Miele PWD 8531, PWD 8532, PWD 8532 WS Operating instructions

Operating instructions

WASHER-DISINFECTOR

PWD 8531

PWD 8531 WS

PWD 8532

PWD 8532 WS

Read the operating instructions carefully before

installing and using the machine. This will help

protect users from personal injury and help

prevent damage to the machine.

en – GB, AU, IE, NZ

Contents

Contents

GENERAL RULES ................................................................................................................................. 6

1.

1.1

Limitation of liability ...................................................................................................................... 6

1.2

Validity, content and storage ........................................................................................................ 6

2.PRODUCT INFORMATION .................................................................................................................... 7

2.1

Intended use ................................................................................................................................. 8

2.2

Authorisation for service and user training ................................................................................... 8

2.3

Safety instructions and warnings ................................................................................................. 9

Appropriate use ........................................................................................................................ 9

Risk of injury ............................................................................................................................. 9

Quality assurance ................................................................................................................... 11

Using accessories .................................................................................................................. 12

Disposing of your old machine ............................................................................................... 13

Warning signs ......................................................................................................................... 13

2.4

Technical data ............................................................................................................................ 14

2.5

Recommendations for proper operation .................................................................................... 15

2.6

Training ....................................................................................................................................... 16

User profiles ............................................................................................................................ 16

3.INSTALLATION .................................................................................................................................... 17

3.1

Water connection ....................................................................................................................... 17

Water quality ........................................................................................................................... 17

Connecting the drain hose ..................................................................................................... 18

3.2

Electrical connection .................................................................................................................. 19

3.3

Installation site ventilation .......................................................................................................... 20

4.BUILT-IN WATER SOFTENER ............................................................................................................ 21

4.1

Refilling the salt .......................................................................................................................... 22

5.DISPENSING ....................................................................................................................................... 23

5.1

Volume flow control and lack of product ................................................................................... 23

5.2

Refilling process chemicals ........................................................................................................ 24

PWD 8531 and PWD 8531 WS ............................................................................................... 24

PWD 8532 and PWD 8532 WS ............................................................................................... 25

Warnings ................................................................................................................................. 26

6.OPERATION ........................................................................................................................................ 27

6.1

Checking consumption ............................................................................................................... 27

6.2

Opening and closing the door .................................................................................................... 28

Opening the door using the emergency release device ......................................................... 29

6.3

Switching on and off ................................................................................................................... 29

6.4

Preparation ................................................................................................................................. 30

REV.0.01_COD.500224_A4 Page 3

Contents

Preparing the load .................................................................................................................. 30

Preparing the machine ........................................................................................................... 32

Checks after a programme ..................................................................................................... 33

7.CONTROL PANEL AND SYMBOLS USED ......................................................................................... 34

7.1

Control panel .............................................................................................................................. 34

7.2

Buttons ....................................................................................................................................... 35

Buzzer ..................................................................................................................................... 35

7.3

Display ........................................................................................................................................ 36

8.PROGRAMMES ................................................................................................................................... 39

8.1

Starting the programme ............................................................................................................. 39

8.2

Programme structure .................................................................................................................. 40

8.3

Programme sequence ................................................................................................................ 41

9.MACHINE STATUS ............................................................................................................................. 42

9.1

Ready for operation .................................................................................................................... 42

9.2

Programme ................................................................................................................................. 42

9.3

Error messages ........................................................................................................................... 42

9.4

Power failure ............................................................................................................................... 43

9.5

Reset after error messages ........................................................................................................ 43

10.MENU ............................................................................................................................................. 44

10.1Entering the password ................................................................................................................ 44

10.2Setting the buzzer volume .......................................................................................................... 45

10.3Setting the date and time ........................................................................................................... 45

10.4Historical data output ................................................................................................................. 46

10.5Selecting a language .................................................................................................................. 47

10.6Changing user names ................................................................................................................. 48

10.7Parameter overview .................................................................................................................... 49

11.HISTORICAL DATA ......................................................................................................................... 50

11.1Outputting cycle reports retrospectively .................................................................................... 50

11.2External software ........................................................................................................................ 50

12.MESSAGES AND WARNINGS ....................................................................................................... 51

12.1Warning list ................................................................................................................................. 51

12.2Message list ................................................................................................................................ 52

