Page 1

Operating instructions

for washing machines

To avoid the risk of accidents or damage to the machine, it is essential

to read these instructions before it is installed and used for the first time.

en-GB M.-Nr. 10 165 360

Page 2

Contents

Caring for the environment................................................................................... 6

Warning and Safety instructions ......................................................................... 7

Operating the washing machine......................................................................... 14

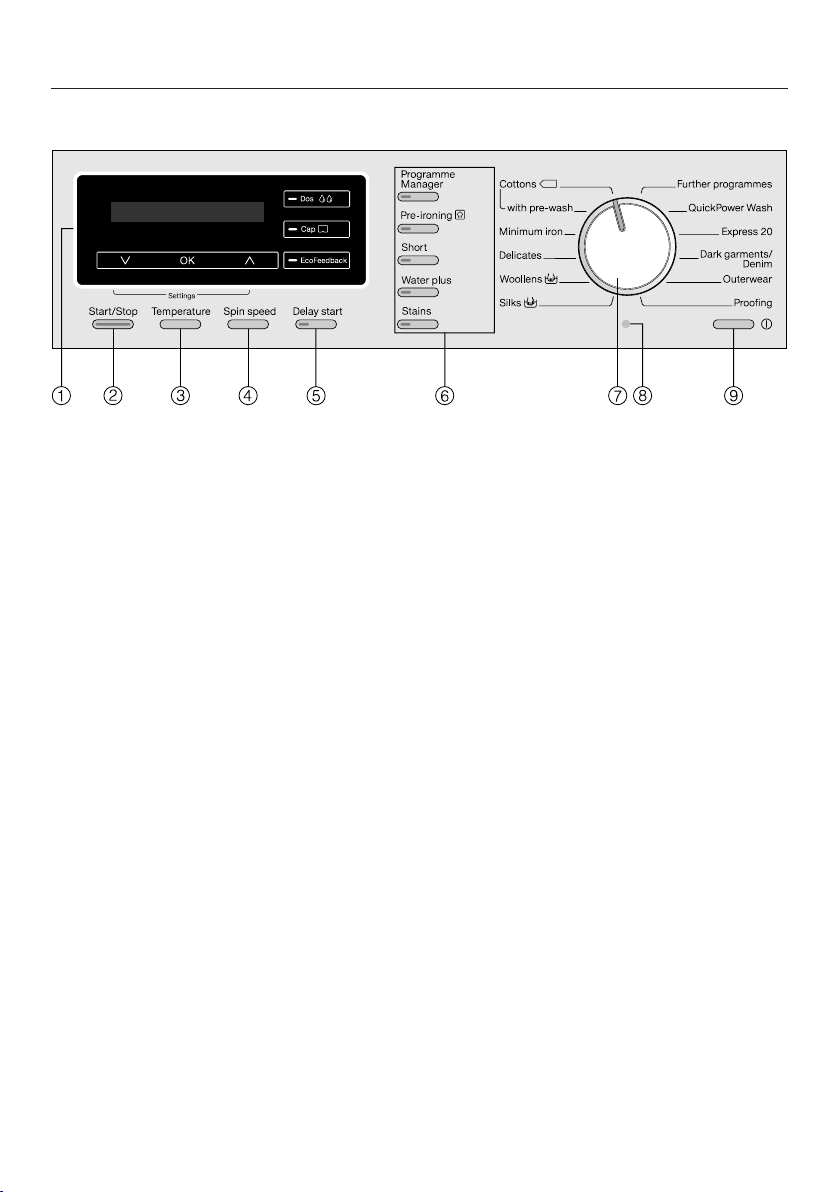

Control panel.......................................................................................................... 14

Examples on how to operate the machine ............................................................ 16

Before using for the first time............................................................................. 17

Removing the detergent cartridges from the drum................................................ 17

Setting the language.............................................................................................. 18

Messages............................................................................................................... 18

Running the first programme ................................................................................. 18

TwinDos ................................................................................................................ 19

Inserting cartridges/containers .............................................................................. 20

Using cartridges................................................................................................ 20

Using containers............................................................................................... 21

Open the Settings menu ........................................................................................ 22

Settings for UltraPhase 1 and UltraPhase 2 ..................................................... 22

Settings for other types of detergent................................................................ 22

Running the first programme ................................................................................. 24

Washing environmentally and economically..................................................... 25

EcoFeedback......................................................................................................... 26

1. Prepare the laundry ......................................................................................... 27

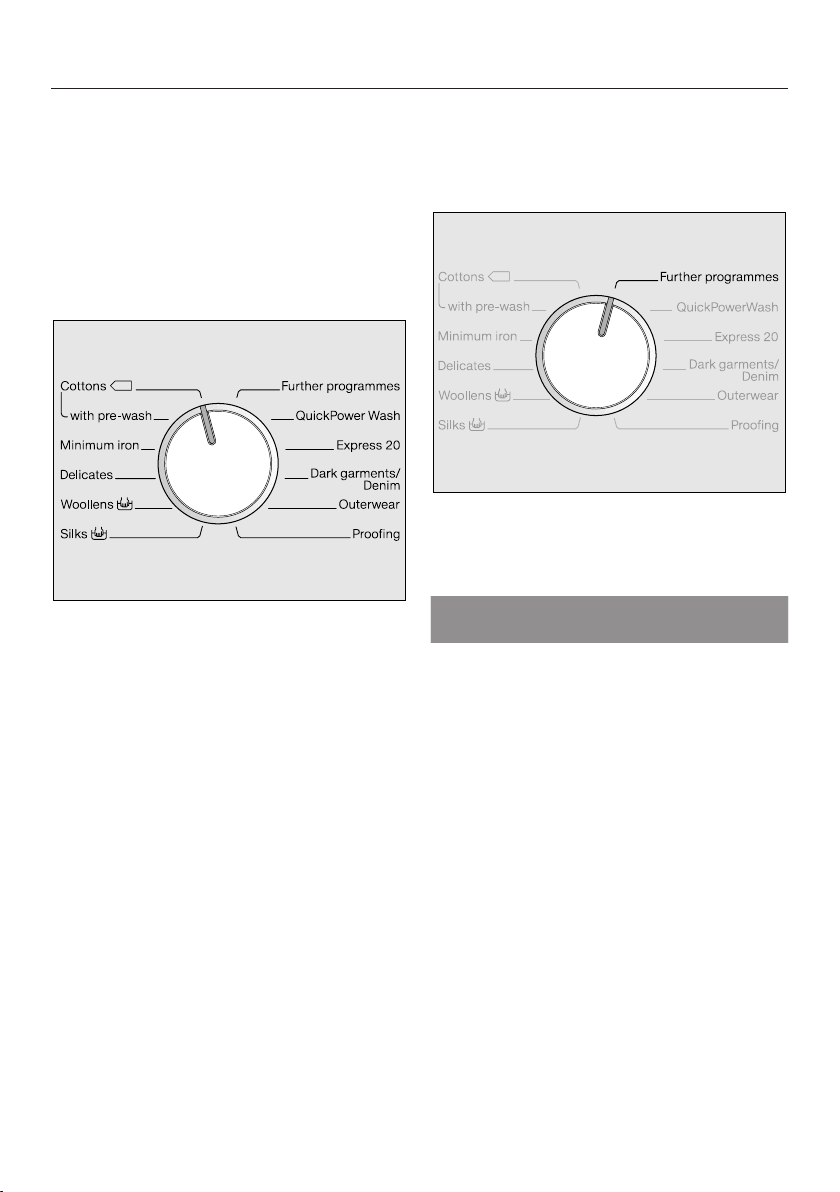

2. Select a programme ........................................................................................ 28

3. Load the washing machine ............................................................................. 29

4. Select programme settings............................................................................. 30

5. Add detergent................................................................................................... 32

TwinDos ................................................................................................................. 32

Detergent dispenser drawer................................................................................... 33

CapDosing ............................................................................................................. 34

6. Start the programme - the end of a programme........................................... 36

2

Page 3

Contents

Spinning ................................................................................................................ 37

Delay start............................................................................................................. 39

To select delay start............................................................................................... 39

To change delay start............................................................................................. 39

To cancel delay start and begin the programme straight away............................. 39

Programme chart................................................................................................. 40

Options.................................................................................................................. 45

ProgrammeManager .............................................................................................. 45

Intensive............................................................................................................ 45

ECO .................................................................................................................. 45

Extra gentle....................................................................................................... 45

Extra quiet......................................................................................................... 45

AllergoWash...................................................................................................... 45

Short ...................................................................................................................... 46

Water plus.............................................................................................................. 46

Stains ..................................................................................................................... 46

Wash programme chart - ProgrammeManager ..................................................... 47

Garment care label symbols ............................................................................... 49

Programme sequence ......................................................................................... 50

Changing the programme sequence ................................................................. 52

Cancelling a programme........................................................................................ 52

Interrupting a programme...................................................................................... 52

Changing a programme ......................................................................................... 52

Adding or removing laundry after the programme has started.............................. 53

Safety lock ............................................................................................................. 54

Detergent.............................................................................................................. 55

The correct detergent ............................................................................................ 55

Water softeners...................................................................................................... 55

Dispensing aids...................................................................................................... 55

Fabric conditioner and liquid starch ...................................................................... 55

Miele recommended detergents............................................................................ 56

Recommended detergents in accordance with Directive (EU) Nr. 1015/2010 ...... 57

3

Page 4

Contents

Cleaning and care................................................................................................ 60

Cleaning the drum (Hygiene info)........................................................................... 60

External casing and fascia panel ........................................................................... 60

Cleaning the detergent dispenser drawer.............................................................. 60

Cleaning the TwinDos system................................................................................ 62

Cleaning the containers and hoses .................................................................. 62

Cleaning the water inlet filter ................................................................................. 63

Problem solving guide......................................................................................... 64

The programme does not start .............................................................................. 64

The following fault messages appear in the display and

the programme stops .............................................................................................

The following fault messages appear in the display at the end of

the programme....................................................................................................

Problems with TwinDos.......................................................................................... 68

General problems with the washing machine........................................................ 69

An unsatisfactory wash result................................................................................ 71

The door will not open ........................................................................................... 72

Opening the door in the event of a blocked drain outlet and/or power failure...... 73

After sales service ............................................................................................... 75

Repairs................................................................................................................... 75

Guarantee: U.K....................................................................................................... 75

Guarantee: Other countries.................................................................................... 75

Optional accessories ............................................................................................. 75

