Page 1

VHF

(WIDE

BAND)

SERVICE

MANUAL

LAND MOBILE RADIO

1690

North

Kansas

Topping Avenue

City,

Missouri

bUVUUU

64120

MANUAL

09-342/442 XL

SM-8/86-1.5M

NO.

70-342442

Page 2

PREFACE

70-342https://manualmachine.com/442~~

This service manual

the 70-342XL and 70-442XL transceivers. In the first section of this

manual, after transceiver description and specifications, instructions

for transceiver preparation

stallation, and summaries of available support equipment.

The second section of this service manual, entitled SERVICING,

dedicated to transceiver repair. Troubleshooting flow charts for

locating likely problem

General information follows, such

replacement instructions and realignment procedures.

Transceiver circuitry

herein respectively. Each PC board

diagrams;

Each schematic page has

be vi.ewed with

Because the PC boards have components and plating on both sides,

layout diagrams show superimposed images of plating patterns and

respective other-side-component maps. Any double-image layout of the

three PC boards can be viewed with their respective schematic without

turning pages.

all

of which can be viewed with their respective schematics.

it.

is

intended to facilitate set-up and service of

are

found-- programming, calibration, ir-

areas

is

contained on three PC boards and categorized

a

list

are

in the beginning of t-his section.

as

chip component identification and

is

detailed in text, charts, and

of other applicable diagrams that can

is

,

Information in this book

of the variety of readers' requirements, details of option add-ons

are

OPTIONS,

each add-on kit.

As

buted on the following forms:

Many useful facts and tips

intends to service several of the transceivers described herein,

spending

not included.

is

provided for allocating technical literature acquired with

necessary, service manual supplements

Manual Addition (MA)

Change Notice (CN)

Manual Correction (MC)

Technical Bulletin (TB)..For solutions to field problems and tips

time

to read applicable text

is

A

divider

.....

......

focused on the basic transceiver. Because

at

the end of this book, entitled

will

For supplemental information useful in

product alignment, service, or improvement. Printed on BLUE paper.

For circuitry change details made during

production by model and

Printed on YELLOW paper.

...

For correcting literature errors not

related to production changes. Printed

on GREEN paper.

for performance improvement. Print.ed on

PINK paper.

are

provided in the text. If the reader

will

be published and distri-

save

time

serial

in the end.

number.

Page 3

TABLE

OF

Preface

Table of Contents

Description 3

Specifications:

ElPROM Programming:

Transceiver Calibration:

Installation:

Automotive Receiver Interference 31

Optional Accessories

Service Equipment 37

Service Tools

Optional Feature Add-on Kits 39

CONTENTS

.................................................

.......................................

70-342https://manualmachine.com/442~~

PAGE

ii

1

.............................................

General

Transmit

Receive

Scan and CTCSS

Programmable Parameters

H1

Version Programmer Software 10

ElPROM Module Removal

Programming

Set-up

Error Codes

Procedure 20

Instructions 22

Under-Dash Configuration 24

Trunk-Mount Configuration

Under-Dash Power/Accessory Plug 26

Trunk-Mount Power and Accessory Plugs 28

.............................................

............................................

.............................................

......................................

.............................

......................

...............................

.........................................

..............................................

.........................................

...........................................

........................................

............................

...........................

.....................

...............

........................

....................................

.......................................

...........................................

4

5

6

7

9

10

11

18

19

25

35

38

............................

SERVICING

Troubleshooting Charts:

General 45

CPU/Phase-Lock-Loop

Transmitter

Modulator

Receiver

Component Replacement:

Chip Component Identification

Replacing Components with Leads

Chip Capacitor and Resistor Replacement

Complete Alignment:

Set Up 53

Error Codes

Realignment

Factory Presets

.............................................

.................................

.........................................

...........................................

............................................

.......................

.....................

.............

..............................................

.........................................

.........................................

.....................................

continued

46

47

47

48

49

50

51

55

55

60

......

Page 4

SERVICING continued:

Circuit Analysisf

Transmitter Board

Microprocessor Pinouts Chart

RF Power Amplifier Board

Receiver Board

Simplified Squelch Circuit Schematic

Metering

Block Diagram 77

Under-Dash Circuitry:

Under-Dash Interconnect Diagram

Front Panel Schematic Diagram

Front Panel PCB Layouts

70-342XL/442X~ Receiver PCB Layouts

DC Voltages

70-342XL Receiver Board Schematic Diagram

Trunk-Mount Circuitry:

Trunk-Mount Interconnect Diagram

Control Head

Control-Cable Interface Board

DC Voltages - Receiver Board

70-442XL Receiver Board Schematic Diagram

Transmitter Board:

DC Voltages - Transmitter Board

Microprocessor Pinouts (Duplicate Chart) 89

RF Power Amplifier PCB Layout 90

E/PROM Module Layout 90

Transmitter PCB Layouts

Transmitter

Under-Dash Exploded Mechanical

70-2301 Microphone

70-2195 Hang Up Box

Trunk-Mount Exploded Mechanical

Parts List 97

Parts Ordering 109

................................................

...........................................

..............................................

..........................................

...................................

........................

............................

......................................

....................

.....................

.......................

.............................

.................

-

Receiver Board

........................

...........

....................

........................................

.......................

........................

...........

.....................

............

.......................

................................

.............................

Board Schematic Diagram

View

Detail

Detail

...............................

..............................

View

.................

.....................

....................

61

63

69

71

75

76

78

80

81

82

83

83

84

85

86

87

87

88

91

93

94

95

95

96

OPTIONS

...................

Page 5

GENERAL DESCRIPTION

The MIDLAND SYN-TECH 70-342XL and 70-442XL VHF wide-band Land-Mobile

transceivers are mobile two-way radios designed to operate on FM

channels between 136 to 174 MHz. There are two varieties of the SYNTECH 70-342XL and 70-442XL transceivers, each designed to operate on

different channel frequency range: the A-band radios (70-342AXL

442AXL) on the 136-163 MHz range; the B-band radios (70-342BXL

442BXL) on the 148-174 MHz range. SYN-TECH transceivers have the

capacity to operate on up to eighty operator selectable channels, each

of which can be programmed in the service shop.

is

The SYN-TECH 70-342XL transceiver

It

ing.

panel for easy access to the operator. The SYN-TECH 70-442XL transceiver

location.

pin

receptacle

long Control Cable that interconnects the 70-442XL remote unit with

its

Control Head. The Control Head contains all the operator controls

and

operator.

As

the SYN-TECH 70-342 and 70-442 transceivers, the XL models are

wide-band radios. Electronic tuning of critical stages

allow them to operate over a 24 MHz spread of channel frequencies.

has a control knobs, push buttons, and display all on a front

is

configured for mounting in a vehicle trunk or other remote

It

does not have front panel controls; instead

in

its

face-piece. The receptacle accepts the 4-meter

is

much smaller in size for mounting where accessible by the

configured for under-dash mount-

70-342https://manualmachine.com/442~~

&

&

it

has a 34-

is

used to

a

70713-

It

5

A

is

is

The XL models are revised 70-342 and 70-442 transceivers that used

KHz for their main VCO comparator frequency. The 70-342XL and 70442XL models use 2.5 KHz, thus allowing channel frequency increments

of 2.5 KHz for half-channels.

as

Many optional features, such

Complete add-on kits for field installation are readily available.

listing

Operating parameters such

and a variety of feature timing and codes

in an alterable memory module for easy customizing. The plug-in

memory module

E/PROM Programmer.

The 70-342XL and 70-442XL transceivers contain three major printed

circuit boards. The Transmitter Board contains transmitter, synthesizer, and microprocessor control circuitry.

components facing up, on the top side of the chassis center divider.

The Receiver Board also lays horizontally, but on the underside of the

chassis divider with components facing down. The third PC board

the RF Power Amplifier Board located inside the rear heat sink.

accessible by removal of the heat sink top cover.

with

brief kit descriptions can be found in later sections.

as

channel frequencies, CTCSS frequencies,

is

reprogrammable in the service shop using the MIDLAND

CTCSS, can be added at the factory.

are

electronically contained

It

lays horizontally, with

Page 6

SPECIFICATIONS

OPERATING VOLTAGE: Nominal....

Range 10.5 to 16 VDC

..........

GENERAL

....

13.6 VDC, negative ground

70-342https://manualmachine.com/442~~

TEMPERATURE RANGE

ANTENNA IMPEDANCE

MICROPHONE

FREQUENCY CONTROL

FREQUENCIES OF OPERATION:

Models 70-342AXL1442AXL 136 to 162 MHz

Models 70-342BXLl442BXL 148 to 174 MHz

CHANNEL CAPABILITY: Standard

CHANNEL FREQUENCY SPREAD without retuning:

FREQUENCY TOLERANCE

DUTY CYCLE

.........................

.........................

..................-

..................

..................

.......

.......

......

Transmit....

Receive.

AND

STABILITY..+/- 5 ppm both TX and

.....

.........

30°C to +60°C

50 ohms, unbalanced

Dynamic element (with amplifier)

Phase-Lock-Loop synthesized with

EPROM Programming

Up to 80 transmit and 80 receive

24 MHz

24 MHz

2.5 ppm optional

+/-

2.0 ppm'optional

+/-

Intermittent. 1 min TX, 4 min

(Per EIA RS-152B)

maximum

maximum

RX

(standard)

RX

HIGH

VIBRATION STABILITY

SHOCK STABILITY...

CURRENT

DIMENSIONS (H

WEIGHT:

HUMIDITY. 95%

DRAIN:

Standby

Receive..

Transmit (40W

Transceiver (70-342XLl442XL) 65xl88x270mm (2.6" x 7.4" x 10.6")

Control Head for 70-442XL 5Ox88x80mm (2" x 3.5" x 3.2")

Speaker for 70-442XL 100x100x77mm (4" x 4" x 3")

Transceiver (70342XL1442XL)

Control

Speaker

--All

.....................

................

.................

....................

..................

@

x

W

x D):

50ohms)

....

at

50°C per EIA RS-152B, sec.13

Per EIA RS-152B,

Per EIA RS-152B,

0.35 ampere DC (max)

1.00 ampere DC (max)

8.50 amperes DC (max)

sec.

sec.

14

15

....

.......

............

.....

Head for 70-442XL 0.8 Kg (1.8 lb)

for 70-442XL

specifications subject to change without notice.--

............

.......

3.15

0.71 Kg (1.58 lb)

Kg (6.96 lb)

Page 7

SPECIFICATIONS

TRANSMITTER

Refer to EIA RS-152B and DOC RSS-119-Issue 3 for Method of Measurement

and Standard of Performance.

70-342https://manualmachine.com/442~~

CARRIER POWER OUTPUT

MODULATION SYSTEM

AUDIO FREQUENCY RESPONSE Per EIA and DOC specifications

AUDIO HARMONIC DISTORTION 3% THD

SYSTEM DEVIATION

MODULATION LIMITING

HUM AND NOISE

OCCUPIED BANDWIDTH...........

TRANSMIT CARRIER ATTACK TIME

CONDUCTED SPURIOUS EMISSIONS.

......................

...............

..................

...........

..........

...................+/-

................

......

.......

......

40

watts minimum,

adjustable from 20 to 40 watts

Phase Modulation

(1 KHz tone at 3.0 KHz deviation)

5

KHz maximum

Instantaneous peak clipping with

low-pass audio filtering

50 dB

Less than -60 dB of carrier power

30 KHz outside carrier frequency

100 ms max. for

Less than

25

50%

rated power

uW from 1 to

1000

MHz

MICROPHONE INPUT LEVEL.

OUTPUT PROTECTION: Shall withstand withcut damage,

OUTPUT STABILITY: Shall not exceed spurious emission limits herein

--All specifications subject to change without notice--

............-

operation into a 20:l load mis-match with any

standing wave variance.

while operating into a 5:l load mis-match with

full standing-wave variance.

8

dBm

+/-3

dB at

600

ohms

5

minutes of

Page 8

SPECIFICATIONS

RECEIVER

Refer to EIA RS-204C and DOC RSS-119 for Method of Measurement and

Standard of Performance.

....

SENSITIVITY: 12 dB SINAD......

0.25 uV into 50 ohms

70-342https://manualmachine.com/442~~

SQUELCH SENSITIVITY: Tight

Threshold....0.2 uV maximum or

SQUELCH BLOCKING.. 13 dB

RECEIVER ATTACK TIME......... 100

(squelch release)

RECEIVER SQUELCH CLOSING TIME...

ACCEPTABLE RF DISPLACEMENT.........+/- 3.5 KHz minimum

ADJACENT CHANNEL REJECTION

SPURIOUS RESPONSE IMMUNITY.... 85 dB

INTERMODULATION IMMUNITY..... 75 dB

AUDIO POWER OUTPUT:

Under-Dash Radio (70-342XL)

Trunk-Mount Radio (70-442XL) 5 watts at 5% THD into the 3.2 ohm

.................

........

......

.........

.....

......

.....

1.0 uV minimum, 2.0 uV maximum

6

dB SINAD

ms

...

200

ms

80

dB at +/-30 KHz

1

watt at 5% THD into its internal

speaker, or

5 watts 5% THD into a 3.2 ohm

external speaker

....

external speaker

AUDIO FREQUENCY RESPONSE.....

HUM AND NOISE: Un-squelched

Squelched 50 dB

CONDUCTED SPURIOUS EMISSIONS.. 200 uV across 50 ohms

INTERMEDIATE FREQUENCIES 21.4 MHz (1st) and 455 KHz (2nd)

--All specifications subject to change without notice--

......

