Page 1

Midea Drum Washing Machine

Service Manual

Sicily Glory (6.0/7.0/8.0kg)

Page 2

1 ….........................................…………………............

2 INTRODUCTION ………………....................…...........…..

2.1 C …………………….…………………………………….....

2.2 ………………….…………………………………………………...

2.3 ……………………………………………………............

2.4 …………………………………………………............

2.5 Introduction ……………….…………………………………………..

2.6 …………………………………………………………………………...

2.7F of s ……………………..........................................................

2.7.1 of a ……………………………………………………….

2.7.2 F ofa ……………………………………..…..

2.7.3 F of b ……………………………………………………....

2.7.4 F of …………………………………………………….…....

2.7.5 F of c ……………………………………………………………..

2.7.6 m …………………………………………………………………..

2.7.7 F of m ………………………………………..…….....

3 ………………………………………………………………………........

3.1 ……………………………………………………….....…………..

3.2 ……………………………………………………..……..…...

3.3 ……………………………………………………………...………………..

3.4 …………………………………………………………...………….

3.5 …………………………………………………………...……….…..

3.6 …………………………………………………………..……….

3.7 ……………………………………………………….....

4. …………………………………………………..

4.1 …………………………………………………………………………….

4.2 ………………………………………………………………………...

4.3 ………………………………………………………………………..

4.4 ……………………………………………………………………………….

4.5 ……………………………………………………………………………..

4.6 ……………………………………………………………………………….

4.7 ………………………………………………………………………...….

4.8 ……………………………………………………………..……..……..…….

4.9 ………………………………………………………………..…..

4.9.1 …………………………………………………………………..…....

4.9.2 .....................................................................................................

4.10 ............................................................................................

4.11 ......................................................................................................

SAFETY PRECAUTION

OF WASHING MACHINE

haracteristics of product

Working principle

Summary model of product

Exploded view & List of parts

of control panel

Basic function

unction afety guard

Function void overflow

unction void heating without water

unction ubble checking

unction auto-balance

unction hild lock

Program emory

unction otor self-protection

INSTALLATION

Select the location

Remove transport bolts

Adjust leg

Connect inlet pipe

Place outlet hose

Electrical connection

Installing and checking items

OVERVIEW OF MAIN COMPONENTS

Top cover kit

Drawer panel kit

Control panel kit

Front plate

Lower panel

Cabinet kit

Panel support

Absorber

Drum tub assembly

Rear tub kit

Drum kit

Detergent box hose

Inlet system

. ........

5

6

6

6

7

8

13

14

15

15

15

15

16

16

16

16

16

17

17

17

18

18

18

19

20

20

20

21

21

21

22

22

23

23

23

24

24

25

P.02

TABLE OF CONTENTS

Page 3

28

28

28

28

28

29

29

29

29

30

31

33

34

35

35

36

36

36

36

37

37

37

38

38

39

39

40

40

40

41

41

41

42

42

42

43

43

28

4.12.2 ..................................................................................................

4.12.3 ........................................................................................

4.13 ....................................................................................................

4.13.1 .........................................................................................

4.13.2 .................................................................................................

4. 14 ...........................………………..............………………………….…….

4.15 ...........................………………..............…………………………………..

4.16 ...........................………………..............………………………….……

4.17 ...........................………………................................….

4.18 ...........................………………..............…………………………………...

4.19 ...........................………………..............…………………………………….

4.20 ...........................………………..............……………………………....

4.21 ...........................………………..............……………………………….…..

4.22 ...........................………………..............……………………………....

4.23 ...........................………………..............……………………....

5 ...........................………………..............…….

5.1 ...........................………………..............……………………..

5.2 ...........................………………..............……………………….

5.3 ...........................………………..............…………………..

5.4 ...........................………………..............…………………….

5.5 ...........................………………..............………………………

5.6 ...........................………………..............………………….….

5.7 ...........................………………..............………………………….

5.8 ...........................………………..............………………….….

5.9 ...........................………………..............………………….

5.10 ...........................………………..............……………………

5.11 ...........................………………..............……...……….

5.12 ...........................………………..............……………………..….

5.13 ...........................……………….......……………...

5.14 ...........................………………..............…………..……...

5.15 ...........................………………..............…………………………..

5.16 ...........................………………..............…………….……..

5.17 ...........................………………..............…………………….…..

5.18 ...........................……………..………………...

5.19 ...........................………………..............……………..……..

5.20 ...........................………………..............………………...

5.21 ...........................………………..............…………...

4.12.1 ..............................................................................................Pressure switch

Inlet valve

Detergent box kit

Drain system

Drainage system

Drain pump

Door kit

Gasket

Door lock

NTC temperature sensor

Heater

Filter

Condenser

Motor

PCB panel

Main harness assy

UNPACKING WAYS OF MAIN PARTS

Undo the back cover

Undo the top cover

Undo the control panel

Undo the lower panel

Undo the door lock

Undo the front panel

Undo the gasket

Undo the PCB panel

Undo the detergent box

Undo the inlet valve

Undo the pressure switch

Undo the pulley

Undo the upper counterweight

Undo the absorber pin

Undo the filter

Undo the drain pump

Undo the heater

Undo the NTC temperature sensor

Undo the door glass

Undo the panel support

Undo the drum tub assembly

P.03

TABLE OF CONTENTS

Page 4

5.22 ...........................………………..............……………………...

5.23 ...........................……….…………………………..

5.24 ...........................………………..............…………………………

6 ……...........................………………..............……………......

6.1 ...........................….....………………

6.2 ...........................………………..............……………………....

6.3 ...........................…….....…....…....…......

6.4 ...........................………..……………

6.5 ....................………………..............…………………………........

6.6 ...........................………………..............…………………………..........

6.7 ...........................………………..............…………………………….

7 T ...........................……………….....………………......

7.1 .......................……………………….…..

7.2 ...........................………………..............……………..

Undo the absorber

Undo the lower counterweight

Undo the motor

TROUBLESHOOTING

Circuit program & wiring connection figure

PCB wiring figure

Schedule of failure alarm & its disposal

Electrical parts working & testing principle

Service Mode

Fault tree

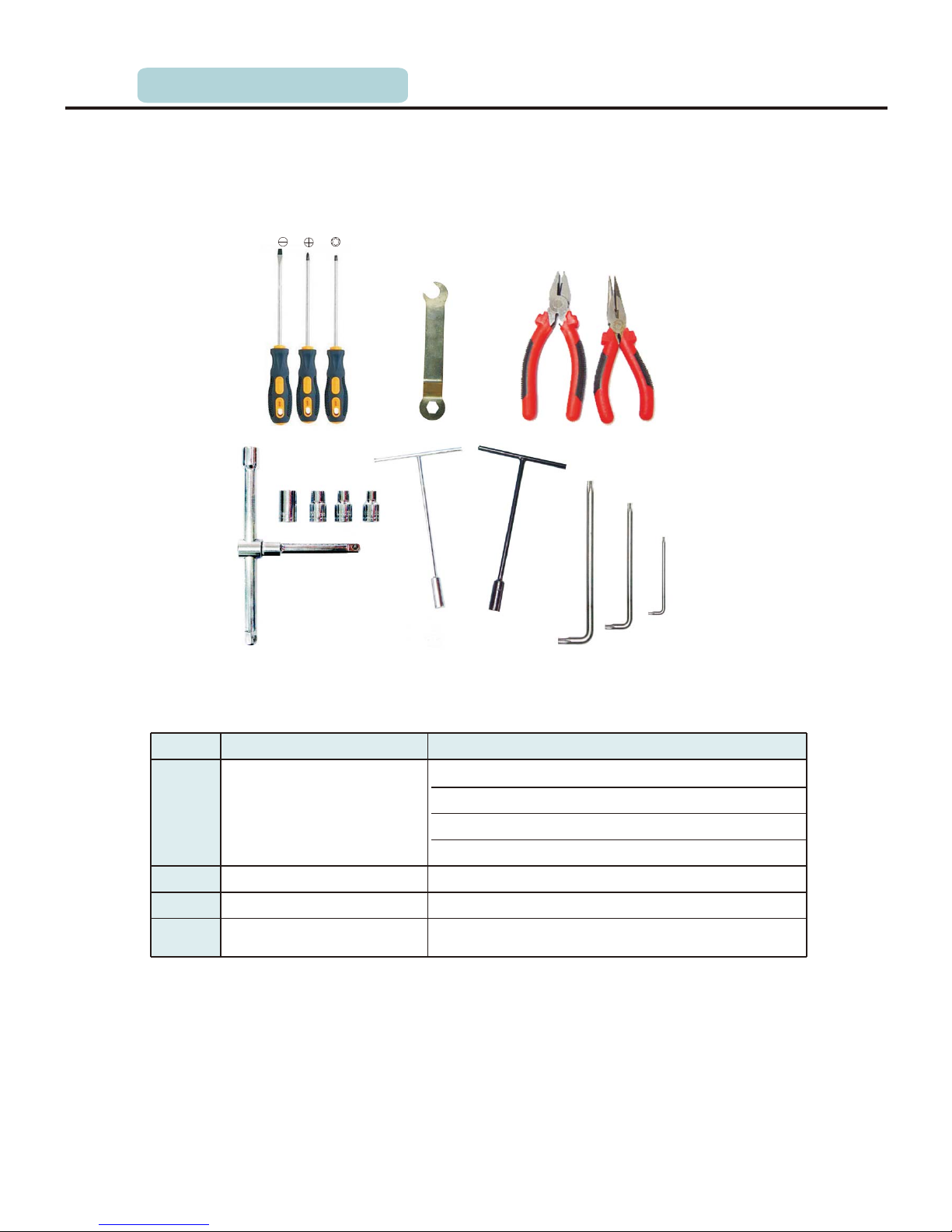

Service tools

ECHNICAL SPECIFICATION

Product technical specification parameter

Table of washing procedure

TABLE OF CONTENTS

44

44

44

45

45

46

47

48

53

55

63

64

64

65

P.04

Page 5

1.SAFETY PRECAUTION

P.05

1.Do not try to repair the machine by yourself. The machine may be damaged and its life

be shortened. What is worse, it will injure yourself.

2.Pull out its plug from the power socket before maintenance. Electricity!

3.Do not use several power plug with one socket.

To avoid fire, don’t use any socket with its actual current more than rated current.

4.Please check the power plug and socket whether damaged or not.

To avoid an electrical shock and fire, the power plug and socket should be replaced if

they are damaged.

.Don’t try to clean up the washing machine with water, or else, it’s possible to cause an

electrical shock or fire and shorten its life.

6.Forbid the harness contact with water for avoiding wet and don’t extend it during

maintenance. Don’t twist the harness to avoid it distorted.

7.Please clean up the dirt and dust on the surface of the cabinet, harness and connection

parts during maintenance.

Please avoid fire because of the electric leakage of harness.

8.Check electrical parts, harness whether they have become moist and replace them if

they are wet.

9.Check all parts of the machine and make sure to keep them in good condition after

maintenance.

10.Fasten upon the power plug and pullit out .

Be careful of a fire and electric shock when power cord is damaged.

11.Pull out its power plug when this machine doesn’t work.

Be careful of an electric shock and fire because of levin.

12.Don’t put tinder or sprayer beside the washing machine.

Be careful of a fire and explosion because of electric spark.

13.Don’t put a basin of water or wet clothes on the washing machine.

It is possible to cause an electric shock or fire if water from wet clothes leaks in to

the washing machine.

14.Do not place the washing machine in the place where it can be exposed to rain and

snow. Or else, it may cause an electric shock or fire, and therefore shorten its life.

15.Don’t press the button with sharp items such as nail, screw etc. Or else, it may cause

an electric shock or other damages.

16.This machine should be placed on the horizontal ground and installed correctly.

The machine is liable to shift on the gradient ground.

17.If the harness is damaged, it should be replaced completely.

18.It is necessary to put a mat on the floor and recline down the washing machine along

its side when repair it.

It is possible to damage the electrical components if the front of the washing machine

is placed at the ground.

19.During changing the heater of this machine, please check whether it is fixed on the

blanket correctly and whether the screw is fastened tight or not.

5

Page 6

2.INTRODUCTION OF PRODUCTS

P.06

2.1 haracteristics of product

It is the latest designed machine, which have many advantages such as fashion, large

rated washing capacity and large washing range. Specifically, its feature is as following:

1.Large washing range from cotton to wool and silk.

2.Gentle washing: no twist and little abrasion.

3.Electron auto-balance system, that is, the PCB panel controls the speed of spin and

ensures uniform distribution of clothes to reduce the wear of textile caused by its

vibration.

4.The drum of this machine is made of stainless steel of high quality and the cabinet is

durable.

5.The maximum temperature of washing water could be controlled independently and it

is up to 90℃.

6.Unique washing methods: rain, soak, throwing-knocking knead and so on, which can

wash clothes uniformly and improve washing performance.

7.Safety guard: water level control, door lock, child lock etc.

8.Anti-crease function: there is an automatic anti-crease and soak function in the

synthetic program, that’s, it doesn't drain at the end of washing and leave the clean

textile in the water of the drum to achieve the function of less crease.

9.Function of adjusting spin speed : select different spin speed according to textile.

10.Electronic water distribution system: The machine uses PCB to control the inlet valve

and distribute water properly at the different stages and dissolve detergent and softener

absolutely to improve washing performance.

2.2.Working principle

Drum washing machine wash clothes mainly in virtue of mechanical friction, chemical

force and temperature force. When the machine works, the motor runs clockwise several

seconds and runs anti-clockwise several seconds to drive the drum whose three lifters

hold up the clothes pressing against the inside of the drum. When clothes rise close to the

top, because the speed of motor is low and the centrifugal force is not enough to overcome

the gravity, clothes fall and impinge with washing liquid (like manual throwing-knocking

washing). The second force is the extrusion force of clothes (like manual extrusion). The

last force is the friction between clothes, clothes and lifters(like manual knead). To

improve washing performance, automatic drum washing machine could automatically

heat the washing liquid, whose temperature can be adjusted from 30℃ to 90℃. The high

temperature quickens the movement of the numerator of the washing liquid and speedups

C

Page 7

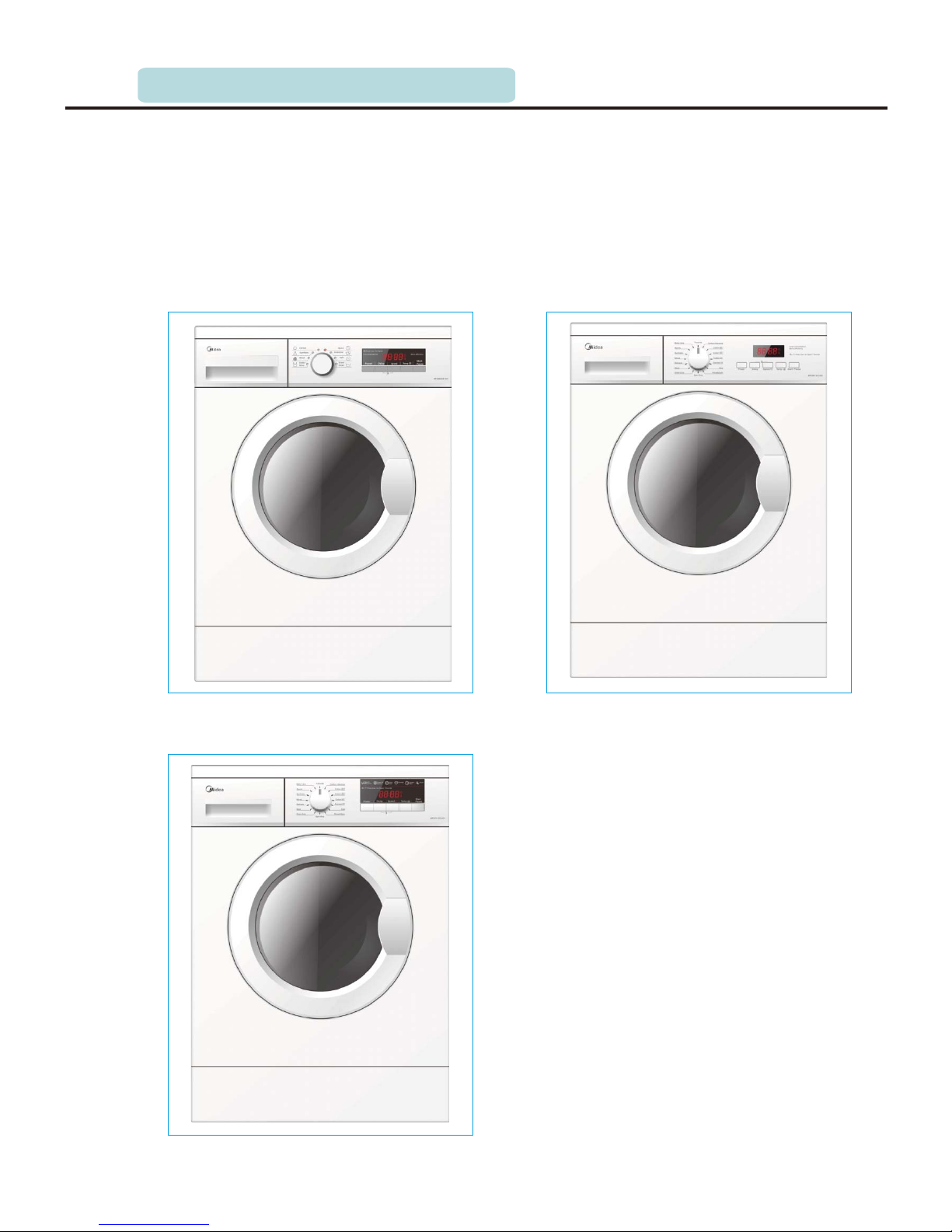

2.3 Summary model of product

P.07

G01

2.Overview of products2.INTRODUCTION OF PRODUCTS

the Chemical reaction. In a word, drum washing machine destroys bonding force between

dirt and clothes in virtue of intergraded force of water, detergent and mechanical force, to

clean away the dust.