13.PROCESS DOCUMENTATION ....................................................................................................... 53

13.1Serial interface ............................................................................................................................ 53

13.2User administration..................................................................................................................... 53

13.3USB port ..................................................................................................................................... 53

14.MAINTENANCE .............................................................................................................................. 54

14.1General recommendations on maintenance .............................................................................. 54

14.2Maintenance reminder ................................................................................................................ 54

14.3Routine maintenance .................................................................................................................. 54

REV.0.01_COD.500224_A4 Page 4

Contents

14.4Table of routine maintenance tasks ........................................................................................... 54

14.5Special maintenance .................................................................................................................. 59

Table of special maintenance work ...................................................................................... 59

15.PROBLEM – CAUSE – REMEDY .................................................................................................... 60

15.1Introduction................................................................................................................................. 60

15.2Problem (P) – Cause (C) – Remedy (R) ....................................................................................... 60

16.DISPOSING OF YOUR OLD MACHINE .......................................................................................... 61

REV.0.01_COD.500224_A4 Page 5

GENERAL RULES

1. GENERAL RULES

Further on in these operating instructions, the washer-disinfector is referred to simply as a

machine. Reprocessable medical devices are referred to as “items” if they are not defined in

more detail.

1.1 Limitation of liability

The manufacturer shall not be held liable for faults or problems which arise due to tampering

or incorrect or improper use and operation of the machine.

The operator must comply with all instructions set forth in the operating instructions, most

notably:

Always consider the intended use of the machine

Always carry out the required maintenance work

Use of the machine should be limited to persons who have been properly trained and

instructed on the use of the machine

Use only original spare parts

Any modifications, adaptation or similar which may be made to machines which are

subsequently placed on the market do not oblige the manufacturer to intervene on previously

supplied machines, nor to consider the machine and the related operating instructions

lacking and inadequate.

The operating instructions on the following pages are designed to guarantee the longevity

and functionality of your machine.

The instructions in this manual do not replace, but rather supplement employer requirements

to adhere to current legislation on standards of prevention and safety.

1.2 Validity, content and storage

It is important to keep this instruction manual with the machine for future reference.

If the machine is sold or transferred, the manual must be handed over to the new owner or

users so that they can become acquainted with its functioning and the relevant safety

instructions and warnings.

Read the warnings carefully before installing and using the machine.

REV.0.01_COD.500224_A4 Page 6

2. PRODUCT INFORMATION

Compliance with safety standards allows the user to work without the risk of harm.

Before starting work, the user must be completely familiar with the functions and proper

operation of the machine. The user must know the precise functions of all command and

control devices of the machine.

PRODUCT INFORMATION

PWD 8531

PWD 8531 WS

PWD 8532

PWD 8532 WS

REV.0.01_COD.500224_A4 Page 7

PRODUCT INFORMATION

2.1 Intended use

This machine can be used to reprocess a wide range of reusable medical devices for dental

use. Follow all instructions issued by instrument manufacturers (in compliance with EN ISO

17664) and national legislation and guidelines relating to the machine-based reprocessing of

medical devices.

Medical devices such as dental instruments, saliva extractors, transmission instruments, etc.,

which are designated as reprocessable by the manufacturer, can be reprocessed in this

machine.

Improper use of this machine is any use other than that for which the machine is intended.

CAUTION

Inappropriate use can lead to personal injury and damage to property.

Miele cannot be held liable for damage caused by improper or incorrect

use or operation of the machine.

Note: According to EN ISO 17664, the manufacturer of medical devices is obligated to

provide reprocessing instructions for their products. These must include instructions on how

medical devices are to be reprocessed, cleaned, disinfected, inspected and stored. If,

during use, medical devices come into contact with blood or potentially contaminated

tissue, such products must be reprocessed in compliance with national and local standards.

Washer-disinfectors are part of the process for reprocessing reusable medical devices.

2.2 Authorisation for service and user training

Miele & Cie. KG (hereinafter referred to as Miele) has been authorised by Steelco S.p.A, the

original equipment manufacturer, to provide technical training and user training for this

machine.

If reference is made to Miele Service or an authorised service agent, this is authorised by

Steelco S.p.A as the manufacturer.

The machine may only be installed, commissioned, repaired and maintained by Miele Service

or an authorised service technician.

