Page 1

Operating and Installation

Instructions

Ventilation System

DA 6590 W

DA 6520 W

To prevent accidents

and appliance damage,

read these instructions

before

installation or use.

en-US

M.-Nr. 09 523 600

Page 2

Contents

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Guide to the ventilation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Turning the fan on K ...............................................10

Selecting the power level............................................10

Intensive setting IS ..............................................10

Delayed shut down 5 ¢15...........................................11

Overhead lighting I ...............................................11

Filter timer [....................................................12

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning the casing................................................14

Glass or stainless steel panels and grease filters .........................15

Resetting the grease filter timer ....................................17

Installing / replacing the odor-free filter.................................18

Resetting the odor-free filter timer ..................................18

Changing the light bulbs ............................................19

After Sales Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Caring for the environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Appliance dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Plywood backing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation instructions .............................................29

Protective film ....................................................29

Dismantling ......................................................29

Installation material ................................................30

Air extraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Reducing Collar ...................................................34

Condensate trap ..................................................34

Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE

INSTRUCTIONS

Keep these instructions in a safe

place and pass them on to any future

user.

Read these instructions carefully

before installing or using the

Ventilation System.

This appliance is intended for

~

residential use only. Use the appliance

only for its intended purpose.

This appliance complies with current

~

safety requirements. Improper use of

the appliance can lead to personal

injury and material damage.

,CAUTION

For General Ventilating Use

Only. Do Not Use To Exhaust

Hazardous Or Explosive

Materials And Vapors.

This appliance is designed to vent

~

cooking smoke and odors only.

This appliance is suitable for

~

installation above gas or electric

cooking surfaces.

,WARNING

TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

a) Use this appliance only in the

~

manner intended by the manufacturer.

If you have questions, contact Miele.

b) Before servicing or cleaning the

~

appliance, switch power off at the

service panel and lock the service

disconnecting means to prevent power

from being switched on accidentally. If

the service disconnecting means

cannot be locked, securely fasten a

prominent warning device, such as a

tag, to the service panel.

c) Be certain your appliance is

~

properly installed and grounded by a

qualified technician.

To guarantee the electrical safety of this

appliance, continuity must exist

between the appliance and an effective

grounding system. It is imperative that

this basic safety requirement be met. If

there is any doubt, have the electrical

system of the house checked by a

qualified electrician.

This appliance is not intended for

~

outdoor use.

This appliance must not be used in

~

a non-stationary location (e.g. on a

ship).

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

d) Before connecting the appliance

~

to the power supply make sure that the

voltage and frequency listed on the

data plate correspond with the

household electrical supply.

This data must correspond to prevent

appliance damage. If in doubt consult a

qualified electrician.

e) Installation work and repairs

~

should only be performed by a qualified

technician in accordance with all

applicable codes and standards.

Repairs and other work by unqualified

persons could be dangerous.

f) Only open the housing as

~

described in the enclosed "Installation

diagram" and in the "Cleaning and care"

section of this manual. Under no

circumstances should any other parts

of the housing be opened. Tampering

with electrical connections or

components and mechanical parts is

highly dangerous to the user and can

cause operation faults.

g) Before discarding an old

~

appliance, disconnect it from the power

supply and remove the power cord to

prevent hazards.

Use

,WARNING

TO REDUCE THE RISK OF A

COOKTOP GREASE FIRE:

a) Never leave surface units

~

unattended at high settings. Boilovers

cause smoking and greasy spillovers

may ignite. Heat oils slowly on low or

medium settings.

b) Always turn the hood on when

~

cooking at a high heat.

c) Clean the ventilation hood

~

frequently. Grease should not be

allowed to accumulate on the fan or

filter.

d) Use the proper pan size. Always

~

use cookware appropriate for the size

of the cooking area.

e) Do not flambé or grill with an

~

open flame beneath the hood.

Flames could be drawn up into the

hood by the suction and the grease

filters may catch fire.

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

,WARNING

TO REDUCE THE RISK OF

INJURY TO PERSONS IN THE

EVENT OF A COOKTOP

GREASE FIRE, OBSERVE THE

FOLLOWING

a) SMOTHER FLAMES with a close

~

fitting lid, cookie sheet, or metal tray

then turn off the burner.

BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE

DEPARTMENT.

b) NEVER PICK UP A FLAMING

~

PAN - You may be burned.

c) DO NOT USE WATER, including

~

wet dishcloths or towels - a violent

steam explosion will result.

d) Use a fire extinguisher ONLY if:

~

1) You have a class ABC

extinguisher, and you know how to

operate it.

*

:

Do not allow children to play with or

~

operate the appliance or its controls.

Supervise its use by the elderly or

infirm.

Always turn on the hood when using

~

the cooktop to prevent damage from

condensation.

Never operate gas burners without

~

cookware. Turn the burner off when not

in use. Adjust the burner so that the

flames do not extend beneath the

cookware. Do not overheat the

cookware, e.g. when using a wok. The

hood can be damaged due to

excessive heat from the burners and

the cookware.

Do not use the hood without the

~

grease filters in place.

Do not use a steam cleaner to clean

~

the hood. Steam could penetrate

electrical components and cause a

short circuit.

2) The fire is small and contained in

the area where it started.

3) The fire department is being

called.

4)You can fight the fire with your

back to an exit.

*

Based on "Kitchen Firesafety Tips"

published by NAFTA

5

Page 6

IMPORTANT SAFETY INSTRUCTIONS

Installation

,WARNING

TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

a) Installation work and electrical

~

wiring must be done by qualified

person(s) in accordance with all

applicable codes and standards,

including fire-rated construction.

b) Sufficient air is needed for

~

combustion and exhausting of gases

through the flue (chimney of fuel

burning equipment to prevent back

drafting. Follow the heating equipment

manufacturer’s guideline and safety

standards such as those published by

the National Fire Protection Association

(NFPA) and the American Society for

Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and

the local code authorities.

c) When cutting or drilling into the

~

wall or ceiling, do not damage electrical

wiring and other hidden utilities.

g) Do not install this hood over

~

cooktops that burn solid fuel.

h) Provided a larger distance is not

~

given by the manufacturer of the

cooktop, follow the minimum safety

distances between a cooktop and the

bottom of the hood given in the

"Appliance dimensions" section of this

manual.

If local building codes require a greater

safety distance, follow their

requirement.

If there is more than one appliance

beneath the hood and they have

different minimum safety distances

always select the greater distance.

i) Never connect an exhaust hood to

~

an active chimney, dryer vent, vent flue,

or room ventilating ductwork.

j) Seek professional advice before

~

connecting an exhaust hood vent to an

existing, inactive chimney or vent flue.

k) Any fittings, sealant, or materials

~

used to install the ductwork must be

made of approved non-flammable

materials.

d) Ducted hoods must always be

~

vented to the outdoors.

e) Do not use this hood with any

~

solid-state speed control device.

f) Do not use an extension cord to

~

connect the appliance to electricity.

Extension cords do not guarantee the

required safety of the appliance,

(e.g. danger of overheating).

6

,WARNING

TO REDUCE THE RISK OF

FIRE USE ONLY METAL

DUCTWORK.

