Page 1

Operating Instructions

for washing machine

W 820

It is essential to read these operating instructions before installing or

using the machine to avoid the risk

of accident, or damage to the

machine. M.-Nr. 04580320

Q

Page 2

Contents

Page

Guide to the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Caring for the environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before using for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Warning and Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preparing the wash load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wash care symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adding detergent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adding fabric conditioner/starch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Programme selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Changing a programme sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Programmes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Programmable functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

After washing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Problem solving guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Help to protect our environment

Disposal of the packing material

The transport and protective packing is mostly manufactured from the following reuseable materials:

– Corrugated paper / card

– Polystyrene - CFC free

– Polyethylene foil (transparent)

– Fibre board - solvent free

– Wood - untreated

– Packaging straps: Polyamide (blue)

Polypropylene (black)

Rather than just throwing these materials away, please take them to the nearest

local authority collection point for specific waste.

Disposal of your old machine

Old machines contain materials which can be recycled. Please contact your local

authorities or scrap merchant about potential recycling schemes, before disposing

of the appliance.

2

Page 3

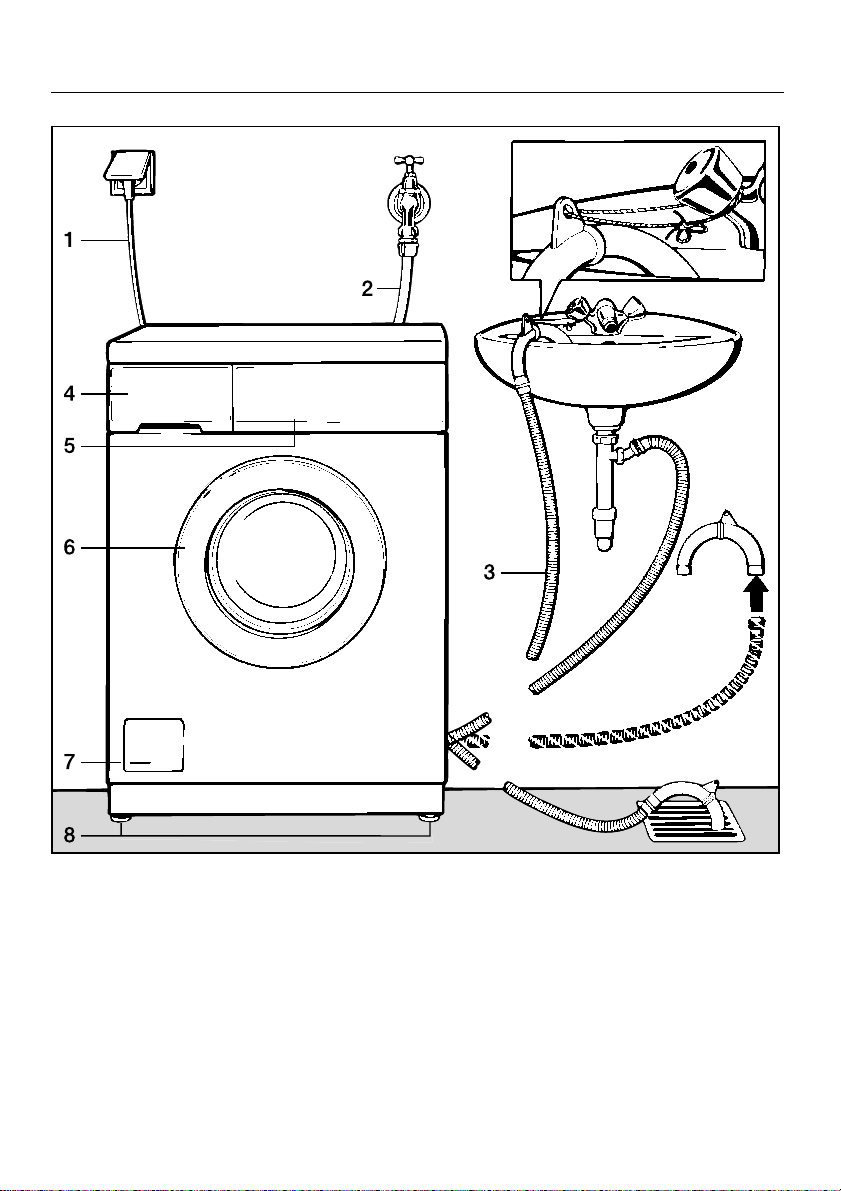

Guide to the machine

1 Supply cable

2 Inlet hose (able to withstand press

ures up to 70 bar)

3 Flexible drain hose, with detachable

swivel elbow

4 Detergent dispenser drawer

5 Facia panel with controls

6 Drum door

7 Access panel - drain pump and fil-

ter, emergency door opener

8 Four height adjustable feet

Page 4

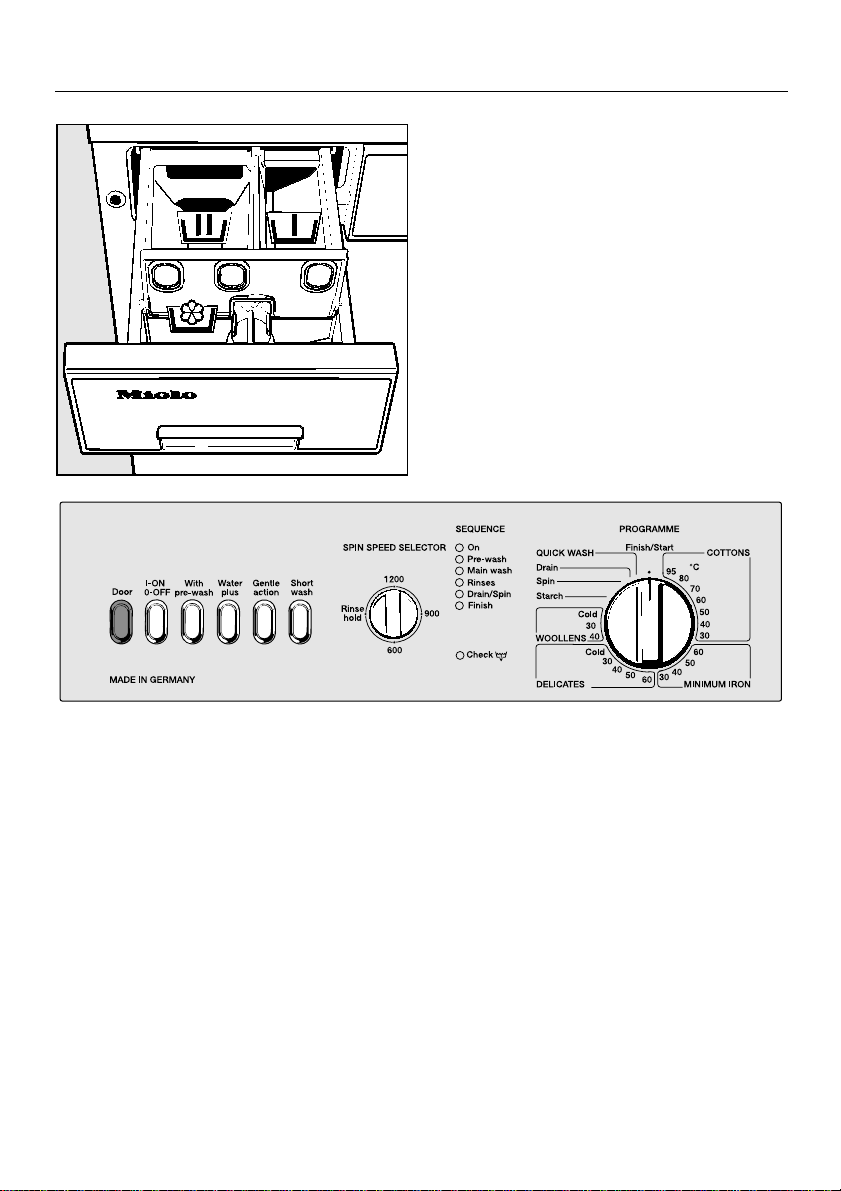

Guide to the machine

Detergent dispenser drawer

Compartment i - for the pre-wash

Compartment j - for the main wash

Compartment p (with extra lid) - for

fabric conditioner or liquid starch formulation

Button “Door”

opens the drum door

Button “On/Off”

to switch on or off or

interrupt a programme

Light “On” illuminates

Pushbutton switches for additional functions

4

Spin speed selector

Programme sequence indicator

(LED indicator lights)

Programme selector switch

Page 5

Caring for the environment

Caring for the environment

Caring for the environment means saving water, energy and detergent when

washing. This machine is equipped

with the Hydromatic System and the

Ball Valve for economical use of resources. These systems offer a variety

of technical innovations e.g. the drum

ribs, which are designed to enable

economical washing without compromising on results.

