Page 1

MCAC-RTSM-2012-07 M-thermal Technical Manual(part 1)

1

Midea M-thermal

Heat Pump Water Heater

Technical Manual

Midea reserves the right to discontinue, or change at any time, specifications or designs without notices and

without incurring obligations.

LRSJF-V120/SN1-610

LRSJF-V140/SN1-610

Outdoor unit

LSX-300XP/D15B11

Water tank

SMK-120/CSD80GN1

SMK-140/CSD80GN1

Indoor unit

TMK-01

Solar kit

Page 2

MCAC-RTSM-2012-07 M-thermal Technical Manual(part 1)

2

Part 1

System Outline

1. Measurements ................................................................. 3

2. External Appearance ...................................................... 4

3. Nomenclature .................................................................. 5

4. Features ........................................................................... 7

5. Specifications .................................................................. 9

5.1 Specifications of outdoor units .......................................................... 9

5.2 Specifications of Hydraulic indoor unit .......................................... 10

5.3 Specifications of water tank and solar kit ........................................11

6. Performance data .......................................................... 12

6.1 Heating performance data of 14kw model ...................................... 12

6.2 Cooling performance data of 14kw model ...................................... 12

6.3 Heating performance data of 12kw model ...................................... 13

6.4 Cooling performance data of 12kw model ...................................... 13

7. Wiring Diagrams ........................................................... 14

7.1 Outdoor units wiring diagram .......................................................... 14

7.2 Hydraulic indoor units wiring diagram ............................................ 15

8. Exploded View ............................................................... 16

8.1 Exploded view of outdoor units ....................................................... 16

8.2 Exploded view of hydraulic indoor units ........................................ 18

8.3 Exploded view of water tank ............................................................ 20

8.4 Exploded view of solar kit ................................................................ 22

Page 3

MCAC-RTSM-2012-07 M-thermal Technical Manual(part 1)

3

1. Measurements

Outdoor units

Model name

Dimension (mm)

Net/Gross weight (kg)

Power supply

LRSJF-V120/SN1-610

Width: 900

Height: 1327

Depth:348

89/101

380V~415V-50Hz

3 Ph

LRSJF-V140/SN1-610

Hydraulic indoor unit

SMK-120/CSD80GN1

Width: 900

Height:500

Depth:375

63/75

380V~415V-50Hz

3 Ph

SMK-140/CSD80GN1

Solar kit

TMK-01

Width: 810

Height: 310

Depth:295

8/10

220V~240V-50Hz

1 ph

Water Tank

Model name

Dimension (mm)

Net/Gross weight (kg)

Packing Dimension W×D×H

LSX-300XP/D15B11

Ф580×1800

75//84

620×1960×635

Page 4

MCAC-RTSM-2012-07 M-thermal Technical Manual(part 1)

4

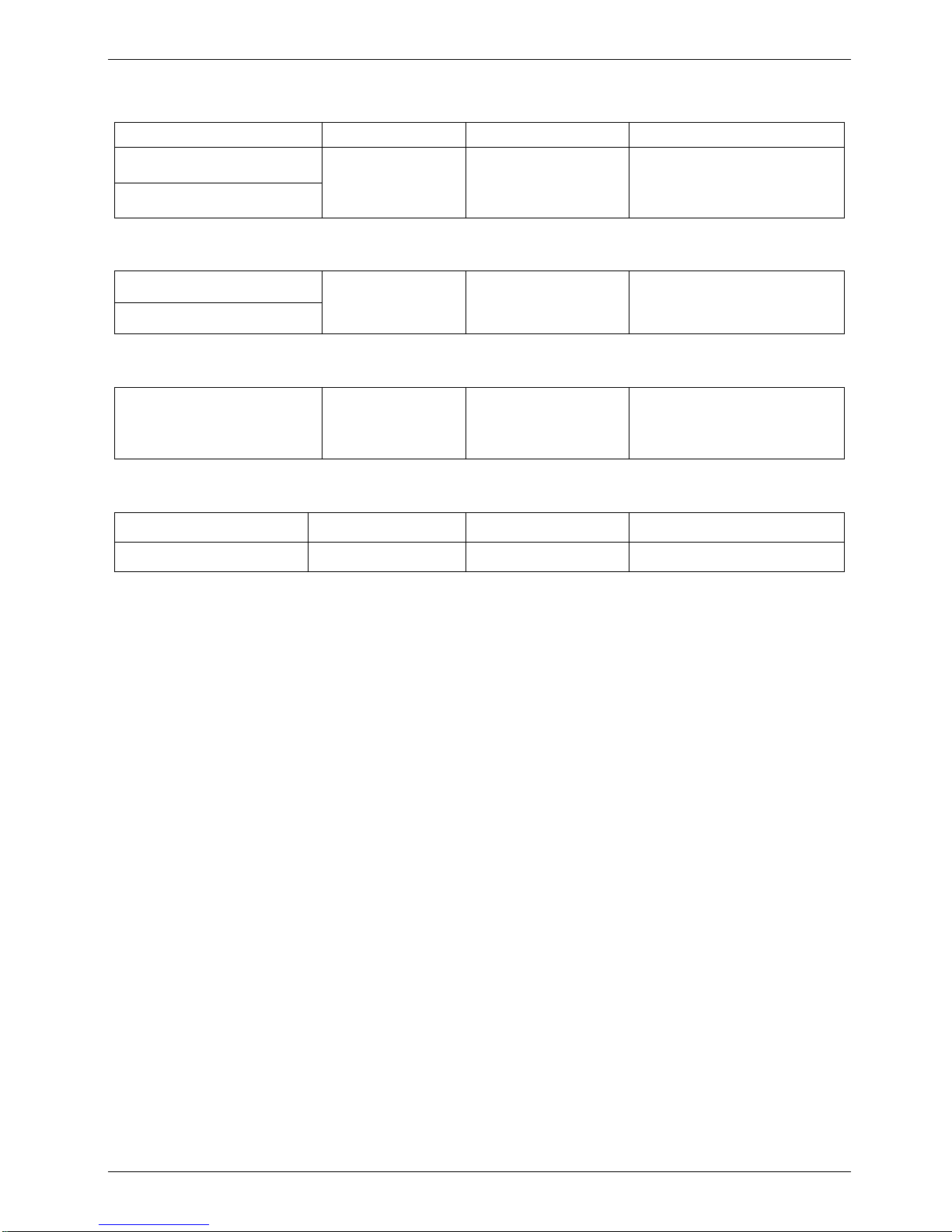

2. External Appearance

LRSJF-V120/SN1-610

LRSJF-V140/SN1-610

SMK-120/CSD80GN1 SMK-140/CSD80GN1

TMK-01

Page 5

MCAC-RTSM-2012-07 M-thermal Technical Manual(part 1)

5

3. Nomenclature

Outdoor unit

CE-L RSJF-V120/SN1- 610

Design code

Refrigerant type (R410a)

380-415V~ 3phase 50Hz

Heating Capacity (12000W)

Compressor type (DC inverter compressor)

Split type

Midea Heat Pump water heater

Heating and cooling mode (Omit for heating)

Export model code

LSX-300XP/D15B11

Page 6

MCAC-RTSM-2012-07 M-thermal Technical Manual(part 1)

6

Indoor unit

CE- SMK – 80 / C S D 80 G N1

Solar kit

CE-TMK-01

CE-L SX-300XP/ D15 B11

Refrigerant type (R410a)

Heating type (Floor heating)

E-heater Capacity (8000W)

Electric heater

Power type (3ph, 380V)

Water cycle type

Heating Capacity (8000w)

Hydraulic modular

Export model code

Design code

Solar heating unit

Export model code

Design code

E-heater power(1500w)

Electric heater

Water tank appearance code (spraying appearance)

Water tank inner tank code (Stainless Steel inner tank )

Water tank volume (300L)

Water tank code

Water tank type code (vertical type)

Export model code

Page 7

MCAC-RTSM-2012-07 M-thermal Technical Manual(part 1)

7

4. Features

4.1 Safety

a. Realize isolation between water and electricity. No electric shock problem, more safety.

b. No fuel tubes and storage, no potential danger from oil leakage, fire, explosion etc. Five operating

mode:

1). Space cooling

2). Space heating

3). Water heating

4). Space cooling + water heating

5). Space heating + water heating

4.2 Environmental friendly.

a. R410a refrigerant;

b. No discharge of poisonous gas;

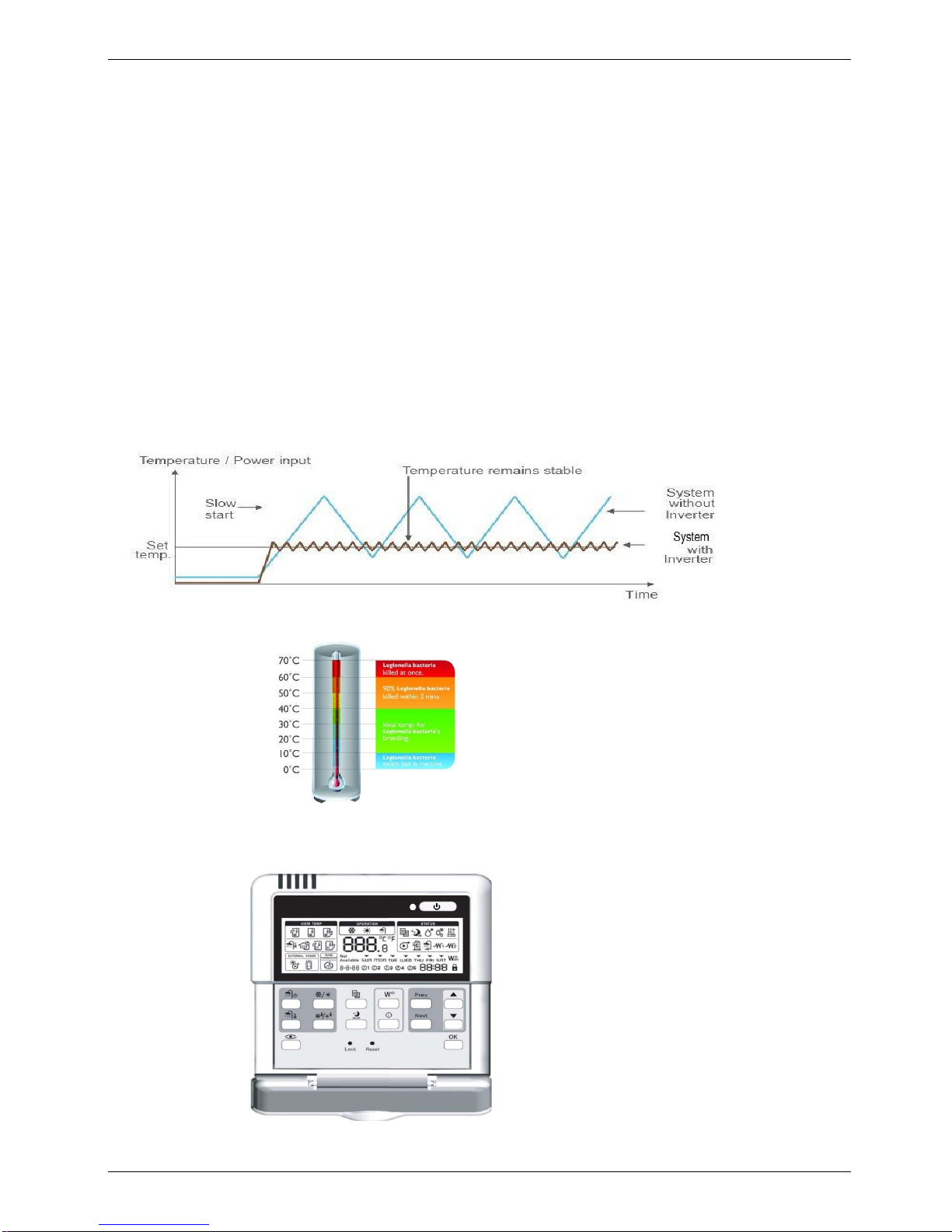

4.3 DC inverter system.

.