Page 7

The ventilation system can be operated

Description of functions

Air extraction

The air is drawn in and cleaned by the

grease filters and directed outside.

The hood comes equipped with a

non-return flap. This flap automatically

closes when the hood is turned off so

that no exchange of outside air and

room air can occur. When the hood is

turned on, the air pressure of the

exhaust fan automatically opens the

flap blowing the inside air and cooking

odors outside.

Recirculation mode

The recirculation mode requires a

conversion kit and odor-free filter

(optional accessories for the

DA 6590 W only, see "Technical data")

Air is drawn in and cleaned by the

glass or stainless steel panels, grease

filters as well as an odor-free filter. The

filtered air is then recirculated back into

the kitchen through a vent at the top of

the hood’s chimney.

In air recirculation mode, please

ensure that the odor-free filter is in

place, see "Cleaning and care".

7

Page 8

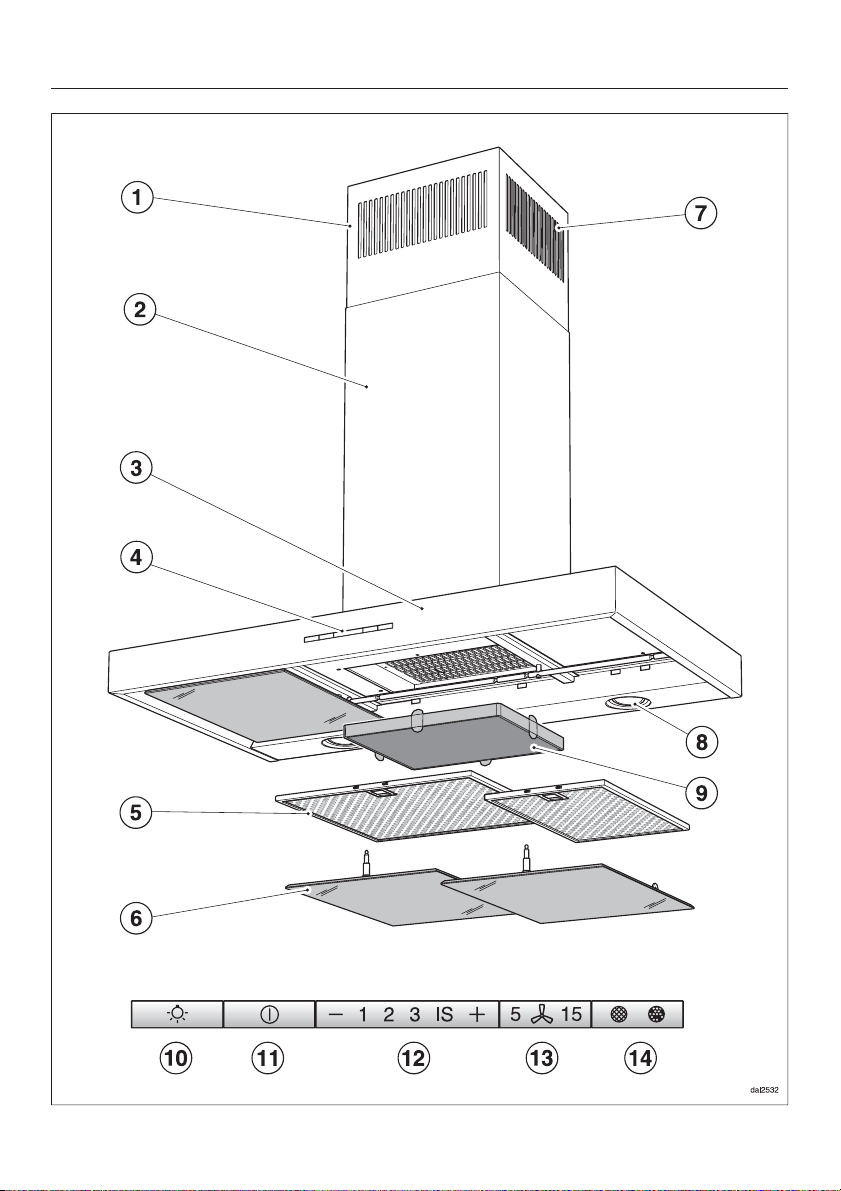

Guide to the ventilation system

8

Page 9

Guide to the ventilation system

a Chimney extension

b Chimney

c Canopy

d Control panel

e Grease filter

f Glass or stainless steel panels

Optional accessories

DRP 6590 W glass (3 elements)

DRP 6590 W stainless steel

(3 elements)

g Recirculation vent

(only for the DA 6590 W in recirculation

mode)

h Overhead lighting

i Odor-free filter

Optional accessory for recirculation

mode (DA 6590 W only)

j On/Off button for the overhead

lighting

n Filter button

The indicator l of the grease filter

button lights when the grease filters

need to be cleaned.

The odor-free filter symbol comes

on when the odor-free filter (for

recirculation mode) needs to be

replaced. When first using the system,

the operating hours timer must be

activated.

This button can be used at any time to

reset the respective timer after cleaning

the grease filter or changing the

odor-free filter (see "Cleaning and

care").

You can also check the operating hours

and change the setting.

This button turns the light on and off

and also dims it.

k On/Off button

l Fan power selection

m Delayed shut down

This button activates the Delayed Shut

Down feature. The fan can be set to

turn off automatically after either 5 or 15

minutes.

9

Page 10

Operation

Turning the fan on K

Press the On/Off button K.

^

The fan turns on at level 2. The K

symbol and power level 2 indicators

light up.

Selecting the power level

Use the "–/+" controls to select the

^

desired power level.

+ = increases the fan speed

– = decreases the fan speed

Levels "1" to "3" are usually sufficient for

normal cooking.

Intensive setting IS

The IS level should be used

temporarilyf or a short period of time

when frying or cooking food with a

strong aroma.

Automatically switching back from

the IS setting

The intensive level can be programmed

to automatically switch back to level 3

after 10 minutes.

Turn the fan and the lights off.

^

Press and hold the delayed shut

^

down button 5 ¢15 for approx.

10 seconds until power level 1 lights

up.

Then press the following buttons one

^

after another:

– overhead lighting I,

– the – button, and

– the overhead lighingt button I

again.

If the indicators 1 and IS flash,

automatic switch-back is not activated.

^ To activate automatic switch-back,

press the + button.

Power level indicators 1 and IS come

on.

To deactivate, press the – button.

10

^

To save the setting, press the

delayed shut-off button 5 ¢15.

If the procedure is not stored within 4

minutes of programming, the hood will

automatically default to the "old" data.

Page 11

Operation

Delayed shut down 5 ¢15

For both air extraction and recirculation,

it is recommended that run the fan for

several minutes after cooking is

completed.

This helps clear the kitchen air of any

remaining vapors and odors.

The Delayed Shut Down feature can be

selected to turn the fan off automatically

after a preselected length of time.

After cooking, and with the fan on,

^

press the Delayed Shut Down button

5 ¢15 :

– once: the fan automatically turns off

after 5 minutes (5 ¢ lights up).

– twice: the fan automatically turns off

after 15 minutes (¢15 lights up).

