Page 1

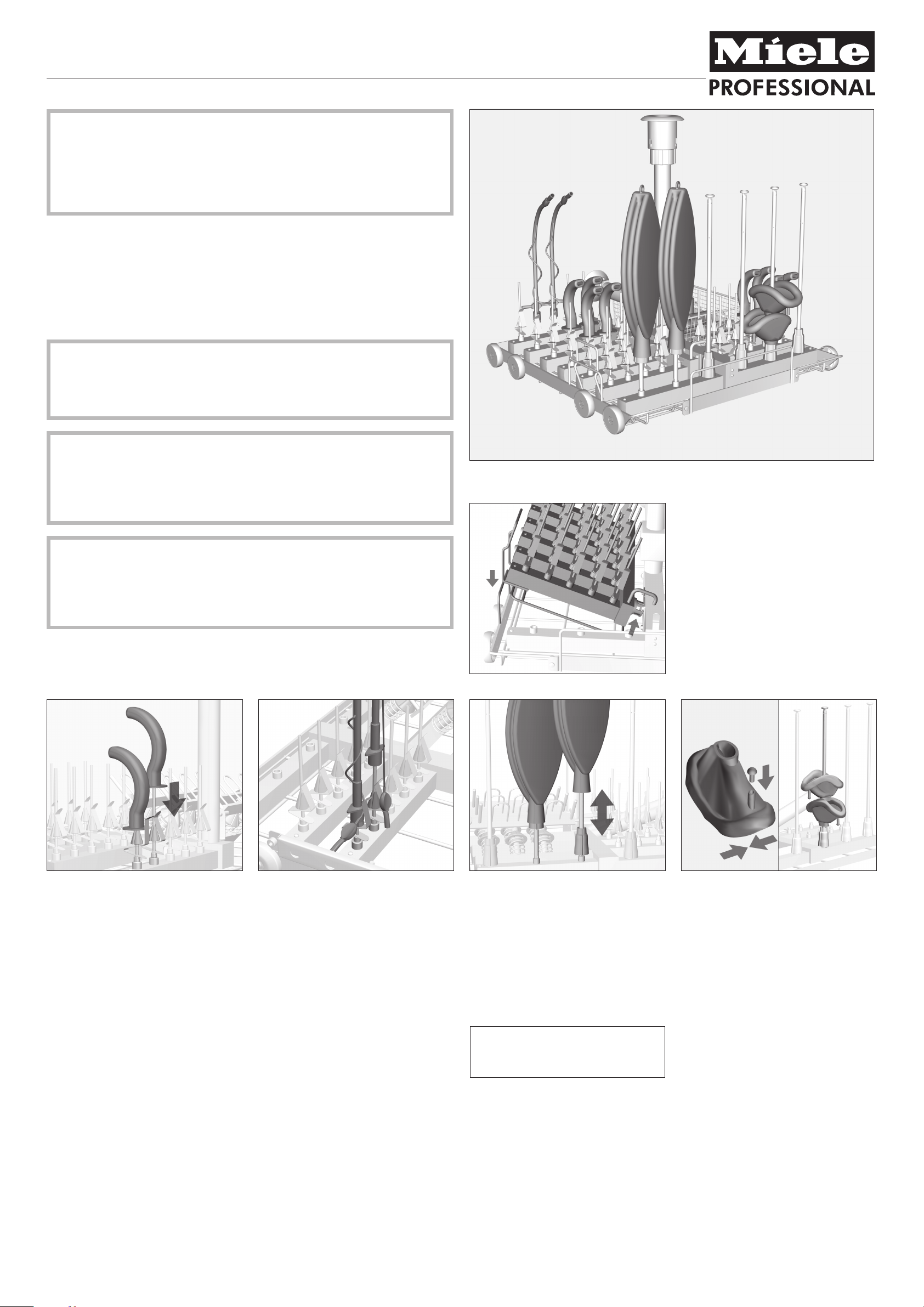

Module E 505 for intubation equipment

Please read the Warning and Safety instructions in the Operating

,

Instructions for your washer-disinfector carefully. You should only process

instruments/medical products in this module if they have been declared as

suitable for machine processing by the manufacturer. Please also observe the

manufacturer's care instructions. The programme selected must be suitable for

the materials from which the items to be processed are made. Where possible

the programme should include thermal disinfection.