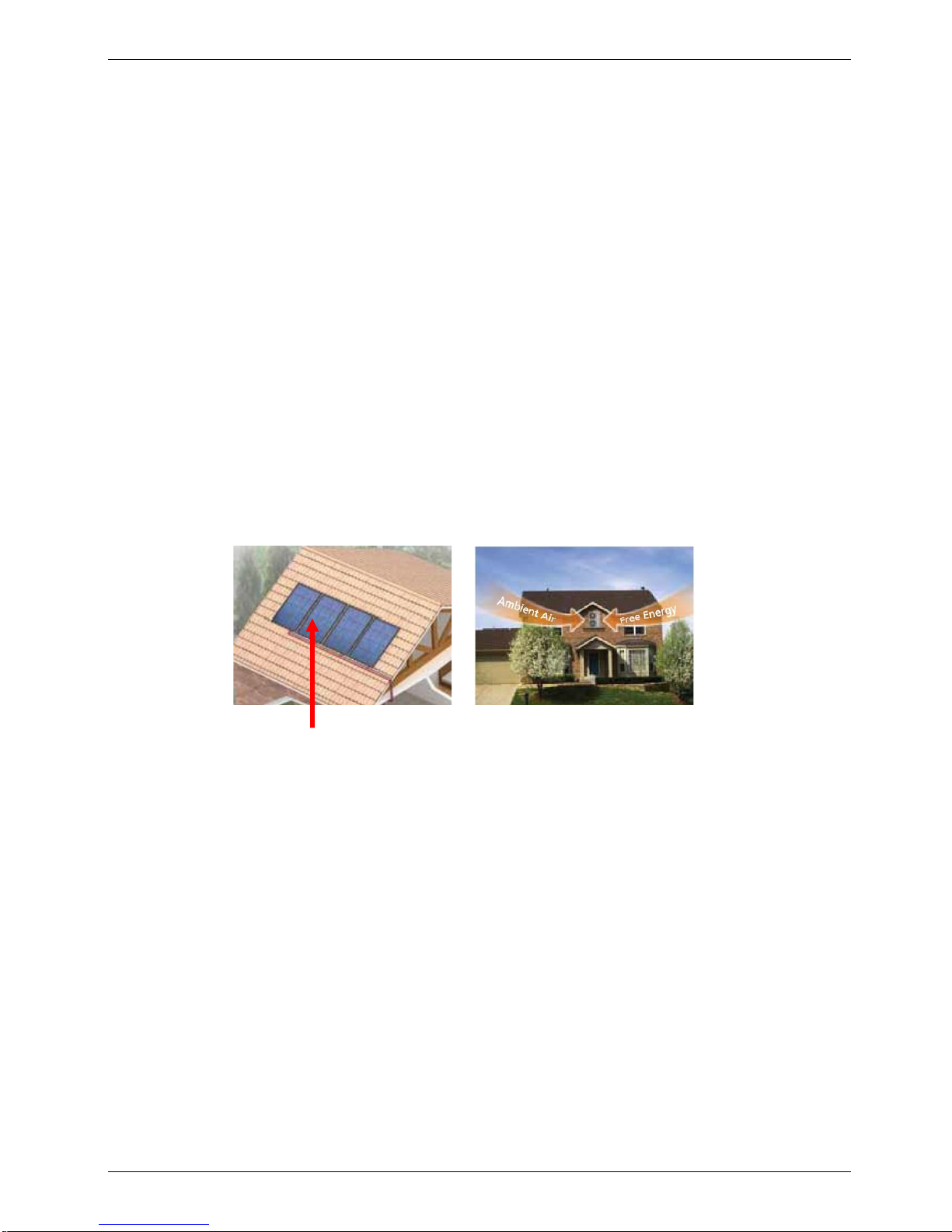

4.4 Automatic weekly anti-legionella function

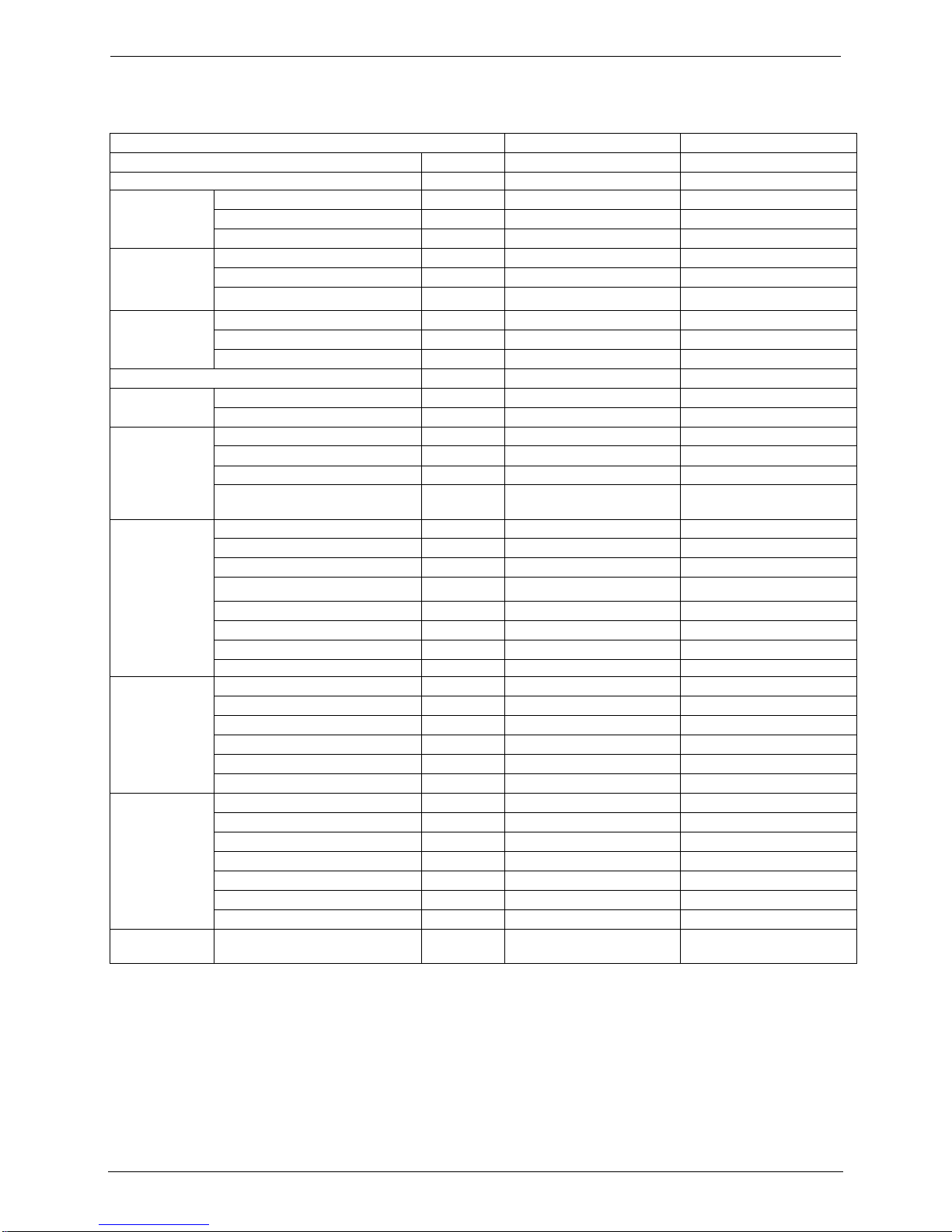

4.5 Easy operation and automatic control.

The system can be controlled simply through the wire controller.

Page 8

MCAC-RTSM-2012-07 M-thermal Technical Manual(part 1)

8

4.6 High efficiency and energy-saving.

The unit adopts heat pump principle, which absorbs heat from outdoor air and produce heat water, thermal

efficiency for water heating be up to 4.3.

4.7 All the weather the system can run.

Within the temperature range from -20 to 43℃, it will not be affected by night, overcast sky, rain and snow.

4.8 Convenient installation and maintenance

The quadrate type can be easily installed in a corner of the verandah even if it’s very narrow.

4.9 Total Heating Solution

When floor heating is conducted in a new house, warm air spreads gently across the house, making it

comfortable and enabling the use of broad space without necessitating radiators or FCU.

4.10 Comfort System

When floor heating is applied, warm air spreads gently across the house, making it comfortable. The system

can help blood circulation and metabolism, further boosting our health.

The installation of M-Thermal will eliminate oil or gas tank, making the household surrounding neat and safe,

enabling the use of more space, and avoiding refueling.

4.11 Reduce CO2 emission

When the system is connected to solar panels, CO2 can be reduced more sharply.

In addition, M-thermal can significantly cut CO

2

emission when being connected to solar thermal panel a

completely pure energy source.

4.12 CE approval

Solar Panel

Page 9

MCAC-RTSM-2012-01 M-thermal Technical Manual

9

5. Specifications

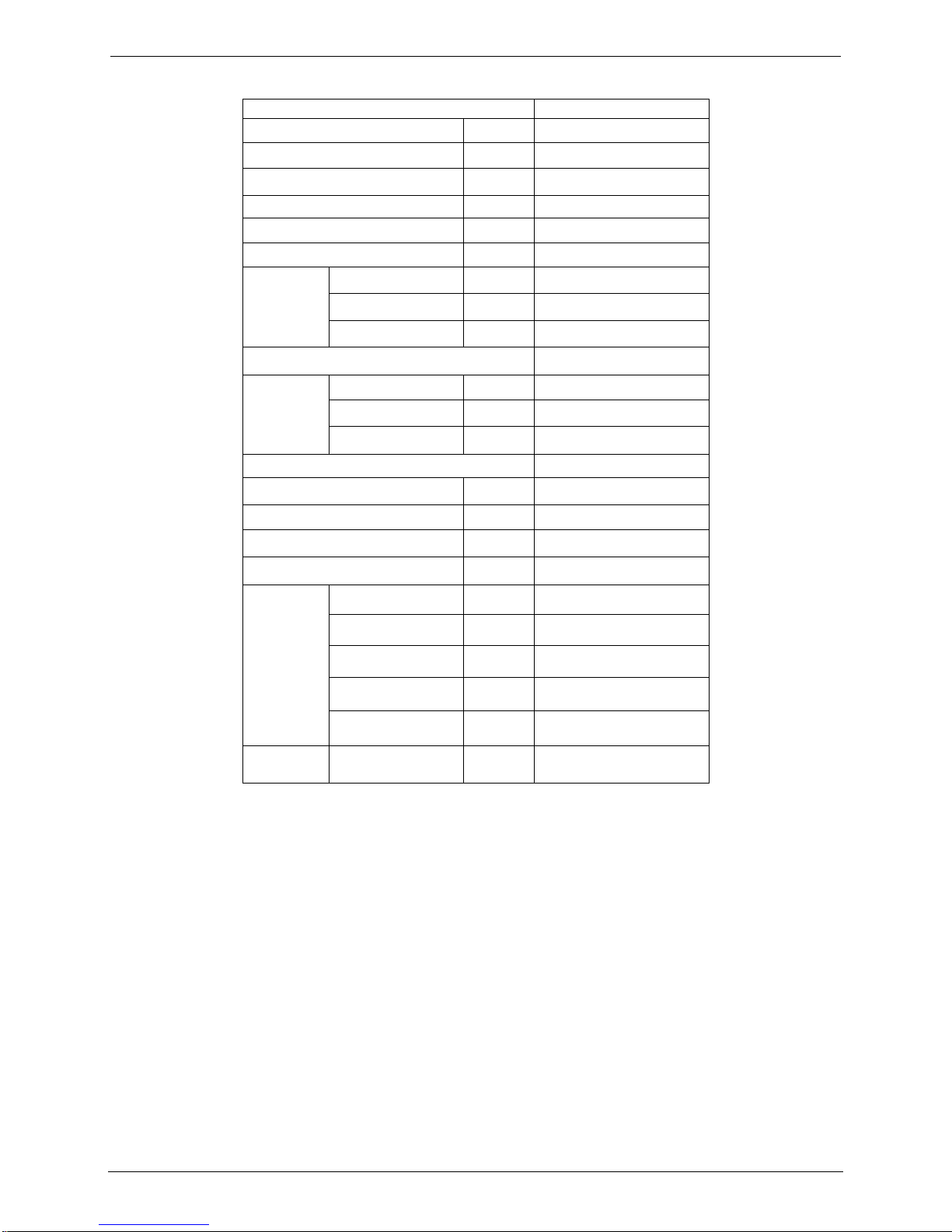

5.1 Specifications of outdoor units

DC Inverter outdoor unit

LRSJF-V120/SN1-610

LRSJF-V140/SN1-610

Power supply

Ph-V-Hz

3-380~415-50

3-380~415-50

Max. current

A 9 9

Heating

Capacity

kW

12

14

COP

kW/kW

4.17

4.13

Ambient Temp.

℃

-20~43

-20~43

Cooling

Capacity

kW

8.8

8.8

COP

kW/kW

2.22

2.28

Ambient Temp.

℃

15~43

15~43

Unit

Dimension (W×H×D)

mm

900×1327×320

900×1327×320

Packing (W×H×D)

mm

1016×1456×435

1016×1456×435

Net/gross weight

kg

89/101

89/101

Noise level

dB(A)

58

58

Refrigerant

type/quantity

kg

R410a/2.7kg

R410a/2.7kg

system pressure

MPa

4.4/2.6

4.4/2.6

Refrigerant

pipe

Liquid side

mm

Ф9.52

Ф9.52

Gas side

mm

Ф16

Ф16

Max. length

m

50

50

Max. difference between

outdoor unit and indoor unit

m

15

15

Compressor

Model

TNB306FPNMC

TNB306FPNMC

Type

Rotary

Rotary

Brand

Mitsubishi

Mitsubishi

Capacity

kW

9.88

9.88

Input

w

3010

3010

Locked rotor current

A

45

45

Rate current

A

9.3

9.3

Crankcase

W

30

30

Fan motor

Brand

Panasonic

Panasonic

Model

WZDK100-38G(×2)

WZDK100-38G(×2)

Type

DC MOTOR

DC MOTOR

Input

w

100*2

100*2

Output

w

110*2

110*2

Speed

r/min

800

800

Outdoor coil

Number of rows

2 2

Tube pitch(a)x row pitch(b)

mm

25.4/22

25.4/22

Tube dia. and type

mm

7.94(female screw)

7.94(female screw)

Fin space

mm

1.7

1.6

Fin type (code)

Hydrophilic aluminum

Hydrophilic aluminum

Coil length x height

1276*870

1276*870

Number of circuits

7 7

Loading

Quantity

20'/40'/40H

Pcs

28/58/58

28/58/58

Page 10

MCAC-RTSM-2012-01 M-thermal Technical Manual

10

5.2 Specifications of Hydraulic indoor unit

Hydraulic indoor unit

SMK-120/CSD80GN1

SMK-140/CSD80GN1

Power supply

Ph-V-Hz

3-380~415-50

3-380~415-50

Function

Types

Heating &Cooling

Heating &Cooling

Space

Heating

℃

15~55

15~55

Space

Cooling

℃

7~22

7~22

Sanitary Hot

Water

℃

35~60

35~60

Max. current

A

13.8

13.8

Noise level

dB(A)

32

32

Unit

Dimension

(W×H×D)

mm

900×500×375

900×500×375

Packing

(W×H×D)

mm

1110×610×510

1110×610×510

Net/gross

weight

kg

63/75

63/75

E-heater

Size

kW

4 4 Quantity

1 1 specification

Ph-V

3-400

3-400

E-heater(standby)

Size

kW

4 4 Quantity

1

1

specification

Ph-V

3-400

3-400

Water pipeline

Water inlet

pipe

mm

DN32

DN32

Water outlet

pipe

mm

DN32

DN32

Loading Quantity

20'/40'/40H

Pcs

66/138/184

66/138/184

The testing Condition:

1. Heating: Outdoor temp. 7/6℃(DB/WB), inlet water temp. 30℃, outlet water temp. 35℃.

2. Cooling: Outdoor temp. 35/24℃(DB/WB), inlet water temp. 12℃, outlet water temp. 7℃.

Page 11

MCAC-RTSM-2012-01 M-thermal Technical Manual

11

5.3 Specifications of water tank and solar kit

Sanitary hot water tank

LSX-300XP/D15B11

Power supply

Ph-V-Hz

1-220~240-50

Storage size

L

300

Max. water output temp.

