 mm 3'7" 1100 mm 3'7"

8

405 mm 1'4" 405 mm 1'4"

9

10

555 mm 1'10" 555 mm 1'10"

11

12

13

14

15

16

17

18

19

1750 mm 5'9" 2150 mm 7'0"

2550 mm 8'4" 2550 mm 8'4"

615 mm 2'0" 615 mm 2'0"

2580 mm 8'5" 2580 mm 8'5"

5180 mm 17'0" 5290 mm 17'4"

785 mm 2'7" 785 mm 2'7"

695 mm 2'3" 695 mm 2'3"

400 mm 1'4" 400 mm 1'4"

1980 mm 6'6" 1980 mm 6'6"

305E CR Lift Capacities at Ground Level*

Lift Point Radius 3000 mm (9'8") 4500 mm (14'9")

Front Side Front Side

Blade Down kg

lb

Blade Up kg

lb

* The above loads are in compliance with hydraulic excavator lift capacity rating standard ISO 10567:2007 and they do not exceed 87% of hydraulic lifting capacity

or75% of tipping capacity. The excavator bucket weight is not included on this chart. Lifting capacities are for standard stick.

2340 1200 1260 640

5,159 2,646 2,778 1,411

1450 1070 760 570

3,197 2,359 1,676 1,257

18

Page 19

305.5E CR Dimensions

Standard Stick Long Stick Standard Stick Long Stick

3470 mm 11'4" 3870 mm 12'8"

1

2330 mm 7'8" 2730 mm 9'0"

2

5630 mm 18'6" 6020 mm 19'9"

3

5790 mm 19'0" 6170 mm 20'3"

4

5330 mm 17'6" 5590 mm 18'4"

5

3820 mm 12'7" 4080 mm 13'4"

6

2400 mm 7'10" 2530 mm 8'3"

7

1130 mm 3'8" 1130 mm 3'8"

8

405 mm 1'4" 405 mm 1'4"

9

10

555 mm 1'10" 555 mm 1'10"

11

12

13

14

15

16

17

18

19

1740 mm 5'8" 2150 mm 6'11"

2550 mm 8'4" 2550 mm 8'4"

615 mm 2'0" 615 mm 2'0"

2580 mm 8'6" 2580 mm 8'6"

5330 mm 17'6" 5460 mm 17'10"

785 mm 2'7" 785 mm 2'7"

695 mm 2'3" 695 mm 2'3"

400 mm 1'4" 400 mm 1'4"

1980 mm 6'6" 1980 mm 6'6"

305.5E CR Lift Capacities at Ground Level*

Lift Point Radius 3000 mm (9'8") 4500 mm (14'9")

Front Side Front Side

Blade Down kg

lb

Blade Up kg

lb

* The above loads are in compliance with hydraulic excavator lift capacity rating standard ISO 10567:2007 and they do not exceed 87% of hydraulic lifting capacity

or75% of tipping capacity. The excavator bucket weight is not included on this chart. Lifting capacities are for standard stick.

2590 1290 1380 690

5,710 2,844 3,042 1,521

1550 1150 820 620

3,417 2,535 1,808 1,367

19

Page 20

303.5E CR, 304E CR, 305E CR, 305.5E CR Standard Equipment

Standard Equipment

Standard equipment may vary. Consult your Cat dealer for details.

• 1-way and 2-way (combined function) auxiliary hydraulic lines

• Adjustable auxiliary ow control for work tools

• Adjustable wrist rests

• Alternator

• Anti-theft security system

• Automatic engine idle

• Automatic swing park brake

• Automatic two speed travel

• Auxiliary line quick disconnects

• Boom cylinder guard

• Cab mounted work light

• Canopy with FOPS ISO 10262 (Level 1) and

Tip-Over Protection (TOPS) ISO 12117

• Coat hook

• COMPASS display panel

• Cup holder

• Continuous ow

• Control pattern changer (not available in Europe)

• Dozer blade with oat function

• Economy mode setting for up to 20% fuel savings

• Floor mat

• Foot travel pedals

• Gauges or indicators for fuel level engine coolant temperature,

hour meter, engine oil pressure, air cleaner, alternator and

glowplugs, service interval

• Horn

• Hydraulic oil cooler

• Lifting eye on bucket linkage

(standard equipment for all regions except Europe)

• Lockable storage box

• Low maintenance linkage pin joints

• Maintenance free battery

• Rubber track

• Retractable seatbelt

• Standard stick

• Suspension seat, vinyl covered

• “Thumb Ready” sticks

(standard equipment for all regions exceptEurope)

• Travel alarm (optional in Europe)

20

Page 21

303.5E CR, 304E CR, 305E CR, 305.5E CR Optional Equipment

Optional Equipment

Optional equipment may vary. Consult your Cat dealer for details.

• Air conditioning • Hydraulic quick coupler lines

• Angle dozer blade with oat function • Lifting eye on bucket linkage

• Beacon socket for canopy machines

• Boom check valve (Europe only)

• Boom mounted light

• Cab, radio ready with FOPS ISO 10262 (Level 1) and Tip-Over

Protection (TOPS) ISO 12117 with heater/defroster, interior light • Seatbelt, 75 mm (3 in) wide

and windshield wiper/washer (optional in Europe, standard in all other regions)

• Ecology drain valve for hydraulic tank • Secondary auxiliary hydraulic lines

• High back suspension seat, fabric covered • Steel track and steel track with rubber pads

(optional in Europe, standard for all other regions)

• Long stick

• Mechanical quick coupler

• Mirrors for cab and canopy

21

Page 22

Notes

22

Page 23

23

Page 24

303.5E CR, 304E CR, 305E CR, 305.5E CR Mini Hydraulic Excavators

For more complete information on Cat products, dealer services, and industry solutions,

visit us on the web at www.cat.com

© 2012 Caterpillar Inc.

All rights reserved

Materials and specications are subject to change without notice. Featured machines

in photos may include additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow”

and the “Power Edge” trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

20

AEHQ6558 (05-2012)

Loading...

Loading...