Page 1

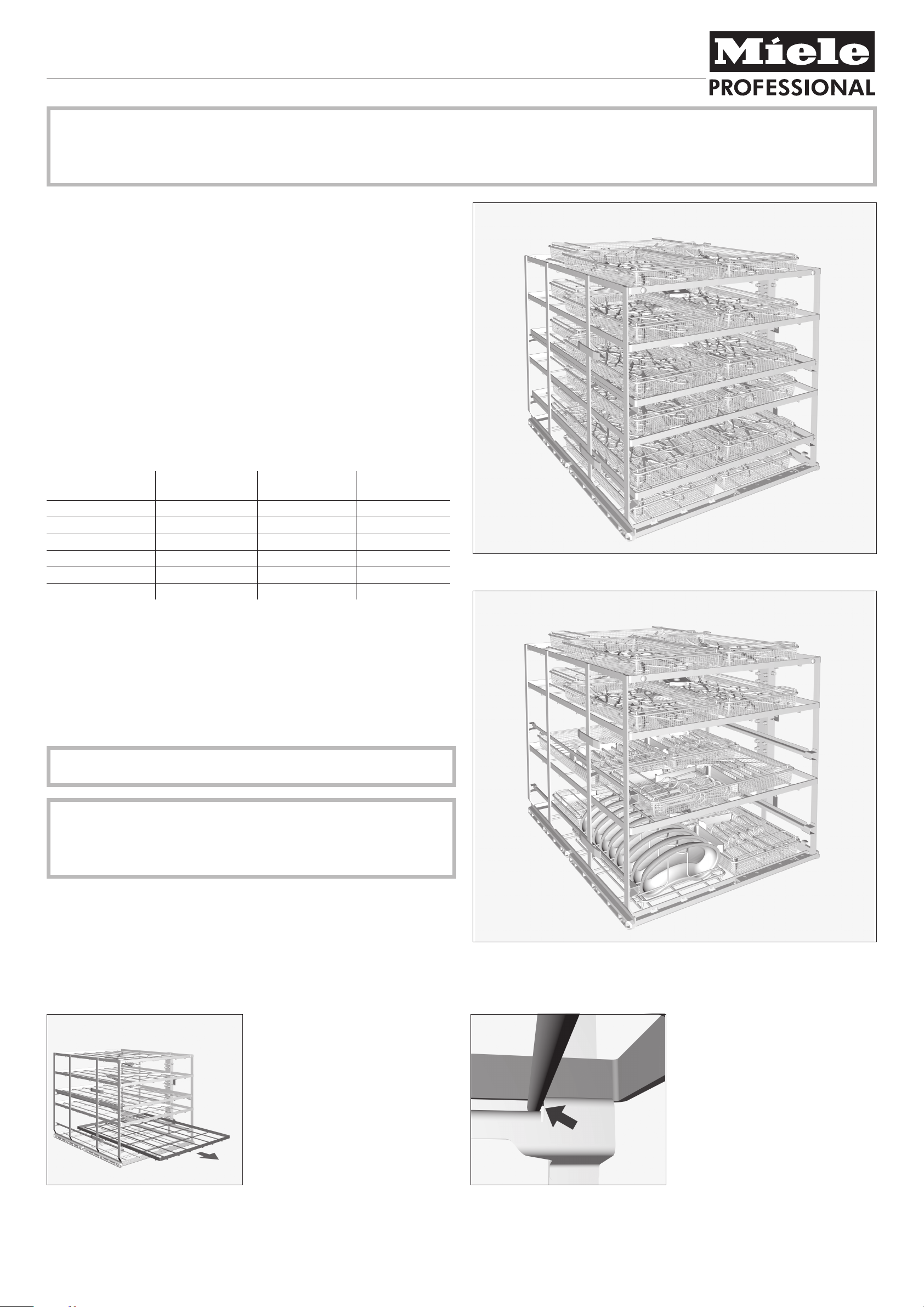

Mobile unit E 900-6 for surgical instruments

Please read the Warning and Safety instructions in the operating instructions for your G 7827/7828 or PG 8527/8528 Washer-disinfector carefully. You should only

,

process instruments/medical devices in this insert if they have been declared as suitable for machine processing by the manufacturer. Please also observe the

manufacturer's care instructions. The programme selected must be suitable for the materials from which the items to be processed are made. Where possible the

programme should include thermal disinfection. The final rinse should, if possible, always be carried out with fully demineralised water.

