Operating instructions

Heat pump dryer

PT 8203 SL WP

To avoid the risk of accidents or damage to the

machine, it is essential to read these instructions

before it is installed and used for the first time.

en - GB, IE

M.-Nr. 10 534 650

Caring for the environment

Disposal of the packing material

The packaging is designed to protect the

appliance from damage during transportation. The packaging materials used are selected from materials which are environmentally friendly for disposal and should be

recycled.

Recycling the packaging reduces the use of

raw materials in the manufacturing process

and also reduces the amount of waste in

landfill sites.

Disposing of your old appliance

Electrical and electronic appliances often

contain valuable materials. They also contain specific materials, compounds and

components, which were essential for their

correct function and safety. These could be

hazardous to human health and to the environment if disposed of with your domestic

waste or if handled incorrectly. Please do

not, therefore, dispose of your old appliance

with your household waste.

Tips for saving energy

This heat-pump tumble dryer offers the

latest technological features. These help

reduce its energy consumption during drying by about 50% compared to the energy

consumption of conventional electrically

heated tumble dryers.

The following tips will help you to make further savings in energy consumption:

– Make sure your laundry is spun in the

washing machine at the maximum spin

speed.

– Carry out the final rinse in the washing

machine with hot water. This results in a

lower residual moisture content and increased residual heat in the laundry after

washing. This reduces the time required

for drying and thus saves energy.

– Sort the laundry:

- by fibre and weave,

- by the required level of drying,

- by residual moisture.

Please dispose of it at your local community

waste collection / recycling centre for electrical and electronic appliances, or contact

your dealer or Miele for advice. You are also

responsible (by law, depending on country)

for deleting any personal data that may be

stored on the appliance being disposed of.

Please ensure that your old appliance poses

no risk to children while being stored prior

to disposal.

– Dry the maximum amount specified for

the drying programme whenever possible.

Energy consumption is more economical

for a full load. Partial loads are not economical. Over loading the drum hampers

drying results and affects the finish.

– The drying process is more efficient with a

clean fluff filter and heat-exchanger. This

reduces the time it takes to dry the laundry as well as the amount of energy required.

– Ensure sufficient room ventilation.

2

Contents

Caring for the environment ................................................................................................2

Tips for saving energy ........................................................................................................... 2

Warning and Safety instructions........................................................................................5

Description of the machine ..............................................................................................11

Drying .................................................................................................................................13

Laundry preparation ............................................................................................................ 13

Important notes about drying.............................................................................................. 14

Before using for the first time.............................................................................................. 15

Commission the machine............................................................................................... 15

Switch the tumble dryer on ................................................................................................. 15

Load capacities (dry weight) ............................................................................................... 15

Selecting a programme ....................................................................................................... 16

Lowering the temperature ................................................................................................... 17

At the end of the programme .............................................................................................. 17

After the end of a programme ............................................................................................. 18

Interrupting a programme.................................................................................................... 18

Adding or removing individual items .............................................................................. 19

To continue the drying programme ................................................................................ 19

To switch the tumble dryer off........................................................................................ 19

Reprogramming.................................................................................................................20

Changing standard options................................................................................................. 20

To access programming level.............................................................................................. 20

Go to programming level................................................................................................ 20

Example of reprogramming ................................................................................................. 21

To alter the buzzer at the end of a programme .............................................................. 21

Reprogramming for the visually impaired....................................................................... 21

Programmable functions ..................................................................................................... 22

Problem solving guide ......................................................................................................24

Trouble shooting.................................................................................................................. 24

What to do if...................................................................................................................... 24

Service................................................................................................................................. 25

Cleaning and care .............................................................................................................26

Cleaning the tumble dryer ................................................................................................... 26

Cleaning the fluff filters........................................................................................................ 27

Cleaning the filter behind the air inlet.................................................................................. 28

Installation and connection ..............................................................................................29

Installation requirements ..................................................................................................... 29

General operating conditions .............................................................................................. 29

Transporting the machine.................................................................................................... 29

Removal of transport packaging .................................................................................... 29

Set up .................................................................................................................................. 30

Securing the machine.......................................................................................................... 31

Fitting the programme card................................................................................................. 31

Electrical connection ........................................................................................................... 32

Air intake vent...................................................................................................................... 33

Air outlet vent ...................................................................................................................... 33

Condensate drainage .......................................................................................................... 33

3

Contents

Communication module XKM RS232.................................................................................. 34

Technical data ..................................................................................................................... 35

Electrical connection ...................................................................................................... 35

Installation data .............................................................................................................. 35

Emissions ....................................................................................................................... 35

4

Warning and Safety instructions

This tumble dryer complies with current safety requirements. Inappropriate use can,

however, lead to personal injury and damage to property.

To protect yourself and to avoid the risk of damage to the tumble dryer, please read

these instructions carefully before using it for the first time. They contain important information for your safety, and about using and looking after the tumble dryer.

If other persons are being shown how to operate the tumble dryer, they must be given

and/or made aware of these important safety instructions.

Keep these instructions in a safe place and ensure that new users are familiar with the

content. Pass them on to any future owner.

Correct application

This tumble dryer is intended only for use in a commercial environment and must only

be operated indoors.

This tumble dryer must only be operated by expert staff or trained personnel.

If the tumble dryer is to be operated in an area accessible to the public, the supervisor

must ensure that it can be operated safely without risk of danger to others.

This tumble dryer must be used as described in these instructions and must be checked

on a regular basis to make sure it is functioning correctly.

This tumble dryer is only intended for drying fabrics which have been washed in a water

solution, and marked on the manufacturer's care label as being suitable for tumble drying.

Any other applications may be dangerous. Miele cannot be held liable for damage resulting

from incorrect or improper use or operation.

This tumble dryer is not intended for outdoor use.