65

66

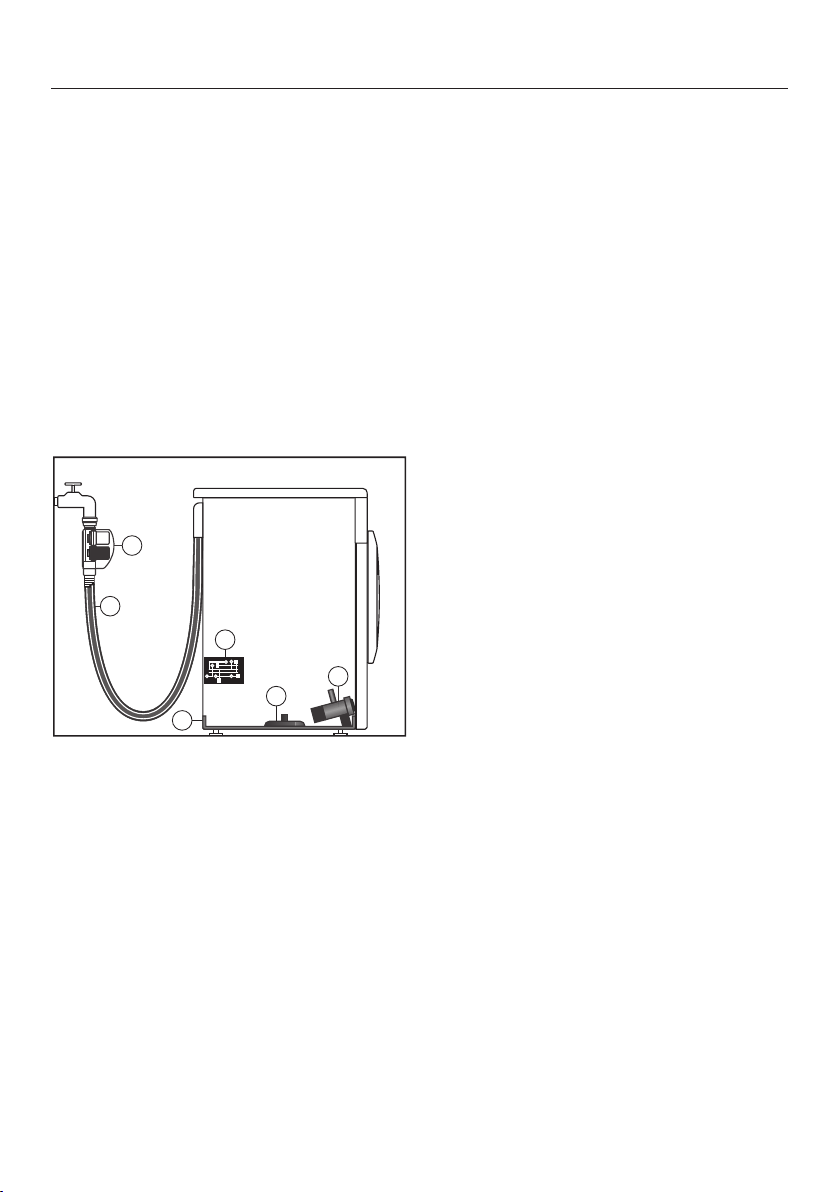

Installation and connection................................................................................. 76

Front view............................................................................................................... 76

Rear view ............................................................................................................... 77

Installation surface................................................................................................. 78

Transporting the washing machine to its installation site ...................................... 78

Removing the transit bars...................................................................................... 78

Re-fitting the transit bars ....................................................................................... 80

Levelling the machine ............................................................................................ 81

Screwing out and adjusting the feet................................................................. 81

Building under a continuous worktop/ in a kitchen run.................................... 82

Washer-dryer stack........................................................................................... 82

The water protection system ................................................................................. 83

Connection to the water supply............................................................................. 85

Connection to the drainage system....................................................................... 87

Electrical connection U.K....................................................................................... 88

4

Page 5

Contents

Technical data ...................................................................................................... 89

Consumption data ............................................................................................... 90

Note for test institutes............................................................................................ 91

Settings................................................................................................................. 92

Language ............................................................................................................ 93

Detergent/amount.................................................................................................. 93

Degree of soiling .................................................................................................... 93

Buzzer volume ....................................................................................................... 93

Keypad tone........................................................................................................... 93

Total consumption ................................................................................................. 93

Code ...................................................................................................................... 94

Temperature unit.................................................................................................... 94

Display brightness ................................................................................................. 94

Dark display ........................................................................................................... 94

Machine switch-off ................................................................................................ 95

Memory.................................................................................................................. 95

Pre-wash Cottons.................................................................................................. 95

Gentle action.......................................................................................................... 95

Reduce temp.......................................................................................................... 96

Water plus.............................................................................................................. 96

Water plus level...................................................................................................... 96

Maximum rinse level .............................................................................................. 96

Suds cooling .......................................................................................................... 97

Anti-crease............................................................................................................. 97

Optional accessories........................................................................................... 98

Detergent ............................................................................................................... 98

Specialist detergents ............................................................................................. 98

Fabric care ............................................................................................................. 99

Additives ................................................................................................................ 99

5

Page 6

Caring for the environment

Disposal of the packing mate‐

rial

The packaging is designed to protect

the washing machine from damage dur‐

ing transportation. The packaging ma‐

terials used are selected from materials

which are environmentally friendly for

disposal and should be recycled.

Recycling the packaging reduces the

use of raw materials in the manufactur‐

ing process and also reduces the

amount of waste in landfill sites. Ensure

that any plastic wrappings, bags etc.

are disposed of safely and kept out of

the reach of babies and young children.

Danger of suffocation.

Disposal of your old machine

Electrical and electronic machines often

contain valuable materials. They also

contain materials which, if handled or

disposed of incorrectly, could be po‐

tentially hazardous to human health and

to the environment. They are, however,

essential for the correct functioning of

your machine. Please do not therefore

dispose of it with your household

waste.

Please dispose of it at your local com‐

munity waste collection / recycling cen‐

tre or contact your Dealer for advice.

Ensure that it presents no danger to

children while being stored for disposal.

6

Page 7

Warning and Safety instructions

This washing machine complies with current safety requirements.

Inappropriate use can, however, lead to personal injury and dam‐

age to property.

To avoid the risk of accidents and damage to the machine, please

read these instructions carefully before using it for the first time.

They contain important information on its safety, use and mainte‐

nance.

Keep these instructions in a safe place and ensure that new users

are familiar with the content. Pass them on to any future user.

Correct application

This washing machine is intended for use in domestic households

and similar working and residential environments.

The washing machine is not intended for outdoor use.

It must be used only as a domestic appliance to wash items

which are specified by the manufacturer as being washable on the

wash care label. Miele cannot be held liable for damage resulting

from incorrect or improper use or operation.

The washing machine can only be used by people with reduced

physical, sensory or mental capabilities, or lack of experience or

knowledge, if they are supervised whilst using it or have been shown

how to use it safely and recognise and understand the consequen‐

ces of incorrect operation.

7

Page 8

Warning and Safety instructions

Safety with children

Children under 8 years of age must be kept away from the wash‐

ing machine unless they are constantly supervised.

Children 8 years and older may only use the washing machine un‐

supervised if they have been shown how to use it safely and recog‐

nise and understand the consequences of incorrect operation.

Children must not be allowed to clean or maintain the washing

machine unsupervised.

Please supervise children in the vicinity of the washing machine

and do not let them play with it.

Technical safety

Please observe the instructions in "Installation and connection"

and "Technical data".

Before setting up the washing machine, check it for any externally

visible damage. Do not install or use a damaged machine.

Before connecting the washing machine, ensure that the connec‐

tion data on the data plate (fuse rating, voltage and frequency)

match the mains electricity supply. If in any doubt, consult a quali‐

fied electrician.

Reliable and safe operation of this washing machine can only be

assured if it has been connected to the mains electricity supply.

8

Page 9

Warning and Safety instructions

The electrical safety of this washing machine can only be guaran‐

teed when correctly earthed.

It is essential that this standard safety requirement is met. If in any

doubt, please have the wiring system of the building tested by a

qualified electrician.

Miele cannot be held liable for the consequences of an inadequate

earthing system (e.g. electric shock).

Do not connect the washing machine to the mains electricity sup‐

ply by a multi-socket adapter, extension lead or similar. These do

not guarantee the required safety of the machine (fire hazard due to

the risk of overheating).

Faulty components must only be replaced by genuine Miele origi‐

nal spare parts. Only when these parts are fitted can Miele guaran‐

tee the safety standards of the machine.

The electrical socket must be easily accessible after installation

so that the machine can be disconnected from the electricity supply

if necessary.

Unauthorised repairs could result in unforeseen dangers for the

user, for which the manufacturer cannot accept liability. Repairs

should only be undertaken by a Miele authorised service technician,

otherwise any subsequent damage will not be covered by the guar‐

antee.

If the electrical connection cable is faulty it must only be replaced

by a Miele authorised service technician to protect the user from

danger.

9

Page 10

Warning and Safety instructions

The machine must be isolated from the electricity supply when

cleaning and maintaining the machine and in the event of a fault.

The Miele "Water protection system" protects from water damage

provided the following conditions are met:

– the machine is correctly plumbed in and connected to the elec‐

tricity supply.

– if a fault or damage has been identified, the machine must be ex‐

amined by a competent person before further use, and repaired if

necessary.

The water flow pressure must be at least 100 kPa and should not

exceed 1000 kPa.

In areas which may be subject to infestation by cockroaches or

other vermin, pay particular attention to keeping the machine and its

surroundings in a clean condition at all times. Any damage which

may be caused by cockroaches or other vermin will not be covered

by the guarantee.

The machine must not be used in a non-stationary location (e.g.

on a ship).

Do not make any alterations to the machine, unless authorised to

do so by Miele.

10

Page 11

Warning and Safety instructions

Correct use

Do not install the washing machine in a room where there is a risk

of frost. Frozen hoses may burst or split. The reliability of the elec‐

tronic control unit may be impaired at temperatures below freezing

point.

Before using the machine for the first time, check that the transit

bars at the rear of the machine have been removed (see "Installation

and connection - Removing the transit bars"). During spinning, a

transit bar which is still in place may result in damage to both the

machine and adjacent furniture or appliances.

Turn off the stopcock if the machine is to be left for any length of

time (e.g. holiday), especially if there is no floor drain (gully) in the

immediate vicinity.

Flooding danger.

If hooking the drain hose into a wash basin, check that the water can

drain off quickly enough to prevent the sink from overflowing. Make

sure the drain hose is secure, so that the force of the water flowing

out of the hose does not dislodge it.

Take care to ensure that foreign objects (e.g. nails, pins, coins,

paper clips) do not find their way into the machine with the laundry.

These may damage components of the machine (e.g. suds contain‐

er, drum), which in turn can result in damage to the laundry.

11

Page 12

Warning and Safety instructions

Take care when opening the drum door after using the steam

function. Danger of burning due to escaping steam and the high

temperature of the surface of the drum as well as the porthole glass.

Stand back away from the machine and wait until the steam has dis‐

sipated.

The maximum load for this washing machine is 8 kg (dry weight).

See the "Programme chart" for the maximum recommended loads

for individual programmes.

If the correct amount of detergent is dispensed, the machine

should not need to be descaled. If, however, you do wish to descale

it, only use a proprietary natural citric acid based descaling agent.

Miele recommends using Miele descaling agent which is available to

order online at www.miele-shop.com or from Miele. Strictly observe

the instructions on the packaging.

Textiles which have been pre-treated in solvent based cleaning

agents must be thoroughly rinsed in clean water before being wash‐

ed in the machine.

Do not use solvent based cleaning agents, e.g. those containing

benzine, in this machine, as this may result in damage to component

parts and create toxic fumes. Such agents also pose a fire and ex‐

plosion hazard.

Do not use solvent based cleaning agents, e.g. those containing

benzine, to clean the surfaces of the machine. They can cause dam‐

age to plastic surfaces.

Only use dyes specified by the manufacturer as being suitable for

use in a domestic washing machine. Always observe the manufac‐

turer's instructions carefully.

12

Page 13

Warning and Safety instructions

Colour run and dye removers contain sulphur compounds which

can cause damage such as corrosion. Do not use these products in

this machine.

If detergent comes into contact with the eyes, rinse them thor‐

oughly with lukewarm water immediately. If swallowed, seek medical

assistance immediately and retain the packaging or label for refer‐

ence. Those with skin problems or sensitive skin should avoid their

skin coming into contact with detergent.

Accessories

Accessory parts may only be fitted when expressly approved by

Miele. If other parts are used, guarantee, performance and product

liability claims will be invalidated.

A Miele tumble dryer can be stacked on top of a Miele washing

machine using the appropriate stacking kit (available as an optional

accessory). Please make sure you order the correct one for the Miele

washing machine and Miele tumble dryer.

If installing the machine on a Miele plinth, (available as an optional

accessory, depending on country), please make sure you order the

correct one for this washing machine.

Miele cannot be held liable for damage caused by non-compli‐

ance with these Warning and Safety instructions.