G02

G03

Page 8

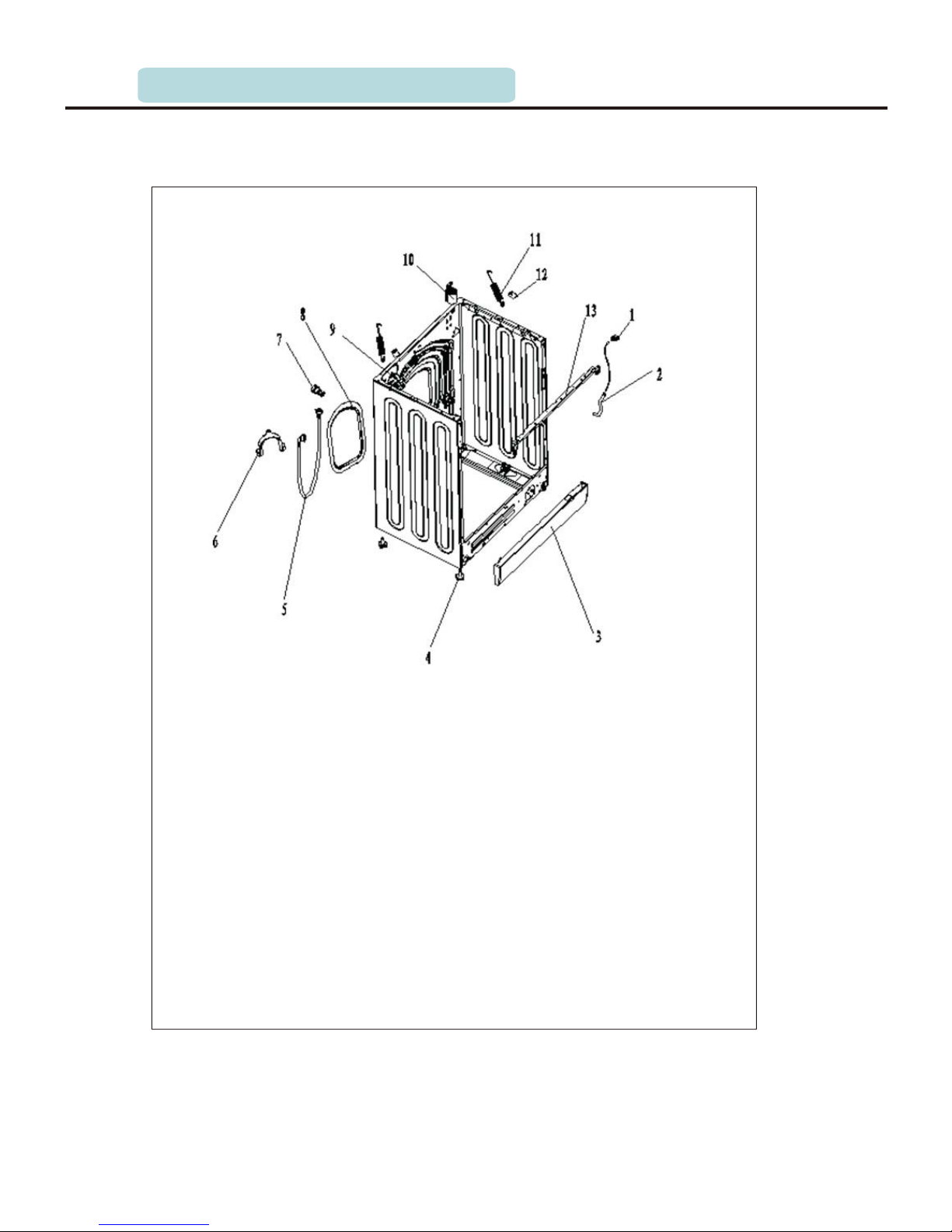

2.4 Explored & list of partsview

P.08

01 Pressure Switch

02 Chamber Pressure

03 Service Panel

04 Leg_Sub

05 Water_ Inlet_Pipe_Kit

06 The Bend Of Drain Hose

07 Transport Bolt Kit

Rear_ Cover

09 Water_ Inlet_ Valve

10 FILTER

11 Suspension Spring

12 Spring Hanger

13 Top_ Bracket

08

2.INTRODUCTION OF PRODUCTS

Page 9

P.09

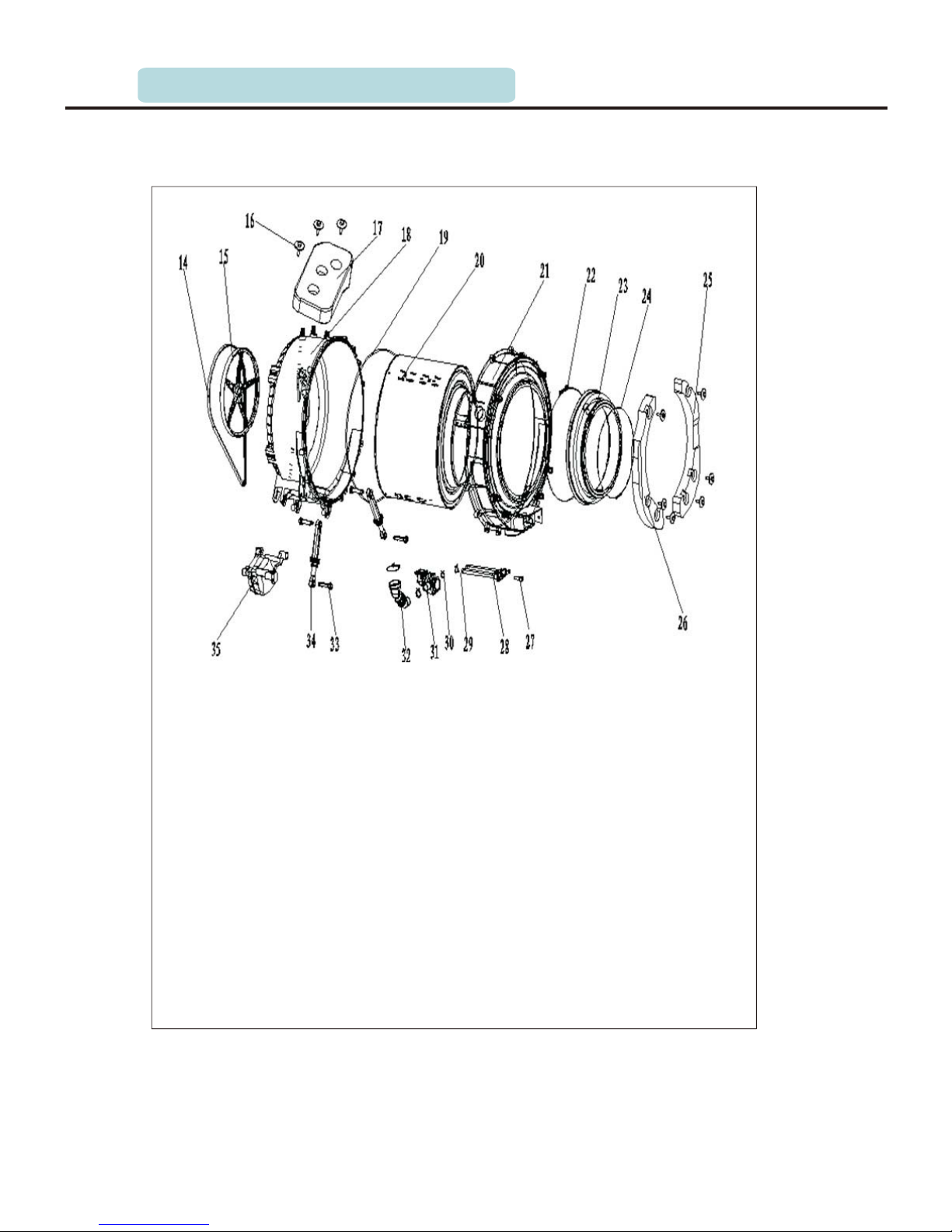

2.4 Explored & list of partsview

14 Belt

15 Driving_Pulley

16 Screw

17 Upper counterweight

18 Rear Tub

19 Tub_Seal

20 Drum Kit

21 Front_Tub

22

Inner Clamp

23 Gasket

24 Outer Gasket Clamp

2.INTRODUCTION OF PRODUCTS

25 Front_Right_Counterweight

26 Front_Left_Counterweight

27 NTC

28 Heater

29 Heating Brasket

30 Hose Clamp

31

Pump

32 Tub_Drain_Hose Kit

33 Damper_Pin

34 Damper

35 Motor

Page 10

P.10

2.Overview of products

2.4 Explored & list of partsview

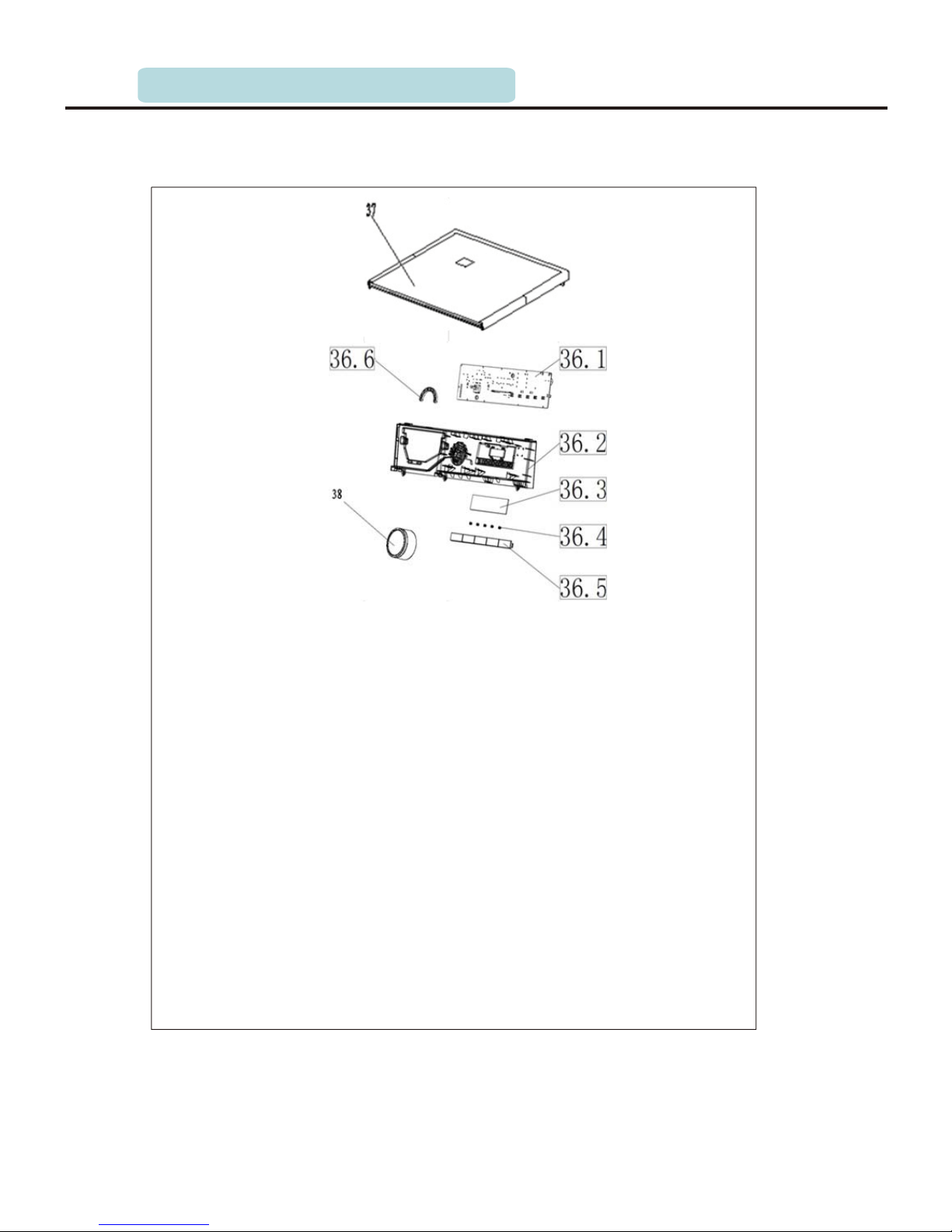

36 Control Panel Sub

36.3 dalle

36.2 Control_Panel

36.1 PCB

36.4 Start_pause_spring

36.5 Button

36.6 Light_Transferrer

37 Top_Cover_Board

38 Cycle_Select_Knob

2.INTRODUCTION OF PRODUCTS

Page 11

P. 11

2.4 Explored & list of partsview

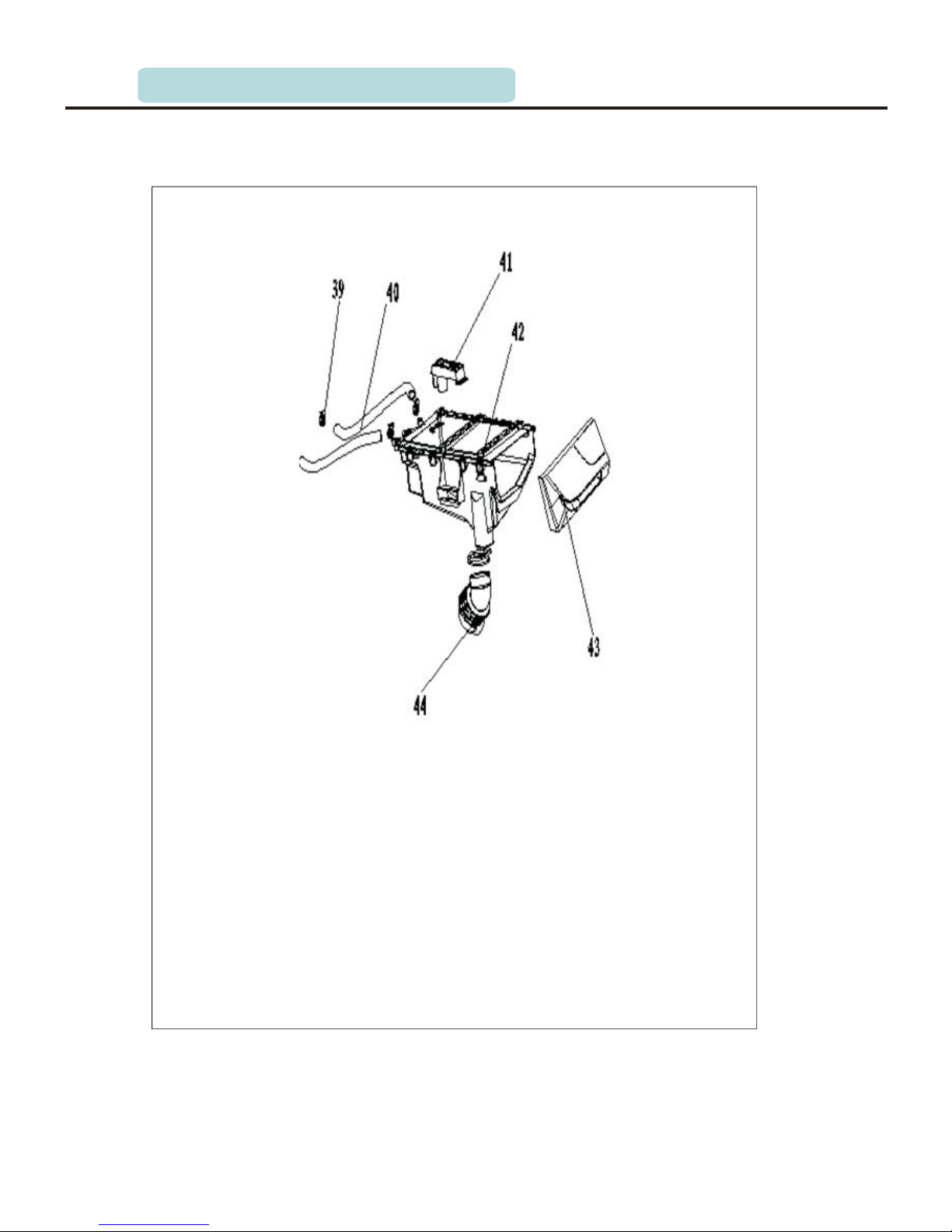

39 Hose Clamp

40 Inleft Hose

41 Softener Cap

42 Detergent Box

43 Drawer Panel

44 Tub Water Inlet Hose

2.INTRODUCTION OF PRODUCTS

Page 12

P.12

2.Overview of products

2.4 Explored & list of partsview

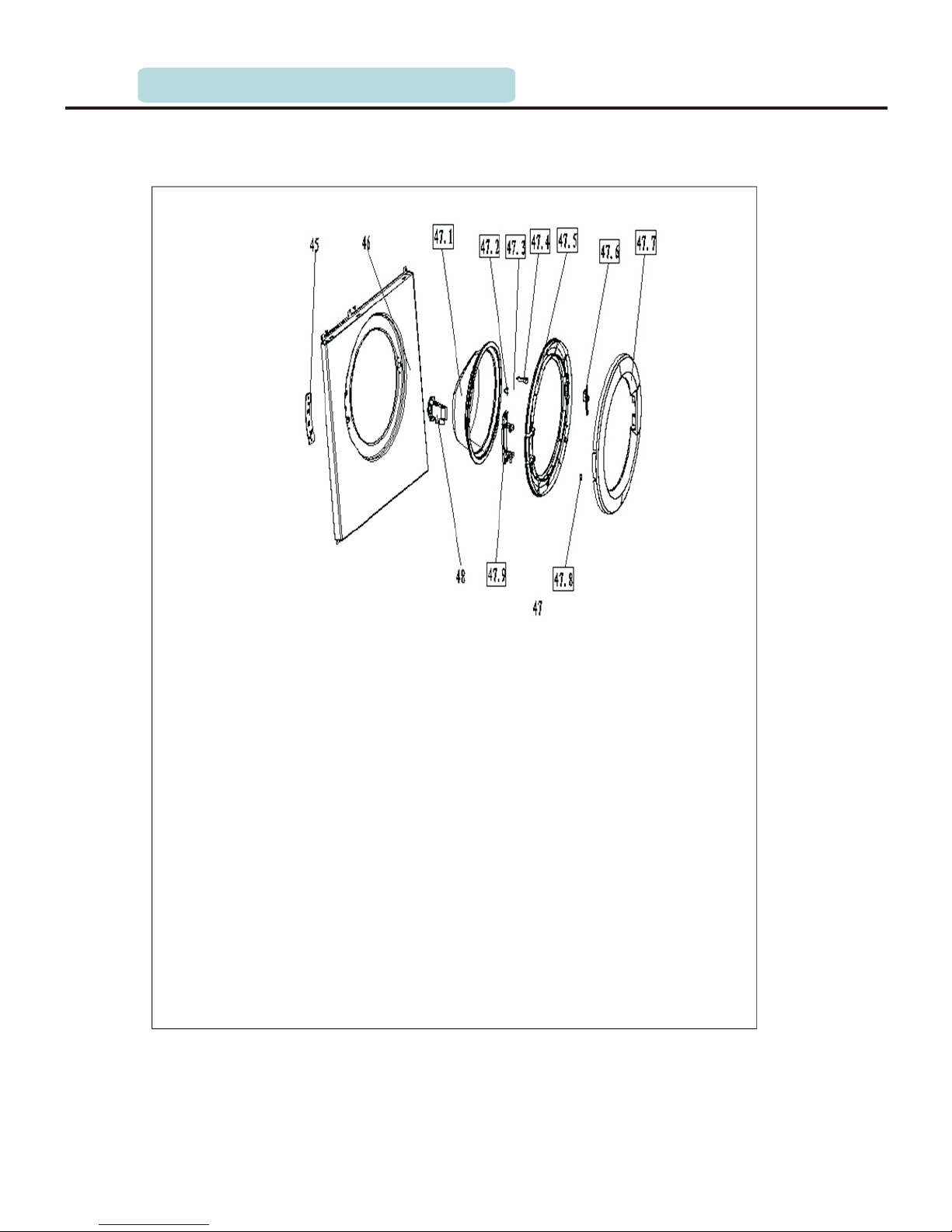

45 Door Support Plate

46 Front Panel

47 Door Sub

47.1 Door Glass

47.2 Door_Plunger_Spring

47.3 Hook Pin

47.4 Door Plunger

47.5 Inner Ring

47.6 Door Handle

47.7 Outer_Frame

47.8 Door_Hinge_Pin_Cover

47.9

Door Hinge

48 Door Lock

2.INTRODUCTION OF PRODUCTS

Page 13

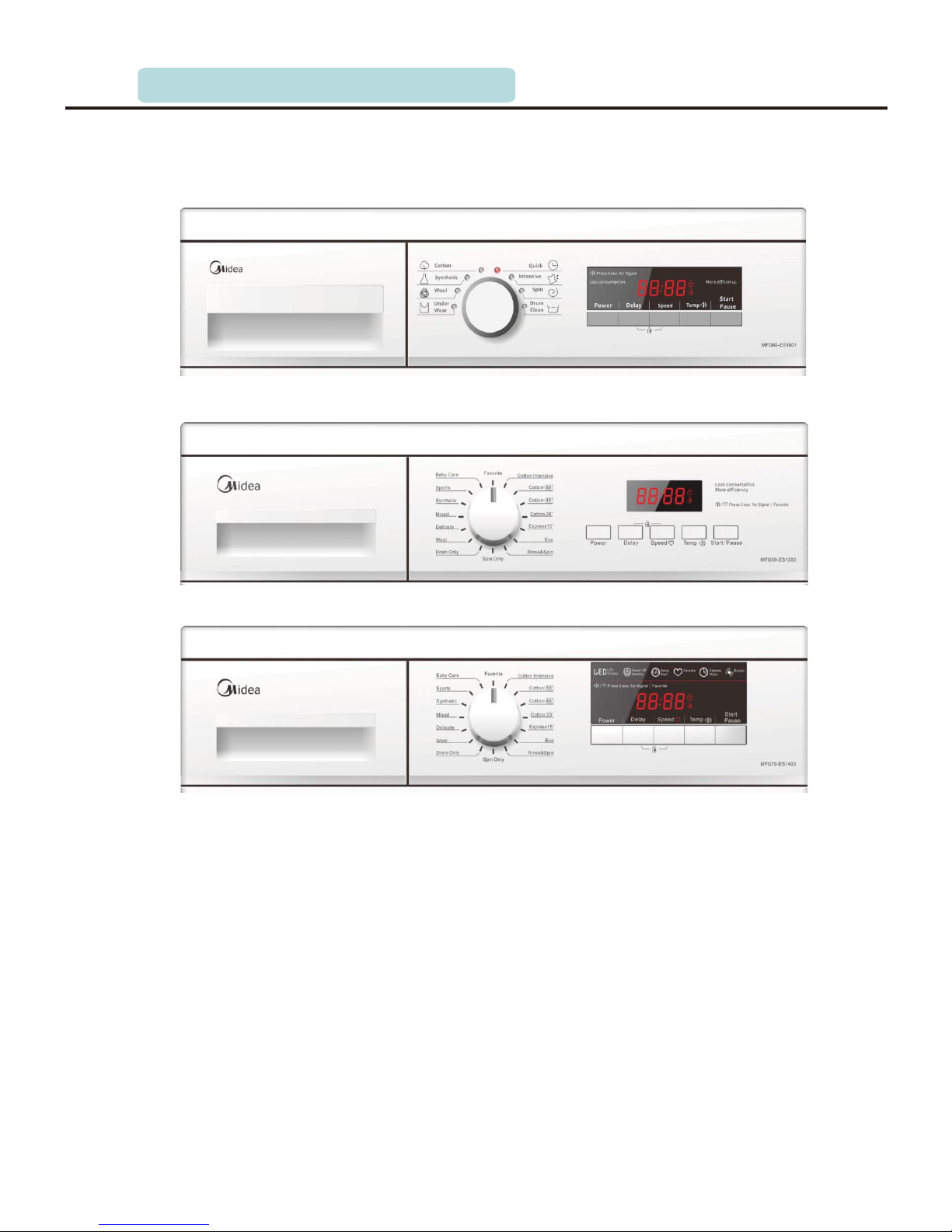

2.5 Introduction of control panel

G02

P.13

G01

1.Drawer Panel: put detergent into detergent box by pulling out Drawer.

2.Control Panel: manipulate washing machine with the panel.

3.Knob: revolve this knob and select washing program accordingly ( cotton, synthetic,

wool) can be selected circularly.

4.Function Button: achieve functions of speed selection, temperature selection etc.

5.Start/Pause Button: press this button to restart or pause will be done.

6. Display screen: show washing process and relative error information.

2.INTRODUCTION OF PRODUCTS

G03

Page 14

P00

P01

P02

P03 Cotton 40°

P04 Cotton 20°

P05 Quick 15'

P06

P07

My Cycle

Cotton Intensive

Cotton 60°

ECO Wash

Rinse & Spin

Programs corresponding with the encoder knob

P.14

2.6 of basic Function

2.INTRODUCTION OF PRODUCTS

P08

P09

P10

P11 Delicate

P12 Mixed

P13 Synthetic

P14

P15

Spin Only

Drain Only

Wool

Sports

Baby Care

- Cotton

You can select this procedure to wash the daily washable clothes. The washing period is quite long

with quite strong washing intensions. It is recommended to wash the daily cotton articles, for

example: bed sheets, quilt covers, pillowcases, gowns, underwear etc.

′

- Synthetic

You can select this procedure to wash the quite delicate clothes. The procedure is shorter

compared with that for cottons and the washing intension is quite gentle. It is recommended to

wash synthetic articles, for example: shirts, coats, blending. As for curtains and laced textiles,

the procedure “Synthetic ” shall be selected. While washing the knitting textiles, detergent

quantity shall be reduced due to its loose string construction and easily forming bubbles.

- Wool

You can select this procedure to wash the wool textiles labeled with “Machine Wash”. Please select

the proper washing temperature according to the label on the articles to be washed. Furthermore, the

proper detergent shall be selected for wool textiles.

- Cotton Intensive

To increase the washing effects, main additional washing time is increased.

It is recommended to wash the clothes for babies or worn by the persons with allergic skin.

- Quick 15

This procedure is suitable for washing few and not very dirty clothes quickly.

- Eco Wash

As for few light dirty clothes, the maximum temperature of washing is limited to 40℃ , and saving

more energy.

- Baby care

Baby care procedure with an extra rinse, it can make the baby's wear cleaner and make the rinse

performance better to protect the baby skin.

- Sports

You can select this procedure to wash the activewear.