5

Warning and Safety instructions

Preventing problems

Empty all pockets to prevent the risk of flammable items such as lighters and cosmetics

getting into the tumble dryer.

To prevent the risk of fire, do not dry the following textiles in the tumble dryer:

– Items which have not been washed.

– Items, such as workwear, which have not been thoroughly cleaned and which are still

soiled with grease, oil or other deposits (such as cooking oil, cosmetics, lotions etc). If

items have not been thoroughly cleaned there is a danger that these might ignite when

heated, even after they have been removed from the dryer at the end of the programme.

– Items (e.g. mops and floor cloths) which have been treated with inflammable cleaning

agents or which contain residues of acetone, alcohol, benzene, petrol, kerosene, stain

remover, turpentine, wax and wax remover or other chemicals.

– Items that have been cleaned using industrial chemical agents.

– Items which have been splashed with hair lacquer, hair spray, nail varnish remover or

similar substances.

Heavily soiled laundry must be washed particularly thoroughly.

Increase the detergent dosage and select a high wash temperature.

Wash the laundry several times if necessary.

To prevent the risk of fire, the following textiles must not be dried in this tumble dryer:

– Items which contain a large proportion of rubber, foam rubber or rubber-like materials.

For example, products made from latex foam rubber, shower caps, waterproof textiles,

rubberised articles and items of clothing and pillows with foam rubber filling.

– Damaged items which contain padding or fillings (e.g. pillows, jackets). When damaged,

the filling can get out with the risk of it igniting in the dryer.

The heating-phase is followed in many programmes by cooling-down phase. The pro-

gramme is not finished until this cooling-down phase has finished. This ensures that the

laundry is at a safe temperature which will not damage it.

Unload the drum completely as soon as the programme has finished.

Danger of laundry self-igniting if it is put away or stored whilst still hot.

During the drying process the door glass and frame around the door will get hot.

Danger of burning!

Always make sure that the drum is stationary before reaching in to remove laundry.

Reaching into a moving drum is extremely dangerous.

Never operate the tumble dryer without the fluff filter fitted.

Fire hazard without the filter!

A damaged filter must be replaced immediately. Otherwise the airways and the heater elements will get clogged up by fluff. The correct functioning of the tumble dryer cannot be

assured if the filters or airways are impeded.

6

Warning and Safety instructions

Technical safety

This tumble dryer complies with current safety requirements. Inappropriate use can,

however, lead to personal injury and damage to property.

This tumble dryer must only be set up and commissioned by a Miele Service technician

or authorised Miele Service Dealer.

Before installation check the tumble dryer for any obvious damage. A damaged tumble

dryer must not be installed and/or used.

The electrical safety of this tumble dryer can only be guaranteed when correctly earthed.

It is essential that this standard safety requirement is met. If in any doubt, please have the

on-site wiring system tested by a qualified electrician. Miele cannot be held liable for the

consequences of an inadequate earthing system (e.g. electric shock).

This tumble dryer is only completely isolated from the electricity supply when the plug

has been withdrawn from the socket, it has been switched off at the mains isolator, or the

mains fuse is disconnected.

Machines with a damaged control panel, wires or cables must not be used until they

have been repaired.

Unauthorised repairs could result in unforeseen dangers for the user, for which Miele

cannot accept liability. Repairs should only be undertaken by a Miele approved service

technician, otherwise any subsequent damage will not be covered by the guarantee.

Faulty components must only be replaced by genuine Miele original spare parts. The

manufacturer can only guarantee the safety of the machine when Miele replacement parts

are used.

This tumble dryer must not be operated in the same room as a machine that uses

solvents containing CFCs. Vapours given off by these break down to form hydrochloric

acid which can have a damaging effect on the laundry and the machine. If installed in adjoining rooms there must be no exchange of air between the two rooms.

Make sure the tumble dryer has a supply of fresh air. Do not expose it to air which is

contaminated with vapour from chlorine, fluorine or other solvents.

The air intake for the tumble dryer is located at the front of the machine. This opening

must never, under any circumstances, be blocked or hindered by objects such as laundry

baskets etc.

Cool air is extracted out to the rear of the tumble dryer. This area must not be blocked.

Please ensure that the minimum gap required, as shown on the installation drawing, is

maintained.

Do not store or use benzine, petrol, paraffin, or other easily flammable liquids near the

machine. Do not use the machine lid as a resting place.

Danger of fire or explosion.

To ensure the correct performance of the tumble dryer and to prevent the risk of faults

and fire, it is important to carry out maintenance on a regular basis.

This tumble dryer contains fluorinated greenhouse gases as a refrigerant. They are her-

metically sealed. Designation: R 134a

7

Warning and Safety instructions

Heat pump and refrigerant:

– This tumble dryer uses refrigerant gas which is not flammable and not explosive.

– After transporting the machine to its installation site allow it to stand for approx.

30minutes before connecting it to the electrical supply.

This is to protect the heat-pump from damage.

If the heat-pump has been subjected to an inclination greater than 45° during transportation, or if there is a significant difference in temperature between the tumble dryer and

the installation room, the standing time should be increased accordingly.

8

Warning and Safety instructions

Correct use

The max. dry laundry weight is 10 kg.

Do not damage, remove or bypass the safety features and control elements of the

tumble dryer.

Only operate the tumble when all removable outer panels are in place so that it is im-

possible to touch an electrical component or moving part.

Danger of squashing or cutting fingers etc. around the drum door hinges and the fluff fil-

ter cover. Use the appropriate handles and release catches only.

The area necessary to open the drum door completely must not be obstructed by doors

or other structures.

Disinfecting and cleaning agents often have compounds containing chlorides in them. If

these agents dry on to stainless steel surfaces, the residual chlorides will attack the steel

and can cause rusting. To protect your machine from rust damage, we recommend only

using chloride free disinfecting and cleaning agents for washing and disinfecting programmes and for cleaning stainless steel surfaces of the machine itself. If you are unsure

about a particular agent, contact the manufacturer of that agent for advice. Accidental

spillages of agents containing chlorides should be rinsed off affected surfaces with water

and then dried with a soft cloth.