13

Page 14

Operating the washing machine

Control panel

a

Display with sensors

See the next page for more informa‐

tion.

b

Start/Stop button

For starting the programme selected

and cancelling a programme once it

has started.

c

Temperature button

For selecting the temperature.

d

Spin speed button

For selecting the spin speed.

e

Delay start button

For selecting delay start.

f

Option buttons

Various options can be added to the

wash programme.

g

Programme selector

For selecting the wash programme.

h

Optical interface PC

For service technicians.

i

button

For switching the washing machine

on and off.

To save energy the washing machine

will switch off automatically 15 mi‐

nutes after the end of the pro‐

gramme/anti-crease phase or after

being switched on if no other selec‐

tion is made.

14

Page 15

Operating the washing machine

Programme duration

After the programme has started the

programme duration will appear in the

display in hours and minutes.

If delay start has been selected, the

programme duration will appear at the

end of the delay start time.

Delay start

The delay start time selected will ap‐

pear in the display.

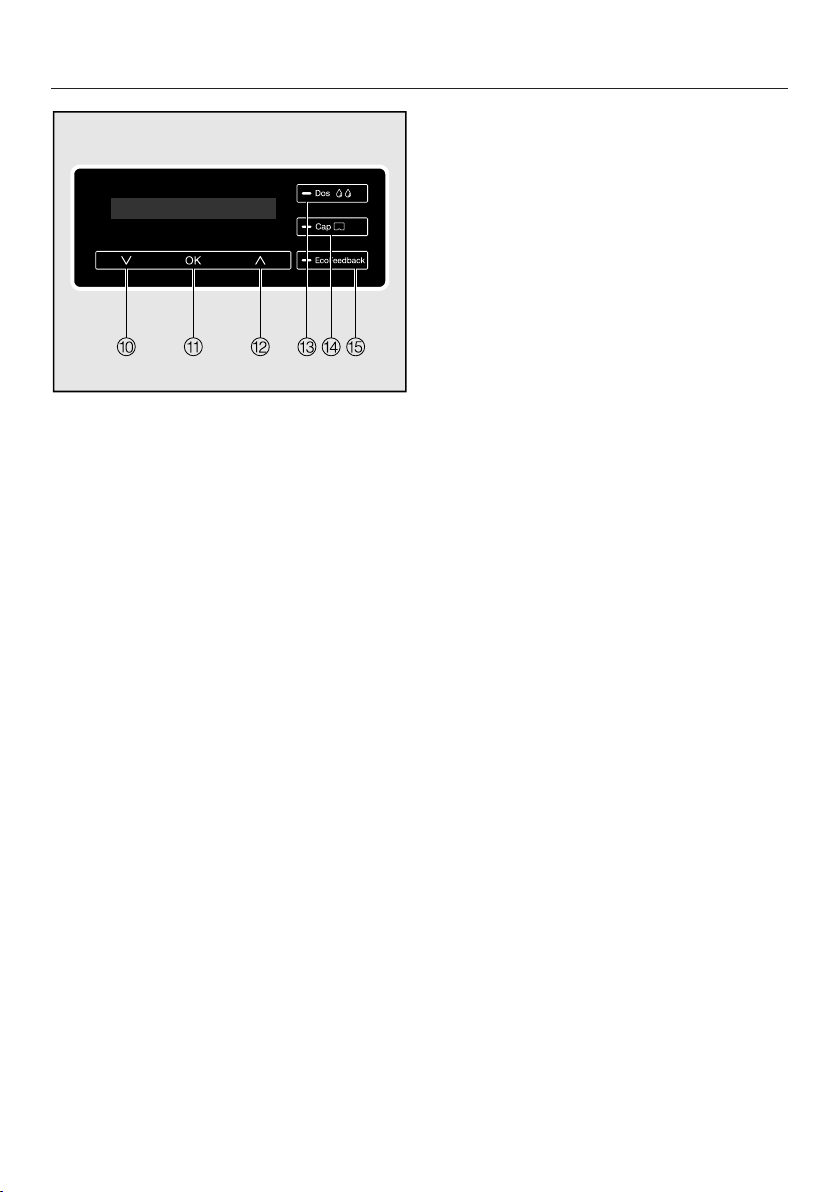

j

sensor

Scrolls down the list to the next op‐

tion or decreases a value.

k

OK button

Confirms the programme selected, a

value set or opens a sub-menu.

l

sensor

Scrolls up the list to the next option

or increases a value.

m

Dos sensor

Switches on automatic detergent

dispensing.

n

Cap sensor

Activates cap dosing via the deter‐

gent dispenser drawer.

o

EcoFeedback sensor

Provides information about the ener‐

gy and water consumption of the

programme. Please also refer to

"Washing environmentally and eco‐

nomically - EcoFeedback".

Sensors to light up when the dis‐

play can be operated via the sensors.

After the programme has started the

delay start time will begin to count

down.

Once the delay start time has elapsed,

the estimated programme duration will

appear in the display.

15

Page 16

Operating the washing machine

2:59 1600

Language

Cap

Start in h00 :00

Standard display

The standard display shows the follow‐

ing from left to right:

– the programme duration

– the selected wash temperature

– the selected spin speed

Examples on how to operate the machine

Scrolling through a list

The arrows in the display indicate

that a list is available.

Touching the sensor scrolls down the

list to the next option and touching the

sensor scrolls up the list to the next

option. The OK sensor is used to acti‐

vate the option which is currently in the

display.

Setting numerical values

A numerical value is highlighted in

white. Touching the sensor decrea‐

ses the value and touching the sen‐

sor increases it. The OK sensor is used

to activate the value which is currently

in the display.

Exiting a sub-menu

Select Back to exit a sub-menu.

Identifying options selected

If an option has been activated, this will

be indicated by a tick next to it.

16

Page 17

Before using for the first time

Before using the machine for the

first time ensure that it is correctly in‐

stalled and connected. See "Installa‐

tion and connection". Also check

that the drain filters are securely

tightened to prevent the risk of water

leaks during use.

Removing the protective foil and stickers

Remove

– the protective foil from the door.

– any stickers from the front and the

lid.

Please do not remove any labels

(e.g. the data plate), visible when you

open the door.

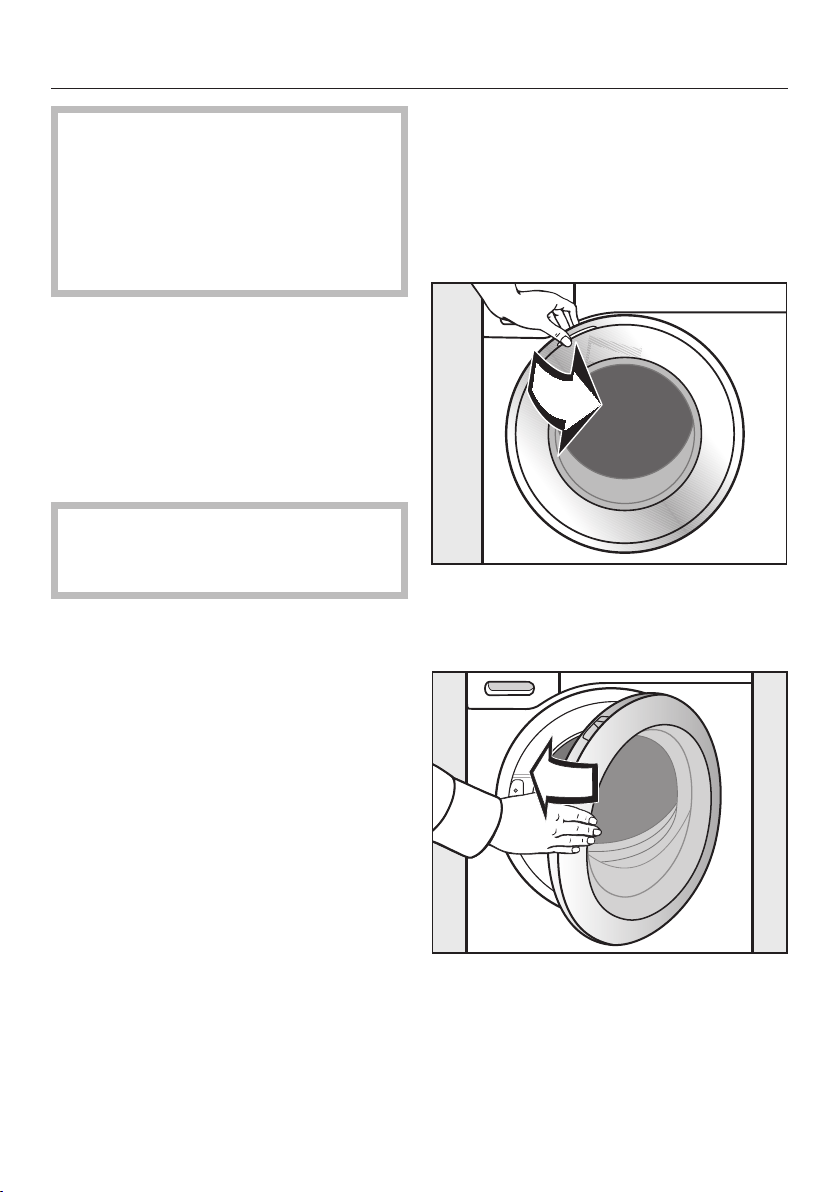

Removing the detergent car‐

tridges from the drum

There are two cartridges containing

UltraPhase1 and UltraPhase2 detergent

for automatic detergent dispensing in

the drum.

Pull open the door.

Take the two cartridges out of the

drum.

Shut the door with a gentle swing.

17

Page 18

Before using for the first time

deutsch

This washing machine has undergone

a complete functional test at the fac‐

tory and there will be some residual

water in the drum from this process.

For safety reasons, spinning is not pos‐

sible until the machine has been pre‐

pared for using for the first time. To ac‐

tivate the spinning function you must

run a wash programme without laundry

and without detergent.

Using detergent could result in an ex‐

cessive build-up of foam.

Press the button in.

The welcome screen will light up.

Setting the language

You will be asked to select the lan‐

guage you want for the display. It is

possible to change the language at any

time via "Settings".

Touch the or sensor until the

language you want appears in the

display.

Confirm your selection of the lan‐

guage by touching the OK sensor.

Messages

Two messages about removing the

transit bars and preparing the washing

machine for use will appear in the dis‐

play.

Confirm the messages with the OK

sensor.

Running the first programme

18

The TwinDos unit needs to be activa‐

ted before running the first pro‐

gramme.

Please see "TwinDos".

Page 19

TwinDos

The washing machine has an integrated

detergent dispensing unit.

The detergent dispensing unit can be

used with

1. the Miele 2 Phase System

or

2. any other liquid detergent and/or fab‐

ric conditioner

The Miele 2 Phase System

The Miele 2 Phase System uses a base

detergent (UltraPhase 1) and a deter‐

gent enhancer (UltraPhase 2). In order

to achieve optimum results, the agents

are dispensed separately during the

wash process. The 2 Phase System

cleans both white and coloured textiles

thoroughly. UltraPhase 1 and

UltraPhase 2 single use cartridges are

available to order from Miele or via the

internet at www.miele-shop.com (see

end of this booklet for contact details).

Liquid detergent/Fabric conditioner

The washing machine is supplied with

two refillable containers which you can

fill with liquid detergent and/or fabric

conditioner.

How TwinDos works

Automatic detergent dispensing for a

wash cycle is activated via the Dos

sensor.

To use the TwinDos function, you need

to specify the following information for

the electronic unit:

1. the detergent type and/or fabric

conditioner with which the contain‐

ers are filled.

2. the dosage amount of the liquid de‐

tergent or fabric conditioner. The

dosage amount for Miele products is

pre-set at the factory.

Do not fill the containers with any

specialist detergents. Use cap dos‐

ing or the detergent dispenser draw‐

er for these.

Automatic dispensing cannot be selec‐

ted with some programmes, depending

on the detergent present in the TwinDos

system. For example, automatic dis‐

pensing cannot be activated for the

Woollens programme if the Miele 2

Phase System is being used. This pre‐

vents woollen garments being dam‐

aged by a detergent which is not suita‐

ble for washing wool.

