Page 1

Operating and Installation Instructions

..............................................................................................................................

Cooker Hoods

DWF 956-2 DWF 956 EX

DWF 950-2 DWF 950 EX

Q

Page 2

Contents

Contents

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Guide to the appliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation

Main switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Switching on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Selecting the power level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Run-on option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Switching off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Switching the lighting on or off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Filter operating hours counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Reading the filter operating hours counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Altering the filter operating hours counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning and care

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Grease filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Changing a halogen light bulb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Appliance dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Fitting dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation

Retaining plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Vapour canopy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Motor unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Preparation for extraction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Telescopic extension piece . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fitting the tower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation - extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connection for extraction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Condensate trap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

External fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2

Page 3

Caring for the environment

Disposal of packing material

The transport and protective packaging has been selected from materials

which are environmentally friendly for

disposal and can normally be recycled.

Rather than just throwing these materials away, please ensure they are offered for recycling.

Caring for the environment

Disposal of your old appliance

Old appliances contain materials which

can be reclaimed or recycled. Please

contact your dealer, your waste collection centre or scrap merchant about

potential recycling schemes.

Ensure that the appliance presents no

danger to children while being stored

for disposal.

See the appropriate section in the

Warning and Safety instructions.

3

Page 4

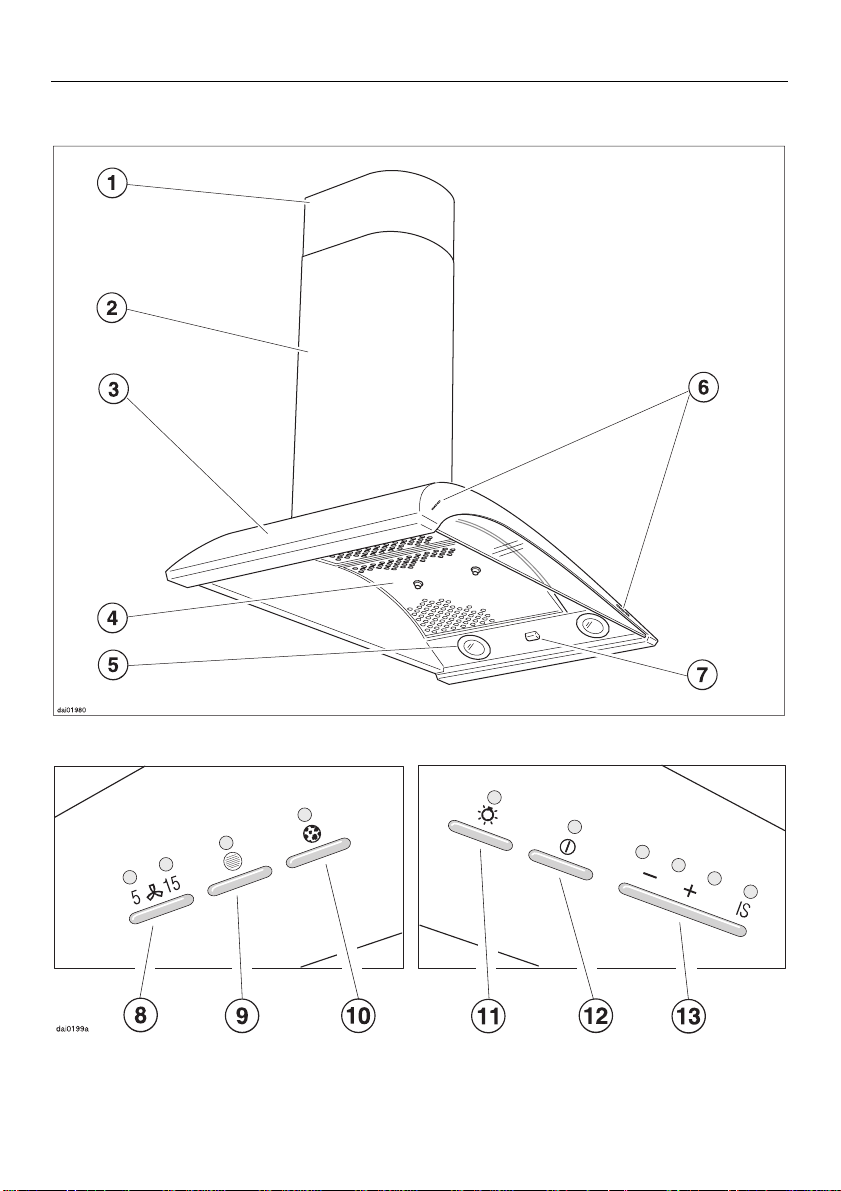

Guide to the appliance

Guide to the appliance

4

Page 5

Guide to the appliance

T elescopic

b

extension piece

T ower

c

Vapour canopy

d

e Grease filter

f Halogen lighting

g Control panel

h Main switch

If the cooker hood is not to be used for

a longer period of time (e.g. overnight

or during holidays), switch it off using

the main switch.