Do not use a pressure washer or hose pipe to clean the tumble dryer. This also applies

to the area behind the service panel at the front of the tumble dryer.

After use there is a danger around the refrigerant pipework and adjoining components of

hot or cold surfaces and parts being under pressure. Allow sufficient time for the machine

to cool down before opening any panels.

This tumble dryer can only be used by people with reduced physical, sensory or mental

capabilities, or lack of experience or knowledge, if they are supervised whilst using it or

have been shown how to use it in a safe way and understand and recognise the consequences of incorrect operation.

Children under 8 years of age must be kept away from the tumble dryer unless they are

constantly supervised.

Children 8 years and older may only use the tumble dryer unsupervised if they have

been shown how to use it safely and recognise and understand the consequences of incorrect operation.

Children must not be allowed to clean or maintain the tumble dryer unsupervised.

Please supervise children in the vicinity of the tumble dryer and do not let them play

with it.

Close the drum door after each drying cycle. This is to avoid the risk of children trying to

climb into the tumble dryer or hide things it, and animals getting into the drum.

Safety measures in the event of leaking refrigerant

The heat-pump coolant circuit contains a non-toxic, odourless refrigerant (R134a). If re-

leased into the atmosphere it is rapidly volatised. Because it is heavier than air it can displace oxygen and pose a danger of asphyxiation in small unventilated rooms!

9

Warning and Safety instructions

If any damage is found on the copper pipes on the heat-pump stop using the machine

and vacate the room.

– Warn other people present of the danger.

– Please see the safety data sheet for further information regarding the handling of this re-

frigerant.

– Call Miele Service.

Using accessories

Accessory parts may only be fitted when expressly approved by Miele. If other parts are

used, guarantee, performance and product liability claims will be invalidated.

Decommissioning the tumble dryer

Before disposing of a tumble dryer, render the door lock inoperable so that children can-

not lock themselves in the machine by mistake and endanger their lives.

Observe legal safety requirements regarding the disposal of refrigerants.

Miele cannot be held liable for damage caused by non-compliance with these Warning

and Safety instructions.

10

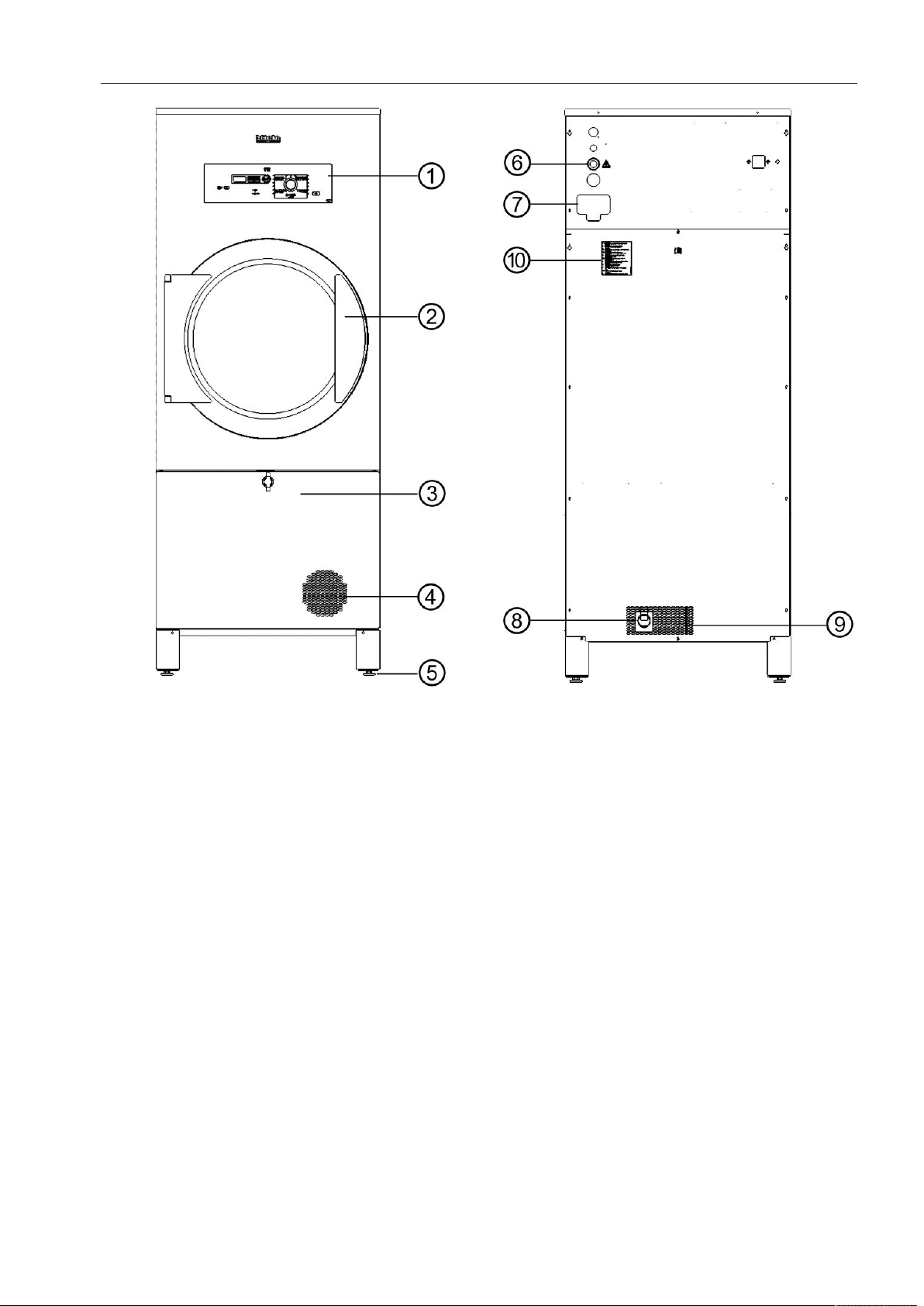

Description of the machine

a

Control panel

with controls

b

Drum door

Pull the door handle to open the drum

door. Never use force to open the door.

