Page 1

Installation Instructions

Gas Cooktops

KM 342

KM 344

To prevent accidents and

machine damage,

read these instructions

before installation or use.

®

UV

M.-Nr.

®

05 649 320

Page 2

WARNING:

If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury or death.

Do not store or use gasoline or other flammable

–

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

–

ß Do not try to light any appliance.

ß Do not touch any electrical switch.

ß Do not use any phone in your building.

ß Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

ß If you cannot reach your gas supplier, call the

fire department.

– Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

(In Massachusetts a licensed plumber/gasfitter)

–

Note to the installer:

Please leave this instruction book with the con

-

sumer for the local electrical/gas inspector’s use.

2

Page 3

Contents

Important safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Appliance dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Setting the cooktop into place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Gas pressure regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Nominal Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Converting to LP gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

To convert the regulator: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

To convert the burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Changing the needle valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Changing the orifices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Check the intake air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

After conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3

Page 4

Important safety instructions

Installation

The minimum distances given in

these Installation Instructions must

be observed in order to ensure safe

operation. Failure to do so increases

the risk of fire.

The countertop must be bonded

with heat resistant (212 °F/100 °C)

adhesive to prevent distortion or dis

solving.

-

fig. 1 recommended

Deep fat fryers must not be in

stalled next to gas cooktops. Gas

flames can ignite splattering oil. A distance of at least 12" (305 mm) should

be maintained between these two appliances. The mimimum distance between two cooktops must be 4"

(10 cm).

The cooktops should only be in-

stalled as shown in Figs. 1 & 2,

while maintaining the required safety

distances shown. Do not install the

cooktop between two tall cabinets as

this is a fire hazard.

a = minimum distance between

cooktop and a tall cabinet:

12" (300 mm)

Cooktops should not be installed

above a dishwasher, washer, dryer,

freezer or refrigerator. The heat gener

ated by cooktops could damage these

appliances.

-

fig. 2 possible but not recommended

fig.3 not allowed

4

Page 5

Important safety instructions

Gas appliances should only be in

stalled in a well ventilated area.

Install the appliance so that the

power cord or gas piping does not

come into contact with any portion of

the cooktop which may become hot

during use.

This appliance must be installed

with its own shut off valve and the in

cluded gas pressure regulator. Both

the valve and the regulator must be

easily accessible to the consumer to

turn on or shut off the gas supply af

ter the appliance is installed.

This appliance must be disconnected from the gas supply during

any pressure testing of that system

performed in excess of

1 / 2 psi

(3.5 kPa), or isolated at test pressures equal to or less than

1 / 2 psi

(3.5 kPa).

Any pipe connections must be made

using a thread sealant approved for

gas connections. Failure to correctly

install these items could lead to a

gas leak and subsequent explosion.

Safety distance above the appliances

-

-

As a general rule there must be at least

30 inches (762 mm) between the top of

the appliance and any cabinet above it,

b. If the cabinet manufacturer recommends a greater distance, follow that

manufacturer’s recommendation.

The maximum depth, c, of cabinets installed above a cooktop must not exceed 13" (330 mm).

When installing the cooktop under a

venting hood, always observe the minimum safety distance recommended by

the hood manufacturer.

Keep this instruction book in a safe

place for future reference and pass it

on to any future owner.

5

Page 6

Appliance dimensions

KM 342

3/8"

(9mm)

3 / 8 "

3

(86mm)

5/16"

21

(542mm)

36"

(914mm)

b

3 / 8 "

3

(86mm)

* max.R 3/16

(max.R4 mm)

a Built-in depth

"

3 / 4 "

2

(min.70mm)

35"

(889mm)

3 / 8 "

20

(518mm)

25"

(min.635mm)

1

7 / 8

”

(min.47mm)

6

Page 7

KM344

3/8”

(9mm)

3 / 8 "

3

(86mm)

* max.R 3/16"

(max.R4mm)

5 / 1 6 "

21

(542mm)