REV.0.01_COD.500224_A4 Page 8

2.3 Safety instructions and warnings

This machine conforms to current safety requirements. Inappropriate use can, however,

lead to personal injury and material damage.

Read the operating instructions carefully before using this machine. This will help protect

users from personal injury and help prevent damage to the machine.

Keep these operating instructions in a safe place.

Appropriate use

Use of the machine is only permitted for the applications expressly approved in the

operating instructions. Alterations or conversion of the machine, or using it for purposes

other than those for which it was intended, are not permitted and could be dangerous.

The cleaning and disinfection processes are only designed for medical devices which are

designated reprocessable by the manufacturer. Instructions issued by load and

instrument manufacturers must be heeded.

Miele cannot be held liable for damage caused by improper or incorrect use or operation

of the machine.

This machine is intended for indoor use only.

Risk of injury

Please pay attention to the following information to avoid injury:

The machine may only be installed, commissioned, repaired and maintained by Miele

Service or an authorised service technician. A Miele service contract is recommended to

ensure full compliance with medical device regulations (such as the German Medical

Device Ordinance). Incorrect repairs can cause considerable danger to users.

Do not install the machine in an area where there is any risk of explosion or of freezing

conditions.

In order to reduce the risk of water damage, the area around the machine should be

limited to furniture and fittings that are designed for use in commercial environments.

With some metal parts, there is a risk that you may be injured or cut. Wear cut-resistant

protective gloves when transporting and setting up the machine.

If the machine is installed under a worktop, it must only be installed under a continuous

worktop which is firmly secured to adjacent units to improve stability.

The electrical safety of the machine can only be guaranteed when it is correctly earthed.

It is essential that this basic safety requirement is met. If in any doubt, please have the

on-site wiring system tested by a qualified electrician. Miele cannot be held liable for the

consequences of an inadequate earthing system (e.g. electric shock).

A damaged or leaking machine can pose a threat to your safety. Always switch off a

damaged or leaking machine immediately and call Miele Service.

Machine operators must be instructed on the use of the machine and trained regularly.

Untrained personnel must not be allowed access to the machine or its controls.

Only use process chemicals which have been approved by their manufacturer for the

relevant application. The manufacturer of the process chemicals is liable for any negative

influences on the material of the load and the machine.

Take care when using process chemicals. Some chemicals may be caustic, irritating and

toxic.

The relevant safety regulations and safety data sheets issued by the process chemical

manufacturers must be observed.

Wear gloves and protective goggles.

PRODUCT INFORMATION

REV.0.01_COD.500224_A4 Page 9

PRODUCT INFORMATION

The machine is only designed for use with water and appropriate process chemicals. The

use of organic solvents or inflammable liquids is not permitted.

This could cause an explosion, damage rubber or plastic components in the machine and

cause liquids to leak out.

The water in the wash chamber must not be used as drinking water.

Do not lift the machine by protruding parts such as the door handle or the opened

service flap as these could be damaged or torn off.

Do not sit or lean on the opened door. This could cause the machine to topple over and

become damaged or cause you an injury.

Be careful when sorting items with sharp, pointed ends. Position them in the machine so

that you will not hurt yourself or create a danger for others.

Broken glass can result in serious injury when loading or unloading. Broken glass items

must not be processed in the machine.

Please be aware that the machine may be operating at high temperatures. Deactivating

the lock to open the door can result in a risk of burns and scalding.

Should personnel accidentally come into contact with toxic vapours or chemical agents,

follow the emergency instructions given in the manufacturer's safety data sheets.

Load carriers and the load should be allowed to cool down before removal. Any water

remaining in containers could still be very hot. Empty this water into the wash chamber

before removing items.

Never clean the machine or near vicinity with a water hose or a pressure washer.

The washer-disinfector must be disconnected from the mains electricity supply before

any maintenance or repair work is carried out.

REV.0.01_COD.500224_A4 Page 10

Quality assurance

The following points should be observed to assist in maintaining quality standards

when reprocessing medical devices in order to protect patients and to avoid damage to

the loads being cleaned.

Only authorised personnel may interrupt a programme in exceptional circumstances.

The standard of cleaning and disinfection in the programmes must be routinely confirmed

by the user. Process results must be inspected and documented on a regular basis.

For thermal disinfection, use temperatures and temperature holding times to achieve the

required infection prophylaxis in accordance with current health and safety regulations.

Only reprocess undamaged and suitable items. When washing plastic items, ensure that

they are thermally resistant. Nickel-plated items and items made of aluminium require

special procedures and are not generally suitable for machine reprocessing.

Items containing iron that can rust or corrode must not be added to the load or

introduced into the wash chamber.

Under certain circumstances, process chemicals may damage the machine. Users are

urged to follow the recommendations issued by manufacturers of process chemicals.

Contact Miele in the event of damage and any suspicion of material incompatibility.

Instrument-care products based on paraffin oils (white oils) can damage the elastomers

and plastics in the machine. Such care products must not be dispensed as chemical

agents in this machine, even if they are recommended for machine use by the care

product manufacturer.

Abrasive substances should not be introduced to the machine as these could cause

damage to mechanical components in the water circuit. Abrasive residues on the load

must be removed completely before reprocessing.

Pre-treatment with cleaning or disinfecting agents and certain types of soiling and

chemical agents can create foam. Foam can have an adverse effect on the disinfection

and cleaning result.

Reprocessing should not result in foam being discharged from the chamber. Foam

discharge can compromise the operation of the machine.

The process used must be monitored on a regular basis by the operator to check

foaming levels.

Even when a process chemical, e.g. detergent, is recommended, Miele takes no

responsibility for the effect of such chemicals on the load items. Please note that

changes in product formulation, storage conditions, etc., which are not announced by

manufacturers of process chemicals may impair the quality of cleaning results.

PRODUCT INFORMATION

REV.0.01_COD.500224_A4 Page 11

PRODUCT INFORMATION

When using process chemicals, always consult the instructions issued by individual

manufacturers. Process chemicals must only be used for the purpose they are designed

for by the manufacturer to avoid any material damage or the occurrence of very strong

chemical reactions (e.g. oxyhydrogen explosion).

Always follow the relevant manufacturer's instructions on storage and disposal of

chemical agents.

Particles ≥ 0.8 mm are removed by the filters in the wash chamber. Smaller particles may

find their way into the circulation system. For this reason, reprocessing loads with narrow

lumens requires additional filtering of the wash water.

In critical applications where very stringent requirements have to be met, it is strongly

recommended that all the relevant factors for the process, such as chemical agents,

water quality, etc., are discussed with Miele.

Load carriers which hold the load must be used only as intended.

Lumened items must be thoroughly cleaned, internally and externally.

Place small and light items in a mesh tray for small items so that they do not block the

spray arms.

Empty any containers or utensils before loading them.

The amount of solvent residues on the load items must be minimal when they are placed

in the chamber.

Solvents with a flash point below 21 °C may only be present in traces.

Chloride solutions, particularly hydrochloric acid, must not be introduced into the

chamber.

Ensure that solutions or steam containing chlorides or hydrochloric acid do not come into

contact with the stainless steel outer casing of the machine in order to avoid any damage

through corrosion.

After any plumbing work, the water pipework to the machine will need to be vented. If

this is not done, components can be damaged.

The gaps between a built-in machine and adjacent cabinetry must not be sealed, e.g.

with silicone sealant, as this could compromise ventilation of the circulation pump.

Follow the installation instructions in the operating and installation instructions.

Using accessories

Only use genuine Miele original spare parts and accessories suitable for the application

they are required for. Model designations are available from Miele.

Only use Miele mobile units, baskets, modules and inserts. Using baskets and inserts

made by other manufacturers or making modifications to Miele accessories can result in

an unsatisfactory cleaning and disinfection result. Any resultant damage would not be

covered by the guarantee.

REV.0.01_COD.500224_A4 Page 12

Disposing of your old machine

Please note that the machine may contain contamination from blood and other bodily

fluids, pathogens and facultative pathogens, and must be decontaminated before

disposal.

For environmental and safety reasons, dispose of all process chemical residues in

accordance with safety regulations (wear safety goggles and gloves).

Remove or disable the door lock prior to disposal of the machine, so that children cannot

become trapped inside. Then make appropriate arrangements for safe disposal of the

machine.

Warning signs

To inform operating personnel of their obligations and to warn of residual risks, the machine

is equipped with safety labels in accordance with the relevant legislation.

General warning signs

PRODUCT INFORMATION

Caution!

Danger of electric shock!

The evaluation of risks for the health and safety carried out on-site, as well as the evaluation

of residual risks, determine the safety equipment which the operator must provide for the

user.

Miele cannot be held liable for damage or injury caused by noncompliance with the safety

instructions and warnings.

Observe the operating

Caution!

instructions!

Caution!

Hot surfaces!

REV.0.01_COD.500224_A4 Page 13

PRODUCT INFORMATION

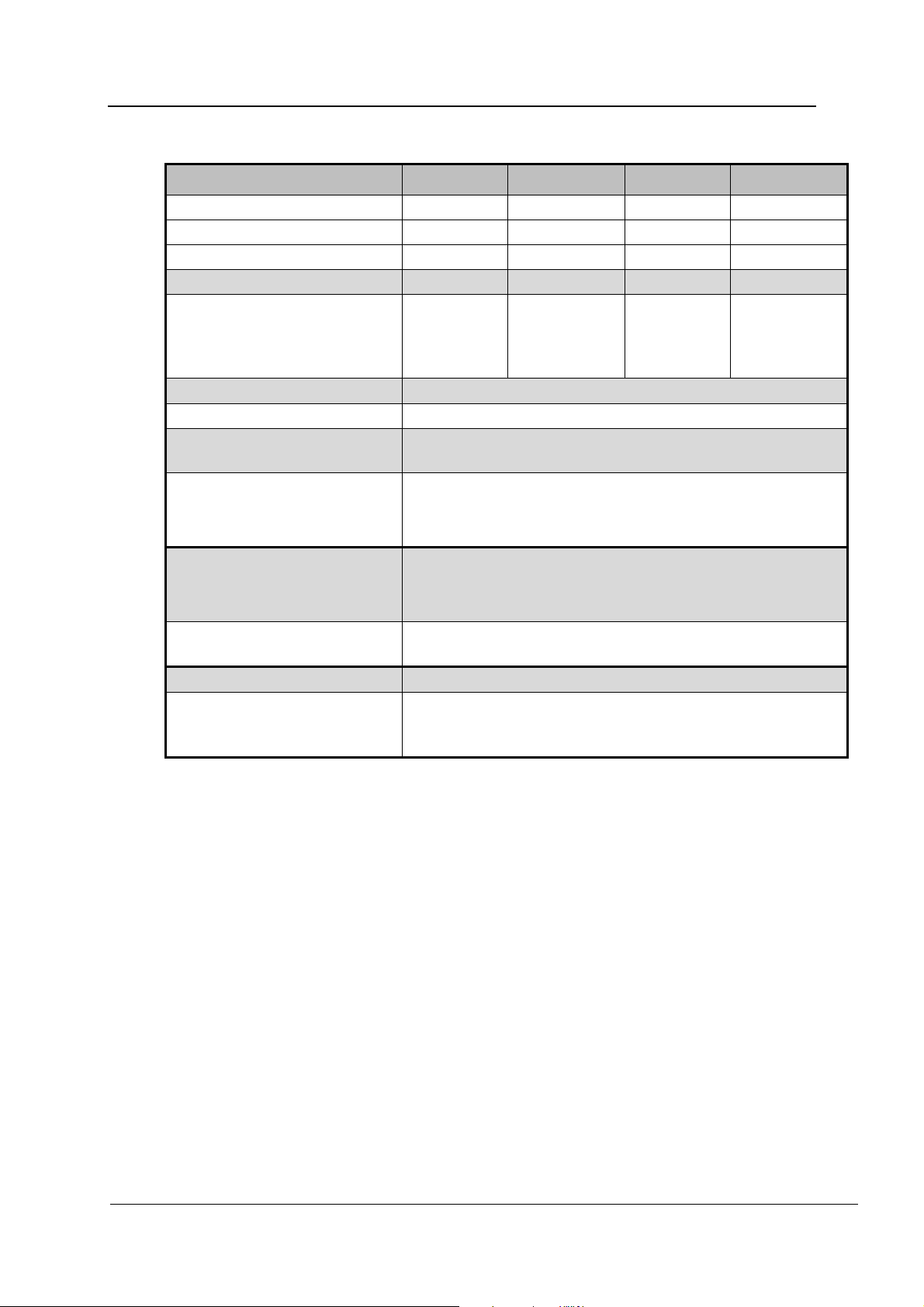

2.4 Technical data

PWD 8531 PWD 8531 WS PWD 8532 PWD 8532 WS

Width (mm) 570 (+ 75) 570 (+ 75) 560 560

Depth with closed door (mm) 575 575 577 577

Height (mm) 535 535 825 825

Total weight (kg) 55 55 67 67

Wash chamber dimensions:

- Width (mm)

- Depth (mm)

- Height (mm)

Voltage, rated load, fuse rating See data plate and installation plan

Average sound pressure level < 70 dB(A)

Protection rating (according to

IEC 60529)

Operation: Temperature range +5 to +40 °C

415

480

375

IP 21

Relative humidity range 20 to 90 % without condensation

Maximum altitude: 2000 m ASL

415

480

375

415

480

375

415

480

375

Storage and transportation

conditions

Overvoltage category

(according to IEC EN 60664)

CE mark Medical Device Directive 93/42/EEC, Class IIb

Manufacturer address Steelco S.p.A

-5 to +50 °C

20 % to 90 % without condensation

500 hPa to 1060 hPa

II

Via Balegante, 27

31039 Riese Pio X (TV), Italy

REV.0.01_COD.500224_A4 Page 14

PRODUCT INFORMATION

2.5 Recommendations for proper operation

The user must supervise the machine during operation.

Load carriers with injector connections must be connected to the water supply.

When the machine is running, do not interrupt the programme as this will jeopardise

the reprocessing result.

The standard of cleaning and disinfection in the programmes must be routinely

confirmed by the user. Process results must be inspected and documented on a

regular basis.

Only use process chemicals which have been approved by their manufacturer for the

relevant application. The manufacturer of the process chemicals is liable for any

negative influences on the material of the load and the machine.

Do not introduce items containing substances which must not be discharged into the

sewage system. These substances must be disposed of separately.

The machine is designed for use with water and process chemicals.

The use of organic solvents or inflammable liquids is not permitted as there is a risk of

explosion. Such substances can result in premature wear on components.

Solvent residues, chloride solutions and acids, particularly hydrochloric acid, can

damage steel components and must not be introduced into the wash chamber.

Do not use powder cleaning agents.

Do not use domestic detergents.

Accessories which are not approved by the manufacturer may compromise

reprocessing results as well as user safety.

The user must carry out a general check-up and clean the machine regularly as

indicated in the maintenance instructions.

Carry out a visual check of the load for cleanliness.

The on-site stopcock must be easily accessible so that the inlet can be turned off

when not in use.

REV.0.01_COD.500224_A4 Page 15

PRODUCT INFORMATION

2.6 Training

Instructions for use of the machine will be provided by Miele Service or an authorised service

technician during machine commissioning.

It is the duty of the supervisor to ensure that users are sufficiently trained and instructed.

User profiles

The user profiles are identified as follows:

SERVICE Service technician:

The machine may only be installed, commissioned, repaired and maintained by

Miele Service or an authorised service technician.

ADMIN Responsible for the machine in the workplace:

More advanced tasks, e.g. interrupting or cancelling a programme, require

more detailed knowledge of machine reprocessing of medical devices.

Alterations or adaptations of the machine, e.g. to accessories used or on-site

conditions, require additional specific knowledge of the machine.

Validation processes assume specialist knowledge about machine

reprocessing of medical devices, the processes involved and applicable

standards and legislation.

USER User:

Users must be instructed in operating and loading the machine and trained

regularly to guarantee safe daily use.

They require knowledge of machine reprocessing of medical devices for dental

use.

REV.0.01_COD.500224_A4 Page 16

3. INSTALLATION

3.1 Water connection

Water quality

The quality of the water used in all the cleaning stages is essential in achieving good results.

The water must be compatible with the material from which the machine is made.

The water must be compatible with process chemicals.

The water must be compatible with process requirements for the various stages of the

process.

In order to achieve good cleaning results, the machine requires a supply of soft water with a

low calcium content. Hard water results in the build-up of calcium deposits on the load and in

the machine.

Mains water with a hardness level higher than 0.7 mmol/l (4 °dH – German scale) must be

softened. This occurs automatically during a programme sequence on machines with a builtin water softener. The water softener must be set to the exact hardness of the water supply.

The water softener must be reactivated at regular intervals. This requires the use of special

reactivation salt. Reactivation is carried out automatically during a programme sequence.

INSTALLATION

Note: The water hardness is set by Miele Service.

CAUTION

Water from the chamber is not suitable for drinking!

The machine must be connected to the water supply in strict accordance with local

regulations.

The water used must comply with European regulations for drinking water quality as a

minimum. If the water supply has a high iron content, there is a danger that corrosion may

occur on load items and the machine itself. If the chloride content of the water exceeds

100 mg/l, the risk of corrosion to the load in the machine will be further increased.

A non-return valve is installed inside the machine in accordance with the applicable European

standards.

The machine is fitted as standard with connections for cold and DI water. Connect inlet hoses

to the valves for cold and DI water.

The minimum flow pressure is 100 kPa at the cold water connection and 30 kPa at the DI

water connection.

The recommended flow pressure for the cold water connection is ≥ 200 kPa and for DI

water ≥ 200 kPa in order to avoid excessively long water intake times.

The maximum permissible static water pressure is 800 kPa.

If water pressure is not within the specified range, contact Miele Service for advice.

A booster pump is required if the flow pressure is below 200 kPa. If the pressure is higher

than 800 kPa, a pressure reducer must be installed.

A stopcock valve with a ¾” threaded union must be provided on-site. The valve must be

easily accessible to allow the inlet to be turned off when not in use.

REV.0.01_COD.500224_A4 Page 17

INSTALLATION

CAUTION

Do not overtighten the threaded unions on the hoses.

CAUTION

When the machine is not in operation for long periods, always close the

stopcocks.

Connecting the drain hose

Carefully check the drain hose.

Only use drain hoses resistant to organic and chemical materials and hot liquids (max.

91 °C).

The diameter of the drain hose is listed in the installation plan.

The drain hose must not be extended.

The drain hose must be connected by using a clamp.

The drain hose must not be kinked.

Wall drain: The drain point in the wall should be no higher than the machine drain

connection.

ATTENTION

If the drain pipe is blocked, avoid skin and eye contact with potentially

contaminated water.

Use suitable glasses and gloves.

ATTENTION

Drainage must comply to national regulations.

The manufacturer cannot be held responsible if the incorrect use of

machine causes pollution.

REV.0.01_COD.500224_A4 Page 18

3.2 Electrical connection

CAUTION

Only qualified, skilled personnel may connect the machine to the mains

supply.

The machine must only be operated with the voltage, frequency and fuse rating shown

on the data plate.

The connection to the power supply should be via a suitably rated plug and socket.

Check that the power supply voltage does not differ from its nominal value by

+/- 10 % (+10%/-6% for the UK).

The frequency of the power supply voltage must not differ by more than 1 %.

The electrical safety of the machine can only be guaranteed when it is correctly

earthed. Equipotential bonding is required.

Make sure that the electrical systems are properly earthed.

The earth conductor must be connected to the earth terminal

identified by the standard symbol.

If the machine is hard-wired to the power supply, it must be

connected via a mains switch with all-pole isolation. The mains

switch must be designed to operate at the rated current.

For increased safety, it is recommended to protect the machine with a suitable

residual current device (RCD) with a trip current of 30 mA (DIN VDE 0664).

The machine should be disconnected from the mains supply when not use for a

longer period of time.

The electrical connection and fuse rating must comply with local and national

regulations.

The connection to the power supply must comply with national regulations (plug and

socket must be accessible for service and maintenance work after the machine has

been installed). An electrical safety test must be carried out after installation and after

any servicing work.

INSTALLATION

CAUTION

Please refer to the installation plan provided.

REV.0.01_COD.500224_A4 Page 19

INSTALLATION

3.3 Installation site ventilation

During operation, the machine releases energy to its environment and increases humidity

levels at the place of installation. This applies particularly during drying.

These machines are equipped to be connected to an on-site extraction system.

CAUTION

The machine should not be obstructed to guarantee proper ventilation.

In order to reduce the risk of water damage, the area around the machine

should be limited to furniture and fittings that are designed for use in

commercial environments.

Please refer to the installation plan provided.

REV.0.01_COD.500224_A4 Page 20

Loading...

Loading...