- Mixed

You can select this procedure wash the tough cltohes, that need much more time and strength .It is

used for the daily clothes fo cotton,such as sheets, chained, pillowcases bathrobe and underwear.

- Delicate

You can select this procedure to wash your delicate clothes. Its washing intension is gentler and

revolution speed is less compared with the procedure “Synthetic”. It is recommended for the articles

to be washed softly.

Page 15

P.15

2.7 Function of safety guard

2.7.1 Function of avoid overflow

When the water level is up to the abnormal height in the drum(the set warning level),

washing machines will automatically switch on drainage pump to drain by pressure

switch, even if the inlet valve failure which can not stop the inflowing water, the

washing machine will not be in the overflow. At the same time, the pressure switch will

feed back to control panel a signal of fault and the washing machine will alarm.

2.7.2 Function of avoid heating without water

When there is no water or not enough to submerge the heater, and at the same this

machine is in fault, the fuse in the heater will melt to cut off the heater and avoid danger.

2.7.3 Function of bubble checking

About wiping off bubble: When the water level is lower than level I during draining, the

2.INTRODUCTION OF PRODUCTS

spin function will start. If there is over much bubble in the drum, it will increase the

pressure in the drum and switch on the pressure switch , at the same time the PCB panel

begin the bubble checking function and clean it away.

Page 16

P.16

2.7.4 Function of auto-balance

1. This function will start before spin and after drainage.

2. Drum reverses the speed of 50 rounds per minute in the first six seconds.

3. In the next 10 seconds, the rotational speed from 50r/m to 100r/m slowly.

4. In the following 18 seconds, the washing machine rotates in the speed of 100r/m and

estimates the degree of imbalance according to the signal of the motor.

5. If the degree of imbalance is more than the setting value, the auto-balance system will

feed back imbalance information of 12 cycles.

2.7.5 Function of child lock

To avoid the fault operation by children and then making this wash procedure work

abnormally, you can select this function in which other buttons can't be work except knob.

As for this machine, press the second button and the first button at the same time for 2.5

seconds from left , the buzzer rings and the pre-wash button, auxiliary function button,

start/stop and knob are locked. And then, press them at the same time for another 2.5

seconds, the buzzer rings again and the locked buttons are unlocked. Child lock function

is cancled after the whole program is completed when child lock is effective, press the

non-child lock button and then buzzer rings to remind that operation is invalid.

2.7.6 Program memory

If the running washing machine is powered off, its washing procedure will be stored in

chips. When the power is on, washing machine will run from the memorying procedure.

If washing machine is powered off during spin, the machine will spin from the start of the

procedure again.

2.7.7 Function of motor self-protection

When the washing machine works in the poor conditions, the enormous load on the motor

will make its temperature increase and its performance decrease even burned motor.

When its temperature increases to a set value, the thermal protector of motor will

automatically cut off the power supply to achieve self-protection and alarm.

2.INTRODUCTION OF PRODUCTS

Page 17

P.17

3.1 Select the location

1. Washing machine must be placed in the formation, firm, dry and well-ventilated places.

2. Washing machine need a certain space and the shortest distance from the wall is not

less than 12cm generally.

3. Don't place the washing machine in the condition of freeze-easy.

4. Washing machine should be placed away from heat, sunlight to prevent pieces of

plastic and rubber become aging.

5. Do not put the washing machine in the place where it can be exposed to rain and snow.

6. It is not suitable to use the washing machine on vessels, aeroplanes and vehicles.

7. To avoid walling up the vent, please don't put washing machine on the carpet.

NOTE: Washing machine should be put in the room which have enough space, such as its

door can be fully opened.

