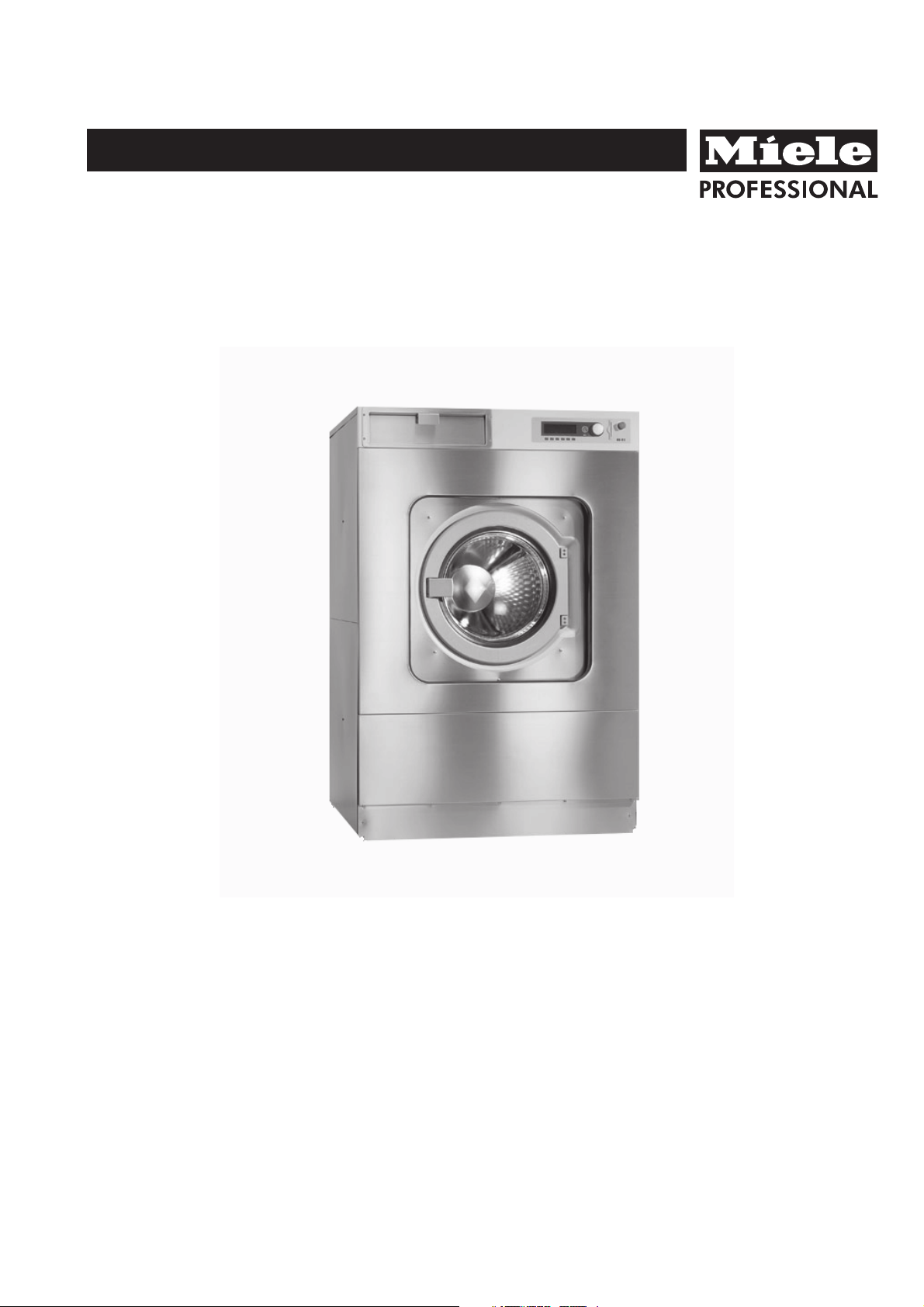

Operating instructions

Washer-Extractor

PW 6241

PW 6321

To avoid the risk of accidents or damage to the machine it is

essential to read these instructions before installing,

commissioning and using it for the first time.

en - AU, NZ

M.-Nr. 09 179 270

Gas-heated appliances

Safety precautions to take if you smell gas

Turn off the gas emergency control valve immediately.

^

This is usually located near the gas meter.

Eliminate all sources of ignition in a safe manner.

^

Do not smoke, light cigarette lighters or matches.

Do not operate electrical lights or switches, i.e. do not switch them "On" or "Off".

^

Open all doors and windows to ventilate the area.

^

If the smell of gas persists, evacuate the building.

^

Contents

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Description of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How to wash correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sort the laundry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maximum loads for the standard programmes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Add cleaning agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Detergent dispensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Select a programme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Open the door at the end of the programme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Card operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Card access operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Additional options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Language selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Start date and time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Programme stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Programme cancellation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Changing the programme order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Optional modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Liquid dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Peak load cut-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Communication module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Operating data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Weighing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Problem solving guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

The door will not open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Power cut during a wash programme - Emergency door release . . . . . . . . . . . . . . . . . . . . . . . 29

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Explanation of symbols on the data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Notes for the installer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Transit fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Water inlet / drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Dispenser system connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connecting the dispenser pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Steam connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Abbreviated operating instructions PW 6241, PW 6321 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

M.-Nr. 09 179 270 3

Warning and Safety instructions

Explanation of the Warning and

Safety symbols on the machine

It is essential to read these

operating instructions.

Please refer to specific

instructions, e.g. Installation

instructions

Caution, hot surfaces.

Caution, voltage up to 1000 volts.

Earthing

Petrol, paraffin, or any easily flammable

liquid must not be stored or used near

the machine. Do not use the machine lid as

a storage shelf.

Fire and explosion hazard.

Do not store any chemicals on the

machine lid (liquid detergent, fabric

conditioners etc). They could discolour the

lid and also damage the surface finish. If

any chemicals should come in contact with

the surface, wipe them away immediately

with clean water. Then dry with a soft cloth.

When used in a commercial environment

ensure that all operators are trained to

use the machine correctly.

If the machine is used in a publically

accessible room, please ensure that

operators are able to use it safely.

This machine is not intended for outdoor

use.

To avoid the risk of accidents and

damage to the machine read the

operating instructions carefully before

using it for the first time. They contain

important information about the

installation, safety, use and maintenance

of the machine. Keep these operating

instructions in a safe place and ensure

that new users are familiar with the

content. Pass them on to any future owner

of the machine.

Correct application

This machine is not designed for

washing items which have been treated

with dangerous or flammable substances.

Only use the machine to wash items

which are specified by the manufacturer

to be machine-washable on the wash-care

label.

Any other applications may be dangerous.

The manufacturer is not liable for damage

resulting from improper use or operation.

Technical and electrical safety

The electrical safety of this machine can

only be guaranteed if connected to a

correctly installed earthing system on site. It

is most important that this basic safety

requirement is present and tested regularly,

and where there is any doubt, the on-site

electrical wiring should be inspected by a

qualified electrician. The manufacturer

cannot be held liable for the consequences

of an inadequate earthing system (e.g.

electric shock).

Do not damage, remove or bypass the

safety features, fixtures and control

elements of this machine.

Do not use a machine with damaged

controls or cables. These must be

repaired before it is used again.

Any removable outer panels must be

back in place, and all moving or

electrical parts shielded before the machine

is switched on.

Chemical dry cleaning agents must not

be used in this machine. Most dry

cleaning agents, e.g. benzine, pose a fire

and explosion hazard.

4 M.-Nr. 09 179 270

Warning and Safety instructions

Connection should be made via a

suitable isolator which complies with

local and national safety regulations and

which is easily accessible for disconnecting

the machine from the electricity supply.

Provision must be made on site to switch off

all poles.

The machine is only completely isolated

from the electricity supply either when it

is switched off at the isolator switch or the

mains fuse has been withdrawn.

Repairs to electrical, gas or steam

operated machines may only be carried

out by a suitably qualified person in

accordance with national and local safety

regulations Repairs and other work by

unqualified persons could be dangerous.

The manufacturer cannot be held liable for

unauthorised work.

Do not force the drum door open. The

door handle is fitted with a safety device

to ensure that the door lock functions

correctly.

Faulty components must only be

replaced by genuine Miele original spare

parts. Only when these parts are fitted can

the safety standards of the machine be

guaranteed.

The best materials are used in the

manufacture of this machine, and every

care is taken to check all parts. However,

with time, deterioration of parts can occur,

especially with such components as hoses,

giving rise to leaks. Check the inlet hoses

regularly for signs of wear and tear. Change

in good time to avoid the risk of leaks and

subsequent damage.

Local regulations regarding regular

inspection and maintenance of this

machine must be observed. A log book

should be kept with the machine.

Gas-heated washer-extractors

Important After installation, maintenance,

conversion, repairs and before using for the

first time it is essential that a test for possible

leakages is carried out. All components

which carry gas must be checked, including

the gas valve and burner jets.

Particular attention must be paid to the test

nipple on the gas valve.

Testing must be carried out with the burner

switched on and switched off.

Using the washer-extractor

This machine is not intended for use by

people reduced physical, sensory or

mental capabilities, or lack of experience

and knowledge, unless they are supervised

whilst using it or have been shown how to

use it correctly by a person responsible for

their safety.

This machine is not a toy! To avoid the

risk of injury never allow children to play

on or near the machine, or to operate it

themselves.

Remember that the porthole glass will be

hot when washing at very high

temperatures. Do not let children touch it.

Always close the door after use. This

way you will avoid the danger of:

–

children climbing onto or into the

washer-extractor or hiding things in it.

–

pets or other small animals climbing into it.