Areas of application:

This module is designed for use in mobile unit E 501 (which is supplied with

separate operating instructions). It is designed for cleaning, disinfecting and

drying hollow anaesthetic instruments and equipment.

Special holders and injector jets are used for securing breathing tubes, breathing

bags, Guedel tubes and endotracheal tubes, laryngeal masks and bellows.

To ensure a suitable standardised spray pressure for all connections, all

,

screw connectors must be fitted with jets, adapters, sleeves or blanking screws.

Damaged jets, adapters or sleeves etc. must not be used.

Empty jets, etc. do not have to be replaced with blanking screws.

To ensure that hollow instruments are thoroughly cleaned and disinfected

,

internally, it is essential to connect them to the correct holders/jets in the mobile

injector unit. They must not detach themselves from their holders during the

programme.

If, however, a hollow instrument does become dislodged from its holder during

a programme, it must be processed again.

To avoid damage to certain items, observe the maximum permitted drying

,

temperature.

The maximum temperature permitted for the elastomers in some breathing bags

and masks is below 85°C.

Drying results must be inspected after the cleaning programme has finished.

If necessary, adjust the drying time at the end of the cleaning programme.

The illustration above shows module E 505 in mobile unit E 501.

Fit module E 505 into mobile unit

^

E 501.

To do this:

Place the two positioning guides over

^

the middle water inlet.

The inlet pipe needs to be positioned in

front of the cover in the water inlet.

^ Press the bracket on the left hand

side down until the handle engages

behind the rail on the mobile unit.

^

Attach Guedel tubes to injector jets

with spring clips.

^

Expel air from the balloon lead.

^

Endotracheal tubes are fitted onto the

injector jets so that spring clips

secure them to the jets.

^

Place the balloon lead with the valve

behind the spring clip.

^

Fit the breathing bags onto the

injector jets.

^

Make sure the opening of the

breathing bag fits securely over the

plastic cone.

This will prevent the breathing bag

from sticking together during the

cleaning and drying process and

ensure it is thoroughly cleaned

internally.

The breathing bag is attached

correctly when it cannot dislodge

itself from the plastic cone.

^

Remove the stopper from breathing

masks which have a closable air

cushion. Expel as much air as

possible and then replace the

stopper.

^

Several breathing masks can be

placed onto one breathing bag

injector jet.

Miele Company Ltd., Fairacres, Marcham Road, Abingdon, Oxon, OX14 1TW, Tel 0330 160 6600,

Internet: http://www.miele.co.uk / ! 0297 Alteration rights reserved / Publication date 2015-11-01

M.-Nr. 10 338 880 / 00 en

Page 2

If bellows are to be processed, one of

the E 466 injector jets must be replaced

with a special E 431 injector jet for

bellows which has a larger support

ring.

To do this:

Usea7mmspanner to unscrew one

^

of the E 466 injector jets.

Then screw the E 431 injector jet into

^

the vacated position and tighten with

the spanner.

Fit the bellows onto the E 431

^

injector jet.

A special combination of E 464 and

E 454 jets (optional extra) is required

for processing laryngeal masks.

Remove the height adjustment spring

^

from injector jet E 454.

Screw injector jet E 454 onto the

^

E 464 holder.

Now screw the jet combination into

^

the position released by one of the

E 466 injector jets and tighten with a

7 mm spanner.

Expel as much air as possible from

^

the laryngeal mask and the balloon

lead.

Attach the laryngeal mask to the jet

^

combination.

Attach the balloon lead with the valve

^

to the spring clip.

After processing, check that

,

items are airtight and function

correctly.

To process laryngeal masks with two

tubes, exchange one of the injector jets

with a spring clip for a short injector jet

(supplied separately). To do this:

^

Usinga9mmscrewdriver, unscrew

the injector jet with the spring clip.

^

Screw the short injector jet into the

holder, and tighten with the

screwdriver.

^ Push the cone and spring clip up the

long injector jet so that the longer

tube on the laryngeal mask on the

short injector jets is not kinked.

^

Expel as much air as possible from

the laryngeal mask and the balloon

lead.

^

Attach the laryngeal mask to the two

injector jets.

^

Attach the balloon lead with the valve

to the spring clip.

^ Arrange small items, such as

Y-pieces, couplings or connectors, in

insert E 507.

^

Lightweight items should be secured

to prevent them blocking the spray

arm or being caught up with the

magnetic strip on the automatic

mobile unit recognition system.

Loading...

Loading...