Miele E 524, E 525 Operating instructions

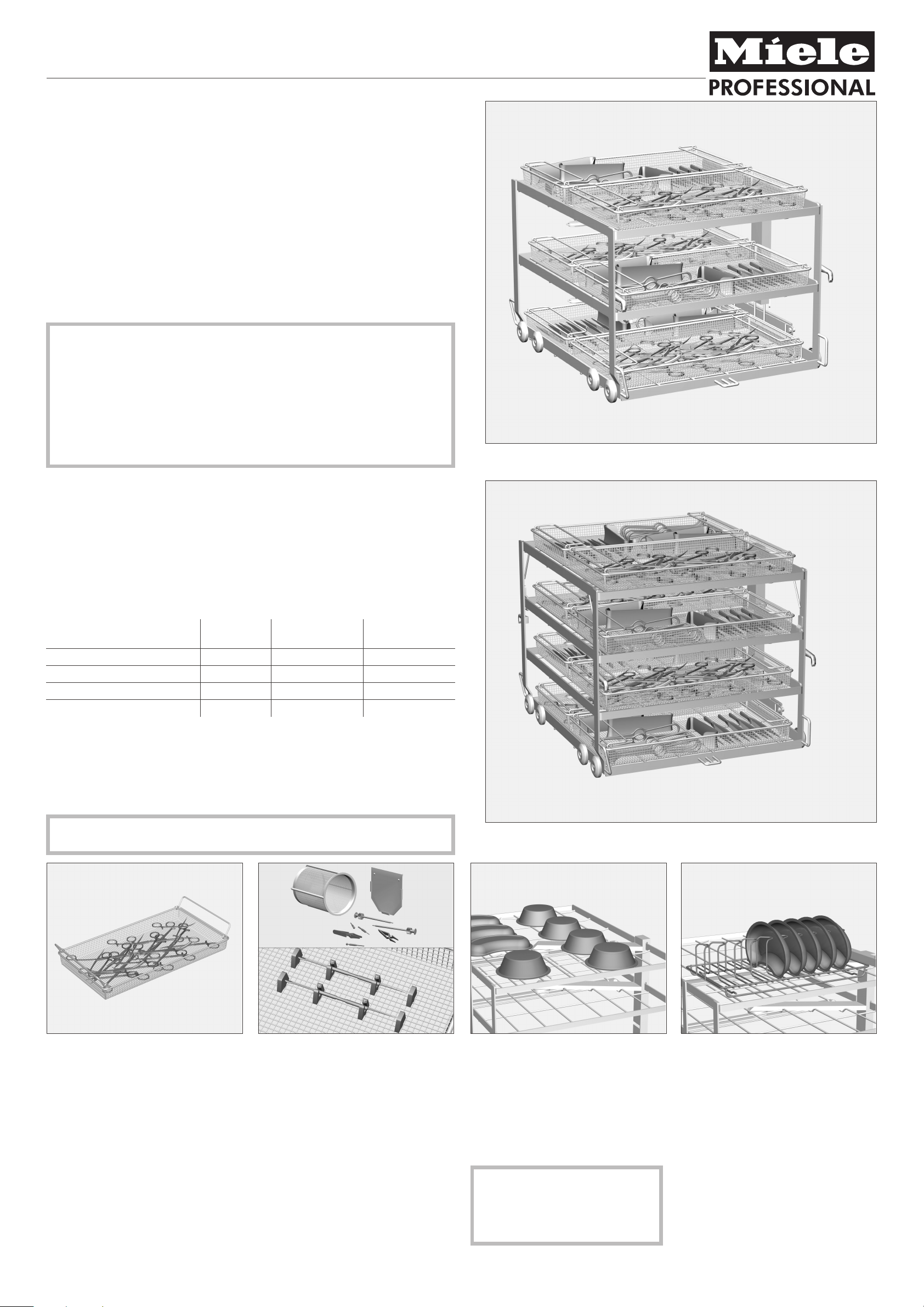

E 524 and E 525 mobile units for surgical instruments

Items supplied:

Mobile unit E 524 with three levels, H 390, W 530, D 653 mm, fitted with a magnet

strip for automatic mobile unit recognition (without magnets)

Mobile unit E 525 with three levels, H 298, W 530, D 653 mm, fitted with a magnet

strip for automatic mobile unit recognition (without magnets);

a fourth level can be added by fitting add-on module E 702, H 160, W 530, D 546

or an injector module E 703, H 170, W 80, D 560 for hollow instruments such as

suction instruments.

Accessories available to order

E 142 DIN mesh tray

–

A2 1/2 cover net, 216 x 456 mm

–

5 magnets for automatic mobile unit recognition (ML)

–

Add-on module E 702

–

Injector module for hollow instruments E 703

–

Please read the Warning and Safety instructions in the Operating

,

Instructions for your G 7823/24 Washer-disinfector carefully. You should only

process instruments/medical products in this mobile unit if they have been

declared as suitable for machine processing by the manufacturer. Please also

observe the manufacturer’s care instructions. The programme selected must be

suitable for the materials from which the medical products to be processed are

made. Where possible the programme should include thermal disinfection. The

final rinse should, if possible, always be carried out with fully de-mineralised

water. If using automatic mobile unit recognition please make sure that the co

ding is correctly set.

-

E 524

Areas of application:

Mobile units E 524 and E 525 enable surgical instruments to be cleaned and

disinfected in 6 DIN mesh trays or in 3 ISO mesh trays.

The E 702 add-on module enables 8 DIN mesh trays or 4 ISO mesh trays to be

cleaned and disinfected in the E 525 mobile unit.

The E 703 injector module enables 6 DIN mesh trays or 3 ISO mesh trays and up to

7 hollow instruments / suction instruments to be cleaned and disinfected in the

E 525 mobile unit.

2 DIN mesh trays can be accommodated on each level.

Loading height (levels numbered from the bottom upwards)

Level 1

Level 2

Level 3

Level 4

Before loading the machine and before starting a programme please check:

–

that the spray arms rotate freely,

–

that the spray arm jets are clean and free of any blockages,

–

that the mobile unit is correctly fitted into the cabinet and that it has connected

correctly with the water intake.

E 524

125 mm 80 mm 80 mm

125 mm 80 mm 80 mm

125 mm 219 mm 90 mm

– – 80 mm

E 525 (with E 703) E 525 (with E 702)

For validation purposes please make sure that you follow the loading

instructions given on the template.

^

Hinged instruments must be opened

up before being placed in the mesh

trays to minimise the risk of surfaces

not being accessed during

processing.

^

To prevent the risk of light

instruments such as bulldog clips

and other small items being moved

about during processing silicone

holders e.g. E 473 and closable

inserts e.g. E 476 can be used to

keep them secure.

E 525 (with E 702)

^

Containers e.g. beakers and kidney

dishes should be placed in the

mobile unit with the open side facing

downwards, ensuring that all

surfaces can be accessed easily

and that water can flow freely off

them. They must also be secure so

that they cannot be flipped over by

the force of water during processing.

^

Where necessary use an A 2 cover

net or an insert e. g. E 492 (on

mobile units without E 702).

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel (01235) 554455,

Fax (01235) 554477, Internet: http://www.miele.co.uk / Alteration rights reserved / 1005

If hollow items are placed such that

cleaning solution can collect in

recesses etc. they will not get

properly clean and rinsing results

will be impaired.

M.-Nr. 06 250 680 / 00

G

Loading...

Loading...