19

Page 20

TwinDos

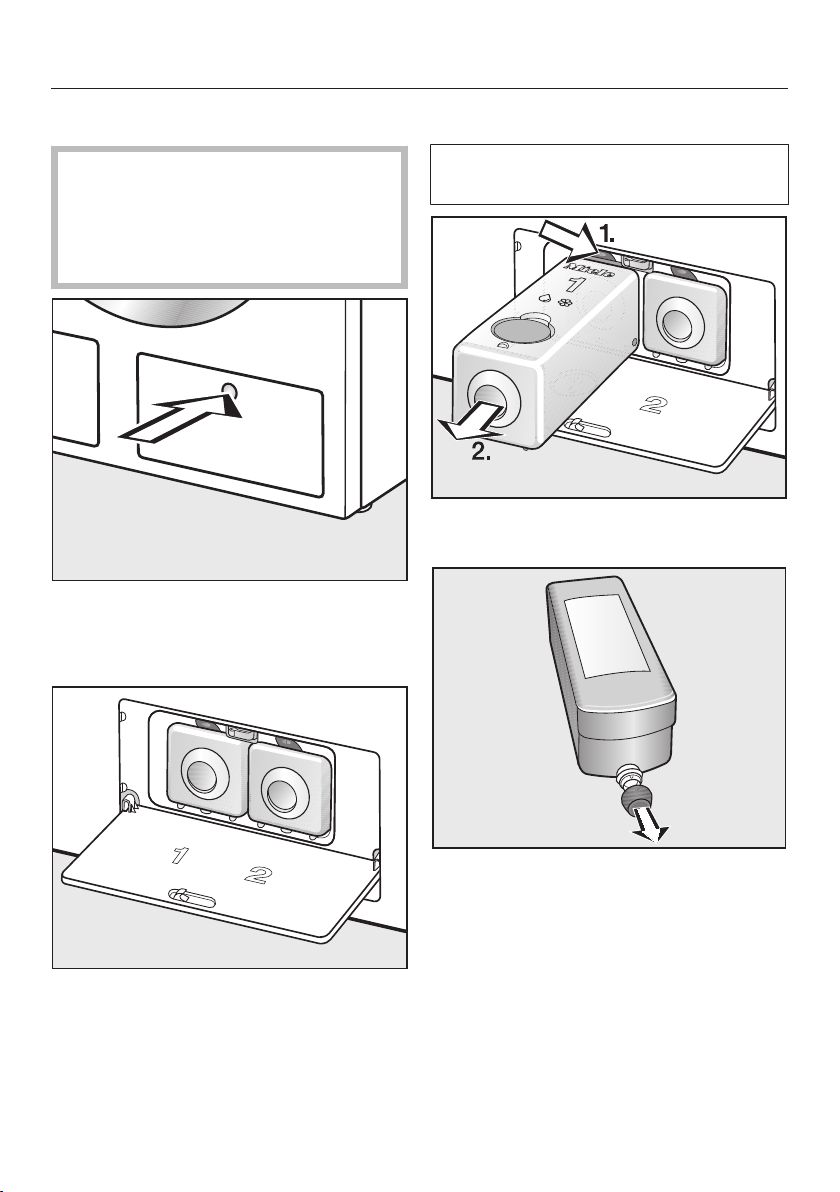

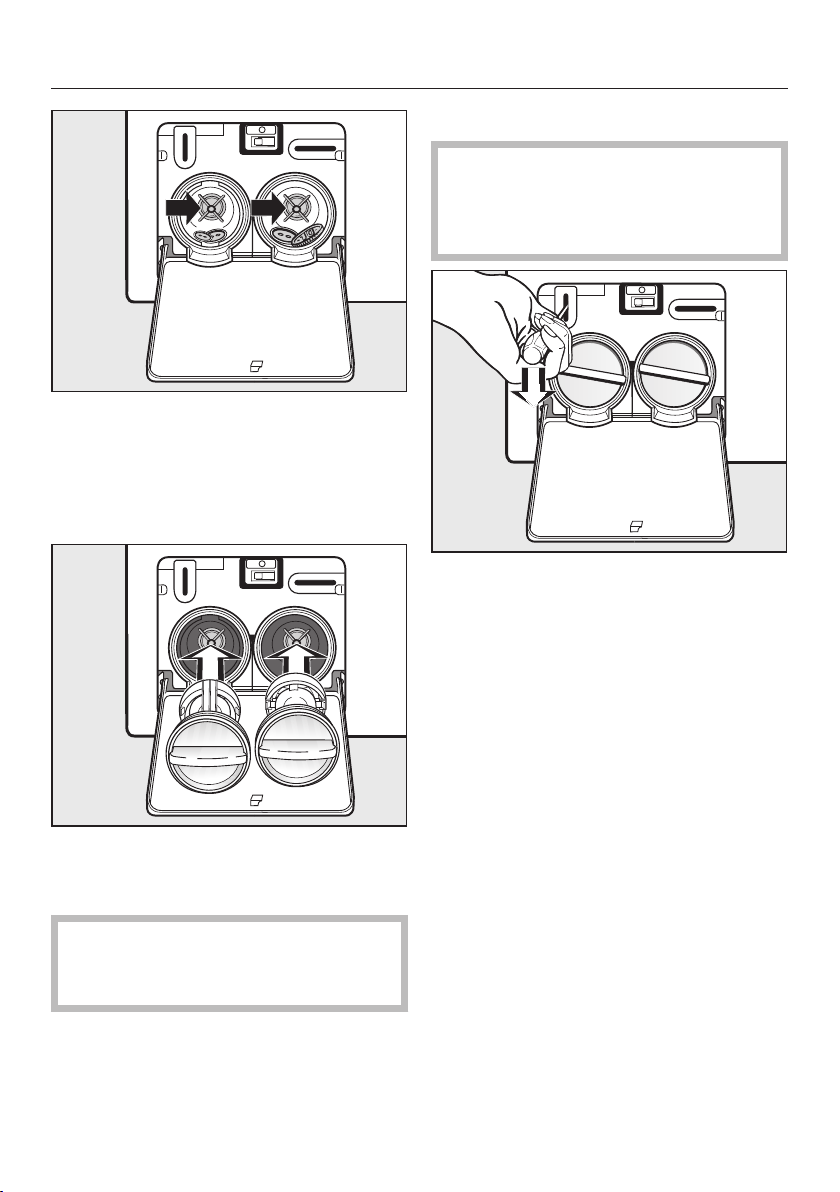

Inserting cartridges/containers

Keep filled containers or car‐

tridges out of the reach of children.

Observe the instructions for use and

warning instructions given by the de‐

tergent manufacturer.

Press the TwinDos container access

panel.

The panel will spring open.

Using cartridges

UltraPhase 1 and UltraPhase 2 are

supplied in single use cartridges.

Press the yellow release button (1.)

and pull the container out (2.).

Drop the panel down.

20

Remove the cap from the cartridge.

Page 21

Push the UltraPhase 1 cartridge into

Compartment 1 until it locks into po‐

sition.

Remove container 2 and push the

UltraPhase 2 cartridge into Com‐

partment 2 until it locks into position.

Keep the containers in a safe place.

They can be used for other types of

detergent.

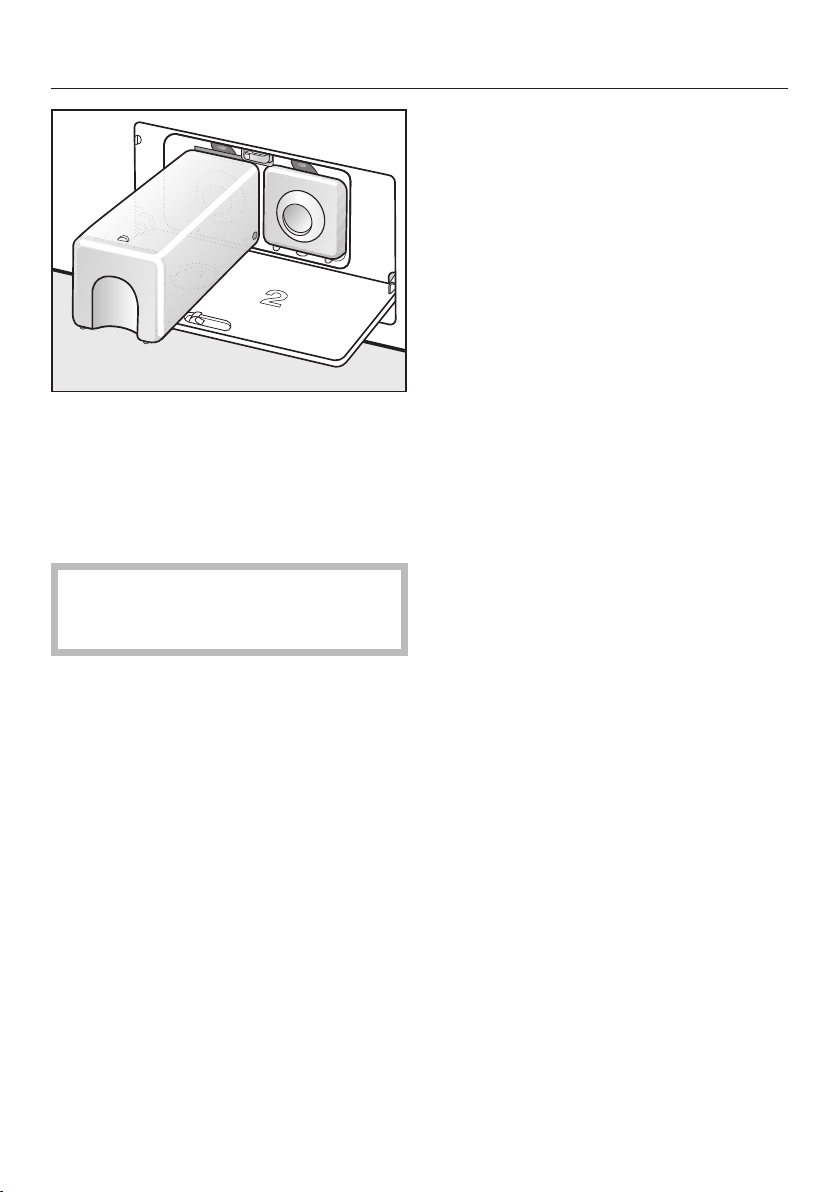

TwinDos

Using containers

Take the containers out of the com‐

partments.

Open the yellow stopper and fill the

container with your detergent of

choice.

Close the stopper and push the con‐

tainer back into the compartment.

Make sure that it locks into position.

Tip: Make a note of which detergents

you have filled the containers with so

that you then enter the correct settings

in the electronics later on.