Always make sure that the drum is

stationary before reaching into the

machine to remove laundry. Reaching into a

moving drum is extremely dangerous.

Take care in the area of the hinges of the

drum door. Danger of injury.

The drum door must be able to be

opened to its fullest extent. This area

must not be restricted by doors or structural

features.

The water used for washing is a suds

solution and is not drinking water.

The suds solution must be drained away via

an appropriate drainage system.

M.-Nr. 09 179 270 5

Warning and Safety instructions

The washer-extractor may only be

operated without supervision if there is a

floor drain (gully) in the immediate vacinity.

If the washer-extractor is switched off

and the drum door is closed, you need

to switch the machine on before you can

open the door.

If water comes out of the suds container

when the door is opened, close the door and

switch the washer-extractor on. Drain the

water away before you try and open the

door.

It is the operator's responsiblity to ensure

that the standard of disinfection in

thermal as well as chemo thermal

procedures is maintained (in accordance

with § 18 IFSG and national health and

safety regulations) by carrying out suitable

validation tests. These procedures should

be checked on a regular basis, either

thermo-electrically using loggers, or

bacteriologically with bio indicators. The

operator must pay particular attention to

maintaining the correct parameters in the

procedure, including temperature and with

chemo thermal programmes, the chemical

concentration used. Disinfection

programmes must not be interrupted, as this

can have a limiting effect on the disinfection

result.

should be removed using specialist

detergents and/or programmes.

Do not use a pressure washer or hose to

clean the machine.

Further notes

Cleaning and disinfecting agents often

contain chlorine-based substances. Do

not let such agents dry out on stainless steel

surfaces, as the chlorine can have a

corrosive effect. Use chlorine-free agents for

washing and disinfecting and also for

cleaning stainless steel surfaces to protect

them from corrosion.

If in doubt, confirm with the manufacturer

that their product is suitable. If any agent

containing chlorine comes into contact with

the stainless steel surfaces, wipe it away

immediately with clean water. Then dry with

a soft cloth.

The manufacturer cannot be held liable

for the effect of a chemical cleaning

agent on laundry or the machine, even when

the use of such agents is recommended.

Please note that changes to the product

which have not been made known by the

manufacturer can affect the quality of the

wash result.

It is particularly important to observe

manufacturer's instructions when using a

combination of cleaning agents and special

application products. Only use the product

for the application described by the

manufacturer, to avoid any material damage

or the occurrence of strong chemical

reactions.

Confirm with the detergent manufacturer that

their product can be used in combination

with another type of product.

Only use dyes, colour run and dye

removers specified as being suitable for

use in washing machines. Always observe

the manufacturer's instructions carefully.

Laundry that was soiled with biological

oils or fat should be washed using a

suitable detergent and /or wash programme.

It must also be inspected after washing. If

oils or fat are not sufficiently removed they

could cause the laundry to self ignite during

the drying process. This type of soiling

Using accessories

Accessory parts may only be fitted when

expressly approved by Miele. Using

spare parts or accessories from other

manufacturers will invalidate the warranty,

and Miele cannot accept liability.

Any additional components used, e.g.

suction devices for liquid agents,

electronic water meters or dispenser

monitors, must conform to Safety Class II.

If connected to an external PC, this must

conform to EN 60950-1:2001 (IEC

60950-1:2001).

6 M.-Nr. 09 179 270

Warning and Safety instructions

Chlorine and component damage

Notes on using chlorine bleach and

perchlorethylene

Frequent use of chlorine increases the

risk of component damage.

The use of agents containing chlorine, such

as sodium hypochlorite and chlorine bleach

in powder form, can damage the protective

upper surface of stainless steel and cause

corrosion to components. Factors affecting

this are chlorine concentration levels,

contact time and temperature. It is therefore

advisable to avoid the use of such agents.

Oxygen based bleaching agents should be

used instead.

If, however, chlorine based bleaching

agents have to be used for particular types

of soiling, then anti-chlorine measures must

also be carried out. If this is not done

irreparable damage can occur to

components in the machine and to laundry.

Disposing of your old machine

Before disposing of an old machine, first

make the door lock unusable. This way

you will prevent children from accidentally

locking themselves in and endangering their

lives.

All personnel working with this machine

must be fully trained in all aspects of its

use and safety.

Keep these instructions in a safe and

accessible place.

Anti-chlorine treatment

Anti-chlorine treatment has to be carried out

immediately after chlorine bleach has been

used. The use of hydrogen peroxide or an

oxygen based cleaning or bleaching agent

is recommended and the laundry should not

be drained in between.

With thiosulfate, especially when used with

hard water, gypsum can form, which can

lead to incrustations on laundry or deposits

in the machine. The use of hydrogen

peroxide is preferable as it aids the chorline

neutralising process.

The exact quantity of additives and the

treatment temperatures required must be set

and tested on site in accordance with the

dosage recommendations of the detergent

and additive manufacturers. The laundry

must also be tested to check whether it

contains any active chlorine residues.

M.-Nr. 09 179 270 7

Caring for the environment

Disposing of the packing material

The packaging is designed to protect the

machine from damage during transportation.

The packaging materials used are selected

from materials which are environmentally

friendly for disposal and should be recycled.

Recycling the packaging reduces the use of

raw materials in the manufacturing process

and also reduces the amount of waste in

landfill sites.

Packaging materials such as plastic

,

film and bags must be kept out of the

reach of babies and children. Danger of

suffocation.

Disposing of your old machine

Electrical and electronic machines often

contain valuable materials. They also contain

materials which, if handled or disposed of

incorrectly could be potentially hazardous to

human health and to the environment. They

Tips on saving energy

To save energy and water, try to load the

maximum for the programme selected.

Underloading is uneconomical. Overloading

gives a poorer quality of wash result and

may cause unnecessary creasing.

Make sure that your laundry is thoroughly

spun before drying. This saves time and

energy.

Carrying out the final rinse with hot water

helps to reduce the residual moisture level,

and the residual heat in the laundry will help

keep processing time down in dryer and for

ironing, thus saving energy.

Follow detergent manufacturer's advice

regarding the right amount of detergent to

use.

This will depend on the size of the load, the

water hardness level and the amount of

soiling in the laundry.

Chose the correct programme (with

pre-wash or intensive options selected) and

the correct temperature.

are, however, essential for the correct

functioning of your machine. Please do not

dispose of it with your general waste.

Please dispose of it at your local community

waste collection/recycling centre.

Please contact your dealer, your local waste

collection centre or scrap merchant about

recycling schemes.

Please store it out of the reach of children

whilst awaiting disposal.

8 M.-Nr. 09 179 270

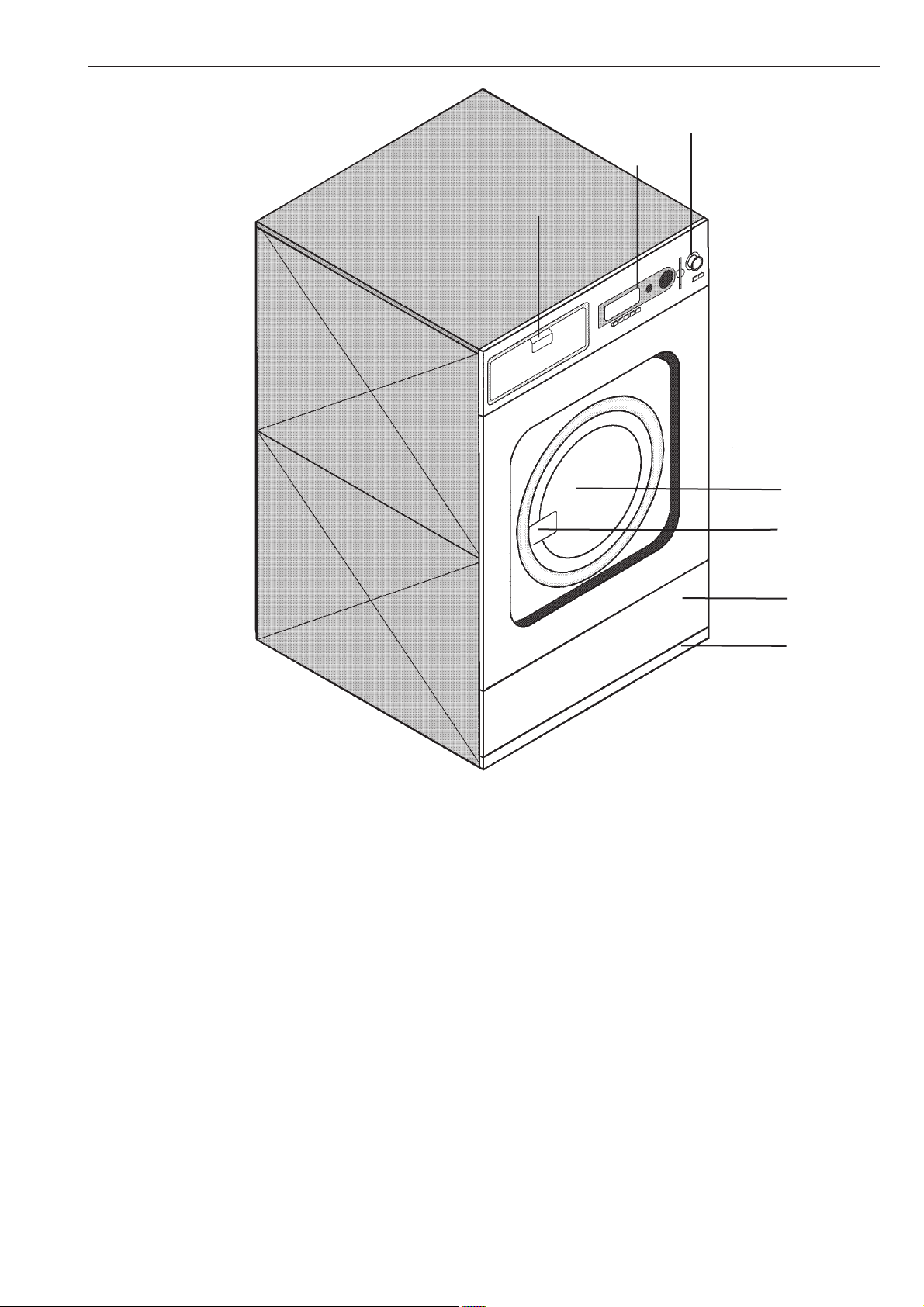

Description of the machine

a

b

c

d

a Emergency stop switch

Press the red button to switch the machine

off.

b Control panel

e

f

g

f Service panel

g Plinth

c Detergent dispenser drawer

Pull the handle to open the compartment.

d Drum door

Pull the door handle to open the drum door.