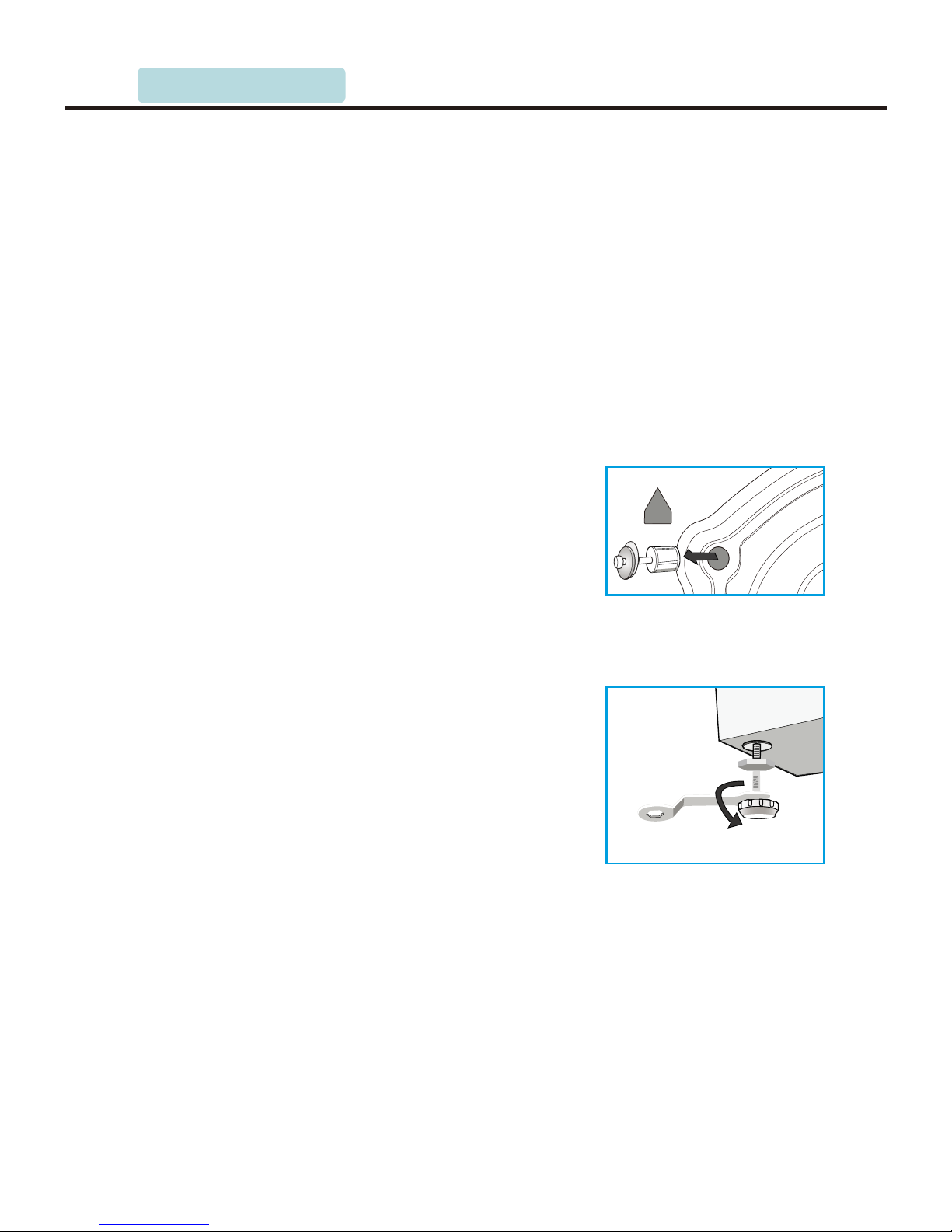

3.2 Remove transport bolts

Before using this washing machine, transport

bolts must be removed from the backside of

this machine.

Please take the following steps to remove the bolts:

1. Loosen all bolts with spanner and then

remove bolts.

2. Stop the holes with transport holes plugs.

3. Keep the transports bolts properly for future

use.

3.3 Adjust leg

1. When positioning the washing machine,

please first check whether the leg are closely

attached to the cabinet. If not, please turn them

to the original position with hand or spanner

and tighten them with spanner.

2. After position washing machine, press four

corners on top cover of this machine in

sequence. If the machine is not stable, this

leg should be adjusted.

3. To ensure the positioning status of washing machine, loosen the lock nut with spanner

and turn the leg with hand until it closely attaches to floor. Press the leg with one hand

and fasten the nut closely to the cabinet with the other hand.

4. After being locked properly, press four corners again to make sure that they have been

adjusted properly. If it is still unstable, above-mentioned steps shall be repeated by 2

to 3.

NOTE: In principle, there is only one loosen leg at most. If this leg is located at back of

this machine and it is inconvenient for adjustment, then another leg at its diagonal position

can be adjusted to achieve the same effect.

3.INSTALLATION

Page 18

100cm

140cm

Min60cm

Max100cm

110cm

P.18

1.Connect the elbow to tap and fasten itclockwise.

2.Connect the other end of inlet pipe to the inlet

valve at the backside of washing machine and

fasten the pipe tightly clockwise.

NOTE: after connection, if there is any leakage with

hose, then repeat the steps to connect inlet pipe. The

most common type of tap shall be used to supply

water. If tap is square or too big, then standard tap

shall be changed.

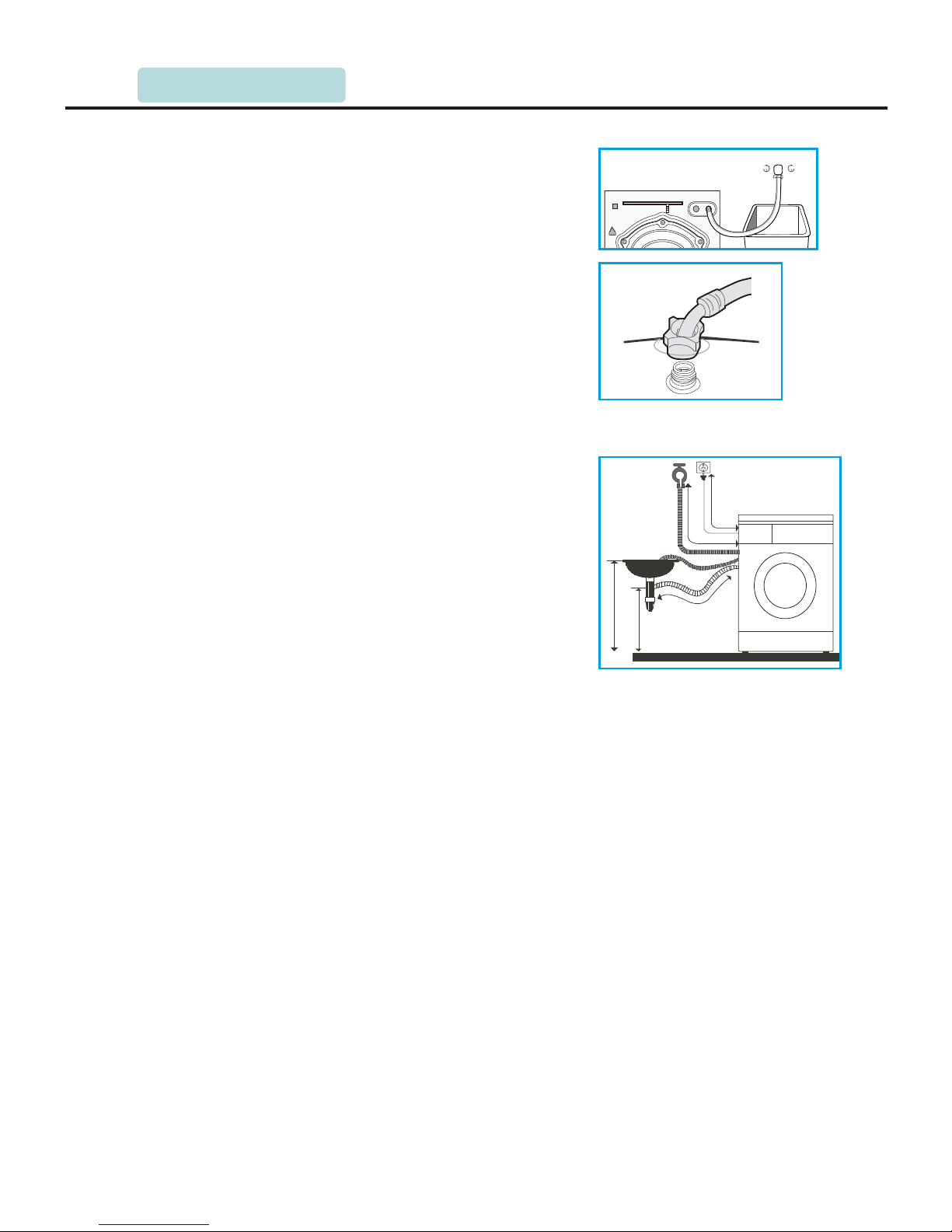

3.4 Connect inlet pipe

Connect the inlet pipe as indicated in the figure.

3.5 Place outlet hose

There are two ways to place the end of outlet hose:

1. Put it beside the water trough.

1) Washing machine shall be located nearby the

slipway’s inlet so that it is convenient for this

machine to drain.

2) Take out splint from PE bag and fasten it on the

end of the drain hose, and then put it beside the

water through or the slipway’s inlet.

NOTE: clean up the filter of outlet valve, don’t fold it,

don’t clog the inlet/outlet hose to make sure them

expedite to inlet or drain.

2. Connect it to the branch drain pipe of the though.

3.6 Electrical connection

1. The maximum current through the unit is 10A when this machine heats the washing

liquid, and please make sure that your household power supply system (current, power

voltage and wire) can meet the normal loading requirements of the electrical appliances.

2. Please connect the power to a socket which is correctly installed and properly earthed.

3. Please make sure your household power voltage is same as that of the machine’s rating

label.

4. Power plug must match the socket and cabinet must be properly and effectively earthed.

5. Do not use multi-purpose plug or socket as extension cord.

6. Do not connect and pull out plug with wet hand.

7. When connect and pull out plug, hold the plug tightly and then pull it out. Do not pull

power cord forcibly.

8. If power cord is damaged or has any sign of being broken, special power cord must be

gotten from its manufacturer or service center for replacement.

9. Has been positioned, the plug of Washing machine should get to socket properly and

effectively.

3.INSTALLATION

Page 19

P.19

3.7 Installing and checking items

1. Check whether remove transport bolts or not.

2. Check whether the socket is installed and properly earthed.

3. Check whether this machine is level or not.

4. Check whether inlet pipe/outlet pipe is wringed or not .

5. Guide user to operate the washing machine and make sure no leakage and no abnormal

sound.

NOTE: please read instruction manual carefully to ensure the proper operation of this

washing machine.

3.INSTALLATION

Page 20

4.OVERVIEW OF MAIN COMPONENTS

P.20

4.1 Top cover kit

1. Parts component

Top cover is made up of hyperbaric plate, top

cover-f and top cover-b. Both top cover-f and

top cover-b are ABS materials. Front of top

cover lock to the panel support of this machine's

cabinet, and back of top cover fastnesses to the

U-type backside of cabinet with screw.

Two-piece of hyperbaric plate is covered by

melamine which is waterproof and fireproofing,

and furthermore, the dirt and smudge on its

surface could be erasured easily.

2. Summery about function

The two screws fixing the top cover screw into the

cabinet to avoid loosening.

Chang and maintain PCB kit, pressure sensor,

filter, inlet valve after unpack top cover kit.

4.2 Drawer panel kit

1. Drawer, Drawer panel and Softener cap

Drawer panel kit is consist of drawer, drawer panel and softener cap. Drawer panel is

clipped on the face of draw without screw and softener cap in the center of drawer.

According to the need of costumers, different detergent could be placed in three boxes

of drawer respectively, and concretely the right one is pre-wash box, the left one is main

wash box and the center one is softener box. Certainly user can put decolourant, spicery

and softener in the center one to improve washing performance.

After water fill in the drum through drawer, siphon structure of inlet system ensure that

drawer have no remanent water or wash liquid.

Drawer can be taken out and cleaned up: Unfold the drawer up to 10cm, and then take

out the drawer at the same time press the elastic plate to avoid injuring the softener box.

What is noticeable: during cut the softener cap in the detergent box, you have to press

the protuberant support of its end.

During the washing machine’s in work, it should remind user of closing the drawer, or

else, the detergent can’t be flowed into the drum completely, and what is worse water

may flow out from the outside of the cabinet.

2. Draw panel deck

The material of drawer panel kit is PMMA.

Page 21

P.21

4.Overview of main parts

4.3 Control panel kit

Control panel kit consists of control panel, dalle,spring, button,light transferrer etc.

As the key apparance part of washing machine, control panel's appearance and quality

have direct influence on costumers. Midea washing machine is known as fashionable and

compact appearance.

The material of control panel is the slap-up and splendid ABS material and its mold is

specular polished.

4.4 Front plate

The material of front plate is PCM and its thickness

is 0.8mm. Connection of Front plate and cabinet is

pensile structure with screw. Both sides of the back

of the front plate have a hole respectively which is

to append front plate support. Finally maintainer

can fasten front plate on cabinet with five screws.

Three holes at the top of the front plate is used to fix

the control panel.

Door hole is in the center of front plate, and its left

side is hinge and the right side is door lock.

4.5 Lower panel

Lower panel is locked to lower

reinforce and then fixed with a

screw.

4.OVERVIEW OF MAIN COMPONENTS

Page 22

P.22

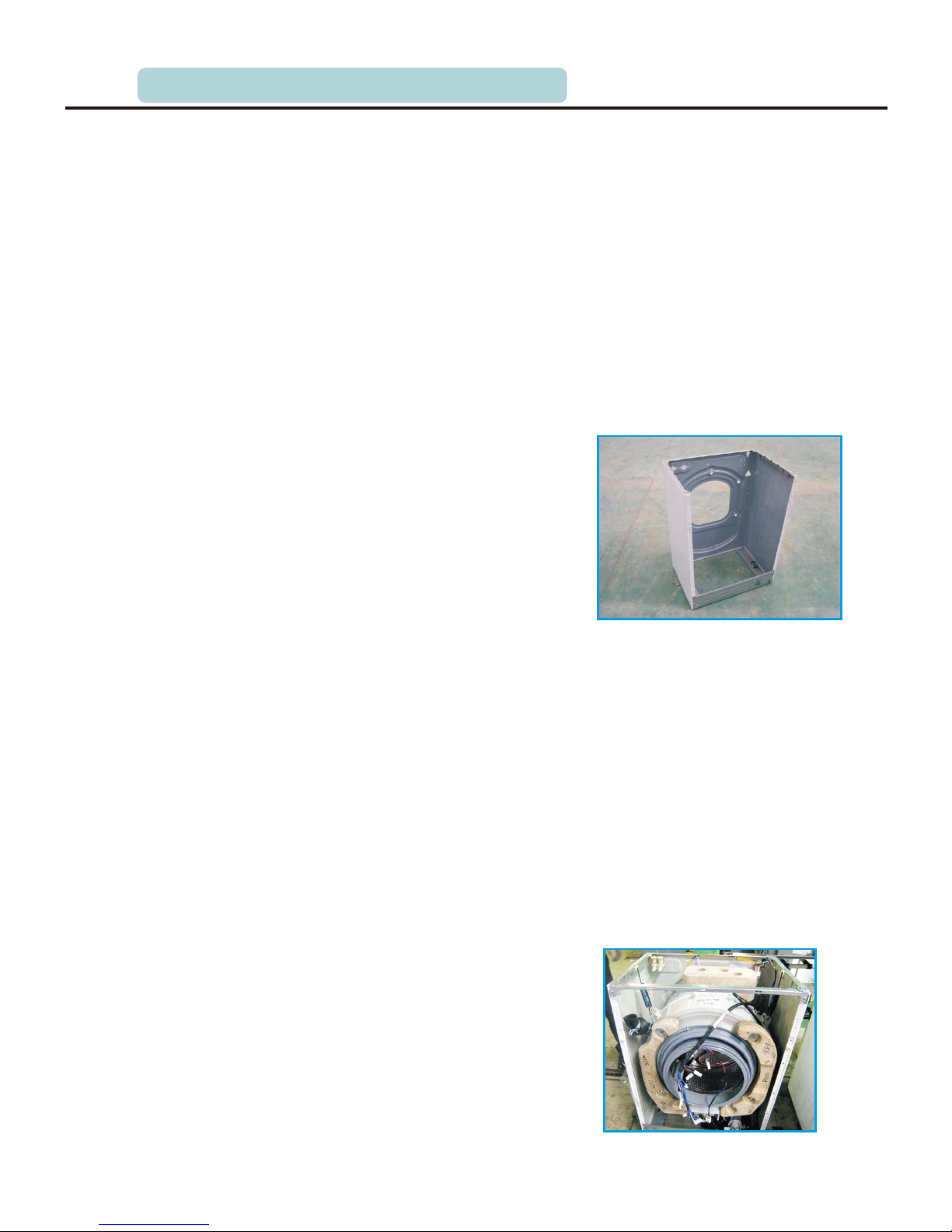

4.6 Cabinet kit

The material of the cabinet is PCM colorful metal,

and cabinet fold and reinforce are fixed by TOX

riveting technique, the panel support is fixed with

cabinet with screws.

Fixed in the top of the cabinet through TOX riveting

technique, left and right-up reinforce reserve spring

hole, pressure switch assembly hole, cable channel

hole and screw hole of the PCB board support.