The automatic load control facility enables loads of between 1 and 5 kg to

be washed using only as much water

and electricity as is required for an effective wash.

Spinning at the high speed of

1200 rpm reduces drying times and energy consumption if laundry is dried in

a tumble dryer after washing.

Economy tips

To help you wash most economically,

remember the following tips:

Always wash with the maximum

laundry load specified for each programme. This uses the energy to the

best advantage.

Only use the correct amount of detergent required for the water hardness

level in your area, as recommended

by the manufacturer.

If laundry is not heavily stained, select a lower temperature setting than

indicated on the laundry care label

(but when using a lower temperature

do not select the “short”-option).

Lightly soiled laundry can be

washed using a “short”-programme

(additional temperature reduction

not recommended).

5

Page 6

Before using for the first time

Important:

the appliance must be properly installed and connected to the water

and electricity supply according to

local and national regulations.

For further information read the instructions on pages 31 - 37

Check that the transit fitting at the

rear has been removed.

Before using for the first time prime

the ball valve as follows:

Switch on the machine.

Turn the selector switch to “Starch”.

Once the drum starts turning: set the

programme selector to “Drain”.

When the water has drained: turn the

programme selector to the “Finish/Start” position.

Switch the machine off.

The ball valve is operational.

Any residual lubricants and water

from testing still in the machine

should be flushed out as follows:

Do not load any laundry in the machine.

Add a little detergent to compartment j.

Switch on the machine.

Turn the programme selector switch

to the “Cottons 60°C” programme.

Press the “Short” button.

The residues will have been flushed

out once the programme has finished.

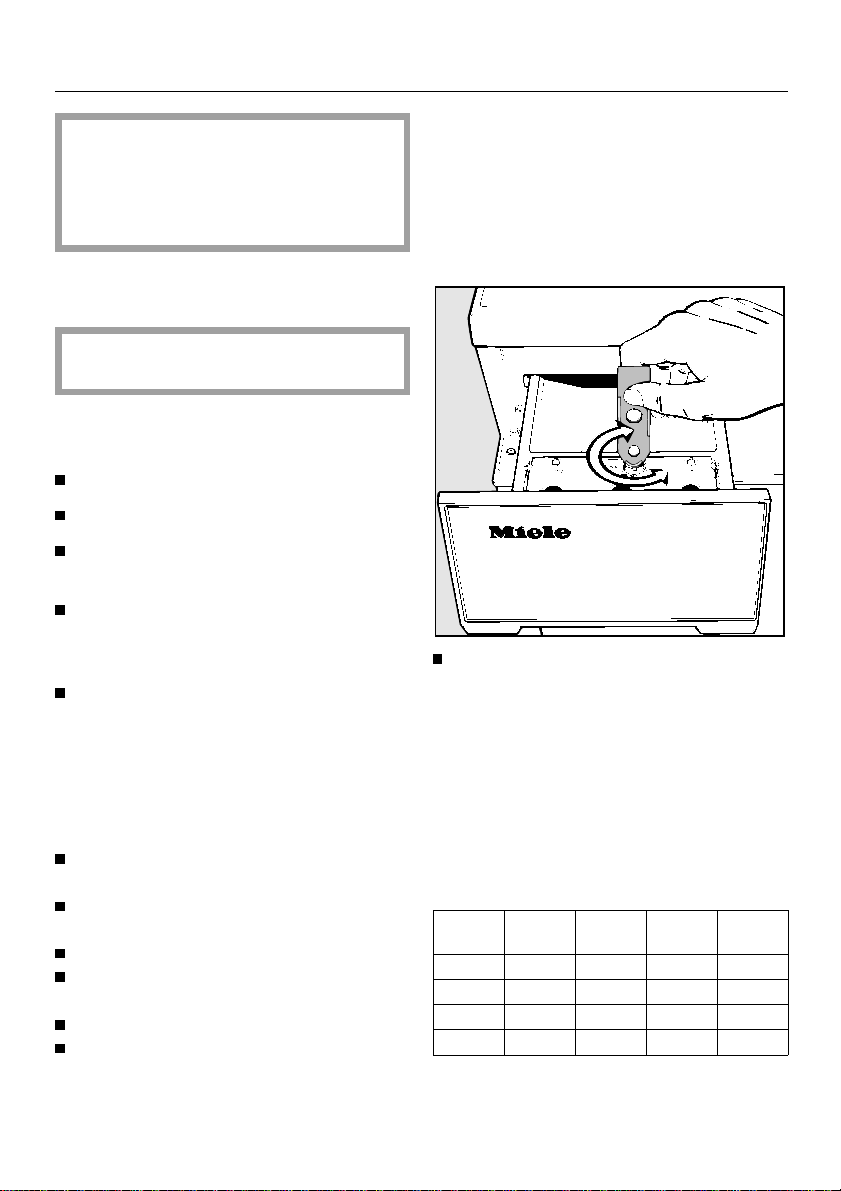

Water hardness reminder.

The amount of detergent will depend

on various factors including the water

hardness level in your area. Set the

water hardness dial located in the

detergent dispenser box as a reminder.

Turn the dial to the required setting.

Use the spatula supplied with the

machine. It is located at the rear of

the dispenser drawer facia (see

page 23).

If you do not know how hard the water

is in your catchment area, please contact your local water authority.

Water har dness

Hardness

range

1 soft up to 135 up to 10° 0-7°

2 medium up to 250 10°-20° 7°-14°

3 hard up to 380 20°-25° 14°-21°

4 very hard over 380 over 25° over 21°

water mg/litre Clake’s

scale

°dH

(German)

6

Page 7

Warning and Safety Instructions

This appliance is designed and intended only for normal household use

in the U.K. It should never be operated

by children. Supervise its use by the elderly or infirm.

Read the operating instructions through

before using this machine for the first

time, as this is for your safety and the

protection of the machine. They give

notes on the safety, the use and the

maintenance of the machine.

Further warning and safety instructions

are given in the text as appropriate.

...before using for the first time

Do not install your washing ma-

chine in rooms where sub-zero

temperatures may occur. Frozen hoses

may burst under pressure.

The reliability of the electronic control

system may be impaired at temperatures below freezing point.

Before using the machine for the

first time, check that the transit fitting at the rear of the machine has

been removed (see page 31).

During spinning, a transit fitting which

is still in position may result in damage

to both the machine and adjacent furniture or appliances.

If the drain hose is attached to a

wash basin or sink, make sure it is

secure, (see illustration in the section“Guide to the machine”),

so that the force of the water flowing

out of the hose does not dislodge it, as

this will otherwise result in flooding.

If hooking the hose into a wash basin,

check that the water can drain off

quickly enough to prevent the sink from

overflowing.

Keep these operating instructions

in a safe place.

...when using your machine

Only wash items which are de-

clared by the manufacturer to be

machine-washable on the care label

(textile care G.B. laundry care, AUS),

(see Care labels on page 10).

Descaling agents contain acid.

Only use proprietary non-corrosive

descaling agents and strictly observe

the manufacturer’s instructions. After

descaling, always run several full rinse

cycles to remove any acid residue and

to protect component parts from corrosion.

Never use detergents containing

solvents in this machine, as this

may result in damage to component

parts and create toxic fumes. Such

detergents also pose a fire and explosion hazard.

Textiles which have been pre-

treated in detergents containing

solvents must be thoroughly rinsed in

clean water before being washed in

this machine.

Do not use dye removers as these

contain sulphur compounds which

may damage washing machines.