T ouch control for the

i

run-on option

This control activates the run-on option.

The fan is switched off automatically

after either 5 or 15 minutes.

jT ouch control for the

grease filter

The indicator lamp above the grease filter touch control lights up when the

grease filter needs to be cleaned.

The touch control is used

– to show how long the grease filter

has been in use (see section on

"Operation / Filter operating hours

counter").

– together with the run-on option touc h

control to alter the number of hours

counted by the filter operating hours

counter (see section "Operation / Altering the filter operating hours

counter").

No function allocated to this touch

k

control.

l Lighting touch control

This control is used to switch the lighting for illuminating the hob on and off,

regardless of whether the cooker hood

is in operation or not.

On/Off touch control

m

This control is used to switc h th e fa n on

or off.

Po w er level touch controls

n

You can select one of three power levels or an intensive level, depending on

how much the air needs to be filtered.

5

Page 6

Description of the functions

Description of the functions

The cooker hood works:

. . . by air extraction

The air is drawn in, cleaned by the

grease filter and directed outside.

The cooker hood is fitted with a

non-return flap, (see "Installation").

This flap is closed when the cooker

hood is switched off. No exchange of

room air and outside air can take

place. When the cooker hood is

switched on the non-return flap opens

for the cooking smells to be blown directly outside.

. . . with an external fan

The EX models are designed to be connected to an external fan located outside the room.

The external fan is connected to the

cooker hood by a control cable and is

operated by the control panel on the

cooker hood.

6

Page 7

Wa rning and Safety instructions

Warning and Safety instructions

This appliance conforms to current

safety requirements. Inappropriate

use could, however lead to risk of

accidents to the user and damage

to the appliance.

Before using this appliance for the

first time read the operating instructions carefully. They contain important information on safety, use and

maintenance of the appliance. This

way you will avoid the risk of accidents and damage to the appliance.

Keep these operating instructions in

a safe place and ensure that new

users are familiar with the content.

Pass them on to any future owner.

Appropriate use

The appliance is intended for do-

mestic use only.

The manufacturer cannot be held responsible for any damage caused by

improper use or by non-observance of

these instructions.

system which complies with local and

national regulations. It is most important that this basic safety re qu irement is

tested by a qualified electrician.

The manufacturer cannot be held responsible for the consequences of an

inadequate earthing system. (e.g. electric shock).

Installation work and re pa ir s may

only be carried out by suitably

qualified and competent persons to ensure safety. Repairs and other work by

unqualified persons could be dangerous and the manufacturer will not

be held responsible.

The appliance is only completely

isolated from the mains supply

when:

– it is switched off at the fused spur

connection, or

– it is switched off at the wall socket

and the plug has been withdrawn

(do not pull on the cable, only on the

plug), or

– the mains fuse is withdrawn.

T echnical safety

Before connecting the cooker

hood to the mains supply make

sure that the voltage and frequency details given on the data plate correspond with the on-site electricity supply, otherwise the appliance could be

damaged. If in doubt consult a qualified electrician.

The electrical safety of this ap-

pliance can only be guaranteed

when continuity is complete between

the appliance and an effective earthing

Ensure current is not supplied to the appliance while maintenance or repair

work is being carried out.

Do not connect the appliance to

the mains electricity supply by an

extension lead.

Extension leads do not guarantee the

required safety of the appliance.(e.g.

danger of overheating).

7

Page 8

Wa rning and Safety instructions

Use of the appliance

Do not let small children play with

the appliance or its controls. Super-

vise its use by the elderly or infirm.

Never use an open flame beneath

the cooker hood. To avoid the

danger of fire do not flambé or grill over

an open flame. When switched on the

cooker hood could draw flames into the

filters. Fat particles drawn into the

cooker hood present a fire hazard.

When using the cooker hood over

a gas hob ensure that any burners

in use are always covered by a pan.

Otherwise flames could be drawn up

by the suction of the cooker hood,

parts of which could then be damaged.

Always switch the cooker hood on

when a cooking zone is in use,

otherwise condensation may collect in

the hood, which could cause corrosion.

When cooking with oil or fat, chip

pans and deep fat fryers etc, do

not leave the pans unattended. Nev er

leave an open grill unattended when

grilling. Overheated oil and fat can ignite and could set the cooker hood on

fire.

Do not use the cooker hood with-

out the grease filter in place.

This way you will avoid the risk of

grease and dirt getting into the appliance and hindering its smooth operation.

Clean or change the filter regularly.

An over-greasy filter is a fire hazard.

Under no circumstances use a

steam cleaner to clean this ap-

pliance. Pressurised steam could reach

the electrical components and cause a

short circuit.