The following liquid detergents and/or

fabric conditioners can be used in the

containers:

– Miele Ultra Color

– Miele wool and delicates detergent

– Miele fabric conditioner

– Universal detergent

– Detergent for coloureds

– Detergent for delicates

– Wool and delicates detergent

– Fabric conditioner

21

Page 22

TwinDos

OK

2:59

1600

Language

Dispensing unit

Detergent / amount

Container 1

Not defined

Dosage amount ml48

Dosage amount ml36

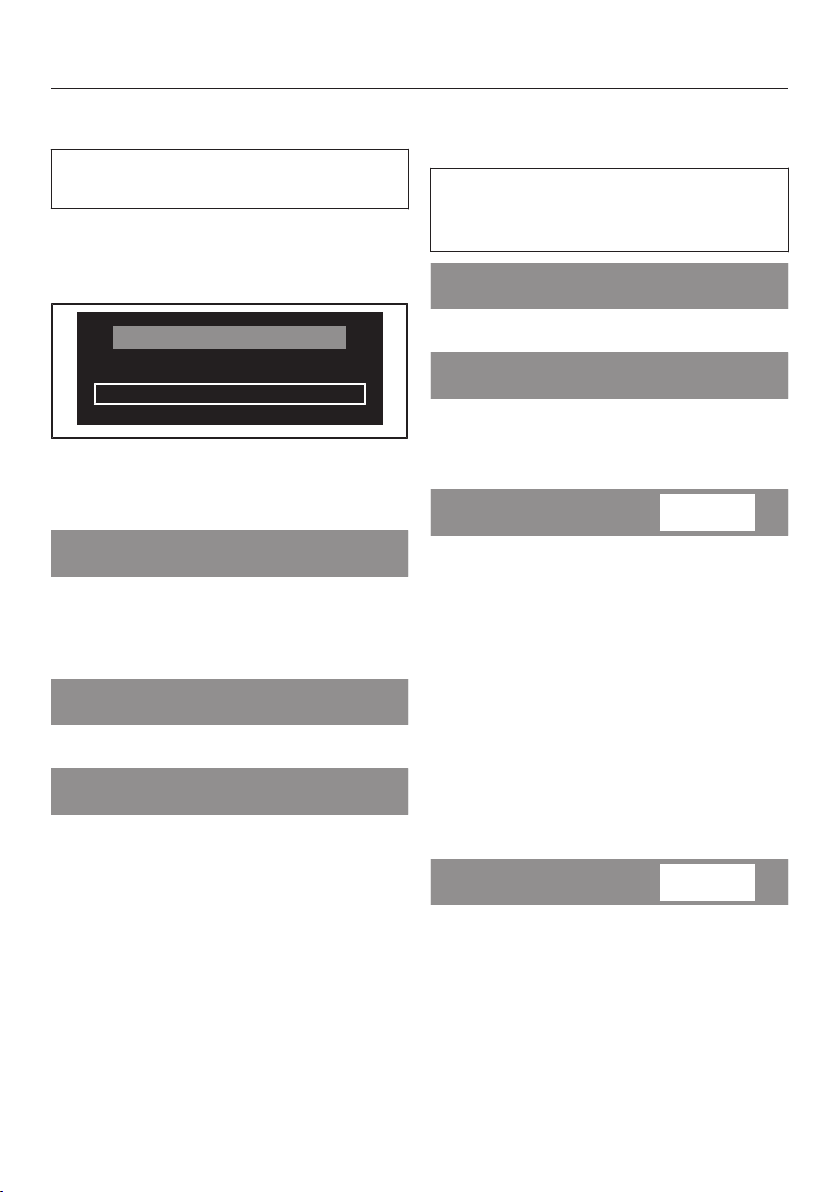

Open the Settings menu

You have to enter the type of deter‐

gent being used in the Settings menu.

Switch on the washing machine and

wait until the standard display lights

up.

Touch the and sensors at the

same time until the following appears

in the display:

The "Settings" menu has been opened.

Touch the sensor, the following will

appear in the display:

Touch the OK sensor.

Touch the OK sensor.

Settings for UltraPhase 1 and UltraPhase 2

The dosage amounts for UltraPhase 1

and UltraPhase 2 are pre-set for hard‐

ness range I ().

Touch the OK sensor.

Use the or sensor to select

UltraPhase 1 and confirm your choice

with the OK sensor.

Tip: If you live in an area with water

hardness levels II () or III (), adjust

the dosage for Miele products accord‐

ing to the information given on the

packaging.

Use the OK sensor to confirm the

dosage amount or use the and

sensors to change the amount.

The washing machine will automatically

assign UltraPhase 2 to compartment 2.

You just need to confirm or change the

dosage amount.

22

Use the OK sensor to confirm the

dosage amount or use the and

sensors to change the amount.

Page 23

Container 1

Not defined

Dosage amount ml95

Settings for other types of detergent

The dosage amount for Miele prod‐

ucts is pre-set for water hardness lev‐

el l ().

Touch the OK sensor.

Touch the or sensor to select

the type of product being used and

confirm with the OK sensor.

Tip: If you live in an area with water

hardness levels II () or III (), adjust

the dosage for Miele products accord‐

ing to the information given on the

packaging.

Use the OK sensor to confirm the

dosage amount or use the and

sensors to change the amount.

TwinDos

Set compartment 2 as described

above.

When adding universal liquid deter‐

gent or liquid detergent for coloureds

do not load more than 8 kg of laun‐

dry and when adding liquid deter‐

gent for wool and delicates do not

load more than 2.5 kg of laundry.

23

Page 24

TwinDos

Load 1 - 8 kg

2:59 1600

Degree of soiling

Normal

For whites

Running the first programme

The TwinDos system needs to be

primed before you can use the wash‐

ing machine.

To do this you must run a wash pro‐

gramme without laundry.

Open the stopcock.

Turn the programme selector to Cot‐

tons.

The following will appear in the display:

The standard display will then appear:

Touch the Dos sensor.

The following will appear in the display:

If the Miele 2 Phase System is being

used, a query about the colour mix of

the items will also appear.

Confirm the For whites option with the

OK sensor.

Press the Start/Stop button.

Switch the washing machine off at

the end of the programme.

The TwinDos unit is now ready for use.

The display will change automatically to

the degree of soiling query:

Select the Heavy degree of soiling

setting with the sensor and con‐

firm your selection with the OK sen‐

sor.

24

Page 25

Washing environmentally and economically

Energy and water consumption

– Water consumption and energy us‐

age are determined by the size of the

load.

To make the most of your machine,

load the maximum dry load for the

programme you are using.

– When smaller amounts of laundry are

washed, the automatic load recogni‐

tion system will reduce the amount of

water and energy used.

– Use the Express 20 programme for

small, lightly soiled loads.

– Modern detergents make it possible

to wash at lower temperatures (e.g.

20°C). Washing using lower tempera‐

ture settings will save energy.

– To maintain the hygiene of the ma‐

chine, carry out a hot wash (60°C or

above) using powder detergent at

regular intervals. Hygiene info will ap‐

pear in the display to remind you to

carry out a hot wash.

Detergent

– For precise dispensing use automatic

detergent dispensing.

– Adjust the dosage to the degree of

soiling of the laundry.

– Do not exceed the amounts of deter‐

gent recommended by the manufac‐

turer on the packaging.

When drying with a tumble dryer

Selecting the highest possible spin

speed for the wash programme will

save energy when drying in a tumble

dryer afterwards.

25

Page 26

Washing environmentally and economically

Energy

Water

Energy kWh0,9

EcoFeedback

You can call up information about the

energy and water consumption of your

washing machine with the EcoFeed‐

back sensor.

The following information will appear in

the display:

– an estimate of the consumption be‐

fore the programme begins.

– the energy and water consumption to

date during the programme.

– the energy and water consumption of

the programme which has just been

run at the end of the programme.

1. Estimate

After selecting a programme, touch

the EcoFeedback sensor.

The estimated energy consumption lev‐

els will be displayed as a bar chart.

2. Actual consumption

Tip: At the end of the programme, be‐

fore opening the door, you can view the

actual amount of energy and water

used by the programme which has just

been run.

Touch the EcoFeedback sensor.

Touch the or to switch to the

water consumption display.

If the door is opened or the washing

machine switches off automatically

at the end of the programme, the da‐

ta will revert to the estimated con‐

sumption.

Total consumption setting

– This setting gives a total of the ener‐

gy consumption and water consump‐

tion to date.

See "Settings".

Touch the or sensor to change

to the estimated water consumption

levels.

The more bars () visible, the higher the

energy or water consumption.

The estimate will vary depending on the

wash programme, temperature and any

options selected.

The display will change automatically or

you can return to the standard display

by touching the OK sensor.

26

Page 27

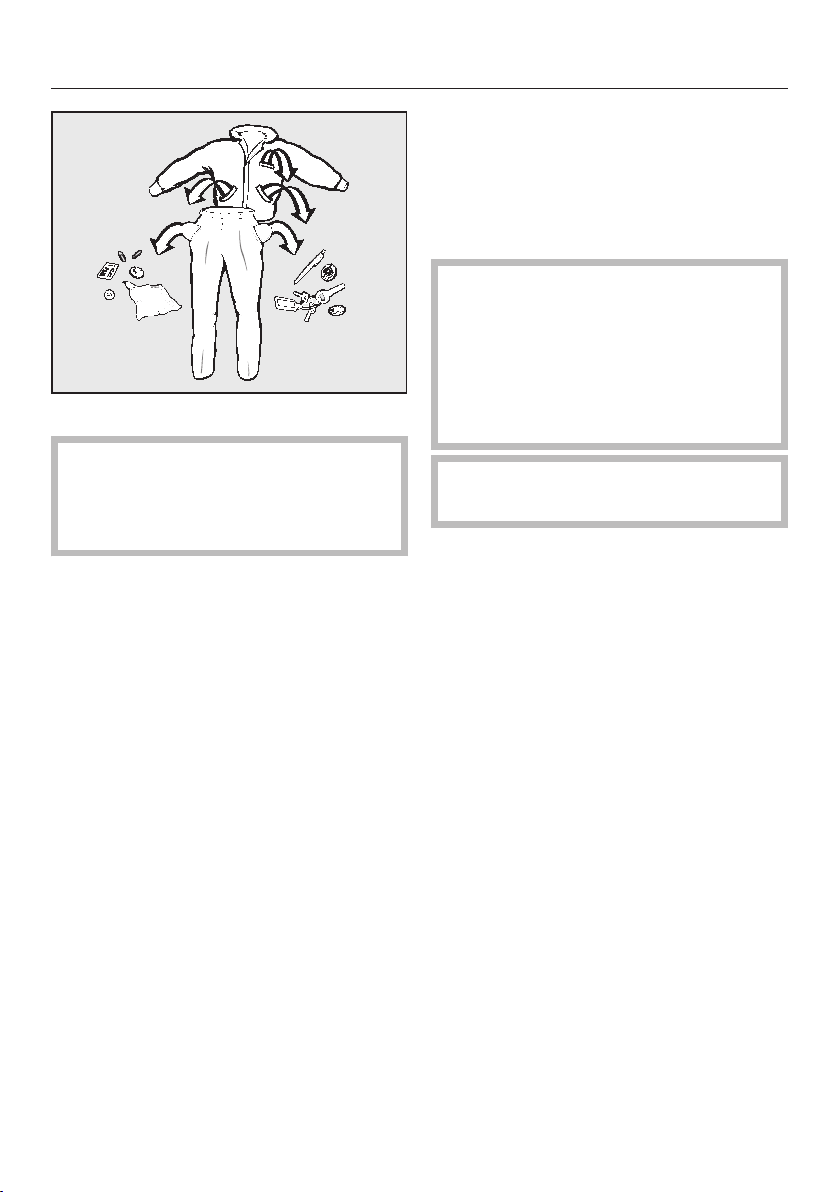

Empty all pockets.

1. Prepare the laundry

Tip: Badly soiled areas can be pre-trea‐

ted with liquid detergent, stain remov‐

ers etc. first, following the manufactur‐

er's instructions. With particularly stub‐

born stains ask your dry cleaner for ad‐

vice.

If you use a solvent-based

cleaning agent (e.g. one containing

benzine) to pre-treat a stain, make

sure that any plastic parts (e.g. but‐

tons) are protected, and that the

cleaning agent is rinsed off before

washing the garment in the machine.

Foreign objects (e.g. nails, coins,

paper clips, etc.) can cause damage

to garments and to components in

the machine.

Sort the laundry

Sort the laundry by colour and by

care label. Most garments have a tex‐

tile care label in the collar or side

seam.

Tip: Dark textiles often contain excess

dye and should be washed separately

several times before being included in a

mixed load. Always wash whites and

coloureds separately.

Pre-treat stains

Badly soiled areas, stains etc. should

be cleaned as soon as possible, pref‐

erably whilst still fresh. Spillages

should be carefully dabbed off using

a soft, colourfast cloth. Do not rub.