If using automatic mobile unit recognition, please make sure that the coding is correctly set.

Items supplied:

Mobile unit E 900-6 with six levels, of which two are removable, H 553, W 636,

D 790 mm fitted with a magnetic strip for automatic mobile unit recognition and

spray arm magnets for spray arm monitoring (PG 8527/8528 only).

Optional accessories

E 142 DIN mesh tray

–

E 473/1 insert for small instruments

–

E 476, holders for instruments C 4-8mm

–

E 479, holders for instruments C up to 4 mm

–

E 492 insert for kidney dishes

–

E 518, hose connector

–

Areas of application:

The E 900-6 mobile unit can be used for processing surgical instruments in up to

18 DIN mesh trays. There are 4 additional connections on each of 4 levels for

hollow items.

Loading dimensions*

[HxWxDinmm]

Level 1

Level 2

Level 3

Level 4

Level 5

Level 6

* Levels are numbered from the bottom upwards

Before loading the machine and before starting a programme, please check

that:

– the spray arms rotate freely,

– the spray arm jets are clean and free of any blockages,

– the removable levels are locked

–

the mobile unit is correctly aligned with the water intake of the washerdisinfector.

E 900-6 without level 2 without level 2

and level 4

71 x 555 x 780 162 x 555 x 780 162 x 555 x 780

71 x 565 x 780 – –

71 x 555 x 780 71 x 555 x 780 162 x 555 x 780

71 x 565 x 780 71 x 565 x 780 –

71 x 580 x 780 71 x 580 x 780 71 x 580 x 780

71 x 595 x 780 71 x 595 x 780 71 x 595 x 780

E 900-6

For validation purposes please make sure that you follow the loading

instructions given on the template.

To ensure a suitable standardised spray pressure for all connections, all screw

connectors must be fitted with jets, adapters, sleeves or blanking screws.

Damaged jets, adapters or sleeves etc. must not be used.

Empty jets, etc. do not have to be replaced with blanking screws.

Removable levels

The second and fourth levels are

removable to give more loading height

capacity for levels 1 and 3 if needed.

To remove a level

^

Lift the level and pull it out towards

you.

E 900-6 without level 2 and level 4.

To insert a level

^

Place the level onto the runners and

push it in.

Engage the bars on the underside of

the level behind the lugs on the runners

on either side of the mobile unit.

Make sure the level clicks into position

correctly.

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel 0330 160 6600,

Internet: http://www.miele.co.uk / ! 0297 Alteration rights reserved / Publication date 2015-11-01

^

Check that the level is securely

locked into the runners.

M.-Nr. 10 332 160 / 00 en

Page 2

Mobile unit E 900-6 for surgical instruments

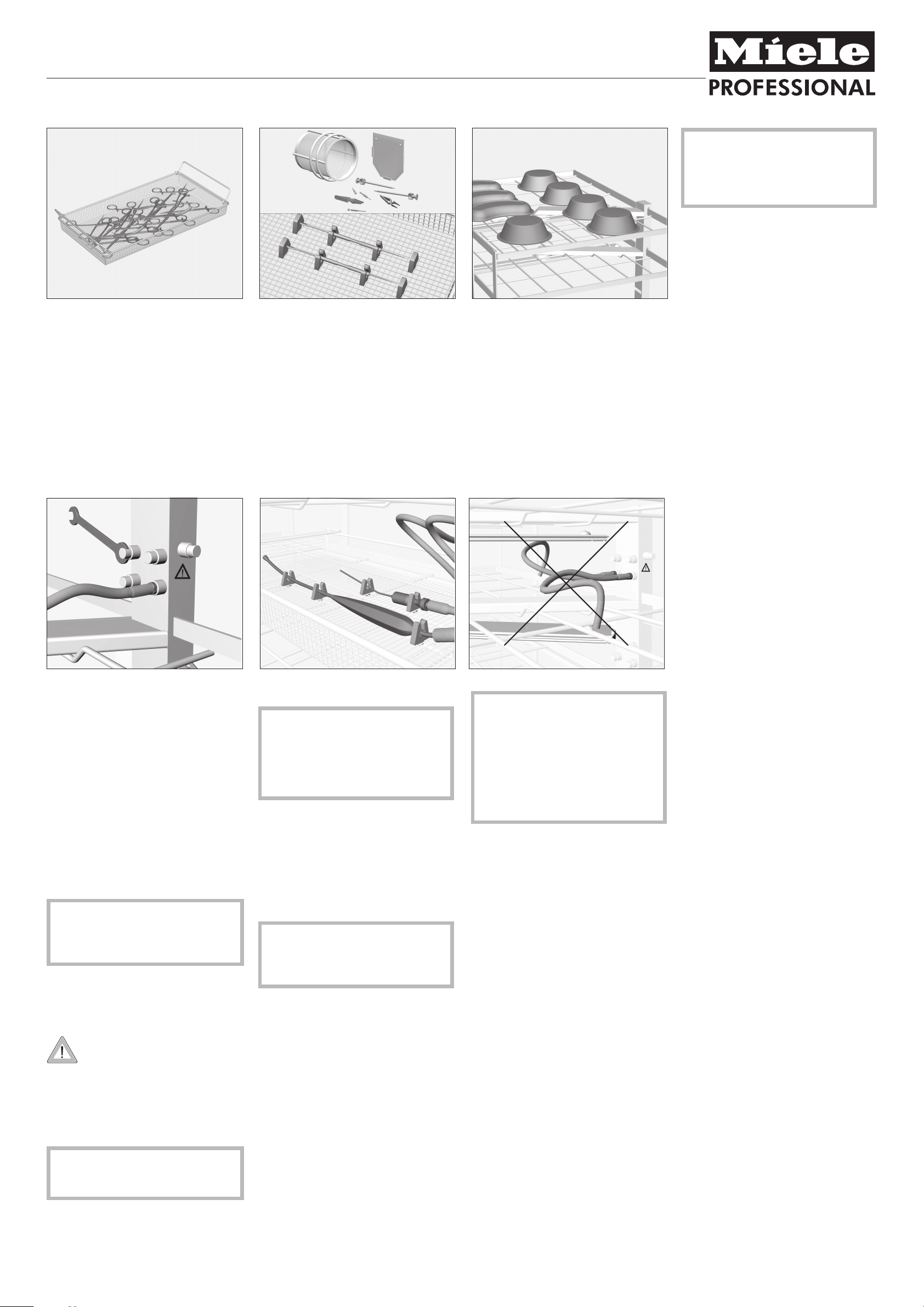

If hollow containers are placed such

that cleaning solution can collect in

recesses etc., they will not get

properly clean and rinsing results

will be impaired.

To prevent the risk of light

Containers e.g. beakers and kidney

^

dishes should be placed in the mobi

le unit with the open side facing

downwards, ensuring that all surfa

ces can be accessed easily and that

cleaning solution can flow freely off

them. They must also be secure so

that they cannot be flipped over by

the force of water during processing.

-

^

-

instruments such as bulldog clips

and other small items moving about

during processing, closable inserts

(e.g. E 473) and silicone holders

(e.g. E 476) can be used to keep

them secure.

E 518 hose connectors (optional accessory)

Hinged instruments must be opened

^

up before being placed in the mesh

trays to minimise the risk of surfaces

not being accessed during

processing.

To insert hose connectors

E 518 hose connectors can be fitted if

necessary in the water intake of the

mobile unit. Hollow instruments, e.g.

surgical suction devices, can be

connected to them and placed in a

mesh tray in the levels of the mobile

unit.

To do this:

^

Unscrew the blanking screws from

the connectors using an SW 9

spanner.

^

Screw hoses into the connectors and

tighten with the spanner.

,

Do not connect any junctions or

extensions to the hose connectors as

this will severely reduce water

pressure.

Test point for cleaning pressure

measurement

To connect hollow instruments

,

Before connecting hollow

instruments, please make sure that

all hollow sections are free of

blockages. Otherwise the cleaning

solution will not be able to access all

areas properly.

^

Secure hollow instruments in a mesh

tray with holders E 476 or E 479.

^

Place the mesh tray on a level in the

mobile unit and connect the hollow

instruments to a hose connector.

^

After successful processing, remove

the hollow instruments from the hose

connectors.

,

Any hollow instruments that have

become disconnected from the hose

connectors during processing must

be reprocessed.

,

Any hose connectors not in use

must be fitted with E 362 blanking

screws.

Water pressure can cause the

unattached ends of the hose con

nectors to spin around which can

result in the spray arms becoming

blocked.

-

Cleaning pressure for

performance checks and

validation according to

DIN EN ISO 15883 can be

measured using this test point.

^

To measure cleaning pressure,

replace the sealing screw with a

Luer-Lock-Adapter,e.g. E 447.

,

Ensure that no instruments,

rinsing lines, etc. are connected to

the test point.

Loading...

Loading...