Installation

– The distance between the top of the

cooker/hob and the bottom of the

cooker hood must measure at least:

– 45 cm above electric cookers/hobs

– 65 cm above gas cookers/hobs.

– 65 cm above an Open grill.

For other manufacturer’s cooking appliances maintain the safety distance

as recommended in their Installation

and Operating instructions.

If more than one appliance is fitted beneath the cooker hood and they have

different minimum safety distances to

the cooker hood, select the higher distance.

Safety regulations prohibit the fitting of a cooker hood over solid

fuel stoves.

All ducting, pipework and fittings

must be of non-flammable material. These can be obtained from the

Spare Parts department or from builders’ merchants.

The appliance must not be con-

nected to a chimney or vent flue

which is in use. Neither should it be

connected to ducting which ventil ates

rooms with fireplaces.

If exhaust air is to be extracted into

a chimney or ventilation duct no

longer used for other purpose s, ta ke

professional advice.

8

Page 9

Wa rning and Safety instructions

When using the cooker hood at the

same time as another heating appliance which depends on the air in the

room, (e.g. gas, oil or coal fired

heaters, continuous flow or other water

heaters, gas cooker, gas hob or gas

oven) special care must be taken, as

the action of the cooker hood extracts

air from the room, which these types of

heater need for combustion.

In order to ensure safe operation, and

to prevent the gases given off by the

heating appliances from being drawn

back into the room when the extractor

and the heater are in operation simultaneously, an underpressure in the room

of 0.04 mbar (4 pa) is the maximum

permissible.

Ventilation can be maintained by air inlets which cannot be blocked, in windows, doors and outside wall vents, or

by other technical measures, such as

ensuring that the extractor can only be

switched on when the heating appliance is switched off or vice-versa.

N.B.: The overall ventilation condition of

the dwelling must be taken into account.

roaches or other vermin will not be

covered by the appliance guarantee.

Appliances with external fans

For appliances with an external fan

motor fitted (EX models) the connection

of the two units must be made using

the connection cable and the plug connectors. Make sure the correct combination of the two appliances has been

selected.

Separate fitting instructions are supplied with the external fan.

Disposal of your old appliance

Before discarding an old ap-

pliance switch off and disconnect

it from the power supply. Cut off and

render any plug useless. Cut off the

cable directly behind the appliance to

prevent misuse. This should be done

by a competent person.

The manufacturer cannot be held responsible for any damage caused

by non-observance of these instru c tions.

If in any doubt, the advice of a competent builder or, for gas, a “Corgi” installer must be sought.