Do not use solvent-based clean‐

ing agents in or on this machine.

General tips

– Curtains: Remove lead weights first

or place in a laundry bag.

– Underwiring and collar stiffeners: Any

loose wiring in bras, shirt collar stiff‐

eners, etc. should be removed or

sewn in.

– Close any zips, attach velcro fasten‐

ers, fasten hooks and eyes etc. be‐

fore washing.

– Fasten duvet covers, pillow cases

etc. to prevent small items from being

rolled up inside them.

Do not wash any items in this washing

machine which are specified by the

manufacturer as not washable on the

care label ( symbol).

27

Page 28

2. Select a programme

Automatic plus

Switch on the washing ma‐

chine

Press the button.

Programme selection

A. Selecting a programme via the programme selector:

Turn the programme selector to the

required programme.

The load for the programme selected

will appear in the display. This will then

be replaced by the standard display.

B. Selecting a programme via the

programme selector at the "Further

programmes" setting and the dis‐

play:

Turn the programme selector to the

Further programmes setting.

The following will appear in the display:

Touch the or sensor until the

programme you want appears in the

display.

Confirm the programme with the OK

sensor.

28

The load for the relevant programme

will appear in the display. Pre-set pro‐

gramme parameters will be displayed

depending on the programme selected.

Page 29

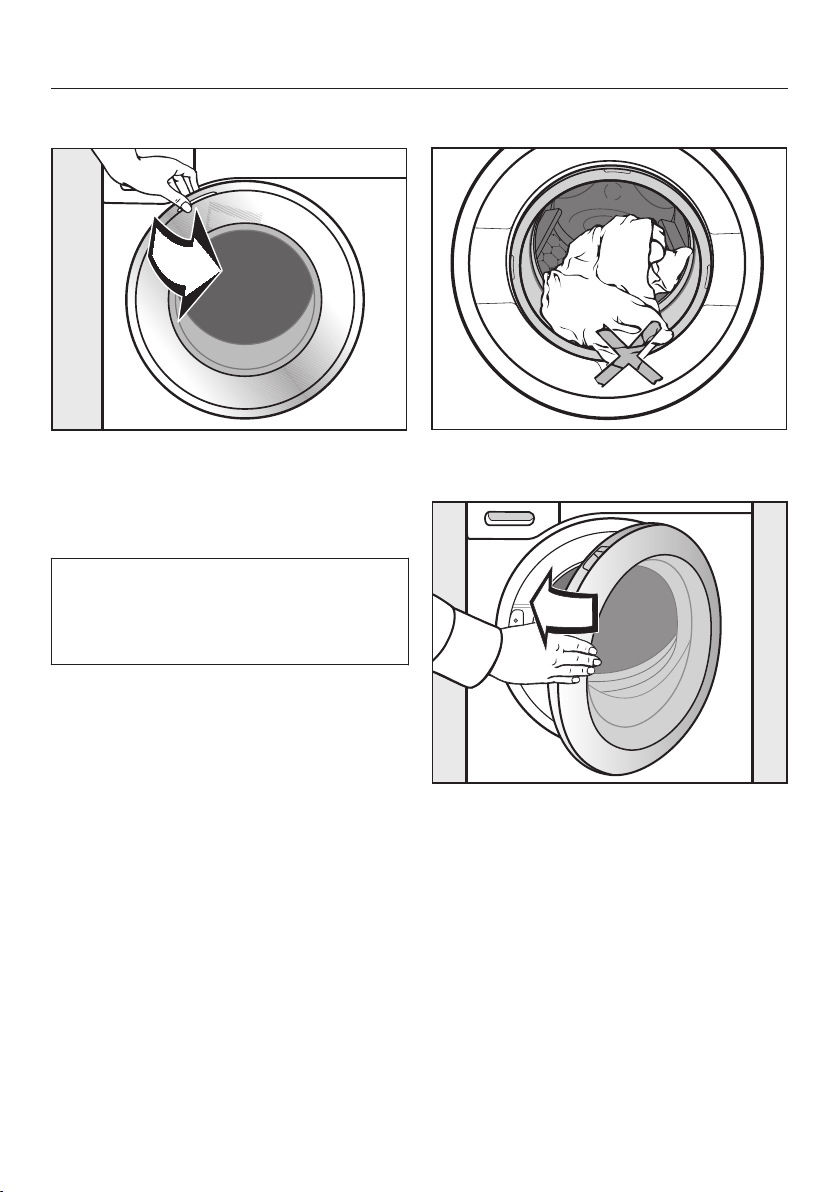

3. Load the washing machine

Open the door

Take hold of the door and pull it

open.

Unfold the laundry and load loosely

into the drum.

Mixing both large and small items

gives better wash results and also

helps distribute the load evenly during

spinning.

Please note the maximum load for the

different wash programmes. The rele‐

vant programme load is always shown

in the display when you select a pro‐

gramme.

The most efficient use of energy and

water is achieved when a full load is

washed. However, do not overload as

this reduces cleaning efficiency and

causes creases.

Close the door

Make sure that no items are caught

between the door and the seal.

Shut the door with a gentle swing.

29

Page 30

4. Select programme settings

Degree of soiling

Normal

Temperature °C

Degree of soiling

Lightly soiled

No visible dirt or stains. Possibly slight

body odour.

Normally soiled

Visibly dirty and/or just a few slight

stains.

Heavily soiled

Soiling and/or stains clearly visible.

The following will appear in the display:

The display will change automatically to

the degree of soiling query:

Set the degree of soiling with the

and sensors and confirm your se‐

lection with the OK sensor.

The following parameters will change

depending on the degree of soiling se‐

lected:

Tip: You can alter the default setting for

the degree of soiling or switch off the

degree of soiling query in Settings (see

"Settings - Degree of soiling").

Select a temperature

You can alter the pre-set temperature

of a wash programme.

Press the Temperature button.

The following will appear in the display:

Set the temperature you want with

the and sensors and confirm

your selection with the OK sensor.

– the detergent dosage amount with

automatic detergent dispensing

– with the Heavy degree of soiling set‐

ting, a pre-wash will be carried out

automatically for some programmes,

see "Options".

– the rinse water level will be adjusted

– the programme durations (with light

soiling the programme duration will

be shorter)

The degree of soiling cannot be selec‐

ted for some programmes. These pro‐

grammes are designed for normally

soiled laundry.

30

Page 31

4. Select programme settings

Spin speed rpm1600

Selecting a spin speed

You can alter the pre-set spin speed

of a wash programme.

Press the Spin speed button.

The following will appear in the display:

Set the spin speed you want with the

and sensors and confirm your

selection with the OK sensor.

Select options

Switch on delay start (if re‐

quired)

The start of a programme can be de‐

layed from 15 minutes up to 24 hours,

allowing you to make use of night-time

economy electricity rates, for example.

See "Delay start".

Press the button for the option you

want.

The indicator light in the button will

come on.

Not all options are suitable for use

with every programme. You can only

select options which are compatible

with the programme being used.

See "Options".

31

Page 32

5. Add detergent

For whites

Both agents

There are several options for adding de‐

tergent.

TwinDos

Depending on which agents have been

added in Compartments 1 and 2:

Miele 2 Phase System

The optimum amount of UltraPhase1

and UltraPhase2 will be dispensed au‐

tomatically according to the colour mix

of the load.

Press the

Depending on the programme selected,

the following will appear in the display:

Use the and sensors to select

the dosage mix (for whites or for col‐

oureds) and confirm your selection

with the OK sensor.

Base detergent and detergent en‐

hancer will be dispensed in the appro‐

priate dosage mix at the ideal time

during the wash cycle.

Dos sensor.

Liquid detergent/Fabric conditioner

The most suitable agent will appear in

the display with a tick () beside it.

If both the agents present in the con‐

tainers are suitable (e.g. detergent for

coloureds and fabric conditioner) then

both agents will be selected.

Confirm the option displayed with the

OK button or select another deter‐

gent or fabric conditioner with the

and sensors.

Detergent and/or fabric conditioner will

now be dispensed in accordance with

the wash cycle.

Adding stain remover

There are two options for adding stain

remover in addition to using the auto‐

matic dispensing system:

– Use cap dosing.

– Add the stain remover to the

compartment.

32

Page 33

Detergent dispenser drawer

Too little detergent results in:

– Laundry not getting properly clean

and with time it may become grey

and hard to the touch.

– Greasy particles clinging to laundry.

– Limescale deposits on the heater ele‐

ments.

Too much detergent results in:

5. Add detergent

– Excessive foam which causes a low

level of agitation and poor wash,

rinse and spin results.

– High water consumption (an addi‐

tional rinse cycle will automatically

switch in).

– A burden to the environment.

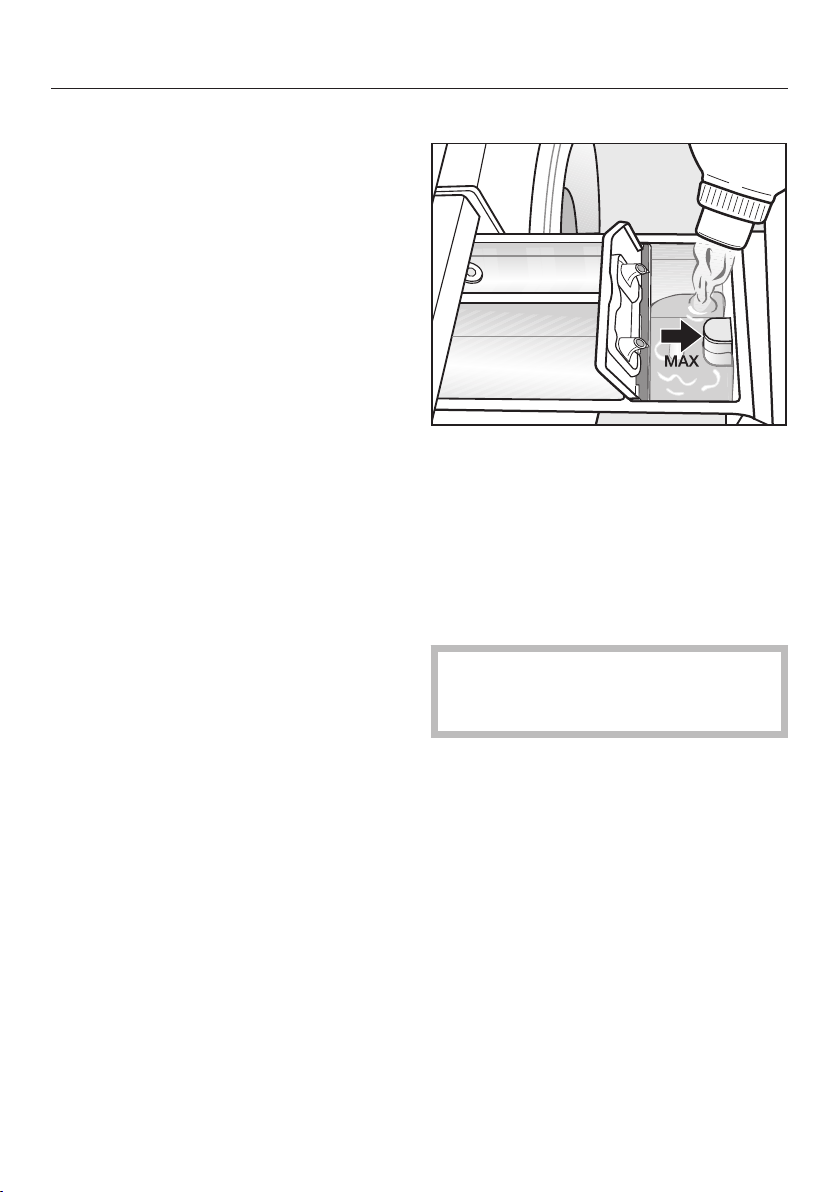

Pull out the detergent dispenser

drawer and add detergent to the

compartments as follows:

Detergent for the pre-wash (divide the

total recommended amount as follows:

add 1/3 to compartment and 2/3 to

compartment )

Detergent for the main wash

/

Fabric conditioner, liquid starch or cap‐

sules.