If you press the Delayed Shut Down

button 5 ¢15 again, the fan will not turn

off automatically (5 ¢15 goes out).

Turning off the fan K

^

Press the On/Off button to turn the

fan off K.

The K indicator goes out.

Overhead lighting I

Turning the overhead lighting on

The overhead lighting and the fan can

be turned on and off separately.

Press the light button I briefly to

^

turn the light on.

The I indicator comes on.

The overhead light comes on at

maximum brightness.

Dimming the overhead lighting

The brightness of the light can be

adjusted.

^ While the light is turned on, press

and hold the light button I.

The light dims until the button is

released.

^ If the button I is pressed and held

down again, the light brightens until

the button is released.

If the I button is pressed continuously,

the light cycles between light and dark.

Turning the overhead light off

^

Briefly press the light button I to

turn the light off.

The I indicator goes out.

11

Page 12

Operation

Automatic safety shut-off

The fan will turn automatically off 10

hours of use. The lighting however will

remain on.

Press the On/Off button K to turn the

^

fan back on again.

Filter timer [

A timer counts the hours of fan

operation.

The timer signals that the filters need to

be cleaned or replaced by turning on

the grease filter symbol [ or the

odor-free filter symbol .

See "Cleaning and care" for information

on cleaning and replacing filters and

resetting the timers.

Reprogramming the grease filter

timer [

The timer may be set to suit your

cooking habits.

–

If you often roast and fry foods,

choose a shorter operating time.

Press the On/Off button K to turn the

^

fan off

Press the delayed shut down button

^

5 ¢15 and the filter button [ at

the same time.

The grease filter symbol [ of the filter

button and one of the power level

indicators flash.

The 1 to IS indicators show the

programmed time:

Indicator 1 ................20hours

Indicator 2 ................30hours

Indicator 3 ................40hours

Indicator IS ...............50hours.

^ Press – to select a shorter operating

time or + for a longer one.

^ Save the setting by pressing the filter

button [.

All the lights will go out.

If the procedure is not stored within 4

minutes, the hood will automatically

default to the original setting.

–

If you tend to cook fat-free, choose a

longer operating time.

–

If you cook only occasionally, it is

better to choose a shorter operating

time. This is because accumulated

grease will harden over time, making

cleaning difficult.

The factory setting for the grease filter

timer is 30 hours. You can adjust the

time to 20, 30, 40 or 50 hours.

12

Page 13

Operation

Activating/changing the odor-free filter

timer

(in recirculation mode)

The odor-free filter is necessary for

recirculation mode.

The odor-free filter timer is not pre-set.

The timer may be set to suit your

cooking habits.

Press the On/Off button K to turn the

^

fan off

Press + and the filter button — at

^

the same time.

The odor-free filter symbol of the

timer button and one of the power level

indicators flash.

The 1 to IS indicators show the

programmed time:

Indicator1................120hours

Indicator 2 ...............180hours

Indicator 3 ...............240hours

Indicator IS ............deactivated.

^

Press – to select a shorter operating

time or + for a longer one.

^

Save the setting by pressing the filter

button [.

Checking the filter operating hours

counter

Even before the maximum operating

time has been reached, you can check

what percentage of the time has

elapsed.

Press the On/Off button K to turn the

^

fan on.

Press the filter button [ –

^

once, to check the grease filter

–

operating time. The grease filter

symbol [ comes on.

– twice, to check the odor-free filter

operating time. The odor-free filter

symbol comes on.

At the same time one or more power

level indicators start flashing.

The number of flashing indicators

shows the elapsed operating time:

Indicator 1 ...................25%

Indicators 1 and 2 .............50%

Indicators 1 to 3 ...............75%

Indicators 1 to IS

This information will remain stored in

memory in the event of a power failure.

.............100%

All the indicator lights go out.

If the procedure is not stored within 4

minutes, the hood will automatically

default to the original setting.

13

Page 14

Cleaning and care

,WARNING

TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Before cleaning or servicing the

hood, disconnect it from the power

supply, see "Important Safety

Instructions".

The halogen bulbs are very hot

,

when in use. They stay hot for some

time after turned off. Use caution,

danger of burns.

Wet cleaning the hot bulbs will

cause damage.

Wait a few minutes after turning

them off before cleaning.

Cleaning the casing

Never use abrasive cleaners,

scouring pads, steel wool or caustic

(oven) cleaners on the hood. They

will damage the surface.

Avoid:

cleaning agents containing soda,

–

acids or chlorides,

abrasive cleaning agents

–

e.g. powder or cream cleansers,

abrasive sponges, e.g. pot scourers

–

or sponges which have been

previously used with abrasive

cleaning agents.

sharp metal scrapers,

–

oven spray.

–

Special instructions for stainless

steel surfaces

(not applicable to the controls)

Stainless steel surfaces can be cleaned

using a non-abrasive stainless steel

cleaner.

To help prevent resoiling, a conditioner

for stainless steel can be applied.

Special instructions for colored

casings (RAL)

(Special order)

^

All external surfaces and controls can

be cleaned with a mild solution of

warm water and liquid dish soap

applied with a soft sponge.

Do not use too much water when

cleaning the controls. Water could

penetrate the electronics and cause

damage.

^

Wipe dry using a soft cloth.

14

It is very difficult to clean this type of

surface without causing minor marks to

the surface material. This can become

particularly noticeable with darker

colors and if there is halogen lighting in

the kitchen.

Page 15

Cleaning and care

Special instructions for glass

surfaces

Glass surfaces should be cleaned

^

with a normal glass cleaner.

Stainless steel colored controls

These controls may become dis

colored or damaged if not cleaned

regularly.

Do not use a stainless steel cleaner

on these controls.