c

Fluff filter compartment cover

Turn the handle to open the fluff filter

compartment cover.

d

Air intake vent

e

Machine feet

Qty 4, adjustable

f

Electrical connection

with cable gland

g

Shaft for communication module

XKMRS232

Optional accessory

h

Condensate drainage

i

Air outlet vent

j

Data plate

11

Description of the machine

①

②

③

④

⑤

⑥

⑦

⑧

Delicates

20% moisture

10% moisture

Dry

A: Minimum iron

B: Cottons

Woolens

Timed drying - warm air Timed drying - cool air

40% moisture

25% moisture

20% moisture

Dry

Extra dry

a

"Residual moisture"/"Time left" display

Depending on programme this display

shows the residual moisture content as a

% or the time remaining in minutes. Once

a programme has started the actual residual moisture level will be shown until

the end of the programme. Faults will also

be shown in this display, see "Problem

solving guide".

b

"Programme sequence" display

The programme sequence is shown in

three stages. The current stage is highlighted in yellow.

Drying

Cooling down

End of programme / Anti-crease phase

c

"Low temperature" button

This button is used for reducing the drying temperature for sensitive textiles. The

LED lights up when the button is pressed.

d

Fault display

Lights up at the end of the programme if

the fluff filters or heat-pump require

cleaning.

Lights up if the programme is cancelled,

e.g. if a fault has been detected in the

heat-pump.

e

PC interface

For Service technician use.

f

"START/STOP" button

Press this button to start or stop a programme.

g

Rotary "Programme selector switch"

The rotary programme selector switch is

used for selecting the drying programme.

h

"On/Off" button

This button is used for switching the

tumble dryer on and off or for interrupting

a programme.

12

Drying

Laundry preparation

Not all textiles are suitable for drying in a tumble dryer. Please observe the symbols on the textile care label.

Symbols on care labels:

– dry with normal temperature.

– dry with low temperature

– do not tumble dry

Tip: For even drying results and to avoid damaging textiles sort the

laundry by fibre and weave.

Only dry items in this tumble dryer which have a care label stating

that they are suitable for tumble drying.

Machine drying unsuitable textiles poses a fire hazard.

The following textiles must not be tumble dried:

– Fabrics which contain a large proportion of rubber, foam rubber or

rubber-like materials.

Woollen or linen

textiles.

– Fabrics treated with inflammable cleaning agents.

– Items which have been splashed with hair lacquer, hair spray, nail

varnish remover or similar substances.

– Items soiled with oil, grease and similar residues e.g. kitchen linen

and linen used in beauty clinics.

– Items such as mop heads and cleaning cloths containing residual

wax or chemicals.

– Damaged items that contain fillings, e.g. pillows and jackets.

– Textiles that are soiled with grease or oils that have not been ad-

equately washed. Use a heavy-duty detergent for very heavily

soiled items (e.g. workwear). Seek the advice of the detergent manufacturer for advice if necessary.

Woollen items and textiles containing wool have a tendency to felt.

Use the "Woollens" programme only for woollen items and textiles

containing wool.

Pure linen has a tendency to roughen if tumble dried.

Please follow the manufacturer's instructions on the care label.

13

Drying

Important notes about drying

Protect the drum from damage (scratches and dents).

Before placing items in the tumble dryer wrap any large metal parts

such as buckles, hooks, clasps and zips etc. with a cloth.

Items with closed metal zips can cause the moisture sensing electrodes in the drum ribs to be bridged. This can lead to the drying process running on for too long or to not finish at all.

Dry these items with the zip open.

Loopknit and woven textiles (e.g. t-shirts) have a tendency to shrink

depending on quality. This can be made worse by over-drying.

Do not use the "Cottons Extra Dry" programme for these items.

Starched laundry can be machine dried. Select the most appropriate

programme for ironing by hand.

Sort the laundry according to the level of dryness required.

It is not necessary to sort according to size.

Small items can find their way into duvet covers and pillow cases

during the drying programme.

Close or fasten duvet covers and pillow cases before drying them.

Underloading is uneconomical. Overloading will impair the drying result and the laundry finish.

Dry using the maximum load for the programme whenever possible.

Rinse laundry in the washing machine using hot water in the final

rinse.

This reduces the residual moisture level and maintains heat in the

laundry which helps keep processing time down, thus saving energy.

14

Before using for the first time

Drying

Commission the machine

Before commissioning the machine clean the

drum.

Load the laundry

The tumble dryer must be installed and commissioned by a Miele

technician or Miele authorised service dealer only.

The drum must be cleaned before laundry is placed in the drum.

Wipe the inside of the drum with a soft, dry cloth.

Switch the tumble dryer on

Switch the machine on at the on-site mains switch.

Press the button.

Open the drum door.

Load the laundry.

Unfold the pre-sorted laundry and place loosely into the drum.

Make sure that any dispensing aids such as detergent balls have

been removed from the laundry.

Close the drum door.

Be careful not trap any items in the door when closing it.

Trapped items can get damaged.

Load capacities (dry weight)

PT 8203 SL WP

Drum volume 200 litres

Cottons

Load capacity 8-10 kg

Minimum iron

Load capacity 6 kg

Delicates

Load capacity 2 kg

Woollens

Load capacity 5 kg

15

Drying

Dry

10% moisture

20% moisture

Delicates

Woollens

Timed drying - warm air

A: Minimum iron

Timed drying - cool air

20% moisture

Dry

Extra dry

25% moisture

40% moisture

B: Cottons

Selecting a programme

A

Minimum iron

For drying synthetic and mixed fibre textiles.