Do not use force to open it.

e Door handle

The door handle is fitted with a safety device

to ensure that the door lock functions

correctly (see page 29).

M.-Nr. 09 179 270 9

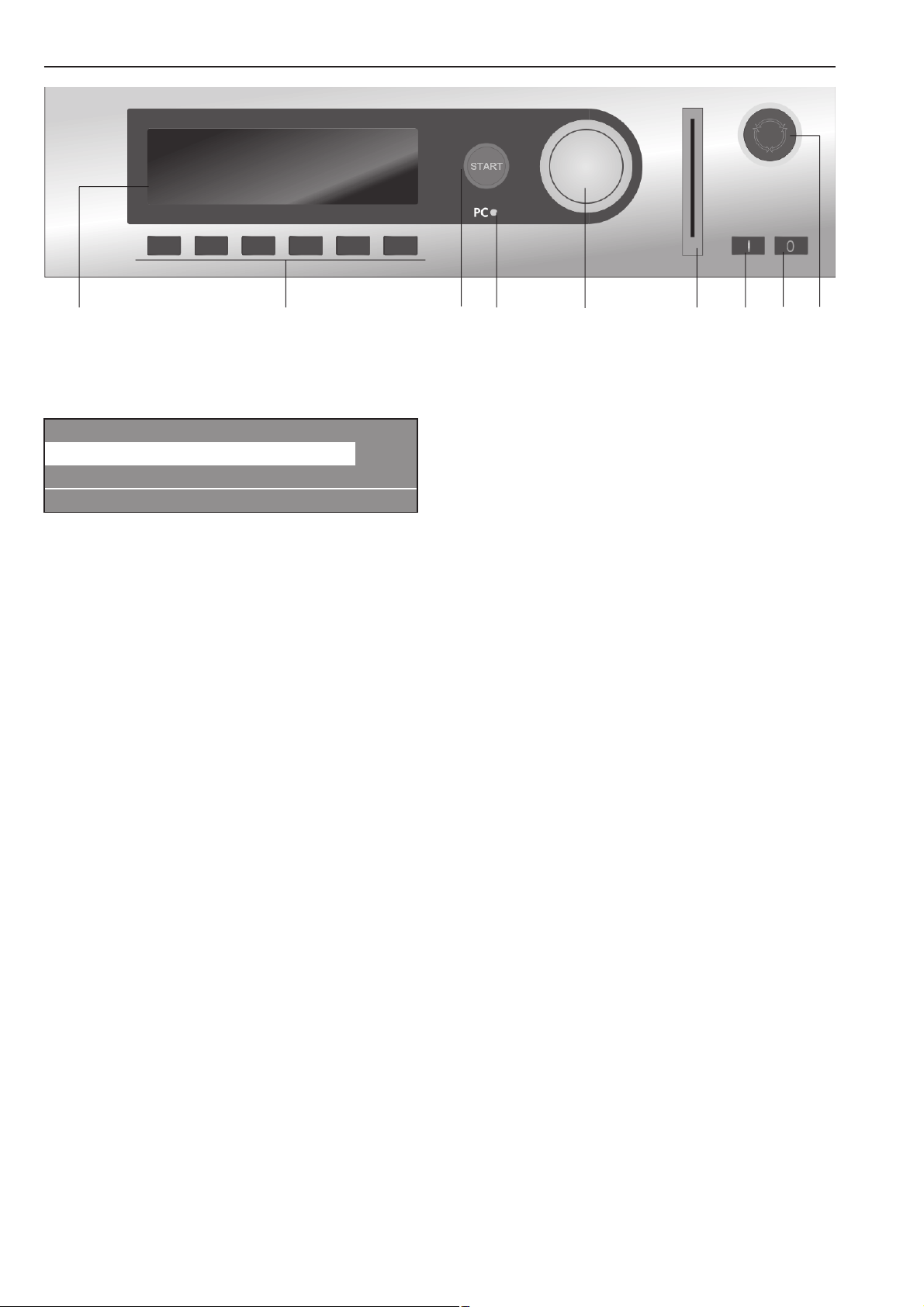

Description of the machine

a b c d e f g h i

Control elements

a Display

1 Cottons 90 °C

2 Cottons universal 60 °C

3 Cottons intensive 60 °C

i FC A

After switching on the "Welcome" display will

appear for a short time followed by the

programme list. The most recently used

programme is highlighted.

b Function buttons

The six buttons underneath the display are

the function buttons. These buttons have

specific functions depending on the status

of the machine.

These functions will be listed in the display

above the buttons and will be highlighted

once selected.

If the machine is reprogrammed to "Direct

button allocation" the first 6 programmes

listed in the display can be selected directly

via these buttons.

c START button

The lightring will flash when a selected

programme can be started. Pressing the

Start button will start the programme. After a

programme has started, pressing this button

will show the display as it was before the

start of the programme.

d PC / Optical interface

This interface is used for transferring data to

the control unit from a PC and vice versa.

e Rotary selector

Turning the selector brings up options and

menus in the display.

Pressing the selector confirms your

selection.

f Chip card reader

When a chip card is inserted, the

programmes on the chip card can be used.

Insert the card in the direction of the arrow

(on the card).

g I Mains on switch

Switches the machine on.

h 0 Mains off switch

Switches the machine off.

i Emergency stop switch

Only for use in an emergency.

Press the red button to switch the machine

off. After the problem has been resolved,

turn the red dial clockwise to release it. Then

press the START button to continue the

interrupted programme.

10 M.-Nr. 09 179 270

Description of the machine

Function buttons

Pressing the button activates the function

and pressing the button again deactivates it.

f Stop/End

The function button on the right-hand side is

used to stop a programme after it has

started.

Pressing it again finishes the programme.

+i Block plus

The relevant programme block (e.g.

Pre-wash) is added to the programme.

m Starch stop

Press this button if you wish to laundry to be

starched.

k Without spin

Press this button if you do not want the

laundry to be spun after being rinsed.

FC Settings

Press this button to switch to another

language temporarily.

m Start time

Press this button before the start of a

programme to display the message that a

start time can be selected.

$ Programme locked

Once a locked programme has been

started, the End button can only be used to

stop and cancel it during the first minute.

) Programme unlocked

ß Dispensing

ä Dispensing switched off

\ Operating data

> I < 0- Setting (calibration)

If the display does not show 00.0 when the

drum is empty press this button to reset it.

D Data transfer

Chip card operation

The chip card is supplied without any

programmes.

See the programming instruction booklet for

information on transferring data from the

control unit to the chip card and vice versa.

K Information

Press this button to call up programme

information in the display.

q Water drainage

i Manual control

See the programming instruction booklet.

Change order

ü The order of the programme in progress

can be changed or programme blocks can

be repeated.

A Back

Takes you back to the previous display.

e/- Indicates more information on the next

/ previous line

S Save

See the programming instruction booklet.

A chip card is available to order as an

optional extra. It can store a maximum of 30

programmes, each with 6 blocks. The back

of the chip card can be labelled.

M.-Nr. 09 179 270 11

How to wash correctly

The machine must be commissioned by a

Miele service technician or a technician

authorised by the manufacturer before it is

used for the first time.

Turn on the on-site taps for water and

^

depending on the type of heating, gas or

steam.

Switch on the on-site mains switch.

^

Press the "On" I switch to switch the

^

machine on.