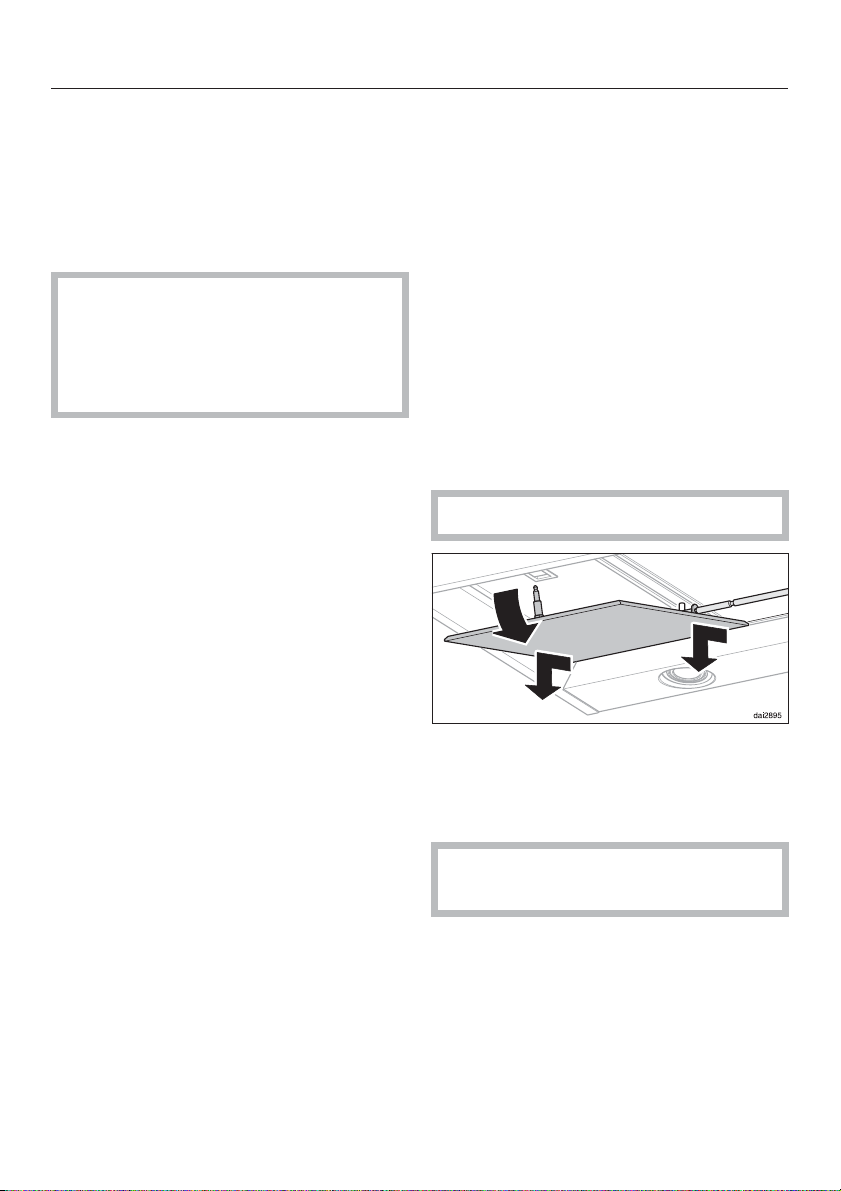

Glass or stainless steel panels

and grease filters

The glass or stainless steel panels and

the reusable metal grease filters

remove solid particles from the vented

kitchen air (grease, dust, etc.) and

-

prevent soiling of the hood.

Clean the panels and grease filters at

the latest when the grease filter symbol

[ of the timer button comes on.

The grease filters should be cleaned

every3-4weeks, as the collected

grease hardens over time and makes

cleaning more difficult.

A dirty filter is a fire hazard!

,

^

Pull the front edge of the panels

down out of the lock, lower them

slightly, unhook them at the back,

and take them out.

Support the panel so that it does not

fall and damage the cooktop.

15

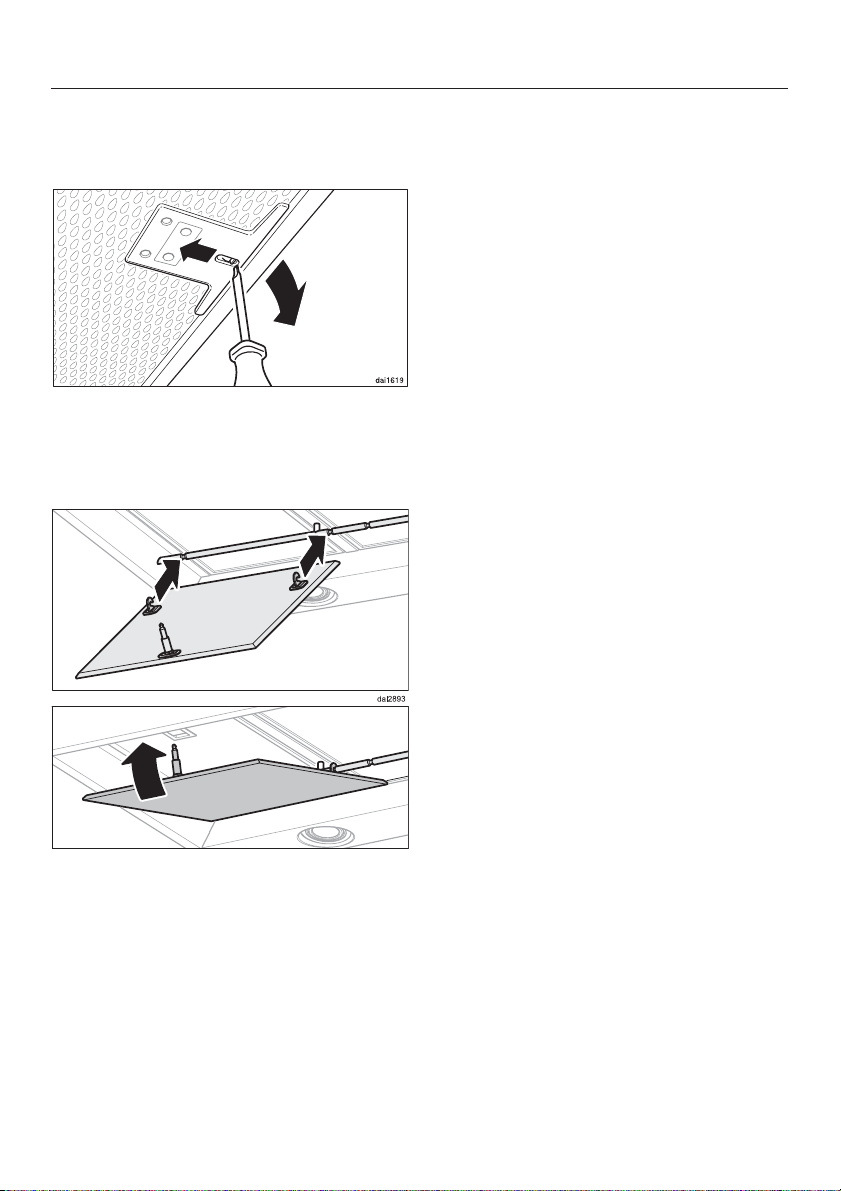

Page 16

Cleaning and care

Open the grease filter lock, lower the

^

grease filter slightly, unhook it at the

back, and take it out.

Support the grease filter so that it

does not fall and damage the

cooktop.

Cleaning the panels by hand

^ Follow the instructions under

"Cleaning the casing".

Cleaning the grease filters by hand

^

Use a scrub brush with a solution of

warm water and mild dish soap.

Do not use the pure detergent,

aggressive all purpose cleaners,

oven sprays, abrasive cleaning

agents or limescale removers. They

could damage the filter.

Cleaning the grease filters and

panels in the dishwasher

Place the filters vertically in the lower

^

basket, making sure that the spray

arm is not blocked.

Use a wash program with a max.

temperature of 150°F (65°C). In a

Miele dishwasher use the "Normal"

program.

Use the recommended amount of

dishwasher detergent. Overuse could

destroy the filter.

Depending on the detergent,

cleaning the grease filters in a

dishwasher may cause permanent

discoloration of the filter surface.

Filter performance will not be

affected by this discoloration.

^ After cleaning, place the filters on a

towel to dry.

^ While the panels and the filters are

removed, clean any dirt or grease

from the casing parts that are

accessible. This reduces the risk of

fire.