See "Detergent" for further information.

33

Page 34

5. Add detergent

Cap

CapDosing

Three different types of capsule are

available:

= Fabric care (e.g. fabric condi‐

tioner, proofing agent)

= Additives (e.g. detergent en‐

hancers)

= Detergent (for the main wash

only)

Each capsule contains the correct

amount for one wash cycle.

You can order the capsules online at

www.miele-shop.com or from Miele

(see the end of this booklet for contact

details).

Keep capsules out of the reach

of children.

Activating CapDosing

Touch the Cap sensor.

Inserting a capsule

Open the detergent dispenser draw‐

er.

Open the lid of the / compart‐

ment.

The first type of capsule which can be

selected for the programme will appear

in the display.

Select the type of capsule you want

with the and sensors and con‐

firm your selection with the OK sen‐

sor.

34

Press the capsule in firmly.

Page 35

Close the lid and press it firmly shut.

Close the detergent dispenser draw‐

er.

The capsule is opened by the act of

inserting it in the detergent dispenser

drawer. The contents can run out of

the capsule if you then remove it

from the drawer before it is used.

In this case, dispose of the capsule

and do not re-use it.

5. Add detergent

Deactivating/changing CapDosing

Touch the Cap sensor and follow

the instructions in the display.

If a capsule is being used, fabric

conditioner cannot be added to the

compartment at the same time,

as water intake into the compart‐

ment when using CapDosing is sole‐

ly through the capsule.

The wash programme will dispense the

contents of the capsule at the correct

time.

Remove the empty capsule at the

end of the programme.

35

Page 36

6. Start the programme - the end of a programme

Anti-crease/Finish

Press Start/Stop

Start the programme

Press the flashing Start/Stop button.

The door will lock (the will appear in

the display to show this) and the pro‐

gramme will start.

If a delay start time has been selected,

then this will count down in the display.

At the end of the delay start time or im‐

mediately after the programme has

started (if no delay start time has been

selected), the programme duration will

appear in the display.

The programme sequence is also

shown in the display. The washing ma‐

chine lets you know which section of

the programme has been reached.

At the end of a programme

The door is still locked during the anticrease phase and the following will ap‐

pear alternately in the display:

Check the folds in the door seal for

any small articles, e.g. buttons, which

might be lodged there.

Switch the washing machine off with

the button.

Close the door. Otherwise there is a

danger of objects being placed inad‐

vertently in the drum. If these re‐

mained unnoticed and were washed

in the next load, they could damage

the laundry.

and

Press the Start/Stop button. This will

unlock the door.

Pull open the door.

Remove the laundry.

Check that all items have been re‐

moved from the drum. Items left in

the drum could discolour other items

in the next wash or become discol‐

oured themselves.

36

If applicable, remove the used capsu‐

le from the detergent dispensing

drawer.

Page 37

Spinning

Final spin speed

Programme rpm

Cottons 1600

Minimum iron 1200

Delicates 900

Woollens

Silks

Automatic plus 1400

Down filled items 1200

Shirts 900

Sportswear 1200

Separate rinse / Starch 1600*

Drain / Spin 1600

Maintenance wash 900

QuickPower wash 1600*

Express 20 1200

Dark garments / Denim 900

Outerwear 800

Proofing 1000

1200*

600*

Final spin speed in the pro‐

gramme

When a programme is selected the op‐

timum spin speed for that programme

will appear in the display. For pro‐

grammes marked with a * in the chart,

the optimum spin speed is not the max‐

imum spin speed.

You can reduce the final spin speed.

However, you cannot select a final spin

speed higher than that shown in the

chart.

Rinse and interim spin

There is a spin after the main wash and

between the rinses. A reduction in the

final spin speed will also reduce the in‐

terim spin speed. If a spin speed of less

than 700 rpm is selected for the Cot‐

tons programme, an additional rinse is

introduced.

37

Page 38

Spinning

To omit the final spin (Rinse hold)

Use the Spin speed button to select

the setting (Rinse hold). The laun‐

dry is not spun after the final rinse

and remains in the final rinse water.

This helps prevent creasing if the

laundry is not going to be removed

from the drum immediately after the

end of the programme.

– To start the final spin:

The washing machine will display the

maximum spin speed possible. You

can select a spin speed lower than

this. Start the final spin by pressing

the

Start/Stop button.

– To end the programme:

Use the Spin speed button to select

the 0 rpm setting (Without spin) and

press the Start/Stop button.

The water will drain away.

To omit rinse and interim spin and the final spin

Press the Spin speed button.

Select the 0 rpm setting.

After the last rinse, the water will be

pumped away and the anti-crease

phase will switch in.

In some programmes an additional

rinse is introduced with this setting.

38

Page 39

Delay start

Start in h00 :00

Start in h05: 00

Start in h05: 00

Change the time

Start in h05 :29

Change the time

Start immediately

With delay start you can choose when

you want the programme to start. You

can delay the start of the programme

from 15 minutes up to a maximum of 24

hours, allowing you to make use of

night-time economy electricity rates, for

example.

To select delay start

Press the Delay start button.

The following will appear in the display:

Use the and sensors to enter

the hour and confirm your entry with

the OK sensor.

The display will change:

Use the and sensors to enter

the minutes and confirm your entry

with the OK sensor.

To change delay start

You can change delay start at any time.

Press the Delay start button.

Touch the OK sensor.

Now enter the time you want.

To cancel delay start and begin the programme straight away

Press the Delay start button.

Touch the sensor.

Touch the OK sensor. The wash pro‐

gramme will start immediately.

Tip: The values will count upwards and

downwards automatically if you touch

the or sensor continuously.

To begin delay start

Press the Start/Stop button to begin

delay start and the wash programme.

The following will appear in the display:

When the delay start time has elapsed,

the programme will begin and the dis‐

play will show the programme duration

and the programme sequence.

39

Page 40

Programme chart

Cottons cold to 90°C Max. load 8.0 kg

Use for Cotton, linen or cotton mix fabric, e.g. table linen, towelling, under‐

wear, T-shirts etc.

Note

Cottons

Use for Normally soiled cotton garments.

Notes – These settings are the most efficient in terms of energy and water

Note for test institutes:

The test programme conforms to EN 60456 and the energy label to Directive

1061/2010.

Minimum iron cold to 60°C Max. load 4.0 kg

Use for Synthetic, mixed fibre and easy care cotton.

Note Reduce the spin speed for fabric which creases easily.

The settings 60°/40°C differ from / as follows:

– Shorter programme durations

– Longer temperature holding times

– Higher energy consumption

Where particularly high levels of hygiene are required please select a

temperature of 60°C or higher.

/

consumption for washing cottons.

– With the actual wash temperature reached will be lower than

60°C although the wash performance is the same as with the

standard Cottons 60°C programme.

Max. load 8.0 kg

40

Page 41

Programme chart

Delicates cold to 60°C Max. load 3.0 kg

Use for Delicate garments made from synthetic fibre, mixed fibre, rayon and

viscose.

Curtains, including net curtains, specified as machine-washable by

the manufacturer.

Notes – Dust in curtains usually makes a programme with pre-wash advis‐

able. Select the Heavy setting for the degree of soiling so that a

pre-wash will be carried out.

– Deselect the spin for items which crease easily.

Woollens

Use for Machine-washable or hand-washable wool or wool blend fabric. If

the care label does not specify a temperature, wash using the cold

setting.

Note Reduce the spin speed for items which crease easily.

Silks

Use for Silks and other handwashable fabric with no wool content.

Note Place tights, bras etc. in a laundry bag.

Automatic plus cold to 40°C Max. 6.0 kg

Use for Mixed loads of garments suitable for the Cottons and Minimum iron

programmes.

Note The wash parameters (e.g. water level, wash rhythm and spin

speed) are adjusted automatically in this programme to ensure the

best possible care and wash result for each item.

cold to 40°C Max. load 2.0 kg

cold to 30°C Max. load 1.0 kg

41

Page 42

Programme chart

Down filled items cold to 60°C Max. load 2.0 kg

Use for Jackets, sleeping bags, pillows and other down-filled items.

Notes – Remove air from the items before washing to prevent an exces‐

sive build-up of foam. To do this either push the items into a nar‐

row laundry bag to compress them or tie the items together with a

washable strap.

– Observe the instructions on the wash care label.

Shirts cold to 60°C Max. load 2.0 kg

Use for Shirts and blouses made of cotton and mixed fibre.

Notes – Pre-treat soiled cuffs and collars if necessary.

– Wash silk shirts and blouses in the Silks programme.

Sportswear cold to 60°C Max. load 3.0 kg

Use for Sportswear such as singlets and leggings as well as microfibre and

fleece garments.

Notes – Do not use fabric conditioner.

– Observe the manufacturer's care label.

Separate rinse / Starch Max. load 8.0 kg

Use for – Rinsing handwashed items.

– Starching table cloths, serviettes and workwear.

Notes – Reduce the spin speed for items which crease easily.

– The laundry should be washed but not treated with fabric condi‐

tioner.

– Items will be rinsed very effectively using two rinse cycles by acti‐

vating the Water plus option.

42

Page 43

Programme chart

Drain / Spin –

Notes – Drain only: Select 0 rpm for the spin speed.

– Make sure you select the appropriate spin speed.

Maintenance wash 75°C Empty

With frequent washing at low temperatures there is a danger of a build-up of

bacteria in the washing machine.

Cleaning the washing machine will significantly reduce bacteria, fungus and bio‐

film and prevent the build-up of unpleasant odours.

Notes – Optimum results can be achieved by using Miele machine cleaner.

Alternatively, a universal powder detergent can be used.

– Dispense the machine cleaner or universal powder via the deter‐

gent dispenser drawer.

– Do not load any laundry. The drum must be empty for the mainte‐

nance wash.

QuickPower wash 60°C – 40°C Max. load 5.0 kg

Use for Normally soiled garments which are also suitable for washing in the

Cottons programme.

Note – A special saturation process and wash rhythm ensure that the

laundry is cleaned particularly quickly and thoroughly.

Express 20 cold to 40°C Max. load 3.5 kg

Use for Cotton garments that have hardly been worn or are only very lightly

soiled.

Note The Short option is activated automatically.

43

Page 44

Programme chart

Dark garments /

Denim

Use for Black and dark items made of cotton, mixed fibre or denim.

Notes – Wash inside out.

– Denim often contains excess dye and may run during the first few

washes. Wash light and dark coloured items separately.

Outerwear cold to 40°C Max. load 2.5 kg

Use for Performance outerwear (e.g. jackets and trousers) made from mem‐

brane fabric such as Gore-Tex®, SYMPATEX®, WINDSTOPPER®

etc.

Notes – Zip up or close jackets before washing.

– Do not use fabric conditioner.

– If wished, these garments can also be re-proofed using the Proof‐

ing programme. Proofing should not be done every time the gar‐

ment is washed.

Proofing 40°C Max. load 2.5 kg

Use for Treating microfibre fabric, skiwear and table linen made from mainly

synthetic fibres to provide a water and dirt resistant finish.

Notes – The items should be freshly laundered and spun or dried before

proofing.

cold to 60°C Max. load 3.0 kg

44

– For best results, the items should be heat-treated afterwards ei‐

ther in a tumble dryer or by ironing.

Page 45

Options

Options are selected and deselected

via the relevant buttons and the display.

Press the button for the option you

want.

The relevant button will light up.

Not all options are suitable for use with

every programme.

You can only select options which are

compatible with the programme being

used.