M

PROFESSIONAL

PW 6321

Welcome

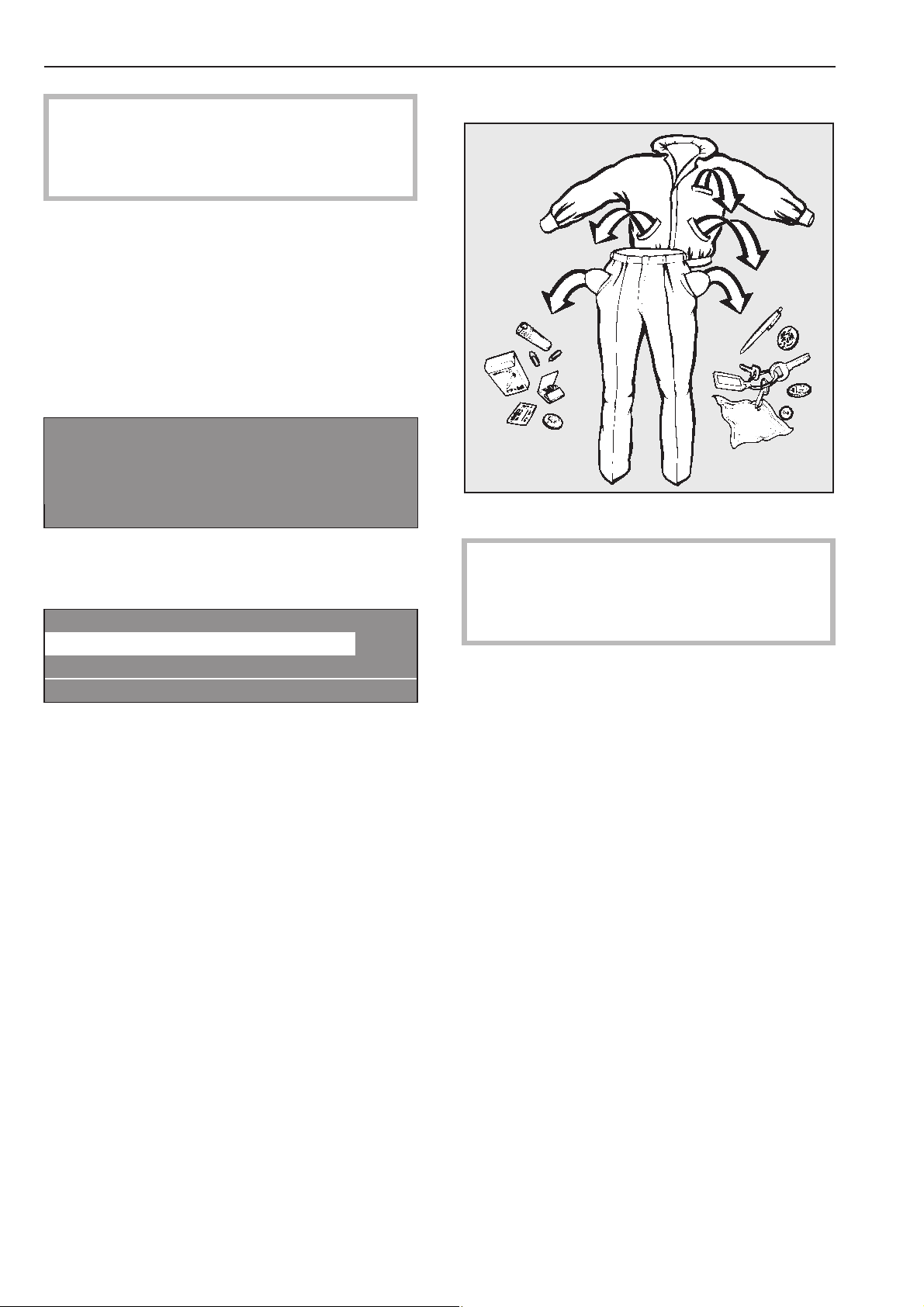

Sort the laundry

Empty any pockets.

^

A "Welcome" message will appear in the

display.

1 Cottons 90 °C

2 Cottons universal 60 °C

3 Cottons intensive 60 °C

i äFC A

This is followed by the programme list (with

the most recently used programme

highlighted).

Turn the selector dial to highlight the

programme you want. The programme can

be then started by simply pressing the

START button.

Foreign objects (e.g. nails, coins, paper

clips, etc.) can cause damage to

garments and components in the

machine.

12 M.-Nr. 09 179 270

How to wash correctly

Maximum loads for the standard

programmes

(Dry weight of laundry)

PW 6241 PW 6321

1 Cottons 90°C

2 Cottons universal 60°C

3 Cottons intensive 60°C

4 Cottons universal 30°C

5 Cottons intensive 30°C

6 Cottons Eco short

max. 24 kg max. 32 kg

7 Minimum iron 60°C

8 Minimum iron intensive 60°C

9 Minimum iron 30°C

10 Minimum iron intensive 30°C

max. 12 kg max. 16 kg

11 Delicates

12 Woollens 30°C

13 Handwashable woollens 30°C

max. 9.6 kg max. 12.8 kg

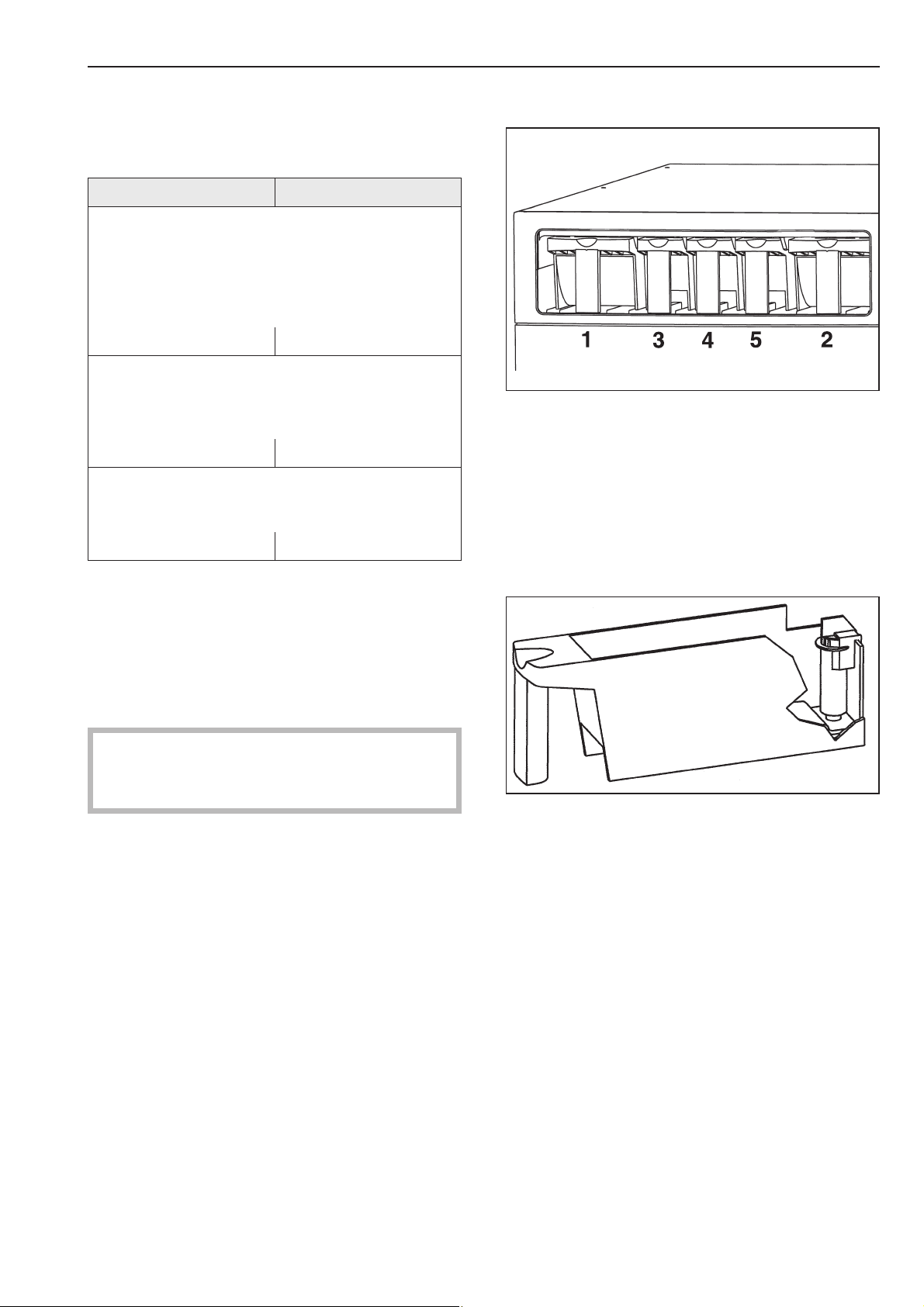

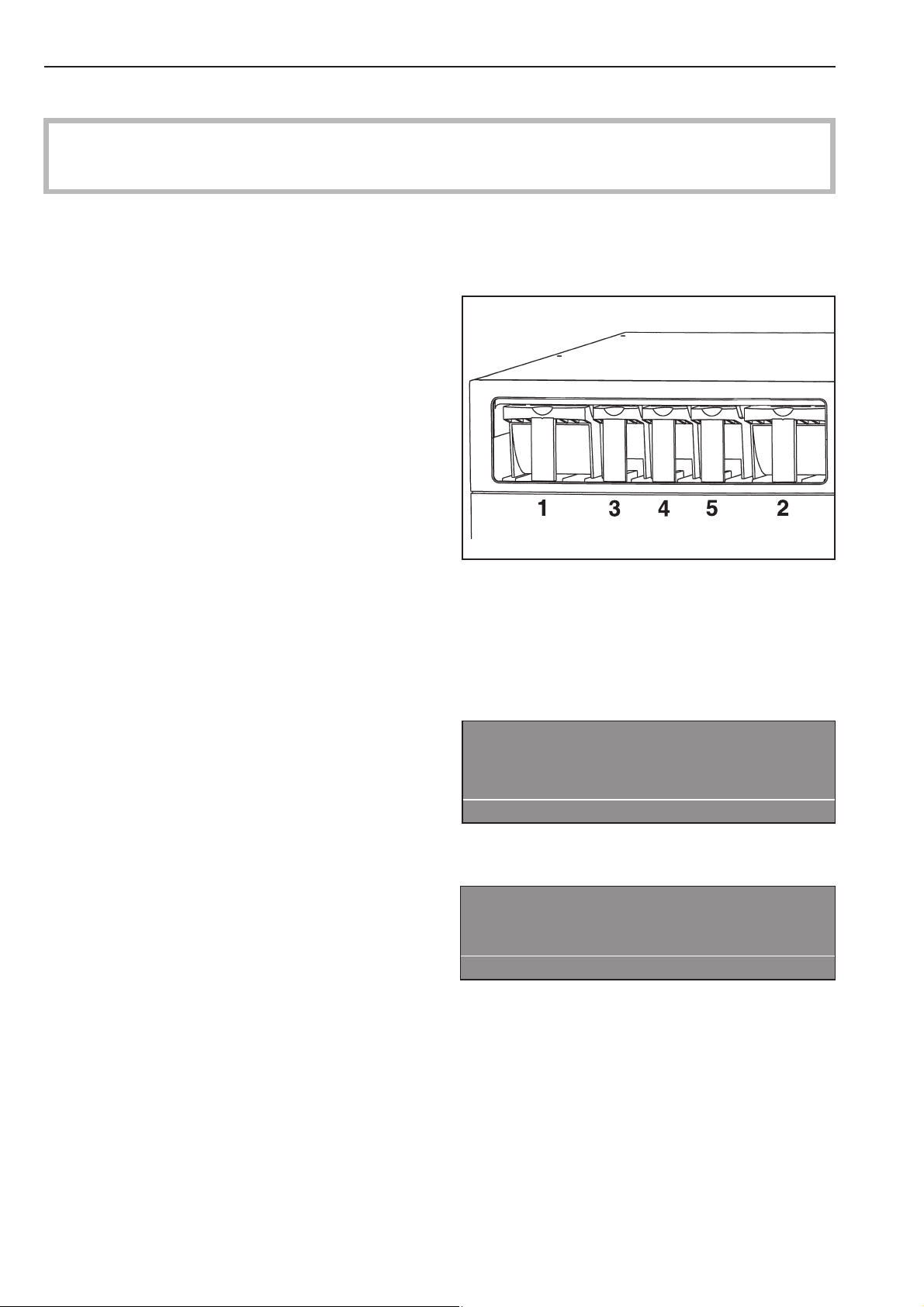

Add cleaning agent

For the standard programmes add

^

detergent for the Main wash into dispenser

compartment 2 - and as required,

detergent for a Pre-wash into dispenser

compartment 1, fabric conditioner into

compartment 3, bleach into compartment

4, and liquid detergent into compartment

5.

The maximum load for other programmes is

given in the relevant programme overview.

^ Load the laundry

^ Close the drum door with the door handle.

Do not slam it shut.

Make sure that no garments are caught

between the drum door and the drum

opening.

?

^

Do not fill fabric conditioner or bleaching

agent higher than the level marker in the

relevant dispenser compartment.

Otherwise they can run through the siphon

into the suds container.

M.-Nr. 09 179 270 13

How to wash correctly

Bleaching agents

Only use bleaching agents on textiles with

the x symbol on the wash care label.

Liquid bleaching agents may only be placed

in the compartment designated for them.

This is to ensure that the agent is added

automatically at the second rinse. Liquid

bleaching agents should only be used with

coloureds if the textile manufacturer's wash

care label states that the textile is colour fast

and suitable for bleaching.

A 3rd rinse cycle must be programmed in

if bleach is to be used (see Profitronic

programming manual).

Frequent use of chlorine increases the

,

risk of component damage.

Detergent dispensing

It is important to avoid adding too much

detergent as this causes excessive foam.

Do not use detergents which create a lot

–

of foam.

Follow the detergent manufacturer's

–

instructions for use.

The right amount to dispense will depend on

the following:

The amount of laundry

–

The water hardness level

–

The soiling level of the laundry

–

The amount to dispense

Take the water hardness into account and

follow the detergent manufacturer's

instructions on the packaging.

Only use dyes, colour run, dye removers

and descaling agents which are specified

as being suitable for use in washing

machines. Always observe the

manufacturer's instructions carefully.

Water hardness levels

Hardness

range

I soft 0 - 1.3 0 - 7

II medium 1.3 - 2.5 7 - 14

III hard 2.5 - 3.8 14 - 21

IV very hard above 3.8 above 21

Check with your local water supplier if you

do not know the hardness level in your area.

Gas heated machines

On gas heated machines the suds solution

is pumped around the heater elements. This

additional agitation of the suds solution

creates foam. It is therefore important to use

a low-foaming detergent and not to use too

much detergent.

Water

properties

Hardness

level in

mmol/l

German

scale

°d

If over-foaming occurs use a reduced foam

detergent or call in a detergent application

specialist.

14 M.-Nr. 09 179 270

How to wash correctly

Select a programme

Turn the rotary dial to select a programme

^

(e.g. Programme 1 Cottons universal).

For this example, the following will appear in

the display:

18 Separate drain

1 Cottons 90 °C

2 Cottons universal 60 °C

i äFC A

Select the Pre-wash, Starch stop or

Without spin additional option

Confirm the selection of the programme by

^

pressing the rotary selector.

For this example, the following will appear in

the display:

If you do not wish to make any further

alterations to the programme:

Press the START button. The programme

^

will start.

1 Cottons 24.0 / 24.0 kg

90 °C Main wash

Rinses 1100 rpm

+im k m A

^ If wished you can now select the Pre-wash

programme block, by pressing the +i

function button.

When the +i function button is pressed,

the following will appear in the display:

1 Cottons 24.0 / 24.0 kg

40 °C Pre-wash

90 °C Main wash 1100 rpm

+i mk m A

"+i" is highlighted.

Press the function button again to deselect

the function.

Press the m Starch stop button if the

laundry is to be starched.

Press the k Without spin button if you do

not want the laundry to be spun after being

rinsed.

M.-Nr. 09 179 270 15

How to wash correctly

If you wish to make alterations before the

start of the programme, e.g. to the load

size, temperature or spin speed:

Load weight

You can enter the weight of the load

manually before the start of the programme.

1 Cottons 10.0 24.0 kg

40 °C Pre-wash

90 °C Main wash e

+im k m A

Turn the rotary dial until "Load" (10.0 /

^

24.00 kg) is highlighted. Press the dial to

confirm your selection. Turn the dial to

alter the weight and confirm your selection

by pressing it.

Temperature in 1 °C increments from cold,

15 to max. 95 °C .

^ Turn the rotary dial to select the

"Temperature" field (40°C for pre-wash)

and press it to confirm your selection.

Spin speed in 25 rpm increments from 0,

300 to max. 1100 (PW 6241) or 1000 rpm

(PW 6321).

Turn the rotary dial to select the "Spin

^

speed" field (1100 rpm for the final spin)

and press it to confirm your selection.

1 Cottons 10.0 / 24.0 kg

90 °C Main wash

Rinses 1100 rpm

+im k m A

Turn the rotary dial to alter the spin speed

^

and then press it to confirm your selection.

Maximum spin speeds

PW 6241 PW 6321

1100 rpm 1000 rpm

^ Press the START button. The programme

will start.

1 Cottons 10.0 / 24.0 kg

40 °C Pre-wash

90 °C Main wash e

+im k m A

^

Turn the rotary dial to alter the temperature

value and then press it to confirm your

selection.

16 M.-Nr. 09 179 270

Once a programme has started the

programme sequence will appear in the

display.

1 Cottons

40 °C Pre-wash 20 °C

Main wash Ready at 12:35

+im k mKf

In the 2nd line of the display, pre-wash in

this example, the actual suds temperature

will also be shown.

1 Cottons

90 °C Main wash 60 °C

Rinse 1 Cold Ready at 12:35

+im k mKf

Once the pre-wash programme block has

finished the programme block for the main

wash will appear in the 2nd line of the

display together with the actual suds

temperature. Under that the following

programme block will be listed. Rinse 1 in

this example.

The time that the programme will finish is

shown on the right hand side of the display.

1 Cottons

90 °C Main wash 60 °C

Rinse 1 Cold Ready at 12:35

+im k m K f

Pressing the K "Information" button will call

up further information about the programme

e.g.:

How to wash correctly

Block 2: Rinse 2

Block step: Wash time 1

Actual level: 22 mm e

Rqrd. level: 60 mm

Actual temperature: 35 °C

Rqrd. temperature: 60 °C e

1 Cottons

Spin speed: 40 rpm

Rhythm: 12 / 3 -

A

Press the A "Back" button to return to the

^

programme sequence display.

Open the door at the end of the

programme

The following message will appear in the

display at the end of the programme as long

as there is no water in the machine and the

drum is stationary:

1 Cottons

Programme finished

The door can be opened.

m FC A

At the same time an acoustic buzzer will

sound for 5 seconds to let you know that the

programme has finished.

^

Pull the door handle to open the drum

door.

1 Cottons

Start date and time: 10.7.2003

Start time: 9:47 e

A

Time after start: 0h 23 min

Time left: 0h 11min

Time after start: 0h 23 min e

Time left: 0h 11min

Repeat: No

Area 3: rinse e

Important: If the door will not open press

against it and then pull on the handle again.

Do not use force to open it.

^

Unload the drum.

M.-Nr. 09 179 270 17

How to wash correctly

If the programme was interrupted with water

in the drum, or if the programme was

stopped, for example, during the spin the

following message will appear in the display:

1 Cottons

Programme finished. Water in the drum.

m FC A

or

1 Cottons

Programme finished. Drum still rotating.

m FC A

The machine door is locked. Never

,

use force to try and open the door.

^ Press the q "Water drainage" function

button or select the Separate spin

programme and press the START button.

Open the door at the end of the

programme.

If no more laundry is to be processed:

^ Leave the drum door open to air the

machine.

^

Switch the machine off by pressing the

"Off" 0 button and then switch off at the

on-site mains switch.

^

Turn off all taps for water, gas and steam

as applicable.

18 M.-Nr. 09 179 270

Card operation

Cards on which a programme has been

saved can only be used on the machine

type for which they have been written.

Unwritten cards can be used universally.

Press the "On" I button to switch the

^

machine on.

The Welcome screen will appear.