℃

60

Dimension (D×H)

mm

Ф580×1800

Packing (W×H×D)

mm

670×1885×670

Net//gross weight

kg

80/91

E-heater

specification

kW

1.5

Quantity

1

Power supply

Ph-V

1-220~240-50

Tank material

SUS304

Water

pipeline

Water inlet pipe

mm

DN20

Water outlet pipe

mm

DN20

PT valve joint

MPa

DN20

Solar kit

TMK-01

Power supply

Ph-V-Hz

1-220~240-50

Dimension (W×H×D)

mm

810×310×295

Packing (W×H×D)

mm

830×340×315

Net weight

kg

8/10

solar coils

OD+T

mm*mm

¢22*0.8

Length

m

11

Material

SUS316L

Inlet pipe

mm

DN20

Outlet pipe

mm

DN20

Loading

Quantity

20'/40'/40H

Pcs

300/624/728

Page 12

MCAC-RTSM-2012-01 M-thermal Technical Manual

12

6. Performance data

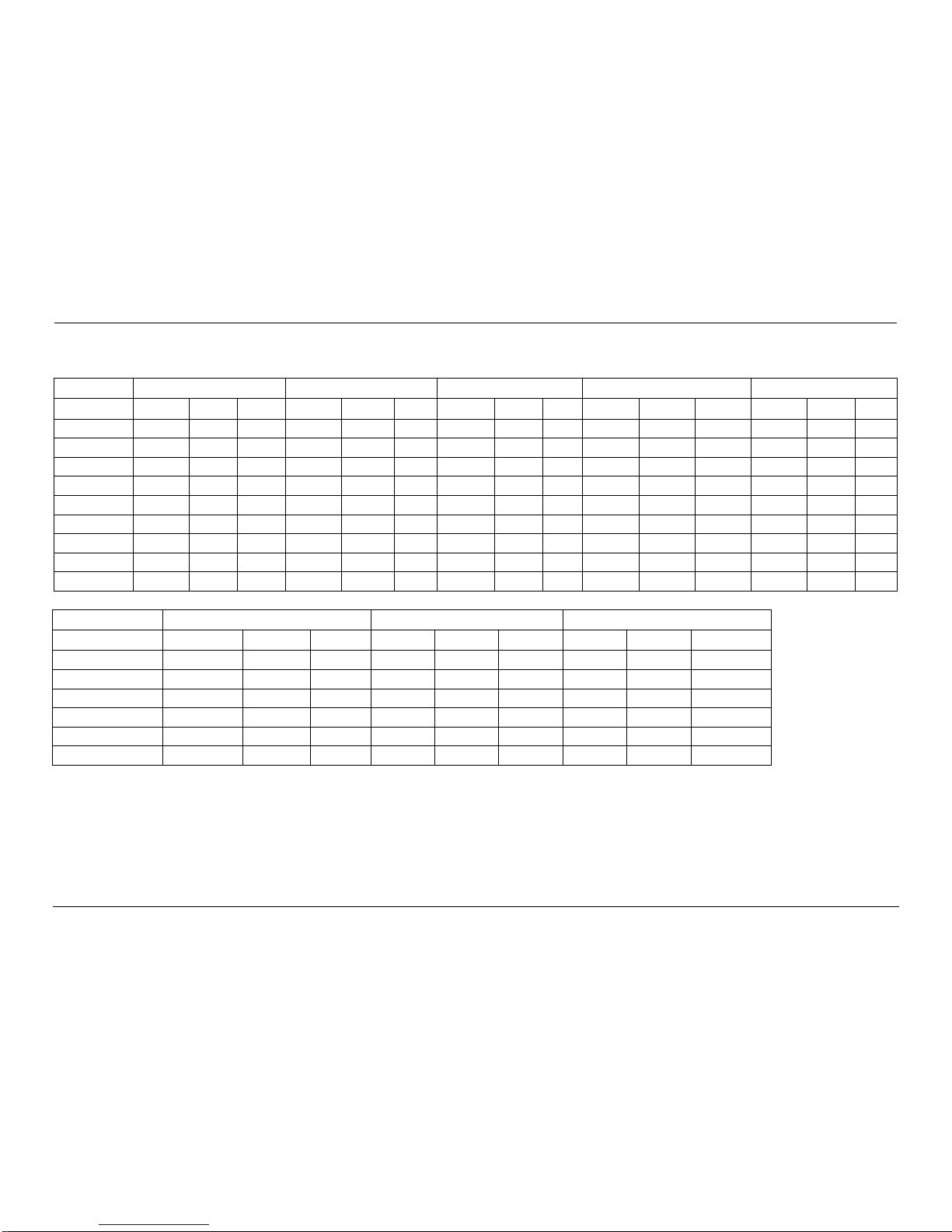

6.1 Heating performance data of 14kw model

LWE[℃]

25

32

40

43

50

Tamb [℃]

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

-20

4850

1725

2.81

3511

1887

1.53 / / / / / / / /

/

-10

6943.5

2471

2.81

6426

2758

2.33

5476

3094

1.77

5120

3220

1.59 / /

/

-5

10555

3586

2.94

8935

3327

2.69

7804

3722

2.1

7391

3883

1.9 / /

/

0

9138

3662

2.5

11254

4115

2.73

10101

4353

2.32

9317

4274

2.18 / /

/

2/1

12614

3835

3.29

13017

4244

3.07

10882

4410

2.47

9922

4369

2.27 / / / 7/6

15601

3851

4.05

14871

4251

3.5

13036

4472

2.92

11897

4410

2.7

6531

3293

1.98

15/12

17258

3629

4.76

17077

4046

4.22

14503

4003

3.62

13969

4205

3.32

7162

2676

2.68

25/17

13570

2331

5.82

14152

2640

5.36

11336

2573

4.41

7696

2288

3.36

6299

2029

3.1

35/24

/ / / / / / 13060

2769

4.72

10902

2530

4.31

6059

1781

3.4

6.2 Cooling performance data of 14kw model

Remark:

CC= cooling capacity PI = power input HC = heating capacity

LWE[℃]

10

15

20

Tamb [℃]

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

15

4120

1289

3.2 / / / / / /

20

5122

1378

3.72

11441

2980

3.84 / /

/

25

5584

1450

3.85

12009

3217

3.73

14153

3587

3.95

30

5468

1608

3.41

11349

3504

3.24

13596

3504

3.88

35

5463

2110

2.59

10264

3836

2.68

12326

4272

2.89

43

5922

3259

1.82

7357

3365

2.19

8853

3450

2.57

Page 13

MCAC-RTSM-2012-01 M-thermal Technical Manual

13

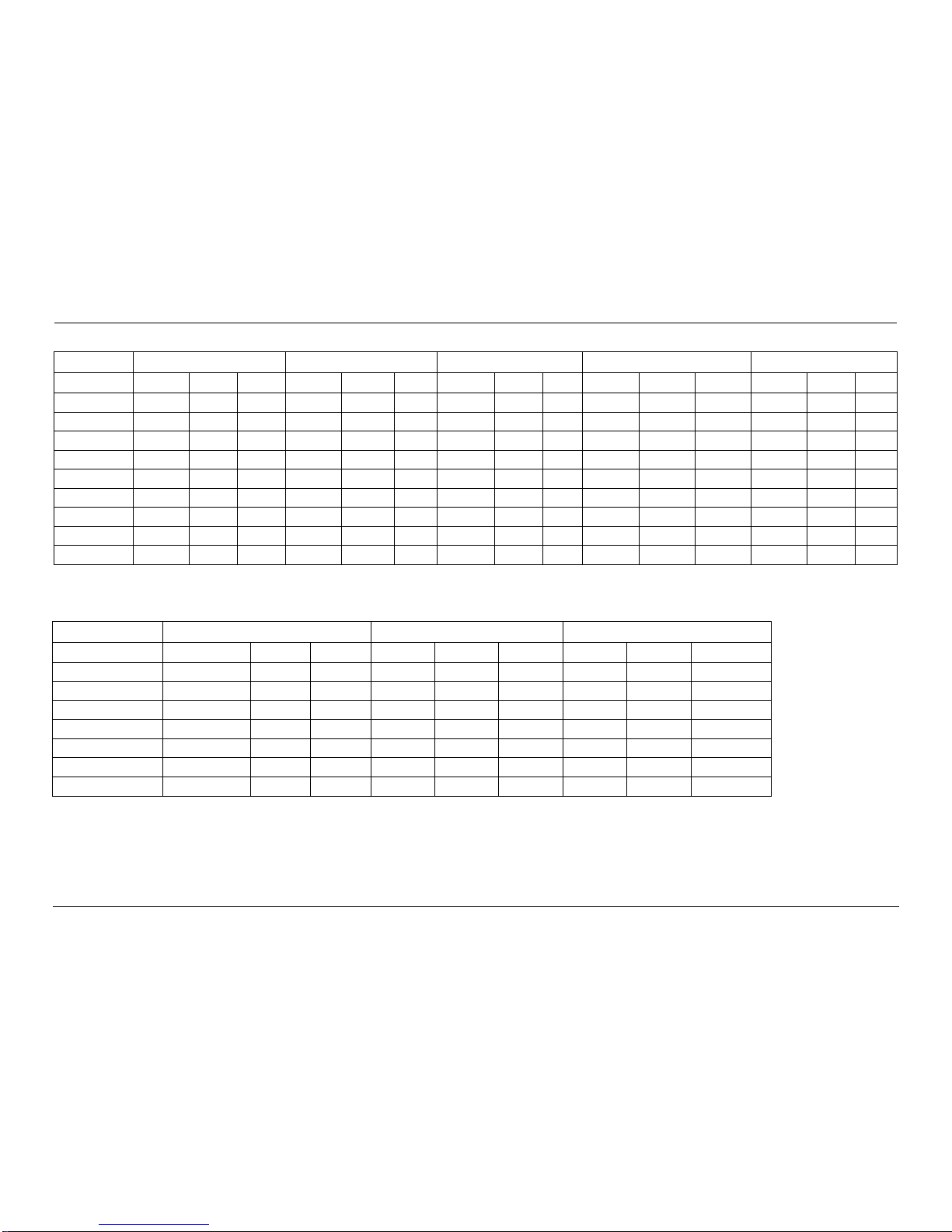

6.3 Heating performance data of 12kw model

LWE[℃]

25

32

40

43

50

Tamb [℃]

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

-20

2883

1749

1.65

2453

1891

1.30 / / / / / / / /

/

-10

7090

2481

2.86

6656

2772

2.40

5514

3107

1.77

4721

3230

1.46 / /

/

-5

9652

3030

3.19

9234

3344

2.76

8498

3750

2.27

7819

3908

2.00 / /

/ 0 5662

2951

1.92

10921

3949

2.77

10277

4363

2.36

9267

4311

2.15

6433

3578

1.80

2/1

11208

3388

3.31

10601

3641

2.91

9432

3768

2.50

9177

4030

2.28

8272

4078

2.03

7/6

14824

3677

4.03

14241

4049

3.52

11589

3978

2.91

11257

4171

2.70

5731

3015

1.90

15/12

17436

3682

4.74

17029

4100

4.15

14311

4056

3.53

13508

4226

3.20

6872

2618

2.62

25/17

13181

2133

6.18

13412

2436

5.51

11683

2457

4.75

10320

2365

4.36

6299

2029

3.10

35/24

/ / / / /

/

11683

2432

4.80

9770

2333

4.19

6748

2031

3.32

6.4 Cooling performance data of 12kw model

Remark:

CC= cooling capacity PI = power input HC = heating capacity

LWE[℃]

10

15

20

Tamb [℃]