7

Page 8

War n ing and Safety Instructions

Dyes must be specified as suitable

for use in washing machines. Always observe the manufacturer’s instructions.

If washing at very high tempera-

tures remember that the porthole

glass will be hot.

Do not let children touch it during a

wash programme.

The machine should only be oper-

ated unsupervised if there is a floor

drain in the immediate vicinity.

The best materials are used in the

manufacture of this machine, and

every care is taken to check all parts.

However, with time, deterioration of

parts can occur, especially with such

components as hoses, giving rise to

leaks. This should be borne in mind if

operating the machine without supervision. Check the hose regularly for signs

of wear, and change in good time, to

avoid leaks and subsequent damage.

...in the event of faults

Electrical appliances should only

be repaired by suitably competent

personnel. Incorrectly repaired machines may pose a considerable risk to

the user.

Disconnect the machine from the

mains power supply by switching

off at the wall socket, unplugging, or

withdrawing the mains fuse.

Always make sure the drum is sta-

tionary before reaching in to

remove washing. Reaching into a moving drum is extremely dangerous.

Foreign objects (e.g. nails, coins,

paper clips etc.) can cause damage to textiles and components in the

machine. Take care to empty all

pockets etc. so that these do not go

into the machine.

8

Page 9

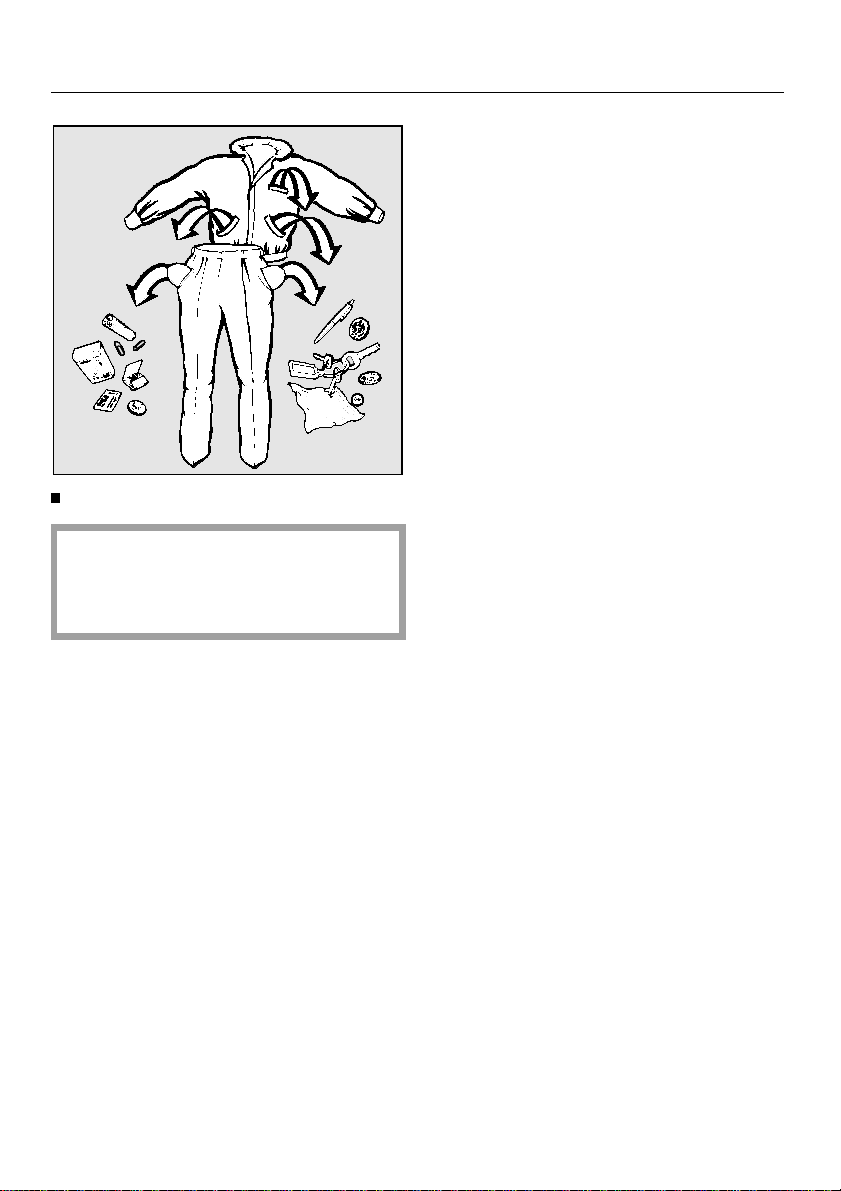

Empty all pockets.

Foreign objects (e.g. nails, coins,

paper clips etc.) can cause damage to textiles and components in

the machine.

Sort the laundry

Most garments have a textile care label

in the collar or side seam. Sort the

laundry by care label symbols.

Only wash items in this machine which

are declared by the manufacturer as

being machine washable on the textile

care label.

Dark textiles often contain“excess

dye,” and should be washed separately several times before being included in a mixed load.

Delicate textiles should be washed separately in a delicates programme.

Only wash textiles made from wool or

wool mixtures if they are declared as

being suitable for machine washing on

the textile care label.

Preparing the wash load

Pre-treating the washing

Badly soiled areas, e.g. collars and

cuffs, and water soluble stains, can be

pre-treated with bar soap, liquid detergent or detergent mixed into a solution

or paste.

With particularly stubborn stains ask

your Dry Cleaner for advice.

Do not use detergents containing solvents in this machine.

Loading the drum

Unfold laundry and load loosely in the

drum. To achieve best results it is advisable to make up mixed loads consisting of both large and small items. This

improves the washing effect and helps

distribute the load evenly to keep the

machine stable and reduce the noise

level during spinning.

It is advisable to weigh the load first to

make best use of the machine’s capacity.

Maximum load weights are noted

below:

COTTONS. . . . . . . . . . . . . . . . . . 5.0 kg

MINIMUM IRON . . . . . . . . . . . . . 2.5 kg

DELICATES/SYNTHETICS. . . . . 1.0 kg

WOOL . . . . . . . . . . . . . . . . . . . . . 1.0 kg

QUICK WASH . . . . . . . . . . . . . . . 2.5 kg

With curtains: Remove lead weights

and strips or place in a laundry bag.

Woollens and knitted garments should

be turned inside out if the manufacturer

recommends it.

Close the drum door

Make sure that there is no obstruction

between the drum door and seal.

9

Page 10

Textile care symbols

Washing

987 Cottons

4321 Minimum iron

a@ Delicates, Wool

The significance of the bar beneath the

wash tub:

no bar normal (maximum) agitation

e eg Cottons programme

bar reduced (medium) agitation,

f eg Minimum iron programme

+ Gentle action, or Delicates

programme.

broken much reduced (minimum)

bar agitation, Woollens

g programme

Machine washable woollens

Use the special “Wool” programme,

and only wash woollens bearing the

label shown here:

/ Hand wash

h do not wash

ABC dry clean

D do not dry clean

y suitable for chlorine

bleaching

z not suitable for chlorine

bleaching

Tumble dry

q at normal temperature

r at the lower temperature

s do not tumble dry

Ironing

I hot iron

H medium hot iron

G cool iron

J do not iron

This symbol is registered by the IWS

(International Wool Secretariat).

10

N.B. If you have any textiles with the

older wash care labels, select a programme according to the table below.

[:] Cottons

?;\ Minimum iron

={ Delicates

# Woollens

Page 11

Adding detergent

All modern detergents produced for

automatic washing machines are suitable, including liquid, compact (concentrated) and special application

detergents. Use dispensing aids e.g.

balls if these are supplied with the

detergent. Woollens and knitware containing wool mixtures should be

washed using a detergent specifically

designed for washing woollens.

Add the right amount of detergent as

recommended on the packaging The

amount dispensed will depend on the

following:

– the quantity of laundry

– the water hardness level

– the level of soiling

It is important to dispense the correct amount, because...

...too little detergent results in the following:

– The laundry will not get properly

clean and will in time become grey

and hard to the touch.

– Greasy particles cling to the laundry.

– Lime deposits on the heater ele-

ments.