If the card is inserted the wrong way round

the following message will appear in the

display:

Card fault

§

Insert the card the right way round in the

^

Card incorrectly inserted in card reader.

A

card reader.

If the card is not the right one for the

machine it is being used in the following

message will appear in the display:

Card contents

Programmes on the card are

only suitable for machine type PW 6161

A

^ Insert the card in the reader.

The programmes listed on the card will

appear in the display.

Card operation

17 Masks 45 °C

18 Minimum iron 60 °C

i ßFC A

^

Use the rotary dial to highlight the

programme you want to use. Press the

rotary dial to select the programme you

have highlighted.

^

Press the START button. The programme

will start.

^ Insert the correct card for the machine in

the card reader.

Card access operation

Programmes requiring special procedures

are written on to a card which is then used to

run the programme.

"Card access" has to be activated via the

supervisor level in the machine.

The machine will then only run programmes

by using a card (on which one programme

has been saved). Programmes in the

machine's control unit cannot then be

accessed.

After pressing the START button you can

remove the card from the reader. The

programme is deleted from the machine's

memory once it has finished.

,

Never insert any other type of card or

object into the card reader!

M.-Nr. 09 179 270 19

Additional options

Language selection

The language shown in the display can be

changed briefly before starting a

programme if you wish. To do so use the

button underneath the flag symbol.

The language will revert back to the default

setting 5 minutes after the end of a

programme with the door open.

1 Cottons 90 °C

2 Cottons universal 60 °C

3 Cottons intensive 60 °C

i FC A

If you press the FC button the following will

appear in the display:

Settings Back <Main menu Language

Supervisor level

FC A

^ Press the rotary dial to confirm your

selection of the "Language" menu.

The following (example) will appear in the

display:

1 Cottons 10.0 /16.0 kg

Start time: 16 : 10 Start date: 2.4.2010

After selection press the start button

A

The actual time and date will then appear.

The input field for hours will be highlighted.

Press the rotary dial to change the hour.

^

Turn the rotary dial to alter the hour and

then press it to confirm your selection.

Then turn the rotary dial to select the

^

"Minutes" field and press it to confirm your

selection.

Turn the dial to alter the minutes and then

press it to confirm your selection.

^ Then turn the rotary dial to select the "Start

date" field and press it to confirm your

selection.

Turn the dial to alter the date and then

press it to confirm your selection.

Settings deutsch

Language F english (GB)

español

FC A

^

Turn the rotary dial to highlight the

language you want and then press the dial

to confirm your selection.

Start date and time

If you want a programme to start at a later

time use the m button for "Start date and

time".

To set a date and time

After selecting your programme, e.g.

Cottons in the example here, the following

will appear in the display:

1 Cottons 10.0 / 16.0 kg

90 °C Main wash

Rinses 1000 rpm

+im k m A

^ Do the same for the month and the year.

After setting the required start date and time:

^ Press the START button and the

programme selected will commence at the

time specified.

The display will now contain the following

information:

1 Cottons 10.0 / 16.0 kg

90 °C Main wash

16:15 -2.4.2010 Start 6:00 -3.4.2010

+im k m A

The current time and date as well as the

start time will be displayed.

^

If the door is opened again you will have to

press the START button again.

To cancel the start time and date function

Press the m "Start date and time" button

again or press the A"Back", and any

changes will be rejected.

^

Press the m "Start date and time" button.

20 M.-Nr. 09 179 270

Additional options

With pre-wash

For heavily soiled laundry the standard

programmes 1 to 10, can have a pre-wash

added. To do so press the "Block+" button

i.

Pressing the button again deselects the

option.

When the "Blockplus" + i button is

pressed, the following will appear in the

display:

1 Cottons 14.0 / 16.0 kg

40 °C Pre-wash

Main wash e

+i mk m A

The "+i" field will be highlighted in the

display.

Dispensing directly into the drum

Make the starch up following the

manufacturer's instructions on the

packaging. Once the "Starch stop"

programme stage has been reached open

the door and add the starch. Close the drum

door

The following message will appear in the

display again:

1 Cottons

mProg. stopped. Starch stop pressed.

The door can be opened.

i ü f

Press the START button and the programme

selected will commence

Without spin

Starch

Starching via the dispenser drawer

Starch can be selected with all the standard

programmes (except for Separate spin and

Separate drain) before starting a programme

by selecting the m "Starch stop" option.

The m field will be highlighted in the

display.

Pressing the button again deselects the

option.

1 Cottons

mProg. stopped. Starch stop pressed.

The door can be opened.

i ü f

Once the "Starch stop" programme stage is

reached the words "Starch stop" will start

flashing in the display.

Make up the starch solution following the

manufacturer's instructions on the

packaging and then add it to the front

section of compartment p. If necessary

dilute the starch with water. The wash time is

automatically increased by 4 minutes.

"Without spin" can be selected with all the

standard programmes (except for Separate

spin) before starting a programme by

selecting the k "Without spin" option.

The k field will be highlighted in the display.

Pressing the button again deselects the

option.

1 Cottons

kProg. stopped. Without spin pressed.

i ü f

Once the "Without spin" programme stage is

reached the words "Without spin" will start

flashing in the display.

To finish the programme without spinning

and with water left in the drum press the f

button.

To continue with a spin press the START

button.

Press the START button to continue the

programme.

M.-Nr. 09 179 270 21

Additional options

Programme stop

To halt the programme press the f button.

The programme remains stationary.

1 Cottons

Programme stop

i ü f

To continue the programme press the START

button.

Programme cancellation

Press the f button twice in succession to

cancel a programme.

If there is still water in the machine or if it

was cancelled during spinning the following

(example) will appear in the display:

1 Cottons

Programme finished. Water in the drum.

Programme cancelled with a locked

programme

It is not possible to stop or cancel a

programme if the programme is locked.

1 Cottons

90 °C Main wash

Locked Ready at 12:35

)f

The display will show that the machine is

locked if you try to cancel the programme

with the f button.

To cancel the programme you will first have

to select the ) "Unlocked" function and

then enter a password to unlock the

programme.

After entering the password the following will

show in the display:

i ü f

or:

1 Cottons

Programme stopped. Drum rotating.

i ü f

To open the door press the q "Water

drainage" button or select the Separate spin

programme and press the START button.

Unlock programme?

S A

Press the S "Save" button to return to the

normal display and the programme can now

be cancelled.

1 Cottons

90 °C Main wash 60 °C

Rinse 1 Ready at 12:35

mKf

22 M.-Nr. 09 179 270

Changing the programme order

The order of the programme in progress can

be changed or programme blocks can be

repeated.

Press the f button and the programme

^

will stop.

1 Cottons

Programme stop

i ü f

After pressing the ü button the current

^

area, block or step will appear in the

display.

See also "Programme structure" in the

Progamming Manual.

Additional options

Reorganise -> Cottons

Area 2: Main wash e

S A

Area: 2 Main wash

Block 1: Main wash

Step: Wash time 2 -

S A

^ Turn the rotary dial to alter the area and

then press it to confirm your selection.

Area: Select 1 Pre-wash, 2 Main wash or 3

Rinses and confirm your selection.

^

Turn the rotary dial to alter the block and

then press it to confirm your selection.

Block: Select Pre-wash 1-10, Main wash

1-10 or Rinses 1-10 and confirm your

selection.

^

Turn the rotary dial to alter the step and

then press it to confirm your selection.

Select the required programme step and

confirm your selection.

^

Press the S "Save" button and then press

START to reorganise the programme order

or press the A "Back" button to override

the programme stop and not change the

programme order.

M.-Nr. 09 179 270 23

Optional modules

Liquid dispensers

Dispenser pump Suction pipe

a

c

b

To deselect the liquid dispensing system

1 Cottons 90 °C

2 Cottons universal 60 °C

3 Cottons intensive 60 °C

i ä FC A

You can switch off the liquid dispensing

system manually before starting a

programme by setting the ä "Dispensing"

system to off.

Once the programme has started

dispensing will not take place via the

dispenser pumps and the following will

appear in the display:

1 Cottons 10.0/10.0 kg ä

90 °C Main wash

Rinses 1000 rpm

+im k m A

d

a Hose connection socket (suction side)

b Hose connection socket (pressure side)

c Leakage outlet (in case of damaged

hose)

d Suction inlet

e Level checker for empty indicator. The

pump and the machine will switch off

automatically if a liquid agent container is

empty.

e

Dispensing amount

Please follow the manufacturer's instructions

on the packaging for dispensing

requirements.

,

This is particularly important when

using a combination of cleaning agents

and special application products. Only

use the product for the application

described by the manufacturer, to avoid

any material damage or the occurrence of

Dispensing system fault

ö

Fill dispenser 1

Press the start button

if

The machine will warn you that the liquid

dispensing agent level is insufficient.

strong chemical reactions. Confirm with

the detergent manufacturer that their

product can be used in combination with

another type of product.

Liquid agents should be allowed to settle to

room temperature before use to ensure that

their viscosity level is correct and thus

The programme can be restarted after

ensure the correct amount is dispensed.

refilling the liquid agent container by

pressing the START button.

24 M.-Nr. 09 179 270

Commissioning the dispensing pumps

Before the liquid dispensing pumps can be

used the liquid agent must be drawn up into

the system and the amount to be dispensed

set.

Dispenser calibration

Optional modules

Dispenser calibration ~ Main menu

Dispenser pump 1

Dispenser pump 2 e

Select dispenser pump.

^

A

The dispensers need to be calibrated to

ensure the dispenser pumps supply the

correct amount of liquid agent.

To calibrate the dispensers with the machine

switched off:

Press and hold the rotary dial in.

^

Then switch the machine on with the "On"

^

switch.