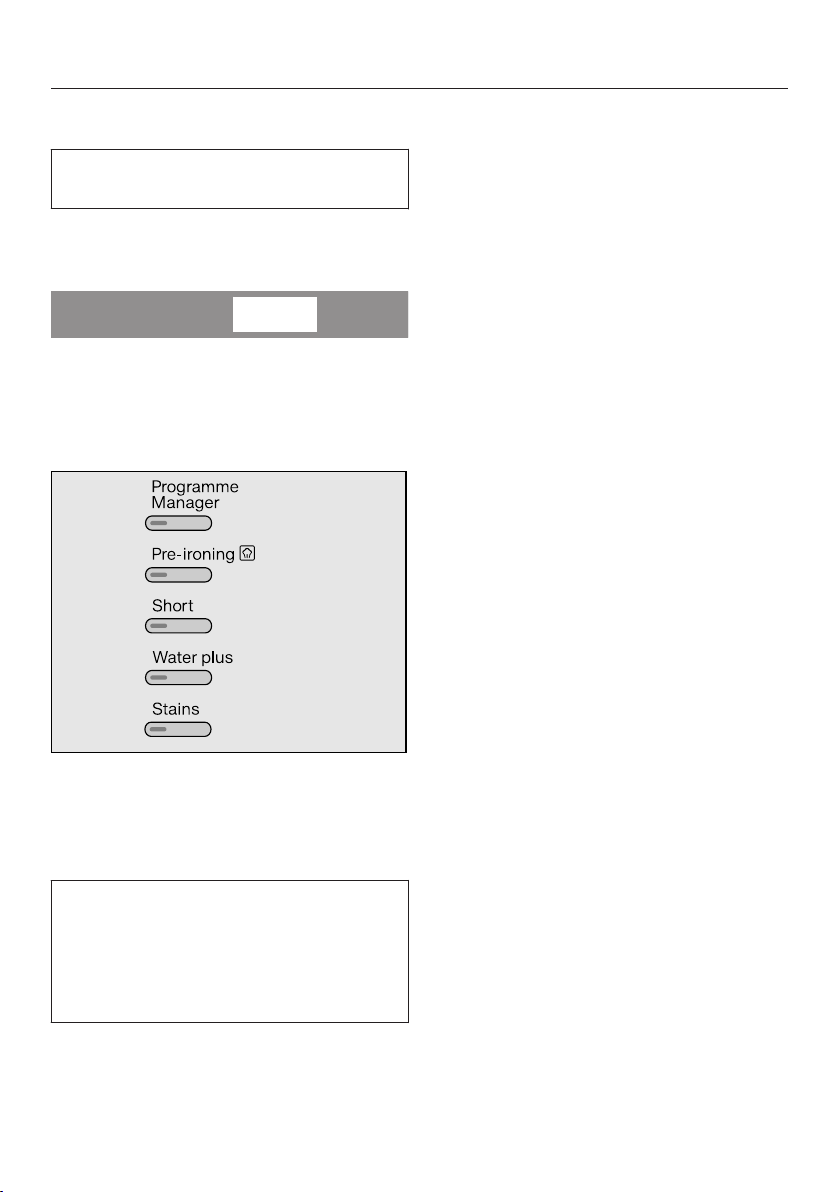

ProgrammeManager

The ProgrammeManager option can be

used to customise the washing pro‐

grammes to suit your requirements.

Intensive

For hard-wearing laundry that is very

heavily soiled. Cleaning efficiency is in‐

creased through more intense mechani‐

cal action and the application of more

heat energy.

ECO

This option reduces energy consump‐

tion whilst maintaining cleaning efficien‐

cy. This is achieved by increasing the

wash duration and at the same time re‐

ducing the wash temperature selected.

Extra gentle

This option decreases mechanical ac‐

tion in order to reduce creasing.

Extra quiet

This option reduces noise levels during

the programme. Use this if you want to

wash during quiet periods (for instance

when children are sleeping). The ma‐

chine will activate the "Rinse hold" op‐

tion and not spin. The programme dura‐

tion is longer.

AllergoWash

This option should be used where high

standards of hygiene are required. More

energy is used to lengthen temperature

holding times and more water is used

to increase rinsing efficiency.

Not all ProgrammeManager options

are suitable for use with every pro‐

gramme. Please refer to the "Wash

programme chart - ProgrammeMan‐

ager" for a list of suitable pro‐

grammes.

45

Page 46

Options

Pre-ironing

In order to reduce creasing, the laundry

undergoes a smoothing process at the

end of the programme. Reducing the

maximum load by 50% will give a bet‐

ter result. Please note the load informa‐

tion in the display. Small loads give a

better result.

The garments must be suitable for dry‐

ing in a tumble dryer and suitable

for ironing .

Short

Use this option for light soiling with no

visible staining.

The wash duration is reduced.

Water plus

The water level in the wash and rinse

stages is increased and a second rinse

is carried out in the "Separate rinse /

Starch" programme.

You can select other functions for the

Water plus button. These are described

in "Settings".

Stains

In order to clean stained laundry more

effectively, you can choose between 7

different types of stain. The wash pro‐

gramme will then adapt to the type of

stain selected. You can select one stain

per wash cycle.

46

Page 47

Options

Wash programme chart - ProgrammeManager

ProgrammeManager cannot be selected with programmes which are not listed in

the chart below.

Intensive ECO Extra

gentle

Cottons X X X X X

Minimum iron X X X X X

Delicates X X X X X

Woollens

Silks

Automatic plus X X X X X

Down filled items X X X X X

Shirts X X X X X

Sportswear X X X X X

Separate rinse / Starch – – – X –

Express 20 – – – X –

Dark garments / Denim X X X X X

Outerwear X X X X X

Proofing – – – X –

X = Can be selected

– – – X –

– – – X –

Extra

quiet

Allergo‐

Wash

– = Cannot be selected

47

Page 48

Options

The following options can be selected in addition to the pro‐

gramme:

None of the options can be selected with programmes which are not listed in the

chart below.

Pre-

wash

1)

Pre-iron‐

ing

Short Water

plus

Stains

Cottons X X X X X

Minimum iron X X X X X

Delicates X X X X X

Automatic plus X X – – X

Down filled items X – – X X

Shirts X

2)

X

X X X

Sportswear X X – X –

Separate rinse / Starch – – – X –

QuickPower wash – X – – –

Express 20 – X

Dark garments / Den‐

X X X X X

2)

X

– –

im

Outerwear X – X X X

X = Can be selected

– = Cannot be selected

1)

= Activated automatically when the Heavy degree of soiling setting is selec‐

ted

2)

= Can be deselected

48

Page 49

Garment care label symbols

Washing

The figure quoted in the bucket is the

maximum temperature the garment

can be washed at. The number of

bars under the symbol indicates the

level of agitation permitted.

No bar under the symbol:

= normal agitation

One bar under the symbol:

= reduced agitation

Two bars under the symbol:

= much reduced agitation

Hand wash (if no temperature is

specified, use the lowest tem‐

perature or cold)

Do not wash

Programme selection examples

Programme Garment care la‐

bel symbols

Cottons

Minimum iron

Delicates

Woollens

Silks

Express 20

Drying

The number of dots indicates the dry‐

ing temperature

Normal temperature

Low temperature

Do not tumble dry

Ironing

The number of dots indicates the iron‐

ing temperature

Hot iron (max. sole plate temp.

approx. 200°C)

Medium hot iron (max. sole

plate temp. approx. 150°C)

Cool iron (max. sole plate temp.

approx. 110°C).

Do not steam iron garments

carrying this symbol as this

could cause irreversible dam‐

age.

Do not iron

Professional cleaning

Dry clean only. The letters indi‐

cate the type of cleaning agent

required.

Professional Wet Clean only

Do not dry clean

Automatic plus

Bleaching

Any oxidising bleaching agent

can be used

Only use an oxygen based

bleach or a non-chlorine bleach

Do not bleach

49

Page 50

Programme sequence

Main wash Rinses Spinning

Water

level

Cottons

Minimum iron

Delicates

Wash

rhythm

Water

level

Rinses

1)2)3)

2-5

2)3)

2-4

2)3)

2-4

Woollens

Silks

Automatic plus

Down filled items

4)

Shirts

Sportswear

Separate rinse / Starch

Drain / Spin – – – –

Maintenance wash

QuickPower wash

Express 20

Dark garments / Denim

Outerwear

Proofing –

Please see the next page for a description of the symbols.

2-4

3-4

3-4

2-3

0-1

3-5

3-4

2

2

2)3)

3)

3)

3)

5)

3

1

1

2)3)

3)

1

50

Page 51

Programme sequence

= Low water level

= Medium water level

= High water level

= Intensive rhythm

= Normal rhythm

= Sensitive rhythm

= Ultra sensitive rhythm

= Handwash rhythm

= Carried out

– = Not carried out

The washing machine has fully elec‐

tronic controls with automatic load rec‐

ognition. It takes in the right amount of

water required for the programme de‐

pending on the amount of laundry and

its absorbency rate.

The programme sequences shown in

the chart are based on the standard

programme with a full load.

The washing machine programme se‐

quence display shows which stage of

the programme has been reached.

Special features in the pro‐

gramme sequence

Anti-crease:

At the end of the programme the drum

continues to turn at intervals for up to

30 minutes to help prevent creasing.

Exception: There is no anti-crease

phase in the

The door can be opened at any time

during the anti-crease phase.

1)

A second rinse is carried out when a

temperature of or above is se‐

lected. A third rinse is carried out

when a temperature below is

selected.

2)

An additional rinse is carried out if:

– there is too much foam in the drum

– a spin speed lower than 700 rpm has

been selected

– the spin speed has been deselected

3)

An additional rinse is carried out if:

– the Water plus option is selected and

the Extra rinse or Water + and Extra

rinse setting has been activated for

the Water plus option in Settings.

4)

Run-up to spin: A run-up to spin is

carried out before the wash process

begins to deflate down filled items.

Subsequent water intake for the main

wash is through compartment .

5)

An additional rinse is carried out if:

the Water plus option is selected.

Woollens programme.

51

Page 52

Changing the programme sequence

Cancel programme

Prog. cancelled

Cancelling a programme

You can cancel a programme at any

time after it has started:

Press the Start/Stop button.

The following will appear in the display:

Touch the OK sensor.

The suds will be pumped away. The fol‐

lowing will appear in the display:

Pull open the door.

Remove the laundry.

If you want to select a different pro‐

gramme

Close the door.

Select the programme you want.

Add detergent to the detergent dis‐

penser drawer, if necessary.

Press the Start/Stop button.

The new programme will begin.

Interrupting a programme

Switch the washing machine off with

the button.

Changing a programme

After the start of a programme it is no

longer possible to select a different pro‐

gramme.

Temperature

With the exception of the Cottons pro‐

gramme, it is possible to select a differ‐

ent temperature up to 5 minutes after

the programme has started.

Press the Temperature button.

Use the , and OK sensors to

change the temperature.

Spin speed

It is possible to change the spin speed

up until the final spin begins.

Press the Spin speed button.

Use the , and OK sensors to

change the spin speed.

Options

It is possible to select or deselect the

Short and Water plus options up to 5

minutes after the programme has star‐

ted.

Tip: It is not possible to make any

changes to the programme or to cancel

it if the safety lock has been activated.

Switch the washing machine back on

with the button to continue with

the same programme.

52

Page 53

Changing the programme sequence

Cancel programme

Add laundry

Adding or removing laundry af‐

ter the programme has started

Press the Start/Stop button.

The following will appear in the display:

Scroll up the list with the or sen‐

sor to:

Touch the OK sensor.

If this message does not appear in the

display then it is no longer possible to

add or remove items of laundry.

The programme will stop and the door

will unlock.

Pull open the door.

Add or remove items.

Close the door.

Press the Start/Stop button.

Please note:

Once a programme has started the

washing machine cannot recognise any

adjustment to the load.

For this reason, if laundry is added or

removed after the start of a programme,

the machine will always complete the