16

Page 17

Cleaning and care

When reinstalling the grease filters,

^

make sure that the locking clips are

facing down.

If the filters are incorrectly installed,

^

insert a small screwdriver into the slit

along its edge to disengage them

from the casing.

Resetting the grease filter timer

After cleaning, reset the grease filter

timer.

With the fan running, press and hold

^

the grease filter button l for

approx. 3 seconds, until only the 1 is

flashing.

The indicator light will l go out.

If the grease filters are cleaned before

the timer has reached its maximum:

Press and hold the grease filter

^

button for l for

approx. 6 seconds, until only the 1 is

flashing.

^

Hook the panels onto the support

ledge.

^

Lift up the front of the panels and

push them into the lock until they

engage.

17

Page 18

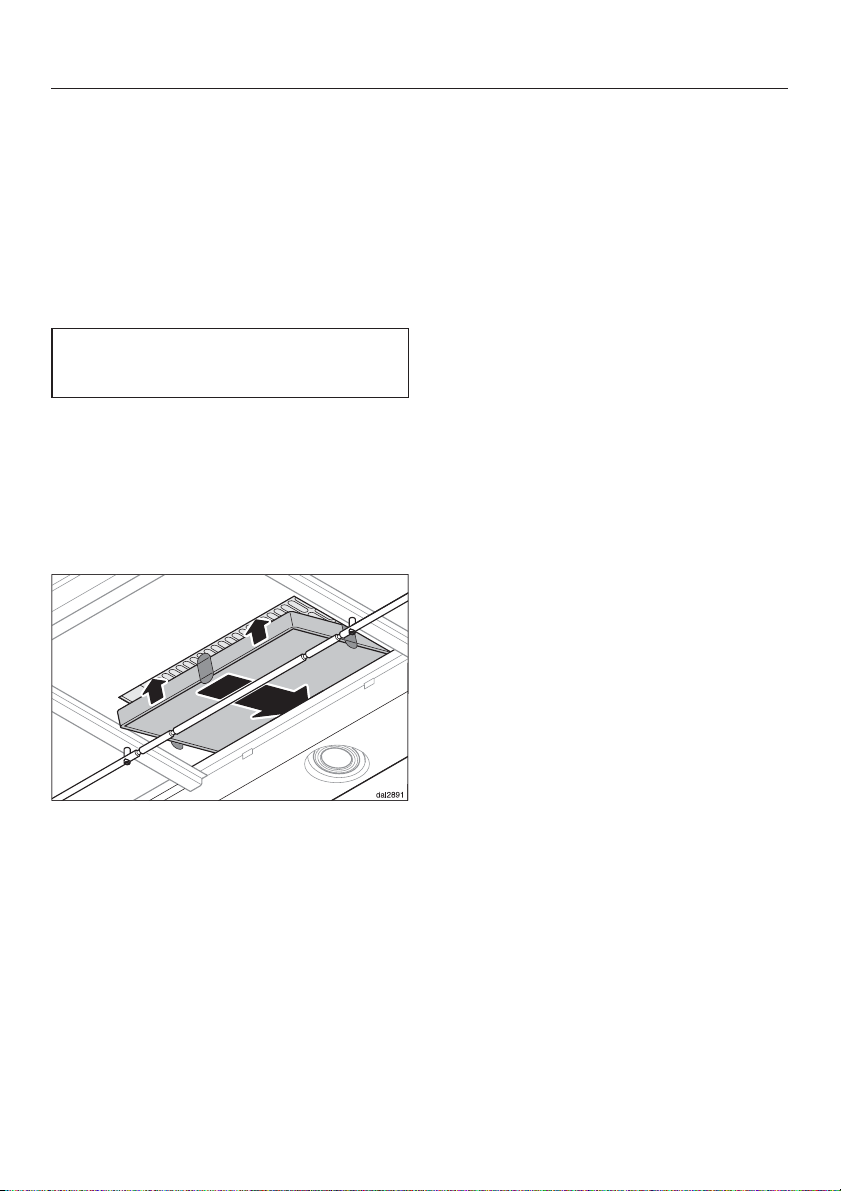

Cleaning and care

Installing / replacing the

odor-free filter

In recirculation mode, an odor-free filter

must be used in addition to the grease

filters. It is designed to absorb cooking

odors.

It is installed in the canopy above the

grease filters.

Replacement active charcoal filters

can be ordered from Miele.

To install or replace the odo-freer

^

filter, the grease filters must first be

removed as described in the

previous pages.

^ Remove the odor-free filter from the

packaging.

Before first use:

Program the filter timer (see

^

"Operation").

Replace the odor-free filter when:

the odor-free filter symbol of the

–

filter button comes on,

or

when the filter no longer absorbs

–

odors efficiently.

However, it should be changed at least

every 6 months.

Used odor filters may be discarded

with the household garbage.

Resetting the odor-free filter timer

After replacing the filter, reset the

odor-free filter operating hours counter.

^ With the fan running, press the filter

button [ twice and hold it for

about 3 seconds, until only the 1

flashes.

The odor-free filter symbol goes

out.

^

Slide the odor-free filter into the rear

of the filter frame, then raise the front

and push it into the frame.

^

Reinsert the grease filters and the

panels.

18

If you clean the odor-free filter before

the operating time elapses:

^

Press the filter button [ twice and

hold it for about 6 seconds, until only

the 1 flashes.

Page 19

Changing the light bulbs

,WARNING

TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Before changing the light bulbs,

disconnect the hood from the power

supply, see "Important Safety

Instructions".

When in use halogen bulbs become

extremely hot, and can burn your

hands. Do not attempt to change the

bulbs until they have had sufficient

time to cool.

Cleaning and care

^ To change the halogen bulb, first

gently press the light cover. The

cover will open and can now be

flipped down.

^

Pull the halogen bulb from its socket.

^

Using a cloth or glove, insert the new

halogen bulb (type 12 V, 20 W, G4).

Please follow the manufacturer's

instructions.

^

Flip the light cover back up, making

sure it clicks into place.

19

Page 20

After Sales Service

Repairs

In the event of a fault which you cannot

easily fix yourself, please contact the

Miele Technical Service Department.

When contacting the Technical

^

Service Department, please quote

the model and serial number of your

appliance.

These are shown on the data plate

which is visible when the grease filters

are removed.

MieleCare

(USA only)

MieleCare, our Extended Service

Contract program, gives you the

assurance of knowing that your

appliance investment is covered by

5 years of worry free ownership.

MieleCare is the only Extended Service

Contract in the industry that guarantees

repairs by a Miele Authorized Service

Provider using genuine Miele parts.

Only genuine Miele parts installed by

factory trained professionals can

guarantee the safety, reliability, and

longevity of your Miele appliance.

Please note that unless expressly

approved in writing by Miele’s Service

department, Extended Service

Contracts offered by other providers for

Miele products will not be recognized

by Miele. Our goal is to prevent

unauthorized (and untrained) service

personnel from working on your Miele

products, possibly doing further

damage to them, you and/or your

home.

20

To learn more about MieleCare

Extended Service Contracts, please

contact your appliance dealer or visit

us online at:

http://mieleusa.com/mielecare

Page 21

Installation Instructions

Read these instructions and the "Important Safety Instructions" before installing

this ventilation system.