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

15

4199

1308

3.21 / / / / / /

20

6960

1781

3.91

9973

2732

3.65 / /

/

25

7908

2355

3.36

11272

2969

3.8

12878

3018

4.27

30

7752

3064

2.53

10532

3253

3.24

12453

3322

3.75

35

10252

3629

2.82

12494

3753

3.33

15884

4233

3.75

40

7039

2812

2.5

9537

3550

2.69

11506

3663

3.14

43

5814

3251

1.79

7237

3350

2.16

8693

3445

2.52

Page 14

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

14

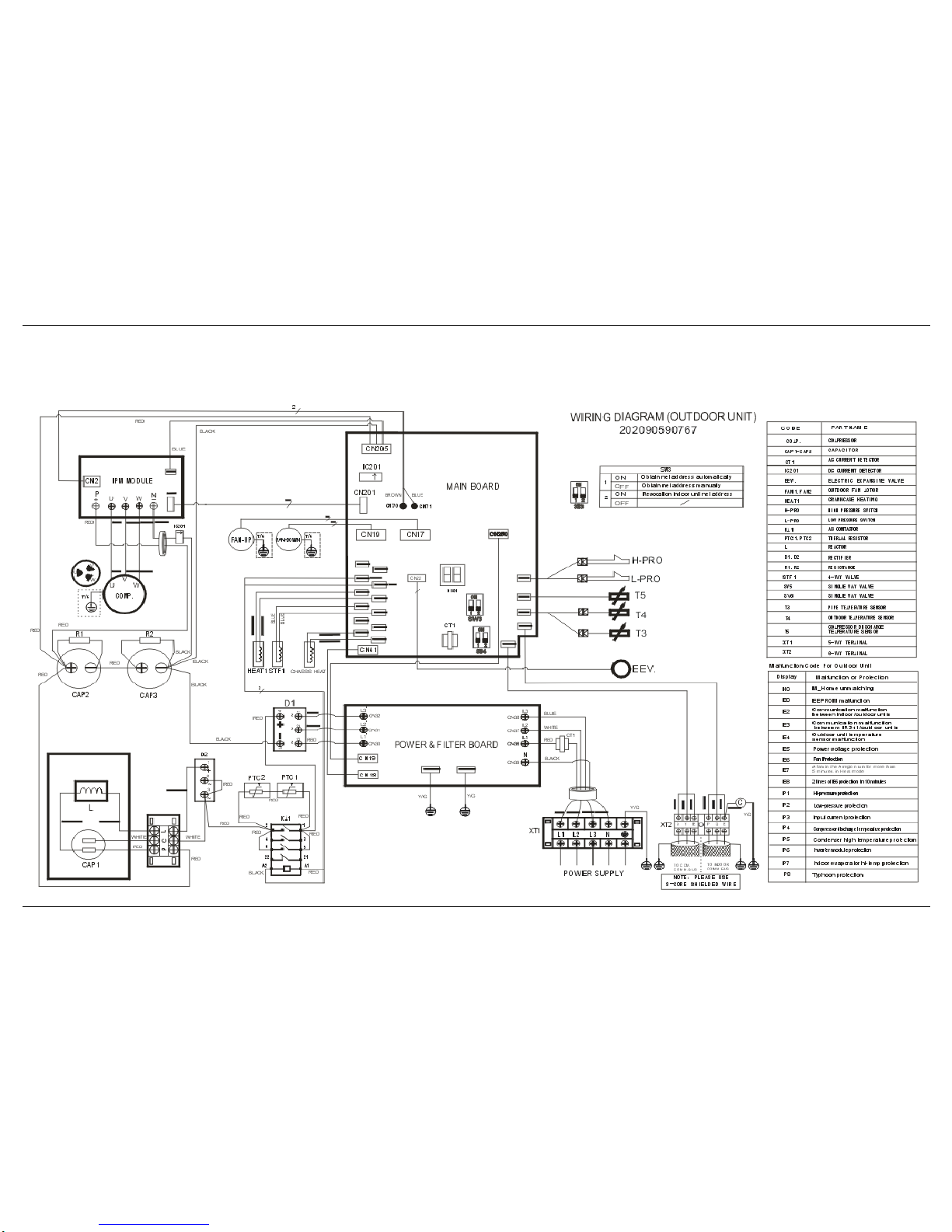

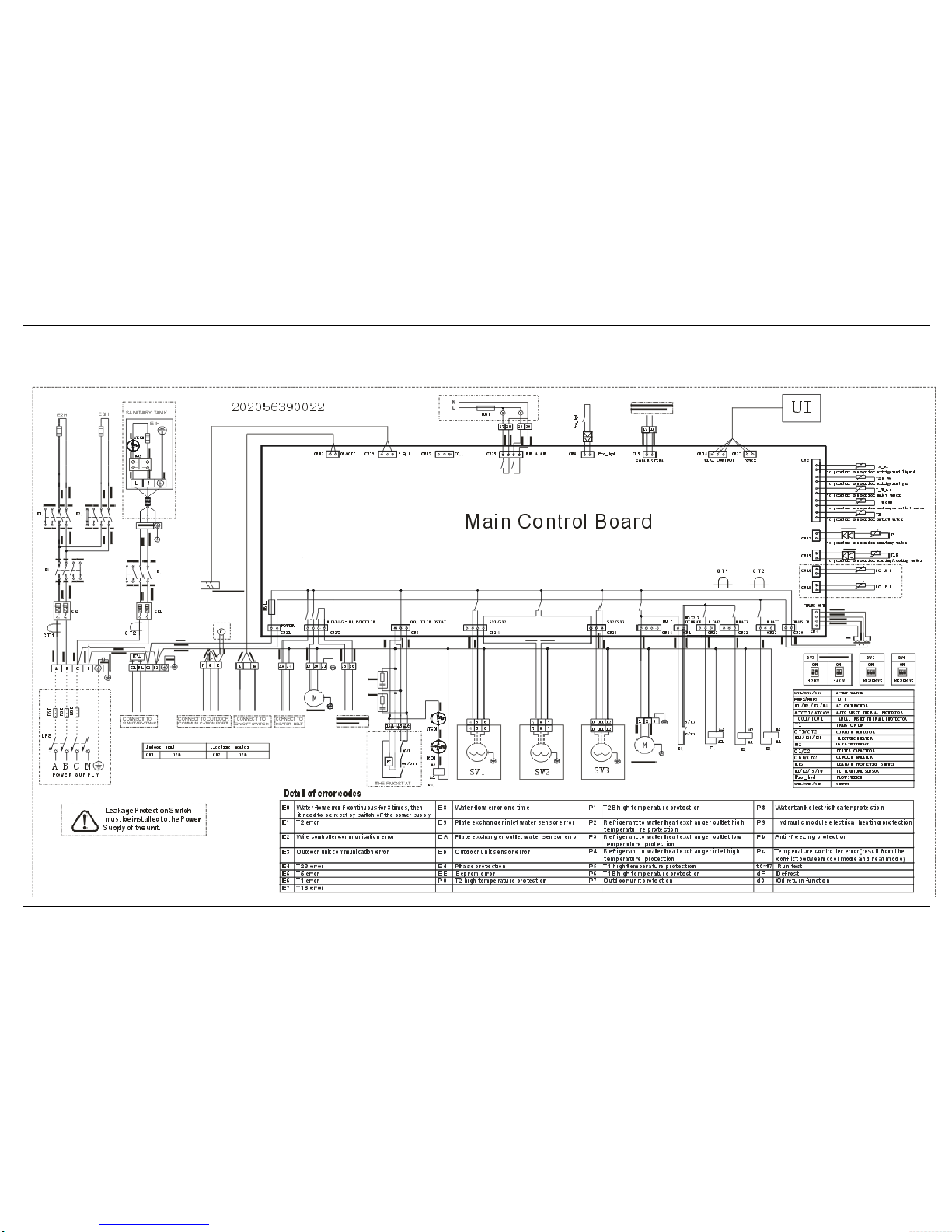

7. Wiring Diagrams

7.1 Outdoor units wiring diagram

Model:CE-LRSJF-V120/SN1-610 CE-LRSJF-V140/SN1-610

Page 15

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

15

7.2 Hydraulic indoor units wiring diagram

Model :SMK-120/CSD80GN1 SMK-140/CSD80GN1

Page 16

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

16

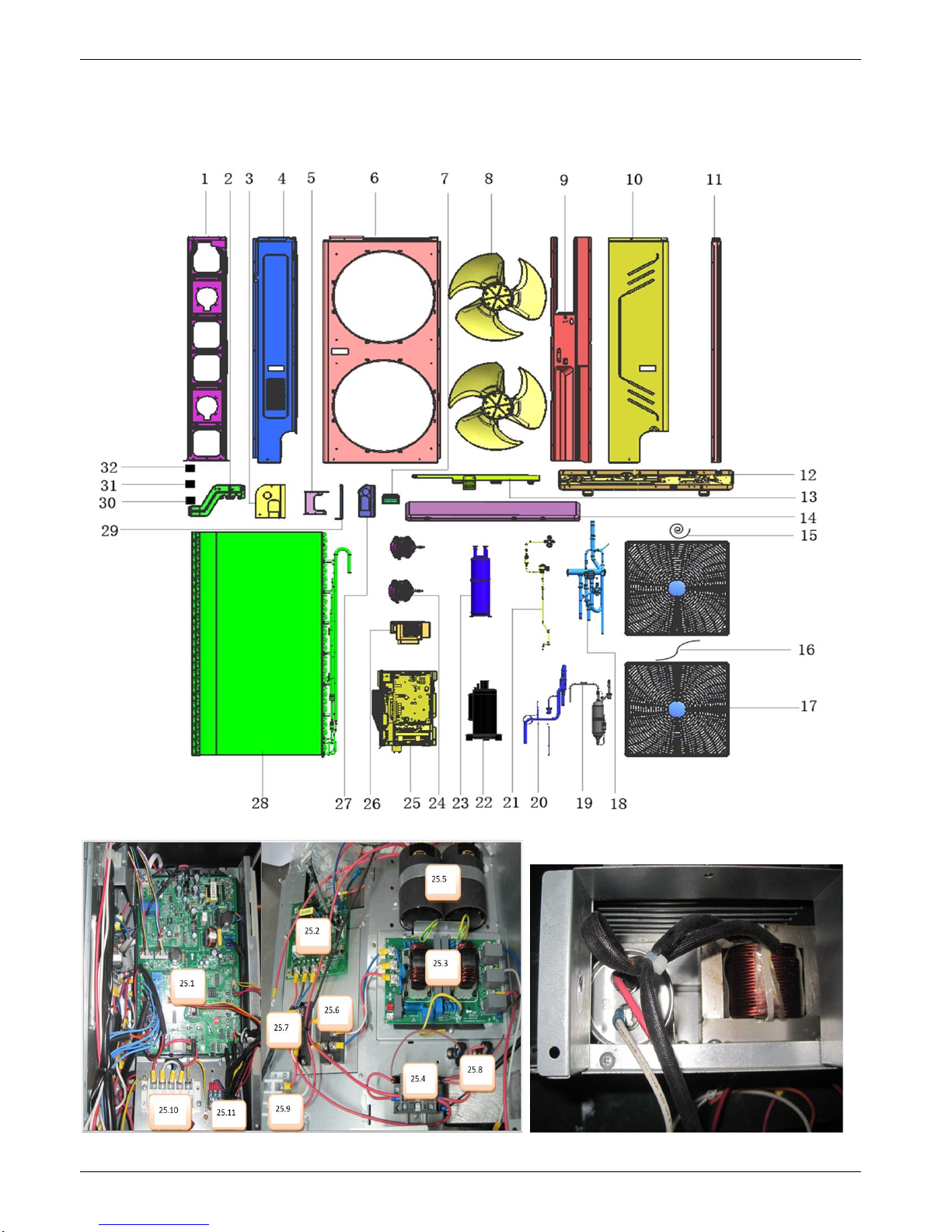

8. Exploded View

8.1 Exploded view of outdoor units

Model: CE-LRSJF-V120/SN1-610 CE-LRSJF-V140/SN1-610

Page 17

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

17

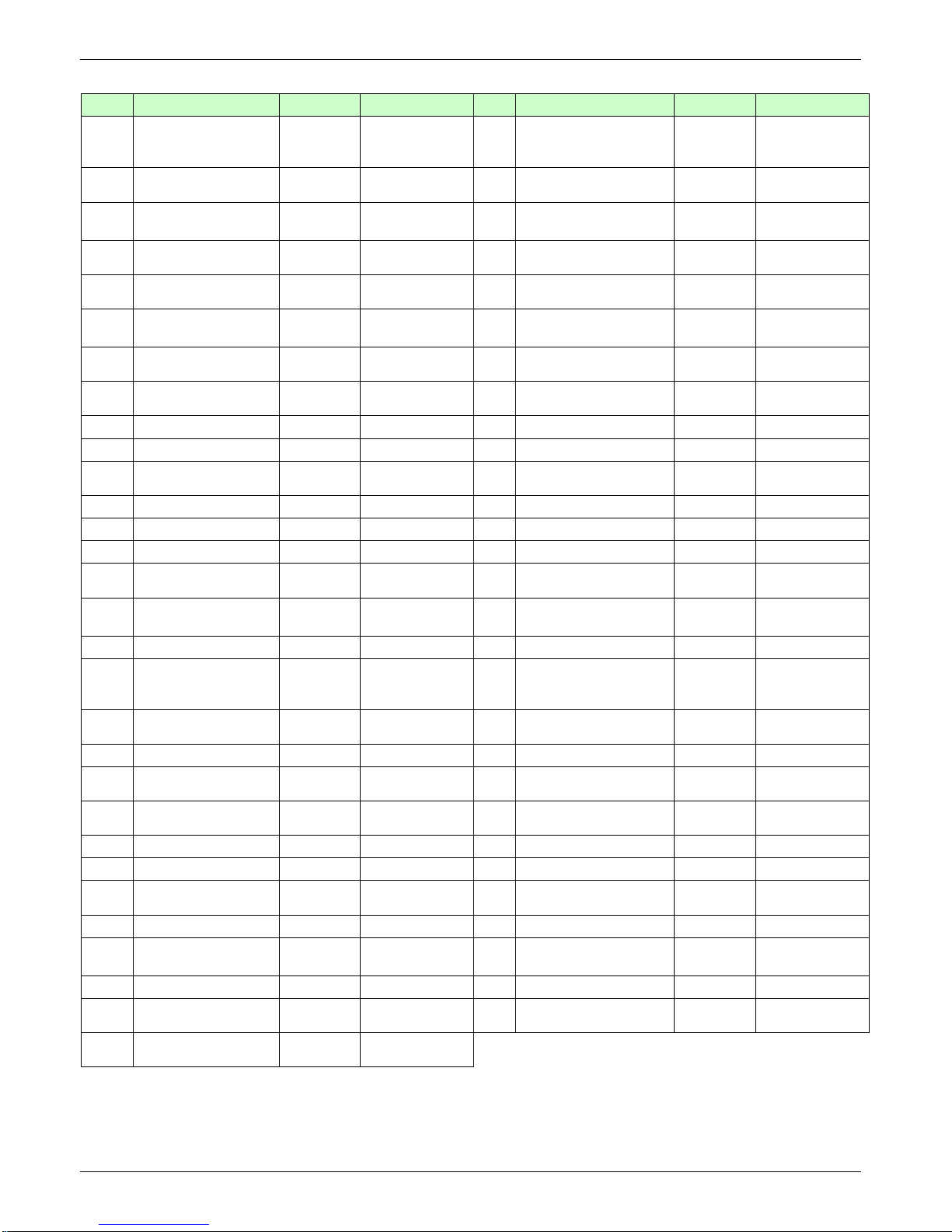

No.