B

Cottons

For drying cotton and linen textiles.

Drying

Dry to 0% residual moisture.

Extra dry

Dry to 0% residual moisture + 10minutes drying time.

10% moisture

Dry to 10% residual moisture.

20% moisture

Dry to 20% residual moisture.

25% moisture

Dry to 25% residual moisture.

40% moisture

Dry to 40% residual moisture.

Delicates

Dry synthetic and artificial silk to 20% residual moisture.

Woollens

5minute drying cycle.

Timed drying warm air

30minutes drying at a high temperature.

16

Timed drying cold

15minute duration for airing textiles.

Drying

Select a programme

Use the "Programme selector" to select your programme.

The LED next to the programme selected will light up. The programme is now set.

The segment display will then either show the residual moisture level

as a % or the time remaining in minutes.

Lowering the temperature

When drying delicate fabric press the "Low temperature" button.

Press the "START/STOP" button.

The segment display will then show the residual moisture content in

the laundry until the programme finishes.

Drying

The "Programme sequence" display shows the programme sequence in three stages. The appropriate field lights up in yellow.

Cooling down

Programme finished/Anti-crease

At the end of the programme

At the end of the programme a buzzer will sound and "0" will appear

in the segment display.

This is followed by a cooling-down phase.

Drying

If laundry is not removed as soon as the programme finishes, the

anti-crease phase will begin. The drum will rotate at brief intervals to

keep the laundry from creasing.

Cooling down

Programme finished/Anti-crease

17

Drying

After the end of a programme

Open the drum door.

If the drum door is left closed, the dryer will start up again for a brief

period every 30 minutes for safety reasons.

Unload the tumble dryer.

Make sure nothing is left in the drum. If items are left in the drum,

they could be damaged by overdrying when the tumble dryer is next

used.

Clean the fluff filters after each drying programme.

Trip hazard when the fluff filter compartment cover is open!

Make sure it is closed properly.

Interrupting a programme

The programme can be interrupted by:

Pressing the button.

Opening the drum door.

Opening the fluff filter compartment cover.

Danger of hot laundry.

Hot laundry can self-ignite and cause a fire when folded or put

away.

Do not unload laundry from the drum until the programme has fin-

ished, i.e. not until the cooling down phase has finished.

To continue the programme:

Press the button.

Close the drum door or the fluff filter compartment.

The time remaining or the required residual moisture level will flash in

the segment display, and a cooling-down phase will follow on at the

end of the programme.

Press the "Start/Stop" button.

18

Drying

Adding or removing individual

items

To continue the

drying programme

To switch the tumble dryer off

Caution when adding or removing laundry after a programme

has started!

Do not reach into a rotating drum to remove laundry. Danger or serious injury to fingers, hands and arms.

Always make sure that the drum is stationary before reaching in to

remove laundry.

Do not touch the drum whilst it is still rotating.

Close the drum door.

The remaining drying time or the target residual moisture level will

flash in the segment display.

The fan will switch itself on automatically for safety reasons if the

temperature in the drum is too high.

Press the "Start/Stop" button.

The programme will continue.

If no more laundry is to be processed:

Close the drum door.

Press the button.

The tumble dryer switches off.

Switch off at the on-site mains electricity switch.

19

Reprogramming

Changing standard options

Tip: Individual drying programmes can be altered to suit specific re-

quirements, practices and processes.

Before you start, first ensure that:

– the tumble dryer has been switched off with the switch.

– the door is closed.

To access programming level

Go to programming level

To select a programmable function

To change a programmable option

Press and hold the/ button and switch the tumble dryer on

with the button.

Hold the / button pressed in until the illuminated light around

the switch stops flashing and lights up constantly.

Then release the /button.

will flash alternately with in the segment display.

There are two ways of selecting programmable functions P1-P27

(See "Programmable functions" chart).

Select programmable functions P1-P27 by turning the rotary se-

lector clockwise (to the right).

Or select programmable functions P1-P27 by pressing the "Low

temperature" button.

You can now alter the programmable option, see the "Programmable

functions" chart .

Select the programmable option e.g. or with the/ button.

To check which programmable function you are currently in you

need to check the "Low temperature" LED on residual moisture controlled machines (ProfitronicBPlus machines): a short flash represents one unit, a long flash represents ten units.

20

With programmable functionP5 the LED will flash rapidly five times.

With programmable function P10 the LED will flash slowly once.

With programmable function P27 the LED will flash slowly twice and

rapidly 7 times.

Example of reprogramming

Reprogramming

To alter the buzzer at the end of a programme

Reprogramming for the visually impaired

Make sure you are in programming level to select the programmable

functionP2.

Turn the rotary programme selector one click clockwise.

The "low temperature" LED will flash briefly twice.

will flash alternately with in the segment display.

Programmable option Off and On.

Press the "START/STOP" button to change the option to .

The buzzer at the end of the programme is now deactivated. The

buzzer indicating a fault remains active.

Switch the tumble dryer off with the button.

The change is now saved to memory.

Go to programming level. The programmable options need to be

changed for P3 Memory function and P4 Acoustic keypad tones

(see also "Programmable functions" chart).

Turn the "Programme selector" two clicks clockwise to P3 Memory

function.

The "Low temperature" LED will flash rapidly 3 times.

will flash alternately with in the segment display.

Programmable option Off and On.

Press the "START/STOP" button to change the option to .

The Memory function is no longer active i.e. after the end of a programme the machine will always run the pre-set "Extra dry" programme the next time it is used.

Turn the "Programme selector" three clicks clockwise to P4

Acoustic keypad tones.

The "Low temperature" LED will flash rapidly 4 times.

will flash alternately with in the segment display.

