Installation plan

Washer-extractor

PW 6207 G

en - GB

12.13 M.-Nr. 09 868 210 / 01

2

M.-Nr. 09 868 210 / 01

Installationsplan / Installation plan

Waschmaschine / Washer

PW 6207 G

Installationsplan / Installation plan

Waschmaschine / Washer

PW 6207 G

A - A

Installationsplan / Installation plan

Waschmaschine / Washer

PW 6207 G

Installationsplan / Installation plan

Waschmaschine / Washer

PW 6207 G

Installationsplan / Installation plan

Waschmaschine / Washer

PW 6207 G

Technical data sheet

Washer-extractor:

Heating type:

PW 6207

Gas (G)

Legend:

Circled, bold-type abbreviations:

Connection required

en - GB

Abbreviations surrounded by broken circle:

Connection optional or required, depending on model

UM

Miele plinth

UG/UO 6020

(UG = Box plinth/UO = Open plinth)

Height/Type

mm

240

Width UG (UO)

mm

920 (900)

Depth UG (UO)

mm

1049 (1009)

BS

Concrete platform

Concrete platform (min. grade B15)

Recommended height

mm

240 Minimum height

mm

100

Recommended width

mm

920

Recommended depth

mm

1020

Good bond to floor is important!

Electrical

connection

1. Standard voltage (standard version)

V 3N AC 380-415

Frequency

Hz

50

Connected load

kW

4.4

Fuse rating

A 3 × 16

Connection cable, min. gauge

mm²

5 × 1.5

Cable grommet

M 20 x 1.5

It is always recommended to make electrical connection in

accordance with IEC 60309 via a plug and socket so that

electrical safety checks, e.g. during repair or service work,

can be carried out easily. For hard-wired connections install a

mains isolator device as per IEC 60947. The socket must be

accessible after machine installation. In order to increase

safety, the installation of an earth leakage circuit breaker is

recommended. In such case, an interrupter sensitive to all

voltages is necessary.

If necessary, equipotential bonding with good galvanic contact

must be guaranteed in compliance with all applicable local

and national installation codes.

Gas connection

Natural gas

On-site threaded union

Inch

½" female thread

Rated heat load

kW

34

Minimum connection pressure (may vary in other

countries)

Pa

1700

Length of connection hose (included)

mm

350

Liquid gas

On-site connection (Ermeto socket)

DN

12

Minimum connection pressure (may vary in other

countries)

Pa

2800 - 5750

Length of connection hose (included)

mm

350

Options / Accessories:

Machine connections:

Installationsplan / Installation plan: PW 6207 G

Datum / Date: 25.11.2013 Seite / Page: 8

The gas stopcock is provided by Miele. A shut-off valve

should be provided on site.

c.f. installation instructions for gas-heated washer-extractors.

Local building and plumbing codes must also be observed.

Cold water

(softened water)

Minimum flow pressure

kPa

100

Maximum pressure

kPa

1000

Max. flow rate (in absence of hot water)

l/min

26 (42)

On-site threaded union in accordance with DIN 44991 (flat

sealing)

Inch

¾" male thread

Length of connection hoses

(2 hoses + Y-piece included)

mm

1500

Water requirement (60°C programme = average value)

Standard connection (with hot water connection)

l/h

approx. 125

In the absence of a hot water supply, add sufficient water to

reach the required amount.

Hot water

(softened water)

Maximum temperature

°C

70

Minimum flow pressure

kPa

100

Maximum pressure

kPa

1,000

Max. flow rate

l/min

16

On-site threaded union in accordance with DIN 44991 (flat

sealing)

Inch

¾" male thread

Length of connection hose (1 connection hose included)

mm

1500

Water requirement (60°C programme = average value)

Standard connection (with hot water connection)

l/h

approx. 126

In the absence of hot water, connect hose to cold water!