Part Name

Quantity

BOM code

1

Motor bracket assembly

1

201295190080

2

Valve mounting plate

1

201295190083

3

Cover before the tube

1

201295190086

4

Right rear side

1

201295190081

5

Installation of gas-liquid separator plate

1

201295190079

6

Front Panel

1

201295190088

7

Handle

3

201195190001

8

Axial fan

2

201100300524

9

Partition components

1

201295190094

10

Right front side components

1

201295190082

11

Left rear support

1

201295190084

12

Base

1

201295190174

13

Layering fence

1

201295190076

14

Cover parts

1

201295190089

15

Compressor electric heater

1

202403100155

16

Electric heater

1

202403101687

17

Net

2

201195190163

18

Four-way valve parts

1

201695190355

19

Discharge pipe ass'y

1

201695190460

20

Suction pipe ass'y

1

201690590359

21

Electronic expansion valve ass'y

1

201690590595

22

Compressor

1

201401500270

23

Gas-liquid separator

1

201601100084

24

DC Motor

2

202400300216

25

E-part box ass'y

1

203390590094

25.1

Main control board ass'y

1

201390590073

25.2

Inverter module

1

201319902223

25.3

outdoor unit power supply board

1

201395190184

25.4

AC contactor

1

202300850054

25.5

Aluminum electrolytic capacitor

2

202300300109

25.6

Three phase bridge

1

202300500348

25.7

Single-phase bridge

1

202300500910

25.8

Resistance

2

202300130008

25.9

Wire joint

1

202301450115

25.10

Wire joint

1

202301450133

25.11

Six Terminal Block

1

202301400242

26

Electrical inductance Ass'y

1

203395100212

26.1

Compressor capacitor

1

202401090058

26.2

inductance

1

202301000927

27

After the tube cover

1

201295190085

28

Condenser ass'y

1

201595190036

29

Transport to strengthen board

1

201295190078

30

Discharge temp sensor ass'y

1

202301300124

31

room temp sensor ass'y

1

202301300197

32

Outdoor coil temp sensor ass'y

1

202301300438

Page 18

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

18

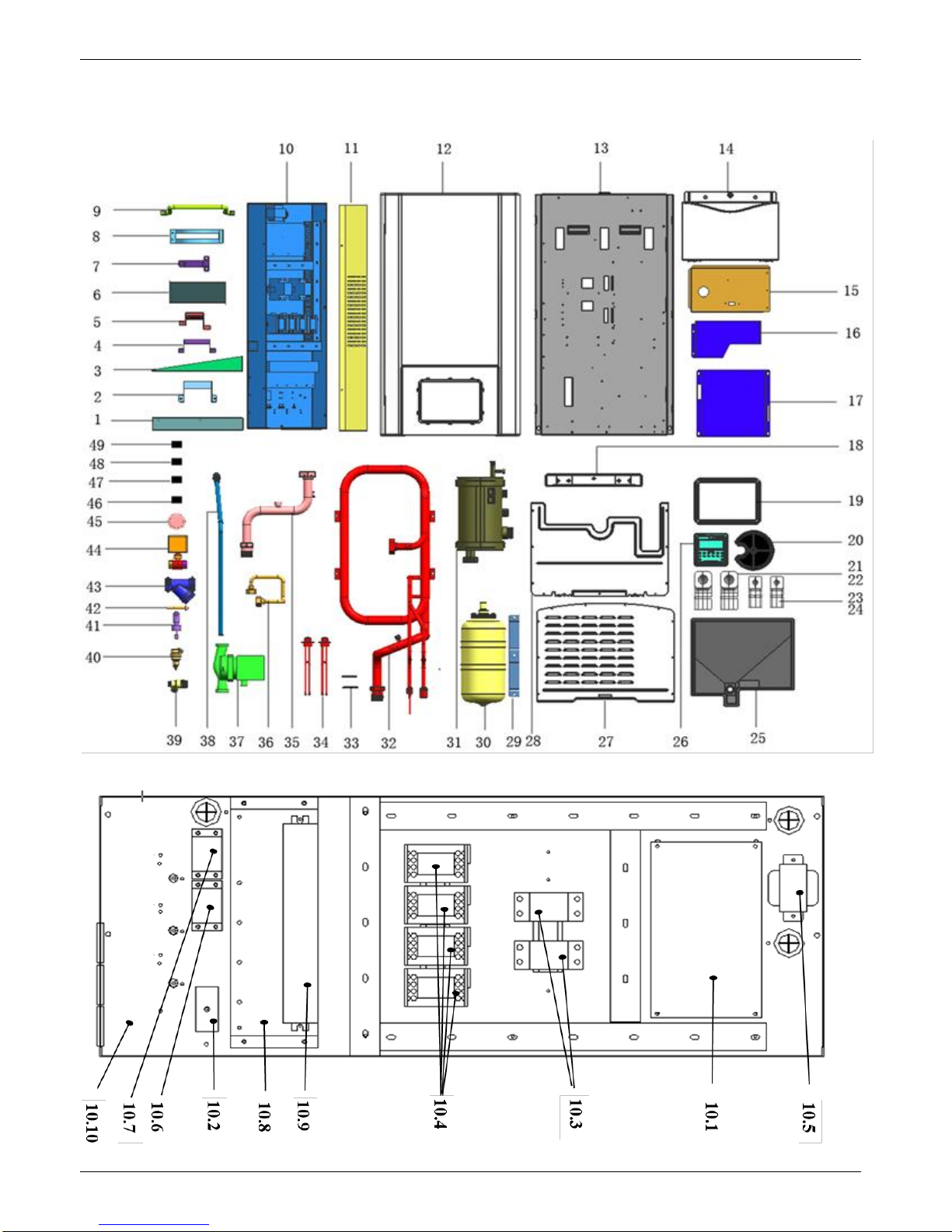

8.2 Exploded view of hydraulic indoor units

Model :SMK-120/CSD80GN1 SMK-140/CSD80GN1

Page 19

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

19

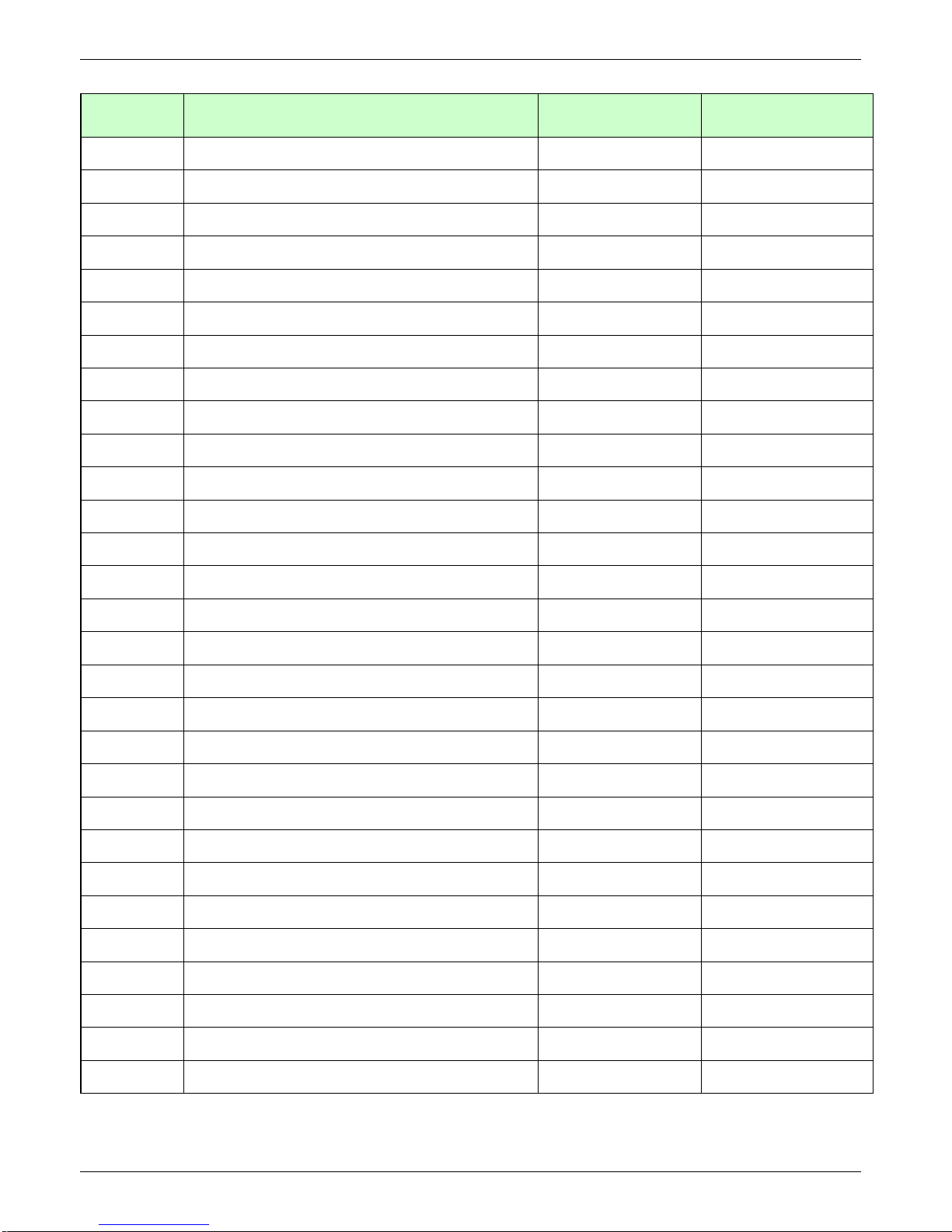

No.

Part Name

Quantity

BOM code

No.

Part Name

Quantity

BOM code

1

Electronic control

box mounting plate

2

1

201256390012

21

Right foam refrigerant

pipe

2

202256390004

2

Pump mounting

plate

1

201256390014

22

Left foam refrigerant

pipe

2

202256390005

3

1 electronic control

box mounting plate

1

201256390013

23

Right out of the

bubble pipe

2

202256390002

4

Refrigerant pipe

fixed plate

1

201256390008

24

Left out of the bubble

pipe

2

202256390003

5

Fixed plate inlet

1

201256390009

25

Water tray

components

1

202256390001

6

Pump Bracket 2

1

201256390004

26

Hydraulic module

wired remote

1

203355100567

7

Outlet pipe fixed

plate

1

201256390010

27

Roof

1

201256390033

8

Expansion tank

clamp

1

201290490010

28

Bottom

1

201256390034

9

Handle

1

201256390011

29

Mounting Bracket

1

201256390017

10

E-part box ass'y

1

203356390006

30

Expansion Tank

1

201601300552

10.1

Main controller

ass'y

1

201356390008

31

Small water tank

1

201256390006

10.2

Wire joint, 6p

1

202301400219

32

Casing components

1

201756390001

10.3

32A MCB

2

202301620210

33

Shaft

2

201256390035

10.4

AC contactor

4

202300850054

34

Electric heater

2

202403101682

10.5

Transformer

1

202300900109

35

Outlet pipe

components

1

201656390016

10.6

Wire joint, 5p

1

202301450039

36

Expansion Tank take

over the components

1

201656390014

10.7

Wire joint

1

202301450133

37

Drain Pump

1

202400600085

10.8

Electronic control

box terminal strip

bracket

1

201256390001

38

Connect hose

1

201119900833

10.9

Thirty Terminal

Block

1

202301400244

39

Safety valve

1

201604100106

10.10

E-part box ass'y

1

201256390036

40

Exhaust valve

1

201601601296

11

Electronic control

box cover

1

201256390003

41

Target Flow Switch

1

202301800869

12

Front Panel

1

201256390031

42

Expansion bolt

assembly

5

202501100838

13

Rear

1

201256300023

43

Electric valve

3

201601601255

14

Flip

1

201256390032

44

Y Type filter

1

201695700020

15

Wired remote

support

1

201256390018

45

Hydraulic meter

1

201800100005

16

Pump bracket

1

201256390015

46

Temp sensor

1

202301300311

17

Small water tank

fixed plate

1

201256390016

47

Pipe temperature

sensor assemblies

1

202301300494

18

Decorative plates

1

201156390003

48

Temp sensor ass'y

1

202301300495

19

Decorative ring

1

201156390004

49

Thermostat

components

1

202456390020

20

Electric heating

cover

1

201156390002

Page 20

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

20

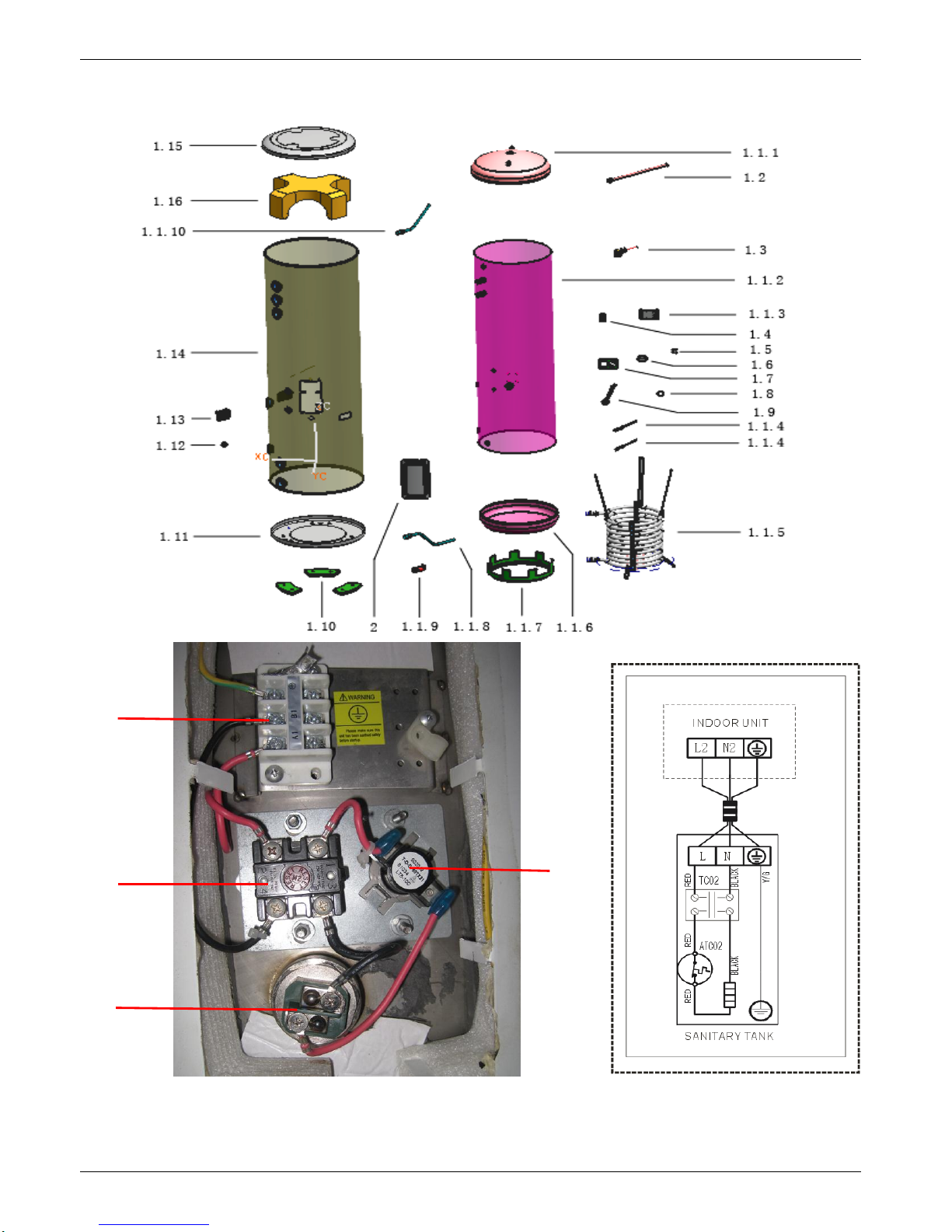

8.3 Exploded view of water tank

1.5

1.4

1.6

1.9

Page 21

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

21

No.

Part Name

Quantity

BOM code

1

Water tank foam components

1

201256190027

1.1

Liner welded components

1

201256190023

1.1.1

Head on liner

1

201256100529

1.1.2

Inner barrel body

1

P0000805371

1.1.3

Terminal Block Bracket

1

201256190025

1.1.4

Temperature control components Ⅱ

2

P0000613681

1.1.5

Solar coil assembly

1

201256190019

1.1.6

Under the head liner

1

201256190024

1.1.7

Interior support frame

1

201290590109

1.1.8

Inlet components

1

P0000613631

1.1.9

Drainage fittings

1

201290590138

1.1.10

Outlet pipe components

1

P0000613665

1.2

Magnesium anode

1

202990590003

1.3

TP relief valve

1

201601601206

1.4

Three Terminal Block

1

202301400246

1.5

Thermometer

1

202301600046

1.6

Temp sensor

1

202301610028

1.7

Stator of temp. sensor

1

201290590034

1.8

seal ring of radiation pipe

1

202790590001

1.9

Electric heating pipe water

1

202403100092

1.10

Plastic foot

3

201190500293

1.11

Tank bottom

1

P0000805356

1.12

Coil rubber too

1

202790500510

1.13

Water tank handle

2

201156100038

1.14

Shell

1

P0000805335

1.15

Tank cover

1

P0000805345

1.16

Top foam liner

1

202256190001

2

Heater Cover

1

201256190015 3 Wiring nameplate

1

202056190049

Page 22

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

22

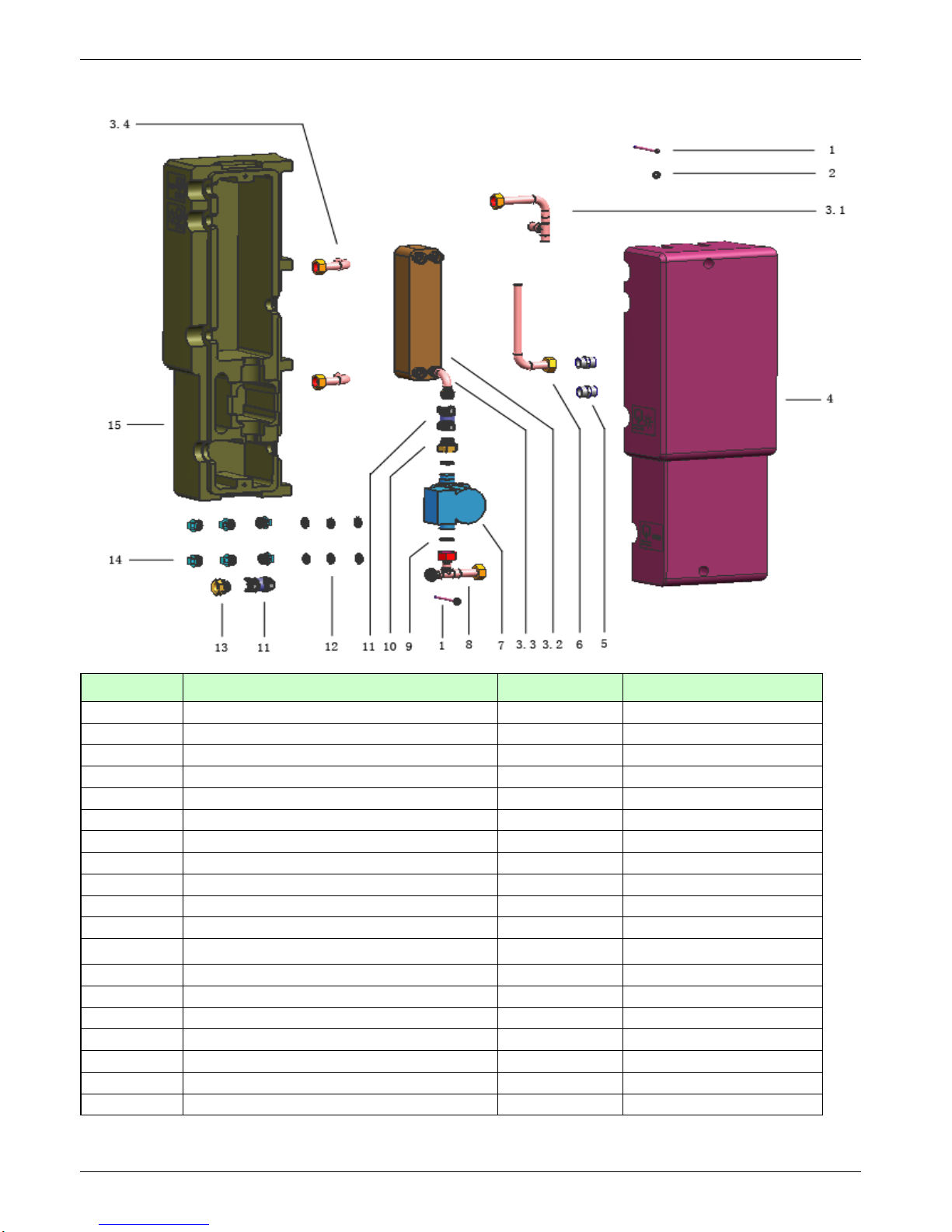

8.4 Exploded view of solar kit

No.

Part Name

Quantity

BOM code

1

Cross Recess Head Screw

2

202500300859

2

washers

2

202502100091

3

plate exchanger ass'y

1

201756390002

3.1

plate exchanger outlet pipe ass'y

1

201656390002

3.2

plate exchanger

1

201700101111

3.3

plate exchanger inlet pipe ass'y

1

201656390005

3.4

plate exchanger inlet/outlet pipe

2

201656390001

4

right foam

1

202656390002

5

adapter

2

201600401064

6

connecting pipe

1

201656390004

7

Shield pump ass'y

1

202400600073

8

pump connecting tube components

1

201656390010

9

seal ring

2

202795700050

10

non-return valve joint II

1

201656390008

11

non-return valve

2

201656390007

12

seal ring

6

202790500050

13

non-return valve joint IV

1

201656390009

14

Seal Stopper

6

201170390002

15

left foam

1

202656390001

Page 23

Part 2 Installation

1. Outdoor unit installation ............................................ 2

2. Hydraulic modular unit installation ......................... 12

3. Installation of the solar kit ....................................... 18

4. Installation of sanitary water tank ........................... 22

5 Filed wiring................................................................ 27

Page 24

1. Outdoor unit installation

1.1 Precaution

1) Ensure that all Local, National and International regulations are satisfied.

2) Read the ”Installation manual” carefully before Installation.

3) The precautions described below include the important items regarding safety. Observe them

without fail.

4) After the installation work, perform a trial operation to check for any problem.

4) Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

5) Turn off the main power supply switch (or breaker) before the unit maintenance.

6) Ask the customer to keep the Installation Manual together with the Owner’s Manual.

7) Some tools as follow table should be prepared before installation:

1

Philips screw driver

12

Hexagonal wrench

2

Hole core drill(65mm)

13

Pipe flaring tool

3

Spanner

14

Pipe bender

4

Pipe cutter

15

Level vial

5

Knife

16

Metal saw

6

Reamer

17

Manifold gauge (Charge hose:R410A special requirement)

7

Gas leak detector

18

Vacuum pump (Charge hose:R410A special requirement)

8

Tape measure

19

Torque wrench 1/4(17mm)16N•m (1.6kgf•m),

3/8(22mm)42N•m (4.2kgf•m), 1/2(26mm)55N•m (5.5kgf•m)

5/8(15.9mm)120N•m(12.0kgf•m)

9

Thermometer

20

Copper pipe gauge adjusting projection margin

Page 25

10

Mega-tester

21

Vacuum pump adapter

11

Electro circuit tester

1.2 Accessory

Please check whether the following fittings are of full scopes. If there are some spare fittings ,

please restore them carefully.

1.3 Installation place

Please keep away from the following place, or malfunction of the machine may be

caused:

1) There is combustible gas leakage.

2) There is much oil (including engine oil) ingredient.

3) There is salty air surrounding (near the coast)

4) There is caustic gas (the sulfide, for example) existing in the air (near a hot spring)

5) A place the heat air expelled out from the outdoor unit can reach

Page 26

your neighbor’s window.

6) A place where the drain water may make problems.

7) A place that the noise interferes your neighbors everyday life.

8) A place that is exposed to a strong wind.

9) A place that is too weak to bear the weight of the unit.

10) A place that block a passage.

11) Uneven place.

12) Insufficient ventilation place.

13) Near a private power station or high frequency equipment.

Caution:

When an outdoor unit is installed in a place that is always exposed to a strong wind like a

coast or on a high storey of a building, secure a normal fan operation by using a duct or a wind

shield.

When the outdoor unit is installed in an elevated position be sure to secure its feet.

Keep indoor unit, outdoor unit, power supply wiring and transmission wiring at least 1 meter

away from televisions and radios. This is to prevent image interference and noise in those

electrical appliances. (Noise may be generated depending on the conditions under which the

electric wave is generated, even if 1 meter is kept.)

The insulation of the metal parts of the building and the heater pump should comply with the

regulation of National Electric Standard.

Page 27

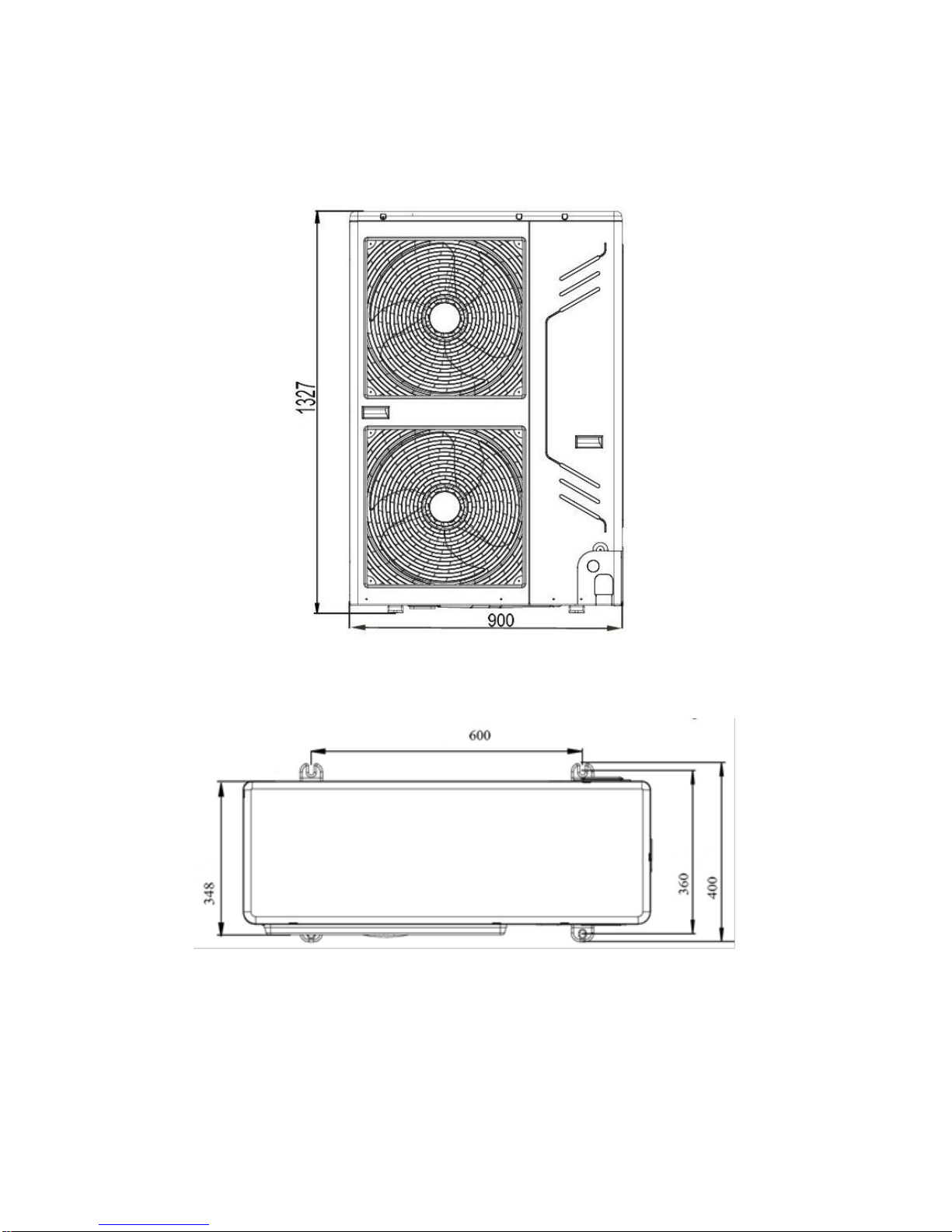

1.4 Dimensions of the outdoor unit

1.5 Installation space

1) Single unit installation

Page 28

2) Parallel connect the two units or above

3) Parallel connect the front with rear sides

Page 29

1.6 Moving and installation

1) Since the gravity center of the unit is not at its physical center, so please be careful when

lifting it with a sling.

2) Never hold the inlet of the outdoor unit to prevent it from deforming.

3) Do not touch the fan with hands or other objects.

4) Do not lean it more than 45°, and do not lay it sidelong.

5) Make concrete foundation according to the specifications of the outdoor units.

6) Fasten the feet of this unit with bolts firmly to prevent it from collapsing in case of

earthquake or strong wind. (Refer to follow fig.)

1.7 Water Outlet

Page 30

Caution:

While installing the outdoor unit, pay attention to the installation place and the drainage

pattern; if it’s installed at the alpine zone, the frozen condensed water will block up the water

outlet, please pull out the rubber stopper of the reserve water outlet. If that still fails to satisfy

for the water draining, please knock open the other two water outlets, and keep the water can

drain in time.

Pay attention to the knock the reserve water outlet from outside to inside, and it will be beyond

repair after knocking open, please pay attention to the installation place, lest cause the

inconvenience. Please do the moth proofing for the knocked out hole, to avoid the pest

processing into and destroy the components.

1.8 Pipe connection

1) Check whether the height drop between the indoor unit and outdoor unit, the length of

refrigerant pipe, and the number of the bends meet the following requirements:

Model

The max height drop(m)

The length of

refrigerant pipe(m)

When outdoor unit

is top

When outdoor

unit is bottom

LRSJF-V120/SN1-610

15

10

50

LRSJF-V140/SN1-610

15

10

50

Model

Gas side/Connection type

Liquid side/ Connection type

LRSJF-V120/SN1-610

LRSJF-V140/SN1-610

Φ15.9/ Flaring

Φ9.5/ Flaring

Page 31

Indoor unit

Φ15.9/ Flaring

Φ9.5/ Flaring

2) Refrigerant piping heat Insulation

Do the heat insulation to the pipes of gas side and liquid side separately. The temperature of

the pipes of gas side and liquid side when cooling, for avoiding condensation please do the

heat insulation fully.

1) The gas side pipe should use closed cell foamed insulation material, which the fire-retardant

is B1 grade and the heat resistance over 120℃.

2) When the external diameter of copper pipe≤Φ12.7mm, the thickness of the insulating layer

at least more than 15mm;

When the external diameter of copper pipe≥Φ15.9mm, the thickness of the insulating layer at

least more than 20mm.

3) Please use attached heat-insulating materials do the heat insulation without clearance for

the connecting parts of the indoor unit pipes.

3) Refrigerant piping connection

We should wash the pipes with high pressure nitrogen, never use refrigerant of the outdoor

units. Make sure there is no dirt or water in the pipes before connecting the pipes to the

outdoor units.

Caution:

● Please pay attention to avoid the components where it is connecting to the connecting

pipes.

● To prevent the refrigerant piping from oxidizing inside when welding, it is necessary to

Page 32

charge nitrogen, or oxide will chock the circulation system.

The indoor and outdoor connecting pipe interface and power line outlet. Can select various piping

and wiring patterns such as out from the front, the back, the side and undersurface etc.(The follow

display the locations of several piping and wiring knock-off interfaces)

Caution:

● Side out pipe: please remove the L-shape metal plate, otherwise can not wiring.

● Back out pipe:

Undersurface outlet pipe: the knock out should from inside to outside, and then piping and wiring

through this. Pay attention to the piping, the fat connecting pipe should out from the largest hole,

otherwise the pipes will be rubbed. Please do the moth proofing for the knocked out hole, to

avoid the pest processing into and destroy the components.

● Please wipe off the piping support rubber blanket beside the inner outlet pipe cover of the

machine while back side getting out pipes.