Programmable option Off and On.

Press the "START/STOP" button to change the option to .

"Acoustic keypad tones" are now switched on.

Switch the tumble dryer off with the button.

The change is now saved to memory.

21

Reprogramming

Programmable functions

No. Programmable function Programming option Factory default

P 1 Buzzer volume 0 = Buzzer quiet

P 2 Buzzer at end of programme and/or in the event of a

fault

P 3 Memory function 0 = off

P 4 Acoustic keypad tones 0 = off

P 5 Conductivity setting 0 = normal

P 6 Function cannot be used 1

P 7 Cottons and Timed drying cool/warm

Drum reversing on (0 to 99 sec.)

P 8 Cottons and Timed drying cool/warm

Drum reversing off (3 to 99 sec.)

P 9 Minimum iron

Drum reversing on (0 to 99 sec.)

P 10 Minimum iron

Drum reversing off (3 to 99 sec.)

P 11 Woollens duration

(1 to 99 min.)

P 12 Woollens programme

Drum reversing on (0 to 99 sec.)

P 13 Woollens drum reversing off

(3 to 99 sec.)

P 14 Delicates drum reversing on

(0 to 99 sec.)

P 15 Timed drying cool air

(1 to 99 min.)

P 16 Timed drying warm air

(1 to 99 min.)

P 17 Timed drying warm air

(1 to 99 min.)

P 18 Function cannot be used 0

1 = Buzzer loud

0 = not used

1 = at end of programme or when there is a fault

2 = only for faults

3 = only at end of programme

4 = not used

1 = on

1 = on

1 = low (<150yS)

0 = 0sec.

99 = 99sec.

3 = 3sec.

99 = 99sec.

0 = 0sec.

99 = 99sec.

3 = 3sec.

99 = 99sec.

1 = 1min.

99 = 99min.

0 = 0sec.

99 = 99sec.

3 = 3sec.

99 = 99sec.

0 = 0sec.

99 = 99sec.

1 = 1min.

99 = 99min.

1 = 1min.

99 = 99min.

1 = 1min.

99 = 99min.

1

1

1

0

0

60

3

60

3

5

20

10

27

3

15

30

22

Reprogramming

No. Programmable function Factory

default

P 19 Residual moisture for prog. 1 Cottons Extra dry 2 -2 % -4 % 0 % -6 % -7 %

P 20 Residual moisture for prog. 2 Cottons Dry 2 0 % -2 % 2 % -4 % -6 %

P 21 Residual moisture for prog. 3 Cottons 20 % moisture 1 20 % 18 % 22 % 16 % 24 %

P 22 Residual moisture for prog. 4 Cottons 25 % moisture 1 25 % 23 % 27 % 21 % 29 %

P 23 Residual moisture for prog. 5 Cottons 40 % moisture 1 40 % 38 % 42 % 36 % 44 %

P 24 Residual moisture for prog. 9 Delicates 1 20 % 18 % 22 % 16 % 24 %

P 25 Residual moisture for prog. 10 Minimum iron 20 % moisture 1 20 % 18 % 22 % 16 % 24 %

P 26 Residual moisture for prog. 11 Minimum iron 10 % moisture 1 10 % 8 % 12 % 6 % 14 %

P 27 Residual moisture for prog. 12 Minimum iron Dry 1 0 % -2 % 2 % -4 % 4 %

Programming option

1 2 0 3 4

23

Problem solving guide

Trouble shooting

With the help of the following guide, minor faults in the performance of the machine, some

of which may result from incorrect operation, can be put right without contacting Miele

Service. This will save time and money.

The following guide may help you to find the reason for a fault, and to correct it. You

should, however, note the following:

Repair work to electrical appliances must only be carried out by an authorised person only. Repairs and other work by unqualified persons could be dangerous. The manufacturer cannot be held liable for unauthorised work.

What to do if...

Problem Cause and remedy

The display shows Problem with the heat pump.

Switch the tumble dryer off.

Wait until it has cooled down.

Make sure the ambient room temperature is below the

permitted temperature for the installation site of 43°C.

Open the fluff filter compartment and wipe any fluff of

both fluff filters with your hand.

Switch the tumble dryer back on.

Check whether the fault is still indicated in the display. It

will not show in the display when it has been rectified.

If the fault is still showing in the display, call Miele Ser-

vice.

The tumble dryer does not

start.

The fluff filter compartment is not properly closed.

Turn the fluff filter compartment handle clockwise as far

as it will go to lock it.

24

Problem solving guide

Service

In the event of a any faults please call Miele Service.

When contacting the Service Department, please quote the model, serial (SN) and material

(M.-Nr) numbers. These are shown on the data plate (visible when the door is open):

Please also pass on the error message appearing in the machine display to the Service

Department

Only use genuine Miele original spare parts. The Service department will also require

model, serial number(SN) and material number (M-Nr) when ordering.

Additional technical data for the machine is given on the data plate at the back of the machine.

25

Cleaning and care

Cleaning the tumble dryer

The tumble dryer must be switched off at the on-site mains switch

before any cleaning or maintenance work.

Danger of electrical shock and damage to components.

Do not use a pressure washer or hose pipe to clean the tumble

dryer.

Clean the machine casing, control panel and plastic parts with a

mild non-abrasive detergent or with a damp cloth only. Wipe dry

with a soft cloth.

The drum must be wiped clean with a damp cloth after drying items

that have been starched.

Scouring agents will scratch the surface.

Do not clean the tumble dryer with abrasive cleaning agents.

After cleaning, check the seals for any damage and make sure the

door and fluff filter compartment catches are clean and undamaged.

Tip: The area surrounding the tumble dryer, in particular around the

air inlet, must be kept free of dust and fluff at all times. If taken into

the dryer, they can cause faults with the machine.