Cold water

(raw water)

(optional)

Minimum flow pressure

kPa

100

Maximum pressure

kPa

1000

Max. flow rate

l/min

32

On-site threaded union in accordance with DIN 44991 (flat

sealing)On-site threaded union in accordance with DIN 44991

(flat sealing)

Inch

¾" male thread

Length of connection hoses

(2 hoses + Y-piece included)

mm

1500

Water requirement (60°C programme = average value)

Standard connection (with hot water connection)

l/h

approx. 72

If connecting to raw water, subtract water requirement from

cold water.

In the absence of raw water, connect hose to cold water!

Exhaust gas

Natural gas heating

Rated heat load

kW

34

Waste gas connection (int dia x wall thickness x l) [DN

150]

mm

150 x 1 x 300

Exhaust gas emissions at nominal heat load

g/s

32.1

Exhaust temperature at nominal heat load

°C

110

CO2 concentration at nominal heat load

%

Approx. 4.0

Liquid gas heating

Rated heat load

kW

34

Exhaust gas connection (int dia x wall thickness x l) [DN

150]

mm

150 x 1 x 300

Exhaust gas emissions at rated heat load

g/s

35.3

Exhaust gas temperature at rated heat load

°C

100

CO2 concentration at rated heat load

%

Approx. 4.0

Atmospheric burner with integrated flow control, Type: B

11BS

c.f. installation instructions for gas-heated washer-extractors.

Local building and plumbing codes must also be observed.

A safe distance should be maintained between combustible or

non-heatproof items and the exhaust gas duct.

Installationsplan / Installation plan: PW 6207 G

Datum / Date: 25.11.2013 Seite / Page: 9

Drainage, version

with dump valve

Maximum temperature

°C

95

Waste water connection on machine (ext dia × wall thickness

× l) [DN 70]

mm

75 × 1.9 × 95

On-site drain connection (di) [DN 70 sleeve]

mm

75

Max. transient flow rate

l/min

200

Vented collector line required; if insufficient venting, use Miele

installation kit, Mat. no. 05238090.

When several machines are connected, ensure that the

manifold is of a sufficient diameter.

Foam venting

In the event of heavy foaming, foam may be released from

the air vent. In order to dispose of this foam, drainage

pipework with an odour trap can be built on site using

standard pipe sections of a suitable diameter. This generally

involves the use of an 87° branch-off with a cap.

Floor anchors

(supplied)

Miele UG/UO 6020 plinths

4 x metal angle brackets (to secure machine to plinth)

4 × wood screws DIN 571 (Ø × length)

mm

12 × 90

4 × rawl plugs (Ø × length)

mm

16 × 80

The machine must be secured!

Anchors for a floating screed floor must be provided on site.

On concrete platform

4 × wood screws DIN 571 (Ø × length)

mm

12 × 90

4 × rawl plugs (Ø × length)

mm

16 × 80

The machine must be secured!

Anchors for a floating screed floor must be provided on site.

Without plinth

4 × wood screws DIN 571 (Ø × length)

mm

12 × 90

4 × rawl plugs (Ø × length)

mm

16 × 80

The machine must be secured!

Anchors for a floating screed floor must be provided on site.

