Page 1

Installationsplan / Installation plan

Installatietekening

Plan d`installation

Pianta di installazione

Plano de instalación

Plano de instalação

Σχέδιο εγκατάστασης

Asennusohje

Installasjonsplan

Installationsplan

UV

PW 6241 D

Materialnummer / Mat. no.: 06 564 000

Änderungsstand / Version: 01

Datum Zeichnung / Drawing date: 19.10.2007

Datum Legende / Legend date: 19.10.2007

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Technical datasheet

Washer:

Heating:

PW 6241

Steam

Legend:

Circled, bold-typed abbreviations:

Connection required

Abbreviations surrounded by broken circle:

Connection optional or required, depending on model

U

V

Options/Accessories:

WI

Special product With integrated scale

Machine connections:

Electrical

connections

Standard voltage (delivery status) * 3 AC 208 V 3 AC 208 V

Frequency 60 Hz 60 Hz

Fuse rating 3 × 15 A 3 × 15 A

Supply lead, wire size 14 AWG 4 × 1,5 mm²

* If power supply includes a stinger leg,

U

V

Rated load 4.3 kW 4,3 kW

please call Technical Service at

USA 1-800-991-9380

CDN 1-800-643-5361

USA CDN

Alternative voltage 3 AC 220-240 V 3 AC 220-240 V

Frequency 50-60 Hz 50-60 Hz

Rated load 4.3 kW 4,3 kW

Fuse rating 3 × 15 A 3 × 15 A

Supply lead, wire size 14 AWG 4 × 1,5 mm²

reversible

Installation plan PW 6241 Steam

Date 19.10.2007 Page 7

Page 8

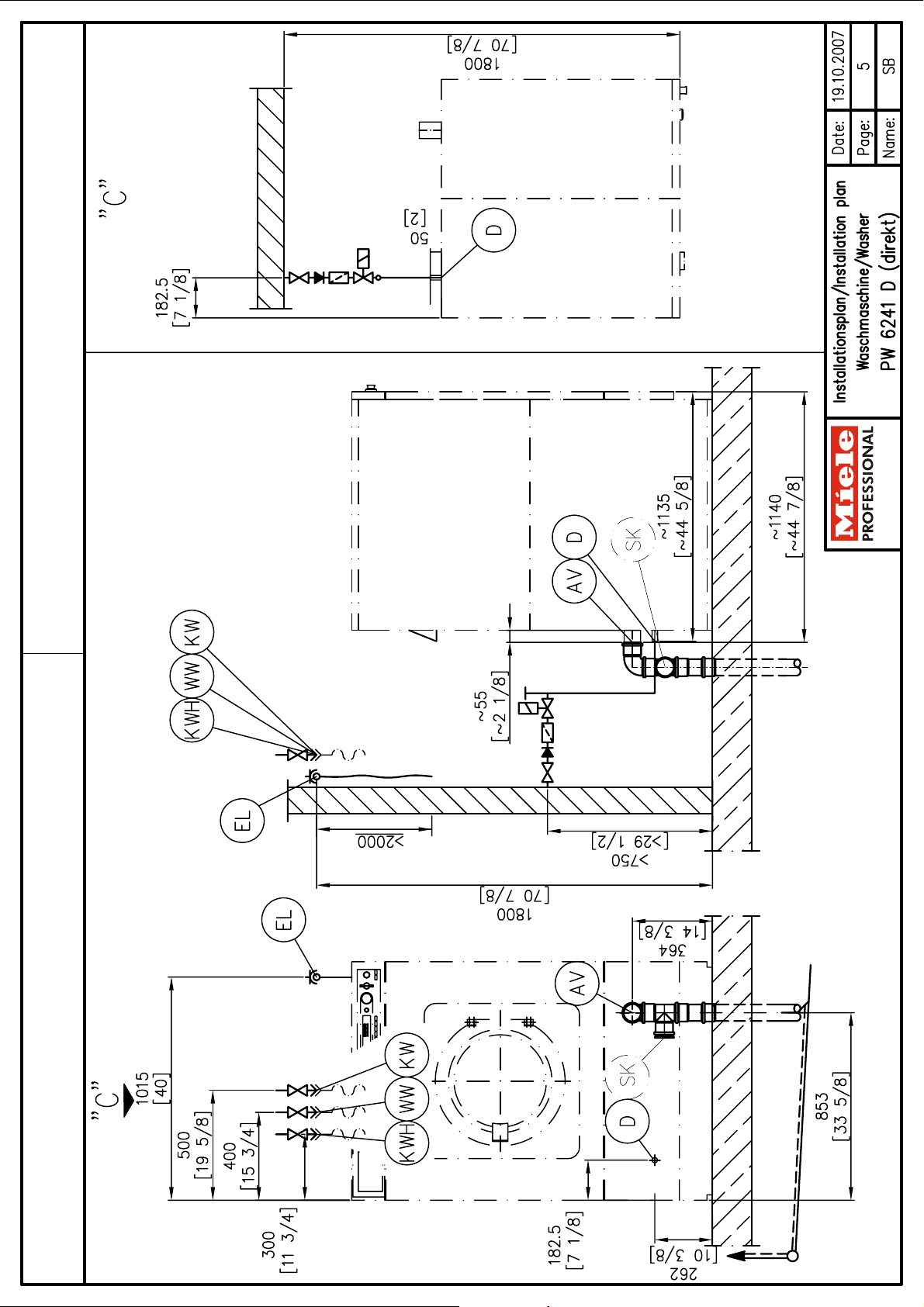

Direct steam (page 5)