...too much detergent results in the following:

Water is taken in through compartment

j in the main wash. If the capacity of

compartment j is insufficient for the

amount of detergent needed where

water hardness is above 380 mg/l (in

hardness area 4), the Customer Service Engineer can adjust the machine

so that water can also be taken in

through compartment i to take detergent into the main wash.

Water Softeners

A water softener can be used to cut

down on the use of detergents in water

hardness ranges 2 - 4. Dispense according to the amount specified on the

packaging. First add detergent and

then the water softener. Detergent can

be dosed as for water hardness range

1.

We recommend: if you wash using sev-

eral components (e.g. special application detergents), dispense the agents

in the following order into compartment

j :

1. Detergent

2. Water softener

3. Stain salts

This way the agents are distributed bet-

ter.

– Excessive foam.

– Low level of agitation.

– Poor washing and rinsing results.

11

Page 12

Fabric conditioners / starch formulations

Fabric conditioners make garments

soft and fluffy to handle and help prevent static cling when tumble drying.

Dispense according to the manufacturer’s recommendations.

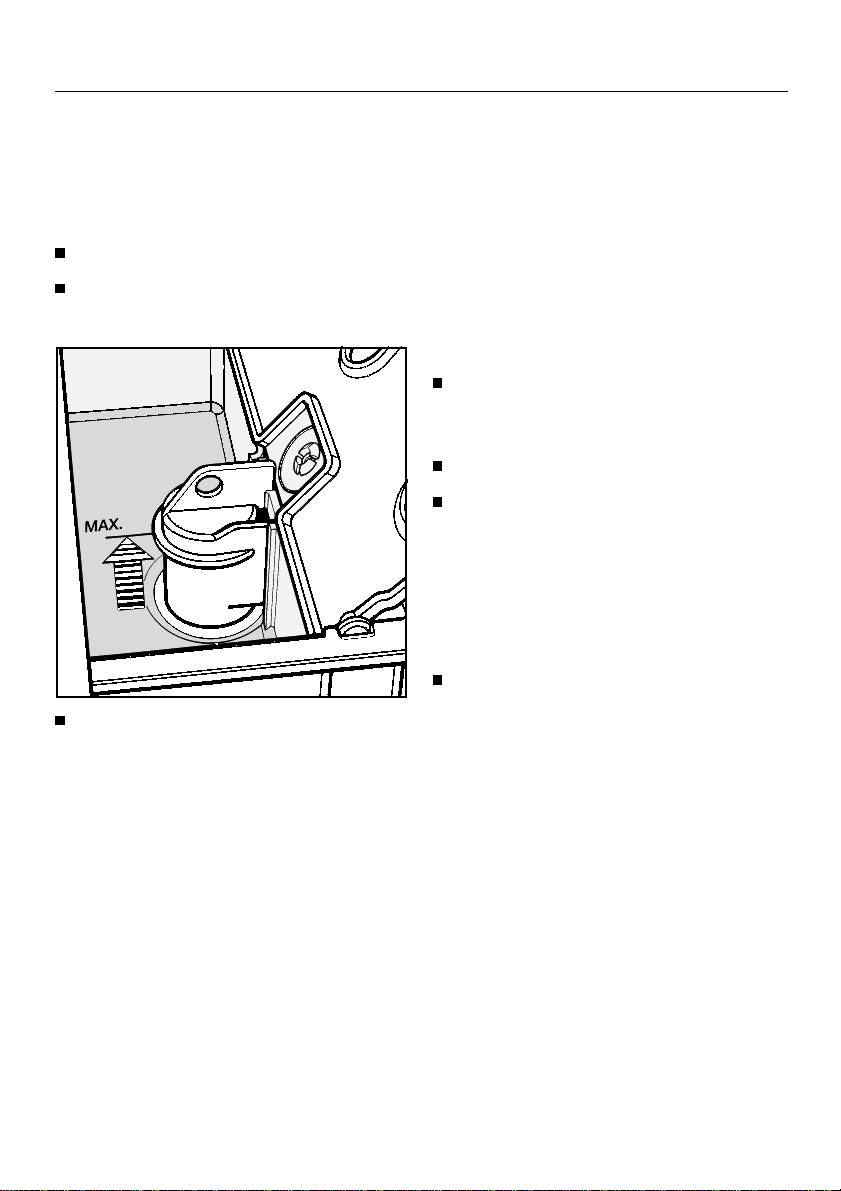

Open the lid of compartment p .

Add fabric conditioner, but do not ex-

ceed the max. level.

Texturiser and liquid starch formulations

These synthetic starch formulations

give body to items e.g. shirts, tablecloths and bed linen. Add starch formulations to the fabric conditioner compartment following the same procedure

as for fabric conditioner.

Powder starch

Prepare and dispense the starch solution in accordance with the manufacturer’s instructions.

Add to compartment i .

Turn the programme selector switch

to the “Starch” position.

If preferred select “rinse hold” to prevent creasing. The laundry remains suspended in the last rinse water.

To continue the programme:

Select “Drain” or “Spin”.

Close the compartment lid and push

in the dispenser drawer.

The conditioner is automatically dispensed in the last rinse. At the end of

the programme a small amount of

water remains in the fabric conditioner

compartment.

12

Page 13

Programme selection

The following basic programmes are

available:

Cottons

Low water level for washing and rins-

ing; 4 rinses; final spin max.

1200 rpm.

Minimum iron

Low water level for washing, medium

water level for rinsing; 3 rinses; final

spin max. 900 rpm.

Delicates

High water level for washing and rins-

ing; 3 rinses; final spin max. 600 rpm.

Woollens

Medium water level for washing,

higher water level for rinsing; 3

rinses; final spin max. 900 rpm.

Reduced drum movement.

By selecting one or more of the push-

button functions basic programmes

can be tailored to the type of laundry

being washed.

for washing and rinsing cottons and

minimum iron items,

for washing delicate items.

“Gentle action”

For gentle washing of slightly soiled

laundry items, e.g. delicate fabrics

which tend to pill (i.e. form

knobbles). Drum movement is reduced by half.

“Short”

For lightly soiled laundry items. The

length of the main wash is shortened. An additional reduction in temperature is not recommended as this

may lead to poorer washing results.

Selecting the spin speed

Set the selector switch to the

highest appropriate setting to save

energy if laundry is to be dried in the

tumble drier. The spin speed in the

“Minimum iron” and “Woollens” programmes is automatically limited to

900 rpm, and in the “Delicates” programme to 600 rpm.

“With pre-wash”

for heavily soiled and stained

laundry items.

“Water plus”

This is recommended if the water

level with the “Gentle action” option

is not sufficient for particularly deli-

cate fabrics,

if more water is required for dispens-

ing the detergent,

“Rinse hold setting”

Laundry remains suspended in

water at the end of the programme.

If the washing is to be spun, turn the

spin speed selector from “Rinse

hold” to the appropriate spin speed,

or turn the programme selector

switch to “Drain”.

13

Page 14

Changing the programme sequence

Selecting a programme

The programme can only be started

when:

The machine is switched on.

The drum door is properly shut.

The programme selector switch is at

the “Finish/Start” position.

Turn the programme selector switch to

the required programme.

To cancel a programme:

Turn the programme selector switch

to the “Finish/Start” position.

To interrupt a programme:

Switch the machine off. To re-start a

programme switch the machine on

again.

To change an incorrectly selected

programme:

Turn the programme selector switch

to “Finish/Start”. When only the “On”

LED is illuminated a new programme

can be selected.

To omit a programme stage:

a programme stage must first be

reached before it can be omitted:

Turn the programme selector to “Finish/Start”.

As soon as the programme sequence

lamp for the stage at which the programme should continue starts flashing:

turn the programme selector switch

to the appropriate programme within

3 seconds.

To repeat a programme stage:

a programme stage must have finished

before it can be repeated:

Turn the programme selector switch

to “Finish/Start”.

When only the “On” LED is illuminated:

a new programme can be selected.

After approx. 5 seconds, turn the pro-

gramme selector switch back to “Finish/Start”.

Once the indicator light of the programme stage to be repeated starts

flashing:

To change a programme where the

child safety option had been set see

page 18.