26

Cleaning and care

Cleaning the fluff filters

A damaged fluff filter must be replaced before the machine is used

again.

The heat-pump and the airways can get blocked by fluff and lint.

This is a fire risk.

Never use the tumble dryer without the fluff filters in place.

This tumble dryer has two levels of fluff filtration. The 1st fluff filter is

located behind the fluff filter compartment cover (at the top). The

2nd fluff filter is below that one.

a

1st fluff filter

b

2nd fluff filter

c

Fluff filter compartment cover

d

Air intake vent

Open the fluff filter compartment

Clean both filters after every drying programme.

Fluff on the 1st filter (made of polyester) must be wiped off by hand

only.

Any other method of cleaning can damage the filter.

– The filters can be cleaned without taking them out.

– With high levels of fluff the fluff filters may need to be cleaned sev-

eral times during the day.

– The second level fluff filter can, if necessary, be cleaned using a va-

cuum cleaner.

27

Cleaning and care

Cleaning the filter behind the air inlet

The air inlet to the dryer is located at the front of the tumble dryer (d).

A fluff filter is located behind this air inlet which has to be cleaned

regularly.

The filter behind the air inlet prevent dust particles from the room

being drawn in by the fan. This filter must be checked daily and

cleaned when necessary.

Open the fluff filter compartment

Wipe fluff off the filter with your fingers. Do not let anything sharp or

pointed come into contact with it.

Do not cover the air intake at the front of the machine or place anything in front of it.

28

Installation and connection

Installation requirements

The tumble dryer must only be installed and commissioned by a

Miele service engineer or a Miele authorised Service dealer.

The tumble dryer must be installed in accordance with all relevant

regulations and standards.

This dryer must only be operated in a room that has sufficient vent-

ilation and which is frost-free.

General operating conditions

Permissible ambient temperature in installation room: +2°C to

+43°C.

Depending on the nature of the installation site, sound emissions and

vibration may occur.

Tip: Have the installation site inspected and seek the advice of a professional in instances where increased noise may cause a nuisance.

Removal of transport packaging

Transporting the machine

When transporting the dryer be aware of its total height.

Be careful when transporting it on a pallet truck that it does not tip

up.

Unscrew Torx screws (T20 and T30) from the wooden pallet and re-

move the wooden battens.

Lift the tumble dryer with a pallet truck and then fit the 4 adjustable

feet (supplied).

29

Installation and connection

Set up

Place the tumble dryer on a totally level, secure and horizontal sur-

face that is able to take the load of the machine (see "Technical

data").

The floor load created by the dryer is concentrated and transferred

to the installation footprint via the machine feet.

To ensure suitable access for further maintenance and service

work, please ensure the minimum distances between the machine

and any walls are maintained.

With the assistance of a spirit level align the dryer horizontally and

vertically by adjusting the height of the feet.

After aligning the tumble dryer tighten the counter nuts by turning

them in an anti-clockwise direction with a spanner. This will prevent

the feet from adjusting themselves.

After setting up the tumble dryer please let it stand for approx. 30

minutes before using it for the first time. If the heat-pump unit was

tilted by an angle exceeding 30° before the tumble dryer was set

up, or if it was subjected to excessive movement, please let the

dryer stand for 24hours before using it.

Otherwise the heat pump can suffer damage.

30

Installation and connection

Securing the machine

The tumble dryer can be secured to the floor by fitting the clamps

supplied over the feet.

Fittings supplied are for installation on a concrete floor. For other

types of flooring please purchase suitable fitting materials separately.

Fitting the programme card

A language specific programme card is supplied with the tumble

dryer that indicates the individual positions around the rotary selector. This card has to be fitted behind the fascia panel before the

machine is set up for the first time.

Peel the protective foil off the control panel.

Carefully lift up the lower part of the control panel foil underneath

the programme selector dial.

Push the programme card in underneath the control panel foil and

align it.

Remove the dividers located underneath it and press the control

panel foil back in at the bottom.

31

Installation and connection

Electrical connection

The electrical connection must be carried out by a qualified electrician who must ensure that all electrical work is carried out in accordance with applicable electrical regulations and standards (BS

7671 in the UK).

The electrical connection may only be made to an electrical system

provided in accordance with all appropriate local and national legislation and regulations. In addition, all regulations of the appropriate utility supply companies and standards relating to safety, and all applicable valid regulations and technical standards must be complied with!

Reliable and safe operation of this tumble dryer can only be as-

sured if it has been connected to the mains electricity supply.

The required voltage, power consumption and fuse rating are

quoted on the data plate on the tumble dryer. Ensure that the supply voltage complies with the voltage quoted on the data plate before connecting the tumble dryer to the mains.

Connection to a supply voltage other than the one quoted on the

data plate can lead to functional faults and damage to the tumble

dryer.

If more than one voltage is quoted on the data plate, the tumble

dryer can be converted for connection to the voltages stated. Conversion to a different voltage must only be carried out by a Miele Service engineer or by an authorised Miele Service dealer. The wiring information given on the wiring diagram must be followed. Settings for

heater ratings in the machine must also be observed and adapted as

necessary.

This dryer can either be hard-wired or connected via a plug and

socket that complies with IEC60309-1.

For hard-wired machines connection should be made via a suitable

mains switch with all-pole isolation which, when in the off position,

ensures a 3 mm gap between all open contacts. These include circuit breakers, fuses and relays (IEC/EN60947).

If the mains supply cannot be permanently disconnected, the isolator

switch (including plug and socket) must be safeguarded against being switched on either unintentionally or without authorisation.

Tip: We recommend connection to the power supply via a suitable IP

44 plug and socket which must be easily accessible for servicing and

maintenance work after the machine has been installed. An electrical

safety test must be carried out after installation and after any service

work.

32

The machine must not be connected to devices such as timers

which would switch it off automatically.