Steam pressure (High pressure) ≤ 58 psi ≤58 psi

Boiling point (High pressure) ≤ 306 °F ≤ 152 °C

Heating capacity (High pressure) 86 kW 86 kW

Steam supply capacity (High pressure) 308 lbs/h 140 kg/h

Steam pressure (Low pressure) ≤7.25 psi ≤7,25 psi

Boiling point (Low pressure) ≤84 °F ≤120 °C

Heating capacity (Low pressure) 29 kW 29 kW

Steam supply capacity (Low pressure) 99.2 lbs/h 45 kg/h

Connection thread (on-site) 3/4" MPT 3/4" MPT

Steam

connection

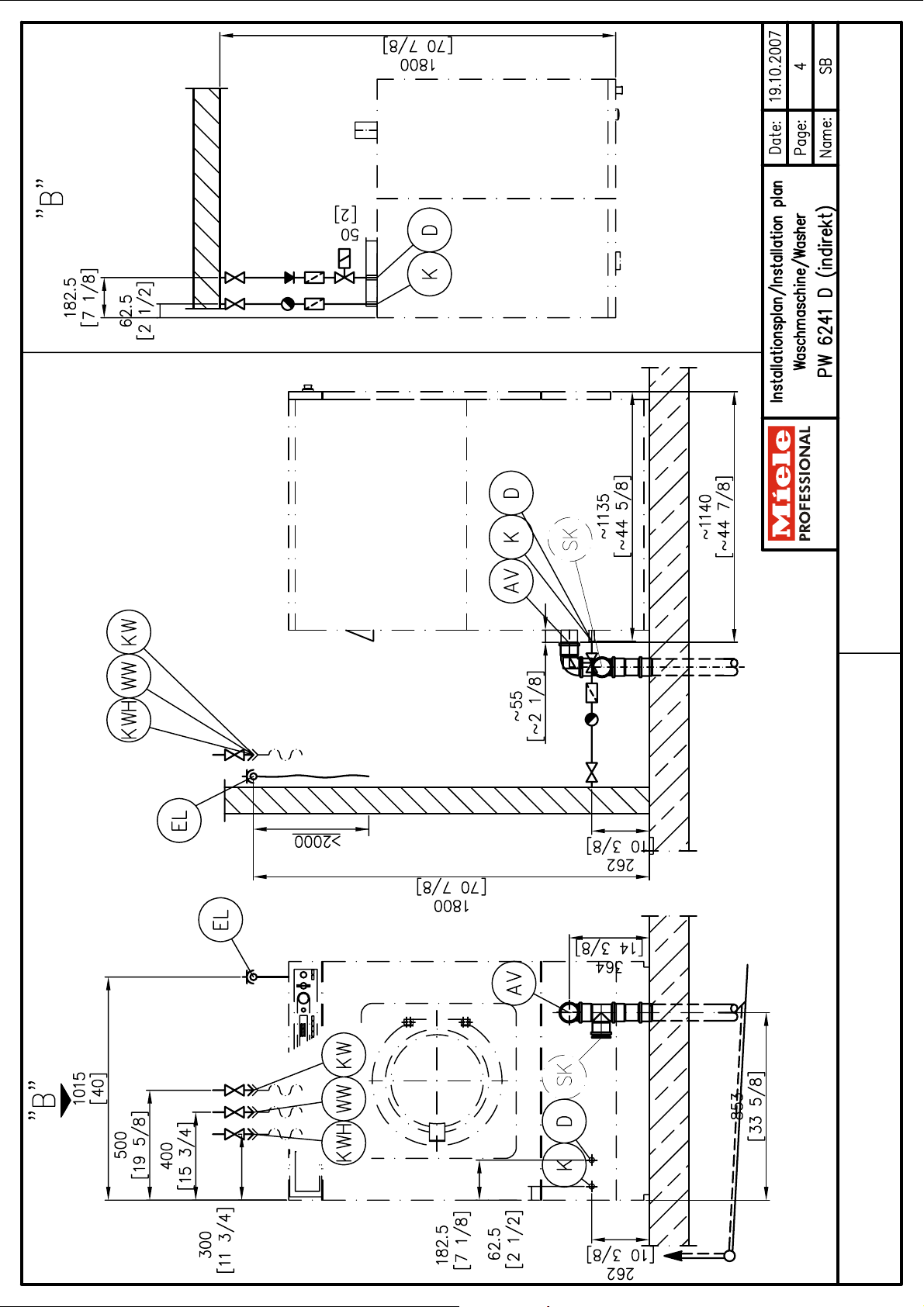

Indirect steam (page 4)

Steam pressure 58 - 145 psi 58 - 145 psi

Steam pressure on dryer version 58 - 72.5 psi 58 - 72,5 psi

Boiling point 306 - 363 °F 152 - 184 °C

Heating capacity 50 kW 50 kW

Steam supply capacity 185 lbs/h 84 kg/h

Connection thread (on-site) 1/2" MPT 1/2" MPT

Steam valve, steam filter and steam faucet must be

provided on-site.

Steam valve, steam filter, steam faucet and non-return

valve must be provided on-site.

USA CDN

On-site connection thread 1" MPT 1" MPT

Length of connection hose (supplied) 59 1/16" 1.500 mm

Water requirements (average 140°F [60°C] program)

Standard connection (with hot water connection) approx. 16.1 gal/h approx. 61 l/h

Additional requirements if hot water supply is not

Max. throughput 7.93 gal/min 30 l/min

On-site connection thread 1" MPT 1" MPT

Length of connection hose (supplied) 59 1/16" 1.500 mm

Water requirements (average for 140°F [60°C] program)

Standard connection (with hot water connection) approx. 15.3 gal/h approx. 58 l/h

Condensate

connection

Cold water

(Soft water)

Hot water

Note installation instructions for steam-heated Miele

washer-extractors.

Indirect steam (page 4)

Connection thread (on-site)

Steam valve, steam filter and steam faucet must be

provided on-site.

Min. flow pressure 14.5 psi 14,5 psi

Max. pressure 145 psi 145 psi

Max. throughput (if hot water supply is not available) 9.4 (21) gal/min 35.5 (80) l/min

available.

Max. temperature 158 °F 70 °C

Min. flow pressure 14.5 psi 14,5 psi

Max. pressure 145 psi 145 psi

If no hot water supply, connect hose to cold water!

1/2" MPT

1/2" MPT

Mains water

(Raw water)

Length of connection hose (supplied) 59 1/16" 1.500 mm

Water requirements (average for 140°F [60°C] program)

Standard connection (with hot water connection) approx. 57.9 gal/h approx. 219 l/h

Installation plan PW 6241 Steam

Date 19.10.2007 Page 8

(Optional)

Min. flow pressure 14.5 psi 14,5 psi

Max. pressure 145 psi 145 psi

Max. throughput 10.6 gal/min 40 l/min

On-site connection thread 1" MPT 1" MPT

If no raw water supply, connect hose to cold water!

Page 9

Drainage via

dump valve

Max. temperature 203 °F 95 °C

Machine drain connection (da × s × l) 3" x 1/16" x 4" 75 × 1,9 × 100 mm

On-site drain connection (d

Max. throughput 52.8 gal/min 200 l/min

Vented drainage required. If ventilation is insufficient, fit

Miele kit, Mat. no. 05238090.

Drain manifolds serving several machines must be of

sufficient cross-section.

USA CDN

) 3" 75 mm

i

Foam vent A drainage system for foam escaping from the drain

(supplied) 2 × screws (Diameter × length)

Machine must be secured! 5/8" x 3 9/16" 16 × 90 mm

Fixing materials provided for securing to concrete floor

4 × screws (Diameter × length) 1/2“ x 3 9/16“ 12 × 90 mm

4 × wall anchors (Diameter × length) 5/8“ x 3 9/16“ 16 × 90 mm

Machine must be secured!

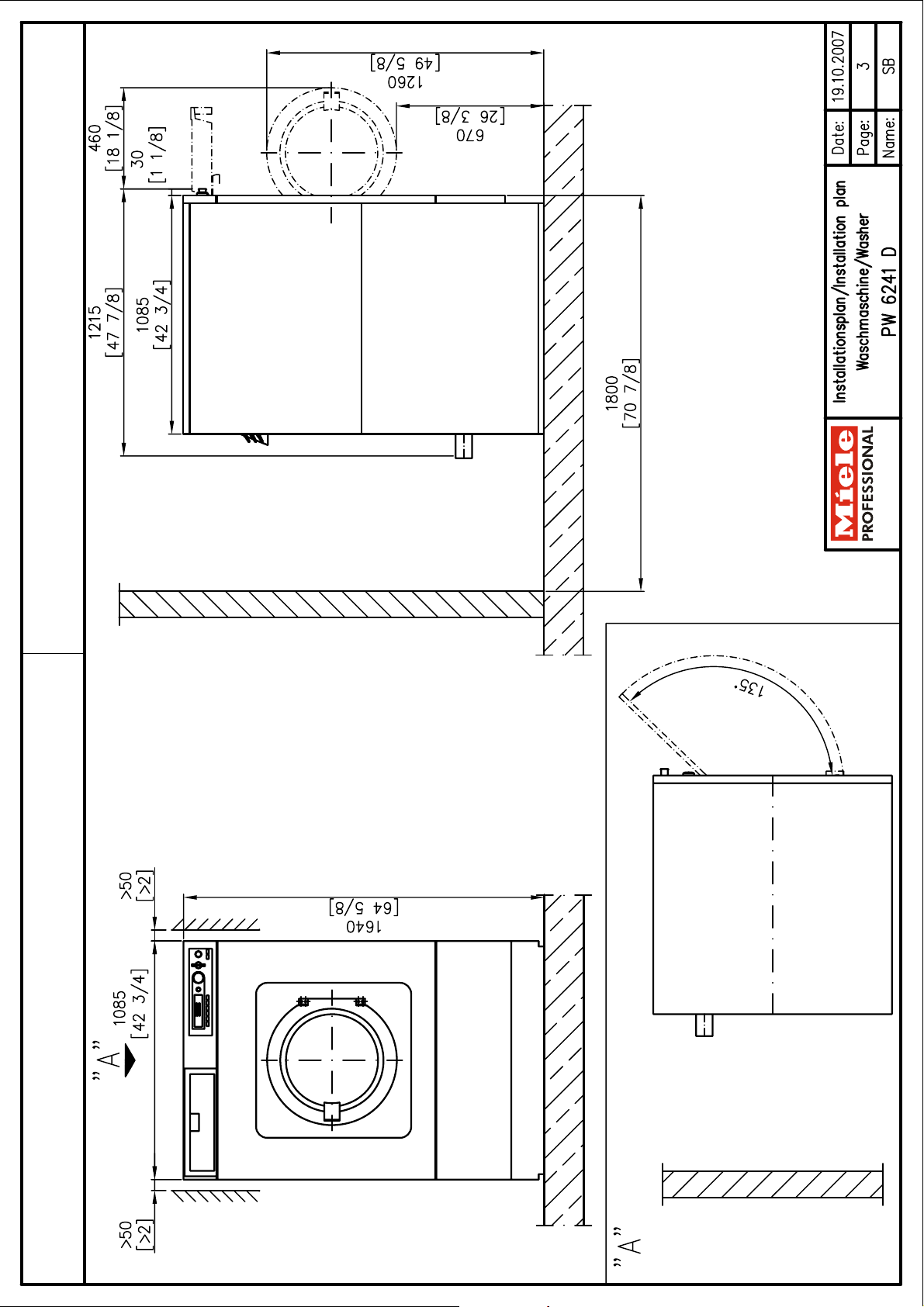

Machine data Width 42 11/16" 1.085 mm

Depth 48 1/4” 1.225 mm

Height 64 9/16" 1.640 mm

Knocked-down dimensions (Width) 42 15/16” 1.090 mm

Recommended clearance to rear wall

Net weight 1,410 lbs 640 kg

Dynamic floor load during operation, max. 8,417 N 8.417 N

Static load, max. 7,036 N 7.036 N

Dynamic load max. 1,353 N 1.353 N

Drum frequency, max. 18.3 Hz 18,3 Hz

Average heat dissipation

2 × wall anchors (Diameter × length) 1/2" x 3 9/16" 12 × 90 mm

Special product

WI:

vent can be built using standard drain pipe sections.

A 87° branch with an end cap should be provided for

this purpose.

Without plinth Fittings

Without plinth

Fixing materials provided for securing to concrete floor

(to machine front edge)

(depending on room temperature and selected program)

70 7/8" 1.800 mm

1,306 W 1.306 W

Installation should only be carried out by authorized installers in accordance with all local and national regulations!

Observe installation instructions when installing machine! All rights reserved!

Installation plan PW 6241 Steam

Date 19.10.2007 Page 9

Loading...

Loading...