41

1 / 2 "

(1054mm)

Appliance dimensions

a

3/ 8"

3

(86mm)

1 / 2 "

42

(1079mm)

3 / 4 "

2

(min.70mm)

3 / 8 "

20

(518mm)

a Built-in depth

”

7 / 8

1

(min.47mm)

25”

(min.635mm)

7

Page 8

Installation

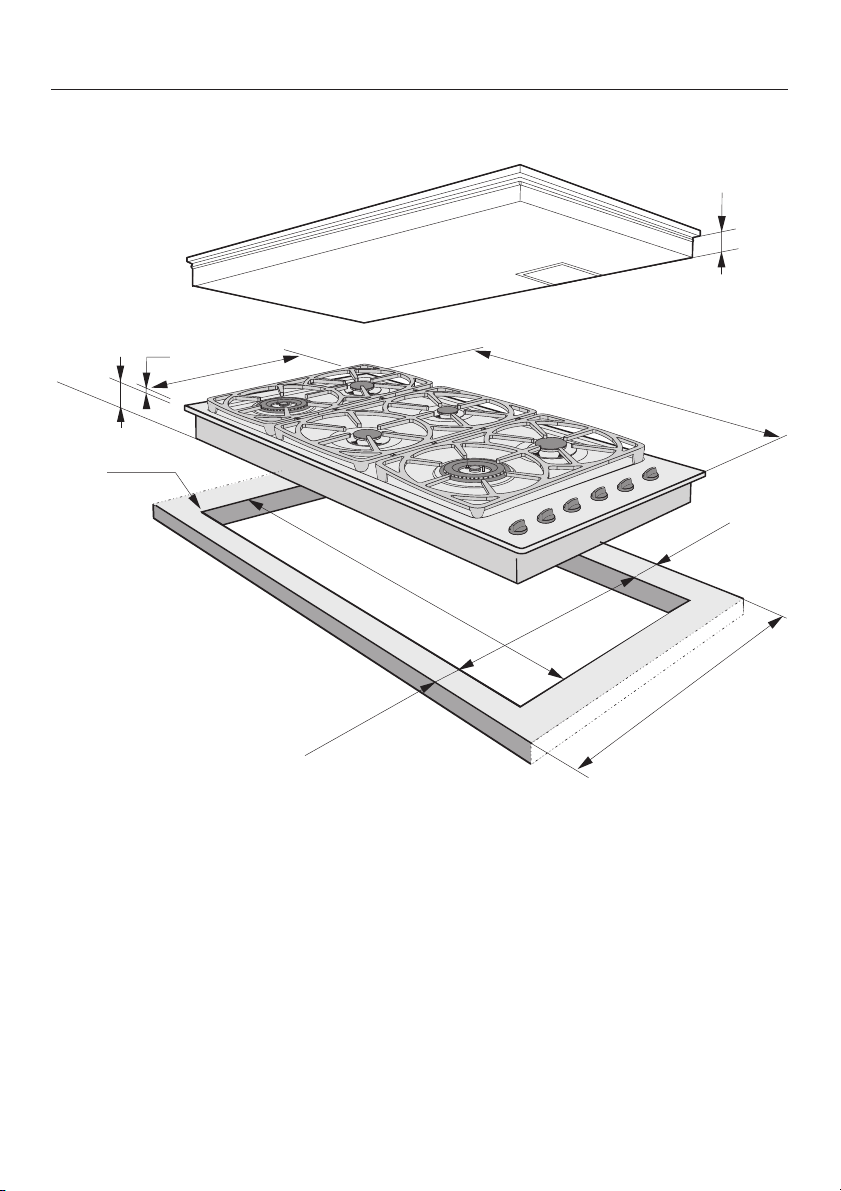

Setting the cooktop into place

e

d

Remove the protective backing, d,

^

from the seal, c, supplied and stick it

under the edge of the cooktop.

Screw the gas regulator onto the nip

^

ple at the rear of the cooktop. (See

"Gas Connection" for more guid

ance).