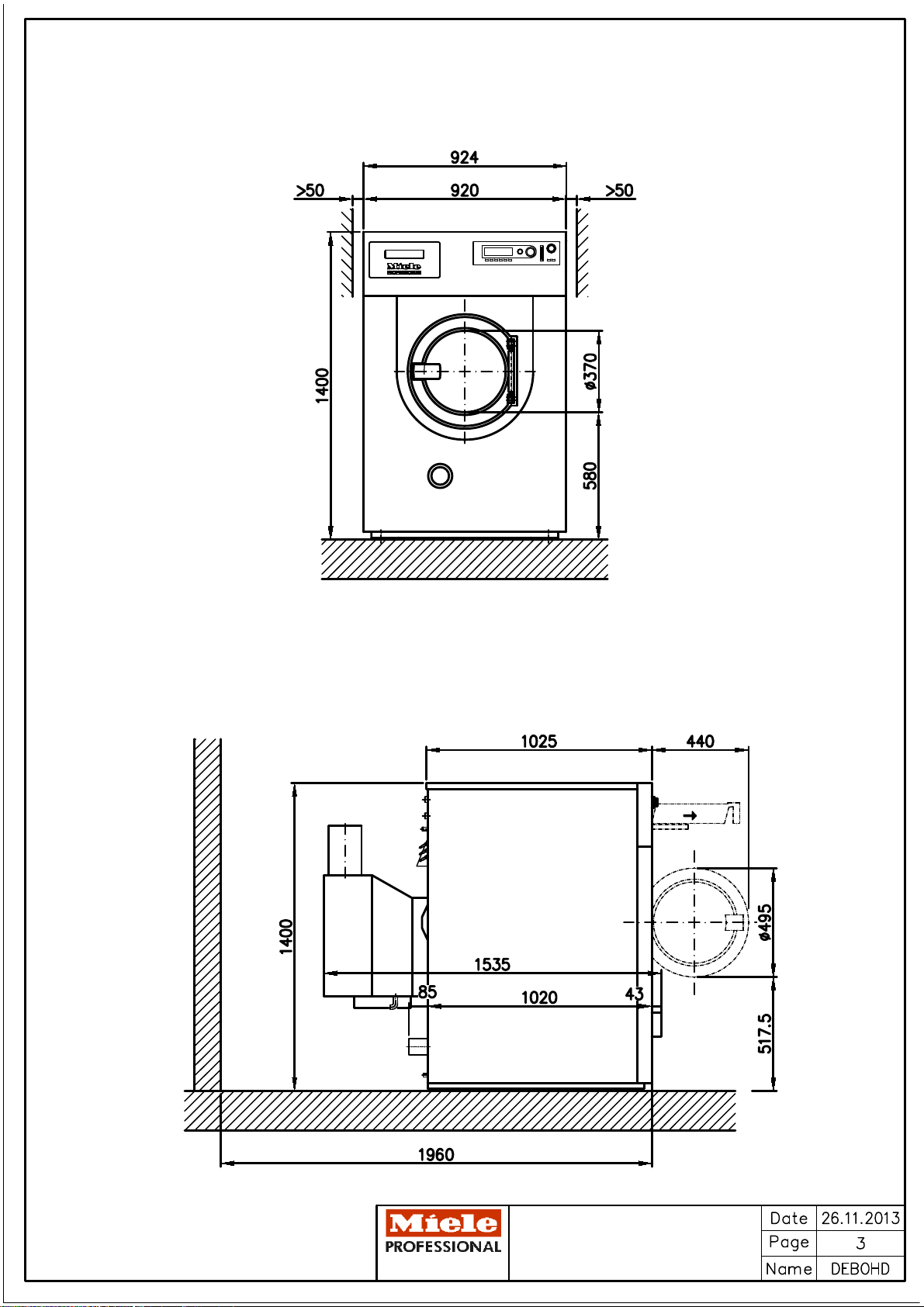

Machine data

Width

mm

924

Depth

mm

1535

Height

mm

1400

Min. access width

mm

930

Recommended distance from opposite wall (to front of

machine)

mm

1965

Net weight

kg

589

Max. floor load in operation

N

6978

Max. static floor load

N

6445

Max dynamic floor load

N

533

Max. drum rotation frequency

Hz

18.3

Average heat dissipation to installation site

(depending on ambient temperature and programme

selected)

W

N/A

Installation should only be performed by qualified fitters in accordance with valid regulations, relevant standards and health

and safety codes!

It is important to comply with installation instructions when installing machines! All rights reserved! Dimensions in mm.

Installationsplan / Installation plan: PW 6207 G

Datum / Date: 25.11.2013 Seite / Page: 10

Loading...

Loading...