The installation steps are described in the enclosed "Installation Diagram".

Leave these instructions with the appliance for the consumer/user.

Information is subject to change. Please refer to our website to obtain the most

current product specification, technical & warranty information.

Page 22

22

Page 23

Caring for the environment

Disposal of packing material

The cardboard box and packing

materials protect the appliance during

shipping. They have been designed to

be biodegradable and recyclable.

Please recycle.

DANGER

,

Ensure that any plastic wrappings,

bags, etc., are disposed of safely

and kept out of the reach of babies

and young children. Danger of

suffocation!

Disposal of an old appliance

Old appliances may contain materials

that can be recycled. Please contact

your local recycling center about the

possibility of recycling these materials.

Before discarding an old appliance,

disconnect it from the electrical

supply and cut off the power cord to

prevent it from becoming a hazard.

23

Page 24

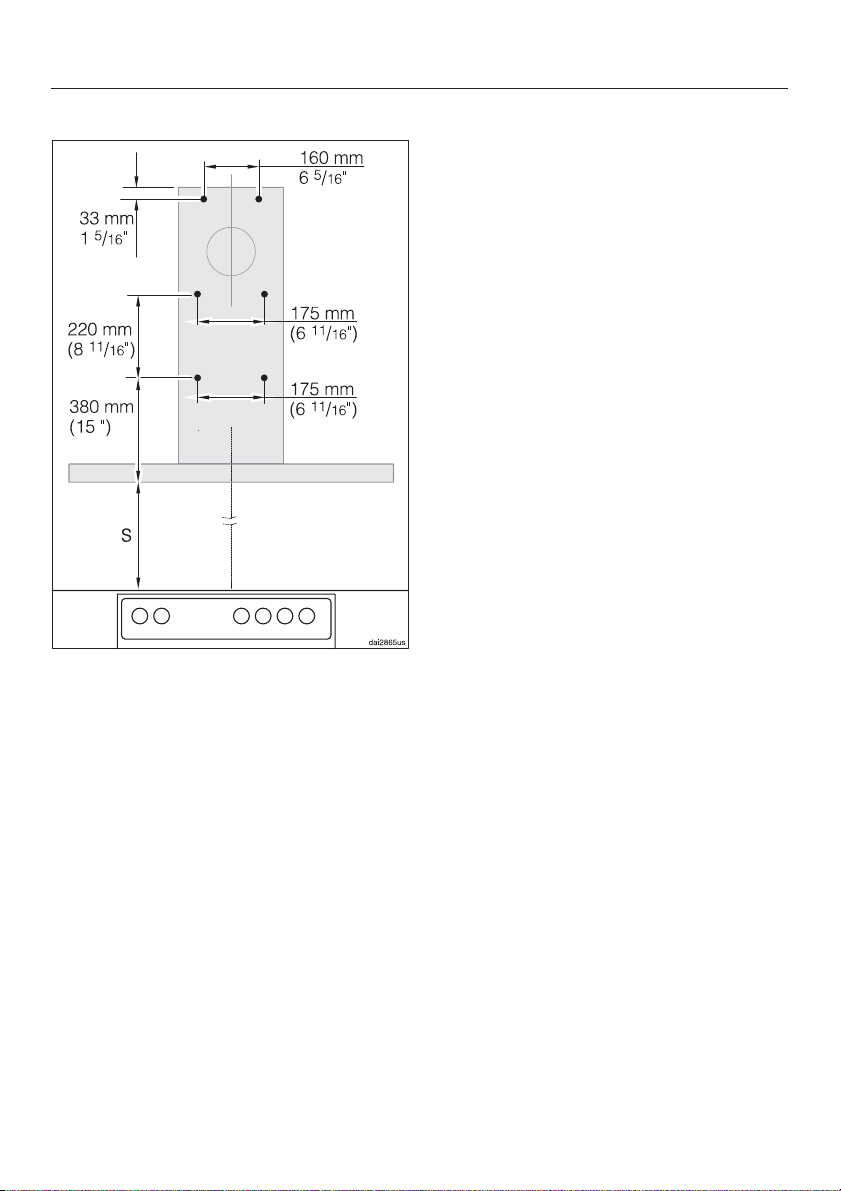

Appliance dimensions

Drawing is not to scale.

24

Page 25

a Air extraction mode

b Recirculation mode

c Recirculation vent positioned at the

top (only for the DA 6590 W in

recirculation mode)

d, e Installation area;

For recirculation mode only d.

Wall/ceiling area respectively for vent

hole and outlet installation.

For recirculation mode only the outlet

installation is required.

Connection for extraction mode

6" (150 mm), with vent pipe adapter

5" (125 mm).

Appliance dimensions

25

Page 26

Appliance dimensions

Distance between cooktop and hood (S)

Do not install this exhaust hood over cooktops burning solid fuel.

Provided a larger distance is not given by the manufacturer of the cooktop, follow

the minimum safety distances between a cooktop and the bottom of the hood:

Miele Cooktops Non-Miele

Cooktops

Electric Cooktops 24" (610 mm)

Electric Barbeques and Fryers 26" (660 mm)

Multiburner Gas cooktops

<

43,000 BTU (12.6 KW)

and no burner > 15,000 BTU (4.5 KW)

26" (660 mm) 30" (760 mm)

Single burner (Wok) <

All other gas cooktops 30" (760 mm)

– If several gas surfaces are installed under the hood, the total output must be

considered when determining the minimum safety distance.

– Be sure to follow the minimum safety distances given by the gas cooktop

manufacturer to easily flammable materials e.g. upper cabinets.

–

If local building codes require a greater safety distance, follow their requirement.

–

If there is more than one appliance beneath the hood and they have different

minimum safety distances always select the greater distance.

See "Important Safety Instructions" for further information.

–

To ensure free access to work under the ventilation hood, a distance of a

minimum of 26" (660 mm) above the electric cooktop is also recommended.

–

Take the user's body height into consideration when selecting the installation

height. Adequate work space at the cooktop and optimal operation of the

ventilation system should be ensured.

–

However, the greater the distance from the cooktop, the less effectively cooking

odors are drawn in.

–

If the top of the hood will be mounted flush to the ceiling, regard the possible

unit height when selecting the installation height.

26

20,500 BTU (6 KW) 26" (660 mm) 30" (760 mm)

Page 27

Drilling diagram

Appliance dimensions

To prepare a backing plate, the

spacings for the 5 mm screws need to

be drilled as shown.

If the ventilation hood will be mounted

directly to the wall, follow the additional

instructions given in the included

"Installation diagram".

27

Page 28

Plywood backing

The majority of the weight of the

installed ventilation system will be

supported by the lower retaining

plate. It must be firmly attached to

the stud framing behind the drywall.

If studs are not available in the

required locations, a plywood

backing (min. ½" (13 mm) thick)

spanning at least two studs must be

installed. Failure to adequately

support the weight as stated may

result in the ventilation system falling

off the wall, causing personal injury

and property damage.

(If plywood backing is not needed,

proceed to the included "Installation

diagram".)

To install a plywood backing

Find the studs to the left and right of

^

the mounting location by tapping the

wall or using a stud finder.

Mark a vertical cutting line along the

^

center of each stud.

CAUTION

,

When cutting or drilling into the wall

or ceiling, do not damage electrical

wiring and other hidden utilities.

Remove the drywall between the

^

cutting lines and replace it with

plywood of a matching thickness

(min. ½" (13 mm) thick). Tape the

joints and refinish the wall.

^ Proceed to the enclosed "Installation

diagram" to complete the installation.

^

Determine and mark the location of

the retaining plate for the canopy as

outlined on the "Installation diagram".

^

Make a cutting line 3" (76 mm) above

and 3" (76 mm) below the outline of

the retaining plate.

28

Page 29

Before installation read the

information in the "Dimensions" and

"Important Safety Instruction"

chapters.

Under certain conditions, there is a

danger of poisonous fumes by when

the ventilation system and a furnace

drawing interior air run at the same

time.

Installation instructions

The individual installation steps are

described in the included Installation

diagram.

Protective film

(stainless steel units)

The casing is covered with a protective

film to prevent scratching during

transport.

Please peel off the film before installing

the casing parts. It can be removed

without tools.

Installation

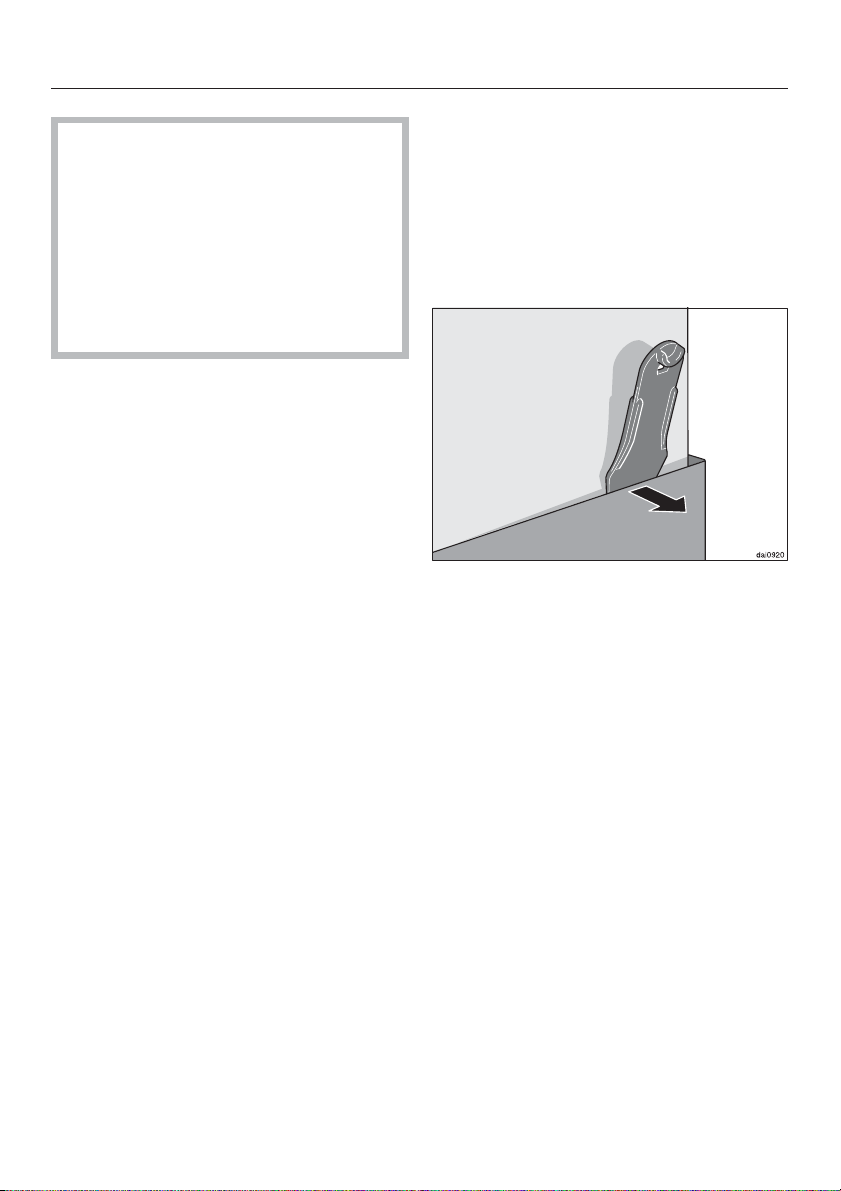

Dismantling

If the hood needs to be disassembled,

follow the instructions on the

"Installation diagram" in the reverse

order.

A lever is enclosed for easier removal

of the chimney extension.

^ After removing the two screws from

the chimney, slide the lever between

the chimney and the chimney

extension and gently apply pressure

to ease the chimney from its hooks.