Dispenser calibration ~ Main menu

Dispenser pump 1

Dispenser pump 2 e

A

Selection choice: Dispenser pumps 1 to 13

After selecting a dispenser pump the

following message will appear in the display:

Dispenser calibration ~ Dispenser pump 1

V: 100ml t: 0s P: no

Dispenser calibration ~ Dispenser pump 1

V: 100ml t: 0s P: no

0/1 S A

Press multi-function button 0/1.

^

To stop the pump press the 0/1 button

again, or it will switch off automatically

after a period of 60 seconds.

Measure the amount collected in the

^

measuring flask.

Dispenser calibration ~ Dispenser pump 1

V: 100ml t: 30s P: 200.0 ml/min

0/1 S A

^ Enter this value in field "V:". Flow rate P in

ml/min will be calculated electronically.

^ Press the S "Save" button to save the

values measured in memory.

0/1 S A

The amount to dispense can be set between

0 and 9999 ml in 1 ml increments.

^

Press the 0/1 multi-function button and the

dispenser hose will start to fill. Press the

0/1 button again to stop filling the hose.

^

Direct the hose of the dispenser pump

being calibrated into a suitable measuring

flask.

,

Avoid contact with the skin and eyes,

and wear suitable protective clothing.

^

Press the A "Back" button to return to the

main menu.

^

Reconnect the hose.

Cleaning and maintaining the dispensing

system

The dispensing system should be flushed

through with clean warm water every two

weeks and before any longer down-times to

prevent the risk of blockages and corrosion.

^

The suction pipes should be cleaned

through with water.

^

Place the suction pipes in a container of

hot water (40 - 50°C).

^

Then use the dispenser calibration system

to operate each pump until the dispensing

system is thoroughly flushed through.

^

After reconnecting all parts check all

connections, hoses, dispensers and seals

for leakages.

M.-Nr. 09 179 270 25

Optional modules

Peak load cut-out

If the peak-load cut out function is activated

the heating will switch itself off and any

programme running will be stopped. The

following message will appear in the display:

Operating data

By pressing the \ "Operating data" button

the operating data module can be used to

read or delete operating data either before

the start of a programme, or after it has

finished.

1 Cottons

Prog. stopped. Peak load cut-out.

Programme will continue

if

Once the peak load has finished the

programme will continue automatically as

before.

1 Cottons 90 °C

2 Cottons universal 60 °C

3 Cottons intensive 60 °C

i \ FC A

After pressing the \ button the following

will appear in the display:

Communication module

This machine can be linked to a PC via a

communication module.

Operating data module

Total data

Programme data e

\ A

The shaft for the communication module is

located at the rear of the machine.

An editor programme is available from Miele.

Selection choice:

– Total data

In this option all programme data is collated

and summarised.

– Programme data

Programme data contains all the data called

up during a programme.

–

Delete data

- Module (Total data including programme

data)

- Total data (only delete total data)

- Programme data (only delete programme

data)

Pressing the button again deselects the \

"Operating data" option.

If there is no more memory available in the

operating data module a message will

appear after pressing the START button to

say that the operating data will be

overwritten.

If you press the A "Back" button or do not

press the START button within 30 seconds

the display will revert to the way it was

before starting the programme.

26 M.-Nr. 09 179 270

Optional modules

Total data

Operating data module

Total data

Programme data e

\ A

After selecting Total data the following

(example) will appear in the display:

Operating data module ~ Total data

Total time power on: 200,987 h

Operating hours: 123456 h e

\ A

Other options:

Total time power on: 200,987 h

Operating hours: 123,456 h

Duration heating active: 123,456 h

Duration drive motor active: 93,456 h

Programme starts: 23,456

Programme stops: 567

Programme cancellations: 67

Water volume: 1,234,567 l

Amount of laundry: 1,234,567 kg

Liquid agent: 2,345 l

Energy: 12,345,678 kWh

Programme data

Operating data module -

Programme data

Delete data e

\ A

After selecting Programme data the

following (example) will appear in the

display:

Operating data module~ Programme data

1 Cottons 90 °C

2 Cottons universal 60 °C e

\ A

Select the programme you want from the list

and press the rotary dial to call up a list of all

programme starts including date and start

time for that programme.

Programme data ~ 1 Cottons

Date: 21.05.2010 Start time: 11:30

Date: 21.05.2010 Start time: 12:30 e

\ A

Select the required programme start from

the list for programme 1 Cottons and confirm

your choice by pressing the rotary dial.

Programme data ~ 1 Cottons

Date: 21.05.2010

Name: Smith e

\ A

Other options:

Town: Abingdon

Serial number: 12345678

Machine type: PW 6321

Amount of laundry: 13 kg

+ Button: Activated

Starch stop button: Activated

Without spin button: Not activated

Programme start: 11:30

Programme finished: 12:05

Total operating time: 0 h 35 min

Electrical energy: 12.5 kWh

Gas energy: 0 kWh

Steam energy: 0 kWh

Total volume of water: 140 l

Max. water temperature: 95 °C

Max. drain temperature: 45 °C

Programme change: 2

and pressing the rotary dial only the last 3 stops and starts

will be displayed.)

(after making your selection

Programme fault: None (only the last 3 faults are

saved.)

Area 1: Pre-wash (after making your selection and

pressing the rotary dial you can display the area or the

block.)

Operating time: 6 min

Water volume: 20 l

Dispensing phase 1: Amount ml (after making

your selection and pressing the rotary dial 6 dispensings

are displayed.)

Max. temperature: 12 °C

Holding time: 6 min

Dispensing phase 2: No

M.-Nr. 09 179 270 27

Optional modules

Delete data

Operating data module

Programme data

Delete data e

\ A

After selecting Delete data the following

message will appear in the display:

Operating data module~ Delete data

Module: 21.02.2010

Total data: 12.07.2010 e

\ A

The module menu option can be used to

delete the total data and programme data

from the operating data memory.

The total data option can only be used to

delete the total data from the operating data.

The programme data option can only be

used to delete programme data from the

operating data.

After making your selection and pressing the

rotary dial you will be prompted to enter your

password.

Password:____

ABCDEFGHIJKLMNOPQRSTUVWXYZ

0123456789

KSA

After keying in your password or inserting

your supervisor level key card in the reader

the following security prompt will appear in

the display:

Weighing system

If the machine has been equipped with a

weighing system module the weight of the

laundry in the machine will be displayed in

0.2 kg increments. The maximum load for

the programme selected will show next to

the actual weight in the drum.

If when the drum is empty the load display is

not showing "00,0", you will need to press

the -> I <- " to reset it

1 Cottons 00,0/ 16.0 kg

60 °C Main wash

Rinses e

+im k m -> I <- A

If after calibrating the sensor to 0 there was

still laundry in the drum the following will

appear in the display:

1 Cottons - -,-/16.0 kg

60 °C Main wash

Rinses e

+im k m -> I <- A

Press the -> I <- button again to set it to 0.

If there is too much laundry in the drum, e.g.

because it is wet, a nominal load will be

calculated after starting the programme and

this value will also be saved by the operating

data module.

At the end of the programme when the drum

has stopped rotating the display will show

the residual moisture content of the laundry.

1 Cottons

Delete operating data?

S A

Programme finished Residual moisture 60 %

The door can be opened

m FC A

After pressing the S button the data will be

deleted!

28 M.-Nr. 09 179 270

The door will not open

Press against the door handle and at the

^

same time switch the machine off and then

on again. Then try to open the door again.

If you still cannot open the door:

The door handle safety mechanism has

disingaged itself. The door handle cannot be

opened or closed.

Problem solving guide

Power cut

y

Programme stop

Press the start button.

i ü f

Press the START button and the

^

programme selected will continue.

With an extended power cut:

Switch the machine off.

^

Switch off the mains supply at the on-site

^

mains switch.

Turn off all taps for water, gas and steam

^

as applicable.

To remove the laundry the drain valve will

need to be opened manually and the drum

door unlocked manually.

The safety mechanism is designed to

protect the handle and the lock from

damage, for instance, if too much force is

being used in an attempt to open the

door.

^

Press firmly against the door handle until

you clearly hear the safety mechanism

engage.

You will now be able to open and close the

door again (as long as there is no water in

the machine).

^

Open the drain valve by partially opening

the venting screw (spanner size 17 mm) at

the rear of the machine. Do not unscrew it

completely. Drain off the suds. Take care

as some water will seep out of the screw

opening (approx. 100 mm). This should be

collected in a suitable container.

^

Tighten up the venting screw again and

check that there is no leak.

Power cut during a wash

programme - Emergency door

release

With a short power cut:

The programme remains in the last position,

and when power is restored the following

message appears in the display:

M.-Nr. 09 179 270 29

Problem solving guide

Insert a screwdriver (head approx. 4 mm)

^

into the opening beside the door lock so

that the head engages with the notch of

the door release mechanism. Turning the

screwdriver slightly anti-clockwise will

unlock the door.

Never use force to open the door!

^ Remove the laundry

Soiling level of the laundry

–

For lightly soiled laundry dispense less

^

detergent in accordance with the

detergent manufacturer's instructions.

Residues e.g. detergent on the laundry

–

Run a pre-wash without detergent and

^

without selecting a temperature.

Laundry which has been soaked before

washing must be thoroughly rinsed before

running a wash programme.

Small loads

–

Reduce the amount of detergent

^

dispensed according to the size of the

load.

Drum speed too high during the wash

–

(Profitronic controls)

Reduce the drum speed and the wash

^

rhythm.

– Gas-heated washer-extractors

On gas heated machines the suds solution

is pumped around the heater elements. This

additional movement of the suds can

produce extra foam.