Left and right-down reinforce on top of which it is

special fold design of fixing absorber is fixed down

of the cabinet through riveting techque.

Down reinforce is riveted down of the cabinet front

cover, on top of which the lower panel fixing hole is

reserved. The bigger hole is used to fix the pump,

down of which is two screw hole used to fasten the

lower panel.

The left and right hole on the up-front of the cabinet

is panel support hole.

There are inlet valve fixing hole, cable holder-s

hole, outlet hose hole, and power cord hole from

left to right on the up-back of the cabinet.

In the convenience of maintenance, there is a

bigger rear panel hole in the middle of the cabinet.

When fixing the rear panel, you should insert the

upper part into the hole, then fix two screws in the

bottom.

The three holes around the rear panel are transmit

bolt holes.

Furthermore there are three outlet hose fixing

support holes on the upper and left of the rear

cabinet to fix the outlet hose and power cord.

And there is two-leg power plug on the left of the

bottom.

4.7 Panel support

As the metal slat, Panel support is used to increase

the intensity of cabinet and fixed on the control panel.

Panel support is fastened on the cabinet with two

screws locating its both sides.

4.OVERVIEW OF MAIN COMPONENTS

Page 23

P.23

4.Overview of main parts

4.8 Absorber

Midea drum washing machine uses the advanced

absorber to damp the vibration by drum tub kit

when this machine wash and spin. Absorber uses

friction damping to achieve its function of damping

vibration. Thanks to its similar the piston-type

structure, the sponge in the cylindrical plastic inner

wall of cylinder and the cavernous metal rod

contacts close, the cylinder rod can sliding along

the axial and longitudinal, which generate a certain

damping force. There is special cavernous damping

oil in the sponge, which is the main part to achieve shock absorber. The damping force

keeps constant and its direction is opposite toroid running. Absorber pin is used to

connect left/right lower reinforce to absorber, the absorber and tub as well.

4.9 Drum tub assembly

4.9.1 Rear tub kit

As a container for water, the tub capability of this washing machine is not only effects

it's rated washing capacity but also decides its rated consumption of water. That is, at the

same condition of water level, the radial dimension and the lengthways dimension of its

tub have larger, the more its rated consumption of water.

The tub material of Midea washing machine is well property and improved PP which is

high intensity, heat-resistant and high rigid. As a good heat guard, PP ensures this

machine save power and improves its washing performance in a sense.

This structure, which is divide tub kit into front tub kit and rear tub kit, improves the

assembly performance of this machine and enhance its airproof.

4.OVERVIEW OF MAIN COMPONENTS

Page 24

P.24

4.Overview of main parts

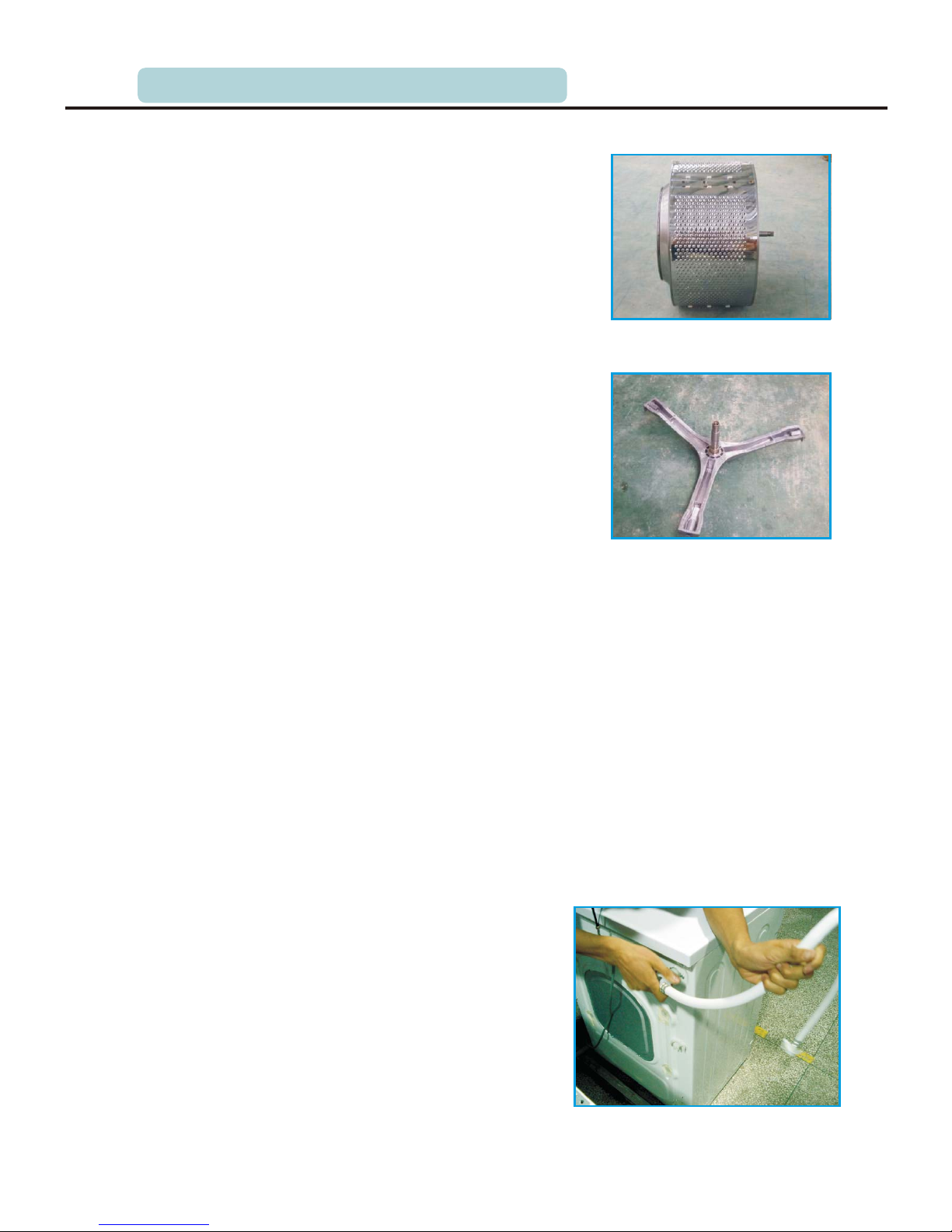

4.9.2 Drum kit

Drum kit consist of drum center, drum front, drum

back, lifter, spider kit (spider, shaft, shaft bush),

and spider bolt etc.

The structure and characteristic of drum:

Drum is made up of drum center using stainless

steel, drum front, drum back. As the class BA of

AISI 430 BA stainless steel, it is blighting.

After rolling the inside of drum front, the sharp

cutting edge rolled up to prevent scratching textiles

and arm during removing and adding textile.

The model shape repression of the meet between

drum back and spider enlarge the space putting

textile. The piercing and drawing reel ensure the

textile no injury during washing and spinning, and

the compact holes make sure the textile soak fully

in the drum.

Drum and drum front/back are connected by

advanced spinning curling process.

During the washing, three lifters hold up the clothes pressing against the affixed surface

of the drum. When clothes raised close to the top, centrifugal force is not enough to

overcome gravity, and therefore clothes fall and impinge washing liquid to improve

washing performance.

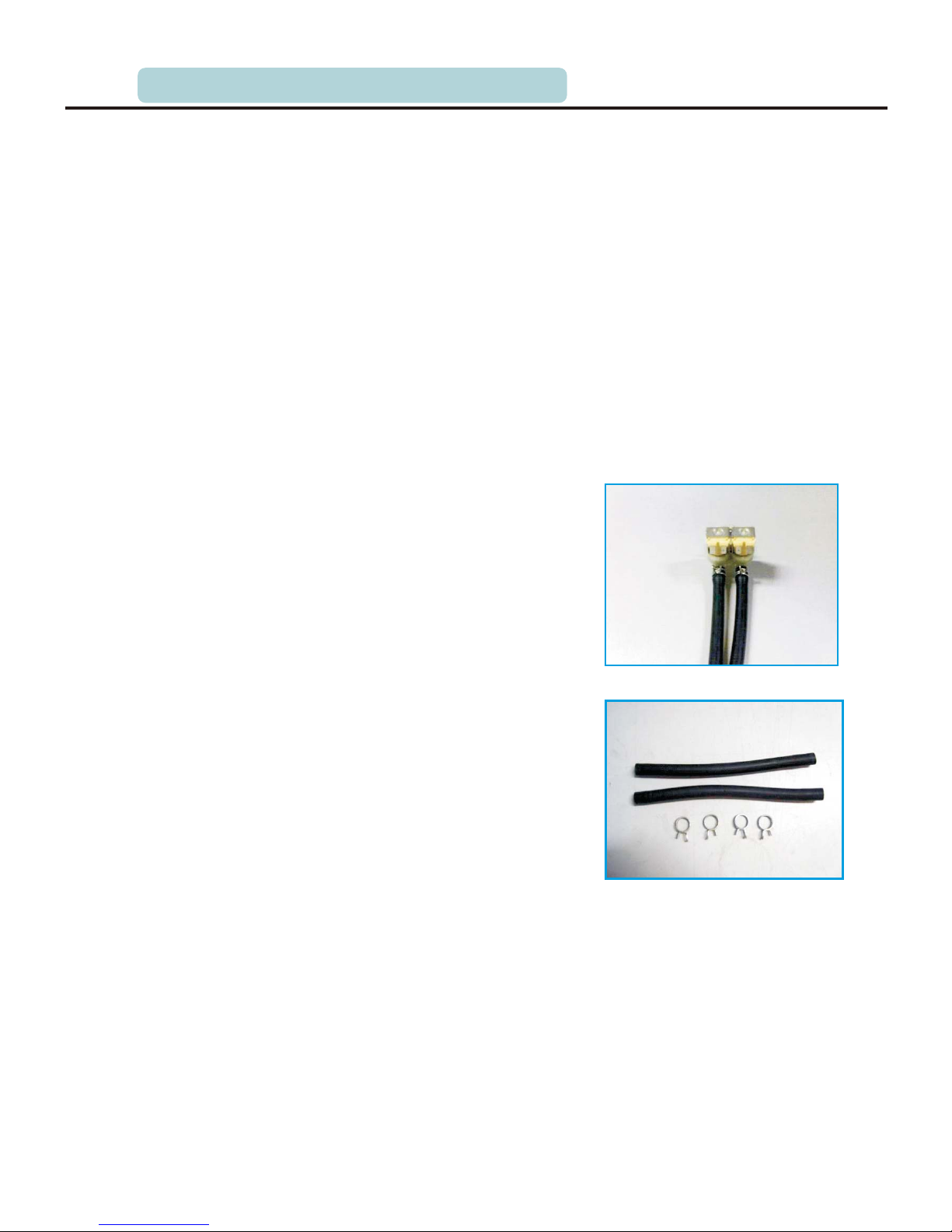

Spider kit

The spider is the aluminum die-casting. There is a bushing in the axis which is to reduce

the wear and tear of V-shaped edge of the oil seal. When installed bushings, the

powder-like debris produced by it cut shaft bushings should be removed, or they will

wear oil seal. To avoid wear and tear, grease should be applied the corresponding

position of the oil seal to ensure that it will play in the role of lubrication in the whole

life of washing machine and not dry or off. Spider kit is fastened on the drum with three

stainless steel bolts.

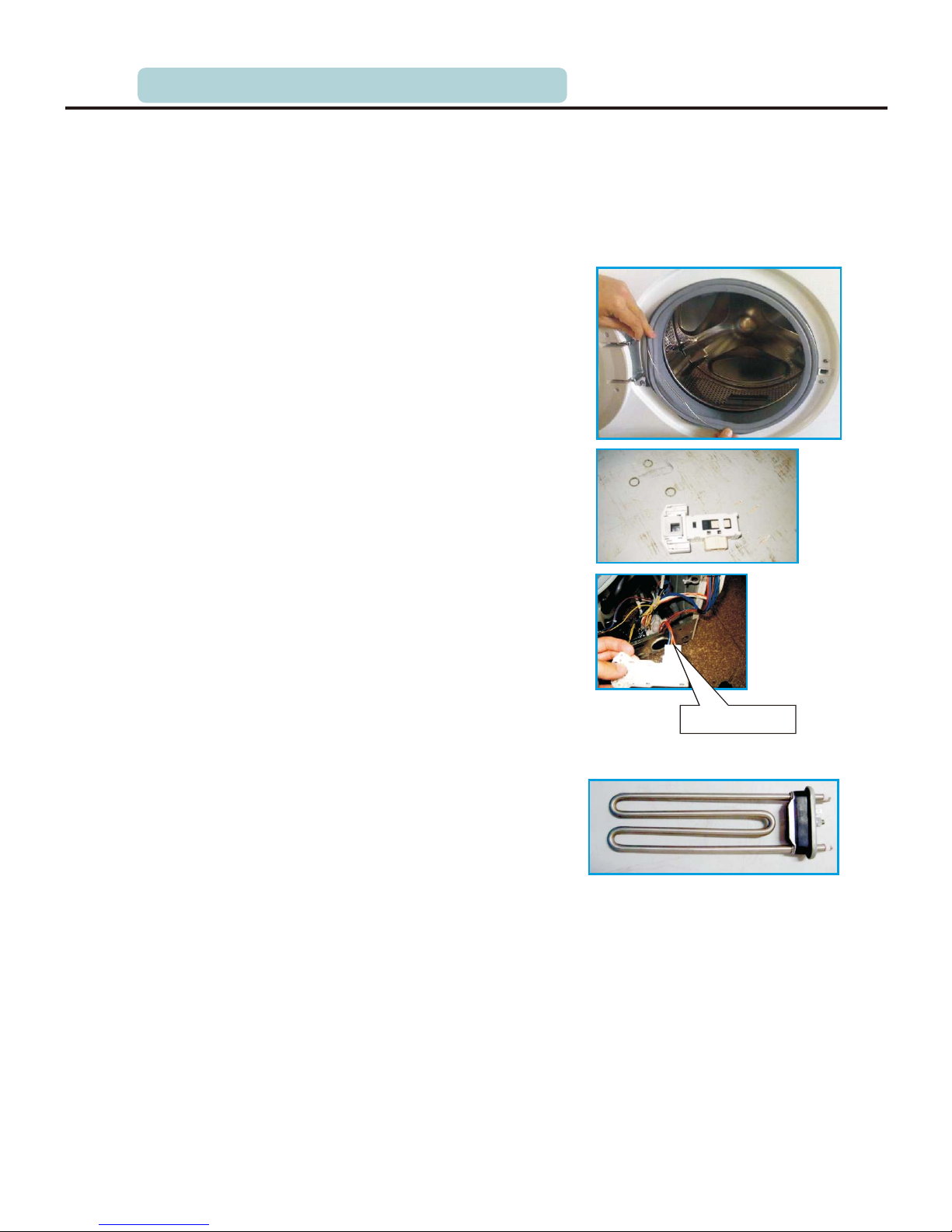

4.10 Inlet hose

Inlet hose connects household tap and washing

machine. The pipe of inlet hose has a high-pressure

capacity which nets the high strength polyester

fiber lines. Generally, household water pressure is

less than 1MPa, and practically the water pipes of

Midea washing machine could stand the pressure

of 2MPa in one minute not dehiscence, not

deformation, and bearing 4MPa pressure not burst.

As for inlet hose, there are many performance

requirements such as hot and cold alternate anti-shocking, anti-bending etc.

4.OVERVIEW OF MAIN COMPONENTS

Page 25

P.25

4.11 Inlet system

4.11.1 Pressure switch

Working principle

Mechanical pressure switch have two main components that is balloon and electrical

structure. The balloon is fastened sealedly on the pressure switch with hose clamp and

the end of balloon is connected on the bottom of tub using press chamber, plastic pipe.

During flowing water, the bottom of tub is firstly submerged and its space linking the

balloon is closed. With the increase of water level and the pressure of closed air increase

gradually until push the needle of rubber membrane.

Another parts is the electrical structure. With the balloon inflating, a needle top spring

chip to make it conduction and then change the current direction.

Usually, the fault of pressure switch is leakage and contact barrier. It is easy to check

them.

Huff the inlet inflatable with your mouth, and you can clearly hear the clatter sound of

spring chip clicks, if it is multi-level control, several clatters sound can be heard.

There is a group of plastic crosser screw in the side nearly line. These screws are used to

control the height of water level (to avoid adjust it, there is a certain color lacquer to

sign).