During a programme it is possible to

omit one or more programme stages

or

repeat one or more programme

stages.

14

turn the programme selector switch

to the appropriate programme within

a period of 3 seconds.

Page 15

Programmes

Cottons

For cotton and linen textiles.

Max. 5 kg

Minimum iron

Minimum iron textiles in synthetic,

mixed fibres or minimum iron cottons.

Max. 2.5 kg

X = additional options

X = additional options

15

Page 16

Programmes

Delicates

For delicate textiles in synthetic, mixed

fibres and delicate cottons, acrylics,

acetate and triacetate

Max. 1 kg

Woollens

For woollen or wool mix textiles which

have the woollens symbols shown

under "Textile care symbols" stating that

they are “machine washable”.

Machine washable curtains (see washing instructions): load loosely in the

drum filling no more than 1/3 full.

Set the temperature according to the

manufacturer’s instructions.

X = additional options

Max. 1 kg

16

Page 17

Programmes

Starching

For freshly washed textiles such as

tablecloths, napkins, uniform garments

etc.

Max. 5 kg

Spin

For spinning garments such as those

previously hand washed. These must

be suitable for spinning in a machine.

Drain

For laundry which is to be taken out of

the machine wet for drip drying.

Quick wash programmme 40°C

for cottons

For new garments which need to be

washed before wearing for the first

time. For freshening up clothes which

have been in storage for a while.

Max. 2. 5 kg

17

Page 18

Programmable functions

Additional programme functions can be

selected if required:

High water level (only in Cottons

rinses)

Where rinse results are particularly important.

5th Rinse for Cottons programme

For soft water areas (hardness range 1,

up to 135 mg/l).

In soft water areas a higher water level

can be selected in addition to a 5th

rinse if rinse results are not as good as

required.

Child-safety feature

The washing machine ignores any

changes after the first three minutes of

starting the programme, i.e. if the programme selector switch is set to a different setting or an additional programme is selected.

The “On” lamp flashes.

Once the programme selector switch is

turned back to its original position the

“On” lamp stops flashing.

To change a programme:

Turn the programme selector switch

to “Finish/Start”.

The programme sequence indicator

lamps start flashing in succession after

about 30 seconds. You can select a different programme as soon as only the

“On” light is lit up.

The three functions described

above can be programmed by the

Customer in four steps as shown on

pages 19-20.

There are however other functions

programmable after Step 2 which

are reserved for Miele Service Engineers. They are not for Customer

use, and are not activated as standard.

18

Page 19

To programme an extra Function:

First switch off the machine, close

the door, and release all switches

and set the programme selector

switch to “Finish/Start”.

Carry out steps 1 and 2 within 4 seconds.

Step 1:

Press in the “On-Off”

button

Step 2:

Press the “Water plus”

button 4 times

(i.e. press in and

out twice)

Programmmable functions

The “On” LED will now

light up and the “Prewash” and “Main-wash”

lights flash.

19

Page 20

Programmable functions

Step 3:

Set the Programme selector to:

”Quickwash“

or

”Drain“

or

programmablefunction:

High water level

programmablefunction:

5th rinse

programmablefunction:

Child - safety

”Woollens cold“

Step 4:

Then: “Rinses/Rinse hold” LED lights up

Step 5:

20

Press the “Water plus” button twice, (i.e. in and out

once).

To store the function: press the “On-Off” button.

Page 21

Programmable functions Programme end

Deleting the programmable function:

Follow the same instructions as given

under “switching on the programmable

functions”, step 1 to step 4 inclusive.

The “Rinses/Rinse hold” lamp goes out.

Press “On/Off”.

The programmable function is deleted.

If after Step 2 you accidentally turn

the selector switch to a setting other

than one of the three in the chart

above:

– Rinses/Rinse hold indicator

does not light up - no function

is activated

– Rinses/Rinse hold indicator

lights up - proceed as for “Deleting the programmable function”.

Exception: the Rinses/Rinse hold indicator lights up if the switch was set

to “Cottons 95°C”.

After washing:

Turn the programme selector switch

to “Finish/Start”.

Open the door.

Switch the machine off.

Only remove laundry from the machine once the drum has stopped

turning, otherwise you may seriously injure yourself.

Check the folds in the door seal for

any small articles such as buttons or

other foreign bodies which might be

lodged there.

Turn off the stopcock.

Close the drum door.

Make sure the drum is empty, otherwise, when the machine is next

used items may become damaged

(e.g. shrink) or cause other laundry

to discolour.

21

Page 22

Cleaning and Care

Programmmable functions

Cleaning the washing machine

Clean the casing with a mild non-abrasive detergent or soap and water.

Wipe dry with a soft cloth.

Clean the facia panel with a damp

cloth and dry with a soft cloth.

The drum can be cleaned using a

proprietary stainless steel cleaner according to the manufacturer’s instructions.

Do not use abrasive cleaners or solvents.

Cleaning the detergent drawer

Pull out the drawer until a resistance

is felt.

Press down the red release knob

and at the same time pull the drawer

right out of the machine.

Clean the dispenser compartments

and the fabric conditioner duct.

Remove the siphon tube from compartment p and wash in warm water.

To programme an extra Function:

First switch off the machine, close

the door, and release all switches

and set the programme selector

switch to “Finish/Start”.

Carry out steps 1 and 2 within 4 seconds.

Step 1:

Press in the “On-Off”

button

Step 2:

Press the “Water plus”

button 4 times

(i.e. press in and

out twice)

The “On” LED will now

light up and the “Prewash” and “Main-wash”

lights flash.

22

19

Page 23

Cleaning and Care

Cleaning the drain pump and fluff filter

Check the fluff filter initially after 3 - 4

washes to ascertain how often it is

likely to require cleaning.

Take the flap opener from behind the

detergent dispenser drawer.

Place a 2 litre capacity dish underneath the drain fixture.

Turn the fluff filter lid round 2-3 times.

Do not take it right out.

Approx. 2 litres of water will drain out

of the hose.

If the drain outlet is clogged, more

water will be retained in the machine,

(max. 25l). In this case, screw the fluff

filter back into position and empty the

dish before repeating the procedure as

often as necessary.

Open the fluff filter flap.

Caution: if laundry has been

washed at a high temperature,

water draining out of the machine

will still be hot!

23

Page 24

Cleaning and Care

Once the flow of water ceases,

remove the fluff filter completely and

clean it.

Programmes

Remove any foreign bodies (e.g. buttons, coins, etc.) and fluff.

Turn the impeller by hand to check

that it is free to rotate. Any foreign objects causing an obstruction should

be removed.

24

Clean inside the fluff filter housing.

Remove any deposits of lime scale and

detergent or foreign bodies from the

thread of the filter housing and filter unit.

Because water has been drained off

the ball valve function has to be restored (see page 6).

Starching

For freshly washed textiles such as

tablecloths, napkins, uniform garments

etc.

Max. 5 kg

Spin

For spinning garments such as those

previously hand washed. These must

be suitable for spinning in a machine.

Drain

For laundry which is to be taken out of

the machine wet for drip drying.

Quick wash programmme 40°C

for cottons

For new garments which need to be

washed before wearing for the first

time. For freshening up clothes which

have been in storage for a while.

Max. 2.5 kg

17

Page 25

Cleaning and Care

The washing machine has two inlet filters to

protect the inlet valve:

To clean the filter in the inlet hose:

Close the stopcock.

Carefully unscrew the knurled coup-

ling connecting the inlet hose to the

stopcock anti-clockwise, using pliers

if necessary.

Remove the rubber seal from the re-

cess.

the surface, or if it has been otherwise

damaged.

If replacing the inlet hose only use a

hose able to withstand pressure up to

70 bar. Miele’s own hoses meet this requirement.

To clean the filter in the water inlet

valve:

Using pliers, carefully loosen the

ribbed plastic nut on the inlet valve,

and unscrew.

Using pointed pliers, take hold of the

plastic filter bar and remove the filter.

Clean under running water and care-

fully remove any grit particles.

Put the filter and seal back in the

reverse order and reconnect the

hose. Turn on the stopcock and

check the connection is watertight.