29

Page 30

Installation

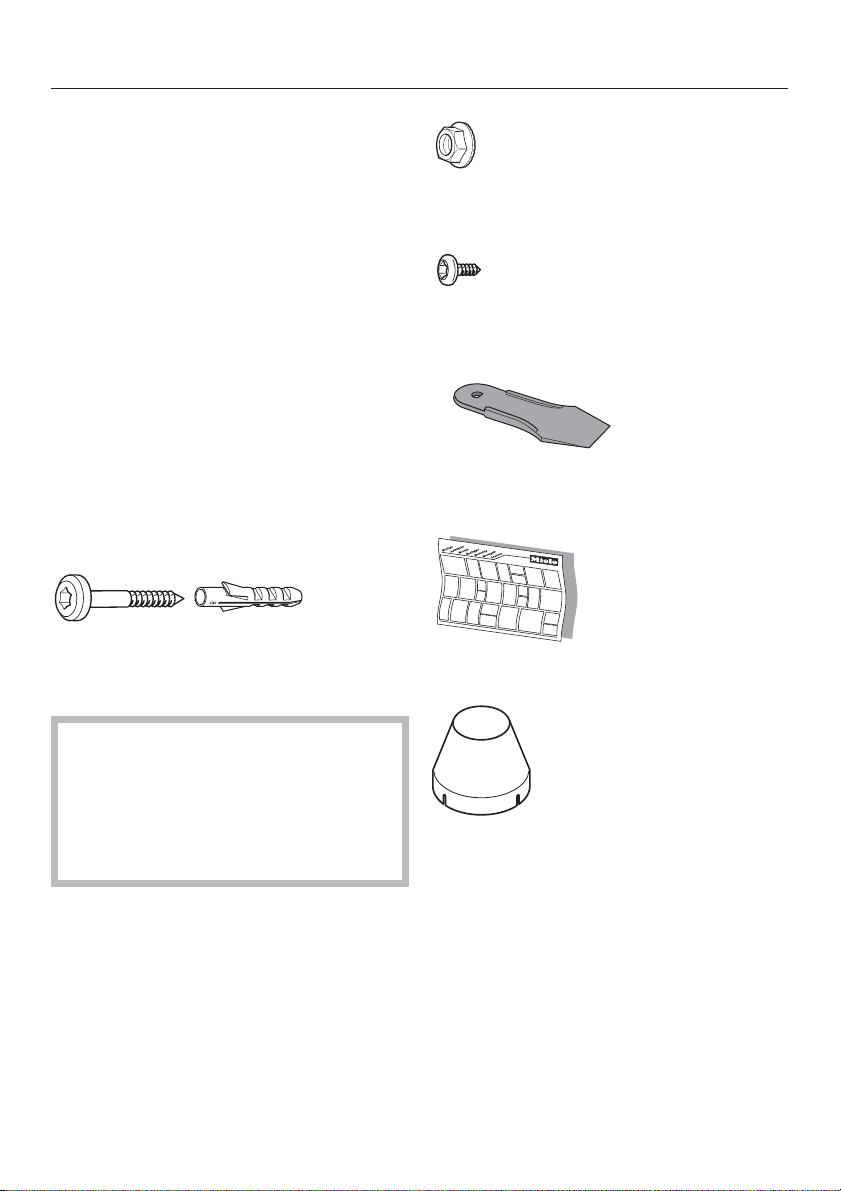

Installation material

30

Page 31

a 3 protective shields

to prevent scratches to the chimney

during installation.

b 1 vent collar

for use with 6" (150 mm) exhaust

ducting.

c 1 vent pipe adapter

for use with 5" (125 mm) exhaust

ducting.

d Telescopic retaining plate to

secure the ventilation hood to the

wall.

e Installation kit for recirculation

mode

contains diverter, hose and hose

clips (optional accessory, see

"Technical data").

Installation

2 M 6 locking nuts

for securing the motor assembly.

2 Screws 3.9 x 7.5 mm

for securing the chimney.

1 Lever

for dismantling the chimney.

6 Screws5x40mm

(S8 wall anchors included in the

packaging are not for use in USA / CDN)

,

The screws and wall anchors are

suitable for solid brick walls.

For other wall constructions, use

appropriate materials.

Ensure that the wall can support the

weight.

Installation instructions

Reducing collar

(optional accessory)

See "Reducing Collar" for more

information.

31

Page 32

Air extraction

WARNING

,

Danger of toxic fumes.

Exhaust ducting and connections

Use smooth or flexible pipework made

from approved non-flammable

materials for exhaust ducting.

Gas cooking appliances release

carbon monoxide that can be

harmful or fatal if inhaled.

To reduce the risk of fire and to

properly exhaust air, the exhaust

gases extracted by the hood

should be vented outside of the

building only.

Do not vent exhaust air into

spaces within walls or ceilings or

in attics, crawl spaces or garages.

To reduce the risk of fire, only use

metal ductwork.

Please read and follow the

"IMPORTANT SAFETY

INSTRUCTIONS" to reduce the risk of

personal injury. Follow all local building

codes when installing the hood.

To achieve the most efficient air

extraction and quietest noise levels,

consider the following:

The diameter of the ductwork should

–

not be less than 6" (150 mm).

If flat ducting is used, the cross

–

section must not be smaller than the

cross section of the ventilation

exhaust.

– The ducting should be as short and

straight as possible.

– Use ductwork with a wide radius.

– The exhaust duct must not be bent

or compressed.

– Make sure all connections are

secure.

– Where the ductwork is horizontal, it

must slope away from the hood at

1

least

/8" per foot (1 cm per meter) to

prevent condensation dripping into

the appliance.

32

–

If the exhaust is ducted through an

outside wall, a Telescopic Wall Vent

can be used.

Page 33

If the exhaust is ducted into an

–

inactive flue, the air must be expelled

parallel to the flow direction of the

flue.

Never connect an exhaust hood to

an active chimney, dryer vent, flue,

or room venting ductwork. Seek

professional advice before

connecting an exhaust hood vent to

an existing, inactive chimney or vent

flue.

Important

Air extraction

If the ductwork runs through rooms,

ceilings, garages, etc. where

temperature variations exist, it may

need to be insulated to reduce

condensation.

33

Page 34

Air extraction

Reducing Collar

(optional accessory)

If you would like to reduce the

environmental impact of your ventilation

system by limiting the CFM output the

Reducing Collar can be installed.

It reduces the air flow to less than

400 CFM.

Check local building codes for

max. CFM requirements.

^

Push the Reducing Collar on the

exhaust port of the fan.

^

Push the exhaust hose over it.

Condensate trap

(optional accessory)

In some cases, a condensate trap may

also be required to collect and

evaporate any condensate which may

occur. This optional accessory is

available for ducts 5" (125 mm) and 6"

(150 mm) in diameter.

When installing a condensate trap,

ensure that it is positioned vertically

and if possible directly above the

exhaust outlet.

^

Fix both with a hose clamp.

34

Page 35

Electrical connection

,WARNING

TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

All electrical work should be

performed by a qualified electrician

in strict accordance with national

regulations (for USA: ANSI-NFPA 70)

and local safety regulations.

Installation, repairs and other work

by unqualified persons could be

dangerous.

Ensure that power to the appliance

is OFF while installation or repair

work is performed.

^ Verify that the voltage, load and

circuit rating information found on the

data plate (located behind the

grease filters), match the household

electrical supply before installing the

hood.

^

Use only with ventilation hood

cord-connection kits that have been

investigated and found acceptable

for use with this model hood.

Grounding Instructions

This appliance must be grounded. In

the event of an electrical short circuit,

grounding reduces the risk of electric

shock by providing a path of least

resistance. This appliance is equipped

with a cord having a grounding wire

with a grounding plug. The plug must

be plugged into an outlet that is

properly installed and grounded.

WARNING - Improper grounding can

result in a risk of electric shock.

If there is any doubt, have the electrical

system of the house checked by a

qualified electrician.

Do not use an extension cord. If the

power supply cord is too short, have a

qualified electrician install an outlet

near the appliance.

Important

The hood comes equipped with a 6.5 ft

(2 m) power cord with a NEMA 5-15

molded plug for connection to a

120 VAC, 60 Hz, 15 A power outlet.

If there is any question concerning the

electrical connection of this appliance

to your power supply, please consult a

licensed electrician or call Miele’s

Technical Service Department.

,WARNING:

THIS APPLIANCE MUST BE

GROUNDED

35

Page 36

Technical data

Total connected load * ........410W

– Fan motor * ................350W

– Overhead light ...........3x20W

Voltage ................. 120VAC

Frequency .................. 60Hz

Fuse rating ...................15A

Length of the

power cord ..............6.5ft(2m)

Weight

DA 6590 W ...........46lbs(21kg)

Optional accessories for

recirculation (DA 6590 W only):

– DUW 20 conversion kit

– Miele DKF 12-1 active carbon filter

363738

Page 37

Page 38

Page 39

39

Page 40

Alteration rights reserved / 5012

INFORMATION IS SUBJECT TO CHANGE. PLEASE REFER TO OUR WEBSITE TO OBTAIN THE MOST

CURRENT PRODUCT SPECIFICATIONS, TECHNICAL & WARRANTY INFORMATION.

M.-Nr. 09 523 600 / 01

Loading...

Loading...