In countries where there are areas

which may be subject to infestation by cockroaches or other vermin,

pay particular attention to keeping the

appliance and its surroundings in a

clean condition at all times. Any damage which might be caused by cock-

9

Page 10

Operation

Operation

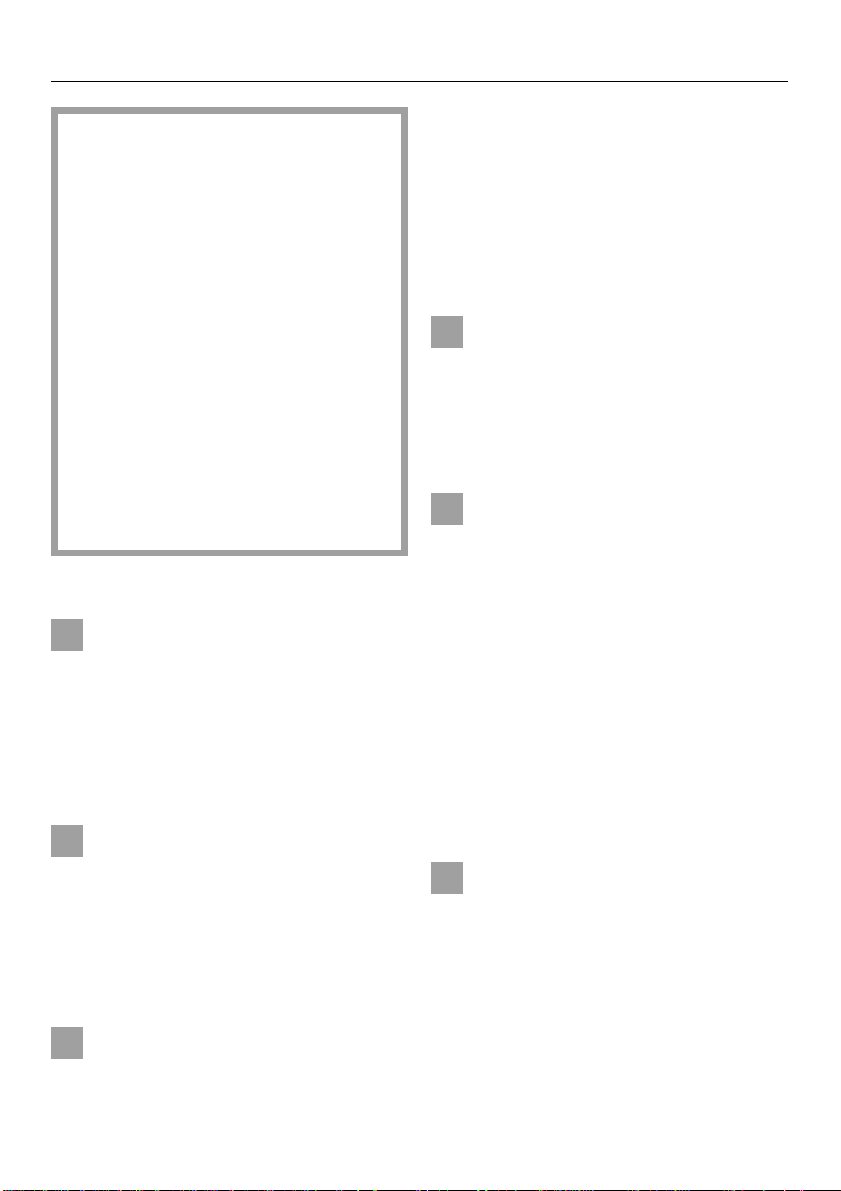

Main switch

When the main switch is set to “I” the

cooker hood is ready for operation.

When the cooker hood is switched off

using the main switch, it will retain the

most recent setting when next switched

on.

Switching on

– Press the On/Off touch control.

The indicator lamp for this touch control

lights up and at the same time the

motor switches on. The motor runs at

power level “lI”.

– Use the power level touch contr o l to

select the power level required.

– Touch control + = higher setting.

Touch control – = lower setting .

The indicator lamps show which power

level has been chosen.

Run-on option

If the air still needs to be cleared after

cooking, the cooker hood can be set to

continue running.

The fan motor will then switch off automatically after a further 5 or 15 minutes.

Selecting the power level

Depending on how much the air needs

to be filtered, there are four power levels available. For normal cooking a

low to medium level is usually sufficient. For frying or cooking food with a

strong aroma the highest level marked

IS (Intensive Setting) is recommended.

10

– Press the run-on option touch control.

Press once = 5 minutes run-on time

Press twice = 15 minutes run-on time

Press three times = fan is switched off

The relevant indicator lamp glows to

confirm the time selected.

To deactivate the run-on option time,

press the run-on option touch control

until both indicator lamps go out.

Page 11

Switching off

– Use the On/Off touch control to

switch the fan off.

Switching the lighting on or off

The lighting for illuminating the hob can

be switched on or off independently of

the fan.

– Press the lighting touc h co nt rol.

Operation

11

Page 12

Operation

Filter operating hours counter

An indicator lamp shows when the

grease filter needs to be cleaned. The

operating hours counter for the grease

filter is set at the factory for a certain

number of hours but these can be

changed if required.

After this set time has elapsed, the

grease filter touch control indicator

lamp glows. The grease filter must then

be cleaned.

After the grease filter has been cleaned

and put back in place, the filter operating hours counter must be re-set.

– To do this press the grease filter

touch control and hold for about 4

seconds.

The indicator lamp will go out.

Reading the filter operating

hours counter

To check the percentage of the time set

already used:

– Use the On/Off touch con trol to

switch the fan on.

– Press the grease filter touch control.

One or several of the indicator lamps

above the power level touch control

will flash.

The number of flashing lamps indicates

the percentage of operating time set already used up.

12

1 lamp = 25%

2 lamps = 50%

3 lamps = 75%

4 lamps = 100%

The number of operating hours used remains in memory, even when the appliance is switched off or there is a

power cut.

Page 13

Operation

Altering the filter operating

hours counter

The operating hours counter for the

grease filter is set to 30 hours. This time

can be lengthened or shortened. Y ou

can choose from 20, 30, 40 or 50 hours.

You can set the operating hours

counter to suit the type of cooking you

do.

Select a short time if you roast or fry a

lot.

If you use very little fat fo r cooking, select a longer time.

If, however, you only cook occasionally

we recommend that you select a short

time because grease which has built

up gradually over a long period of time

will harden on the grease filters and

make cleaning more difficult.

– Use the On/Off touch con trol to

switch the fan off.

– Press the run-on option touch control

and the grease filter touch control at

the same time.

The indicator lamp for the grease filter

touch control and on e of the lam ps

above the power level touch control will

flash.

The power level touch control lamps

show the time which has been set:

1st lamp from left = 20 hours

2nd lamp from left = 30 hours

3rd lamp from left = 40 hours

4th lamp from left = 50 hours

– Use the power level touch contr o l to

select the desired time.