Feed the power cord through the

^

cut-out to the power outlet.

Set the cooktop in the cut-out and

^

center it.

Install the appliance so that the

power cord or gas piping does not

come into contact with any portion of

the cooktop which may become hot

during use.

-

-

8

Page 9

Installation

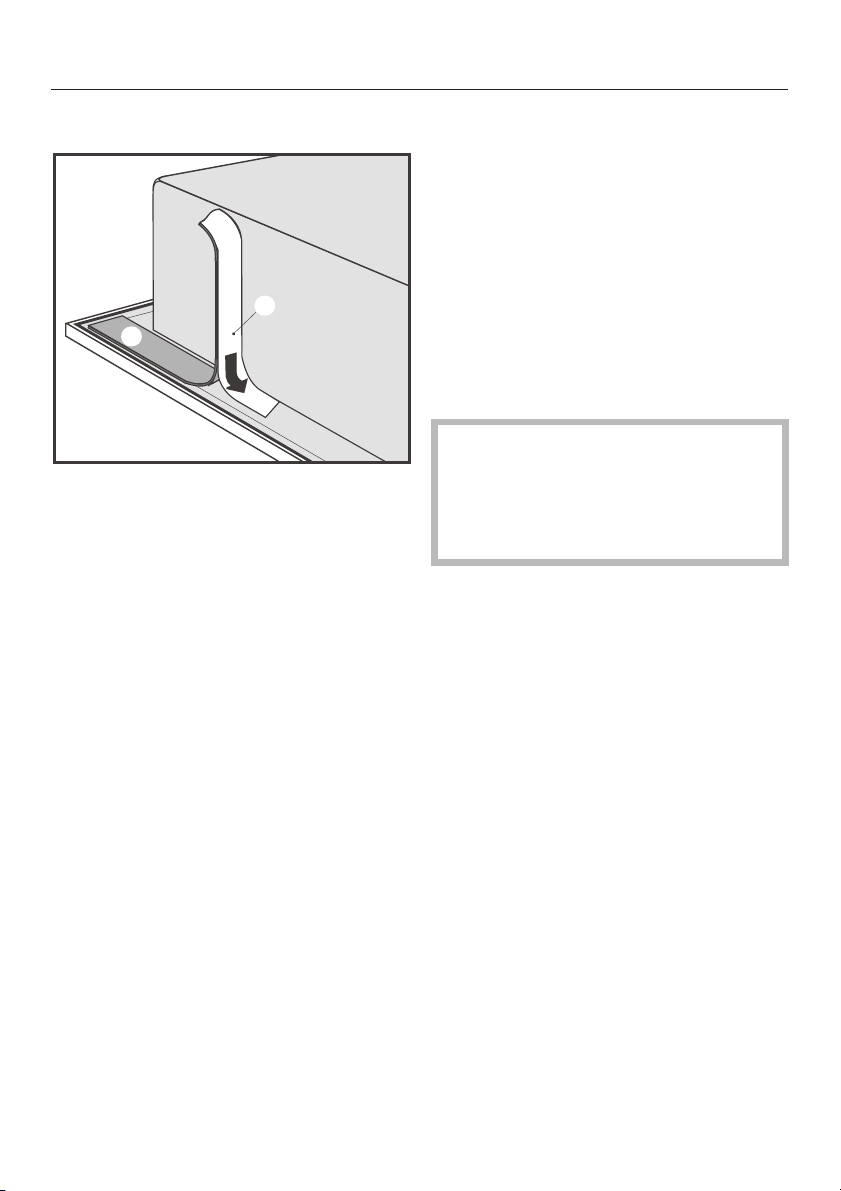

The cooktop must not be perma

nently sealed into the countertop

when installed.

If the cooktop is sealed into position,

the countertop or appliance could be

damaged if the cooktop needs to be re

moved for maintenance or service. The

sealing strip under the edge of the top

part of the cooktop provides a sufficient

seal for the countertop.

-

-

9

Page 10

Electrical connection

This appliance must be electrically

grounded according to local or na

tional codes.

All electrical work should be per

formed by a qualified electrician in

accordance with local codes and

with the

- National Electrical Code

ANSI / NFPA No. 70

for the USA

or

- Canadian Electrical Code Part I

for Canada

(CSA Standard C 22.1)

WARNING:

Disconnect the appliance from the main

power supply before installation or service. To reduce the risk of electric

shock, make sure that the appliance is

properly grounded after installation.

Power supply:

The automatic ignition requires that the

cooktop be connected to a 120 VAC,

60 Hz power supply. The supply line

should be protected by a 15A fuse.

Actual power consumption (during igni

tion only) is 25W.

-

-

This appliance is equipped with a

three-prong grounding plug to pre

vent shock hazards. It should be

plugged directly into a properly

grounded outlet. Do not cut or re

move the grounding prong from the

plug. If the plug does not fit the out

let, have the proper outlet installed

by a licensed electrician.

To guarantee the electrical safety of

this appliance, continuity must exist

between the appliance and an effective grounding system. It is imperative that this basic safety requirement be met. If there is any doubt,

have the electrical system of the

house checked by a qualified electrician.

The manufacturer cannot be held responsible for damages caused by

the lack, or inadequacy of, an effective grounding system.

Note to the installer:

Please leave these instructions with the

consumer or the appliance.

-

-

-

-

This appliance is equipped with a 4 ft.

(1.2 m) long power cord that is ready

for connection to the appropriate outlet.

Please place the power outlet so that it

is accessible after the appliance has

been installed in the countertop.

10

Page 11

Wiring diagram

Electrical connection

11

Page 12

Gas connection

Installation and service must be per

formed by a qualified installer, ser

-

vice agency or the gas supplier.

In Massachusetts a licensed

plumber/gasfitter is required.

This appliance must be installed

with its own shut off valve and the in

cluded gas pressure regulator. Both

the valve and the regulator must be

easily accessible to the consumer to

turn on or shut off the gas supply af

ter the appliance is installed.

This appliance and its individual

shut off valve must be disconnected

from the gas supply during any

pressure testing of that system performed in excess of

1

/2psi (3.5 kPa),

or isolated from the gas supply line

by closing its individual manual shut

off valve at test pressures equal to or

less than

1

/2psi (3.5 kPa).

-

The gas connection must be made

in accordance with local codes or, in

the absence of local codes, with

- the National Fuel Gas Code,

ANSI Z 223.1/NFPA 54

for the USA

or

- the current Can/CGA B 149.1

and .2 Installation Codes for gas

burning appliances for Canada.

-

Any pipe connections must be made

using a thread sealant approved for

gas connections. Failure to correctly

install these items could lead to a

gas leak and subsequent explosion.

12

Page 13

Gas connection

Make sure that the maximum gas sup

ply pressure before the gas pressure

reguator is never more than

1

/2psi for

both natural gas or LP gas.

The minimum required gas pressure to

get the required gas input is

1

5

/2" w.c. for natural gas

11" w.c. for LP gas.

-

KM 342

11/16

2

(68mm)

KM 344

5/8

1

(41mm)

FRONT

FRONT

FRONT

10

(269mm)

FRONT

9/16

7/16

8

(214mm)

13

Page 14

Gas connection

Gas pressure regulator

A pressure regulator that is convertible

from natural to LP gas (Propane) is in

cluded with the appliance. The ad

justed pressure is for:

natural gas - 4" w.c.

LP gas - 10" w.c.

½ " NPT

gas cooktop

use pipe

regulator (included)

As shown in the above diagram, the included regulator must be used when

connecting the Miele cooktop to your

gas supply. This item has been custom

ized by Miele to meet all applicable

safety requirements. Make sure the reg

ulator is easily accessible for adjust

ment after the appliance has been in

stalled.

-

-

dope

-

-

Do not use any regulator unless it

has been supplied by Miele. Doing

so may cause a gas leak.

If there is any doubt concerning instal

lation contact the Miele Technical Ser

vice Department at:

USA 1-800-999-1360

techserv@mieleusa.com

CDN 1-800-565-6435

service@miele.ca

After connecting the appliance check

all fittings for gas leaks e.g. with

soapy water.

When installed properly, the flame will

be steady and quiet. It will also have a

sharp, blue inner core that will vary in

length proportional to the burner size.

Flame adjustment will not be necessary.

-

-

-

-

For convenience, an AGA or CGA ap

proved flexible stainless steel gas hose

(accordion type) may be used between

the gas connection and the regulator.

This will allow the appliance to be lifted

out of the countertop for cleaning or

servicing. Make sure that any drawers,

cabinet doors, etc., do not rub on this

gas hose.

14

Page 15

Gas connection

Nominal Rating Table

KM 342 G KM 344 G

NG / LP-Gas NG / LP-Gas

Normal burner BTU/hr kW BTU/hr kW

Max. output 9.000 2.6 9.000 2.6

Min. output 1.700 0.50 1.700 0.5

Fast burner

Max. output 12.000 3.5 12.000 3.5

Min. output 2.500 0.75 2.500 0.75

Wok burner left

Max. output 15.300 4.5 15.300 4.5

Min. output 620 0.18 620 0.18

Wok burner right

Max. output 15.300 4.5 16.500 4.8

Min. output 620 0.18 620 0.18

All burners

Max. output 60.600 17.7 73.800 21.5

15

Page 16

Converting to LP gas

All cooktops come set for connection to

either natural gas or LP gas. The ad

justment of the included regulator cor

responds with the gas type of the

cooktop. If the appliance is to be con

nected to LP gas, both the regulator

and burners must be converted.

WARNING

The conversion kit must be in

stalled by a qualified technician in

accordance with the manufac

turer’s instructions and all appli

cable local and national codes. If

the information in these instructions is not followed exactly, a fire,

explosion or production of carbon

monoxide may result causing

property damage, personal injury

or loss of life. The qualified technician is responsible for the proper

installation of this kit. The installation is not proper and complete

until the operation of the converted appliance is checked as

specified in the instructions sup

plied with the conversion kit.

-

-

-

-

-

-

-

To convert the regulator:

Unscrew the hexagonal silver cap lo

–

cated on the top of the regulator.

Make sure that the spring stays in

–

place.

Flip it over and screw it back in

–

place. A stamp should be visible on

top of the cap or at the bottom of the

center hole when converted ("LP" for

LPG and "NG" for Natural gas).

-

16

Page 17

Converting to LP gas

To convert the burners

Turn off the main gas supply (if the

appliance has already been in

stalled) and disconnect the appli

ance from the main electrial power

supply before proceeding.

The following orifices and needle valves

should be installed into their respective

burners.

Conversion table KM 342

Code Orifice

Normal

burner

Fast burner 167 1.67 78 0.78

Wok burner

inner

outer

Normal

burner

Fast burner 103 1.03 45 0.45

Wok burner

inner

outer

140 1.40 62 0.62

190

109

size

(Ø mm)

Natural gas

34

No. 34

1.904088

Propane (LP)

90 0.90 41 0.41

7

No. 7

1.092554

-

-

Code Needle

valve

size

(Ø mm)

0.40

0.88

0.25

0.54

Conversion table KM 344

Code Orifice

Natural gas

Normal

burner

Fast burner 167 1.67 78 0.78

Wok burner

left

inner

outer

Wok burner

right

inner

outer

Normal

burner

Fast burner 103 1.03 45 0.45

Wok burner

left

inner

outer

Wok burner

right

inner

outer

140 1.40 62 0.62

34

No. 34

190

34

No. 34

195

Propane (LP)

90 0.90 41 0.41

7

109

7

112

Code Needle

size

(Ø

mm)

1.904088

1.954088

No. 7

1.092554

No. 7

1.122554

(Ø mm)

valve

size

0.40

0.88

0.40

0.88

0.25

0.54

0.25

0.54

Save the orifices and needle valves re

moved from the appliance for future

use.

-

17

Page 18

Converting to LP gas

To change the orifices and needle

valves the appliance has to be opened

by removing the burners.

Normal/Fast burner

b

f

g

^ Remove the grates and the burner

cap, b.

^ Loosen the screws, f, and take off

the burner base, g.

Wok burner

^ Remove the grates, the small burner

cap, b, the large burner cap, c, the

burner ring, d, and the burner base,

e.

18

^

Loosen the screws, f.

^

When all burners have been taken

off, pull all control knobs off of the

cooktop.

Now the top of the appliance can be

taken off.

Page 19

Changing the needle valves

Converting to LP gas

Normal/Fast burner

a

b

^ Take off the ignition switch, a.

^ Loosen the needle valve, b, with a

screwdriver and remove them with a

pair of pliers.

^

Install the new needle valve accord

ing to the conversion table and

tighten.

Wok burner

^ Take off the ignition switch, a.

^ Loosen the needle valves, b,

(smaller diameter) and, c, (larger diameter) with a screwdriver and re

-

move them with a pair of pliers.

^

Install the new needle valves accord

ing to the conversion table and

tighten.

-

-

19

Page 20

Converting to LP gas

Changing the orifices

Normal/Fast burner

Using a 7mm nut driver or socket

^

wrench, unscrew the orifice.

Install the new orifice according to

^

the conversion table.

Wok burner

20

^

Use a 10 mm wrench to remove the

orifice. While doing this, use a 13 mm

wrench to hold the gas tube to pre

vent it from twisting.

^

Screw in the new orifice using the

same procedure.

-

Page 21

Converting to LP gas

Changing the small burner orifice

g

f

b

c

d

efg

1

/

"

16

(2mm)

d Small burner orifice

e Air sleeve

f Air vent

First, loosen fitting, c, using an 8 mm

^

wrench. Hold nut, b, with a 12 mm

wrench while doing this to prevent

the tubing from twisting.

Then remove fitting, b, from fitting,

^

a, by using two 12 mm wrenches.

Remove the orifice, d, and replace it

^

with the new orifice.

Rotate the air sleeve, e, until there is

^

1

a

/16" (2 mm) gap between the

sleeve and the air vent, f, as shown.

Reassemble the burners and test the

^

unit for leaks. It can be operated

without the upper cover in place by

igniting the flames with a match.

21

Page 22

Converting to LP gas

Check the intake air

a Lock screw

b Air sleeve

Gap X must measure:

1

–

/2" (13 mm) for natural gas

1

–

/4" (6.5 mm) for LP gas

To adjust the gap, loosen the lock

^

screw and slide the air sleeve in or

out as necessary.

Tighten the lock screw and reassem

^

ble the cooktop in the reverse order.

Check all fittings for gas leaks be

fore reassembling the cooktop.

-

-

22

Page 23

Converting to LP gas

After conversion

After converting the cooktop unit to

–

LP gas, stick the label supplied with

the conversion kit next to the data

plate underneath the appliance.

Check that the regulator has been

–

converted.

Check that there are no leaks e.g.

–

with soapy water.

Reassemble the appliance in reverse

–

order.

Check that the burner is correctly as

–

sembled.

– Turn on the gas supply.

– Light each of the burners in turn.

The flame should not go out when set

at "low" nor when the control knob is

quickly turned from "high" to "low".

When set at "high" the gas flame must

burn with the center clearly visible.

When installed properly, the flame will

be steady and quiet. It will also have a

sharp, blue inner core that will vary in

length proportional to the burner size.

Flame adjustment will not be necessary.

-

23

Page 24

Alteration rights reserved / 2702

This paper consists of cellulose bleached without the use of chlorine.

M.-Nr. 05 649 320 / V

02

Loading...

Loading...