Installation and connection

Air intake vent

Air intake for the condenser is via an air intake vent at the front of

the dryer. Air is taken from the room in which the dryer is installed.

A fluff filter is located in the air intake vent in the dryer. This must be

regularly cleaned by hand.

The air intake vent must be kept clear. It must not be covered.

Air outlet vent

Because the heat-pump dryer operates with a closed air circuit, separate exhaust ducting is not required.

The warm air expelled from the machine as a result of cooling down

the heat-exchanger warms the room air. It is essential to ensure the

room has adequate ventilation, e.g. by providing ventilation openings

that cannot be closed whilst the machine is in use. Insufficient ventilation in the room increases the time required for drying, which in turn

will increase the amount of energy required for the drying process.

The ventilation openings must, on no account, be closed or

blocked by objects.

Condensate drainage

The heat-pump in this dryer operates on the principle of condensation. A separate floor drain must be provided in the installation room

for condensate from the drying process.

The condensate drainage point is located at the back of the heatpump dryer. The condensate must be drained via a downwards pointing pipe to the floor drain. Condensate must not be able to flow back

into the machine.

33

Installation and connection

Communication module XKM RS232

The serial interface RS-232 can be retrofitted to the tumble dryer via

an XKMRS232 (optional accessory available from Miele). This communication module must only be used with MieleProfessionalmachines that are fitted with an appropriate slot for the module.

The data interface provided via communication module

XKMRS232 complies with SELV (Safety Extra Low Voltage) in accordance with EN60950.

Appliances connected to this interface must also be SELV compliant.

Communication module XKMRS232 is supplied with a connection

cable and a D-sub-connector.

34

Installation and connection

Technical data

Electrical connection

Voltage See data plate

Frequency See data plate

Total connected load See data plate

Current draw See data plate

Heater rating See data plate

Fuse rating See data plate

Installation data

Overall machine width 711 mm

Overall machine height 1800 mm

Overall machine depth 1075 mm

Casing width (without add-on components) 708 mm

Casing height (without add-on components) 1800 mm

Casing depth (without add-on components) 999 mm

Machine weight (net) 202 kg

Max. floor load in operation 2220 N

Minimum width of loading aperture (internal width) 725 mm

Recommended distance between front of machine and the wall 1500 mm

Emissions

Average heat dissipation rate to installation site 650 W

A-weighted noise power level in accordance with EN ISO 9614, part 2 71 dB (A)

A-weighted sound pressure level in accordance with EN ISO 11204, workplace-related 57 dB (A)

35

Miele & Cie. KG, Carl-Miele-Straße 29, 33332 Gütersloh, Germany

Manufacturer:

Malaysia

Miele Sdn Bhd

Suite 12-2, Level 12

Menara Sapura Kencana Petroleum

Solaris Dutamas No. 1, Jalan Dutamas 1

50480 Kuala Lumpur, Malaysia

Phone: +603-6209-0288

Fax: +603-6205-3768

Miele New Zealand Limited

IRD 98 463 631

8 College Hill

Freemans Bay, Auckland 1011, NZ

Tel: 0800 464 353

Internet: www.miele.com.au/professional

E-mail: info@miele-professional.com.au

New Zealand

Miele Pte. Ltd.

29 Media Circle, #11-04 ALICE@Mediapolis

Singapore 138565

Tel: +65 6735 1191, Fax: +65 6735 1161

E-Mail: info@miele.com.sg

Internet: www.miele.sg

Singapore

Miele (Pty) Ltd

63 Peter Place, Bryanston 2194

P.O. Box 69434, Bryanston 2021

Tel: (011) 875 9000, Fax: (011) 875 9035

E-mail: info@miele.co.za

Internet: www.miele.co.za

South Africa

Miele Appliances Ltd.

Showroom 1, Eiffel 1 Building

Sheikh Zayed Road, Umm Al Sheif

P.O. Box 114782 - Dubai

Tel. +971 4 3044 999, Fax. +971 4 3418 852

800-MIELE (64353)

E-Mail: info@miele.ae, Website: www.miele.ae

United Arab Emirates

United Kingdom

Miele Co. Ltd., Fairacres, Marcham Road

Abingdon, Oxon, OX14 1TW

Professional Sales, Tel: 0845 365 6608

E-mail: professional@miele.co.uk

Internet: www.miele.co.uk/professional

Miele Australia Pty. Ltd.

ACN 005 635 398, ABN 96 005 635 398

1 Gilbert Park Drive, Knoxfield, VIC 3180

Tel: 1300 731 411

Internet: www.miele.com.au/professional

E-mail: info@miele-professional.com.au

Australia

Miele Electrical Appliances Co., Ltd.

1-3 Floor, No. 82 Shi Men Yi Road

Jing' an District, 200040 Shanghai, PRC

Tel: +86 21 6157 3500, Fax: +86 21 6157 3511

E-mail: info@miele.cn, Internet: www.miele.cn

China Mainland

Miele (Hong Kong) Ltd.

41/F - 4101, Manhattan Place

23 Wang Tai Road, Kowloon Bay, Hong Kong

Tel: (852) 2610 1025, Fax: (852) 3579 1404

Email: customerservices@miele.com.hk

Website: www.miele.hk

Hong Kong, China

Miele India Pvt. Ltd.

Ground Floor, Copia Corporate Suites

Plot No. 9, Jasola, New Delhi - 110025

Tel: 011-46 900 000, Fax: 011-46 900 001

E-mail: customercare@miele.in, Internet: www.miele.in

India

Miele Ireland Ltd.

2024 Bianconi Ave., Citywest Business Campus, Dublin 24

Tel: (01) 461 07 10, Fax: (01) 461 07 97

E-Mail: info@miele.ie, Internet: www.miele.ie

Ireland

Alteration rights reserved / Publication date: 35.20

M.-Nr. 10 534 650 / 01

Loading...

Loading...