1.9 Airtight Test

Page 33

When we have connected the refrigerant pipe as follows diagram, we should do airtight test to

check whether the system is leakage.

Caution:

● Pressured nitrogen [ 4.3MPa (44kg/cm2 ) for R410A] should be used in the airtight test.

● Tighten high pressure/low pressure valves before applying pressured nitrogen.

● Apply pressure from air vent mouth on the high pressure/low pressure valves.

● The high pressure/low pressure valves are closed when applying pressured nitrogen.

● The airtight test should never use any oxygen, flammable gas or poisonous gas.

1.10 Air Purge With Vacuum Pump

After the airtight test, we should remove the air in the refrigerant connecting pipes.

1) Using vacuum pump to do the vacuum, never using refrigerant to expel the air.

2) Vacuuming should be done from both liquid side and gas side simultaneously.

3) The system should be vacuumized until the vacuum pump indicates the pressure of the pipes

less than 10pa.

1.11 Refrigerant Amount To Be Added

Calculate the added refrigerant according to the diameter and the length of the liquid side pipe

of the outdoor unit/indoor unit connection. If the length of the liquid side pipe is less than 5

meters it is no need to add more refrigerant, so than calculating the added refrigerant the length

of the liquid side pipe must subtract 5 meters.

Page 34

2. Hydraulic modular unit installation

2.1 Accessory

Please check whether the following fittings are of full scopes. If there are some spare fittings ,

please restore them carefully.

Hydraulic

Indoor

Unit

Accessories

Owner's & Installation

Manual

1

Mounting bracket

1

Two-way valve

3

M4 screws

2

Water tank temperature sensor

1

Y-sharp filter

1

Floor heating inlet

temperature sensor, T1B

1

Drain pan kit

1

M8 expansion screws

5

2.2 Installation place

Selecting an installation location

The indoor unit is to be wall mounted in an indoor location that meets the following

requirements:

The installation location is frost-free.

The space around the unit is adequate for serving.

The space around the unit allows for sufficient air circulation.

There is a provision for condensate drain and pressure relief valve blow-off.

Caution:

When the unit running in the cooling mode, Condensate may drop from the water inlet and

water outlet pipes to your furniture and other devices. Please make sure the dropping

condensate will not result in damage of your furniture and other devices.

The installation surface is a flat and vertical non-combustible wall, capable of supporting the

operation weight of the unit.

There is no danger of fire due to leakage of inflammable gas.

All piping lengths and distance have been taken into consideration.

Page 35

Requirement

SMK-120/CSD80GN1

SMK-140/CSD80GN1

Maximum allowable refrigerant piping length between outdoor unit and

indoor unit.

50m

Maximum allowable height distance between outdoor

unit and indoor unit when outdoor unit is top.

15m

Maximum allowable height distance between outdoor

unit and indoor unit when outdoor unit is bottom

10m

Maximum allowable distance between the 2-way valve SV1 and the indoor

unit (only for installations with sanitary hot water tank).

3m

Maximum allowable distance between the sanitary hot water tank and the

indoor unit (only for installations with sanitary hot water tank). The

thermistor cable supplied with the indoor unit is 15 min length.

10m

Maximum allowable be distance between the T1B and the indoor unit .The

temperature sensor cable of T1B supplied with the indoor unit is 10m in

length.

8m

The equipment is not intended for use in a potentially explosive atmosphere.

2.3 Dimensions of the hydraulic indoor units

Unit of measurement: mm

Dimensions of the wall bracket:

Dimensions of the unit

Page 36

2.4 Service space

2.5 Mounting the indoor unit

Fix the wall mounting bracket to the wall using appropriate plugs and screws.

Make sure the wall mounting bracket is completely level.

When the unit is not installed level, air might get trapped in the water circuit resulting in

malfunctioning of the unit.

Pay special attention to this when installing an indoor unit to prevent overflow of the drain pan

Hang the indoor unit on the wall mounting bracket.

Fix the indoor unit at the bottom inside using appropriate plugs and screws. To do so, the unit

is equipped with 2 holes at the bottom outer edges of the frame.

Page 37

2.6 Water pipe insulation

The complete water circuit, inclusive all piping, must be insulated to prevent condensation during

cooling operation and reduction of the cooling and heating capacity.

If the temperature is higher than 30 and the humidity is higher than 80%RH, then the thickness of

the sealing materials should be at least 20 mm in order to avoid condensation on the surface of

the sealing.

Caution:

Failure to do good piping insulation, the cooling/heating capacity

of the unit will be reduced and condensate drop will destroy the furniture and other

devices.

2.7 Water pipework

Checking the water circuit

The units are equipped with a water inlet and water outlet for connection to a water circuit. This

circuit must be provided by a licensed technician and must comply with all relevant European and

national regulations

WARNING:

The unit is only to be used in a closed water system. Application in an open water circuit can

lead to excessive corrosion of the piping.

Before continuing the installation of the unit, check the following points:

The maximum water pressure is 3 bar, but the best pressure range is between 1 to 2 bar. It

will be perfect, if the water pressure is the same as pre-pressure of expansion vessel.

To facilitate service and maintenance install one shut-off value at the water inlet and one

shut-off value at the water outlet of the indoor unit.

Drain taps must be provided at all low points of the system to permit complete drainage of the

circuit during maintenance.

Make sure to provide a proper drain for the pressure relief valve to avoid any water coming

into contact with electrical parts.

Air vents must be provided at all high points of the system. The vents should be located at

points which are easily accessible for servicing. An automatic air purge is provided inside the

indoor unit. Check that this air purge is not tightened too much so that automatic release of air

in the water circuit remains possible.

There might be air in the electric heater water tank. The air will cause the damage of the

electric heater and cause the abnormal operation of the system. The air in the water tank can

be purged by the manual discharging valve in the top of the water tank. The power for the

electric heater cannot be supplied before discharging the air in the water tank. It will last 30

min until discharging the air completely.

Take care that the components installed in the field piping can withstand the water pressure.

The filter (accessory of indoor unit) must be connected into the water circuit.

CAUTION

When the unit running in the cooling mode, there will be condensate drop the water inlet and

Page 38

water outlet pipes. Please make sure the dropping condensate will not result in damage of

your furniture and other devices.

Checking the water volume and expansion vessel pressure

The unit is equipped with an expansion vessel of 6.5 liter which has a default pre-pressure of 1

bar.

To assure proper operation of the unit, the pre-pressure of the expansion vessel might need to

be adjusted and the minimum and maximum water volume must be checked.

Setting the pre-pressure of the expansion vessel

When it is required to change the default pre-pressure of the expansion vessel (1bar), keep in

mind the following guidelines:

● Use only dry nitrogen to set the expansion vessel pre-pressure.

● Inappropriate setting of the expansion vessel pre-pressure will lead to malfunction of the

system. Therefore, the pre-pressure should be adjusted by a licensed installer.

Calculating the water circuit pressure drop

If the water circuit pressure drop excluding the indoor is too high, an auxiliary pump is necessary

to be installed in the water circuit.

Caution

●An auxiliary pump should be installed while the water resistance is more than 30kpa.

●The auxiliary pump should be installed while the water resistance is more than 30kpa. The

pressure drop is too high may cause heating/cooling capacity reduction, the heat exchanger

freeing and the pump damage.

Warning

If the indoor unit is not running for 24 hours, the pump in the indoor unit and the auxiliary pump(if

installed) will turn on and run for 3 minutes to preventing pump from blocking.

Connecting the water circuit

WARNING

Be careful! the unit pipes may be deformed by using excessive force when connecting the piping.

Deformation of the piping can cause some malfunctions.

Water connections must be made in accordance with the outlook diagram delivered with the unit,

respecting the water in- and outlet.

If air, moisture or dust gets in the water circuit, problems may occur. Therefore, always take into

account the following when connecting the water circuit:

● Use clean pipes only.

● Hold the pipe end downwards when removing burrs.

● Cover the pipe end when inserting it through a wall so that no dust and dirt enter.

● Use a good thread sealant for the sealing of the connections. The sealing must be able to

withstand the pressures and temperatures of the system.

● When using non-brass metallic piping, make sure to insulate both materials from each other to

prevent galvanic corrosion.

● Because brass is a soft material, use appropriate tooling for connecting the water circuit.

Inappropriate tooling will cause damage to the pipes.

WARNING

● The unit is only to be used in a closed water system. Application in an open water circuit can

Page 39

lead to excessive corrosion of the water piping.

● Never use Zn-coated parts in the water circuit. Excessive corrosion of these parts may occur

as copper piping is used in the unit’s internal water circuit.

2.8 Charging water

■ Connect the water supply to a drain and fill valve.

■ Make sure the automatic air purge valve is open (at least 2 turns).

■ Fill with water until the manometer indicates a pressure of approximately 1.0~2.0 bar. Remove

air in the circuit as much as possible using the air purge valves. Air present in the water circuit

might cause malfunctioning of the auxiliary heater.

■ Check that the auxiliary heater vessel is filled with water by screw off the vent valve two laps, it

will be full of water until finish draining off the air.

NOTE:

● During filling, it might not be possible to remove all air in the system. Remaining air will be

removed through the automatic air purge valve during first operating hours of the system.

Additional filling with water afterwards might be required.

● The water pressure indicated on the manometer will vary depending on the water temperature

(higher temperature at higher water temperature).However, at all times water pressure should

remain above 0.3 bar to avoid air entering the circuit.

● The unit might dispose some excessive water through the pressure relief valve.

● Water quality must be according to EN directive 98/83 EC.

Page 40

3. Installation of the solar kit

The solar kit is designed to transfer the heat from the solar panels to the heat exchanger of the

sanitary hot water tank and is to be installed in the system.

3.1 Accessories supplied with the solar kit

3.2 Main components of the solar kit

1

left EPP casing

8

Return connection to solar pump station

2

Left right foam fixed screw

9

Non-return valves

3

Sanitary hot water tank

10

Solar kit circulation pump

4

Right EPP casing

11

Return connection to the indoor unit

5

Return connection to the sanitary hot

water tank heat exchanger

12

Non-return valves

Page 41

6

Inlet connection from the indoor unit

13

Inlet connection from the sanitary

hot water tank heat exchanger

7

Heat exchanger

3.3 Selecting an installation location

The solar kit is to be installed in a frost free indoor space, directly connected to the sanitary hot

water tank.

Make sure the service space is available.

The space around the unit has to allow sufficient air circulation.

It shall be made sure that in the case of a leak, leaking water will not cause any damage or

unsafe situations.

Do not install or operate the unit in rooms mentioned below:

Where corrosive gas like sulphurous gas exists: copper tubing and brazed spots may

corrode.

Where volatile flammable gas like thinner or gasoline is used.

Where machines generating electromagnetic waves exist the control system may

malfunction.

Where the air contains high levels of salt such as air near the ocean and where voltage

fluctuates a lot (e.g. in factories).This applies also to vehicles or vessels.

3.4 Dimensions and service space

Service space dimensions below relate to requirements for installation of the solar kit only.

3.5 Installation guidelines

Make sure that all the piping to the solar kit is insulated.

Make sure that all the piping to the solar kit is sufficiently supported so that it will not cause any

stress on the solar kit.

Make sure that the piping coming from outdoors to the solar kit is put through the wall under an

Page 42

angle and the wall hole is sufficiently sealed afterwards, so no water can enter the space.

Make sure the piping is protected against dirt during installation.

Dirt in the piping might clog the heat exchanger of the solar panel and reduce its performance.

3.6 Installing the solar kit

● At delivery, the unit should be checked and any damage should be reported immediately to

the carrier claims agent.

● Check if all unit's accessories are enclosed.

● Bring the unit as close as possible to its final installation position in its original package. in

order to prevent damage during transport.

Procedure

Locate the sanitary hot water tank in a suitable position to facilitate the installation of the solar kit.

It is therefore recommended to first read the entire installation procedure. Refer to the

installation guidelines in the installation manual of the sanitary hot water tank.

The installation of the solar kit as following:

Page 43

Fit the adaptor 3/4" Female BSP x 3/4" Male BSP in the flow inlet connection of the sanitary

hot water tank.

Fit the connection pipe 3/4 " Male BSP x3/4" Male BSP and sealing in the flow inlet connection

of the sanitary hot water tank.

Fit the adaptor 3/4" Male BSP x3/4" Male BSP in the heat exchanger outlet connection of the

sanitary hot water tank.

Fit the solar kit and sealing (x2) on the heat exchanger in let connection and heat exchanger

outlet connection of the sanitary hot water tank. Torque 5 N.m.

Fit the adaptors 3/4" Male BSP x 3/4" Male BSP (x4) to the field piping:

a) Inlet connection from indoor unit

b) Return connection to indoor unit

c) Inlet connection from solar pump station

d) Return connection to solar pump station

Fit the solar kit and sealing (x4) to the field piping .Torque 5N.m.

Mount the left side of the EPP casing onto the solar kit.

Mount the EPP lid onto the right side of the EPP casing.

Mount the right side of the EPP casing onto the solar kit. Take case, that the pump cable is

routed via the holes in the Bottom of the EPP casing.

CAUTION:

Ensure that the pump cable cannot come into contact with piping below the pump when cable

is routed out.

Use the screws and washers (x2) to fix the EPP casing. Screw until tight position.

WARNING

Do not switch inlet and outlet connections.

To install adequate connections between the indoor unit and the solar kit, it is important that

the 2-way valve is fitted correctly.

CAUTION:

Ensure that the water piping connected to the solar kit coming from the solar panel and the

indoor unit are sufficiently supported and do not cause any stress on the solar kit

Charging water

Charge the water on the indoor unit and the tank .Charge the solar panel circuit with a glycol

solution.

CAUTION:

Observe the instructions as given by your solar panel supplier. Make sure to use non-toxic glycol.

Page 44

4. Installation of sanitary water tank

4.1 Accessories of water tank

4.2 Selecting an installation location

Enough space is installation and maintenance shall be preserved.

The bearing surface should be flat able to bear weight of the unit.

No flammable gas is leaked nearby.

It is convenient for piping and wiring.

If the unit need to be installed on a metal holder, make sure they are insulated well and in

accordance with local standard.

Installing the equipment in any of the following places may lead to malfunction of the

equipment (if it is inevitable, consult the supplier).

The site contains mineral oils such as cutting lubricant.

Seaside where the air contains much salt.

Hot spring area where corrosive gases exist, e.g., sulfide gas.

Factories where the power voltage fluctuates seriously.

Place like kitchen where oil permeates.

Place where strong electromagnetic waves exist.

Place where flammable gases or materials exist.

Place where acid or alkali gases evaporate.

Other special environments.

Precautions before installation

Decide the correct way of conveying the equipment.