.......

..........

.....

...........

6

Per EIA and DOC specifications

40

dB

(800

from DC to 1 GHz

pW)

Page 9

SCAN OPTION

Several of these parameters

are

programmable by E/PROM programming.

CHANNEL CAPACITY

OPERATOR CONTROL OF SCAN

PRIORITY CHANNEL SELECTION Any channel selectable by the oper-

INDICATION OF PRIORITY DETECTION

KEY-UP CHANNEL REVERT

EXTRANEOUSLY BUSY CHANNEL SKIP

PRIORITY CHANNEL SAMPLING RATE

SIGNAL DETECTION

...................

...........

.........

...

..............

.....

.....

...................

2 scan groups of 64 each

(duplicates allowed)

Three modes selectable by

push buttons

ator using the channel push buttons

Two-beep audible alert (elective)

Transceiver transmits on Priority

channel or

(depending on scan mode selected)

Channels can be skipped in scan by

DOWN

Every 4 or 8 channels, or every

or 2 seconds during scan hold

of carrier presence or vacancy; or

of correct CTCSS tone presence or

vacancy with

channel selection

last stopped channel

1

carrier

SCAN RESUME DELAY

SCAN SPEED (with standard timing):

Noise squelch busy detection 20 idle channels per second

CTCSS detection

CODE FREQUENCIES

MODULATION LIMITS 500 to 1000

DECODE SENSITIVITY

RECEIVER RESPONSE TIME

ENCODER RESPONSE TIME 50

TRANSMITTER TONE DISTORTION

AUDIO

DISTORTION WITH CTCSS TONE

..................

.....

..................

CTCSS OPTION

...................

..................

.................

.............

..............

........

...

0.3, 2.5, or 5 seconds or

lock

3

All

Less than 5 dB SINAD

200

5%

10%

&

hold until

channels per second if all busy

EIA standard from

Hz

ms

maximum

ms

maximum

maximum

reset

67

carrier

to 241.8Hz

deviation

--All

specifications subject. to change without notice--

7

Page 10

Page 11

E/PROM PROGRAMMING

The 70-342XL and 70-442XL transceivers contain an Erasable/Program-

mable Read Only Memory (E/PROM) module. The module holds specific

customer frequencies, feature selections, and other parameters that

determine radio operation.

Before final alignment and check, the module must be reprogrammed with

customer specifics. If any option add-on kits are to be installed,

appropriate parameters may also need to be programmed as instructed in

respective kit installation literature.

To change ElPROM electronic information, the plug-in module must first

be erased by exposing it to ultraviolet light using the MIDLAND 701100/1101 ElPROM Eraser. Then, reprogramming is necessary using the

MIDLAND 70-1000 ElPROM Programmer. Operation parameter information is

entered into the Programmer through its keypad, converted into binary

data useful to the transceiver, then written into the E/PROM.

The following are programmable operation parameters in the SYN-TECH

mobile transceivers. See the 70-1000 E/PROM Programmer Operator's

Manual (No. 70-999113) for details.

1.

All eighty transmit and eighty receive channel frequencies

2.

All standard CTCSS tones for each TX and RX channel (requires

installation of the CTCSS module within the transceiver)

3. Time-out-timer time (maximum continuous transmission

duration)

4.

Scan parameters as follows:

a. Two scan groups, each containing up to sixty-four

channels

A

b.

c. Either presence or absence of carrier or correct CTCSS

d. Channel sampling rate (time spent looking for carrier

e. CTCSS decode time (time allotted for decoding after

f. Scan hold time (delay of scan resume after channel

g. Post-transmit scan hold time (delay of scan resume

h. Retention of scan list channels deleted (skipped) by

5.

Busy channel lockout with or without alert tone to the

operator. Adding jumpers allows busy channel inhibit by

CTCSS tone status. See "BCLO JUMPERING".

6.

Transmit-to-receive changeover delay of up to 200ms for

special options.

7. Last selected channel recall on power-up may be disabled.

variety of priority/scan channel revert arrangements

utilizing the two channel lists.

tone to indicate a busy channel

presence on each channel)

carrier is detected)

clears)

after PTT release)

operator activation of the DOWN selector while in scan

mode. Normally, these selections are erased by release

of the SCAN and PRI push buttons and power-down. Programming limits erasure to power-down only.

70-342https://manualmachine.com/442~~

Page 12

H1 VERSION UPGRADE

The E/PROM programmer, model 70-1000, must contain H1 or later version

software to program all features and parameters into the 2-273 E/PROM

modules that are used in the 70-342XL and 70-442XL transceivers. The

version level of software installed in the programmer is identified

for one second in the two far right digits displayed after power-up.

If your programmer contains software that,is older (lower letter) than

the H1 version, upgrade is required. To date of this printing, the

newer L3 version software is current and available (in its own E/PROM)

in Update Kit No. 70-1411. The 70-1000 Operator's Manual also has

been rewritten. The May, 1985 printing can be ordered as MIDLAND part

number 70-999113.

CDCSS OPTION

If the Continuous Digital Coded Squelch System option is installed in

the transceiver, the ElPROM Module is different. This Module, MIDLAND

number 70-2402, is larger in size to accommodate an additional receptacle for connection to the CDCSS board. When programming, the ElPROM

type selection entered into the Programmer is the same as for the

standard EIPROM.

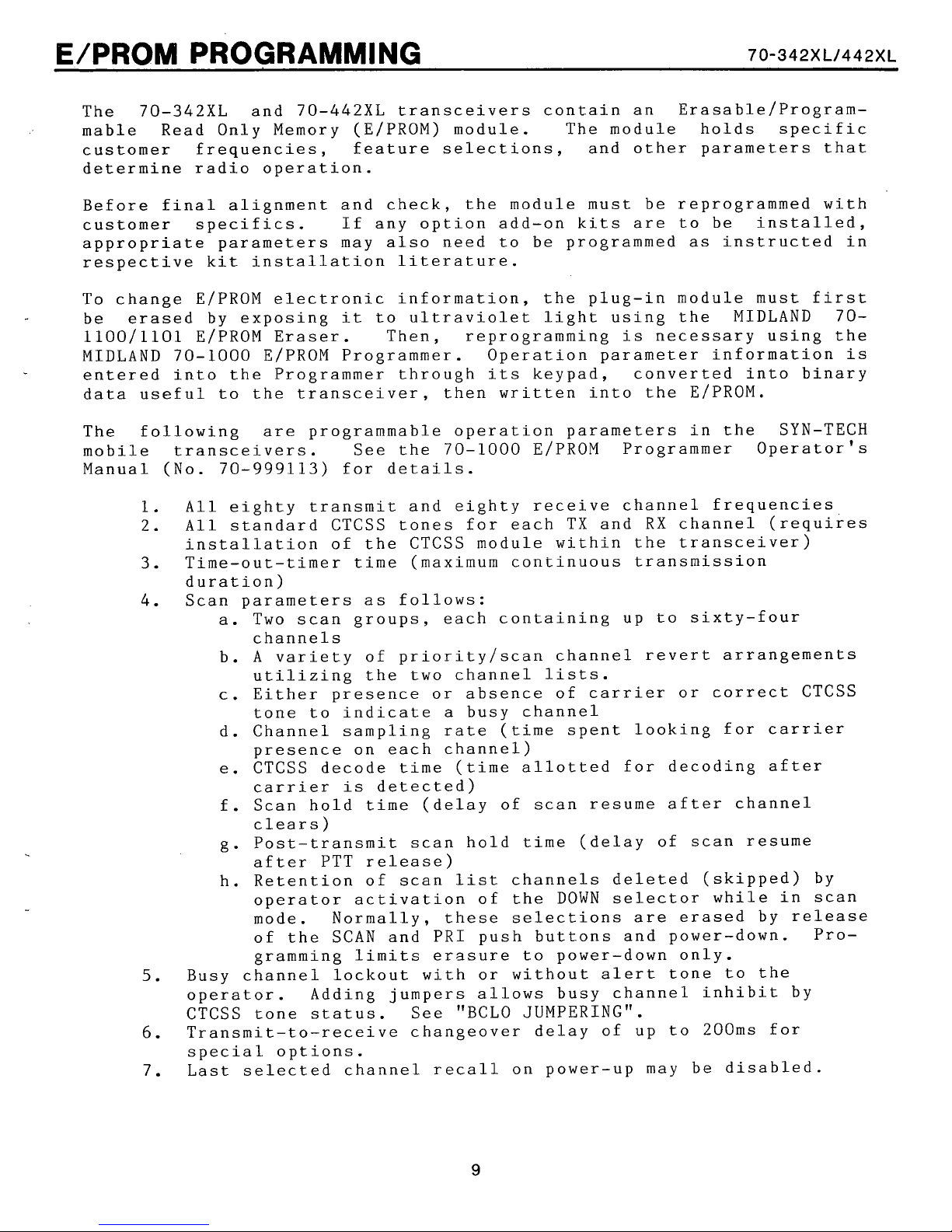

ElPROM MODULE REMOVAL

The E/PROM module is a small (1"

x

2") plug-in printed circuit board

that contains IC951 and IC952, and is labeled 2-273. It is located on

the Transmitter Board, over the microprocessor IC901. For replacement

purposes, the ElPROM module model number is 70-2401.

Always disconnect primary power to the transceiver before removing the

E/PROM module. Loosen the four transceiver top cover screws and lift

the cover off. Pull the E/PROM module straight upward to separate it

from its two connectors (see below).

70-342XL

OR

70-442XL

TRANSCEIVER

E/PROM MODULE LOCATION

Page 13

E/PROM PROGRAMMING

PROGRAMMING

The following E/PROM programming procedure covers most programming for

transceiver operation. Certain infrequently modified parameters are

as

excluded (parameters listed

programming procedures can be found in the Programmer Operator's

Manual.

Heed this precaution:

Do not apply or remove AC-line power to the Programmer while an

E/PROM module

able, to plug the module onto the Programmer until all parameter

information

ready for the BLANK-WRITE-VERIFY operation (step 25).

is

plugged into

is

keystroke entered. Connect the module only when

4h, 6, and 7 on page nine). Complete

it.

It

is

not necessary, nor advis-

70-342https://manualmachine.com/442~~

1.

2. Turn the 70-1000 Programmer on. One of these self-test messages

3.

Erase the E/PROM module in the 70-1100/1101 Eraser. Assure the

E/PROM window

Refer to the Eraser instruction manuax for details.

must appear in the FREQUENCY display for one second: "PASSOL3",

"PASSlL3", "PASSOHll', or "PASSIHll'. The

the required software revision level

programmer. After two seconds, "TYP" should appear in the BAND

display. If an earlier version software

VERSION UPGRADE preceding.

Enter the heading (not necessary for transceiver operation, but

recommended for organization) by pressing [MANUAL], then [ENTER],

then the following:

a. The second part of the transceiver model number ('342A1,

for example). Then [ENTER].

b. Transceiver eight digit

Then [ENTER].

c.

First three digits of a ten digit customer number

(ex.: '123'). Then [ENTER].

d. The last seven digits of the customer number

(ex.: '9ABCDEF1). Then [ENTER].

e.

The month numerically (ex.: March = '3'). Then [/I.

f. The date ('1' through '31'). Then [/I.

g. The

h. Press [RESET] to close heading sequence.

is

last

clean, and

two digits of the year (ex.: '86'). Then [ENTER].

set

serial

exposure

H1

number (ex.: '12345678').

time

last

or L3

is

for 45 minutes.

two digits indicate

is

installed,

installed in the

see

H1

--E/PROM Type Selection--

4.

Press [l] to

should appear. (If the transceiver contains either Talk-Around

option 70-2815 or 70-2816,

by pressing [7] instead of [I]) Press [ENTER].

select

the standard 2-273 E/PROM Module. "2-273"

select

the Z-273TA E/PROM Module type

Page 14

E/PROM PROGRAMMING

70-342https://manualmachine.com/442~~

5.

--Channel Frequency Programming--

The CHANNEL display indicates the numeric channel designator that

appear in the transceiver display. The STEP display indicates what

entry

If an invalid frequency

quency display

frequency.

6.

Select the VHF band and 2.5 KHz PLL reference code by pressing

[2], then [Dl. "15d" should appear in the BAND display (if the

transceiver has been modified with 70-2178 or 70-2179 High-Side

Injection

[ENTER]. The Programmer should now be ready for channel

frequency entry.

is

to be made for that channel--

"1"

"2"

"3"

"4"

CHANNEL

desired receive frequency for channel

point. Then press [ENTER].

Kits,

=

receive frequency

=

receive CTCSS tone frequency or receive CDCSS code

=

transmit frequency

=

transmit CTCSS tone frequency or transmit CDCSS code

will

"1"

use band code [El instead of [Dl). Press

is

entered in the following steps, the fre-

flash. Press [CLEAR], then reenter the correct

and STEP

"1"

should now be displayed. Key in the

1

including the decimal

will

7. CHANNEL

option

or CDCSS code can be entered as described below.

CTCSS Key in the desired CTCSS tone frequency to be decoded

including the decimal point (only standard EIA frequencies

are

Press [ENTER]. If

coded squelch option

CDCSS Key in the desired three-digit standard decode code

(only EIA standard codes

in the FREQUENCY display. If signal

after digits.

carrier squelch operation

option

The Programmer contains

frequencies and CDCSS codes, any of which each

this mode. Press

again to increment through them one

are

stacked on top of the CTCSS tone

scrolling past the highest CTCSS tone. Press [C] to decrement

through the

displayed, press [ENTER] to program.

"l",

is

valid). The digits

STEP "2", should be displayed. If a coded squelch

installed in the transceiver, the CTCSS tone frequency

will

carrier

is

not installed, enter zero.

A

"-"

will

is

installed, enter zero.

a

table of EIA standard CTCSS tone

[Dl

to

call

lists.

When the desired frequency or code

appear in the FREQUENCY display.

squelch operation

are

valid). The digits

is

inverted, key [A]

appear. Press [ENTER]. If

is

desired or no coded squelch

the CTCSS tone frequencies and

at

a

time.

list,

and should appear when

is

desired or no

will

are

accessible in

The CDCSS codes

is

appear

Page 15

E/PROM PROGRAMMING

70-342https://manualmachine.com/442~~

8.

9. CHANNEL

10. Repeat steps 6 through

--Center Frequency Programming--

To afford wideband capability, the self-tuned 70-342XL and 70-442XL

transceivers switch the operating range of their VCO's when selected

channel frequency crosses

controlled by the microprocessor and must programmed into the E!PROM.

Center Frequency values entered into the E/PROM depend on the transceiver frequency band (A-band or B-band).

CHANNEL

transmit frequency for channel

Then press [ENTER]. If the transmitter

channel

is

equipped with a coded squelch option, key in the desired CTCSS

tone frequency or CDCSS code to be transmitted, or nothing for no

tone/code transmission. Then press [ENTER]. The tone/code table

can be used in this mode also.

channels. Channels may be skipped and left unprogrammed.

Channels can be scrolled and re-accessed using the up and down

arrows.

"l",

1,

"l",

STEP

enter zero.

STEP "4", should be displayed. If the transceiver

"3",

should be displayed. Key in the desired

1

including the decimal point.

is

to be disabled in

10

to program the remaining seventy-nine

a

range-center frequency. This switching

is

11.

12. STEP

13.

--Scan Channel Entry--

14. Channel and tone frequency entry

Scroll backward through the channel

arrow push button. Whenever the

channel

accessed and "CF" appears in the CHANNEL display. Stop on the CF

channel.

Frequency entry. Key in '148.12' if the transceiver

model (136-162 MHz range) or key in '160.92' if the transceiver

is

a

STEP

Frequency entry (STEP 2 and 4 do not apply, therefore do not

appear with the CF channel). Key in '147.20' if the transceiver

is

an A-band model (136-161 MHz range) or '160.00' if the

transceiver

[ENTER].

begin scan channel programming sequence. The display

bgank except for the SCAN indicator.

0

to channel 79, the Center Frequency 'channel'

"1"

will

B-band model (148-174 MHz range). Press [ENTER].

"3"

will

also appear, showing readiness for receive Center

appear, showing readiness for transmit Center

is

a B-band model (148-174 MHz range). Press

list

list

is

complete. Press [SCAN] to

with the appropriate

is

looped backwards from

is

will

is

an A-band

be

There are two

list

the transceiver during scan operation differently, depending on

selection of the PRI and SCAN push buttons and Function Mode

programming. Details of operation are found in both the

transceiver and the Programmer operator's manuals.

can be up t.o 64 channels long. The two

lists

of scan channels available--A and B. Each

lists

are used by

Page 16

E/PROM

PROGRAMMING

70-342https://manualmachine.com/442~~

15. Press [A] to program the

display and the first

the BAND display.

16. Key in the channel number to be scanned first in the

press [ENTER]. While

in the CHANNEL display.

17.

18.

19. When the

After [ENTER]

display)

and press enter. If you make an error, press [CLEAR] and

enter. If the channel entered

frequency entry steps above, the CHANNEL display

indicate the error. Press [CLEAR] and enter

Continue entry of the A scan

several scan sequence spots to cause

To

scroll through the

each sequence designator assignment. The highest designator

63.

in the STEP display and the lowest B

designator (0) should appear in the BAND display. Enter B scan

list

highest

will

A

channels in the

list

is

pressed, the

increment to

list

entry

sequence designator

A

list.

list

it

sequence designator "0"

is

keyed, the channel number

1.

list.

A

list,

is

complete, press [B]. "b" should appear

same

manner as A list

"A"

will

A

list

Key in the second A scan channel

was

press the up and down arrows to

sequence designator (BAND

left blank in the channel

A

channel can be entered in

it

list

is

63.

appear in the STEP

will

will

a

valid channel.

to be sampled more often.

scan sequence

entry. Again, the

appear in

A

list,

will

flash to

appear

re-

then

see

is

2C. Press [RESET] to exit the scan programming mode. The Channel

frequency entry mode

"l",

The Busy Channel Lockout feature, Time-Out-Timer feature, and scan

feature parameters

these eight parameters need programming for most applications, therefore attention

program the others (timing adjustments, etc.) can be found in the

Programmer Operator's Manual.

21. BCLO Press [FUNC.] then [ENTER]. "FnC"

display and

programming the Busy Channel Lockout (BCLO) feature,

active. Key in one of the following values, then press [ENTER].

If no entry

value of

for jumper considerations.

and the appropriate frequency.

are

is

given to only these four hereinafter. Procedures to

"1"

in the STEP display. Function Code

is

made, the transceiver

3

--no BCLO. Also

will

programmed in the Function Mode. Only four of

resume displaying CHANNEL

will

will

see

"BCLO JUMPERING'' in this section

operate per the default

appear in the BAND

"OM,

1,

for

is

now

STEP

Page 17

E/PROM

21. continued...

BCLO parameters:

Throughout Function Mode programming, the up and down arrows will

sequentially select the Function Codes.

22. Time-Out-Timer "FnC" and "2" will be displayed. Key in the

parameter value

below, then press [ENTER]. When the transmitter is continuously

keyed for the programmed duration, the timer disables the

transmitter and applies an audible alert tone to the speaker.

The

default value of

inoperative.

PROGRAMMING

O= BCLO without alert. No audible indicating tone will be

heard.

2= BCLO with alert. When the PTT button is pressed while ths

transceiver is inhibited, a tone will be applied to the

speaker.

3= BCLO disabled. No transmit inhibiting per receive status.

to set the Time-Out-Timer duration as listed

timer is reset upon PTT release. If no entry is made, the

0

will be automatic, leaving the Time-Out-Timer

70-342https://manualmachine.com/442~~

O= Disable the Time-Out-Timer

1= 30 seconds

2=

60

seconds

90

3=

23. Press the up arrow four times to skip to Function Code 7.

Function Codes 3 through

their default values.

scan timing, refer to the Programmer Operator's Manual for

procedure.

24. Priority Monitoring '!FnC1' and "7" should be displayed.

Entering a value in this mode either disables priority channel

(see

function is not programmed, the default is one Priority channel

sampling every eight channels scanned, and one Priority sampling

every second when scan is stopped on an active non-priority

channel.

Key in a value listed below, then [ENTER], to program the desired

sampling rates.

erato tor's

O=

1=

2= Sample the Priority channel once every four non-priority

3=

4=

seconds 7= 210 seconds

6

will automatically be programmed with

If

a special application requires altering

manual) sampling or changes its rate.

Sample the Priority channel once every four non-priority

channels scanned, and sample it every second when scan is

stopped.

Sample the Priority channel once every eight non-priority

channels scanned, and sample it every second when scan is

stopped.

channels scanned, and sample it every two seconds when

scan is stopped.

Sample the Priority channel once every eight non-priority

channels scanned, and sample it every two seconds when

scan is stopped.

Disable Priority monitoring

4=

120 seconds

5=

150 seconds

6=

180 seconds

If

this

Page 18

25.

Scan Format "FnC1' and

feature operates in three different mode formats--'Normal1,

'Modified', and 'Secondary'. Each

Manual.

"8"

should be displayed. The scan

is

described in the Operator's

While operating, scan

Programming can

CTCSS detection, absence of detected

correct CTCSS tone with

used in in special applications.

The parameter value determines both scan format and scan stop

aspects

[ENTER]. The default value if no entry

correct whether a coded squelch feature

transceiver or not. If no CTCSS frequency nor CDCSS code

programmed to a channel (steps 6-11), any odd value parameter

programmed

(ex.: If

will

Function Code

*

*

*

*.7=

$5

*

as

listed below. Key in the desired value and press

will

1

is

subtract 1 and operate per parameter 0.).

O=

'NORMAL' Scan Mode with scan stopped by carrier presence

1=

'NORMAL' Scan Mode with scan stopped by presence of

correct CTCSS tone or CDCSS code

2=

'NORMAL' Scan Mode with scan stopped by absence of

3=

'NORMAL' Scan Mode with scan stopped by presence of

without correct CTCSS tone or CDCSS code

4=

'MODIFIED' Scan Mode with scan stopped by

5=

'MODIFIED' Scan Mode with scan stopped by presence of

correct CTCSS tone or CDCSS code

6= 'MODIFIED' Scan Mode with scan stopped by absence of

carrier

'MODIFIED' Scan Mode with scan stopped by presence of

carrier

8=

'SECONDARY' Scan Mode with scan stopped by

9=

'SECONDARY' Scan Mode with scan stopped by presence of

correct CTCSS tone or CDCSS code

A=

'SECONDARY' Scan Mode with scan stopped by absence of

ca'rrier

b= 'SECONDARY' Scan Mode with scan stopped by presence of

carrier without correct CTCSS tone or CDCSS code

set

be decreased by one when read by the transceiver

programmed and CTCSS

8

--

is

stopped by detection of received signal.

scan-stop by noise squelch carrier detection,

carrier

carrier,

presence. The

is

is

is

disabled, the transceiver

or absence of

latter

made

installed in the

is

1,

two

are

which

is

carrier

is

carrier

carrier

without correct CTCSS tone or CDCSS code

carrier

presence

presence

,.

*

:

If the selected channel does not have a CTCSS tone or CDCSS

code programmed to

decrease this parameter value by one and operate accordingly.

26.

Parameter entry

feature

feature

the Programmer Operator's Manual for programming procedures.

This concludes the Function Mode programming sequence. Press

[RESET] to exit.

is

complete. If the last selected channel recall

is

to be disabled, or the operator-deleted scan channel recall

is

to be disabled, or scan timing needs modification; refer to

it,

the transceiver microprocessor

will

Page 19

E/PROM PROGRAMMING

70-342https://manualmachine.com/442~~

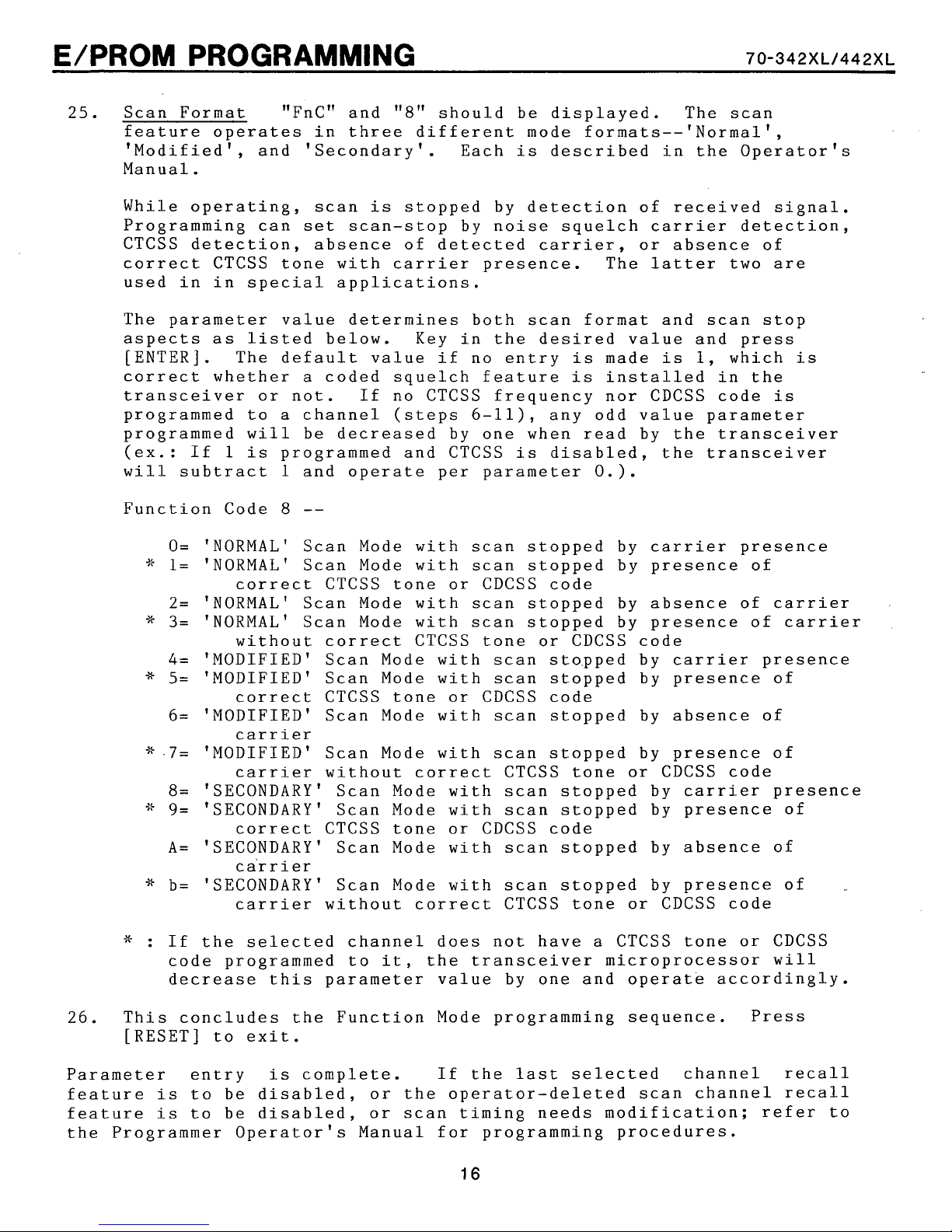

27. Plug the erased 2-273 ElPROM module onto the 70-1000 Programmer

as shown in Figure

2.

2-273

MODE

EIPROM PROGRAMMER

PROGRAMING

EIPROM MODULE

THE

E/PROM MODULE

28. Press [FUNC.] key, then the [4/B.W.V.] key. The BLANK, WRITE,

and VERIFY indicators

module

is

programmed. "PASS"

tent in the E/PROM

will

is

correct. If the readout displays flashing

each illuminate in succession as the

will

be displayed if the new con-

numbers or "ERR", the E/PROM must be erased again, and validity

of the previously entered channel information

is

in question.

29.

Install the E/PROM Module into the transceiver.

BCLO JUMPERING

The Busy Channel Lock-out feature, if programmed as previously described, prevents transmission on

audible

alert

when an attempt

is

a

busy channel and can provide an

made. The standard transceiver

is

configured for BCLO by carrier detection when enabled by programming.

Therefore if neither CTCSS nor CDCSS are used, no jumpers change

necessary. If desired, and if CTCSS (or CDCSS)

transceiver,

a

jumper can be moved to an alternate location inside the

is

installed in the

is

transceiver to prevent transmission only when an appropriate CTCSS

tone

is

received.

The BCLO jumper positions, JP107 and JP108, are located on the Transmitter Board between the modulator (L101, L102) shield and front PC

board edge. Remove the jumper

it

into the JP108 position to

set

wire

from JP107 position and install

BCLO by CTCSS tone (or CDCSS code)

detection. Do not install jumpers in both positions.

Page 20

TRANSCEIVER CALIBRATION

70-342https://manualmachine.com/442~~

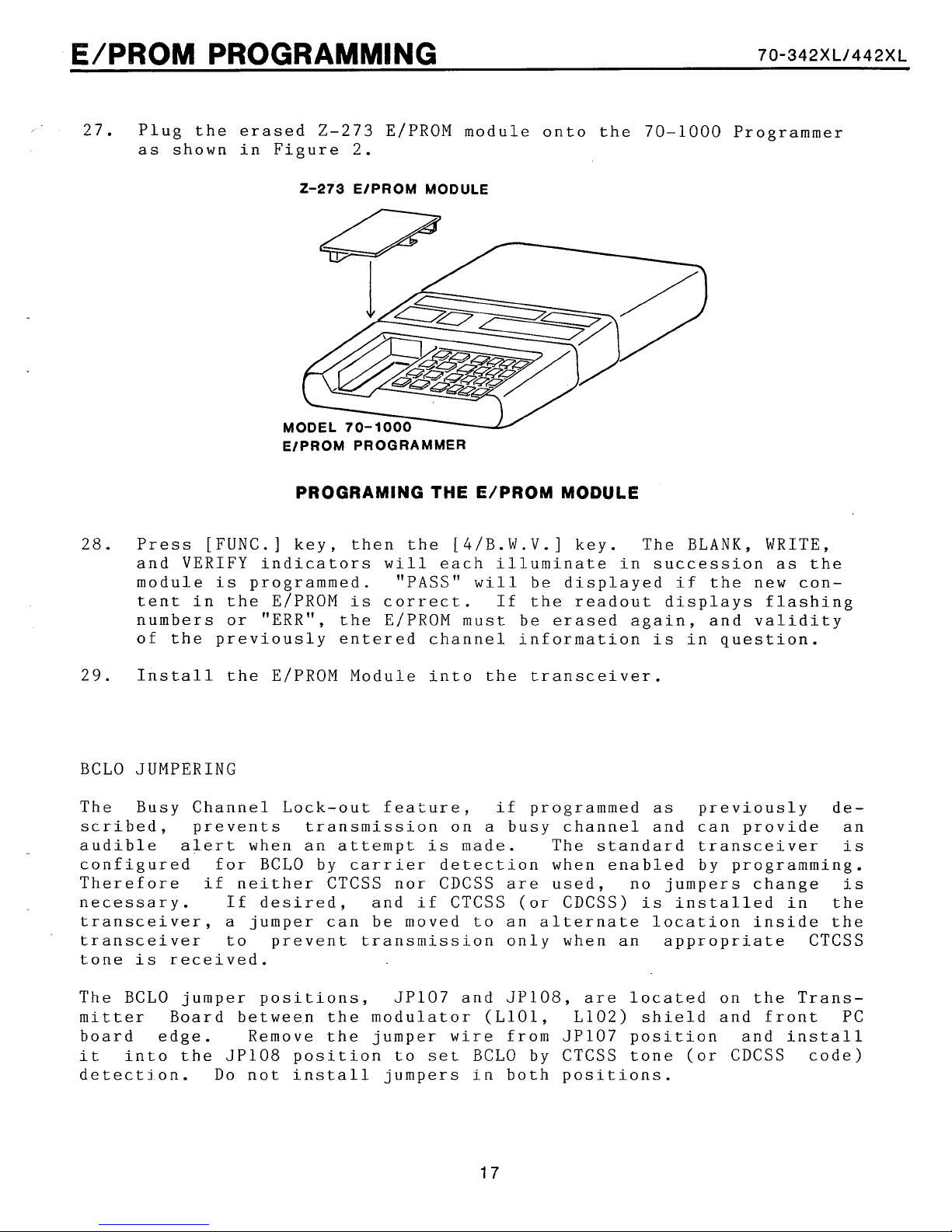

SUGGESTED TEST EQUIPMENT FOR TRANSMITTER CALIBRATION

Test Instrument Instrument Capabilities Instrument Type

DC Power Supply 13.8 VDC, 10 amps Power Mate BPA-20PF

Wattmeter

50 watts, 136-174 MHz Bird model 43 with 50C

element and 50 ohm load

Deviation Meter 136-174 MHz.

p/o Cushman CE-31A

+/-5KHz range

Frequency Meter or 136-174 MHz p/o Cushman CE-31A or.

Frequency Counter 2.0 ppm accuracy Heath SM-4120

Audio Generator 0-10 KHz sine-wave, Heath SG-5218

0-5 Vrms output

POWER

CALIBRATION

SUPPLY

SET-UP

Page 21

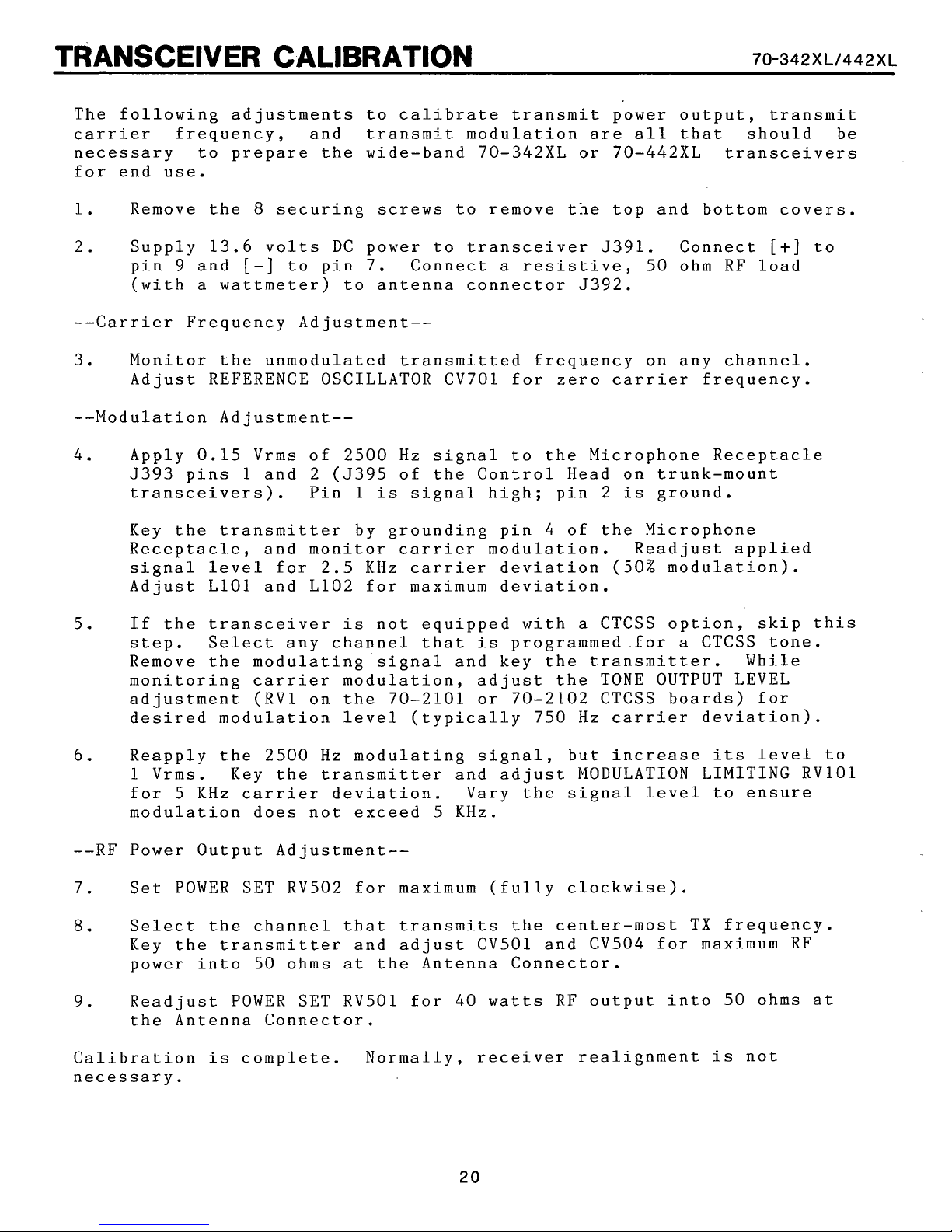

TRANSCEIVER CALIBRATION

The 70-342XL and 70-442XL wideband transceivers are capable of opera-

ting across

realignment

frequencies. Only transmit carrier calibration such as frequency,

modulation, and output power may need adjustment. The transceivers

are shipped from the factory programmed with test frequencies that

must be changed to customer frequencies before installation.

REALIGNMENT

sceiver tuning has been replaced. Realignment requires transceiver

operation on special frequencies, therefore they must be programmed

into the transceiver E/PROM specifically for alignment. The complete

Alignment procedure can be found in the SERVICING SECTION of this

manual.

a

24

MHz channel frequency spread. Therefore, receiver

is

not needed, even when reprogrammed with new customer

MAY

BE NECESSARY ONLY AFTER a component that affects tran-

-

70-342https://manualmachine.com/442~~

Error code 90, 91, 92, 93, or 94 appearing in the channel display with

-

continuous triple-beeps indicates the E/PROM module

improperly inserted, or incorrectly programmed. Check the E/PROM

module or refer to the E/PROM Programming section in this service

manual.

Error code 95 appearing in the channel display with

indicates the synthesizer phase-lock-loop cannot achieve lock.

defect exists and

it

must be corrected.

is

missing,

a

triple-beep

A

Page 22

TRANSCEIVER CALIBRATION

The following adjustments to calibrate transmit power output, transmit

carrier frequency, and transmit modulation are all that should be

necessary to prepare the wide-band 70-342XL or 70-442XL transceivers

for end use.

8

1. Remove the

securing screws to remove the top and bottom covers.

70-342https://manualmachine.com/442~~

2.

--Carrier Frequency Adjustment--

3. Monitor the unmodulated transmitted frequency on any channel.

4.

5.

Supply 13.6 volts DC power to transceiver 5391. Connect

9

and

[-I

pin

(with a wattmeter) to antenna connector 5392.

Adjust REFERENCE OSCILLATOR CV701 for zero carrier frequency.

Apply 0.15 Vrms of 2500 Hz signal to the Microphone Receptacle

5393 pins 1 and 2 (5395 of the Control Head on trunk-mount

transceivers). Pin 1 is signal high; pin 2 is ground.

Key the transmitter by grounding pin

Receptacle, and monitor carrier modulation. Readjust applied

signal level for 2.5 KHz carrier deviation (50% modulation).

Adjust LlOl and L102 for maximum deviation.

If the transceiver is not equipped with a CTCSS option, skip this

step. Select any channel that is programmed.for a CTCSS tone.

Remove the modulating signal and key the transmitter. While

monitoring carrier modulation, adjust the TONE OUTPUT LEVEL

adjustment (RV1 on the 70-2101 or 70-2102 CTCSS boards) for

desired modulation level (typically 750 Hz carrier deviation).

to pin 7. Connect a resistive, 50 ohm RE load

4

of the Microphone

[+]

to

6.

--RE Power Output Adjustment--

7.

8.

9.

Calibration is complete. Normally, receiver realignment is not

necessary.

Reapply the 2500

1 Vrms. Key the transmitter and adjust MODULATION LIMITING RVlOl

5

for

modulation does not exceed

Set POWER SET RV502 for maximum (fully clockwise).

Select the channel that transmits the center-most TX frequency.

Key the transmitter and adjust CV501 and CV504 for maximum RE

power into 50 ohms at the Antenna Connector.

Readjust POWER SET RV501 for

the Antenna Connector.

KHz carrier deviation. Vary the signal level to ensure

Hz

modulating signal, but increase its level to

KHz.

5

40

watts RF output into 50 ohms at

Page 23

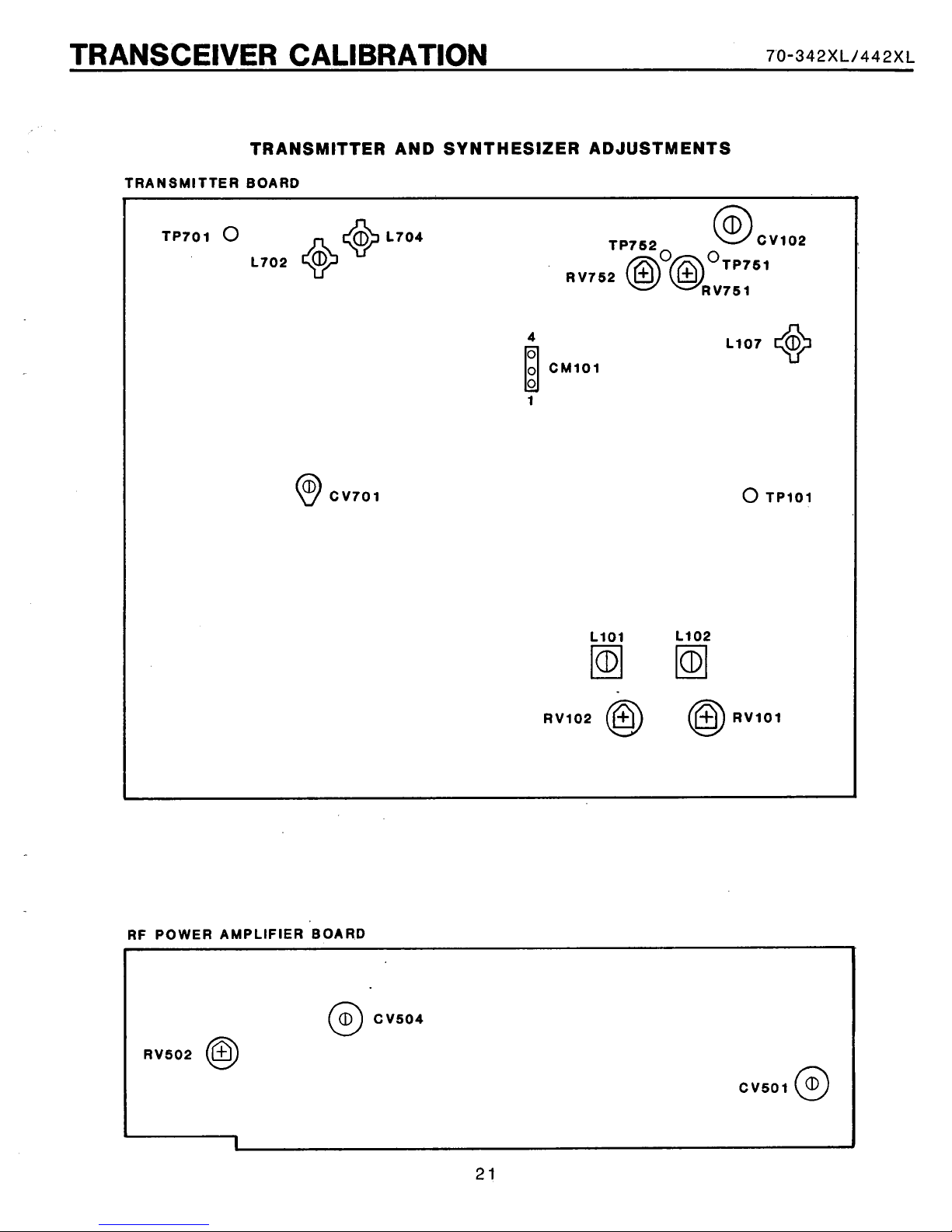

TRANSCEIVER CALIBRATION

TRANSMITTER AND SYNTHESIZER ADJUSTMENTS

TRANSMITTER BOARD

70-342https://manualmachine.com/442~~

RF POWER AMPLIFIER BOARD

Page 24

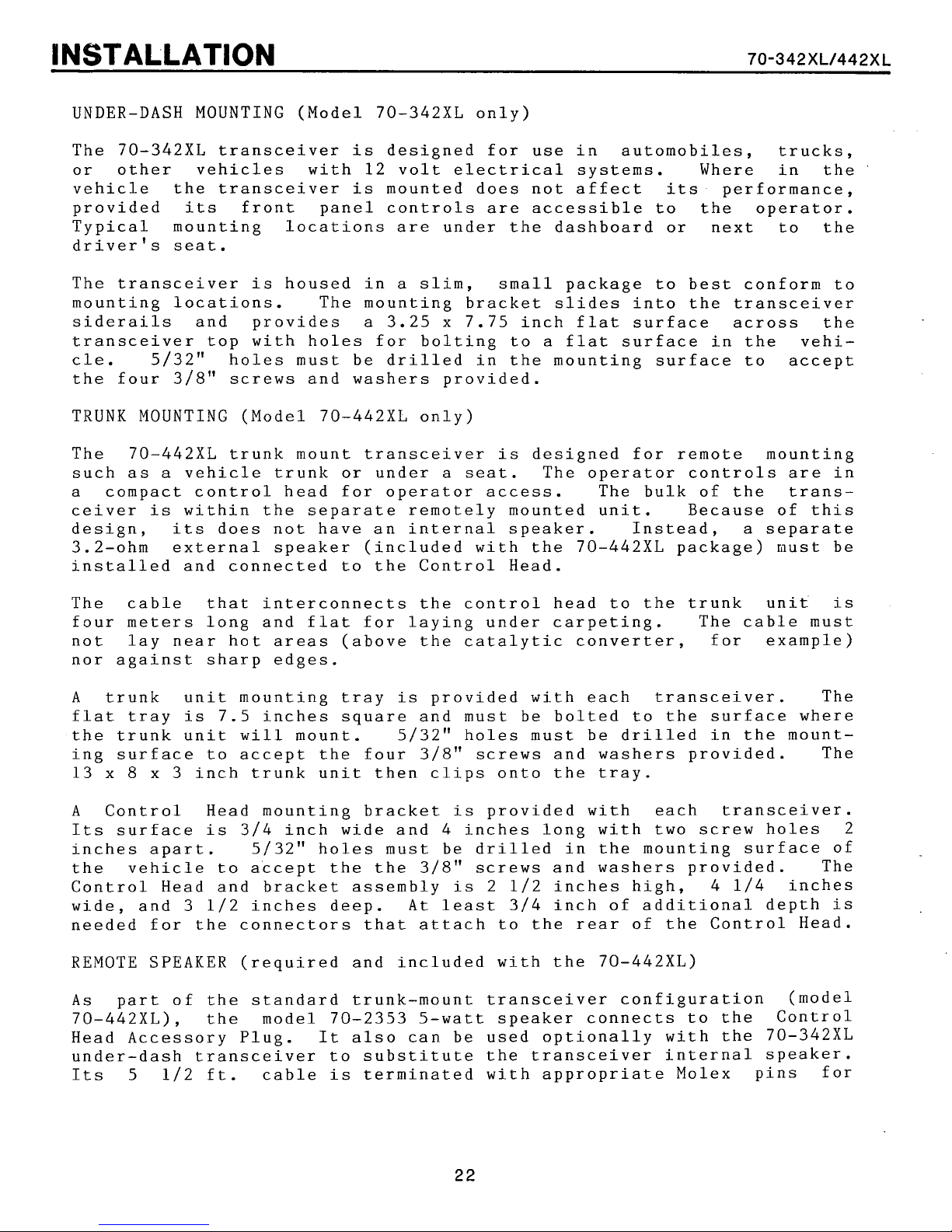

UNDER-DASH MOUNTING (Model 70-342XL only)

The 70-342XL transceiver

is

designed for use in automobiles, trucks,

or other vehicles with 12 volt electrical systems. Where in the

vehicle the transceiver

provided

its

front panel controls

mounted does not affect

are

accessible to the operator.

its

performance,

is

Typical mounting locations are under the dashboard or next to the

driver's

The transceiver

seat.

is

housed in

a

slim,

small

package to best conform to

mounting locations. The mounting bracket slides into the transceiver

a

siderails and provides

3.25 x 7.75 inch flat surface across the

transceiver top with holes for bolting to a flat surface in the vehi-

cle.

the four

5/32" holes must be drilled in the mounting surface to accept

3/8"

screws and washers provided.

TRUNK MOUNTING (Model 70-442XL only)

is

The 70-442XL trunk mount transceiver

such

a

ceiver

design,

as

a

vehicle trunk or under a seat. The operator controls

compact control head for operator access. The bulk of the trans-

is

within the separate remotely mounted unit. Because of this

its

does not have an internal speaker. Instead,

designed for remote mounting

are

in

a

separate

3.2-ohm external speaker (included with the 70-442XL package) nust be

installed and connected to the Control Head.

The cable that interconnects the control head to the trunk unit

is

four meters long and flat for laying under carpeting. The cable must

not lay near hot areas (above the catalytic converter, for example)

nor against sharp edges.

A

trunk unit mounting tray

is

flat tray

the trunk unit

7.5 inches square and must be bolted to the surface where

will

mount. 5/32" holes must be drilled in the mount-

ing surface to accept the four

13

x 8 x 3 inch trunk unit then clips onto the tray.

A

Control Head mounting bracket.

Its

surface

is

314 inch wide and 4 inches long with two screw holes

is

provided with each transceiver. The

3/8"

screws and washers provided. The

is

provided with each transceiver.

2

inches apart. 5/32" holes must be drilled in the mounting surface of

the vehicle to accept the the

318"

Control Head and bracket assembly

wide, and

3

112 inches deep.

At

screws and washers provided. The

is

2 112 inches high, 4 114 inches

least

314 inch of additional depth

is

needed for the connectors that attach to the rear of the Control Head.

REMOTE SPEAKER (required and included with the 70-442XL)

As

part of the standard trunk-mount transceiver configuration (model

70-442XL), the model 70-2353 5-watt speaker connects to the Control

Head Accessory Plug.

It

also can be used optionally with the 70-342XL

under-dash transceiver to substitute the transceiver internal speaker.

Its

5

112 ft. cable

is

terminated with appropriate Molex pins for

Page 25

1

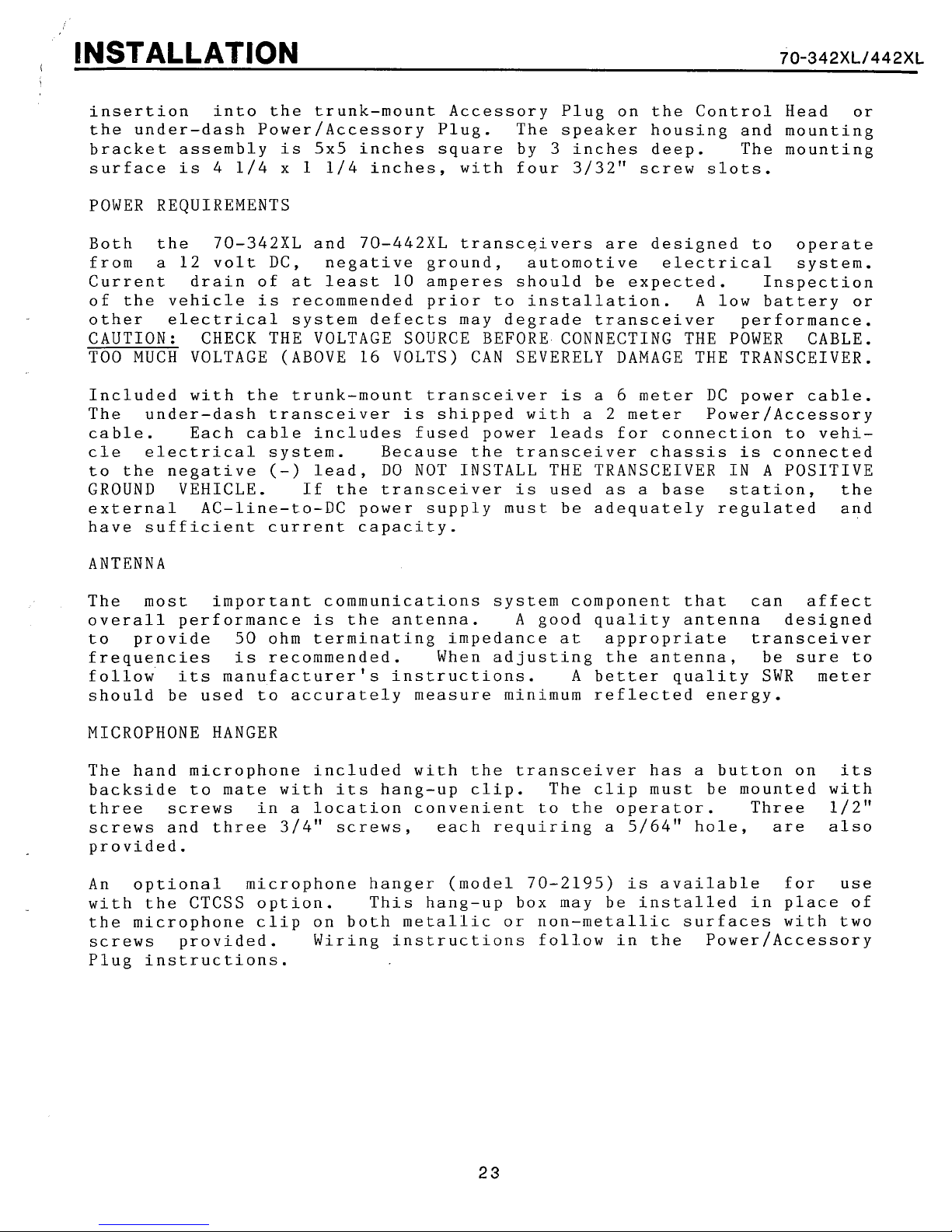

INSTALLATION

insertion into the trunk-mount Accessory Plug on the Control Head or

the under-dash Power/Accessory Plug. The speaker housing and mounting

bracket assembly

is

surface

4 1/4 x 1 114 inches, with four 3/32"

POWER REQUIREMENTS

Both the 70-342XL and 70-442XL transcqivers are designed to operate

a

from

12 volt DC, negative ground, automotive

Current drain of

of the vehicle

other

electrical

CAUTION: CHECK THE VOLTAGE SOURCE BEFORE CONNECTING THE POWER CABLE.

TOO MUCH VOLTAGE (ABOVE

70-342https://manualmachine.com/442~~

is

5x5 inches square by 3 inches deep. The mounting

at

least 10 amperes should be expected. Inspection

is

recommended prior to installation.

screw

slots.

electrical

A

low battery or

system.

system defects may degrade transceiver performance.

16

VOLTS) CAN SEVERELY DAMAGE THE TRANSCEIVER.

Included with the trunk-mount transceiver

The under-dash transceiver

is

shipped with a 2

is

a

6

meter

meter

DC power cable.

Power/Accessory

cable. Each cable includes fused power leads for connection to vehi-

cle

to the negative

GROUND VEHICLE. If the transceiver

electrical

system. Because the transceiver chassis

(-)

lead,

DO

NOT INSTALL THE TRANSCEIVER

is

used as a base station, the

is

connected

IN

A

POSITIVE

external AC-line-to-DC power supply must be adequately regulated and

have sufficient current capacity.

ANTENNA

The most important communications system component that can affect

overall performance

to provide 50 ohm terminating impedance

frequencies

follow

its

is

manufacturer's instructions.

is

the antenna.

A

good quality antenna designed

at

appropriate transceiver

recommended. When adjusting the antenna, be sure to

A

better quality SWR

meter

should be used to accurately measure minimum reflected energy.

MICROPHONE HANGER

The hand microphone included with the transceiver has

backside to

three

screws

screws and three 314"

mate

with

its

hang-up clip. The clip must be mounted with

in a location convenient to the operator. Three 1/2"

screws,

each requiring a 5/64" hole,

button on

are

its

also

a

provided.

An optional microphone hanger (model 70-2195)

with the CTCSS option. This hang-up box may be installed in place of

the microphone clip on both

screws

provided. Wiring instructions fol3.o~ in the Power/Accessory

Plug instructions.

metallic

is

available for use

or non-metallic surfaces with two

Page 26

INSTALLATION

70-342~~

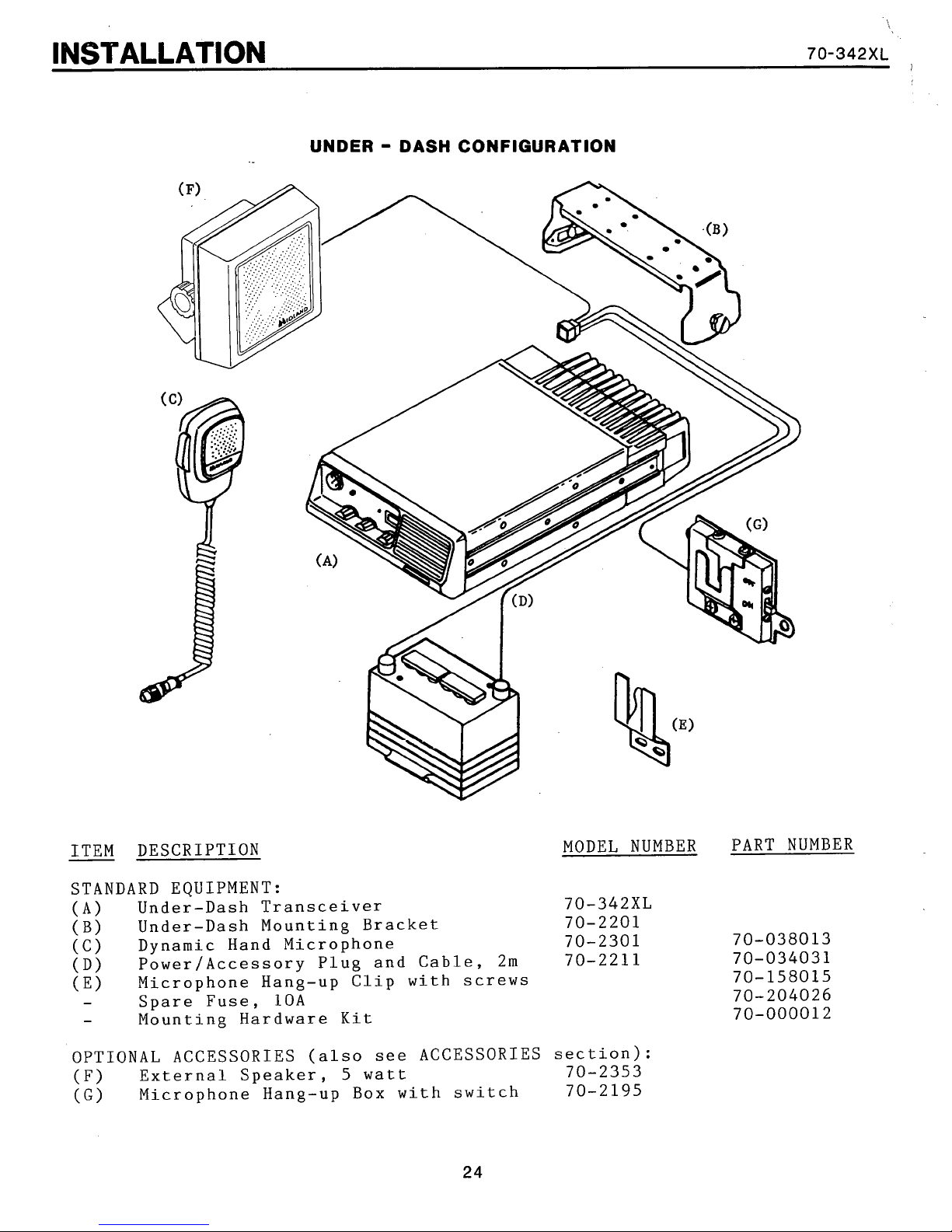

UNDER - DASH CONFIGURATION

ITEM DESCRIPTION

STANDARD EQUIPMENT:

(A)

(B)

(C) Dynamic Hand Microphone

(D)

(E)

-

-

OPTIONAL ACCESSORIES (also see ACCESSORIES

(F)

(G)

Under-Dash Transceiver

Under-Dash Mounting Bracket

Power/Accessory Plug and Cable, 2m

Microphone Hang-up Clip with screws

Spare Fuse, 10A

Mounting Hardware Kit

External Speaker, 5 watt

Microphone Hang-up Box with switch

MODEL NUMBER PART NUMBER

section)

70-2353

70-2195

:

Page 27

lhlSTALLATlON

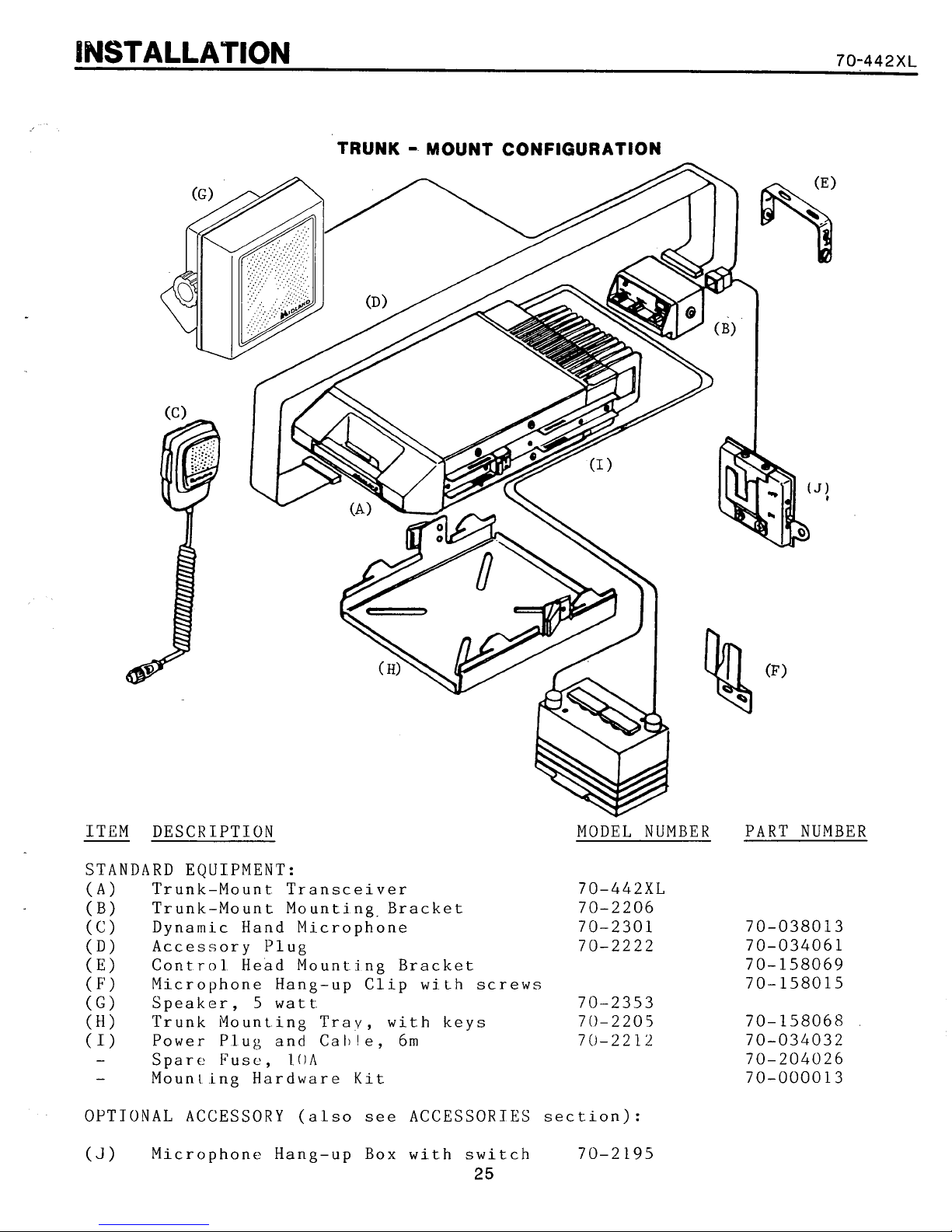

70-442XL

TRUNK - MOUNT CONFIGURATION

ITEM DESCRIPTION MODEL NUMBER PART NUMBER

STANDARD EQUIPMENT:

(A) Trunk-Mount Transceiver 70-442XL

(B) Trunk-Mount Mounting.Bracket 70-2206

(C)

(D) Accessory Plug 70-2222

(E)

(F)

(G)

(I)

(I)

-

-

OPTIONAL ACCESSORY (also

(J)

Dynamic Hand Microphone 70-2301

Control Head Mounting Bracket

Microphone Hang-up Clip with

Speaker,

Trunk Mounting Tray, with keys 70-2205

Power Plug and Calde, 6m 70-2212

Spare Fuse,

Mounr ing Hardware

Microphone Hang-up Box with switch 70-2195

5

watt

LOA

Kit

see

ACCESSORIES section):

screws

70-2353

25

Page 28

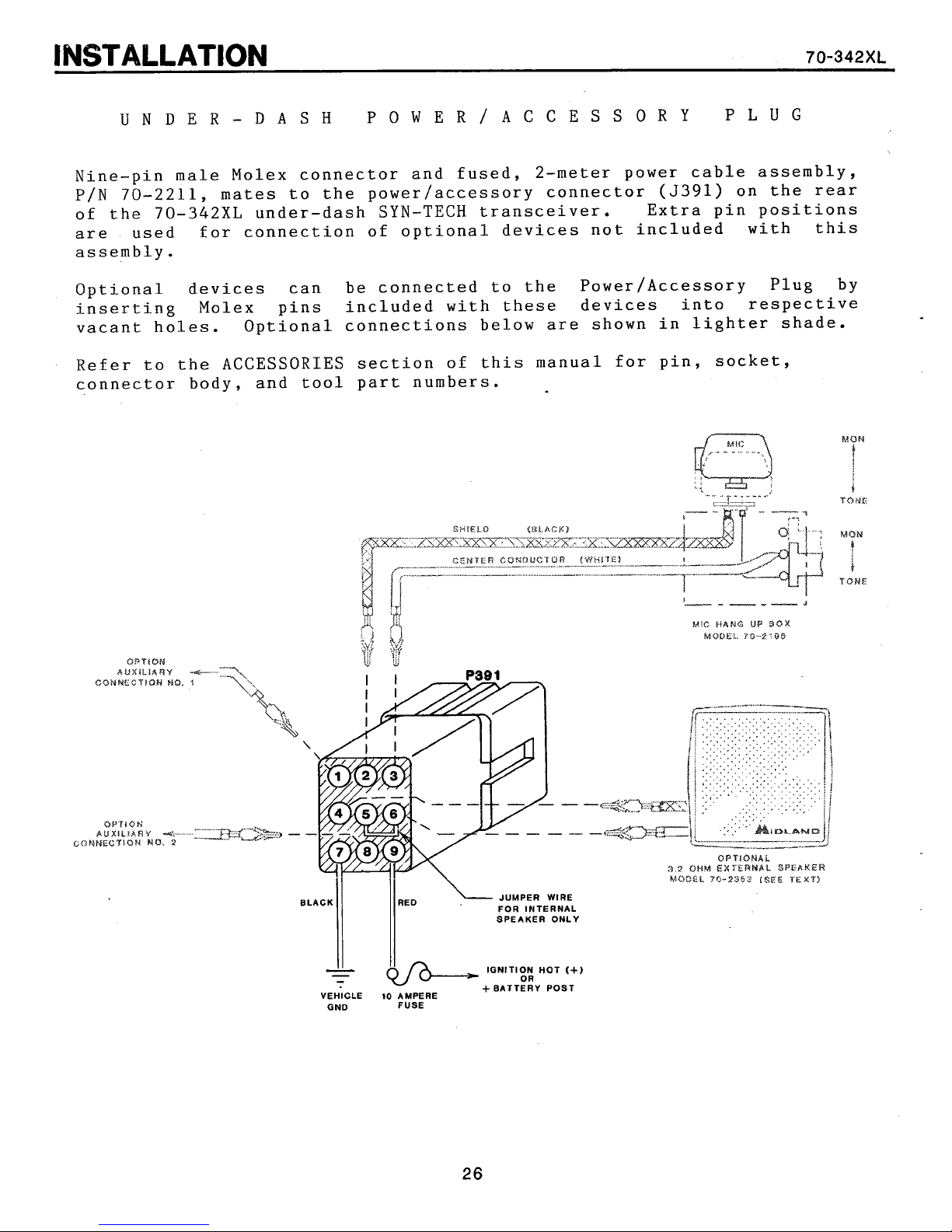

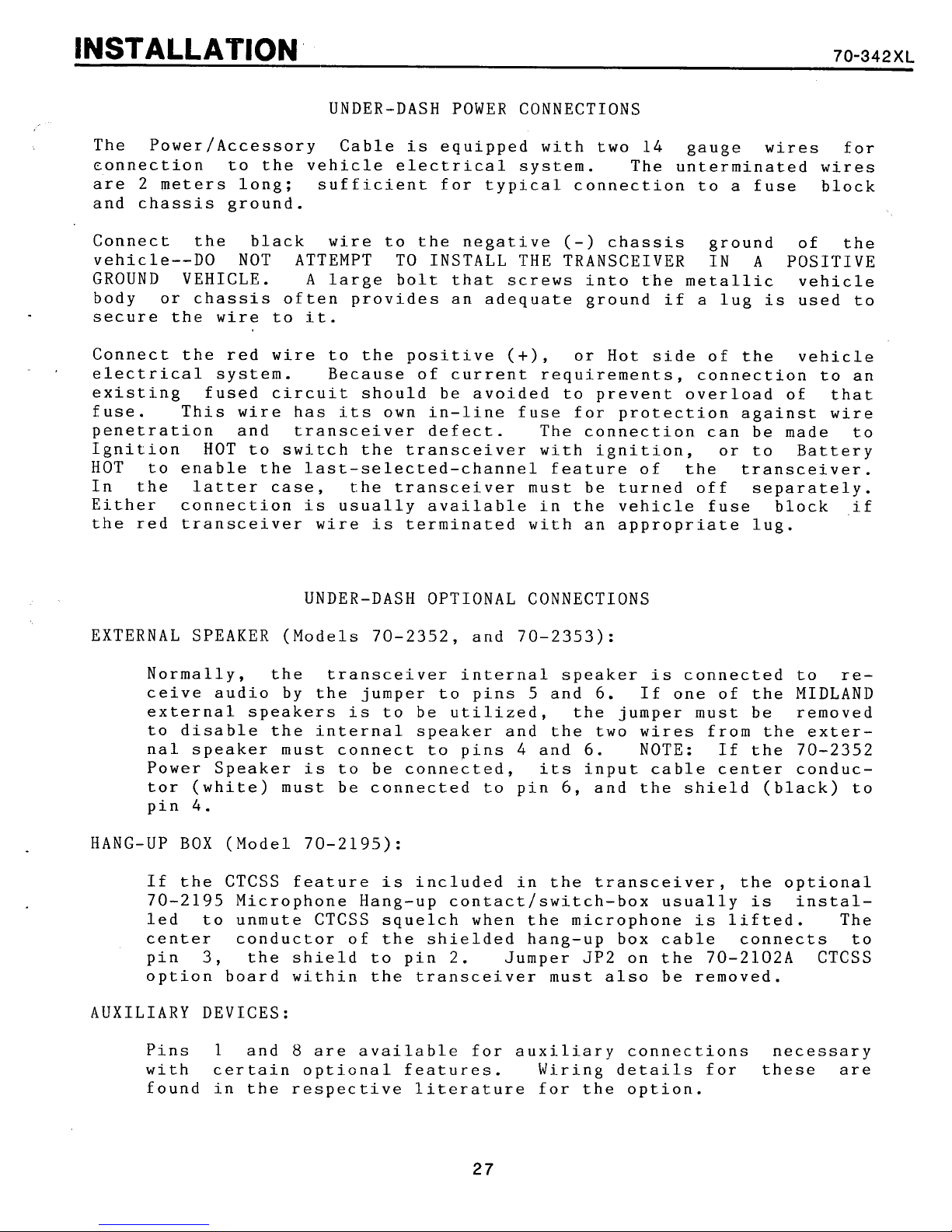

UNDER-DASH POWER/ACCESSORY

PLUG

Nine-pin male Molex connector and fused, 2-meter power cable assembly,

P/N 70-2211, mates to the power/accessory connector (5391) on the rear

of the 70-342XL under-dash SYN-TECH transceiver. Extra pin positions

are used for connection of optional devices not included with this

assembly.

Optional devices can be connected to the Power/Accessory Plug by

inserting Molex pins included with these devices into respective

vacant holes. Optional connections below are shown in lighter shade.

Refer to the ACCESSORIES section of this manual for pin, socket,

connector body, and tool part numbers.

MUM

1

TONE

MON

0

I

TONS

OPTZOW

bU)III.IARY

COHP4ECTIQN

OP'I

10

H

BUXILJhAY

MMEGTIOH

NU.

MO.

*.+.-

2

Page 29

lNSTALLAVlON

UNDER-DASH POWER CONNECTIONS

The Power/Accessory Cable

connection to the vehicle

are

2

meters

and chassis ground.

long; sufficient for typical connection to a fuse block

is

equipped with two 14 gauge

electrical

system. The unterminated

wires

70-342XL

for

wires

Connect the black

vehicle--DO NOT ATTEMPT TO INSTALL THE TRANSCEIVER

GROUND VEHICLE.

body or chassis often provides an adequate ground if

secure the

Connect the red

electrical system. Because of current requirements, connection to an

existing fused circuit should be avoided to prevent overload of that

fuse. This

penetration and transceiver defect. The connection can be made to

Ignition HOT to switch the transceiver with ignition, or to Battery

HOT to enable the last-selected-channel feature of the transceiver.

In the

Either connection

the red transceiver

EXTERNAL SPEAKER (Models 70-2352, and 70-2353):

Normally, the transceiver internal speaker

ceive audio by the jumper to pins 5 and 6. If one of the MIDLAND

external speakers

to disable the internal speaker and the two wires from the external speaker must connect to pins

Power Speaker

tor (white) must be connected to pin 6, and the shield (black) to

pin

wire

wire

latter

4.

to

wire

case,

wire

A

large bolt that

it.

to the positive

has

is

wire

UNDER-DASH OPTIONAL CONNECTIONS

is

to the negative

screws

(+),

its

own in-line fuse for protection against

the transceiver must be turned off separately.

usually available in the vehicle fuse block ,if

is

terminated with an appropriate lug.

is

to be utilized, the jumper must be removed

4

to be connected,

(-)

chassis ground of the

IN

A

POSITIVE

into the

or Hot side of the vehicle

and

6.

its

input cable center conduc-

metallic

a

lug

is

connected to

NOTE: If the 70-2352

vehicle

is

used to

wire

re-

HANG-UP BOX (Model 70-2195):

If the CTCSS feature

70-2195 Microphone Hang-up contact/switch-box usually

led to unmute CTCSS squelch when the microphone

center conductor of the shielded hang-up box cable connects to

3,

pin

option board within the transceiver must also be removed.

AUXILIARY DEVICES:

Pins

with certain opticnal features. Wiring details for these

found in the respective literature for the option.

the shield to pin 2. Jumper JP2 on the 70-21028 CTCSS

1

and 8 are available for auxiliary connections necessary

is

included in the transceiver, the optional

is

instal-

is

lifted. The

are

Page 30

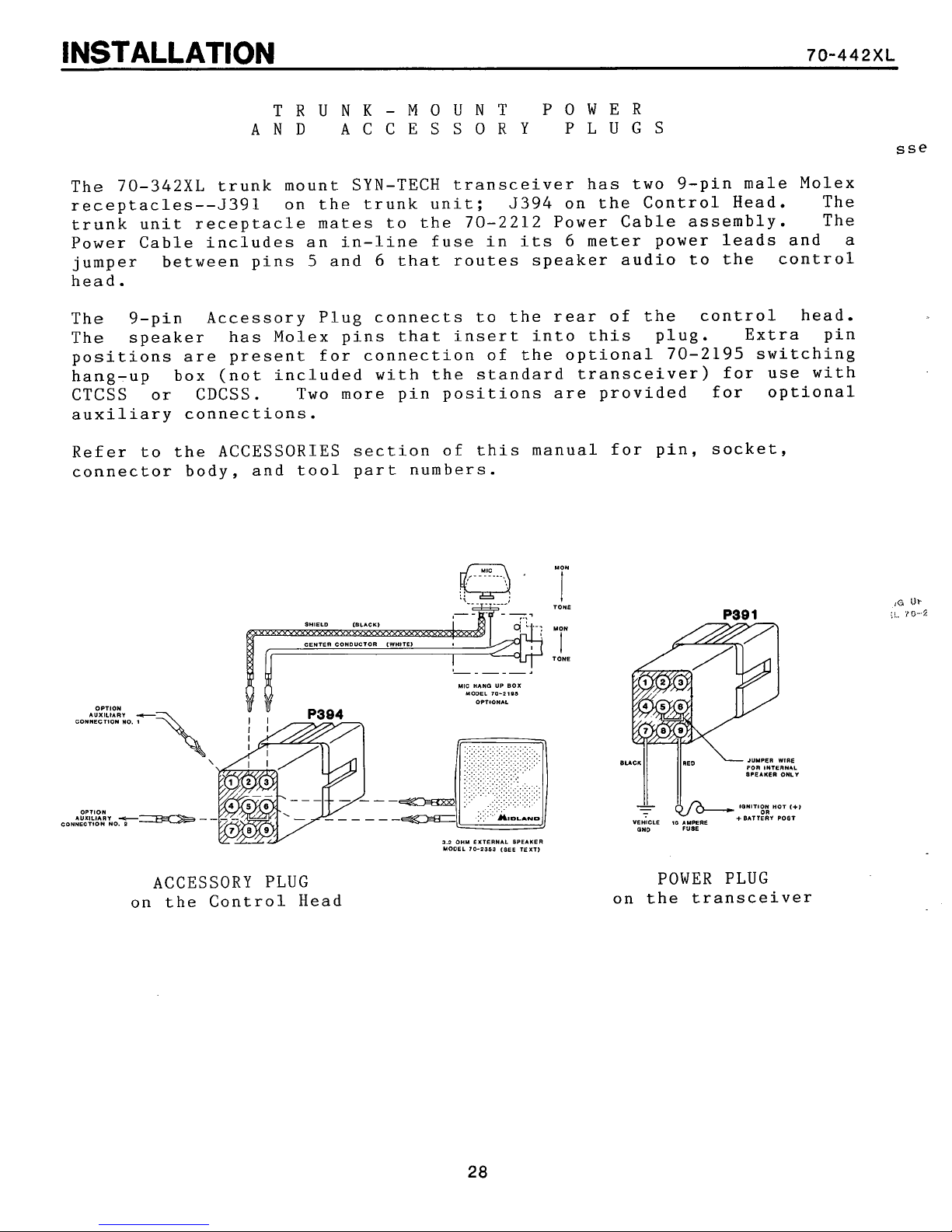

TRUNK-MOUNT POWER

AND

ACCESSORY PLUGS

The 70-342XL trunk mount SYN-TECH transceiver has two 9-pin male Molex

receptacles--J391 on the trunk unit; 5394 on the Control Head. The

trunk unit receptacle mates to the 70-2212 Power Cable assembly. The

Power Cable includes an in-line fuse in

its

6

meter power leads and

a

jumper between pins 5 and 6 that routes speaker audio to the control

head.

The 9-pin Accessory Plug connects to the rear of the control head.

The speaker has Molex pins that insert into this plug. Extra pin

positions

are

present for connection of the optional 70-2195 switching

hang-up box (not included with the standard transceiver) for use with

CTCSS or CDCSS. Two more pin positions are provided for optional

auxiliary connections.

Refer to the ACCESSORIES section of this manual for pin, socket,

connector body, and tool part numbers.

OPTION

AUXILIARV

COHllECIlOW NO

OPIlOll

AUXILIARY

CONWECTlOW NO.

C

2

ACCESSORY PLUG

on the Control Head

WIC

HANO UP

UOOEL

5.2

OHM

EXTERNAL

UOOEL

70-2319 (SEE TEXT)

70-2101

BOX

SPEAKER

TONE

'

r

TOHE

I I

8JL-y;::;;;;;)

VEHICLE

10

AMPERE

(1~0 FUME

POWER PLUG

on the transceiver

Page 31

INSTALLATION

TRUNK-MOUNT POWER CABLE CONNECTIONS

The 70-2212 Power Cable

tion to the vehicle

meters

chassis ground.

long; sufficient for typical connection to a fuse block and

is

equipped with two 12

electrical

AWG

wires

system. The unterminated

70-442XL

for connec-

wires

are 6

Connect the black

vehicle--DO NOT ATTEMPT TO INSTALL THE TRANSCEIVER

GROUND

body or chassis often provides an adequate ground.if

secure the

Connect the red

electrical system. Because of current requirements, connection

existing fused circuit should be avoided to prevent overload of that

fuse. This

penetration and transceiver defect. The connection can be made to

Ignition HOT to switch the transceiver with ignition, or to Battery

HOT. The

transceiver, but the transceiver must be turned off separately. Either

connection

transceiver

STANDARD EXTERNAL SPEAKER (Model 70-2353):

VEHICLE.

wire

to

wire

wire

latter

is

usually available in the vehicle fuse block if the red

wire

CONTROL HEAD ACCESSORY PLUG CONNECTIONS

The two

for insertion into positions

mates

wires

to the Control Head.

wire

A

large bolt that

it.

to the positive

has

enables the last-selected-channel feature of the

is

terminated with an appropriate lug.

of 70-2353 speaker are terminated with Molex pins

to the negative

(-)

chassis ground of the

IN

screws

(+),

its

own i-n-line fuse for protection against

4

and 6 of the Accessory Plug that

into the metallic vehicle

a

lug

or Hot side of the vehicle

A

POSITIVE

is

used to

to

wire

an

OPTIONAL 15 WATT POWER SPEAKER (Model 70-2352):

The 70-2352 power speaker has

terminated with Molex pins for inserting into the Accessory Plug.

The center conductor (white) of this audio signal cable must be

connected to pin 6, and the shield (black) to pin

(+)

red

that the transceiver DC power leads are connected.

OPTIONAL HANG-UP BOX (Model 70-2195):

If the CTCSS feature

microphone hang-up contact/switch-box usually

unmute CTCSS squelch when the microphone

conductor of the shielded hang-up box cable connects to pin

the shield to pin 2. Jumper JP2 on the 70-2102A CTCSS option

board within the transceiver must also be removed.

AUXILIARY DEVICES:

Pins

with certain optional features. Wiring details for these are

found in the respective literature for the option.

and black

1

and 8 are available for auxiliary connections necessary

(-)

power leads that connect to the same points

is

included in the transceiver, the 70-2195

a

shielded coaxial cable that

4.

It

also has

is

installed to

is

lifted. The center

is

3,

Page 32

Page 33

AUTOMOTIVE RECEIVER INTERFERENCE

Occasionally, the technician who installs land-mobile radio equipment

-

is

plagued with interference originating somewhere in the automobile

that produces annoying noises through the transceiver. Interference

problems

into the transceiver, locating

it

the simplest way available.

Interference enters the transceiver two ways: by conduction or induction. Conducted interference passes through the DC power leads.

Inductive interference

may be anywhere in the vehicle.

are

solved by understanding the interference and

its

source logically, then eliminating

is

radiated through the

air

from a source that

70-342https://manualmachine.com/442~~

its

path

Conducted interference

electrical

a

vehicle, current surges produce respective voltage drops across

resistances. Thus, voltage transient (switching) spikes appear

throughout the electrical system. Connecting the transceiver power

leads to this noisy

directly to the radio. Although most of the noise voltage

uated by power-line filters within the radio, spikes that

enough may be audible.

While interference conducted through power leads affects transceiver

audio circuitry; inductive interf:erence

quencies, or even channel frequencies, and

receiver. Inductive interference

induces noise currents in the transceiver antenna, accessory cabling,

or chassis (see Figure

A

spark

frequency spectrum; thus,

cally in modern vehicles, sparks

ignition system, and fan motors.

Other common sources of inductive energy

electronic gadgets found in modern vehicles. Their internal oscilla-

tors produce high frequency signals and radiate energy

the signal frequency.

system. With many electrical devices turning on and off in

is a common source of electromagnetic energy across the radio

is

simple noise voltage present in the vehicle

electrical

system applies the noise voltage

is

atten-

are

imitates

is

an electromagnetic field that

receiver

is

demodulated by the

I.F.

1).

a

source of inductive interference. Typi-

are

found in the alternator, the

are

within

a

variety of

at

multiples of

wire

severe

fre-

THE

LOCATING

The first step toward eliminating interference

interference source and path-of-entry into the transceiver. Listening

to the noise can

transceiver varies with engine speed,

the engine; such

Because the transceiver

coupling into the transceiver (by conduction or ind.uct.ion)

With

transceiver that

could be radiated i.nto the receiver. Because conducted interference

all

SOURCE

tell

as

the alternator, ignition system, or tachometer.

squelch circuits open, apply an unmodulated signal to the

is

is

to determine the

a

lot. For example: if the noise heard in the

its

source must be related to

is

an

FM

radio, determining interference

is

easy.

strong enough to overcome any int-erference that

Page 34

AUTOMOTIVE RECEIVER INTERFERENCE

70-342https://manualmachine.com/442~~

can only affect audio circuitry,

is

Another method of testing

the lowest noise point in the vehicle electrical system: the battery.

Because the battery acts like

ducted,

ELIMINATING CONDUCTED NOISE

If there

in the vehicle electrical system that needs repair.

tion of this nature

creates

noticeably impair vehicle operation.

a

whine in the transceiver that varies in pitch with engine speed.

Also, the defective diode causes excessive arcing in the brushes,

which may produce some inductive interference.

Another possible source of conducted interference

Because

path-of-entry

mostly conducted, find

system for the transceiver that

ELIMINATING INDUCTIVE INTERFERENCE FROM NEARBY OSCILLATORS

will

cease.

is

a

conducted noise path, there probably

is

a defective diode in the alternator, which

a

large current ripple at alternator output but may not

a

fan also produces inductive interference, determine which

is

most predominant (see above). If the interference

to connect the power leads directly to

a

power connection point in the electrical

it

will

a

large capacitor, the noise, if con-

is

further from the fan circuit.

still

A

bad alternator diode produces

be heard if present.

is

a

defective

A

common condi-

is

a

fan motor.

item

is

If testing proves interference

of applicable inductive sources--sparks and high frequency oscillators. Modern vehicles utilize many electronic gadgets and systems

that may produce a hash or whine in the transceiver. Oscillators

within these devices, that sometimes are poorly shielded, may radiate

an electromagnetic field at frequencies many multiples of the oscillator frequency.

Again, listen to the noise to learn about

interfering gadget

with engine speed. The interfering gadget can be isolated by temporarily removing power to

Because lead-in

is

ference

gadget itself. If so, check that the wiring to the device

the transceiver or

nected in

device; close to

'sensitive'

movement.

Inductive interference may also enter through the radio receiver

input--the antenna. This can be verified by substituting the antenna

and

dummy load

Without

the noise stops, interference

its

it,

more often radiated from the gadget's wiring than the

series

wires

cable with a matched dummy load and short cable (The 50 ohm

is

the receiver may become less sensitive to any signal). If

is

part of engine operation, the noise won't vary

it

wires

with the 'sensitive' lead-in wires of the interfering

its

may be identified if noise volume changes with wire

necessary to properly balance the receiver input.

act like radiating antennas, inductive inter-

its

wiring. If necessary, RF chokes can be con-

housing to kill the antenna effect. Sometimes,

is

not conducted, there are two types

its

source. Unless the

to check for absence of noise.

is

entering the antenna port.

is

not near

Page 35

AUTOMOTIVE

ELECTROMAGNETIC

RADIATION AT

RECEIVER

RECEIVER

INTERFERENCE

MODERN ELECTRONIC

DEVICE WITH INTERNAL

OSCILLATOR THAT PRODUCES

INDUCTIVE INTERFERENCE

AS RADIATING

70-342https://manualmachine.com/442~~

NOISE VOLTAGE

ACROSS Rw IS

CONDUCTED DIRECTLY

INTO TRANSCEIVER

VOLTAGE PRODUCED

BY

HIGH CURRENT

SURGES THROUGH Rw.

-

-

-

12

CHOKE KILLS

ANTENNA EFFECT

ELECTRICAL

WIRING TO

DEVICE

IGNITION

ALTERNATOR WITH

BAD INTERNAL DIODE

VOLTS

H

SllRCES ARE

SMOOTH ED

BATTERY CAPACITY

FIGURE

ICH CURRENT

BY

1

-

CONDUCTIVE AND INDUCTIVE INTERFERENCE

HIGY CURRENT

SURGES CAIJSED

BY

DEFECTIVE

ALTERNATOR

Page 36

AUTOMOTIVE RECEIVER INTERFERENCE

70-342https://manualmachine.com/442~~

If interference into the antenna originates from

gadget, reduce radiation from the source with RF chokes

above. Sometimes, positioning the antenna further from the gadget may

work.

ELIMINATING INDUCTIVE INTERFERENCE FROM SPARKS

Only a few areas remain in modern vehicles that produce sparks: the

alternator, ignition system, and fan motors. Sparks in modern alternators generally do not produce sufficient inductive interference

is

a

unless there

produce significant conducted interference, too.

Modern vehicles use higher voltage ignition systems.

electrical leakage occurs more easily through cracks and contaminants.

If the interference produces

in pitch with engine speed, and seems to be the same rate

spark, sparks

plug wires. Check the ignition coil,

distributor cap for signs of arcing through cracks and burns or over

dirt.

If the interference produces a popping sound in the transceiver at

engine idle that seems to occur in time with firing of a single spark

plug, and increases in rate with engine speed,

wire

spark plugs for cracks, burns, and dirt.

are

suspect. Check the distributor cap, spark plug

related defect. If so, the defect probably

a

buzz in the transceiver that increases

are

leaking to ground before distribution to the spark-

its

high voltage

a

poorly shielded

as

described

As

a

result,

as

every

wire,

a

single spark plug or

wires,

will

and

and

Spark plug and ignition coil

(resistive) conductors to reduce electromagnetic radiation. Older

vehicles may not be equipped

applicable.

Fan motor interference from

with fan speed. Badly worn brushes or bearings cause excessive

sparks, therefore replacement may be necessary.

capacitor can be connected to the positive lead

as practical to reduce inductive interference. The capacitor body

must connect securely to the grounded motor housing.

as

its

wires

such.

brushes produces a whine that varies

are

Use

made with suppressive

an ohmmeter to verify, if

A

0.1

as

close to the motor

uF coaxial

Page 37

OPTIONAL ACCESSORIES

The followi.ng ark optional mobile installation accessories that are

available from MIDLAND.

CONTROL CABLE ASSEMBLIES

Assemblies of cables terminated with 34-pin female connectors to

connect the SYN-TECH Control Head to trunk unit.

70-342https://manualmachine.com/442~~

Flat ribbon cable, 6 meters long

Flat ribbon cable, 2 meters long

Round cable, 4 meters long

Round cable, 2 meters long

REMOTE SPEAKER (5 Watt) Model No. 70-2353

A

3.2 ohm, housed speaker with mounting bracket and screws to

substitute the 70-342XL internal speaker (the 70-2353 speaker

standard with the 70-442XL transceiver).

terminated with appropriat-e Molex pins for insertion into the

transceiver Power/Accessory Plug. The speaker with

bracket

POWER SPEAKER (15 Watt) Model No. 70-2352

This self-contained amplified speaker

the 70-2353 Remote Speaker.

nated with appropriate Molex pins to connect to the 70-342XL

Power/Accessory Plug or the 70-442XL Accessory Plug.

fused power leads must be connected to vehicle

ALL WEATHER SPEAKER Model No. 70-SO5

A

5

grill.

for insertion into the 70-342XL Power/Accessory Plug or the 70-

442XL Accessory Plug. The speaker

inches deep, and mounts with a swivel tab.

is

watt,

Its

5x5 inches square by 3 inches deep.

Its

5.5 ft. input cable

4 ohm, outdoor speaker that can be mounted in a vehicle

8

ft. cable

is

terminated with appropriate Molex pins

is

Its

is

identically housed as

5

1/2 inches diameter, 4

Model

Model No. 70-2223

Model

Model No. 70-2227

5.5 ft. cable

(+)

No. 70-2221

No. 70-2226

its

mounting

is

termi-

Its

5.5 ft.

and ground.

is

is

MICROPHONE HANG-UP BOX Model No. 70-2195