Pressure switch is a very important part in the washing machine, which is not only

control water level but also influence the safety of washing machine. Once it is invalid,

water level can’’t be controlled.

Low-frequency analog electronic pressure switch:

its main principle is a group of LC oscillation

circuit, the change of balloon changes the frequency

of LC circuit. Pressure switch feedback to the PCB

signal, and PCB issued in accordance with the

conditions set to decide water level.

The price of low-frequency analog electronic

pressure switch is high and as a result its application

rares.

In a word, pressure switch employs its closed gas

room as the basic condition of normal work. And if

the gas room is damaged, the pressure switch will

be invalid.

In addition, pressure switch is the key part

controlling heating circuit.

4.OVERVIEW OF MAIN COMPONENTS

Page 26

P.26

4.11.2 Inlet valve

Working principle of inlet valve

Inlet valve has two main components: One is the 220V winding which Set in the injection

molding nylon colophony Pa66 outside cylindrical cavity and there is an iron core inside

of cavity. And normally, iron core is not in the center of cavity due to the spring force.

Once power supplys, the magnetic field produced by winding generate force overcoming

the spring force to drive iron core, which open the hole of releasing pressure in the inlet

valve.

The other is the channel part. There is a hole between inlet and outlet that control flux.

The default of the hole is closed and controlled by the hole of releasing pressure in the

inlet valve.

As a result, the fluxing hole can be opened on the condition of power supply, iron core

moving and the hole of releasing pressure.

In a word, inlet valve works in the condition of power supply and water pressure.

Characteristics of inlet valve:

1.Flux: the flux of inlet valve is different by

different manufacturer produced. And the flux

value usual is from 8L/min to 12L/min (the flux

value of this machine is 9.5L/min).

2. Modality: the inlet valve is common single-head

valve for the atmosphere can be programmed for

mechanical models, the direction of water flow

when a cam driven by program - controlled link,

Plectrum agencies to achieve watershed; The

second category is double-head valve, which is

used in electronic-type program - controlled

washing machine, and usually water influent from

the “pre-wash”box, and the other washing box is

the main box, and when the two valve boxes at the

same time electricity, water influent from the rinse

box, its on / off is control by PCB panel.

The last category is three-head valve, which is used

in electronic device programmed with the function

of drying washing machine, two of grids have the

same functions as well followed. And the third one

is used to control condensed water, which has

small flow.

3.Resistance: the resistance of single-head valve is

about 4000Ω。

4.Power value: the power value of single-head

valve is about 5W.

4.OVERVIEW OF MAIN COMPONENTS

Page 27

P.27

4.11.3 Detergent box kit

Detergent box kit is made up of detergent box,

Detergent box-up and Detergent box-middle.

At first, Detergent box-up and Detergent box-middle

are pieces of plastic absolute. They are connected

and produce many flume as the channel of water

flow to weep away the detergent in the box. In order

to achieve European standards, an overflow mouth

is designed in the detergent box to prevent washing

water inflowing the family water system caused

pollution.

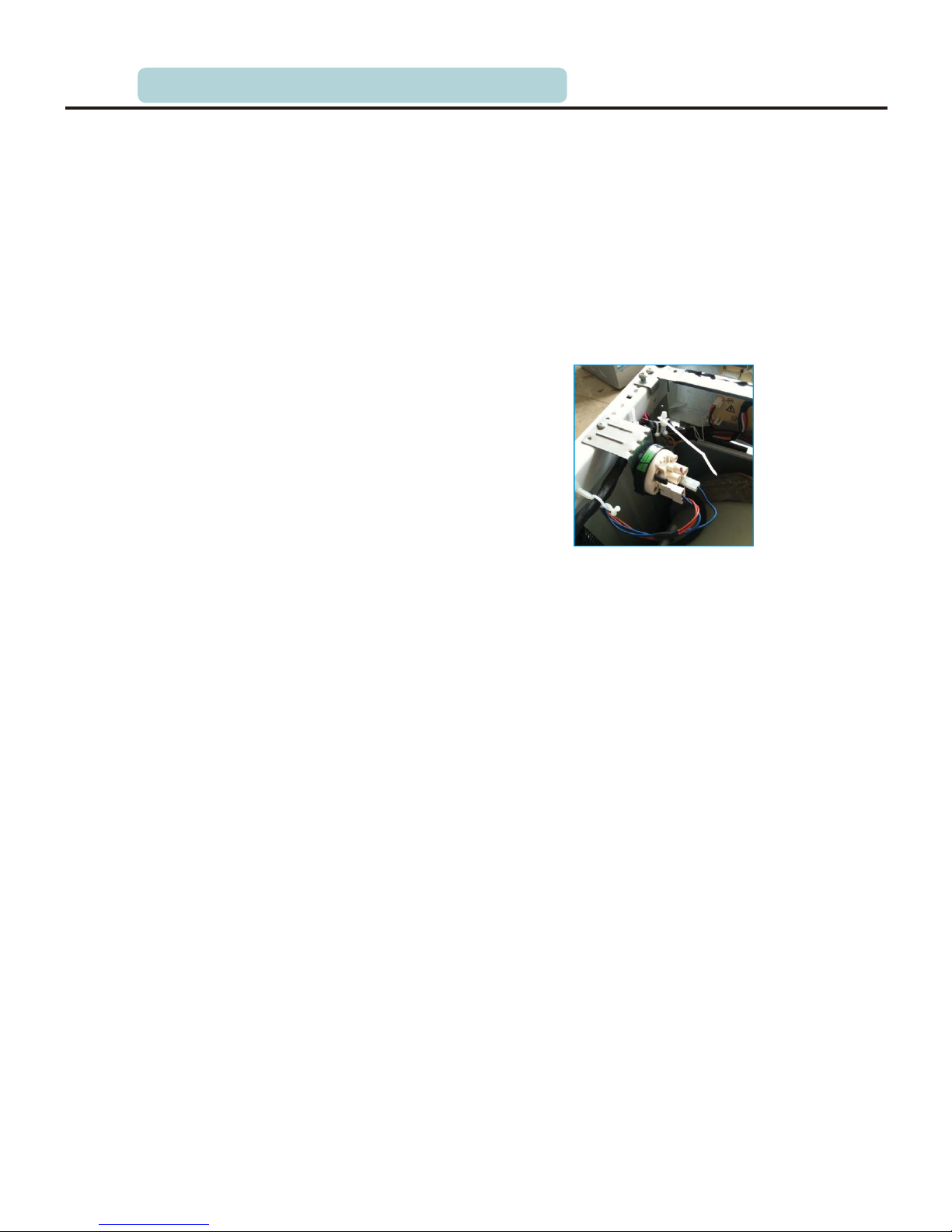

4.11 Drain system

4.12.1 Drainage system

The material of drain hose is Ethylene-Propylene Diene Monomer (EPDM), whose rigidity is 50sha,

default thickness is 2.5mm. The drain hose has

anti-loosen structure and it ensure there is no

leakage during work.

4.OVERVIEW OF MAIN COMPONENTS

Page 28

P.28

4.12.2 Drain pump

As for the up-drainage washing machine, the drum

washing machine need drain pump to provide the

force. The drain pump head is generally 1~1.5m,

tonnage is 24L/min.

Drain pump is made up of motor, body, impeller,

blower fans. Impeller is derived by the motor to

run and drain; the blower fans disperse the heat

produced by motor.

In principle, the drain pump has two categories

of permanent-magnet pump and cover pole pump.

And drum washing machine usually use the permanent-magnet pump now.

The permanent-magnet pump uses the permanent-magnet motor and its winding

resistance DC is about 170Ω. And its resistance usually can be measured by

millimeters. If resistance infinite, it can be concluded its opening.

Actually, the common faults of drain pump was mainly that impeller broken flannel or a

hard object jammed or the hard object interrupted by the impeller, and this will cause

drain pump can not work. the drainage pump will issued swoosh at the end of draining

due to the some water can not be completely discharged from the machine, it is a normal

phenomenon.

Due to the internal structure of a cavity, filter components upper and lower body by

ultrasonic welding.

The filter kit main role is Filtering out clastic produced by washing. If don’t clean it

timely, it will cause many fault such as pipe plug, Drainage difficulties.

Filters should be washed once a month generally. Remove it before draining water and

then put a basin to avoid the remaining water flowing on the

floor. Mold cleaning filters carved steps and attention to the

matter in the back of the trap door. During installing it again,

the filter should be tightened, otherwise easy leakage.

4.13 Door kit

Door kit is made up of outer door, inner door, door glass, door

handle, door hook, door hook spring, hook pin, hinge, hinge

cap and screw.

The material of outer door is Acrylonitrile Butadiene Styrene

(ABS) which have the good anti-aging and anti- ultraviolet

properties, and it is elegant generous.

The material of inner door is the improved PP material.

Door glass is not only good high temperature and impact

resistance properties of hot and cold, but also a high intensity.

Door handle is embedded or external.

When open the door without loosening after assembled door

handle, door hook, door hook spring, hook pin.

4.OVERVIEW OF MAIN COMPONENTS

Page 29

P.29

The material of door hook is zinc alloy. As well hinge, the material of the hinge cap is

POM, and the cap set in the pins of hinge ends.

The door lock control the door after installing it correctly, the clasp of door lock enter

the mouth of the plate front and then they are fixed with screw to avoid scratch between

the door hook and the cabinet. After power supply, door hook will be locked and the door

can’t be opened.

4.14 Gasket

Gasket is injected molding with EPDM which has

many properties such as the high temperature,

corrosion resistance, anti-aging.

The gasket of Midea washing machine has

processed using advanced technique and it has

very well performance and beautiful color. What

is more, gasket achieves the goal of flexible

connectivity between cabinet and tub.

4.15 Door lock

Door lock is the device that is self- locking during

electricity and feedback signal to the PCB panel.

Delay function: the door can be opened after the

unit is off in two minutes.

4.16 NTC temperature sensor

NTC can detect the temperature range from -5℃

to 103℃. The heating function stops in the

condition of fault (open or short circuit).

Change the NTC before loose the crimpling

device.

4.17 Heater

The body of heater is the heating pipe of stainless steel, and its insulation is magnesium

oxide powder and the core is the heating filament. The airproof of heater is EPDM which

has many properties such as the high temperature, corrosion resistance, anti-aging.

The stainless steel heating pipe is welded using sub-arc welding and Seamless Detection.

And then intercept set length to install the heating filament and fill magnesium oxide

powder, and then tamped through vibration. Finally, a diameter of 12mm heating pipe

compressed into 8mm with horizontal compression technology, and that is strictly ensure

the full magnesium oxide powder tamped and the quality of welds.The heater is fastened

on the tub with bolt.

Electrical principle:

Heater uses power of 220V voltage and 50Hz frequency. Due to the rated current is less

than 10A, the most power of washing machine is less than 2200 watts. Reducing the other

Harness plug

4.OVERVIEW OF MAIN COMPONENTS

Page 30

P.30

power, the most power of heating at 90℃ is in the range from 1800 watts to 2000 watts

and 1000 watts at 60℃.

The heater can't heat without water, so firstly the heating function will start only user

selects the heating procedure, and secondly heating function is in some special procedure

to avoid unreasonable heating, and thirdly when water level is up to the set level, its

function will operate. In addition, there is the melting device in the heater, and when the

temperature is up to set value(usual setting 160℃), Fuse is fused and cut off power supply.

4.18 Filter

The power change of drum washing machine is in

the scope and larger, and in order to prevent its

interference on the other household appliance and

interfered by the other large appliance, the filter is

installed in the washing machine by CCC

certification requirements.

Filter is made up of a group of capacitance (usually

three), a group of inductance and a resistor. In the

power supply circuit, it can inhale the high-order

harmonic from washing machine and earth.

The interference is from the high-order harmonic from the power changes of washing

machine as well as the disorders and alternating magnetic field according to the

continuous changes of the current in the power cord. The frequency and magnitude of

change of its power is in the scope and larger that is from zero watts at soak to hundreds

of watts at wash, rinse and spin, to nearly 2000 watts at wash with heating. This change

more easily aroused the obvious voltage fluctuations in the domestic circuit which effects

the normal use of other electrical appliance. These filters can filter out high-order

harmonic and earth.

EMC stressed interference and anti-interference, and as for washing machine, it is

important to reduce interference to others due to it has good anti-interference.The

washing machine use alternating current that can pass capacitor, and in practically, filter

will have a very small leakage current (generally less than 2mA). Good grounding is the

guarantee of the safe using this machine.

And as a result, we particularly stress the importance of grounding. Sometimes, there is

an anesthesia in the working machine, please check their grounding device firstly.

4.OVERVIEW OF MAIN COMPONENTS

Page 31

P.31

4.19 Motor

1. Summary of motor

As the driving components, motor drive the drum during washing and spin. Currently,

the motor of drum washing machine usually have two-speed motor and series motor.

1) two-speed motor is the running capacitance of single-phase AC asynchronous motor.

Stator of the three-phase AC motor embedded in the three-phase windings 120°. If it

has symmetrical in the three-phase windings, it can produce rotating magnetic field.

Due to using single-phase power, the stator windings of washing machine in the

single-phase AC electromagnetic field generate field is a pulsating magnetic field.

And this pulsating magnetic field can be divided into two a rotating magnetic field, and

their speed equal to the opposite direction. And therefore, their synthetic torque is zero

and motor can't be activated except issuing electromagnetic buzzing sound.

To start motor, washing machine motor normally uses two measures: First, put

embedded in the trough of stator two windings, the main windings (running winding)

and the vice winding (start winding), and two windings around axes in space in a 90°

angle. Secondly, put a capacitor in series on the winding and therefore the same

currents have different phase difference on the two winding. As a result, the vice

windings has leading 90° current to the main windings , and make the condition of

starting motor.

The space between stator and rotor is air gap. Motor has two ways of cooling, natural

cooling and fan cooling (air-cool or self-fan cool).

2). Series motor

General speaking, series motor is a DC motor. Its highest speed can be up to 20000r/min.

Performance characteristic: Its electrical characteristic is hard, the size of it output

torque is not effect on the change of voltage. Its has large range of regulating speed and

has relatively high efficiency which value is up to 0.2 at the speed of 700r/min and 0.63

at the spinning.

Work principle:

There are two series ways between exciter stator windings and the armature windings.

The one is that the armature windings series two exciter windings in the figure A; and

the other one is that two exciter windings series before they series the armature windings

in the figure B. And practically, the first way is used more.

ExciterExciter

i i

Armature

Exciter Exciter

Armature

Figure A:armature wires series-wound

between two exciter wires

Figure B:armature wires series-wound

with two exciter wires

4.OVERVIEW OF MAIN COMPONENTS

Page 32

P.32

The structure of single-phase series motor decides it can use not only alternating current

but also DC. To predigest its circuit and reduce cost of this machine, it is usually to use

AC practically. Between the exciter windings and the armature windings are in series one

single-phase power supply. When it is in a positive and negative half-cycle AC, the

current passing the exciter windings and the armature windings are shown in the figure C

and D separately. In a word, the revolve direction of series motor which is used to AC

power supply has nothing to the power supply.

Change the shift of single-phase series motor before change the series polity of the exciter

windings and the armature windings, and show in the figure E.

Series motor usually changes voltage to adjust its rotate speed and the calculating

formula of its rotate speed is following:

(r/min)

E------inductive-voltage of the armature windings

a------the number of shunt-wound pairs of the armature windings

P------the number of magnetic polity

average flux of magnetic polity

N------the number of windings of armature windings

From the followed formula, if you change the structure parameter (P, N, a) of single-phase

series motor, and you can change its rotate speed. But as for the typed series motor, you

can change E and by adjusting the voltage value of the motor to change its rotate speed.

For drum washing machine, modulate the voltage using the electronic actiyator or the

PCB panel to adjust its rotate speed.

n=60aE/(PØN)

Ø------

n

+

-

ØØ

n

+

-

Ø

Ø

Figure C: rotor revolve direction in

a positive half-cycle AC

Figure D: rotor revolve direction in

a negative half-cycle AC

n

+

-

ØØ

SN

n

+ -

ØØ

NS

Figure E:rotating direction of motor after change the series polity of the

exciter windings and the armature windings

4.OVERVIEW OF MAIN COMPONENTS

Page 33

P.33

2. Main parts and structure of motor

Stator and rotor

Stator has rotating magnetic field, including stator windings, the core and upper/lower

cover for fixing it.