If the unit has to be installed on a metal part of the building, electric insulation must be

installed, and the installation must meet the relevant technical standards for electric

devices.

Page 45

4.3 Dimensions and service space

Before installing the unit, reserve the space of maintenance shown in the following figure.

The dimensions of the water tank as following figure.

Page 46

4.4 Installation Of The Sanitary Hot Water Tank

CAUTION:

The total System (Indoor unit and outdoor unit) is designed for combination with a sanitary hot

water tank. In case another tank is being used in combination with the indoor unit we cannot

guarantee neither good operation nor reliability of the system. For those reasons we cannot give

warranty of the system in such case.

Only this tank can be used in combination with the solar kit option.

Sanitary hot water quality must be according to EN directive98/83 EC.

A drain device should be installed on the cold water connection on the sanitary hot water

tank.

For safety reasons, it is not allowed to add ethylene glycol to the water circuit. Adding

ethylene glycol might lead to contamination of the sanitary water if a leakage would occur

in the heat exchanger coil.

It is important that the storage capacity of the sanitary hot water tank meets normal daily

fluctuations In consumption of sanitary hot water without any fall of the water outlet

temperature during use.

Immediately after installation, the sanitary hot water tank must be flushed with fresh water.

This procedure must be repeated at least once a day the first 5 consecutive days after

installation.

At holiday residences or at houses that are occasionally not occupied, the sanitary hot water tank

installation must be fitted with a shunt pump.

The shunt pump can be time-controlled.

The shunt pump must operate to circulate the complete volume of the sanitary hot water

tank 1.5 times per hour.

And the shunt pump must operate or be programmed for operation. during 2 uninterrupted

hours per day at least.

In case of very long field water piping between the sanitary hot water tank and the hot water

end point (shower. bath. etc.) it can take more time before the hot water from the sanitary hot

water tank reaches the hot water end point.

Page 47

If required connect a recirculation pump in between the hot water end point and the outlet pipe

in the sanitary hot water tank.

4.5 Piping Connection

Pipeline Connection Sketch

Page 48

Caution:

When install the main unit, please set a drain valve at the drain orifice of the unit by self.

Pipeline Connection Explanation

Installation of the water inlet or outlet pipes: The spec of the water inlet or outlet thread is

RC3/4” (internal thread). Pipes must be heat-resistant and durable.

Installation of the pipe for PT valve: The specification of the valve connecting thread is RC3/4”

(internal thread). After installation, it must be confirmed that the drainpipe outlet is exposed in

the air. When flexible drainpipe is jointed to the pressure relief orifice of this valve, it must be

confirmed that the flexible drainpipe is downwards vertically and exposed in the air.

NOTE:

A safety valve should be installed at the water inlet of the unit.

The handle of PT Valve should be pulled out once per half year, to

make sure that there is no jam of the valve.

Please beware of burn, because of the high temperature of water.

The drainage pipe should be well installed ,in order to avoid

freezing up in cold weather.

Do not press the handle of PT Valve,

Do not dismantle the PT Valve,

Do not block off the Drainage pipe, It will cause explosion and injury,

if do not comply with the above instruction.

Installation of the one way valve: The specification of the one way valve thread in accessories

is RC3/4”. It is used to prevent backflow of water.

Installation of the Y-shaped filter: The spec of the Y-shaped filter thread in accessories is

RC3/4”. It is used to filtrate inlet water.

After all the pipes installed turn on the cool water inlet and hot water outlet and start effusing

the tank. When there is water normally flowing out from water outlet, the tank is full. Turn off all

valves and check all pipes. If there is any leakage, please repair.

If the inlet water pressure is less than 0.15MPa, a pressure pump should be installed at the

water inlet. For guarantee the long safety using age of tank at the condition of water supply

hydraulic higher than 0.65MPa, a reducing valve should be mounted at the water inlet pipe.

Page 49

5 Filed wiring

CAUTION:

Please select power source for indoor unit and outdoor unit respectively.

The power supply has specified branch circuit with leakage protector and manual switch.

For LRSJF-V120/SN1-610 and LRSJF-V140/SN1-610,indoor unit and outdoor unit both

connect with power supply which is 380-415V 50Hz.

Use 3-core screened wire as indoor and outdoor control wire.

The installation should comply with relevant national electric standard.

Power wiring should be engaged by specialized electrician

5.1 Outdoor unit wiring

■ Field wiring guidelines

Most field wiring on the indoor unit side is to be made on the terminal block inside the control

box. To gain access to the terminal block, remove the indoor unit cover and control box

service panel.

Cable tie mountings are provided at the bottom of the control box. Fix all cables using cable

ties (field supply).

A dedicated power circuit is required for the auxiliary heater.

Installations equipped with a sanitary hot water tank (optional), require a dedicated power

circuit for the electric heater. Please refer to the sanitary hot water installation manual.

1) The Specification of Power

Model

LRSJF-V120/SN1-610

LRSJF-V140/SN1-610

Outdoor Unit Power

Phase

3 Phase

Voltage and Frequency

380-415V~ 50Hz

Power Wiring (mm2)

5X2.5

Circuit Breaker (A)

25

Indoor unit/Outdoor unit Signal wire (mm2) (Weak

electric signal)

3-core shielded wire

3 X 0.5

Caution:

Equipment complying with IEC 61000-3-12.

A disconnection device having an air gap contact separation in all active conductors should be

incorporated in the fixed wiring according to the National Wiring Regulation.

2) Outdoor unit wiring diagram

Page 50

Page 51

5.2 Indoor unit wiring

1) The Specification of Power

Model

SMK-120/CSD80GN1

SMK-140/CSD80GN1

Indoor Unit Power

Phase

3 Phase

Voltage and Frequency

380-415V~ 50Hz

Power Wiring (mm2)

5X4.0

Circuit Breaker (A)

32

Indoor unit/Outdoor unit Signal wire (mm2) (Weak

electric signal)

3-core shielded wire

3 X 0.5

2) Indoor unit wiring diagram

Cable specification

NO

Description

Require number of core

Section of the conductor

1

Power supply cable for indoor unit

3+GND

4 mm2

2

Temperature sensor cable

2

—

3

Power supply cable from indoor unit to

Sanitary hot water tank

2

2.5 mm2

4

Power supply cable for Pump of solar kit

2+GND

1.0 mm2

Page 52

(Pump 3)

5

Power supply cable for motorized 2-way

valve, SV3

3

1.0 mm2

6

Power supply cable for motorized 2-way

-valve, SV2

3

1.0 mm2

7

Power supply cable for motorized 2-way

valve, SV1

3

1.0 mm2

8

Power supply cable for auxiliary pump

(Pump2)

2+GND

1.0 mm2

9

Communication cable between indoor unit

and boiler

2

1.0 mm2

10

Room thermostat cable

4(L, N, C, H)

1.0 mm2

11

Communication cable between indoor unit

and outdoor unit

3 (P, Q, E)

3×0.5 mm2

(3 -Shield wire)

12

Power supply cable for outdoor unit

2+GND

4.0 mm2

13

Power supply cable for solar pump station

2+GND

1.0 mm2

14

Power supply cable for the pump of solar

kit

2+GND

1.0 mm2

15

Signal input from solar pump station to

indoor unit

2

1.0 mm2

16

Power supply cable for the pump of solar

kit

2+GND

1.0 mm2

17

Sanitary hot water tank temperature

sensor cable

2

—

18

Sanitary hot water tank temperature

sensor cable

2

—

19

Water circuit temperature senor T1B cable

2

—

Connection of the indoor unit power supply and communication cable Power circuit

and cable requirements

● Power supply for the indoor units is to be provided through the indoor side. Data

communication with the outdoor unit is provided through the cable which labeled as P, Q, E.

● For all guidelines and specifications regarding field wiring between the indoor unit and the

outdoor unit, please refer to the outdoor unit installation manual.

● Using the appropriate cable, connect the power circuit to the appropriate terminals as shown

on the wiring diagram and the illustration below.

● Connect the earth conductor (yellow/green) to the earthing screw on the control box mounting

plate.

● Fix the cable with cable ties to the cable tie mountings to ensure strain relief.

● When routing out cables, make sure that these do not obstruct mounting of the indoor unit

cover.

Connection of the auxiliary heater power supply Power circuit and cable requirements

This power circuit must be protected with the required safety devices according to local and

national regulations. Select the power cable in accordance with relevant local and national

regulations.

Using the appropriate cable, connect the power circuit to the appropriate terminals as shown

on the wiring diagram.

Page 53

Connect the earth conductor (yellow/green) to the earth screw on the block terminal. Fix the

cable with cable ties to the cable tie mountings to ensure strain relief.

CAUTION:

Be sure to use a dedicated power circuit for the auxiliary heater. Never use a power circuit

shared by another appliance.

Connection of the thermostat cable

Connection of the thermostat cable depends on the application.

See section7.2 “Room thermostat installation configuration” for more information and

configuration options on pump configuration in combination with room thermostat.

● Thermostat requirements

1. Power supply: 220-240V~ 50Hz or battery operated

2. Contact voltage: 220-240V~ 50Hz

● Procedure

1. Connection of the thermostat cable to the appropriate terminals shown on the wiring diagram.

2. Fix the cable with cable ties to the cable tie mountings to ensure strain relief.

3. Set the “Field setting ” about the selection of Room Thermostat.

Connection of the valve cable

Valve requirements

1. Power supply: 220-240V~ 50Hz

2. Maximum running current: 100mA

Wiring the 2-way valve

1. Using the appropriate cable, connect the valve control cable to the terminal as shown

on the wiring diagram.

NOTE:

Wiring is different for a NC (normal closed) valve and a NO (normal open) valve. Make sure to

connect to the correct terminal numbers as detailed on the wiring diagram and illustrations below.

Page 54

NOTE:

For the NC (normal closed) valve, it is necessary to reverse the terminal 4 and 5, 7 and 8, 10 and

11 to get the right opening and closing of the valve.

2. Fix the cable(s) with cable ties to the cable tie mountings to ensure strain relief.

Electrical Connection of Water Pump

Water pump specification:

Power supply: 220-240V~ 50Hz

Maximum running current: 2A

Using the appropriate cable, connected the

pump cable to the terminals

Fix the cable with cable ties to the cable tie mountings to ensure

strain relief.

Page 55

Electrical Connection of Anti-frozen electric heater (Reserved)

Electrical Connection of External Heat Source

Using the appropriate cable, and connect the control terminal of heat source such as gas boiler

etc., the control terminal of this unit is 25-26 terminals in the connector base.

NOTE:

This control terminal of the indoor unit only outputs one switch signal; it needs to change wiring

when matching with different external heat sources.

The signal wire connected the solar energy pump with hydraulic module need to be increased

protection, such as fuse, for avoiding the abnormal operation lead to the device damage.

1. If the external heat source need some switch signal to control the

input situation, then directly connect the corresponding wire terminal

of this machine with the corresponding terminals of the external heat

source.

2. If the external heat source needs one control signal of the

specified voltage (such as 220-240V~ 50Hz), then it need to

supply the control terminal25 and 26 with corresponding

power.

External Wiring of Operation/ Fault

● The terminal 27 and 28 will be conducted when the unit is running, and will be

disconnected when the unit is turned off or stood by.

● The terminal 29 and 30 will be conducted when there is a running fault, and be disconnected

when the unit is running correctly.

● The connection is described in the following figure.

Remote ON/OFF Terminal

“A B” terminal is used for remote ON/OFF switch; it needs to connect external control switch,

the control logic as follow:

Page 56

The connection is described in the following figure.

The wiring terminal diagram as following figure:

Page 57

5.3 Solar kit wiring

The solar pump station will have an auxiliary contact that closes when the contact for the

pump of the solar pump station is operated.

This contact will provide 220-240V~ 50Hz to the input of the indoor unit, and prevent sanitary

water heating by the heat pump and/or electric heater during solar heating.

For wiring examples refer to the following drawings.

If the solar energy pump cannot set the sanitary hot water tank temperature below 60℃, then use

the connecting method as shown below.

.

If the solar energy pump can set the sanitary hot water tank temperature below 60℃ , then use

the connecting method as shown below.

Caution:

If the pump station has a speed controlled pump, make sure to disable this function so that the

indoor PCB receives 220-240V~ 50Hz at all times.

Page 58

5.4 Sanitary water tank wiring

A main or other means for disconnection, having a contact act separation in all poles, must be

incorporated in the fixed wiring in accordance with relevant local and national legislation.

All field wiring and components must be installed by a licensed electrician and must comply

with relevant European and national regulations

The field wiring must be carried out in accordance with the wiring diagram supplied with the

unit and the instructions given below.

The sanitary hot water tank must be earthed via the indoor unit.

Power circuit and cable requirements

CAUTION:

Be sure to use a dedicated power circuit. Never use a power circuit shared by another

appliance.

Select the power cable in accordance with relevant local and national regulations.

Make sure all field wiring is insulated from the tank body and heater element or can resist

temperatures to 90℃

Thermistor cable

The distance between the thermistor cable and power supply cable must always be at least 5 cm

to prevent electromagnetic interference on the thermistor cable.

Connections to be made in the sanitary hot water tank electrical box

Page 59

Page 60

Page 61

M-thermal technical manual – part 3

Part 3

Test running and maintenance

1 Pre-test and test running ............................................................................................................................................. 2

1.1 Checks before initial start-up ...................................................................................................................... 2

1.2 Powering up the indoor unit ........................................................................................................................ 3

2 Setting the pump speed .............................................................................................................................................. 3

3 Field Settings ................................................................................................................................................................ 3

3.1 Wired controller .............................................................................................................................................. 4

a) The basic controller functions are: ..................................................................................................................... 4

Turning the unit ON/OFF ..................................................................................................................................... 4

Operation mode change-over: ............................................................................................................................ 4

Space heating ....................................................................................................................................................... 4

Space cooling ....................................................................................................................................................... 4

Sanitary water heating ......................................................................................................................................... 4

Space heating & Sanitary water heating ........................................................................................................... 4

Space cooling & sanitary water heating ............................................................................................................ 4

Selection of features: ........................................................................................................................................... 4

Silent mode ........................................................................................................................................................... 4

Run test function ................................................................................................................................................... 4

Air purge function ................................................................................................................................................. 4

Note: ............................................................................................................................................................................... 4

The functions “space cooling”, “space heating” and “sanitary water heating” can only be selected when the

corresponding equipment is installed. ....................................................................................................................... 4

b) Clock function ....................................................................................................................................................... 4

The clock functions are: .............................................................................................................................................. 4

24 hour real time clock ........................................................................................................................................ 4

Day of the week indicator .................................................................................................................................... 4

..................................................................................................................................................................................... 4

c) Schedule timer function ....................................................................................................................................... 4

The schedule timer function allows the user to schedule the operation of the installation according to a daily