– Confirm the procedure by pressing

the grease filter touch control.

If the procedure is no t co n firmed

within 4 minutes of programming

the steps, the cooker hood wil l auto matically revert to the “old” data.

13

Page 14

Cleaning and care

Cleaning and care

Before any cleaning or maintenance

work the cooker hood must be disconnected from the mains supply.

Ensure that:

- it is switched off at the fused spur

connection or

- it is switched off at the wall socket

and the plug has been withdrawn

(do not pull on the cable, only on

the plug), or

- the mains fuse is withdrawn.

Ensure current is not supplied to the

appliance while maintenance or repair work is being carried out.

Housing

Lacquered surfaces can be cleaned

using hot water to which a little mild

washing-up liquid has been added.

Dry with a soft cloth.

Grease filters

Re-usable metal grease filters are fitted

which remove solid particles (oil, dust,

etc.) from the kitchen vapo urs, preventing soiling of the cooker hood.

The grease filters should be cleaned

regularly to avoid a build-up of fat, (approx. 3-4 weeks on average, but

sooner if necessary). Always clean the

filters immediately if the lamp for the

grease filter touch control comes on.

An over saturated filter is a fire hazard.

For stainless steel surfaces a mild nonabrasive proprietary stainless steel

cleaner is suitable.

Never use cleaners which scour or

contain chlorine, acids or soda.

These would damage the surface of

the cooker hood.

14

– To remove the grease filters pull the

quick-release catches.

– Carefully remove the filters in a down-

wards direction.

– Clean the filters

– by hand: with a nylon brush in a

mild solution of warm water and

washing up liquid.

– in a dishwasher: place the filter

with the short side upright in the

lower basket, ensuring the spray

arm is not obstructed.

Page 15

Depending on the cleaning agent

used, cleaning the grease filters in

a dishwasher can cause permanent

discolouration to the surface of the

filters. However, this will not affect

the functioning of the grease filters

in any way.

– After cleaning, leave the filters to dry

on an absorbent surface before putting them back in place.

– When removing the filters for clean-

ing also clean off any residues of oil

or fat from the now accessible housing to prevent the risk of these ca tc hing fire.

Cleaning and care

– After putting the grease filters back

in place, press the grease filter touch

control for approx. 4 seconds to reset the operating hours counter.

15

Page 16

Cleaning and care

Changing a halogen light lamp

Before any cleaning or maintenance

work the cooker hood must be disconnected from the mains supply.

Ensure that:

- it is switched off at the fused spur

connection or

- it is switched off at the wall socket

and the plug has been withdrawn

(do not pull on the cable, only on

the plug), or

- the mains fuse is withdrawn.

Ensure current is not supplied to the

appliance while maintenance or repair work is being carried out.

When in use the halogen lamps

become very hot. Do not touch immediately as they remain hot for

some time after being switched off.

You must not touch the surface of a

halogen lamp when changing it as

this will damage it. Please follow the

manufacturer’s instructions.

– To change the haloge n lamp first

remove the outer ring

– Then detach the circlip

care that the cover

out.

– The halogen lamp

push-in connection socket. To replace, pull out the old lamp and fit a

new one.

– Replace the cover

circlip

– Now replace the outer ring

Never use the lighting without the

lamp cover

ter designed to cut out harmful rays.

carefully into the holder.

c

in place as it has a fil-

d

.

b

taking

c

does not fall

d

is fitted to a

e

and press the

d

b

.

16

Page 17

After sales service

In the event of any faults which you cannot remedy yourself, please contact:

– Your dealer

or

– The Service Dept., (see address on

back page).

When contacting the Service department, please quote the Model and Serial number of your appliance, both of

which are given on the data plate

which is visible on removing th e grease

filter.

Please note that telephone calls

may be monitored and recorded to

improve our service.

After sales service

17

Page 18

Electrical connection

Electrical connection

Electrical connection

All electrical work should only be carried out by a suitably qualified and competent person in accordance with national and local safety regulations.

The cooker hood is supplied for connection to a 220-230 V single phase

50 Hz supply.

The data plate gives the necessary

data for connection. This is visible

when the grease filter has been

removed.

Connection should be made either by a

double pole fused spur connection

unit, or a fused plug and a suitable

switched socket. The On-Off switch

should be easily accessible after the

appliance has been built in.

When switched off there must be an allpole contact gap of 3 mm in the switch

(including switch, fuses and relays according to EN 60 335).

If the socket is not accessible after installation (depending on country ) an additional means of disconnection must

be provided for all poles.

Important

The wires in the mains lead are coloured in accordance with the following

code:

Green/yellow = earth

Blue = neutral

Brown = live.

If the appliance is to be connected via

a plug and socket, please note the following:

As the colours of the wires in the mains

lead of this appliance may not correspond with the coloured markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured green and

yellow must be connected to the terminal in the plug which is marked with the

letter E or by the earth symbol z or

coloured green or green and yellow.

The wire which is coloured blue must

be connected to the terminal which is

marked with the letter N or coloured

black.

The wire which is coloured brown must

be connected to the terminal which is

marked with the letter L or coloured red.

For extra safety it is advisable to install

a residual current device (RCD) with a

trip current of 30 mA (in accordance

with DIN VDE 0664).

18

WARNING:

THIS APPLIANCE MUST BE

EARTHED

Page 19

Non-rewireable plugs BS 1363 (UK)

If this machine or appliance is fitted

with a non-rewireable plug, the following information applies:

If the socket outlets are not suitable for

the plug supplied with this product, it

must be cut off and an appropriate

plug fitted. The fuse carrier and the

fuse should be removed from the old

plug and disposed of. The plug cut

from the flexible cord should then be

disposed of, and on no account be inserted into any socket elsewher e in th e

house (electric shock hazard).

The fuse cover must be re-fitted when

changing the fuse and if the fuse cover

is lost the plug must not be used until a

suitable replacement is obtained.

The colour of the correct replacement

cover is that of the coloured insert in

the base of the plug (as applicable to

the design of plug fitted).

Electrical connection

The correct fuse rating of the replacement fuses that are ASTA approved to

BS 1362 should be fitted. Replacement

fuse covers may be purchased from

your local electrical suppliers or Service agent.

19

Page 20

Installation

Installation

Safety regulations prohibit the fitting

of this cooker hood over a solid fuel

stove.

The minimum safe distance between the top of the cooker/hob and

the bottom of the cooker hood

should be at least:

450 mm above electric

cookers/hobs

650 mm above gas cookers/hobs

650 mm above an open grill.

A distance of 650 mm above electric cookers/hobs may be preferrable to give more working space.

See “Warning and Safety instructions”

for further notes on s afe installation.

Appliance dimensions

H = 770 – 1000 mm

When venting to the rear through the

wall the minimum height is 825 mm.

20

Maintain a minimum distance "a" between the top of the hood chimney and

the ceiling of 2 cm, so that the hood

chimney can be remove d if ne c ess ary

at a future date.

Vent hose Ø 150 mm, or

125 mm Ø with reducing collar.

Page 21

Fitting dimensions

Installation

X = Recommended height for fitting

D = Area for vent cut-out

E = Area for socket and cable

path for the connection cable

with EX appliances.

21

Page 22

Installation

Installation

Retaining plates

The retaining plates A, B and C are

used to secure the cooker hood to the

wall.

– Before fitting the retaining plates

draw a centre line on the back wall

at the selected position.

– Mark the measurement X above the

cooking surface. This marks the

height of the lower rim of the cooker

hood.

– Drill four 8 mm Ø holes in the wall as

shown and press S8 plugs into the

holes.

Then drill holes for attaching the vapour

canopy and for fitting retaining plate A.

22

– Screw retaining plate A to the wall

with 5 x 40 mm screws through both

holes and use the two notches to

help you align it with the centre line.

Page 23

Retaining plate C

Installation

– Drill 4 further holes 8 mm Ø through

the now fitted retaining plate.

– Provide the two top holes with S8

plugs and 5 x 40 mm screws, the

two bottom holes with S8 R60 plugs

and 5 x 60 mm screws . Screw the

bottom screws in only loosely so that

they can later be used to secure the

vapour canopy.

Retaining plate B

– Hold retaining plate B up to the wall

and push up until directly below the

ceiling. Use the notches and the

centre line to align it horizontally.

Mark the positions for the holes to be

drilled on the wall.

– Drill four 6 mm Ø holes into the wall,

and push the S6 plugs into the holes.

– Screw on the retaining plate with four

4 x 30 mm screws and four 4.3 mm

washers.

Retaining plate C only needs to be

fitted if dimension Y is greater than 400

mm. It provides greater stability for the

extension piece.

– Hold the retaining pl at e C at a maxi -

mum distance of 400 mm from the

ceiling and use the two notches to

align it with the centre line. Mark the

position of the two drill holes.

– Drill two 6 mm Ø holes into the wall,

and press the S6 plugs into the

holes.

– Screw on retaining plate C with two

4 x 30 mm screws and two 4.3 mm

washers.

23

Page 24

Installation

Vapour canopy

– The grease filters must be removed

before the vapour canopy is fitted.

(See section on "Cleaning and care").

– Hang the vapour canopy on to the

angle brackets and the two screws

on the retaining plate.

– Tighten the two screws.

– Also screw the two 5 x 40 mm

screws through the holes provided in

the vapour canopy from inside.

– Cover the holes in the vapour ca-

nopy with the cover caps supplied.

24

Page 25

Installation

Motor unit

(only for appliances with an integrated

fan)

– Position the non-return unit in the

vent socket so that the flaps can

open upwards.

Non ... EXT models cooker hood are designed to take 150 mm ø exhaust ducting.

If 125 mm ø exhaust ducting has to be

used the reducing collar needs to be

fitted into the exhaust socket on the

motor unit. (See "Installation - Extraction" for details).

– Insert the plug connectors from the

vapour canopy into the corresponding couplings on the motor unit.

– Insert the plug for mains connection

into its socket (or connect up to the

fused unit).

– Mount the motor unit on the hooks in

the retaining plate.

– Secure the motor unit on both sides

to the lugs of the retaining plate

using 3.5 x 9.5 screws.

25

Page 26

Installation

Control unit

(only for EX models)

With EX models (external fan), the con-

trol unit is fitted instead of the motor

unit.

The exhaust stub with integrated nonreturn unit is supplied for a 125 mm Ø

hose.

If 150 mm Ø exhaust ducting is to be

used then:

– Mount the control unit on the hooks

in the retaining plate and secure on

both sides to the lugs of the retaining

plate using 3.5 x 9.5 screws.

– use a sharp knife to cut off the ex-

haust stub of the vapour guide at the

join.

26

– Insert the plug connectors from the

vapour canopy into the corresponding couplings on the control unit.

Page 27

– Now fit the cover of the control unit.

Hook the lower lugs of the cover into

the grille on the vapour canopy.

– Secure the cover from above with

two 3.5 x 9.5 screws.

– Use the connection cable with 6 pole

plug to connect the cooker hood and

the external fan.

Installation

Preparation for extraction

– Use the hose clip to secur e the fle x-

ible hose onto the vent socket for exhaust connection.

– The top end is directed to the open

air through a cut-out in the wall or

ceiling.

– Complete venting installation. (See

the section "Connection for extraction).

– Insert the plug for mains co nnection

into its socket (or connect up th e

fused unit).

27

Page 28

Installation

Installation - Venting

T elescopic extension piece

– Bend the hanging retainers approx.

45° inwards. This makes fitting easier.

– Screw the telescopic extension

piece firmly to the upper retaining

plate at each side with two 3.9 x 7.5

screws.

Protective sheets for tower

The paper protective sheets protect the

extension piece from accidental

scratching when the tower is being

fitted. They are removed when fitting is

complete.

– Pull the telescopic extension piece

apart slightly and hang onto the

upper retaining plate.

28

– Fold the protective sheets at the top.

– Remove the protect i ve foil around

the sticking points.

– Stick the protective sheets on to the

sides of the telescopic extension

piece.

Page 29

Fitting the tower

Installation

– Now hold the main shaft gently apart

and fit it over the extension piece.

– Push the shaft down approx. 1 cm

into the vapour canopy.

– Adjust the shaft.

– Loosen and then remove the protec-

tive sheets.

– Now secure the shaft on both sides

with two 3.9 x 7.5 screws.

– Cover the screw heads with the

cover caps supplied.

29

Page 30

Installation - extraction

Installation - extractio n

Connection for extraction

Danger of toxic fumes.

Please heed the “Warning and

Safety instructions” to avoid the

danger of toxic fumes.

The cooker hood should be installed according to local building

regulations. Seek approval from the

building inspector where necessary.

Air extraction ducting

– All ducting, pipework and fittings

must be of non-flammable material.

– The extraction ducting should be as

short and straight as possible.

To ensure efficient air extract ion the

diameter of the exhaust ducting

should not be less than 150 mm.

If exhaust ducting with a diameter

of less than 150 mm or flat ducting

were to be used the noise level of

the cooker hood would increase

and extraction would be less efficient.

– Only reduce the diameter of the duct-

ing if absolutely necessary, e.g.

where narrower ducting has already

been installed.

– Only use wide radius bends. Tight

bends reduce the air throughput of

the cooker hood.

– Only use smooth pipes or flexible

hoses made from non-flammable ma-

terials for extraction connection .

– When ducting is horizontal it must be

laid to slope away at 1 cm per metre,

to ensure no condensate drains into

the appliance.

– If the exhaust air is to be ducte d in to

the open air the installa tion of a telescopic wall vent is recommended.

– If the exhaust air is to be ducte d in to

a vent flue the ducting must be directed in the flow direction of the flue.

Important

If the exhaust ducting is to ru n

through rooms, ceiling space etc.,

where there may be great variations

in temperature between the different

areas, the problem of sweating or

condensation will need to be addressed.

The exhaust ducting will need to be

suitably insulated.

30

Page 31

Condensate trap

Condensate trap

In addition to insulating the exhaust

ducting we recommend that a suitable

condensate trap is also installed to collect and evaporate any condensate

which may occur.

When installing a condensate trap ensure that it is positioned vertically and if

possible directly above the exhaust

socket.

Installation - extraction

31

Page 32

External fans

External fans

The types of appliance available are listed in the table below.

Fan type: Roof

ventilator

Model: DV 1100 DV 1005/1

Roofventilator

DV 1005/1G

Outside

wall fan

AWG

1005/1

Outside

wall fan

Extractor

fan

Extractor

fan (wall)

AWG 1100 ABLG 940/1 MG 1100

AWG

1005/1G

Dimensions:

width mm

depth mm

height mm

Ø 301

244

380

460

230

380

460

160

Ø 301

124

360

400

245

310

280-390

390

Installed:

on flat roof

–

–

–

–

–

–

on pitched

X

X

–

–

–

–

roof

on / in

–

–

X

X

–

X

outside wall

free choice

–

–

–

–

X

–

Air through-

put:

(unducted)

in practice *

pipe connection

3

/h

850 m

3

/h

730 m

Ø 150 mm

3

/h

950 m

3

/h

780 m

Ø 150 mm/

125 mm

3

/h

950 m

3

/h

780 m

Ø 150 mm/

125 mm

850 m3/h

730 m3/h

Ø 150 mm

3

/h

900 m

3

/h

720 m

Ø 150 mm/

125 mm

850 m

730 m

Ø 150 mm

Nominal

voltage: AC 220 /230 V 50 Hz

Motor

output: 330 W 170 W 170 W 330 W 315 W 330 W

3

/h

3

/h

* Measured in the following

built-in situation:

cooker hood, 90° bend,

4m extraction ducting, external fan.

N.B. Not all models are available in all countries. Consult your supplier for further details.

32

Page 33

External fans

External fan version

Installation:

Depending on the model involved, external fans can be installed on an outside wall, on a pitched roof or in a suitable location indoors.

Model DV 1100

Model DV 1005/1

Model DV 1005/1G

– For installation on a pitched roof,

consult the roof tiler beforehand.

Model AWG 1100

Model AWG 1005/1 - 1005/1G

– Installation on an outside wall:

First unscrew the sheet metal screws

attached to the sides then remove

the housing case.

Fit the flexible hose or exhaust duct

on to the suction socket, and feed

through a prepared opening in the

wall, together with the power cable,

and make connection with the hood.

Then fix the fan to the wall.

Put back the housing case and secure with the sheet metal screws.

drilled. Then drill the holes and insert

plugs.

Screw the housing together.

Position the interior telescopic part

and insert foam into the interv ening

space. Secure the stainless steel lid

to the housing.

Fit the extraction flexib l e hose and

connect the control cable connectors together, (if an extension is

needed use the connection cable

supplied).

Models ABLG 940/1

– Other suitable location

These fan units can be installed at

any suitable location indoors and secured by means of the four holes

drilled in the base plate. Connection

to the hood as well as any possible

extension behind the fan unit is likewise made via a flexible hose or exhaust duct.

Electrical connection:

Electrical connection is made by a

power cable connecting the fan and

the cooker hood, thus allowing the fan

to operate at four different settings.

Model MG 1100

– Installation in an outside wall

Make a hole in the external wall as directed in the installation instructions

for the wall fan.

Remove the four fixing screws and

take off the housing lid. Mark where

the holes for the screws are to be

Separate fitting instructions are supplied with the external fan.

33

Page 34

T echnical data

Technical data

T echnical data

Rated load . . . . . . . . . . . . . . . . . 280 W

Motor . . . . . . . . . . . . . . . . . . . . . 200 W

Lighting . . . . . . . . . . . . . . . . . 4 x 20 W

Voltage. . . . . . . . . . . . . . 230 V - 240 V

Frequency . . . . . . . . . . . . . . . . ~ 50 Hz

Fuse rating (UK). . . . . . . . . . . . . . . 13 A

Fan power

Extraction power according to EN 61591

Extraction system ø 150 mm:

Level I. . . . . . . . . . . . . . . . . . . 220 m

Level II . . . . . . . . . . . . . . . . . . 335 m

Level III. . . . . . . . . . . . . . . . . . 440 m

Intensive level. . . . . . . . . . . . . 640 m

Extraction system ø 125 mm:

Level I. . . . . . . . . . . . . . . . . . . 210 m

Level II . . . . . . . . . . . . . . . . . . 305 m

Level III. . . . . . . . . . . . . . . . . . 405 m

Intensive level. . . . . . . . . . . . . 590 m

Unrestricted . . . . . . . . . . . . . . 690 m

For ...EX models the rated load and extraction power will depend on the type

of external fan fitted.

3

/h

3

/h

3

/h

3

/h

3

/h

3

/h

3

/h

3

/h

3

/h

34

Page 35

Page 36

M-No. 08 255 650 / 00- 1299 Alteration rights reserved.

Loading...

Loading...