Stator windings is the high strength polyester enameled wire enwinding the core which

is sheeted with the silicon steel about 0.5mm thickness by riveting and welding. Both

sides of the silicon steel are coated with insulating paint, as well as rotor.

As the rotating parts, rotor output torque from its shaft, including the rotor windings,

core and axial. There is a belt pulley of the motor to output torque on the extended-rotor

shaft.

Gas gap

The unilateral width of the gas gap between stator core and rotor core usually is 0.3mm.

Due to the magnetic resistance of air is less than metal’s, gas cap is larger, the more is

magnetic resistance and the more is Exciting Current to produce the same size rotating

magnetic field, as a result, power factor of the motor become lower. To reduce the

exciting current, the gas gap should become small, taking into account safety factors of

assembly and transport.

Thermal protector

Usually use restorable double foils to cut off the power when the temperature of motor

more than the set one, to protect motor, the set temperature of foils is115±5℃, the

contractor will restart the power supply when the temperature is lower than the set one.

4.20 PCB panel

General characteristic

1)The control panel executes the main functions below:

2)Control the spinning(high-speed or low-speed spin

and the speed of the last spin)

3)Control the temperature of washing liquid

4)Control and adjust the unbalanced load during spin

The control of spinning speed

The control panel modulates motor’s speed by modulating

its voltage. By modulating the knob position of speed

chooser, the user can set the speed value in the control

panel. Then comparing the value of the speed and the

impulse value from testing motor, when the control panel

makes sure that the motor speed arrive the set speed, it will not modulate the voltage of

motor. As a result, the washing machine’s drum runs at the set speed.

The control of temperature of washing and heating

The user sets the temperature in the control panel by pressing the temperature key; the

control panel compares the set temperature and the washing temperature from the

4.OVERVIEW OF MAIN COMPONENTS

Page 34

P.34

temperature-testing resist value; when the control panel makes sure that the water

temperature arrives the set temperature, it cuts off the heater and stop heating.

The control of unbalanced load during spinning

When the washing machine is running the spinning program, if the clothes in the drum

are put unbalanced or gravely out of center, the washing machine will vibrate greatly, so

the control panel needs to adjust it. The detailed process is as below: when the washing

machine is running the spinning, the drum rotating speed will promote from low to high;

when it gets to 95r/min ,according to the principal that different eccentric clothes have

different rotating speed between ascending and descending, the control panel first checks

the testing motor’s rotating speed difference at 95rpm, after a special computing,

estimates whether the clothes in the drum balanced, such as balanced distribution. If

balanced, the washing machine will run at normal spinning speed until the set highest

rotating speed. If unbalanced, after the control panel cutting off the controlling motor 5

seconds, the drum runs 30 seconds at washing speed. It shakes the clothes, tests and

computes the motor's rotating speed , and estimates whether the distribution balanced.

This procedure runs 12 times until the clothes balanced to spin. If the eccentricity is still

large after 12 modulations, it will display UE urgent.

Now turn off the machine, open the machine door to replace the clothes or put more

clothes to descend the eccentricity, and then choose the spinning program again.

NOTE: usually, a towel, jeans and some fabrics have large eccentricity and suggest that

consumers should put 2~3 or more to wash.

4.21 Main harness assy

Connecting control panel and peripheral

load

(Detailed in PCB connection)

speed [ssp1000r.p.m.]

0

100

200

300

400

500

600

700

800

900

1000

0 50 100 150 200 250 300 350 400 450 500 550 600 650

T(S)

Rotate speed

4.OVERVIEW OF MAIN COMPONENTS

Page 35

P.35

4.23 Bill of damageable parts

NO. Name Qty NO.

Name Qty

1

2

3

4

5

6

7

8

Inlet hose

Absorber

Inlet valve

Tub outlet hose

Outlet hose

Drain pump

Drive pulley

PCB panel

1

2

1

1

1

1

1

1

9

10

11

12

13

14

15

16

Temperature sensor

Door lock

Heater

Door hook

Filter cover

Door glass

Door handle

1

1

1

1

1

1

1

4.22 Sub-harness assy

Connecting motor

(Detailed in PCB connection)

4.OVERVIEW OF MAIN COMPONENTS

Page 36

P.36

5.UNPACKING WAYS OF MAIN PARTS

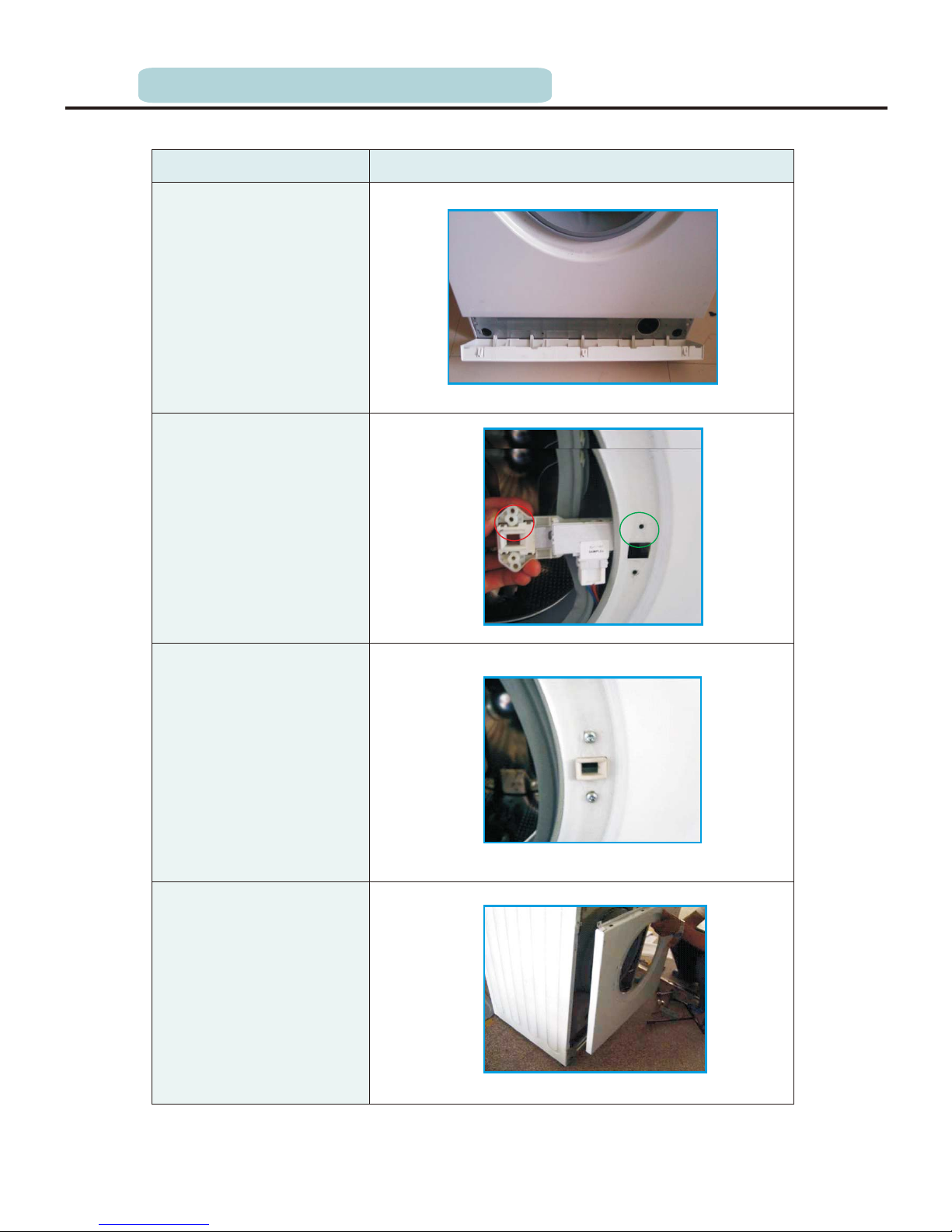

Operation step Picture

1 Undo the back cover

Undo two screws fit

between back plate and

cabinet, and then pull out

the back plate

2 Undo top cover

Undo 2 screws fit

between the top cover and

back cabinet

Push back the top cover

15mm until it leaves away

from, the control panel,

and then take it down.

3 Undo the control panel

Departing the top cover

(means as above)

Draw out the detergent

drawer

Loosen two screws fit

on the control panel

(facial).

Loosen two screws fit

on the control panel(top)

Press three clasps

between top control panel

and panel support.

Take out the control

panel inclined from the

cabinet

.

①

.

②

①

.

②

.

③

④

.

⑤

⑥

.

(5.0/6.0/7.0 counterweight)

(4.5kg counterweight)

Page 37

P.37

Operation step Picture

4 the lower panel

Open the filter cover,

release the screw on the

lower panel.

Turn the washing machine

back at an angle, pinch the

clasp ,and push it out.

5 Undo the door lock

Open the door of

washing machine.

Take the outer gasket

clamp to the drum.

Remove two screws on

the door lock, and take

down the door lock.

Take out the door lock

and draw out the plug; pay

attention to the position

of the plug so as not to

connect a wrong circuit

next time.

6 Undo the front plate

Undo the door lock

(methods as followed).

Remove the lower

cover(methods as

followed).

Undo

①

②

①

②

③

④

①

②

5.UNPACKING WAYS OF MAIN PARTS

Page 38

P.38

Operation step Picture

③ Undo five screws in

the front plate.

④ Put the front plate up

to the clasp of the front

plate away from the

loading holder, and then

take off the front plate.

8 Undo the gasket

① Undo the top cover,

control panel, lower cover,

machine door and the front

plate(methods as

followed).

② Remove the outer

gasket clamp between the

door seal and the front

plate.

③ Loosen the inner gasket

clamp between the door

seal and the front of the

outer tub, and take out the

gasket.

5.UNPACKING WAYS OF MAIN PARTS

7Undo the facade

counterweight

Undo the front plate

(methods as followed).

①

Remove six screws pull

②

out the facade

counterweight.

Page 39

P.39

Operation step Picture

10 the detergent Undo

box

① the top cover Undo

and the control panel

().methods as followed

② Release the hose clamp

and pull out the inlet hose.

③ Release the hose clamp

and pull out the detergent

box hose, and then take

out the detergent box.

11 the inlet valveUndo

① Remove the top cover

().methods as followed

② Undo 2 screws between

cabinet and inlet valve.

5.UNPACKING WAYS OF MAIN PARTS

9 Undo the PCB panel

Undo the top cover

and control panel(methods

as followed).

Page 40

P.40

Operation step Picture

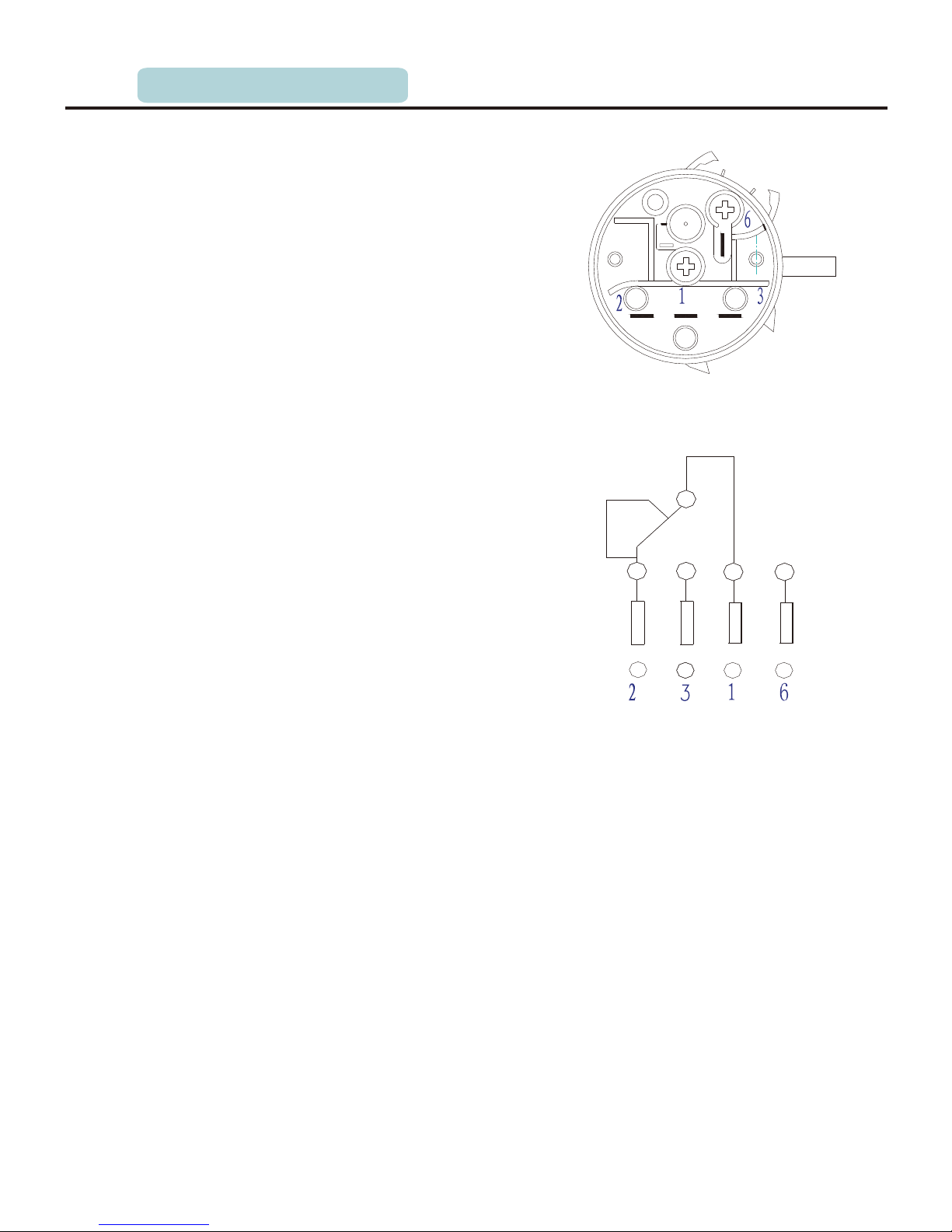

12 Undo the pressure

switch

① Undo the top cover

(methods as followed).

② Pull out the plugs on the

pressure switch. Mind the

position of the plug to avoid

error during the following

assembly.

③ Loosen the pressure switch

hose clamp, and pull out the

hose from the pressure switch

interface.

④ Rotate the pressure switch

anticlockwise by 90º, and then

pull out the pressure switch.

13 Undo the pulley

① Undo the back cover

(methods as followed).

② Rotate the pulley and at

the same time pull out the belt,

and then remove the belt.

③ Remove the screw on the

pulley and then take down the

pulley.

5.UNPACKING WAYS OF MAIN PARTS

③ Release the clamp

fixing the inlet valve and

the inlet hose, and then

pull out the inlet hose.

Take out the inlet valve

and plug. Pay attention to

the position of the plug so

as to connect a wrong not

circuit next time

Page 41

P.41

Operation step Picture

15 Undo the absorber pin

① Undo the front plate

(methods as followed).

② Use pliers to pinch the

absorber pin’s

protuberance, and knock

the absorber pin out from

back lightly; in the same

way, remove the other one.

16 Undo the filter

① Open the filter cover.

② Rotate the filter knob

anticlockwise, and then

pull

out the filter.