Inspect the inlet hose which is sub-

jected to high pressure while the machine is in operation. The hose should

be replaced if there are small cracks in

Use water pump pliers to withdraw

the plastic filter by the bar (see illustration). Clean and put back.

The two filters - one in the pressure

hose union and one in the inlet connection to the solenoid valve - must

not be removed.

25

Page 26

Problem solving guide

Any work on the electrical components of this appliance should only

be carried out by a suitably qualified and competent person in accordance with local and national

regulations. Unauthorised repairs

could be dangerous.

There are, however, minor faults which

can be corrected without contacting

the Service Department.

A selected programme does not

begin

The “On” indicator lamp does not light

up.

Check that

the door is properly closed,

the mains plug is plugged in and

that the fuse or circuit breaker has

not tripped.

The “On” indicator lamp is on, a programme has been selected, but the

“Pre-wash” or “Main wash” indicator

lights do not light up.

The programme selector switch was

not turned to the “Finish/Start” position

before the programme was selected.

The following selection sequence is important:

1. Turn the programme selector switch

to “Finish/Start”.

2. Select a programme.

26

Check

q warning lamp flashes

Drainage fault

Check whether the fluff filter is

clogged. Clean the filter and pump

as described on page 23 if necessary.

Check whether the drain hose is

kinked or trapped.

The check lamp goes out when the programme selector switch is turned to the

“Finish/Start” position.

The “Finish” indicator lamp is on, but

the laundry in the machine has not

been washed.

The water inlet is not open:

Turn the programme selector to “Finish/Start”.

Turn on the water supply at the stopcock.

Select a programme.

The water inlet system is blocked:

The stopcock has not been fully

opened.

The inlet hose is kinked or trapped.

The water pressure is too low

Check if the water flow through the

stopcock is 5 litres in 15 seconds.

The filters in the inlet hose are

clogged (see “Cleaning and Care”

on page 25).

If little or no water is taken in during the

next programme, the water pressure

may be too low. If it is adequate there

may be a technical fault.. In this case,

call your local service dealer or the

Miele Service Department.

Cottons

For cotton and linen textiles.

Max. 5 kg

Minimum iron

Minimum iron textiles in synthetic,

mixed fibres or minimum iron cottons.

Max. 2.5 kg

Programmes

X = additional options

X = additional options

15

Page 27

Problem solving guide

Despite adequate water supply pressure, the machine takes a long time to

fill.

Clean the filters in the water inlet system as described on page 25.

Large amounts of unused detergent

remain in the dispenser drawer.

Water supply pressure is too low.

Clean the filters as described on

page 25.

Select the “Water plus” function if

necessary.

Washing powder becomes viscous

when used together with a water softener.

In future pour washing powder into

the detergent dispenser before ad-

ding water softener.

Fabric conditioner is not completely

dispensed or water re ma in s in the

compartment p .

The dispenser drawer was opened

while fabric conditioner was being

flushed in.

The siphon tube is either incorrectly positioned or clogged. Clean as described on page 22.

Excessive build-up of foam

To avoid this problem from the outset,

take note of the following points:

Follow the manufacturer’s dosage

recommendations on packaging

carefully.

Take the water hardness level into ac-

count.

For lightly soiled articles or a small

load, reduce the amount of detergent accordingly.

Pre-soaked items should be rinsed

thoroughly before washing.

The “Pre-wash” indicator lamp is

flashing.

Start the programme again.

If the indicator still flashes call the Service Department.

The “Main wash” indicator lamp

flashes during, or after the end of a

programme.

If this occurs again with the next programme there is a technical fault. Call

the Service Department.

Laundry is either not spun at all or

not spun satisfactorily.

The selected spin speed was too low.

The machine was not able to distrib-

ute the laundry load evenly. To pro-

tect the machine, laundry was either

only spun at a reduced speed or not

at all.

Large items which tangle or roll up in

the drum (e.g. bath mats) can cause

an imbalance during the spin cycle.

For safety reasons, the machine

does not spin if this is the case. At-

tempts to build up spin speed are re-

peated, however, until the time allo-

cated to spinning has expired.

It is therefore important to make up

mixed loads consisting of large and

small items.

The fluff filter may be clogged.

Clean the filter and the pump as de-

scribed on page 23-24.

27

Page 28

Problem solving guide

Programme selection

The machine shakes during the spin

cycle.

The most likely cause is that the four

machine feet are not resting securely

on the floor. Level the machine as

shown on page 33.

Weak floorboards not only lead to excessive noise but also to shaking during the spin cycle (see page 31 for advice).

Lime deposits are visible on the surface of the drum.

Use a descaling agent to remove the

deposits. Consult the manufacturer’s

instructions before use to ensure that

the product is suitable for use in

washing machines.

Take the water hardness level into account when dispensing detergent.

Opening the drum door in the event

of a power failure

Switch off the washing machine.

Open the drain panel and drain off

any water as described on page 23

if there is water still in the drum.

Pull the ring of the door mechanism

downwards, and the door will open.

Always make sure the drum is stationary before reaching in to remove

washing. Reaching into a moving

drum is extremely dangerous.

The following basic programmes are

available:

Cottons

Low water level for washing and rinsing; 4 rinses; final spin max.

1200 rpm.

Minimum iron

Low water level for washing, medium

water level for rinsing; 3 rinses; final

spin max. 900 rpm.

Delicates

High water level for washing and rinsing; 3 rinses; final spin max. 600 rpm.

Woollens

Medium water level for washing,

higher water level for rinsing; 3

rinses; final spin max. 900 rpm.

Reduced drum movement.

By selecting one or more of the pushbutton functions basic programmes

can be tailored to the type of laundry

being washed.

“With pre-wash”

for heavily soiled and stained

laundry items.

“Water plus”

This is recommended if the water

level with the “Gentle action” option

is not sufficient for particularly delicate fabrics,

if more water is required for dispensing the detergent,

for washing and rinsing cottons and

minimum iron items,

for washing delicate items.

“Gentle action”

For gentle washing of slightly soiled

laundry items, e.g. delicate fabrics

which tend to pill (i.e. form

knobbles). Drum movement is reduced by half.

“Short”

For lightly soiled laundry items. The

length of the main wash is shortened. An additional reduction in temperature is not recommended as this

may lead to poorer washing results.

Selecting the spin speed

Set the selector switch to the

highest appropriate setting to save

energy if laundry is to be dried in the

tumble drier. The spin speed in the

“Minimum iron” and “Woollens” programmes is automatically limited to

900 rpm, and in the “Delicates” programme to 600 rpm.

“Rinse hold setting”

Laundry remains suspended in

water at the end of the programme.

If the washing is to be spun, turn the

spin speed selector from “Rinse

hold” to the appropriate spin speed,

or turn the programme selector

switch to “Drain”.

28

13

Page 29

Problem solving guide

Grey greasy particles cling to

washed laundry.

The wash load was heavily soiled with

greasy substances such as ointments

or lotions, and the amount of detergent

was insufficient to break down the particles of grease.

In future, either add up to 50% more

detergent to the main wash when

washing loads of this nature or use

liquid detergent in programmes up

to 60°C.

Before washing the next load, run a

Cottons 60°C programme with liquid

detergent without a load to clean the

machine.

Brown stains appear on the laundry

after washing.

An excessively high manganese or iron

content in the water supply can cause

stains of this nature to appear on the

laundry, in particular when low-phosphate detergent is used.

Laundry washed with liquid detergent is not cleaned.

Liquid detergent does not contain any

bleaching agents capable of removing

stains, e.g. fruit, coffee and tea stains.

To remove such stains, use a

general-purpose washing powder

which contains bleach or enzymes,

or pre-treat laundry.

pour stain remover according to

manufacturer’s instructions into com-

partment j of the detergent dispen-

ser and dispense the liquid deter-

gent directly using a proprietary

dispensing aid.

Never pour stain remover and liquid

detergent into the same compartment.

Have the quality of the water supply

checked and take remedial action if

necessary.

After washing, knobbles (pilling) appear on the fabric

In normal everyday wear of certain fabrics pilling may occur. The Gentle action function should be selected when

washing these fabrics, or another programme with higher water levels and reduced agitation to lessen the risk of further pilling.

29

Page 30

After sales service

Adding detergent

In the event of any faults which cannot

be remedied, or if the appliance is

under guarantee, please contact:

Your Miele Dealer or

The nearest Miele Service Depart-

ment (see back cover for the address).

When contacting the Service Department, please quote the Model and Serial nos. of your appliance, both of

which are shown on the dataplate

visible above the sight glass on the inside of the door.

Example:

All modern detergents produced for

automatic washing machines are suitable, including liquid, compact (concentrated) and special application

detergents. Use dispensing aids e.g.

balls if these are supplied with the

detergent. Woollens and knitware containing wool mixtures should be

washed using a detergent specifically

designed for washing woollens.

Add the right amount of detergent as

recommended on the packaging The

amount dispensed will depend on the

following:

– the quantity of laundry

– the water hardness level

– the level of soiling

It is important to dispense the correct amount, because...

...too little detergent results in the following:

– The laundry will not get properly

clean and will in time become grey

and hard to the touch.

– Greasy particles cling to the laundry.

– Lime deposits on the heater ele-

ments.

...too much detergent results in the following:

– Excessive foam.

– Low level of agitation.

– Poor washing and rinsing results.

Water is taken in through compartment

j in the main wash. If the capacity of

compartment j is insufficient for the

amount of detergent needed where

water hardness is above 380 mg/l (in

hardness area 4), the Customer Service Engineer can adjust the machine

so that water can also be taken in

through compartment i to take detergent into the main wash.

Water Softeners

A water softener can be used to cut

down on the use of detergents in water

hardness ranges 2 - 4. Dispense according to the amount specified on the

packaging. First add detergent and

then the water softener. Detergent can

be dosed as for water hardness range

1.

We recommend: if you wash using sev-

eral components (e.g. special application detergents), dispense the agents

in the following order into compartment

j :

1. Detergent

2. Water softener

3. Stain salts

This way the agents are distributed bet-

ter.

30

11

Page 31

Installation

Installation surface

Experience has shown that a concrete

floor is the most suitable for a washing

machine. Concrete floors are far less

prone to vibration during the spin cycle

than wooden floorboards.

Please note the following points:

The machine must be level and securely positioned.

To avoid vibrations during spinning,

the machine should not be installed

on soft floor coverings.

If installation must be on a wooden

joist floor: we recommend the use of

a plywood base (at least

59x52x3 cm). Ideally the base

should be large enough to span several joists and should be bolted to

the joists and not just the floorboards. Check for presence of pipes

and cables first.

As a general rule, we recommend

the installation of the machine (or

washer/dryer stack) in the corner of

a room where the stablity of the floor

is at its greatest.

Ensure that the machine feet and the

floor are dry to prevent the machine

from slipping during the spin cycle.

Removing the transit fitting.

Using combination pliers, pull out

the retaining clips on the right and

left of the support plate.

If the machine is installed on a raised

plinth, it must be secured against slippage during spin using retaining clips

(available from the Miele Spare Parts

Dept).

Installation

Lift the machine from its packaging

base and move it to its site. Please

note:

Do not lift the machine by the drum

door.

Using a pipe wrench turn the lefthand transit bar 90° anti-clockwise

and the right-hand transit bar clockwise.

31

Page 32

Installation

Withdraw the two bars together with

the support plate.

32

Plug the two holes with the plastic

caps supplied.

The machine should not be moved without the transit fitting in place.

The transit fitting should be stored

in a safe place for future use. It

must be re-fitted if the machine is to

be moved again. Re-fitting is carried out by reversing the procedure.

Washer-Dryer stack

A Miele tumble dryer can be stacked

with this washing machine. A stacking

kit* can be purchased from the Miele

Spare Parts Department.

All parts marked * are available from

the Miele Spare Parts or Sales Department.

Empty all pockets.

Foreign objects (e.g. nails, coins,

paper clips etc.) can cause damage to textiles and components in

the machine.

Sort the laundry

Most garments have a textile care label

in the collar or side seam. Sort the

laundry by care label symbols.

Only wash items in this machine which

are declared by the manufacturer as

being machine washable on the textile

care label.

Dark textiles often contain“excess

dye,” and should be washed separately several times before being included in a mixed load.

Delicate textiles should be washed separately in a delicates programme.

Only wash textiles made from wool or

wool mixtures if they are declared as

being suitable for machine washing on

the textile care label.

Preparing the wash load

Pre-treating the washing

Badly soiled areas, e.g. collars and

cuffs, and water soluble stains, can be

pre-treated with bar soap, liquid detergent or detergent mixed into a solution

or paste.

With particularly stubborn stains ask

your Dry Cleaner for advice.

Do not use detergents containing solvents in this machine.

Loading the drum

Unfold laundry and load loosely in the

drum. To achieve best results it is advisable to make up mixed loads consisting of both large and small items. This

improves the washing effect and helps

distribute the load evenly to keep the

machine stable and reduce the noise

level during spinning.

It is advisable to weigh the load first to

make best use of the machine’s capacity.

Maximum load weights are noted

below:

COTTONS . . . . . . . . . . . . . . . . . . 5.0 kg

MINIMUM IRON . . . . . . . . . . . . . 2.5 kg

DELICATES/SYNTHETICS. . . . . 1.0 kg

WOOL . . . . . . . . . . . . . . . . . . . . . 1.0 kg

QUICK WASH . . . . . . . . . . . . . . . 2.5 kg

With curtains: Remove lead weights

and strips or place in a laundry bag.

Woollens and knitted garments should

be turned inside out if the manufacturer

recommends it.

Close the drum door

Make sure that there is no obstruction

between the drum door and seal.

9

Page 33

Installation

Levelling the machine

The machine must stand level to ensure smooth operation. Check with a

spirit level.

The feet are levelled using the leg levellers as follows:

Building under

It is possible to install this appliance

under a continuous worktop/in a kitchen run:

A special building under kit * is required.

The machine lid must be replaced

by a cover plate.

This must be fitted by a suitably competent person exactly according to

the fitting instructions included with

the kit to ensure electrical safety.

For installation under a work surface

900/910mm from the floor, a spacer

kit * is required.

Connections for electricity, water and

drainage should be installed in such

a way that they remain accessible

when the machine is in place.

Fitting instructions are included with

the kit.

Unscrew foot or feet until the machine stands level.

Hold the foot tight using a pipe

wrench.

Tighten the counternut using a

screwdriver as indicated.

All parts marked * are available from

the Miele Spare Parts or Sales Department.

33

Page 34

Electrical connection

Warning and Safety Instructions

Electrical connection U.K.

This washing machine is supplied

ready for connection to an a.c. single

phase 230 V, 50 Hz supply. The rated

load is 3.2 kW. The machine is supplied

with a 2 m long mains cable with

moulded plug and the fuse rating is

13A.

All electrical work should be carried out

by a competent person, in accordance

with national and local safety

regulations.

Connection should be made via a

fused plug and a suitable switched

socket which is easily accessible.

For extra safety it is advisable to install

a residual current device (RCD) with a

trip current of 30 mA.

The voltage, rated load and fuse rating

are given on the data plate. Please ensure that these match the household

mains supply.

Important

The wires in the mains lead are col-

oured in accordance with the following

code:

Green/yellow = earth

Blue = neutral

Brown = live

As the colours of the wires in the mains

lead of this appliance may not correspond with the coloured markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured green and

yellow must be connected to the terminal in the plug which is marked with the

letter E or by the earth symbol z or

coloured green or green and yellow.

34

The wire which is coloured blue must

be connected to the terminal which is

marked with the letter N or coloured

black.

The wire which is coloured brown must

be connected to the terminal which is

marked with the letter L or coloured red.

WARNING

THIS APPLIANCE MUST BE

EARTHED.

This appliance is designed and intended only for normal household use

in the U.K. It should never be operated

by children. Supervise its use by the elderly or infirm.

Read the operating instructions through

before using this machine for the first

time, as this is for your safety and the

protection of the machine. They give

notes on the safety, the use and the

maintenance of the machine.

Further warning and safety instructions

are given in the text as appropriate.

...before using for the first time

Do not install your washing ma-

chine in rooms where sub-zero

temperatures may occur. Frozen hoses

may burst under pressure.

The reliability of the electronic control

system may be impaired at temperatures below freezing point.

Before using the machine for the

first time, check that the transit fitting at the rear of the machine has

been removed (see page 31).

During spinning, a transit fitting which

is still in position may result in damage

to both the machine and adjacent furniture or appliances.

If the drain hose is attached to a

wash basin or sink, make sure it is

secure, (see illustration in the section“Guide to the machine”),

so that the force of the water flowing

out of the hose does not dislodge it, as

this will otherwise result in flooding.

If hooking the hose into a wash basin,

check that the water can drain off

quickly enough to prevent the sink from

overflowing.

Keep these operating instructions

in a safe place.

...when using your machine

Only wash items which are de-

clared by the manufacturer to be

machine-washable on the care label

(textile care G.B. laundry care, AUS),

(see Care labels on page 10).

Descaling agents contain acid.

Only use proprietary non-corrosive

descaling agents and strictly observe

the manufacturer’s instructions. After

descaling, always run several full rinse

cycles to remove any acid residue and

to protect component parts from corrosion.

Never use detergents containing

solvents in this machine, as this

may result in damage to component

parts and create toxic fumes. Such

detergents also pose a fire and explosion hazard.

Textiles which have been pre-

treated in detergents containing

solvents must be thoroughly rinsed in

clean water before being washed in

this machine.

Do not use dye removers as these

contain sulphur compounds which

may damage washing machines.

7

Page 35

Electrical connection

Non-rewireable plugs BS 1363

If this machine or appliance is fitted

with a non-rewireable plug, the following information applies:

If the socket outlets are not suitable for

the plug supplied with this product, it

must be cut off and an appropriate

plug fitted.

The plug cut from the flexible cord

should be disposed of and on no account be inserted into a 13 A socket

elsewhere in the house (electric shock

hazard).

The fuse cover must be refitted when

changing the fuse, and if the fuse

cover is lost, the plug must not be used

until a suitable replacement is obtained. The colour of the correct replacement cover is that of the coloured

insert in the base of the plug, or the colour that is embossed in words in the

base of the plug (as applicable to the

design of plug fitted).

The correct fuse rating of the replacement fuses that are ASTA approved to

BS 1362 should be fitted. Replacement

fuse covers may be purchased from

your local electrical suppliers, electricity showroom, or Miele Service

Agent.

(The German standard version is supplied with a 2 m long cable and

moulded plug for connection to a

220/230 V single phase supply. It must

only be connected via a fused

16 A socket. See data plate for rated

load. Electrical installation should be

approved by a qualified electrician).

35

Page 36

Plumbing

Caring for the environment

Connection to water supply

The machine should be connected to a

mains water supply in accordance with

standard regulations. The German authorities do not require it to have a non-return valve as the washing machine has

been designed to comply with DVGW

regulations (German Association of

Gas and Water Engineers, see data

plate).

Connection to a mains water supply

should be carried out by a qualified

plumber and should incorporate a

mains stopcock with 3/4" thread

The 1.5 m long 3/8" pressure hose

should be connected to the stopcock

via the 3/4" threaded union.

If connection is to be made to a stopcock with a short 3/4" thread, the extra

washers enclosed should also be inserted in the inlet hose union to compensate.

The connection points are subject to

mains water pressure. Turn on the stopcock slowly and check for leaks. Correct the positioning of the washers and

screw unions if appropriate.

If replacing the inlet hose only use a

hose able to withstand pressure of up

to 70 bar. This also applies to all fittings

used. Miele original parts fulfil this condition.

Longer hoses 2.5 or 4.0 m in length are

available as optional extras.

The pressure hose and solenoid inlet

valve are designed for a water flowpressures of between 1 and 10 bar

(981 kilonewtons/m

pressures it is essential to fit a reducer

valve.

There is a minimum flow pressure of 1

bar pressure if 5 litres of water flow into

a suitable container in 15 seconds.

The two dirt filters, one at the inlet

point, one in the pressure hose

union, must not be removed.

2

). At higher water

Caring for the environment

Caring for the environment means saving water, energy and detergent when

washing. This machine is equipped

with the Hydromatic System and the

Ball Valve for economical use of resources. These systems offer a variety

of technical innovations e.g. the drum

ribs, which are designed to enable

economical washing without compromising on results.

The automatic load control facility enables loads of between 1 and 5 kg to

be washed using only as much water

and electricity as is required for an effective wash.

Spinning at the high speed of

1200 rpm reduces drying times and energy consumption if laundry is dried in

a tumble dryer after washing.

Economy tips

To help you wash most economically,

remember the following tips:

Always wash with the maximum

laundry load specified for each programme. This uses the energy to the

best advantage.

Only use the correct amount of detergent required for the water hardness

level in your area, as recommended

by the manufacturer.

If laundry is not heavily stained, select a lower temperature setting than

indicated on the laundry care label

(but when using a lower temperature

do not select the “short”-option).

Lightly soiled laundry can be

washed using a “short”-programme

(additional temperature reduction

not recommended).

This hose is not suitable for use for connection to a hot water supply. Please

make sure that the washer sits correctly

in the union.

36

5

Page 37

Plumbing

Connection to drainage

The machine drains via a drain pump

with a delivery head of one metre. The

hose must not be kinked as this restricts drainage. The hooked piece at

the end of the hose can be turned in

either direction.

Hose dimensions:

Length . . . . . . . . . . . . . . . . . . . . - 1.5 m

Internal diameter . . . . . . . . . . . - 22 mm

External diameter. . . . . . . . . . . - 30 mm

External diameter

of hooked end . . . . . . . . . . . . . - 32 mm

The drain hose may be connected as

follows:

Direct into a sink: Hook the hose

over the edge and secure.

Make sure that the water can flow

away freely to avoid flooding and to

prevent water from being sucked

back into the machine.

Connected to a plastic drain pipe

with a rubber nipple. There is no

need to use a non-return valve.

Directed into a standpipe.

Allowing the water to drain off into a

floor drain.

If required, the hose can be extended

to a length of 5 m.

For a delivery head of more than 1 m

up to a maximum of 1.80 m, a second

Duo drain pump is available with the

corresponding conversion kit from the

Miele Spare Parts Department.

37

Page 38

Technical data

Guide to the machine

Height. . . . . . . . . . . . . . . . . . . . . . . . . .

Width . . . . . . . . . . . . . . . . . . . . . . . . . .

Depth . . . . . . . . . . . . . . . . . . . . . . . . . .

Depth with door open . . . . . . . . . . . . .

Weight . . . . . . . . . . . . . . . . . . . . . . . . .

Max. floor load . . . . . . . . . . . . . . . . . . .

Capacity. . . . . . . . . . . . . . . . . . . . . . . .

Connected load . . . . . . . . . . . . . . . . . .

Rated load . . . . . . . . . . . . . . . . . . . . . .

Fuse rating . . . . . . . . . . . . . . . . . . . . . .

Water flow pressure min. . . . . . . . . . . .

Static water pressure max.. . . . . . . . . .

Maximum delivery head. . . . . . . . . . . .

Maximum length for drainage pump . .

Consumption data (DIN EN 60456)

Cottons 60°C . . . . . . . . . . . . . . . . . . . .

Test certificates awarded. . . . . . . . . . .

Electrically suppressed according to. .

85 cm

59.5 cm

60 cm

97 cm

95 kg

1600 Newton (approx. 160 kg)

5 kg dry laundry

see data plate

}

1 bar

10 bar

1 m

5 m

Electricity: 1.1 kWh

Water: 63 litres

Radio/tv suppression, VDE

DIN EN 60555/VDE 0838

1 Supply cable

2 Inlet hose (able to withstand press

ures up to 70 bar)

3 Flexible drain hose, with detachable

swivel elbow

4 Detergent dispenser drawer

5 Facia panel with controls

6 Drum door

7 Access panel - drain pump and fil-

ter, emergency door opener

8 Four height adjustable feet

38

Page 39

39

Page 40

Alteration rights reserved/001 GB - 1396

Loading...

Loading...