Possible reasons for increased

levels of foaming

–

Detergent type

^

Only use detergents formulated for

commercial washer-extractors. Domestic

laundry detergents are not suitable.

–

Using too much detergent

^

Follow the manufacturer's dosage

recommendations on the packaging and

take local water hardness levels into

account.

–

Heavy foaming detergent

^

Use a low foaming detergent or contact

your detergent supplier for advice.

–

Very soft water

^

In areas with very soft water (hardness

level 1) dispense less detergent as

specified by the detergent manufacturer.

^ Follow the dispensing instructions given

above.

^ Use a low lather detergent.

^

On Profitronic controlled machines and in

special circumstances it is possible to

reduce the drum speed and the wash

rhythm during the heating-up phase.

Large articles of laundry stretching

during the spin cycle

Large articles of laundry (e.g. table cloths)

can stretch during the spin cycle. This can

generally be prevented by reprogramming

the machine.

Please contact the Miele Professional

Service Department.

30 M.-Nr. 09 179 270

Service interval

If after switching the machine on the

following message appears in the display

the machine will need to be serviced by the

Miele Professional Service Department.

Service interval 1

§

Call the Service Department

Problem solving guide

Water inlet fault

M

Call the Service Department

if restart does not work.

if

Check the tap and then press the START

^

button.

A

The display will go out after 5 minutes.

Error messages

Repairs to electrical, gas or steam

,

operated machines may only be carried

out by a suitably qualified person in

accordance with national and local safety

regulations.

A message will appear in the display if there

is a problem either before starting a

programme or once it has started:

The display remains dark.

There is no power to the machine.

^

Check the mains switch and the on-site

fuses.

Power cut

y

Programme stop

Press the start button.

f

Door lock fault

a

Call the Service Department

if restart does not work.

if

Push firmly on the door handle until you

^

hear the lock engaging. Confirm by

pressing START.

Heating system fault

§

Programme stopped. Press start.

Programme will continue without heat.

if

^ To continue the programme with heating

press the START button. If a disinfection

programme was running the programme

will be cancelled if this message appears.

Call the Miele Professional Service

Department.

Drive motor fault

m

^

Allow the motor to cool down.

Programme stopped. Press the start button.

Motor overheating.

if

^

Once power has been restored press the

START button.

This error message can also indicate that

§

Call the Service Department

if restart does not work.

i A

the winding on the motor has overheated.

Imbalance fault

^

Allow the motor to cool down.

The imbalance is too great and the

imbalance switch has been activated.

^

Switch the machine off and on again. Then

press the START button.

M.-Nr. 09 179 270 31

Problem solving guide

Gas system fault

§

If this message appears before a

Open the gas tap.

Press the start button.

if

ö

Replace the empty container with a full one.

Dispensing system fault

Fill dispenser 1

Press the start button

if

programme has been started:

Open the gas tap and then press the

^

START button.

§

Card fault

Card incorrectly inserted in card reader.

If this message appears during a

programme the pressure in the gas supply

if

has dropped because of other gas heated

appliances operating at the same time.

Press the START button.

^

Insert the card the right way round in the

^

card reader.

Gas system fault

§

Call the Service Department

if restart does not work.

if

After sales service

In the event of any faults please contact the

Miele Professional Service Department.

^ If the programme still will not start please

call the Miele Professional Service

Department.

Department, please quote the Model, Serial

number (SN) and Material number (M.Nr) of

your machine. These are shown on the data

plate.

Gas system fault

When contacting the Professional Service

§

Clean the lint filter.

Press the start button.

if

This is visible above the door aperture or at

Clean the lint filter as described in "Cleaning

the back of the machine.

and care" and then press the START button.

On gas heated machines heavy foaming can

lead to a fault.

Please let the Professional Service

Department know any error message that

has appeared in the display.

Should you require spare parts ensure that

Drain valve fault

q

Call the Service Department

if restart does not work.

if

you only use original Miele Spare Parts

(and remember to let the Spare Parts

Department know the model, serial number

and material number of your machine).

^

Check the on-site drainage system and

then press the START button.

A defective drain valve must be repaired by

a Miele Service technician only.

32 M.-Nr. 09 179 270

Cleaning and care

The machine should be cleaned and

checked over immediately after use where

possible.

Do not use a pressure washer or hose

,

to clean the machine.

The housing, control panel and any

plastic components should be cleaned

using a suitable mild cleaning agent,

applied with a soft damp cloth. Rub dry with

a soft cloth after cleaning.

Do not use abrasive cleaning agents as

they will damage the surface material.

Parts of the housing made from stainless

steel can be cleaned using a suitable

proprietary stainless steel cleaning agent.

Any deposits on the door seals should be

wiped off using a damp cloth.

The grille over the cooling fan at the back of

the machine should be checked for soiling

from time to time and cleaned if necessary.

Rust

The drum and suds container are

manufactured from rust free stainless steel.

Water with a very high iron content, or

foreign objects such as paper clips, metal

buttons etc. which get into the drum with the

laundry can cause superficial rusting in the

drum and suds container.

To prevent this happening the drum and

suds container should be checked and

cleaned regularly and if rusting does occur it

should be removed using a proprietary

cleaning agent for stainless steel.

The door seals should be checked for

foreign objects regularly and cleaned as

described above.

Clean the detergent dispenser, dispenser

compartments and siphons

The detergent dispenser, dispenser

compartments and siphons must be cleaned

after each use with warm water to thoroughly

remove any residues of detergents or other

agents. If the machine is not going to be

used for a while the detergent dispenser

should be left open to air the compartment.

The siphon in the dispenser compartment

for fabric conditioner should also be

cleaned.

Leave the door ajar after cleaning to allow

the machine to dry.

Remove the siphon and clean with hot water.

Then put it back in place.

M.-Nr. 09 179 270 33

Cleaning and care

The filters in the water inlet valve should be

checked from time to time for soiling and

cleaned if necessary.

Cleaning the filter

Clean the filter as follows:

Place a suitable 2 litre capacity container

^

below the filter.

Turn the lid a half to a full turn

^

anti-clockwise to open the filter.

Any water in the filter housing will then

drain out.

The filter should be checked regularly for

and cleaned when necessary.

Carry out this check only after a

,

programme has finished and the suds

container has been emptied.

A blocked filter is indicated by a flashing

fault message in the display.

Gas system fault

Warning - the water may be hot.

^ Empty the dish and repeat as many times

as is necessary.

§

Clean the filter.

Press the start button.

if

^

When no more water runs out, unscrew the

lid completely. The filter is attached to the

lid.

^

Clean the filter and the inner housing of the

filter compartment.

^

Replace the filter and tighten the lid

making sure it is secure.

34 M.-Nr. 09 179 270

Cleaning and care

Drum bearings

Once the service interval has been reached

the following message will appear in the

display:

Lubricate drum bearings

§

Press the A"Back" button to get rid of the

message in the display. This message will

appear in the display each time you switch

the machine on until the service work has

been carried out by the Miele service

technician.

,

mains.

Call the Service Department.

A

Disconnect the machine from the

When the machine is not in use

If the machine is not going to be used for a

longer period of time (4 weeks or more) the

drum bearings should be lubricated as

described above and the drum rotated a few

turns. The drum should then be rotated

again every 4 weeks to prevent damage to

the bearings.

?

?

The grease nipples on the drum bearings

need to be lubricated after approx. 1000

operating hours with Arcanol L 100.

?

?

Gas-heated washer-extractors.

M.-Nr. 09 179 270 35

Explanation of symbols on the data plate

a

b opq

c

drs

e

ft

g

u

i

hj v

k

lw

m

n

1 Machine type

2 Serial number

3 Article number

4 Material number

5 Voltage/Frequency

6 Control fuse

7 Drive motor

8 Drum data

9 Drum diameter/Drum depth

10 Spin speed

11 Drum volume/Laundry dry weight

12 Kinetic energy

13 Run-up time

14 Braking time

15 Heating

16 Indentification/Year of manufacture

17 Commissioning date

18 Electric heating

19 Fuse rating (on-site)

20 Indirect steam heating

21 Direct steam heating

22 Gas heating

23 Area for test certification labels

Noise emission

Registered on the A scale

Washing Spinning

PW 6241 60 dB 82 dB

PW 6321 60 dB 80 dB

Measured in Germany in accordance with

EN ISO 9614-2

36 M.-Nr. 09 179 270

This machine must be installed by a Miele

authorised technician only.

This machine is not designed for

,

washing items which have been treated

with dangerous or flammable substances.

Transport packaging must be carefully

removed using suitable tools.

The machine must be level and secure after

installation (see installation diagram

supplied with the machine).

To avoid the risk of frost damage do not

install this machine in a room where there is

a risk of frost occuring.

Do not install the machine on carpeted

flooring as the carpet pile can hinder the

free flow of air into the ventilation gaps at the

bottom of the machine.

Notes for the installer

Unscrew the hex screws from the bottom

edge of the front access panel and then take

the access panel off.

Unscrew the hex screws from the back

panel and then take the back panel off.

The front plinth facing is screwed to the

back panel. The rear plinth facing is located

under the machine lid and has to be fitted

after the machine has been successfully set

up. Screws are supplied in the accessories

pack for this.

Store the transit fittings in a safe place for

future use. They will need to be refitted

should the machine every need to be

moved to another location.

Use a pallet lifter to move the machine

around the room.

The machine must not be moved without

all the outer panels in place.

Transit fittings

Brackets "A" (2 on each side) are secured

with hex screws which have to be removed

using a suitable tool.

Transit fittings "B", (2 at the front adn 2 at the

back) are secured with 3 hex screws each.

These have to be removed on site before the

machine is commissioned for use.

To do so the access panel and the rear