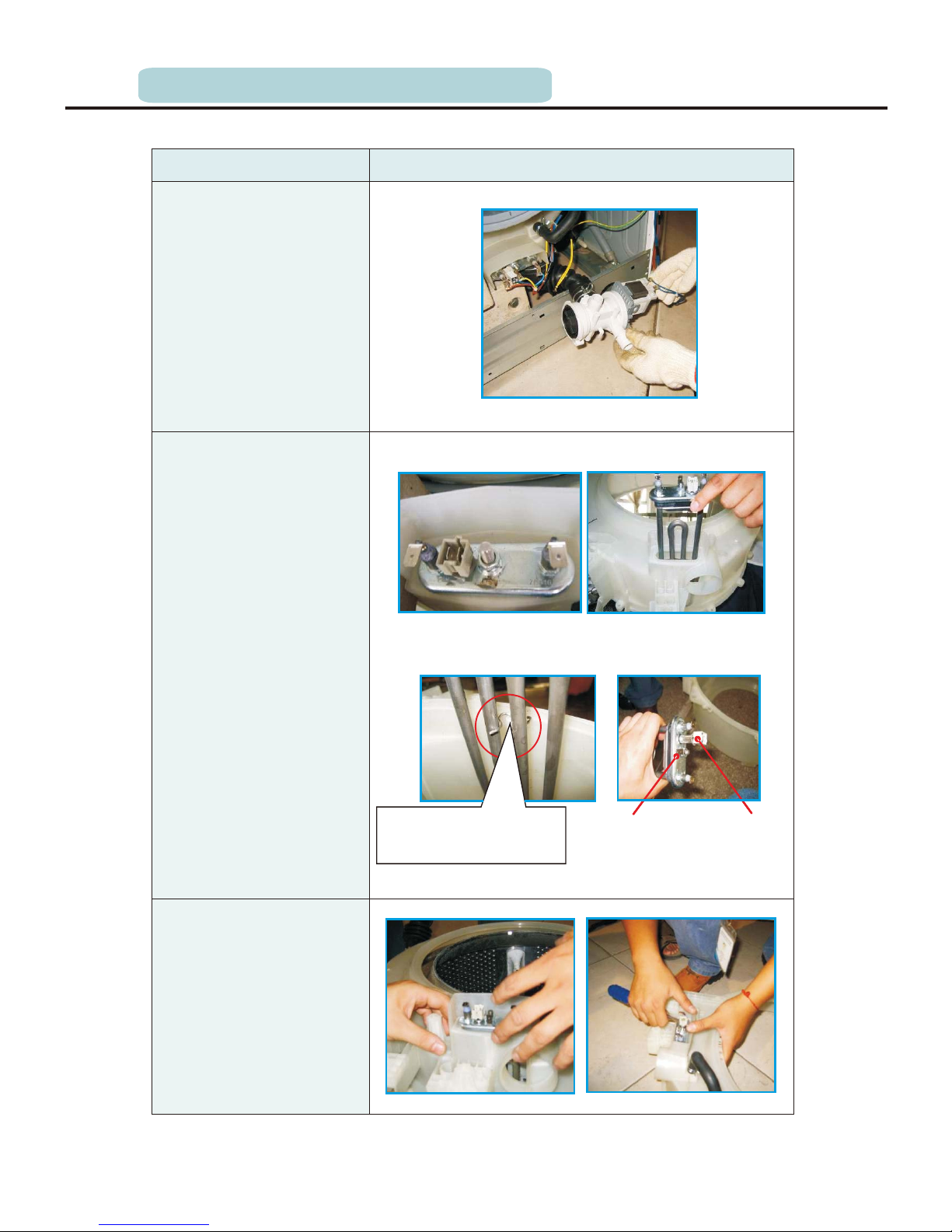

17 Undo the drain pump

① Undo the top cover,

control panel, lower cover

and front plate(methods as

followed).

② Nip out clamp between

the drain hose and the

drain pump, and then pull

out the drain hose.

5.UNPACKING WAYS OF MAIN PARTS

14 Undo the upper

counterweight

① Undo the top cover

(methods as followed).

② Remove three screws

fit on the upper counterweight

and then pull out the upper

counterweight.

(4.5kg counterweight)

(5.0/6.0/7.0kg counterweight)

(4.5kg counterweight)

(5.0/6.0/7.0kg counterweight)

Page 42

P.42

Operation step Picture

18 Undo the heater

① Undo the top cover,

control panel, lower cover

and front plate(methods

as followed).

② Pull out the heater

plug. Pay attention to the

position of the plug so as

to not connect a wrong

circuit next time.

③ Release the screw

fixing the heater.

④ Take out the heater.

19 Undo the NTC

temperature sensor

① Undo the top cover,

control panel, lower cover

and front plate(methods as

followed).

② Undo the NTC with

special tools.

Heater

NTC

In the red circle it is the

heater support, clamping

the heater.

5.UNPACKING WAYS OF MAIN PARTS

③ Nip out the clamp

between the outlet hose

and the drain pump, pull

out the outlet hose.

④ Loosen the screws

fitted on the drain pump,

and then pull out the drain

pump.

Page 43

P.43

Operation step Picture

21 Undo the panel support

① Undo the top cover

(methods as followed).

② Undo the control panel.

③ Remove two screws

fixing the panel support,

and then remove it.

22 Undo the drum tub

assembly

① Remove the motor in

24(methods as followed).

② Pull out the heater.

③ Remove the belt.

④ Remove the screws

fixing the pulley, and then

take out the pulley.

5.UNPACKING WAYS OF MAIN PARTS

20 Undo the door glass

① Open the door, remove

two screws fixing the

hinge and front plate, and

then remove the door.

② Remove six screws on

the inner door.

③ Remove the outer door

and the inner door with

special tool.

④ Take out the door glass.

Page 44

P.44

Operation step Picture

23 Undo the absorber

① Lift out the outer tub kit

(means as 21 above).

② Undo the absorber pin

between absorber and rear

tub, remove the absorber.

24 Undo the motor

① First let the machine lie

down on the back and then pull

out the motor wire and

grounding wire. Use spanner to

remove the motor screw, and

lift up the motor with the other

hand in case of falling to the

drain pump.

② After two screws are

removed, change the motor.

First support it to clasp the

correct position, then install

the screws, and then install the

belt.

5.UNPACKING WAYS OF MAIN PARTS

⑤ Remove the screws

fixing the front and rear

tub, and then remove the

tub.

⑥ Remove the inner

drum kit.

减震器销

密封条

Pin

Airproof Ring

Page 45

P.45

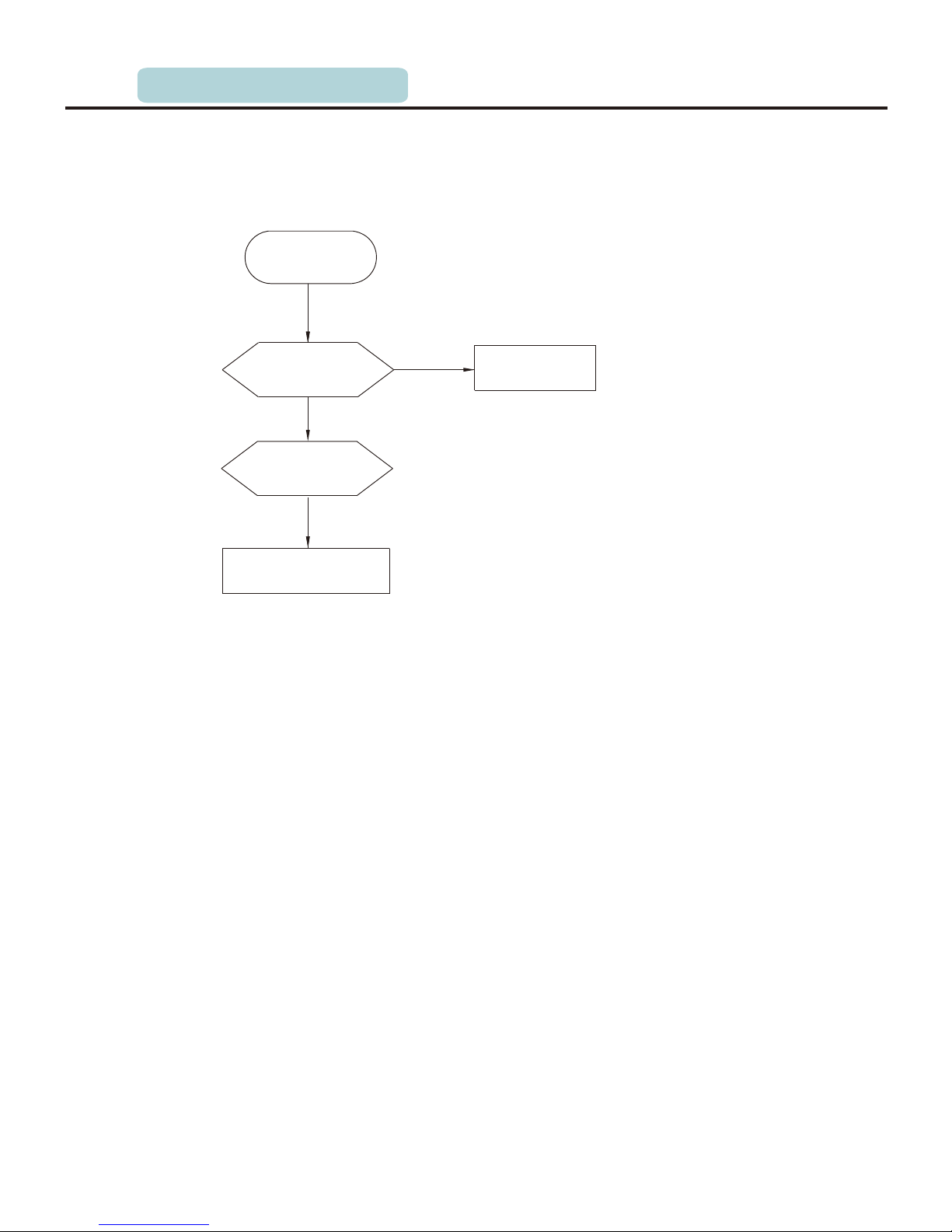

6.TROUBLESHOOTING

During the failure diagnosing and changing components, please do it as following:

1)There is some static harm to the electrical

parts from colophony in the washing machine

or humans. So it is better to eliminate the

potential static by grounding the humans or

touching the plugs.

2)The rated voltage of the SCR in PCB is

220-240V, so it's possible to be electrical

shock. Please take care while strong and

weak electricity is alternative.

3)The design of PCB is out of failure, so

prohibit to change the PCB panel according

to its alarm. Please do it according to the

failure diagnose program.

6.1 The circuit program & wiring connection figure

SICILY circuit principle

POWER SUPPLY PLUG

Pressure

switch

P

S10

S9

S8

M1

M5

M8

M9

M

T

M3

M4

M10

S3

S6

S2

Option

Hot valve

Main valve

Pre valve

S7

#3

#1

#2

PTC

S5

S4

H

Heater

EMI filter

AC source

Power switch

Pump

Stator

Rotor

Tacho

Motor

Wash NTC

Door lock

N

N

NLL

PE

PE

L

1

2

3

6

1

2

1

5

S8-1

S8-2

S8-3

S8-4

S8-5

S8-6

S8-7

S8-8

S8-9

S5-1

S5-2

S5-3

S5-4

S2-5

S2-4

S2-3

S2-2

S2-1

S6-10

S6-9

S6-6

S6-4

S6-2

S7-1

S7-2

S6-8

S6-7

S6-5

S6-3

S6-1

Page 46

P.46

SICILY harness connection

6.2 PCB wiring figure

1

2 Heater harness

3 Motor harness

4 Drain pump/NTC

harness

5 Water Value

6 Filter harness

Door lock harness

6.TROUBLESHOOTING

112

3

3

4

5

6

70

MR10

MR

MR5

MR4

MR3

GD4 黄绿色

MR2

MR1

MN 2

ML 1

PN 1

PL 2

70

100

90

T30R扎扣

T18R扎扣

插销式尼龙扎带

MN

FLN

FLL

FL

1

连接器 FAF 280232-0

FLN(白色) FLL(黑色)

MR6

MR7

MR9

MR8

70

70

10

10

10

45

45

A2

A1

MR6

MR5

80

80

G10

G1

G3

G5

PPN

PPLB6B3

P

S3

S2

S5

E3

G7

0.3

端子 AMP/FAF 737439-2

连接器 LBS DR250-2C 白

端子 AMP/FAF 737440-2(压接双股线)

端子 AMP/FAF 737439-2

连接器 LBS DR250-2C 蓝

压接端子 AMP/FAF 737440-2

标签

0.75

F1

AMP/FAF

175057-1

0.75

AMP/FAF 41332

FLL

F4

E2

DX3

DX2

DX4

DX

DX1

空

0基准

90

45

80

TS1 蓝色

TS2 白色

HRN WS3

HRL E1

GD2

AMP/FAF

175057-1

连接器 FAF 50016HS-2

压接端子 AMP 927831-2

连接器 FAF 280232-0

B5WS1

WS2

WS3

B1

E4

HRN

WS

端子 AMP/FAF 737439-2

连接器 FAF 280232-0白

端子 AMP/FAF 737440-2(压接双股线)

连接器 LBS DR250-2 PA-白

T18R扎扣

60

门锁线 ½º 线

90mm黑胶带

端子AMP:63688-1

连接器 FAF 280232-0

端子AMP:63688-1

DX3

50

GD1 黄绿线

80

T18R扎扣

AMP/FAF 41332

1.0

140mm耐磨胶布,均匀缠绕一层

每圈缠绕重叠胶布宽度的1/2

后面尺寸从耐磨胶布最右边量起

耐磨胶布

端子 AMP/FAF 737439-2

插销式尼龙扎带

外面用耐磨布胶固定

连接器 FAF 280232-0

16AWG

A

A2

A1

MR3

MR4

蓝色 0.75

橙色 0.75

连接器 FAF VH-2Y

压接端子 FAF VH-PT

S1

S2

S3

S4

S5

PL

ML

MN

S

连接器 FAF VH-5Y

压接端子 FAF VH-PT

G5

G6

G7

G1

G2

G3

G4

G8

G

G9

G10

MR7

MR1

MR9

MR10

MR8

连接器 FAF VH-10Y

压接端子 FAF VH-PT

B5

B6

B7

B1

B2

B3

B4

B8

B9

E

FLN

HRL

E4

E3

E1

E2

F

B

F1

F2

F3

F4

TS2

TS1

DX1

FLL

PPL

PPN

WS1

WS2

DX2

WS3

连接器 FAF VH-9Y

压接端子 FAF VH-PT

连接器 FAF VH-4Y

压接端子 FAF VH-PT

橙色

0.3

黄色

0.3

蓝色

0.3

蓝色1.0

灰色1.0

棕色1.0

蓝色16AWG

棕色0.5

蓝色0.5

蓝色

0.5

蓝色0.5

棕色

0.5

白色

0.5

棕色

0.5

红色

0.5

棕色

0.75

橙色

0.75

蓝色

0.75

白色

0.75

红色

0.75

连接器 FAF 520987-1

压接端子 KET ST730268-3

连接器 FAF YTH500-10P

端子 AMP 964201-2

a

a

Page 47

P.47

The alarm display is as below :

6.3 Schedule of failure alarm & its disposal

6.TROUBLESHOOTING

Door lock

problem

Door is not closed properly.

Restart after the door is closed

Reason

Solution

Description

Display

LED

Please call up service line if there are still troubles.

Drain problem

while washing

(drain time

exceeds 3 minutes)

Water injecting

problem when

washing (water

injecting time

exceeds 7

minutes)

Tap is not opened or water

flows too slowly.

Inlet valve filter is blocked.

Inlet pipe is twisted.

If water is not supplied

Open the tap or wait till

the water supply

becomes normal.

Check inlet valve filter.

Straighten the water pipe

Check the other taps in

the room.

Please call up service line if there are still troubles.

Please call up service line if there are still troubles.

Outlet hose is blocked or twisted

Drain pump is blocked

Wash and straighten outlet hose.

Wash drain pump filter

Please call up the service line if there is any other problem.

E30

E10

E21

Please call up service line if there are still troubles.

Please call up service line if there are still troubles.

Please call up service line if there are still troubles.

E12

E60

E61

Overflow protection

: The water

level exceed

overflow level.

The machine lock the door,

close inlet valve, motor

stop working, drain water

in error status.

1. Re- start machine;

2. Change inlet valve.

Motor stalling

warning: Motor

try to start

working 5 times

every 1 min.

The machine lock the door,

close inlet valve, motor

stop working, drain water

in error status.

1、Check motor wire;

2、Change PCB;

3、Change motor

Speed measuring

signature lost

warning: PCB

cannot detect

speed signature

during working.

The machine lock the door,

close inlet valve, motor

stop working, drain water

in error status.

1、Check motor wire ;

2、Change motor.

Page 48

P.48

6.4 Electrical parts working & testing principle

1. Inlet valve

Working principles:

A piece of iron core blocks in the inlet valve, and

one side of the iron core is the push exerted by

spring. When the power is turned on, the winding

in the valve will generate a force to pull the iron

core up, and then the inlet passage is smooth and

the water flow in the drum under the household

water pressure .

Technique datas:

Maximum input voltage: 220-240V

Frequency: 50/60Hz

Resistance: 4.13K ±10%

Flux: 8L/min ±15%

Water pressure: 0.2-10bar

Temperature of hot water: Maximum 25℃

The testing methods of inlet valve is as follows: