Midea MRCT-062EWN1-D, MRBT-100CWN1-D, MRBT-075CWN1-D, MRCT-085EWN1-D, MRBT-125CWN1-D User Manual

...

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

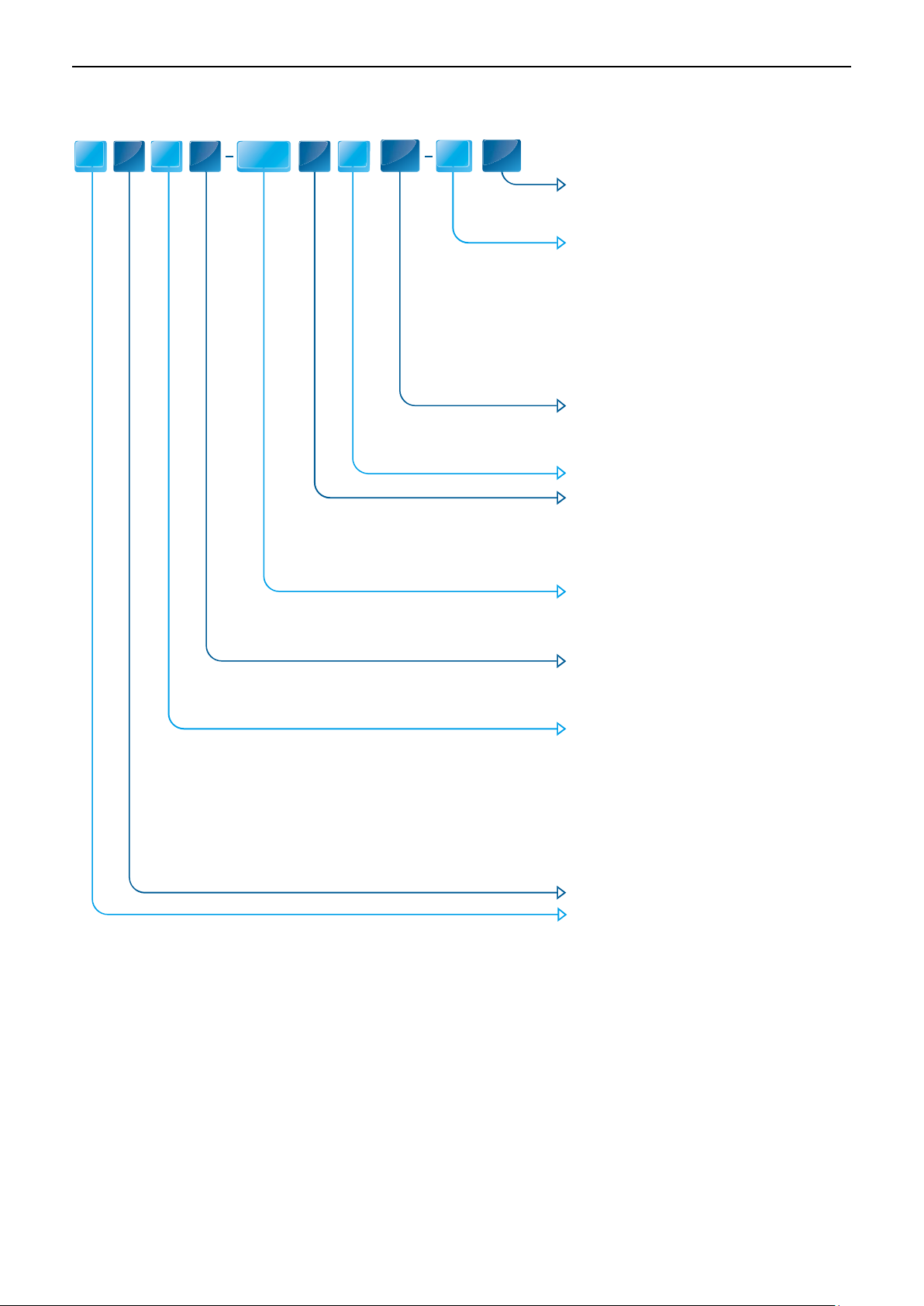

Content

1. Models List .................................................................................................... 1

2. External Appearance .................................................................................... 1

3. Nomenclature ................................................................................................ 2

4. Feature & Benefit .......................................................................................... 3

5. List of Function ............................................................................................. 6

6. Specification .................................................................................................. 8

7. Dimensional Drawing.................................................................................. 18

8. Wiring Diagram ........................................................................................... 24

9. Performance Data ................................ ....................................................... 34

10. Electrical Data ........................................................................................... 43

11. Parameter and Pressure Chart ................................................................. 45

12. Refrigerant Cycle Diagram ....................................................................... 54

13. Operation Limit ......................................................................................... 55

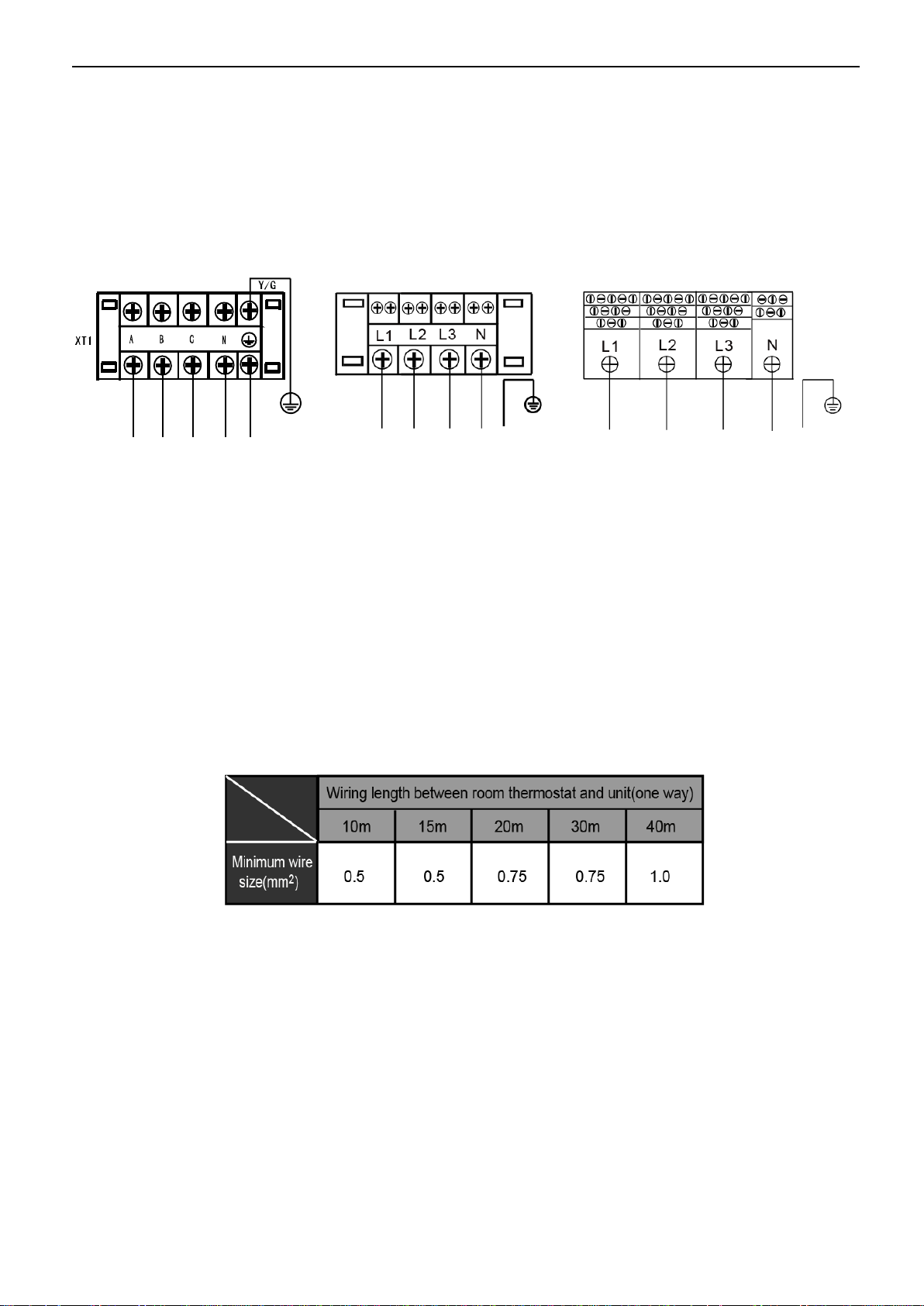

14. Installation ................................................................................................. 56

15 Wired Controller ......................................................................................... 63

16. Error Code ................................................................................................. 69

17. Accessory .................................................................................................. 78

18. Maintenance and Upkeep ......................................................................... 78

Appendix ......................................................................................................... 81

※ Manufacture reserves the right to discontinue, or change at any time, specifications or designs without

notices and without incurring obligations.

0

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

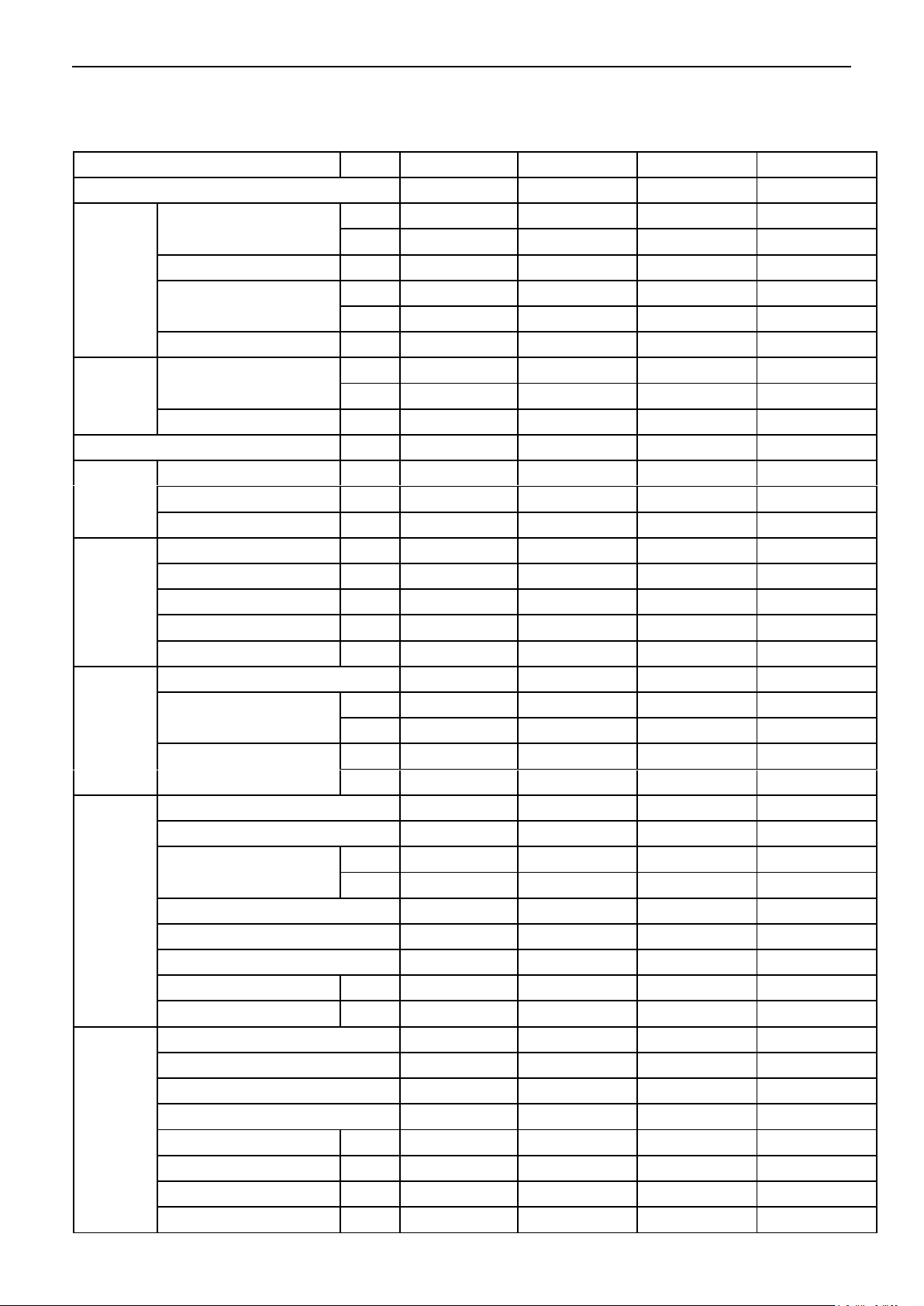

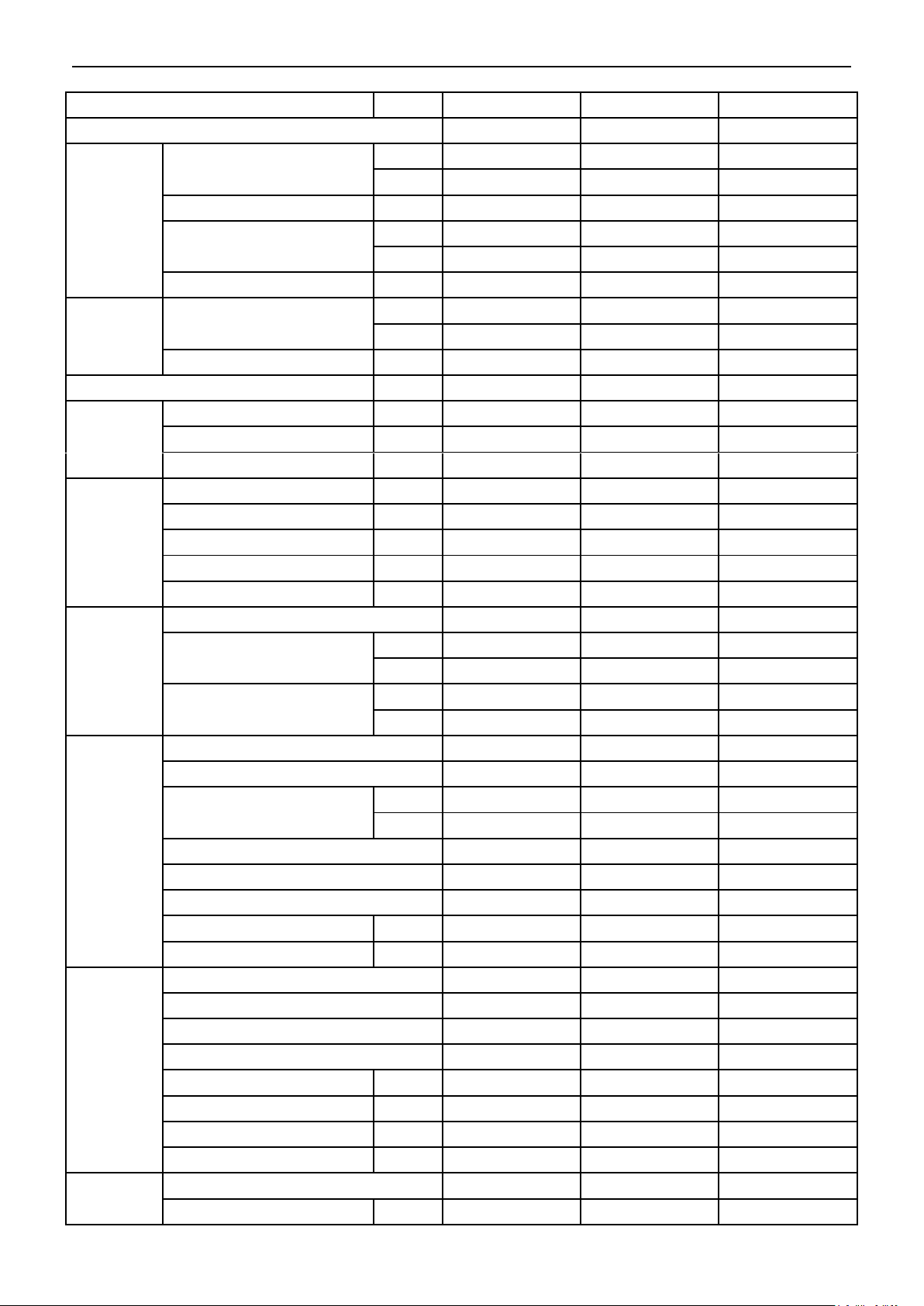

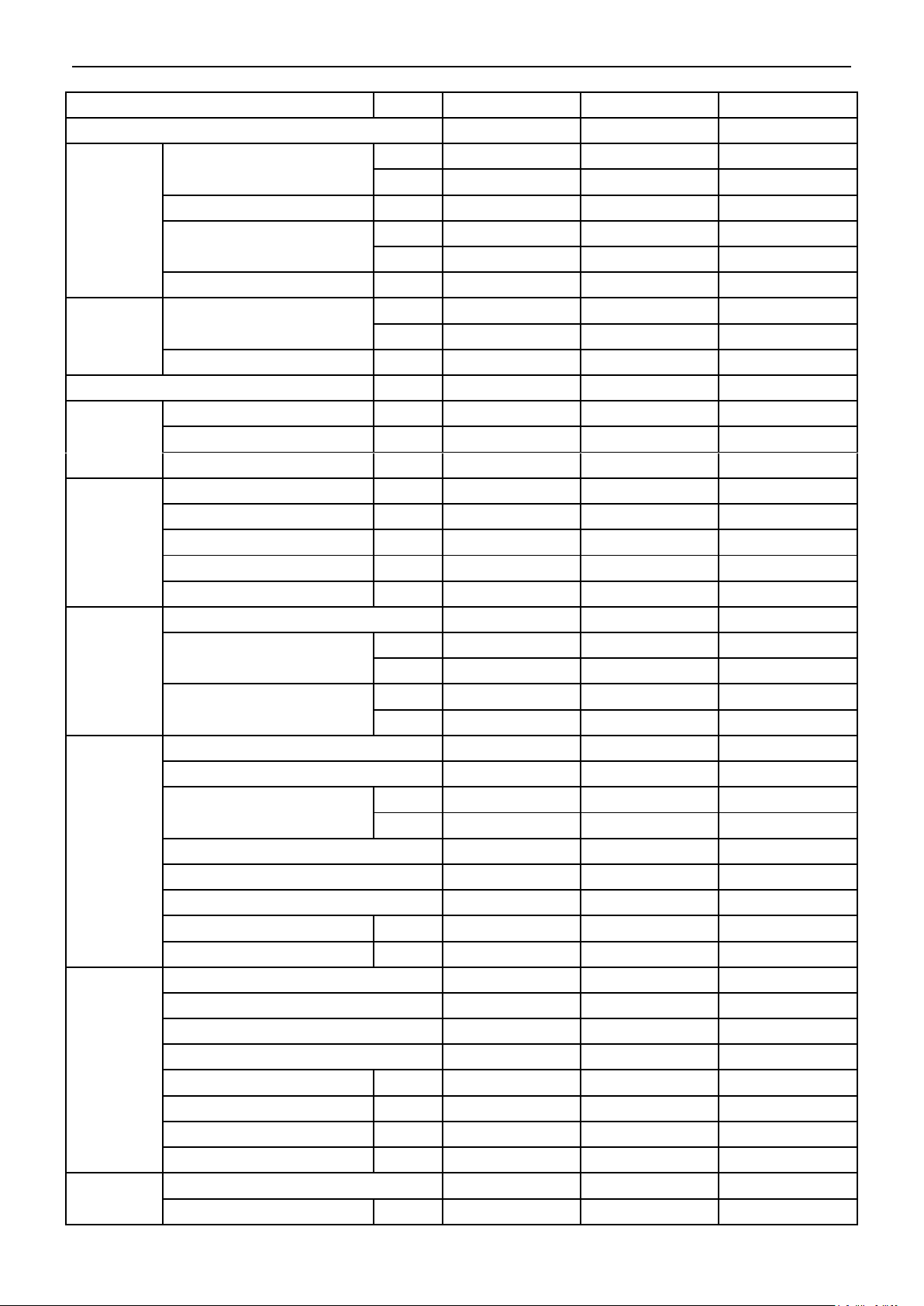

Nominal

Model

Power Supply

Ton

Refrigerant

Model Name

Function

V, Ph, Hz

5

R410A

MRBT-60CWN1-D

Cooling + EAH

220V- 3Ph~60Hz

6.2

MRBT-062CWN1-D

Cooling

6.2

MRCT-062EWN1-D

Cooling + EAH

7.5

MRBT-075CWN1-D

Cooling

7.5

MRCT-075EWN1-D

Cooling + EAH

8.5

MRBT-085CWN1-D

Cooling

8.5

MRCT-085EWN1-D

Cooling + EAH

10

MRBT-100CWN1-D

Cooling

10

MRCT-100EWN1-D

Cooling + EAH

12.5

MRBT-125CWN1-D

Cooling

15

MRBT-150CWN1-D

Cooling

15

MRCT-150EWN1-D

Cooling + EAH

15

MRBT-150HWN1-D

Heating & Cooling

17.5

MRBT-175CWN1-D

Cooling

17.5

MRCT-175EWN1-D

Cooling + EAH

20

MRBT-200CWN1-D

Cooling

20

MRCT-200 EWN1-D

Cooling +EAH

Note: EAH- Electric auxiliary heater

5 Ton

6.2&7.5Ton

8.5&10 Ton

15&17.5&20 Ton

12.5 Ton

1. Models List

2. External Appearance

1

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

Refrigerate type

N1: R410A

Omit for R22

Wired controller

Function mode

C: Cooling only

E: Electric heater and Cooling

H: Cooling and heating

Cooling capacity (6.2ton)

XXX:ton

XX:kBtu/h

Working condition

Omit for T1 condition

T: Tropical application

Air outlet way

A: optional two air outlet ways: side and

bottom

B: optional two air outlet ways: side and

bottom

C: one air outlet way: side

D: one air outlet way: bottom

Rooftop package

Midea

M R 062 C W

N1

(A)

DT

Power supply

R: 380~415V,3Ph,50Hz

Q:220~240V,1Ph,50Hz

V/M:208~230V,1Ph,60Hz

D:220V,3Ph,60Hz

X:208~230V,3Ph,60Hz

C:380~415V,3Ph,60Hz

Omit for 208~230V,1Ph,60Hz

B

Product design sequence

A:The second design

Omit:The first design

3. Nomenclature

2

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

4. Feature & Benefit

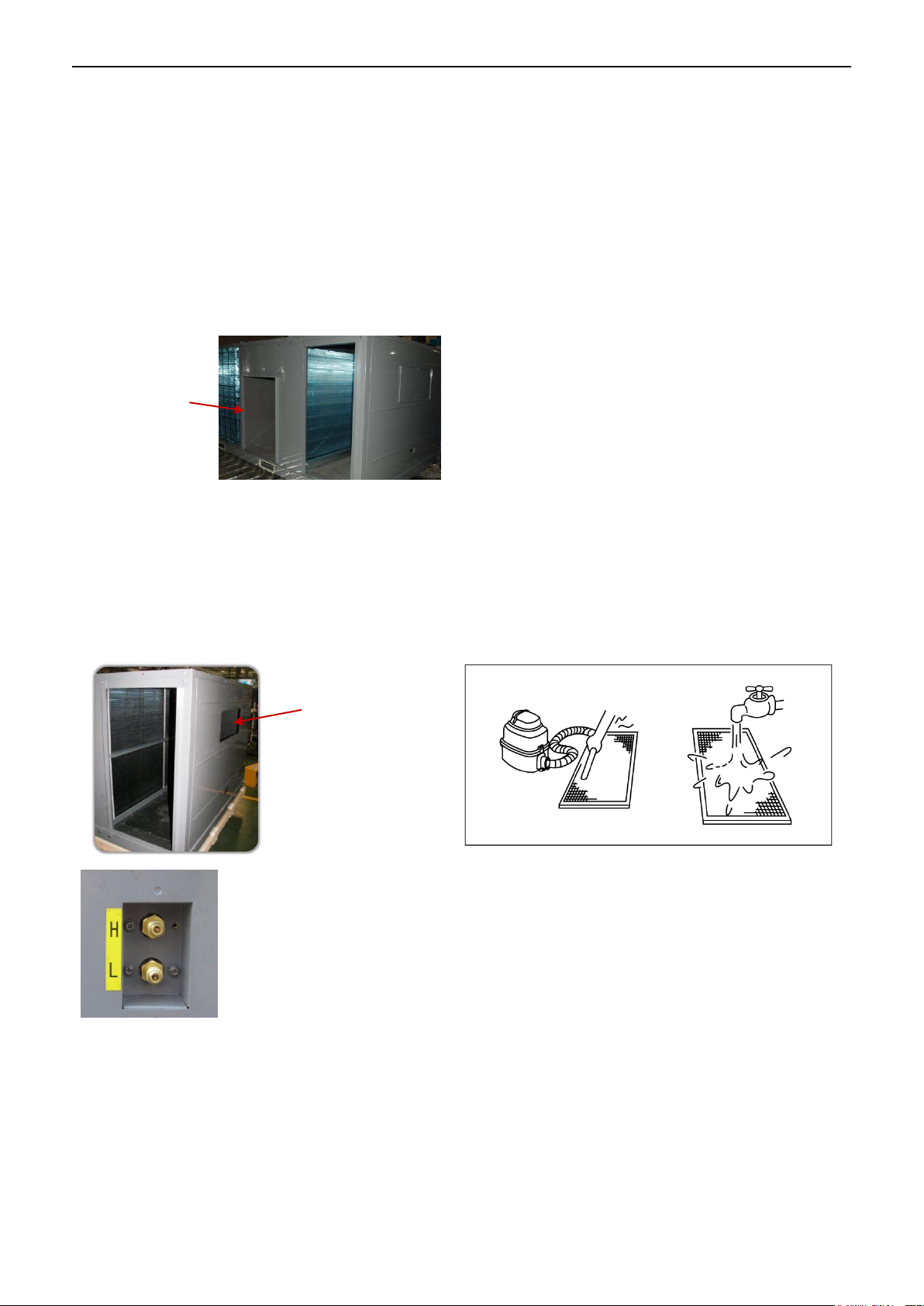

1. The adoption of anticorrosive-box

The reinforced anticorrosion by using galvanization armor plate and coated with man-composed paint.

The appearance is stylish and be easy for maintenance.

(It’s OK for 1000 hours salt spray test)

2. The adoption of credible protection system

2.1 The protection for compressor

High-pressure protection, low-pressure protection, compressor

current protection and so on the series’ protectors can ensure

compressor operating normally.

Adopts independent system, except for protections of sequence and

wire control output, any protection relate to its corresponding

compressor. Once a compressor protection energized, the

corresponding compressor will stop, others are still working.

2.2 Fan motor

The fan motors for evaporator have over-heat protection and

over-current protection function. The fan motors for condenser have the temperature controller

protection function.

3. Energy saving design

3.1 High efficiency compressor

Using technical compressor, heat exchanger and optimum connection pipe, the compressor can startup

under low power input. Provide maximum reliability, efficiency and quiet

operation.

Two refrigerant circuits on larger units (above 12.5ton) provide efficient part load

performance.

Standard low and high pressure safety switches.

Nice compressor control

Compressor staging is controlled directly by the indoor temperature. When the

indoor temperature is warmer than the setting, cooling is staged up; when the

indoor temperature is cooler than the setting, cooling is staged down. However, a

stage change can only occur when the indoor temperature is outside the dead

band. Staging is constrained by an inter-stage delay timer. These constraints

protect the compressors from short cycling while eliminating temperature

variations near the diffusers.

3.2 Condenser

By using high-efficient thin fin, the condenser has high-efficient heat exchanger, the energy waste

decreases greatly.

3.3 Evaporator

By using the high-efficient, super thin fin and inner-whorl copper pipe, the evaporators get the higher

capacity and the lower noise level.

3.4 The heat insulation of indoor unit

The heat insulation of indoor unit can availably decrease heat loss.

3.5 The control and refrigerant cycle system

There are two independent control systems and refrigerant cycle system, the capacity output is adjusted

automatically depending on different demand, save energy when one control system is in running

according to low capacity output.

3

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

Fresh air inlet

(except for 5ton)

Flange

4. Optional collocation

4.1 Operation in high temperature

The air-conditioner designed for high temperature can run until the ambient temperature reaches up to

52℃(125℉).

4.2 Strong air flow

Large air volume from the air inlet is forced ventilating by the condenser fan.

4.3 Minimum installation arrangement

The installation is fast and low cost with the easy installation and ready operation.

4.4 Pre-drilled duct flange

Flanges are prepared at the supply and return duct connections so that they can reduce duct connection

work at site.

4.5 Quiet operation

Noise and vibration have been effectively reduced by adopting new style hermetic compressor. The

centrifugal fan and fan casing are optimum shaped for efficient and low noise operation.

5. Cabinet

5.1 Sloped drain pan and drain pipe.

5.2 Cabinets have forklift and lifting holes for easy transportation.

5.3 Cabinets have fresh air function, and the filter can be washable.

5.4 External pressure gauge port.

The external pressure gauge port, which is identified permanently and clearly the

embossed wording, H is high pressure connection and L is low pressure connection.

With the gauge port mounted externally, an accurate diagnostic for system

operation can be quick and easy without disrupting airflow.

5.5 Durable construction.

Weather-resistant construction with capped seams and sloped top panels.G90 galvanized heavy gauge

plate conforming to ASTM-A-653, Zinc content of galvanized plate is 275 g/m2.

4

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

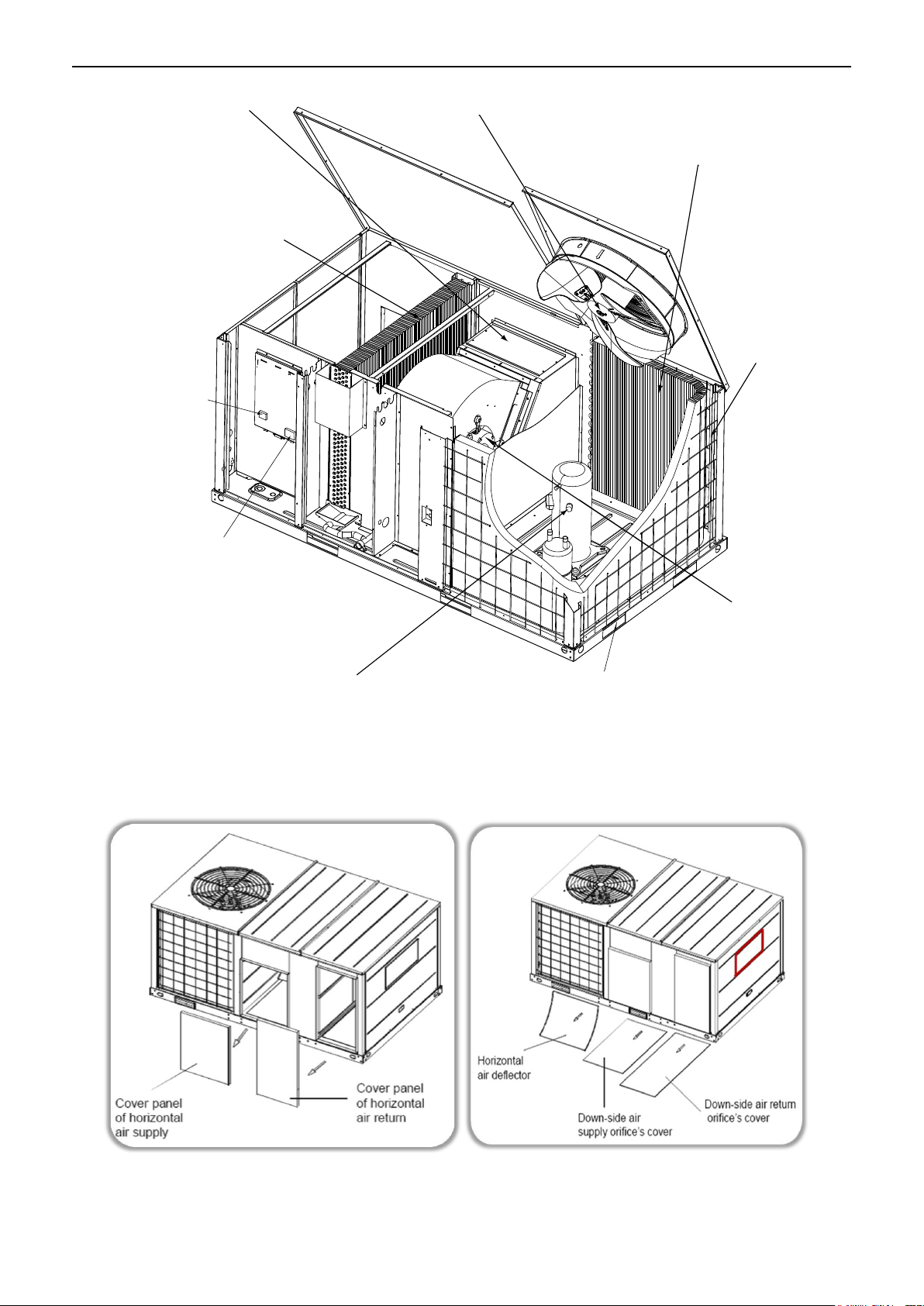

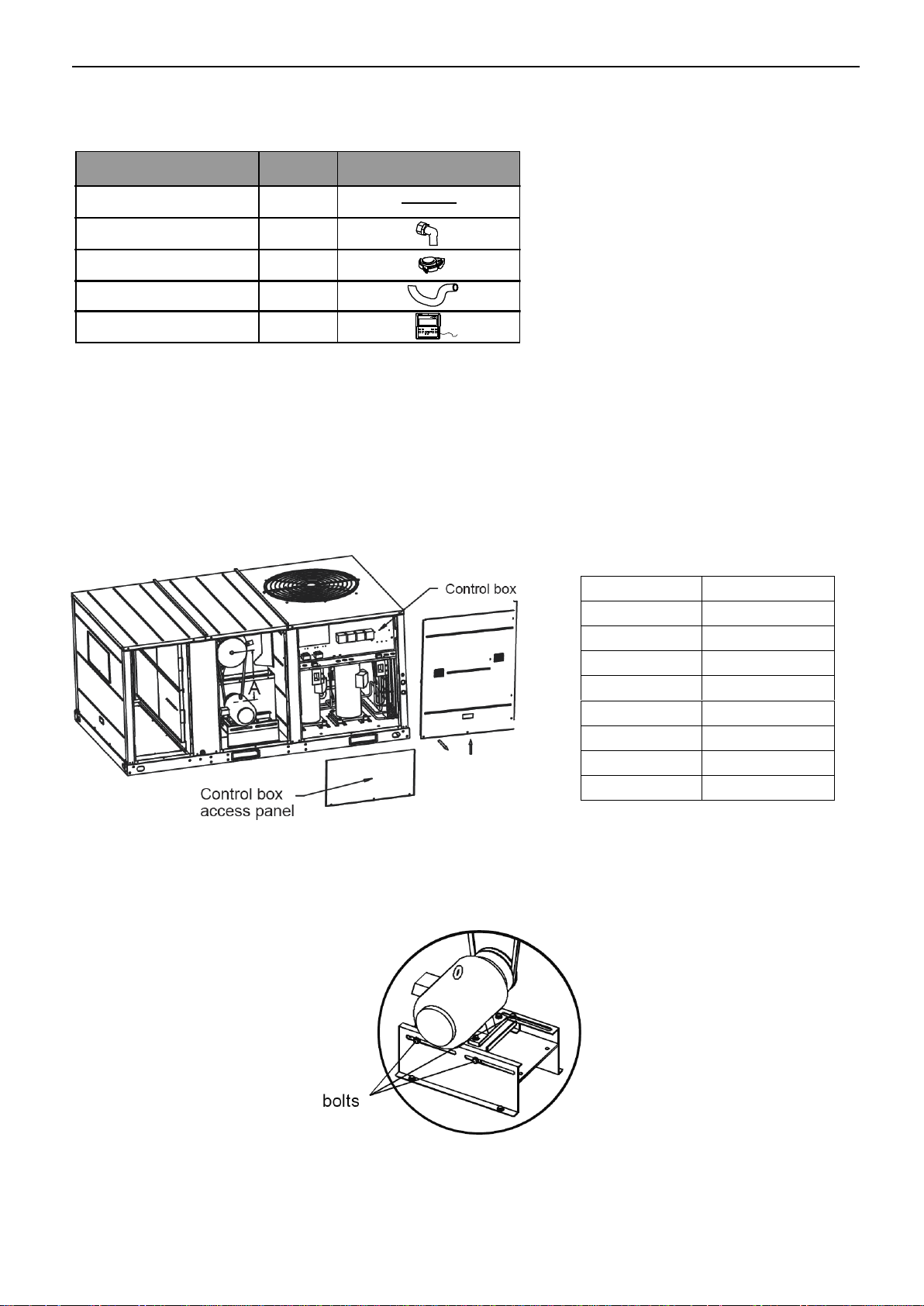

Compressor

Highly efficient enhanced

copper tube / aluminum fin

indoor coil

Compressor

contactor

Low voltage

terminal block

Blower motor with

slide-out blower assembly

Decorative

protective coil

guard

Heavy gauge removable

base rails

Condenser fan motor

Electric heater assembly (optional)

Highly efficient enhanced copper

tube/Aluminum fin outdoor coil

5ton

6. Optional supply/return airflow design, from side or bottom, It could be flexibly

applied to multi-position. The rooftop or ground installation is optional.

7. Certification of the compressor

The compressors have CE certified, UL certified.

5

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

5. List of Function

5.1 Standard specification

A. General

The Packaged cooling or combination heating and cooling unit is suitable for mounting on the roof or

ground. The packaged unit consists of scroll compressors, evaporator coil, condenser coil, control wiring

and interconnecting piping- all factories assembled and mounted on heavy gauge G-90 galvanized steel

sheet press formed base, ready for field connection to utilities and ducts. The packaged unit is of rigid

construction with holes provided in the base rails for overhead rigging. The unit is provided with an integral

weather resistant control panel.

These units are rated and tested in accordance with ARI standard 210/ARI 360.

B. Unit enclosure

Panels are of heavy gauge, G-90 galvanized steel sheet with removable access panels, completely

weatherized for outdoor installation and properly reinforced and brazed. Panels and access door are

provided for inspection and access for all internal parts. Enclosures are provided with adequately

reinforced points of support for setting in the unit. Steel sheet panels are zinc-coated and galvanized by the

hot dip process of lock forming quality conforming to ASTM A 653 commercial weight G-90, followed by

baked on electrostatic polyester dry powder coat paint, on all external panel.

C. Compressor

Compressors are scroll for all the models. They are provided with all the standard controls and accessories

necessary for safe operation. These are equipped with internal motor protector; factory installed crank case

heater and rubber vibration isolator for quiet and efficient operation.

D. Air-cooled condensing section

1. The air-cooled condensing section is enclosed within the unit housing and consists of condenser coil,

fan(s) electric motor(s) and inherently protected compressor(s). As an option, enhanced coated aluminum

fins may be provided. Tube support sheets are galvanized steel, formed to provide structural strength.

2. Fans are propeller type, direct driven, upward discharge and provided with fan grille mounted on the

casing.

3. Motors are totally enclosed air-over type with class F insulation. Inherent thermal protection is automatic

reset type.

E. Evaporator coil section

1. All cooling coils are of enhanced louvered fins and inner grooved copper tubes with wall thickness of

0.3mm, mechanically bonded to aluminum fins. Return bend has 0.022 inch thickness (0.56mm). As option,

enhanced coated aluminum fins may be provided. Tube support sheets are galvanized steel, formed to

provide structural strength.

2. Drainage pan: An insulated drainage pan made of G-90 galvanized steel is provided, for additional

corrosion protection.

3. Insulation: Insulation is supplied in adequate density and thickness for all units to prevent condensation

from forming on the unit casing. Insulation meets the requirements of NFPA 90A and is protected against

deterioration and erosion from air currents.

F. Evaporator fan

Evaporator fan is of centrifugal forward-curved blade design capable of handling total required CFM and

static pressure in the low and the medium ranges. Casings are made of galvanized steel. Blower motors

are of open drip proof type (totally enclosed types are optional) and conform to NEMA MG-1 and MG-2.

Blower motor is mounted on adjustable base and secured by locking device. Fan wheels shafts and

bearing are selected to operate at 25% below first critical speed. Pillow block bearing are selected for at

200,000 hours average life at design operating conditions. Shaft is turned, ground and polished from solid

6

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

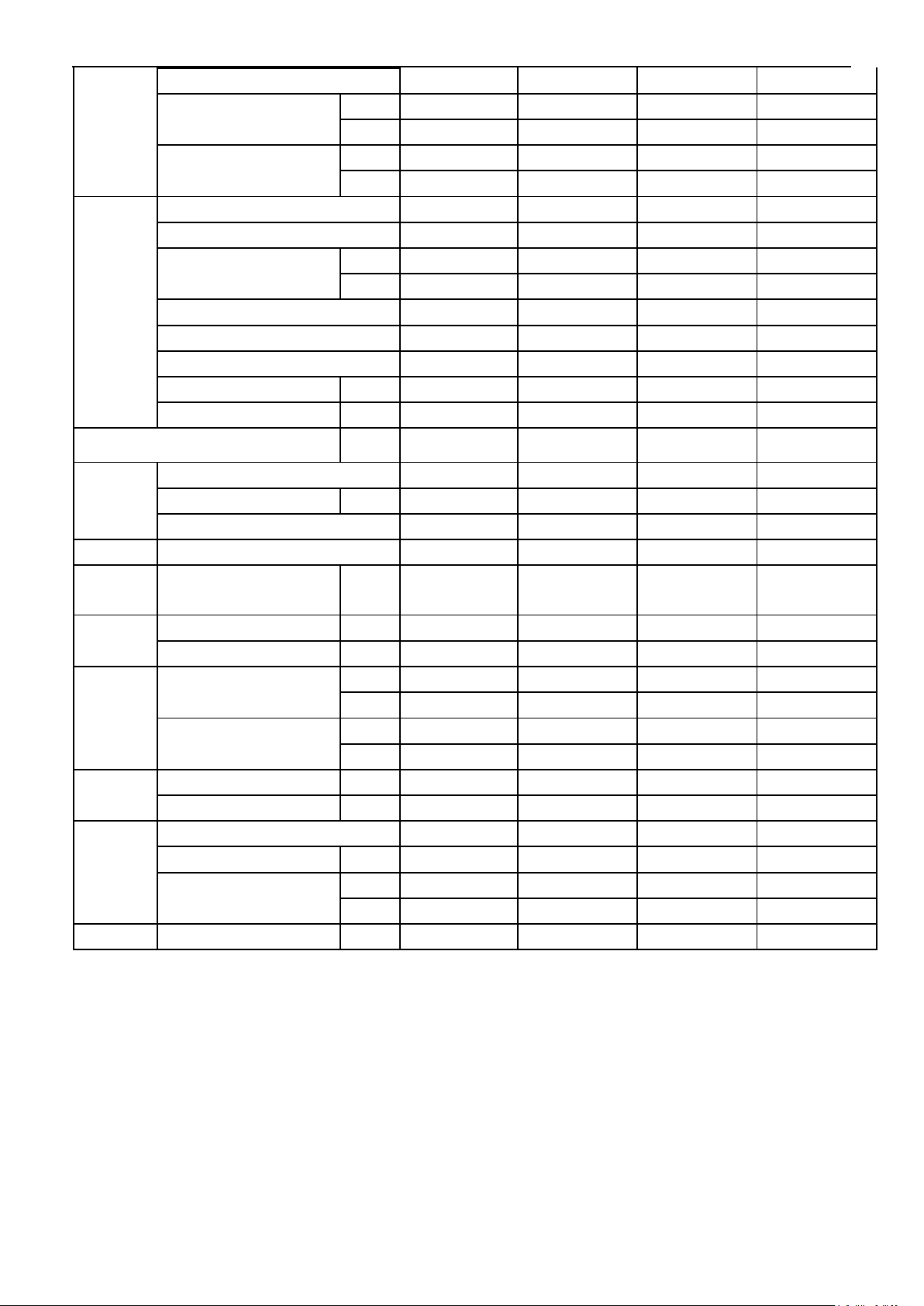

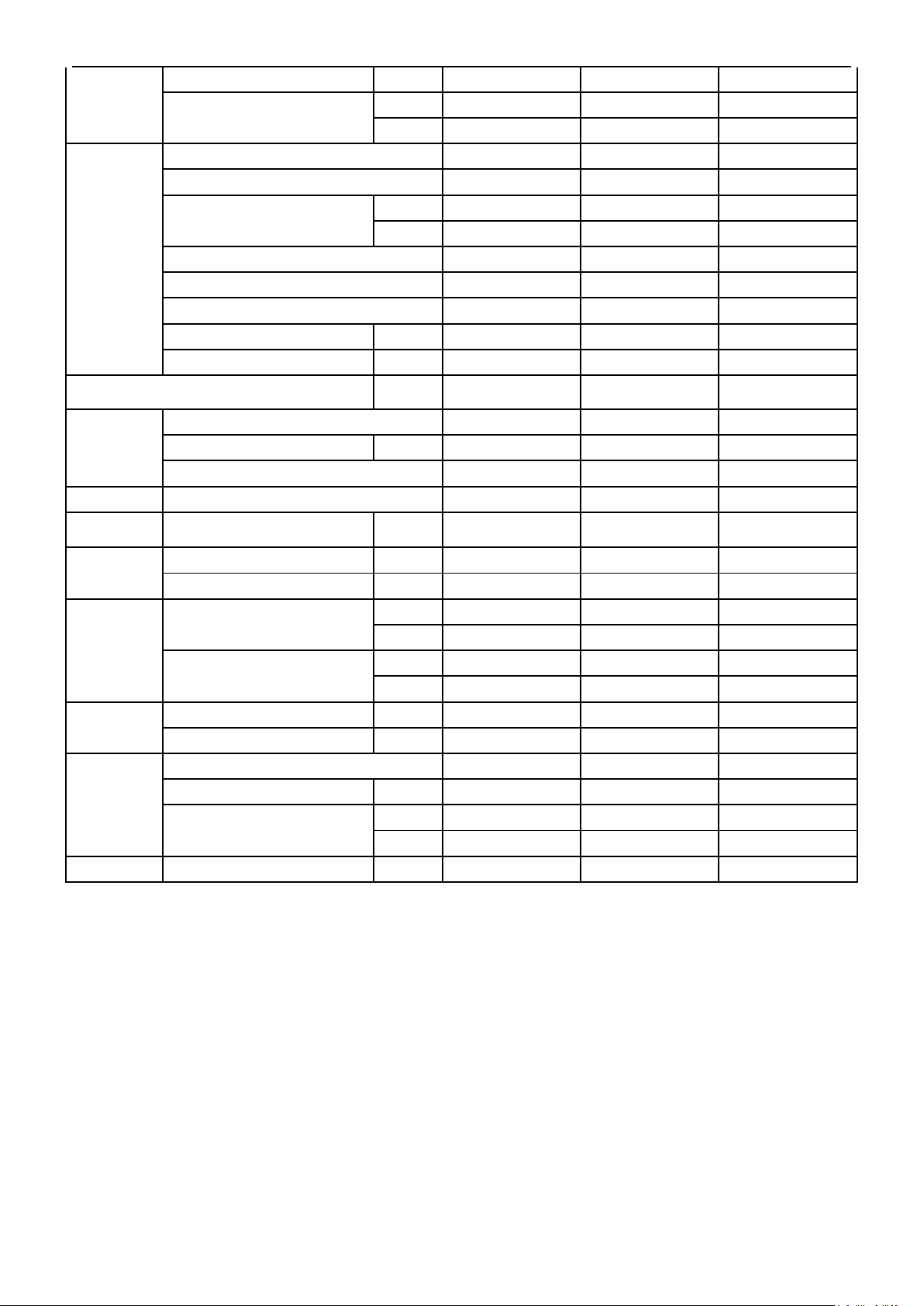

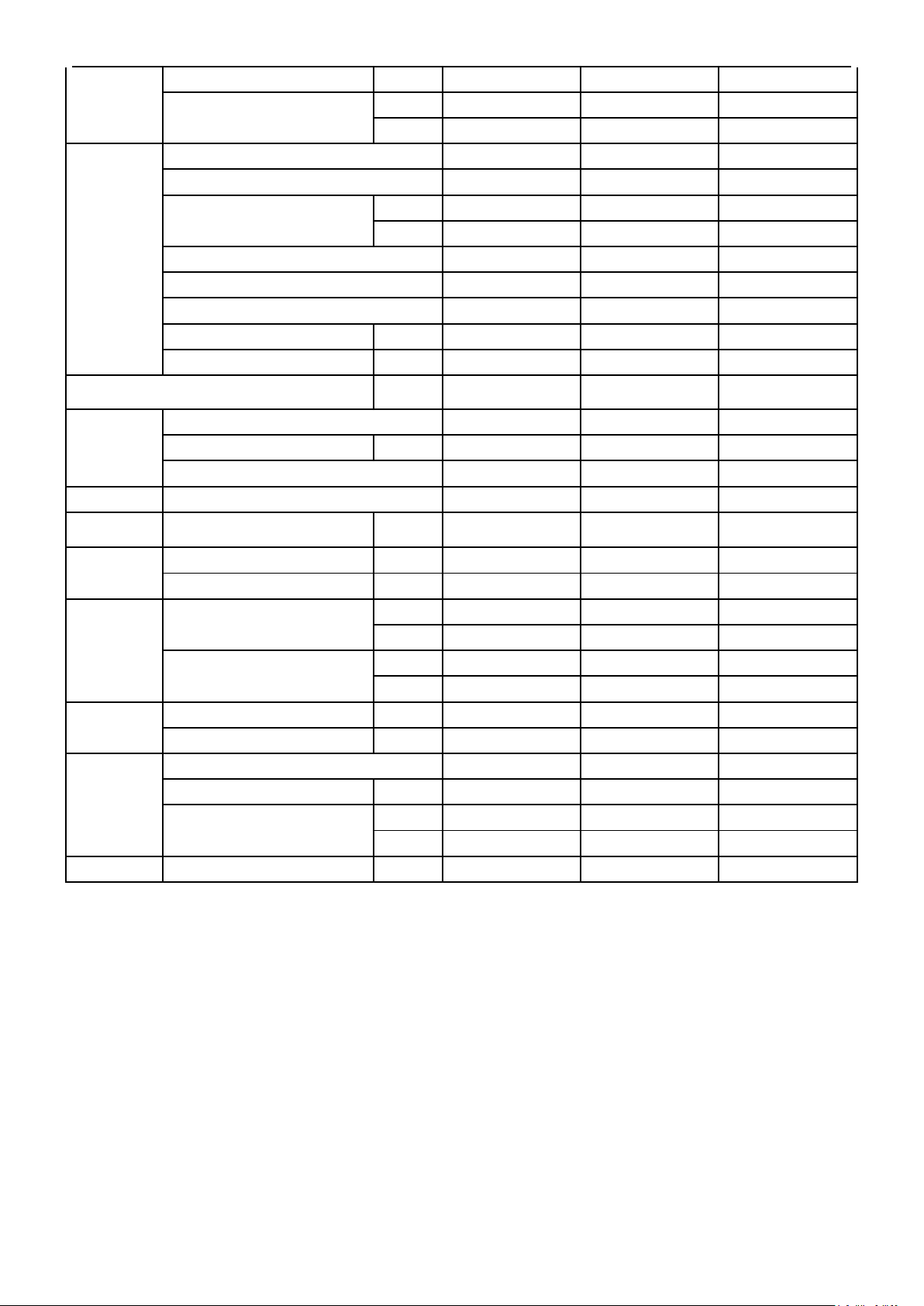

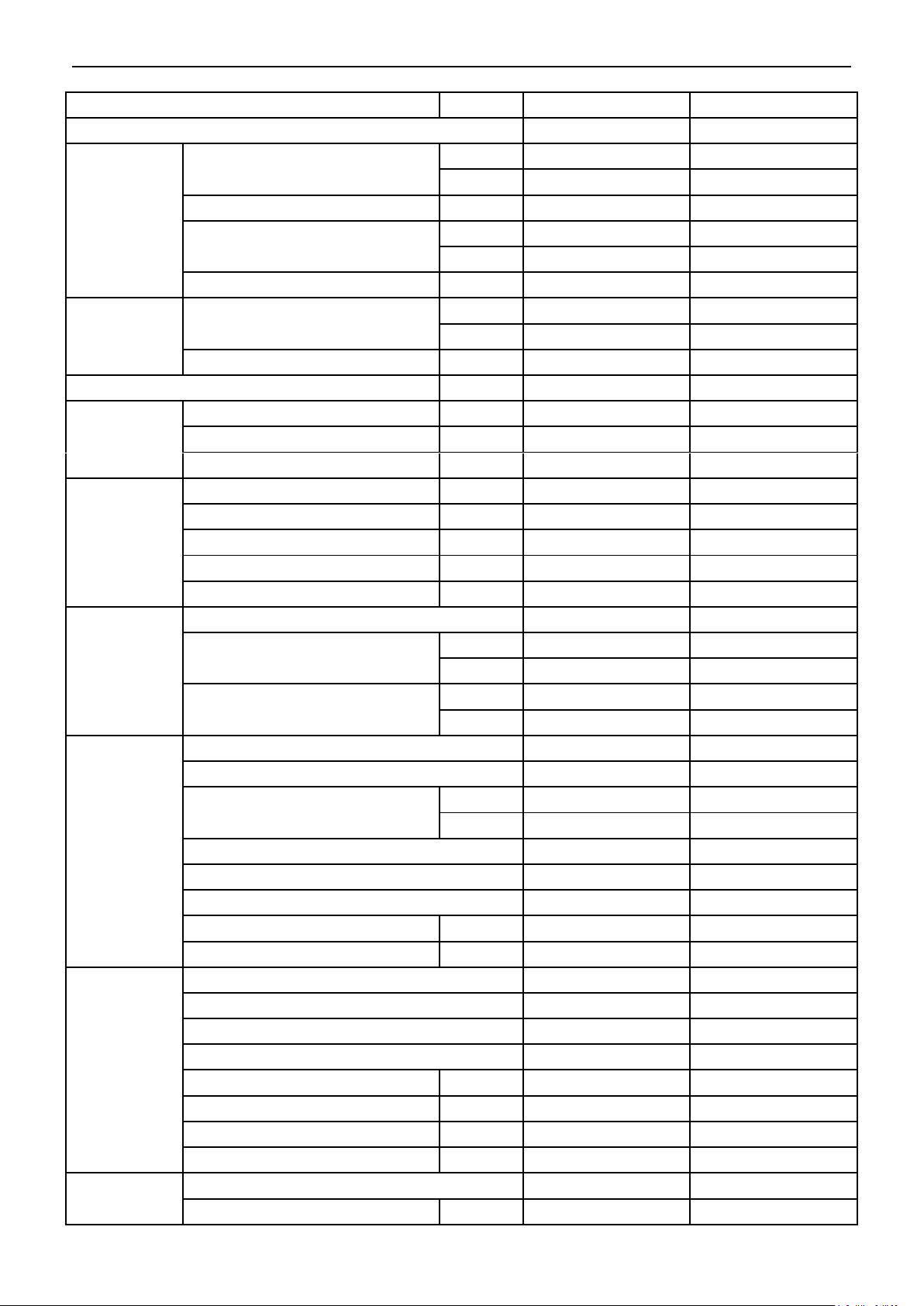

Description

Standard feature

Option

(factory installed)

Accessory

(field installed)

Horizontal discharge

◆

Compressor crankcase heater

◆

Evaporator fan-belt driven

◆

Evaporator fan motor-ODP type(TEFC type optional)

◆

Condenser fan-direct drive, propeller type(Except 5ton)

◆

Condenser fan-direct drive, axial type(Only 5ton)

◆

Condenser fan motor-totally enclosed air-over type

◆

Electric heater ◆

◆

Filter, Nylon(Thickness 10&12.5mm, except 5ton)

◆

Filter, aluminum(Thickness 25mm)

◆

Compressor overload protection

◆

Low pressure switch

◆

High pressure switch

◆

Cooling & heating thermostat

◆

Condenser fan guard

◆

Condenser coil guard

◆

Wired controller KJR-23B

◆

Wired controller KJR-25B

◆

Wired controller KJR-12B

◆

Drainage pipe

◆

Drainage outlet

◆

Snap ring

◆

steel. Fans and pulleys are keyed to shaft and designed for continuous operation at maximum motor horse

power and fan speed. All rotating components and assemblies are statically and dynamically balanced and

every unit is vibration tested before shipment from the factory.

G. Electronic thermostat

General information: A dedicated electronic thermostat is supplied with unit controls as standard. This

thermostat controls one or two stage heating and cooling applications. The thermostat normally displays

room temperature and mode of operation.

The temperature can be set by up/down buttons for both cooling and heating cycles. The thermostat also

allows you to select continuous fan operation, or have the fan on intermittent operation with the equipment.

It also displays the status of unit, thus providing maximum information for the end user.

5.2 Electric heater

Electric heater is the resistance coil type and conforms to the requirement of UL 573 or equivalent.

Electrical characteristic, kW capacity and number of stages are indicated. Airflow switch, fusible link and

overheat limit thermostat are provided to shut-off power in case of airflow failure/overheat. Electric heater

kit is installed as an externally mounted kit at the supply opening.

5.3 Standard feature/option/accessory

7

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

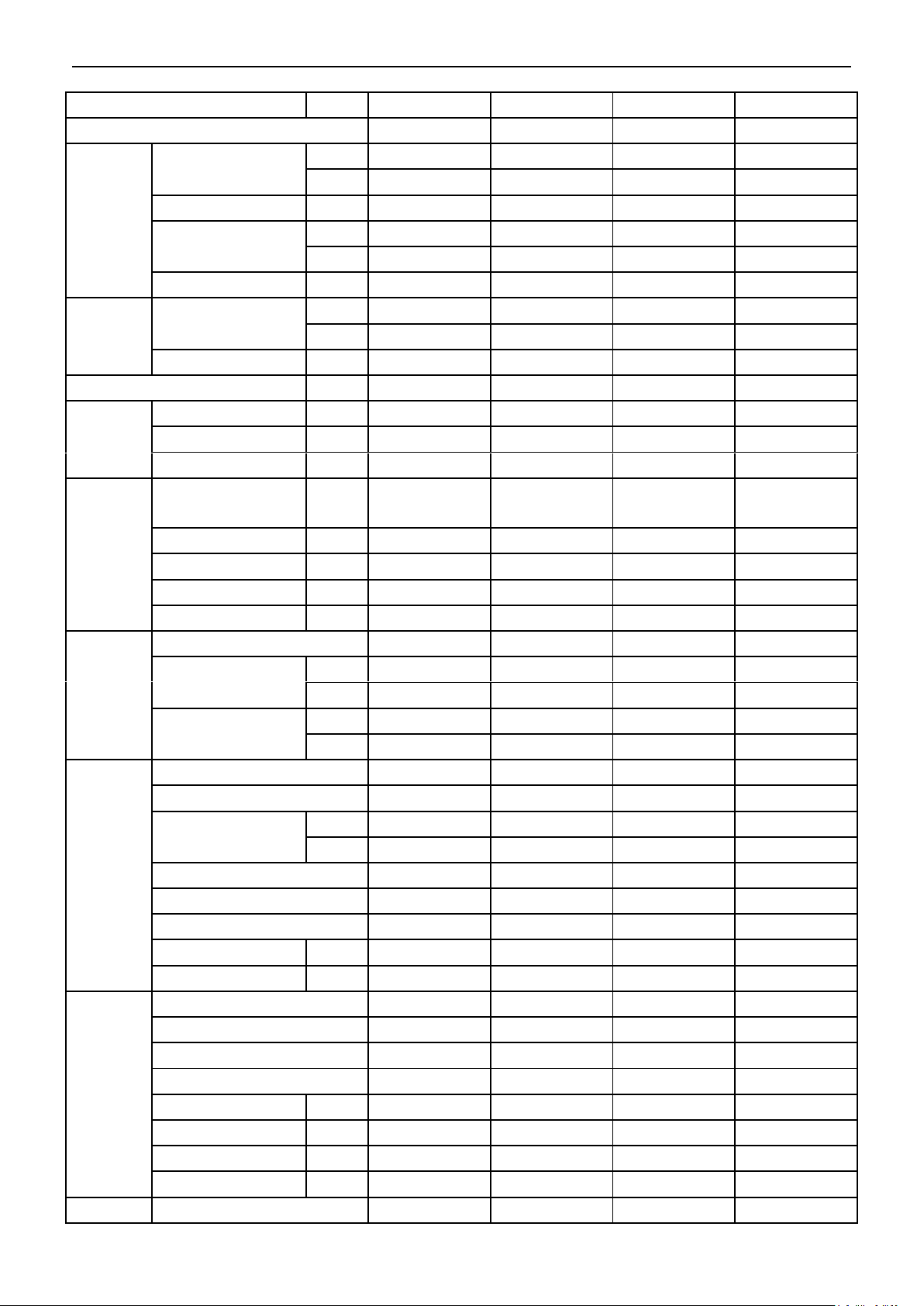

Nominal ton

(Ton) 5 6.2

6.2

7.5

Model

MRBT-60CWN1-D

MRBT-062CWN1-D

MRCT-062EWN1-D

MRBT-075CWN1-D

Cooling

Cooling Capacity (1)

Btu/h

59000

75000

75000

89000

kW

17

22

22

26

Power Input (1)

kW

5.6

7.7

7.7

9.2

Cooling Capacity (2)

Btu/h

51200

62700

62700

74500

kW

15

18.4

18.4

21.8

Power Input (2)

kW

7.5

8.6

8.6

9.9

Heating

Heating Capacity

Btu/h - -

47800

-

kW - -

14

-

Power Input

kW - -

14

-

Capacity steps

%

0/100

0/100

0/100

0/100

Electrical

data

Power supply

V/Ph/Hz

220/3/60

220/3/60

220/3/60

220/3/60

Max. input consumption

kW

8.3

13.2

13.2

13.2

Max. current A 28.5

42

42

42

Performance

Indoor fan air flow (High speed)

CFM

1970

2600

2600

3000

ESP

Pa

70

60

60

60

EER 1

Btu/h/W

10

9.7

9.7

9.7

EER 2

Btu/h/W

6.8

7.4

7.4

7.3

COP

Btu/h/W / / / /

Indoor Coil

Number of rows

4 2 2

2

Fin spacing

mm

1.6

1.6

1.6

1.6

inch

1/16''

1/16''

1/16''

1/16''

Tube diameter

mm

7.94

7.94

7.94

7.94

inch

5/16''

5/16''

5/16''

5/16''

Indoor fan

Type

FC centrifugal

FC centrifugal

FC centrifugal

FC centrifugal

Quantity 1 1 1 1

Diameter(Width)

mm

282

254

254

254

inch

11.1

10

10

10

Drive type

Direct

Belt

Belt

Belt

Motors quantity

1 1 1

1

Motor model

YDK600-6E

YFD90L-4

YFD90L-4

YFD90L-4

Motor output

kW

0.6 2 2

2

Motor rpm

r/min

1004

1120

1120

1120

Compressor

Type

Scroll

Scroll

Scroll

Scroll

Quantity 1 1 1 1

Model

ZP57K3E-TF5-522

SH090A3ALC

SH090A3ALC

SH090A3ALC

Brand

Copeland

Danfoss

Danfoss

Danfoss

Capacity

Btu/h

58000

92465

92465

92465

Input

kW

5.5

8.569

8.569

8.569

Rated current(RLA)

A

22.9

30.7

30.7

30.7

Refrigerant oil charge

ml

1656

3000

3000

3000

6. Specification

8

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

Outdoor Coil

Number of rows

2 3 3

3

Fin spacing

mm

1.3

1.6

1.6

1.6

inch

1/16"

1/16"

1/16"

1/16"

Tube diameter

mm

7.94

7.94

7.94

7.94

inch

5/16"

5/16"

5/16"

5/16"

Outdoor Fan

Type

Axial fan

Propeller

Propeller

Propeller

Quantity 1 1 1 1

Diameter(Width)

mm

600

650

650

650

inch

23.62

25.6

25.6

25.6

Drive type

direct

Direct

Direct

Direct

Motors quantity

1 1 1

1

Motor model

YDK230-6G-1

YS1000-6B

YS1000-6B

YS1000-6B

Motor output

kW

0.23

1.11

1.11

1.11

Motor rpm

r/min

1080

1120

1120

1120

Outdoor sound level(sound pressure level )

dB(A)

62.9

70.3

70.3

70.3

Refrigerant

Type

R410A

R410A

R410A

R410A

Refrigerant volume

Kg

3.6

5.6

5.6

5.6

Refrigerant Control

Capillary

Capillary

Capillary

Capillary

Controller

Wired controller type

KKJR-12B

KJR-12B

KJR-12B

KJR-12B

Operation

temp

℃

17~30

17~30

17~30

17~30

Ambient

temp

Cooling ℃ 18~52

18~52

18~52

18~52

Heating ℃ - - -

-

Dimensions

Net(W×H×D)

mm

1920X840X1068

1630X1065X1068

1630X1065X1068

1630X1065X1068

inch

75.6X33.1X42

64.2 X 41.9 X 42

64.2 X 41.9 X 42

64.2 X 41.9 X 42

Packing(W×H×D)

mm

1955X870X1085

1700X1110X1160

1700X1110X1160

1700X1110X1160

inch

77X34.3X42.7

66.9 X 43.7 X 45.7

66.9 X 43.7 X 45.7

66.9 X 43.7 X 45.7

Weight

Net weight

Kg(Ibs)

228(503)

315(694.4)

323(712)

315(694.4)

Gross weight

Kg(Ibs)

232(511)

335(738.5)

343(756)

335(738.5)

Filter

Type

Nylon

Nylon

Nylon

Nylon

Quantity

Pieces 1 2 2 2

Size (W×H×D)

mm

410 X 495 X 25

447 X 885 X 10

447 X 885 X 10

447 X 885 X 10

inch

16.1X19.5X1

17.6 X34.8 X0.4

17.6 X34.8 X0.4

17.6 X34.8 X0.4

Shipping

Qty'Per 20'/40'/40'HQ

Pieces

12/24/36

12/28/28

12/28/28

12/28/28

Note:

The data are based on the following conditions:

Cooling: (1): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 35°C(95°F) DB.

Heating and Power input: Indoor Temperature 20°C(68°F) DB/15°C(59°F) WB; - Outdoor Temperature 7°C(44.6°F) DB/6°C(42.8°F) DB

Electrical data: Indoor Temperature 32°C(90°F) DB / 24°C(74°F) WB; - Outdoor Temperature 52°C(125°F) DB

(2): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 46°C(114°F) DB.

9

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

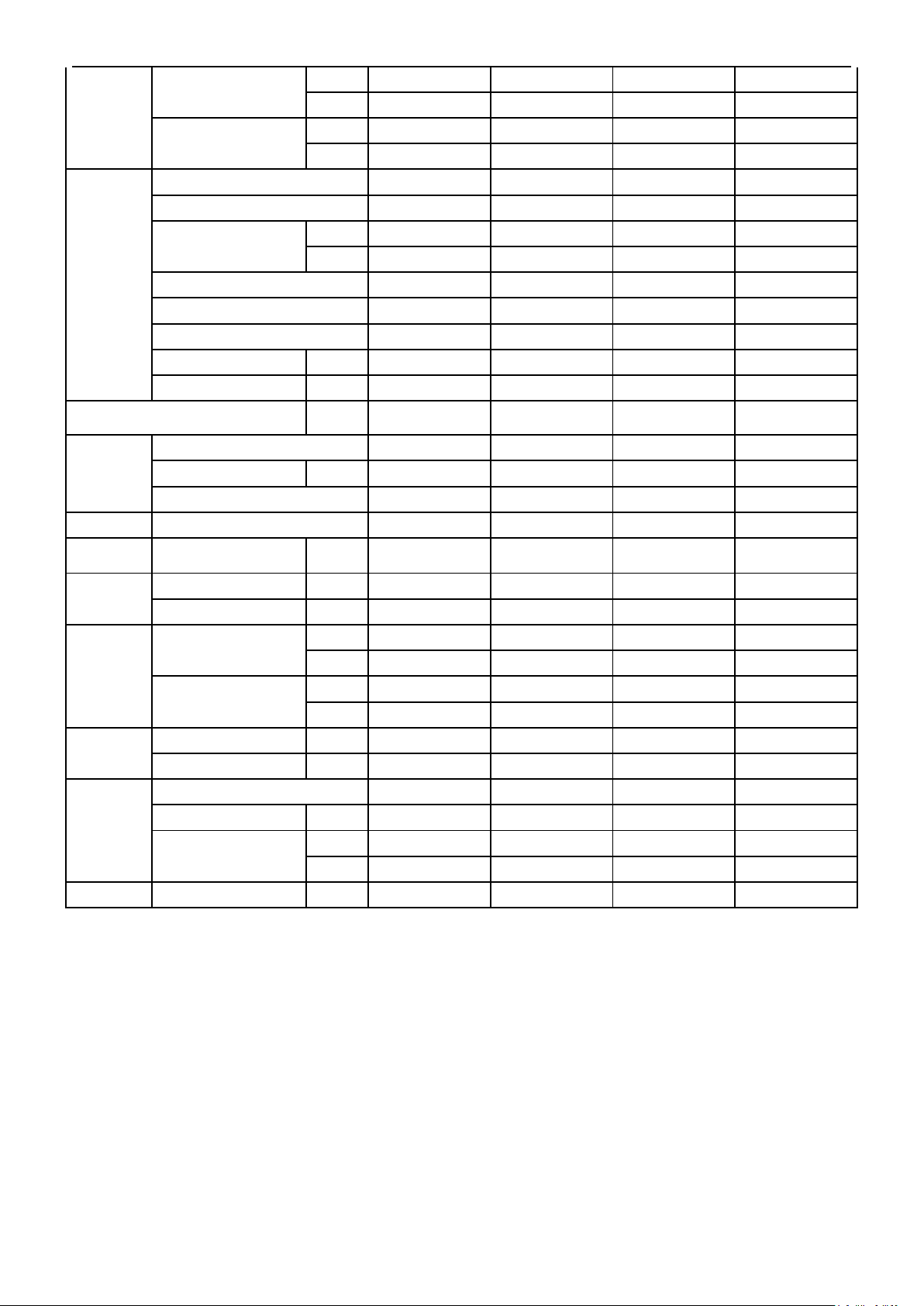

Nominal ton

(Ton)

7.5

8.5

8.5

10

Model

MRCT-075EWN1-D

MRBT-085CWN1-D

MRCT-085EWN1-D

MRBT-100CWN1-D

Cooling

Cooling Capacity (1)

Btu/h

89000

103000

103000

120000

kW

26

30

30

35

Power Input (1)

kW

9.2

10.4

10.4

11.4

Cooling Capacity (2)

Btu/h

74500

85600

85600

100000

kW

21.8

25.1

25.1

29.3

Power Input (2)

kW

9.9

11.4

11.4

13.6

Heating

Heating Capacity

Btu/h

47800 - 71700

-

kW

14 - 21

-

Power Input

kW

14 - 21

-

Capacity steps % 0/100

0/100

0/100

0/100

Electrical data

Power supply

V/Ph/Hz

220/3/60

220/3/60

220/3/60

220/3/60

Max. input consumption

kW

13.2

14.7

14.7

16.8

Max. current A 42

47.1

47.1

55

Performance

Indoor fan air flow (High

speed)

CFM

3000

3600

3600

3800

ESP

Pa

60

75

75

75

EER 1

Btu/h/W

9.7

9.8

9.8

10.5

EER 2

Btu/h/W

7.3

7.7

7.7

7.4

COP

Btu/h/W / / / /

Indoor Coil

Number of rows 2 3 3 3

Fin spacing

mm

1.6

1.4

1.4

1.4

inch

1/16''

1/18''

1/18''

1/18''

Tube diameter

mm

7.94

7.94

7.94

7.94

inch

5/16''

5/16''

5/16''

5/16''

Indoor fan

Type

FC centrifugal

FC centrifugal

FC centrifugal

FC centrifugal

Quantity 1 1 1 1

Diameter(Width)

mm

254

305

305

305

inch

10

12

12

12

Drive type

Belt

Belt

Belt

Belt

Motors quantity 1 1 1 1

Motor model

YFD90L-4

YFD90L-4

YFD90L-4

YFD90L-4

Motor output

kW 2 1.5

1.5

2.2

Motor rpm

r/min

1120

1400

1400

1120

Compressor

Type

Scroll

Scroll

Scroll

Scroll

Quantity 1 1 1 1

Model

SH090A3ALC

SH105A4ALC

SH105A4ALC

SH120A3ALC

Brand

Danfoss

Danfoss

Danfoss

Danfoss

Capacity

Btu/h

92465

119000

119000

1113000

Input

kW

8.569

10.862

10.862

11.246

Rated current(RLA)

A

30.7

21.4

21.4

43.6

Refrigerant oil charge

ml

3000

3300

3300

3300

Outdoor Coil

Number of rows 3 3 3 3

10

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

Fin spacing

mm

1.6

1.6

1.6

1.6

inch

1/16"

1/16"

1/16"

1/16"

Tube diameter

mm

7.94

7.94

7.94

7.94

inch

5/16"

5/16"

5/16"

5/16"

Outdoor Fan

Type

Propeller

Propeller

Propeller

Propeller

Quantity 1 1 1 1

Diameter(Width)

mm

650

700

700

700

inch

25.6

27.6

27.6

27.6

Drive type

Direct

Direct

Direct

Direct

Motors quantity 1 1 1 1

Motor model

YS1000-6B

YS1100-6

YS1100-6

YS1000-6B

Motor output

kW

1.11

1.1

1.1

1.1

Motor rpm

r/min

1120

940

940

1120

Outdoor sound level(sound pressure level )

dB(A)

70.3

72.2

72.2

72.2

Refrigerant

Type

R410A

R410A

R410A

R410A

Refrigerant volume

Kg

5.6

6.7

6.7

6.5

Refrigerant Control

Capillary

Capillary

Capillary

Capillary

Controller

Wired controller type

KJR-12B

KJR-12B

KJR-12B

KJR-12B

Operation temp

℃

17~30

17~30

17~30

17~30

Ambient temp

Cooling ℃ 18~52

18~52

18~52

18~52

Heating ℃ - - -

-

Dimensions

Net(W×H×D)

mm

1630X1065X1068

2165X1021X1335

2165X1021X1335

2165X1021X1335

inch

64.2 X 41.9 X 42

85.2 X 40.2 X 52.6

85.2 X 40.2 X 52.6

85.2 X 40.2 X 52.6

Packing(W×H×D)

mm

1700X1110X1160

2220X1140X1415

2220X1140X1415

2220X1140X1415

inch

66.9 X 43.7 X 45.7

87.4 X 44.9 X 55.7

87.4 X 44.9 X 55.7

87.4 X 44.9 X 55.7

Weight

Net weight

Kg(Ibs)

323(712)

445(981)

455(1003)

445(981)

Gross weight

Kg(Ibs)

343(756)

458(1009.7)

468(1031.7)

458(1009.7)

Filter

Type

Nylon

Nylon

Nylon

Nylon

Quantity

Pieces 2 2 2 2

Size (W×H×D)

mm

447 X 885 X 10

566 X 814 X 10

566 X 814 X 10

566 X 814 X 10

inch

17.6 X34.8 X0.4

22.3 X 32X0.4

22.3 X 32X0.4

22.3 X 32X0.4

Shipping

Qty'Per 20'/40'/40'HQ

Pieces

12/28/28

8/16/16

8/16/16

8/16/16

Note:

The data are based on the following conditions:

Cooling: (1): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 35°C(95°F) DB.

(2): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 46°C(114°F) DB.

Heating and Power input: Indoor Temperature 20°C(68°F) DB/15°C(59°F) WB; - Outdoor Temperature 7°C(44.6°F) DB/6°C(42.8°F) DB

Electrical data: Indoor Temperature 32°C(90°F) DB / 24°C(74°F) WB; - Outdoor Temperature 52°C(125°F) DB

11

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

Nominal ton

(Ton)

10

12.5

15

Model

MRCT-100EWN1-D

MRBT-125CWN1-D

MRBT-150CWN1-D

Cooling

Cooling Capacity (1)

Btu/h

120000

150000

180000

kW

35

43

53

Power Input (1)

kW

11.4

15.3

18.1

Cooling Capacity (2)

Btu/h

100000

125600

159600

kW

29.3

34.2

46.7

Power Input (2)

kW

13.6

16.8

20.2

Heating

Heating Capacity

Btu/h

71700 - -

kW

21 - -

Power Input

kW

21 - -

Capacity steps

%

0/100

0/50/100

0/50/100

Electrical data

Power supply

V/Ph/Hz

220/3/60

220/3/60

220/3/60

Max. input consumption

kW

16.8

20.9

26.8

Max. current A 55

69.2

87.9

Performance

Indoor fan air flow (High speed)

CFM

3800

5200

6600

ESP

Pa

75

90

90

EER 1

Btu/h/W

10.5

9.8

10

EER 2

Btu/h/W

7.4

7.5

7.5

COP

Btu/h/W / /

/

Indoor Coil

Number of rows 3 3

3

Fin spacing

mm

1.4

1.5

1.4

inch

1/18''

1/16''

1/18''

Tube diameter

mm

7.94 7 7.94

inch

5/16''

9/32''

5/16''

Indoor fan

Type

FC centrifugal

FC centrifugal

FC centrifugal

Quantity 1 1

1

Diameter(Width)

mm

305

383

383

inch

12

15

15

Drive type

Belt

Belt

Belt

Motors quantity 1 1

1

Motor model

YFD90L-4

Y2-100L2-4

YFD132S-4

Motor output

kW

2.2 3 5

Motor rpm

r/min

1120

1700

1120

Compressor

Type

Scroll

Scroll

Scroll

Quantity 1 2

2

Model

SH120A3ALC

ZP72KCE-TF5-522

SH090A3ALC

Brand

Danfoss

Copeland

Danfoss

Capacity

Btu/h

111300

72000×2

92465

Input

kW

11.246

6.75×2

8.569

Rated current(RLA)

A

43.6

25.9×2

30.7

Refrigerant oil charge

ml

3300

1774×2

3000

Outdoor Coil

Number of rows

3

3.5

3

Fin spacing

mm

1.6

1.5

1.6

12

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

inch

1/16"

1/16"

1/16"

Tube diameter

mm

7.94 7 7.94

inch

5/16"

9/32"

5/16"

Outdoor Fan

Type

Propeller

Propeller

Propeller

Quantity 1 1

2

Diameter(Width)

mm

700

650

650

inch

27.6

25.6

25.6

Drive type

Direct

Direct

Direct

Motors quantity 1 1

2

Motor model

YS1000-6B

YS1000-6B

YS1000-6B

Motor output

kW

1.1

1.1

1.1 X 2

Motor rpm

r/min

1120

1120

1120

Outdoor sound level(sound pressure level )

dB(A)

72.2

72.3

72.4

Refrigerant

Type

R410A

R410A

R410A

Refrigerant volume

Kg

6.5

3.2+3.1

5.8 X 2

Refrigerant Control

Capillary

Capillary

Capillary

Controller

Wired controller type

KJR-12B

KJR-12B

KJR-12B

Operation temp

℃

17~30

17~30

17~30

Ambient temp

Cooling ℃ 18~52

18~52

18~52

Heating ℃ - - -

Dimensions

Net(W×H×D)

mm

2165X1021X1335

2230x1245x1425

2230 X1245X1824

inch

85.2 X 40.2 X 52.6

87.8X49X56

87.8 X 49X 71.8

Packing(W×H×D)

mm

2220X1140X1415

2265x1280x1455

2236 X1300X1855

inch

87.4 X 44.9 X 55.7

89.2X50.4X57.3

88 X 51.2 X 73

Weight

Net weight

Kg(Ibs)

445(981)

520(1146)

710/ (1565.3)

Gross weight

Kg(Ibs)

458(1009.7)

535(1179.5)

730(1609.3)

Filter

Type

Nylon

Nylon

Nylon

Quantity

Pieces 2 2

2

Size (W×H×D)

mm

566 X 814 X 10

605x1045x12.5

900 X 815 X 12.5

inch

22.3 X 32X0.4

23.8X41.1X0.5

35.4 X32 X 0.5

Shipping

Qty'Per 20'/40'/40'HQ

Pieces

8/16/16

4/8/16

3/6/12

Note:

The data are based on the following conditions:

Cooling: (1): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 35°C(95°F) DB.

(2): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 46°C(114°F) DB.

Heating and Power input: Indoor Temperature 20°C(68°F) DB/15°C(59°F) WB; - Outdoor Temperature 7°C(44.6°F) DB/6°C(42.8°F) DB

Electrical data: Indoor Temperature 32°C(90°F) DB / 24°C(74°F) WB; - Outdoor Temperature 52°C(125°F) DB

13

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

Nominal ton

(Ton)

15

17.5

17.5

Model

MRCT-150EWN1-D

MRBT-175CWN1-D

MRCT-175EWN1-D

Cooling

Cooling Capacity (1)

Btu/h

180000

205000

205000

kW

53

60

60

Power Input (1)

kW

18.1

20

20

Cooling Capacity (2)

Btu/h

159600

180600

180600

kW

46.7

52.9

52.9

Power Input (2)

kW

20.2

23.5

23.5

Heating

Heating Capacity

Btu/h

102400

-

102400

kW

30 - 30

Power Input

kW

30 - 30

Capacity steps

%

0/50/100

0/50/100

0/50/100

Electrical data

Power supply

V/Ph/Hz

220/3/60

220/3/60

220/3/60

Max. input consumption

kW

26.8

32.8

37.4

Max. current A 87.9

98.6

98.6

Performance

Indoor fan air flow (High speed)

CFM

6600

7300

7300

ESP

Pa

90

100

100

EER 1

Btu/h/W

10

10.2

10.2

EER 2

Btu/h/W

7.5

7.7

7.7

COP

Btu/h/W / /

/

Indoor Coil

Number of rows 3 3

3

Fin spacing

mm

1.4

1.4

1.4

inch

1/18''

1/18''

1/18''

Tube diameter

mm

7.94

7.94

7.94

inch

5/16''

5/16''

5/16''

Indoor fan

Type

FC centrifugal

FC centrifugal

FC centrifugal

Quantity 1 1

1

Diameter(Width)

mm

383

383

383

inch

15

15

15

Drive type

Belt

Belt

Belt

Motors quantity 1 1

1

Motor model

YFD132S-4

YFD132S-4

YFD132S-4

Motor output

kW 5 5

5

Motor rpm

r/min

1120

1120

1120

Compressor

Type

Scroll

Scroll

Scroll

Quantity 2 2

2

Model

SH090A3ALC

SH105A3ALC

SH105A3ALC

Brand

Danfoss

Danfoss

Danfoss

Capacity

Btu/h

92465

109530

109530

Input

kW

8.569

9.957

9.957

Rated current(RLA)

A

30.7

32.9

32.9

Refrigerant oil charge

ml

3000

3300

3300

Outdoor Coil

Number of rows 3 3

3

Fin spacing

mm

1.6

1.6

1.6

14

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

inch

1/16"

1/16"

1/16"

Tube diameter

mm

7.94

7.94

7.94

inch

5/16"

5/16"

5/16"

Outdoor Fan

Type

Propeller

Propeller

Propeller

Quantity 2 2

2

Diameter(Width)

mm

650

650

650

inch

25.6

25.6

25.6

Drive type

Direct

Direct

Direct

Motors quantity 2 2

2

Motor model

YS1000-6B

YS1000-6B

YS1000-6B

Motor output

kW

1.1X 2

1.11X 2

1.11X 2

Motor rpm

r/min

1120

1120

1120

Outdoor sound level(sound pressure level )

dB(A)

72.4

72.4

72.4

Refrigerant

Type

R410A

R410A

R410A

Refrigerant volume

Kg

5.8 X 2

4.5 X 2

4.5 X 2

Refrigerant Control

Capillary

Capillary

Capillary

Controller

Wired controller type

KJR-12B

KJR-12B

KJR-12B

Operation temp

℃

17~30

17~30

17~30

Ambient temp

Cooling ℃ 18~52

18~52

18~52

Heating ℃ - - -

Dimensions

Net(W×H×D)

mm

2230 X1245X1824

2230 X1245X1824

2230 X1245X1824

inch

87.8 X 49X 71.8

87.8 X 49X 71.8

87.8 X 49X 71.8

Packing(W×H×D)

mm

2236 X1300X1855

2236 X1300X1855

2236 X1300X1855

inch

88 X 51.2 X 73

88 X 51.2 X 73

88 X 51.2 X 73

Weight

Net weight

Kg(Ibs)

720/ (1609.3)

710/ (1565.3)

720/ (1609.3)

Gross weight

Kg(Ibs)

740(1653.4)

730(1609.3)

740(1653.4)

Filter

Type

Nylon

Nylon

Nylon

Quantity

Pieces 2 2

2

Size (W×H×D)

mm

900 X 815 X 12.5

900 X 815 X 12.5

900 X 815 X 12.5

inch

35.4 X32 X 0.5

35.4 X32 X 0.5

35.4 X32 X 0.5

Shipping

Qty'Per 20'/40'/40'HQ

Pieces

3/6/12

3/6/12

3/6/12

Note:

The data are based on the following conditions:

Cooling: (1): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 35°C(95°F) DB.

(2): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 46°C(114°F) DB.

Heating and Power input: Indoor Temperature 20°C(68°F) DB/15°C(59°F) WB; - Outdoor Temperature 7°C(44.6°F) DB/6°C(42.8°F) DB

Electrical data: Indoor Temperature 32°C(90°F) DB / 24°C(74°F) WB; - Outdoor Temperature 52°C(125°F) DB

15

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

Nominal ton

(Ton)

20

20

Model

MRBT-200CWN1-D

MRCT-200EWN1-D

Cooling

Cooling Capacity (1)

Btu/h

240000

240000

kW

70

70

Power Input (1)

kW

23.6

23.6

Cooling Capacity (2)

Btu/h

213000

213000

kW

62.4

62.4

Power Input (2)

kW

27.7

27.7

Heating

Heating Capacity

Btu/h - 133100

kW - 39

Power Input

kW - 39

Capacity steps % 0/50/100

0/50/100

Electrical data

Power supply

V/Ph/Hz

220/3/60

220/3/60

Max. input consumption

kW

38.2

38.2

Max. current A 127.3

127.3

Performance

Indoor fan air flow (High speed)

CFM

8400

8400

ESP

Pa

100

100

EER 1

Btu/h/W

10.1

10.1

EER 2

Btu/h/W

7.6

7.6

COP

Btu/h/W / /

Indoor Coil

Number of rows 3 3

Fin spacing

mm

1.6

1.6

inch

1/18''

1/16''

Tube diameter

mm

7.94

7.94

inch

5/16''

5/16''

Indoor fan

Type

FC centrifugal

FC centrifugal

Quantity 1 1

Diameter(Width)

mm

452

452

inch

17.8

17.8

Drive type

Belt

Belt

Motors quantity 1 1

Motor model

YFD132S-4

YFD132S-4

Motor output

kW

5.5

5.5

Motor rpm

r/min

835

835

Compressor

Type

Scroll

Scroll

Quantity 2 2

Model

SH120A3ALC

SH120A3ALC

Brand

Danfoss

Danfoss

Capacity

Btu/h

111300

111300

Input

kW

11.246

11.246

Rated current(RLA)

A

43.6

43.6

Refrigerant oil charge

ml

3000

3300

Outdoor Coil

Number of rows 4 4

Fin spacing

mm

1.6

1.6

16

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

inch

1/16"

1/16"

Tube diameter

mm

7.94

7.94

inch

5/16"

5/16"

Outdoor Fan

Type

Propeller

Propeller

Quantity 2 2

Diameter(Width)

mm

750

750

inch

29.5

29.5

Drive type

Direct

Direct

Motors quantity 2 2

Motor model

YS2200-6

YS2200-6

Motor output

kW

5.4 X 2

5.4 X 2

Motor rpm

r/min

1130

1130

Outdoor sound level(sound pressure level )

dB(A)

72.4

74.2

Refrigerant

Type

R410A

R410A

Refrigerant volume

Kg

7.2X 2

7.2X 2

Refrigerant Control

Capillary

Capillary

Controller

Wired controller type

KJR-12B

KJR-12B

Operation temp

℃

17~30

17~30

Ambient temp

Cooling ℃ 18~52

18~52

Heating ℃ -

-

Dimensions

Net(W×H×D)

mm

2230 X1245X1824

2753 X1245X2157

inch

87.8 X 49X 71.8

108.4 X 49 X 84.9

Packing(W×H×D)

mm

2236 X1300X1855

2755 X1300X2180

inch

88 X 51.2 X 73

108.5X51.2 X85.8

Weight

Net weight

Kg(Ibs)

730/ (1609.3)

925(2039.2)

Gross weight

Kg(Ibs)

750(1653.4)

940(2072.3)

Filter

Type

Nylon

Nylon

Quantity

Pieces 2 3

Size (W×H×D)

mm

900 X 815 X 12.5

640 X 1008 X 12.5

inch

35.4 X32 X 0.5

25.2 X39.7 X 0.5

Shipping

Qty'Per 20'/40'/40'HQ

Pieces

2/4/8

2/4/8

Note:

The data are based on the following conditions:

Cooling: (1): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 35°C(95°F) DB.

(2): Indoor Temperature 26.7°C(80°F) DB / 19.4°C(67°F) WB; - Outdoor Temperature 46°C(114°F) DB.

Heating and Power input: Indoor Temperature 20°C(68°F) DB/15°C(59°F) WB; - Outdoor Temperature 7°C(44.6°F) DB/6°C(42.8°F) DB

Electrical data: Indoor Temperature 32°C(90°F) DB / 24°C(74°F) WB; - Outdoor Temperature 52°C(125°F) DB

17

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

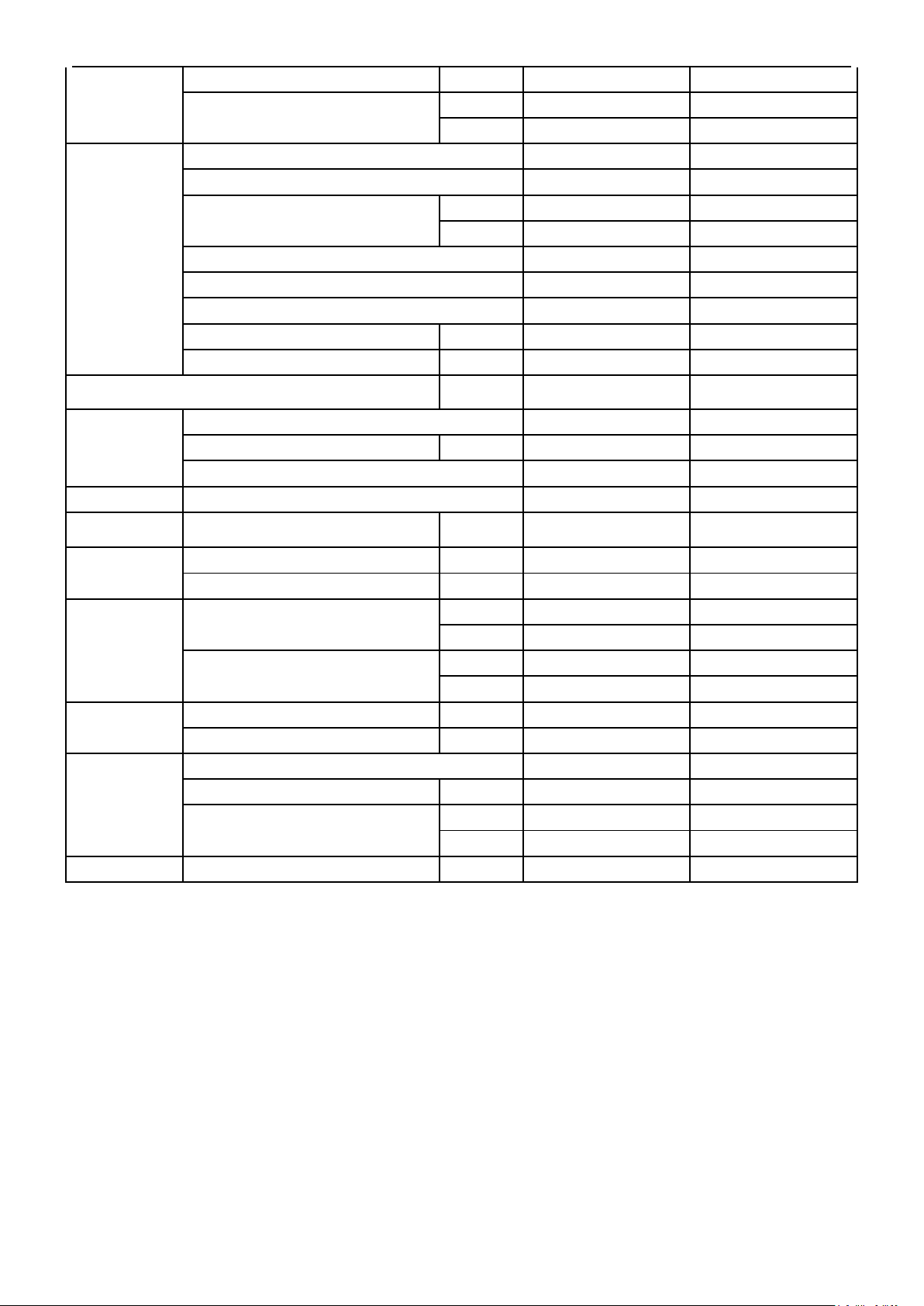

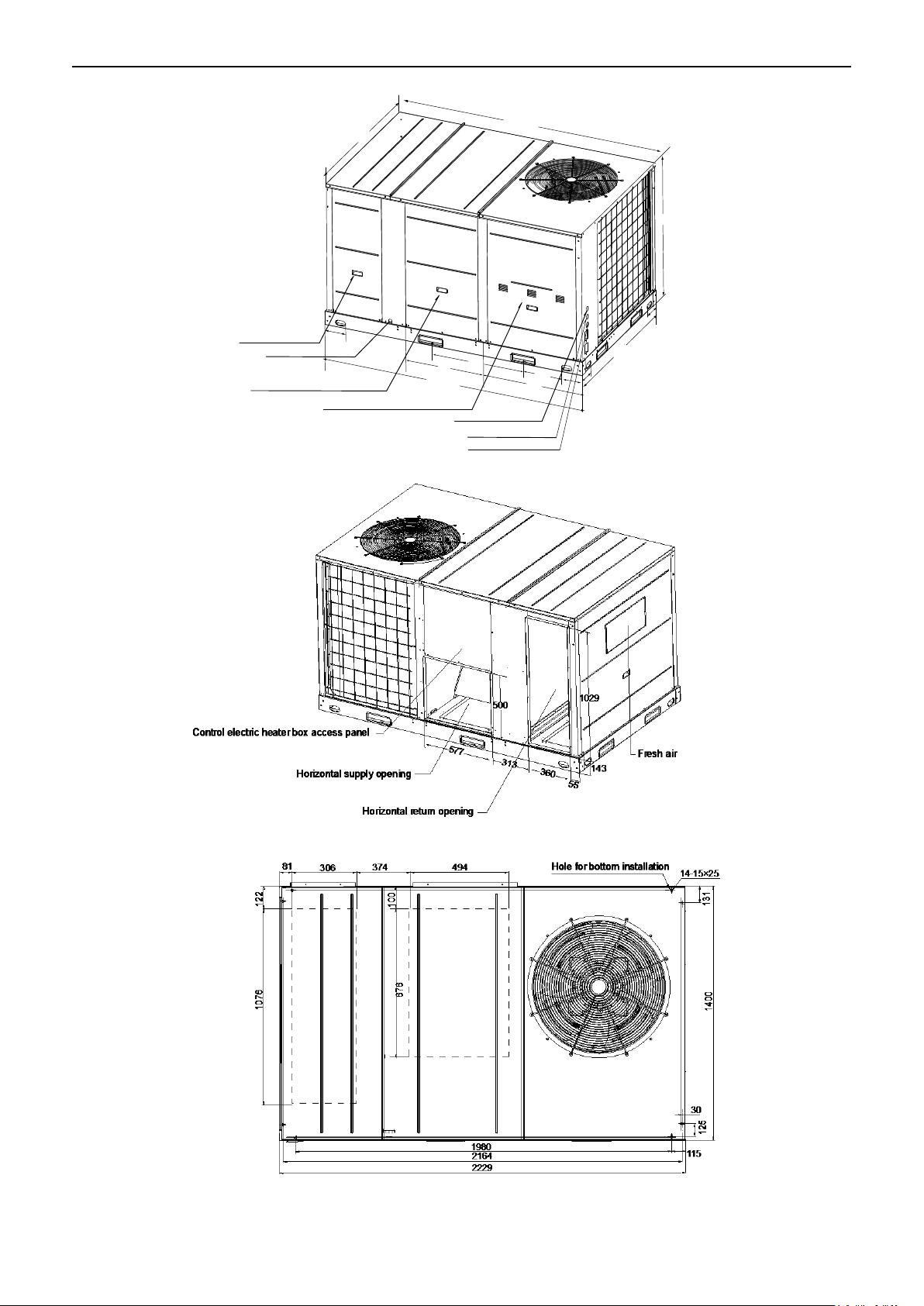

7. Dimensional Drawing

7.1 5ton

18

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

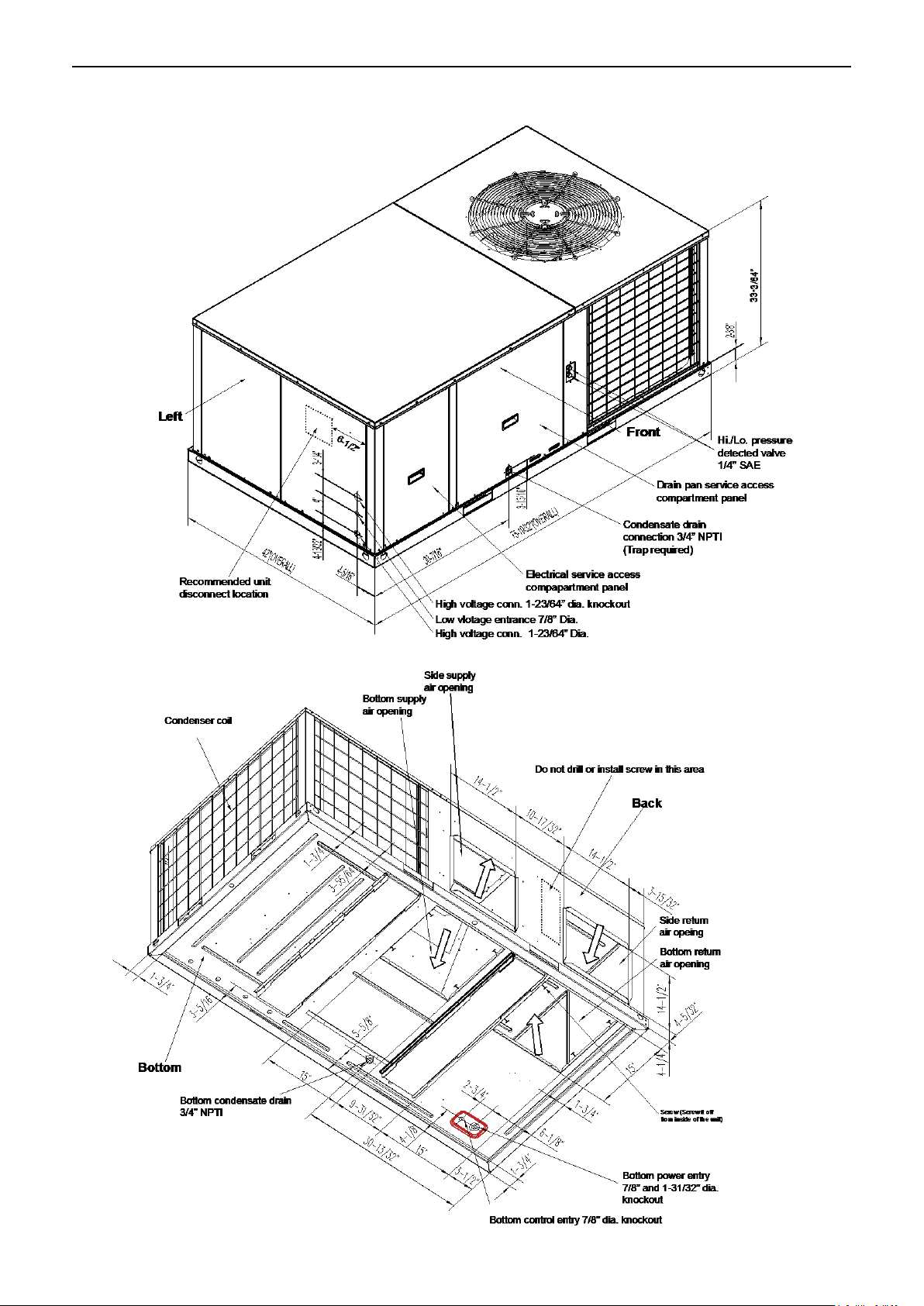

7.2 6.2&7.5ton

19

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

7.3 8.5&10ton

20

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

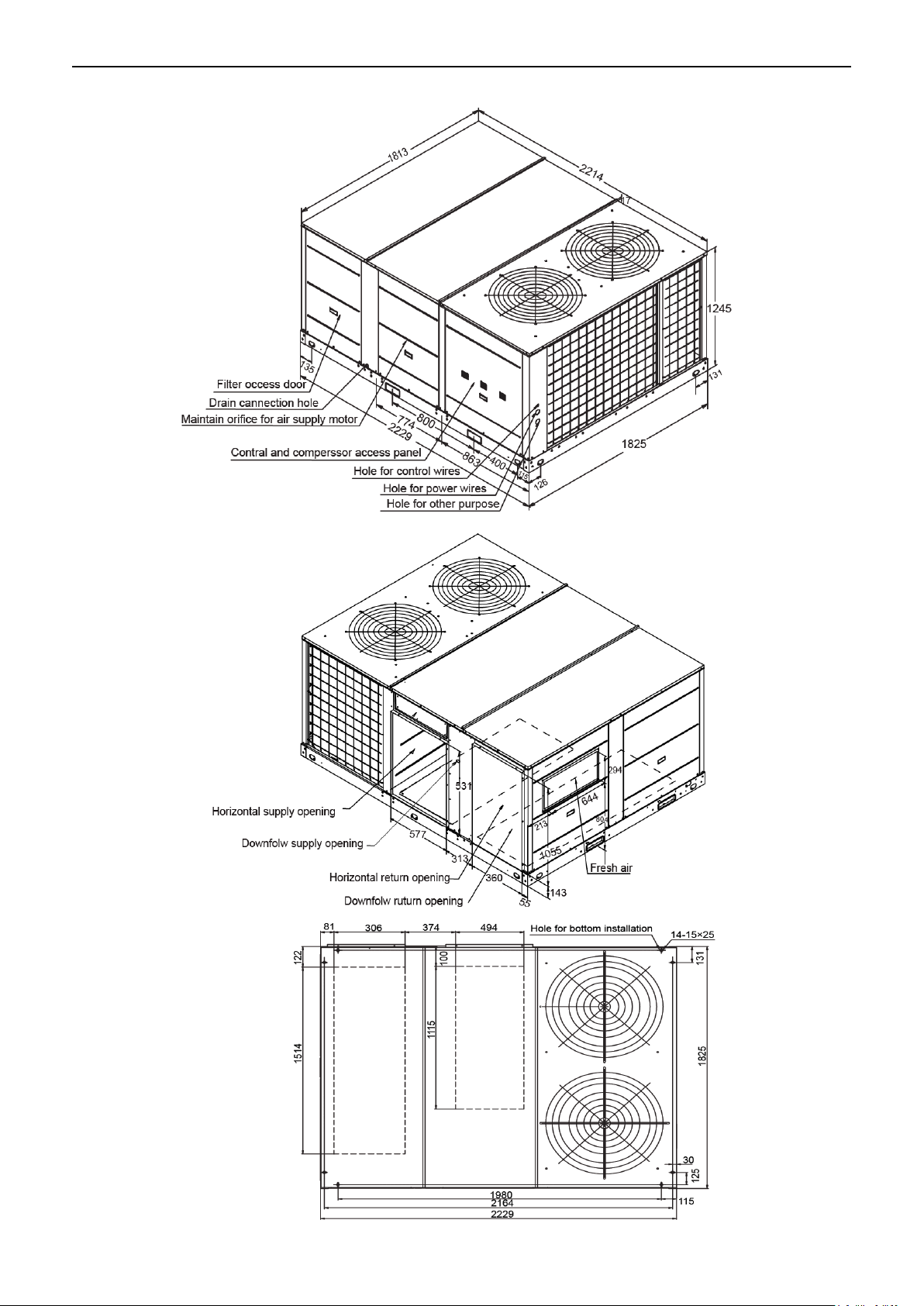

2214

1245

1388

131

126

1

15

135

400

863

774

2229

800

1400

Filter occess door

Drain connection hole

Maintain orifice for air supply motor

Control and comperssor access panel

Hole for control wires

Hole for power wires

Hole for other purpose

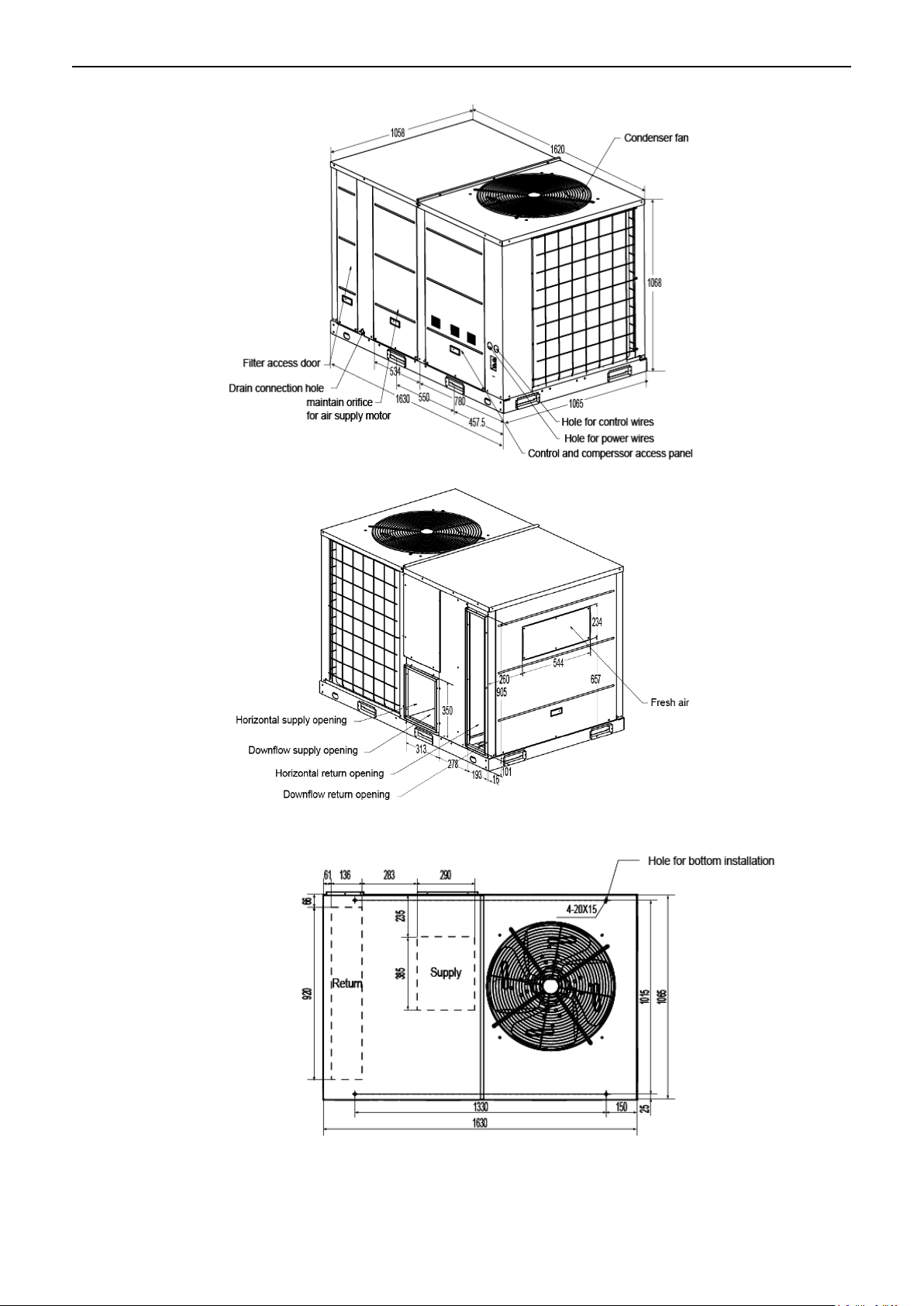

7.4 12.5ton

21

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

7.5 15&17.5ton

22

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

7.6 20ton

23

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

MAINCONTROLBOARD

T

1

24V ~

CN2CN12

21

22

KM1

A1

3

1

5

A2

2

4

6

COMP

RED

FAN2

CAP2

FAN1

CAP1

BROWN

C NXT1 BA

Y/G

POWER

CN6

V

U

W

RED

WHITE

BLUE

RED

BLACK

BLACK

CN3

XT2

BLACK

BLACK

BLUE

T2

CT1

TRANSFORMER(24V~)

5-WAY TERMINAL

HIGH/LOW PRESS SWITCH

AC CONTACTOR

COMPRESSORCOMP

FAN1

RT3-1

XP1~2

XS1~2

CAP1

T2

XT2-5

WIRING DIAGRAM

CONNECTORS

TEMP.SENSOR

CODE

INDOOR FAN

PART NAME

CONNECTORS

FAN2

CAP2

T1

OUTDOOR FAN

INDOOR FAN CAP

OUTDOOR FAN CAP

TRANSFORMER

XT1

H/L-PRO

KM1

MIDDLE TERMINAL

COMP.TEMP. SWITH

K1

S 2

S 1

WHITE

BLACK

CN20

RT4

C

N

4

0

CN13

X p1

X s1

H-PRO K1L-PRO

RT2-1

CN23CN9

XT3OFAN

YELLOW

RT4

10K RESISTANCE

RED

BLUE

XP8

XS8

TO KJR-12B WIRED CONTROLLER

RT1

CN25

RT2-1

CN5

TO HEAT

RED RED

YELLOW

RED

WHITE

TO WIREDCONTROLLERHONEYWELL

BLAKE

CN7CN36

XT6

XT4

Xt6 SMALL 6-WAY TERMINAL

ON

1

SW3

Switch SW3 to the "ON" position

to use 12B wire controller;

switch SW3 to the "1" position

to use Honeywell wired controller.

RY7

BROWN

CN1 CN11

R

S T

XT5

RT3-1

RED

RED

BROWN

BROWN

R

E

D

W

H

I

T

E

B

L

U

E

GREEN

R

E

D

(

M

)

NO

COM

WHITE

BLUE(L)

BLACK(H

)

PURPLE

RED

ORANGE

BROWN

RED

WHITE

BLUE

BLACK

BLACK

BLACK

REDRED

BLACK

X p2

X s2

RT1

RY

RY RELAY

CN21

RT3-2

CN24

RT2-2

CN42

RT2-2 CN42

XP8XP8

Xs8

Y/G

Y/G

Y/G

202096090264

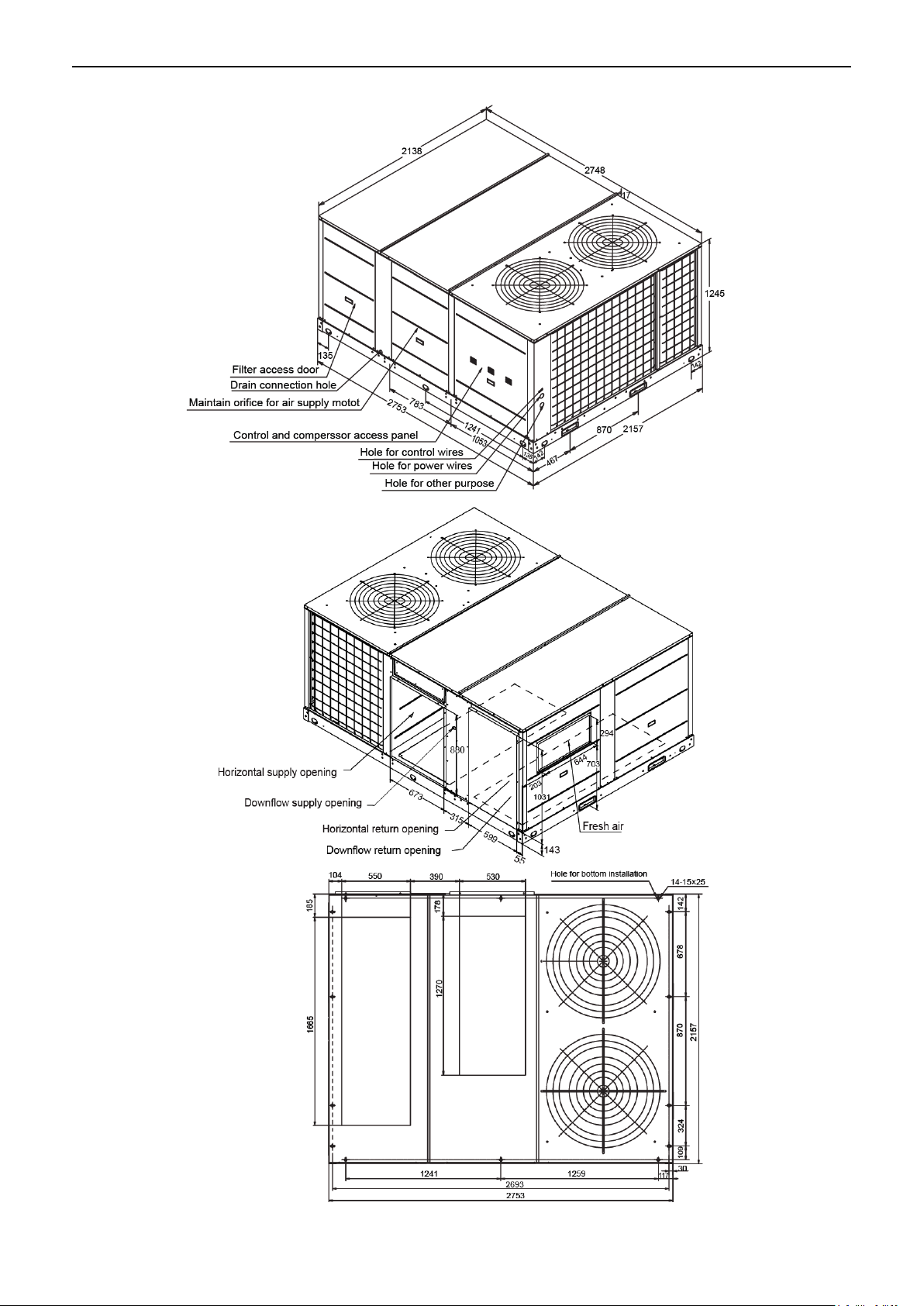

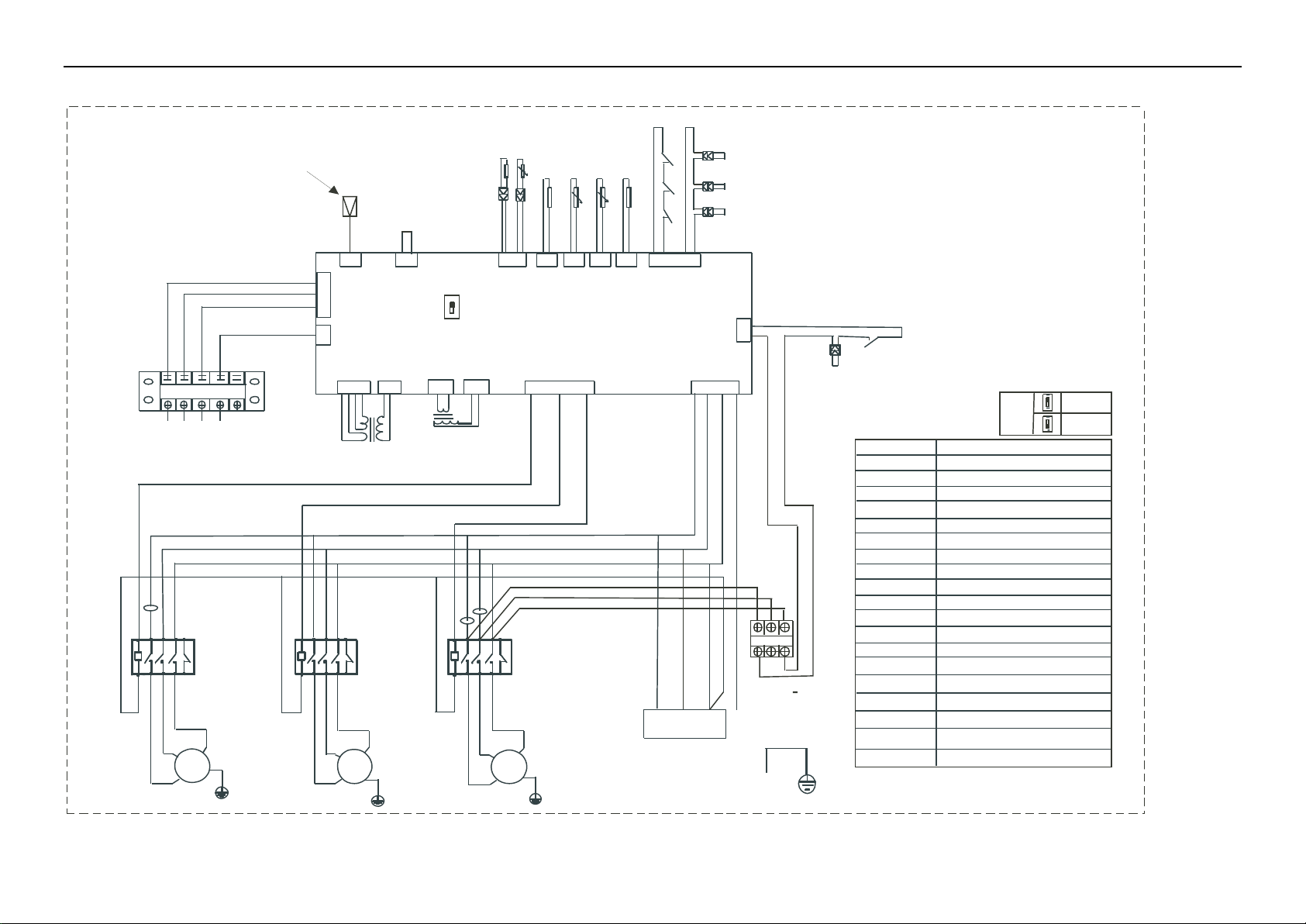

8. Wiring Diagram

MRBT-60CWN1-D

24

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

21

22

5

3

1

A2

6

4

2

A1

21

6

22

A2

2

4

5

A1

1

3

21

A2

6

22

4

2

A1

5

3

1

U

W

V

W

COMP

U

V

T3(W)

FAN_IN

T1(U)

T2(V)

FAN_OUT

POWER

XT1

Y/G

S2

S1

(WHI TE)

(BLACK)

CN20

CN12 CN2

CN3

T2

R

T

3

_

1

R

T

4

C

N

4

0

CN13

T 1

MAIN BOARD

FAN_O

-

PRO

BLACK

BROWN

BLACK

GREY

GREY

GREY

RED

KM1

KM3

Y/G

Y/G

Y/G

XP1-2

XS1-2

H-PRO K1L- PRO

CN11 CN1

RT3_2

CN21

RT2_1

CN24

RT1

CN23

RT2_2

CN25

CN7

CN6

YELLOW

GREEN

CT1

CT3

CT4

202096190102

BROWN

BLACK

BLUE

GREY

BROWN

BLACK

GREY

BROWN

BLACK

GREY

BLACK

L1L2L3

N

GREY

CN36

GREY

CN9

XS3

TO BE CONNECTED KJR-12B

BLUE

RED

NC

R S T

COM

NO

COMPRESSOR

OUTDOOR FAN

HIGH PRESSURE SWITCH

T1,T2

K1

H-PRO

XT2

RT3_1

FAN_IN

COMP

KM1,KM2,KM3

XT1

CT1,CT3,CT4

RT2

L-PRO

FAN_OUT

RT1

FAN_O-PRO

CONTACTOR

INDO OR FAN

TRAN SFORMER

CONNECTORS

CONNECTORS

PIPE TEMP.SENSOR OF UNIT A/B

4-WAY TERMINAL

SMALL 5-WAY TERMINAL

LOW PRESSURE SWITCH

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CODE TITLE

K1

H-PRO

XP1-2

XS1-2

RT4

RT2_1

L-PRO

RT1

CONNECTORS

CONNECTORS

OUTDOOR TEMP.SENSOR

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CURRENT INDU CTOR

RED

RED

ELECTRICALSOURCE

PROTECTIONRELAY

BLUE

BROWN

GREY

BROWN

GREY

SW3

ON

1

SW3

KJR-12B

MODE

KJR-23B

GREY

BLACK

GREY

BROWN

GREY

BLACK

GREY

BROWN

GREY

CN22

KM2

R Y CG

XT2

YELLOW

RED

WHI TE

TOTHEWIREDCONTROLLER

( )

GREEN

RT2_2,RT3_2

RESISTANCEOF 10KILOHMS

BLACK

BROWN

GREY

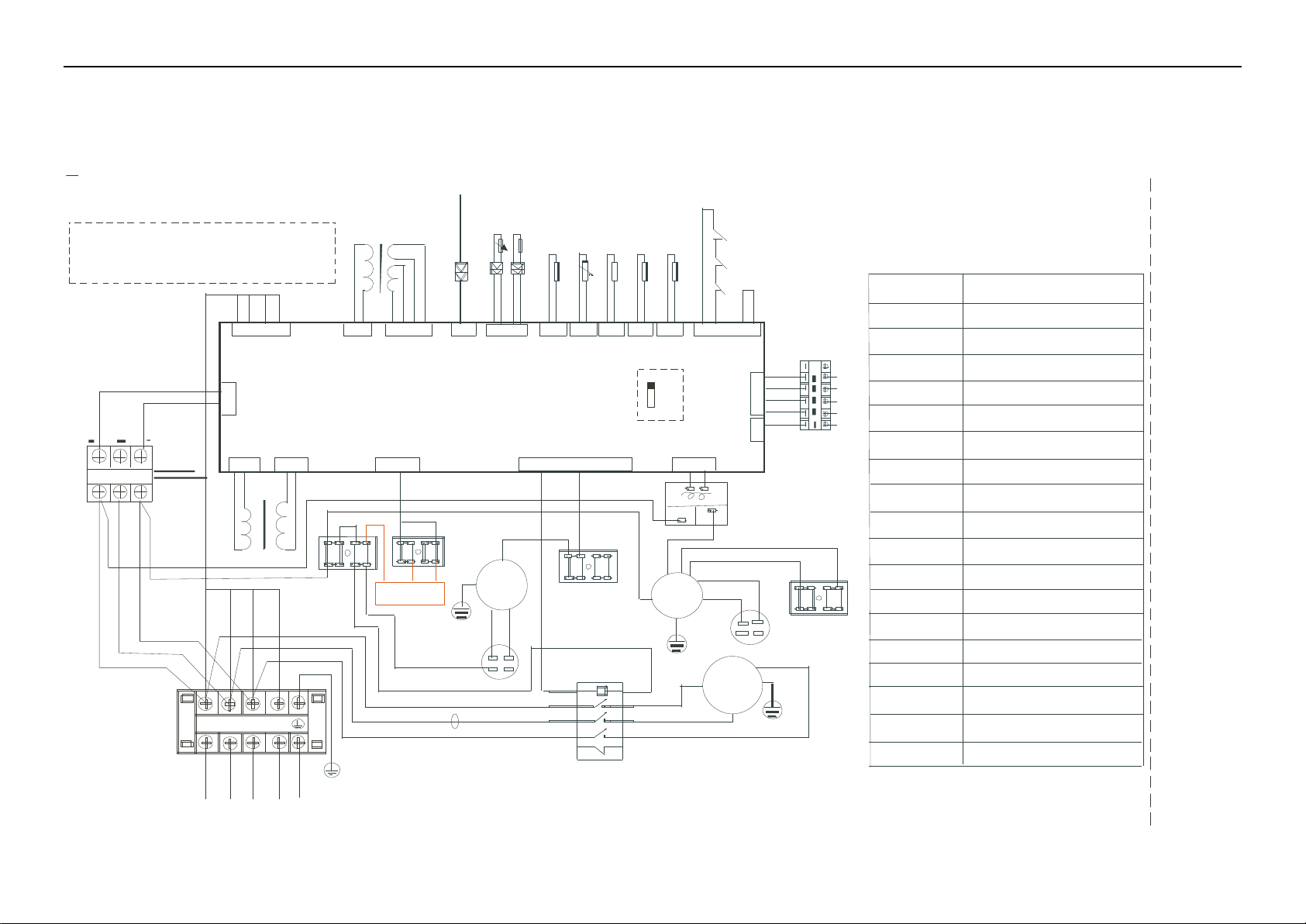

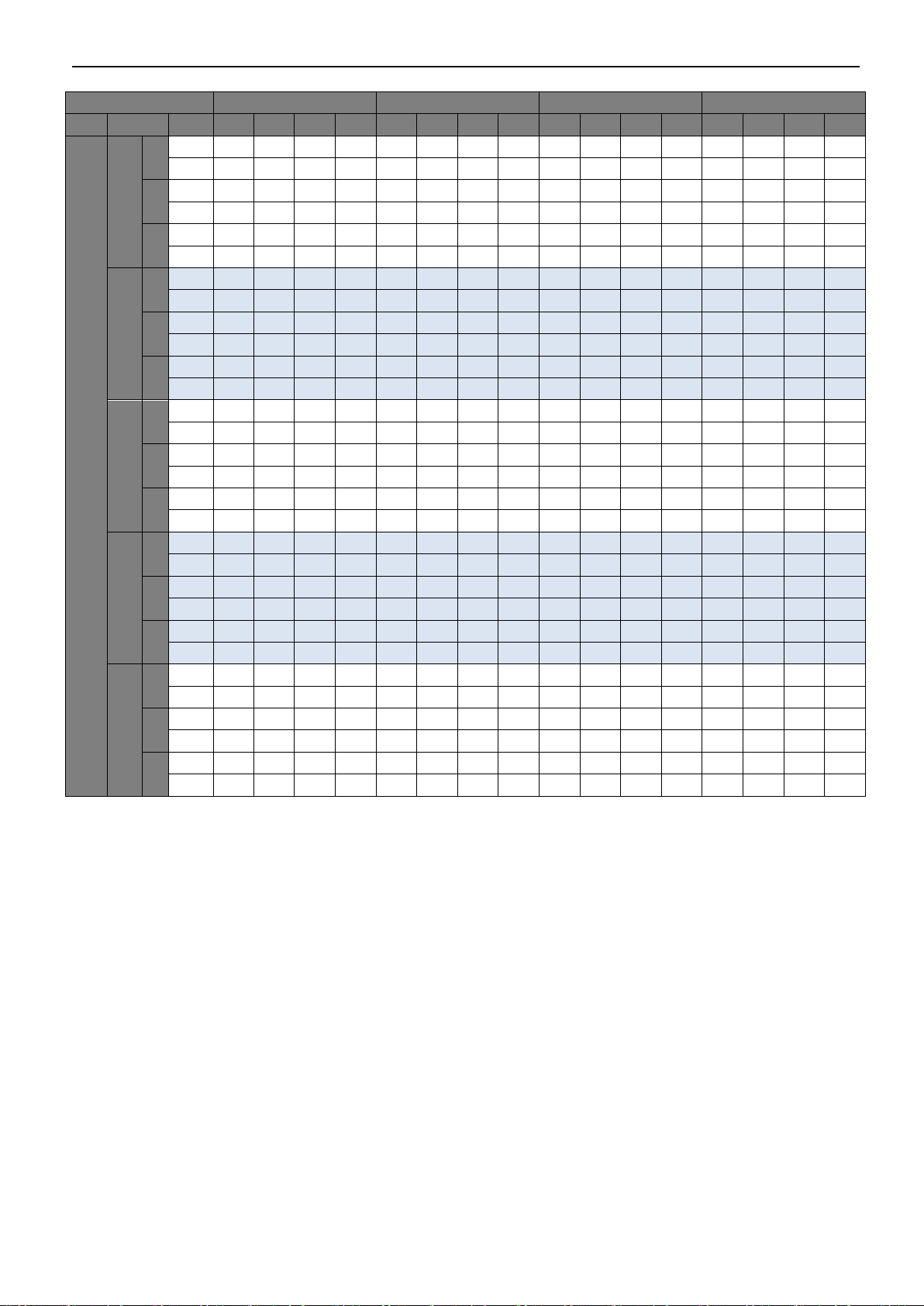

MRBT-062CWN1-D/ MRBT-075CWN1-D

25

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

MRCT-062EWN1-D/ MRCT-075EWN1-D

26

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

21

22

5

3

1

A2

6

4

2

A1

21

6

22

A2

2

4

5

A1

1

3

21

A2

6

22

4

2

A1

5

3

1

U

W

V

W

COMP

U

V

T3(W)

FAN_IN

T1(U)

T2(V)

FAN_OUT

POWER

XT1

Y/G

S2

S1

(WHI TE)

(BLACK)

CN20

CN12 CN2

CN3

T2

R

T

3

_

1

R

T

4

C

N

4

0

CN13

T 1

MAIN BOARD

FAN_O

-

PRO

BLACK

BROWN

BLACK

GREY

GREY

GREY

RED

KM1

KM3

Y/G

Y/G

Y/G

XP1-2

XS1-2

H-PRO K1L- PRO

CN11 CN1

RT3_2

CN21

RT2_1

CN24

RT1

CN23

RT2_2

CN25

CN7

CN6

YELLOW

GREEN

CT1

CT3

CT4

202096290108

BROWN

BLACK

BLUE

GREY

BROWN

BLACK

GREY

BROWN

BLACK

GREY

BLACK

L1L2L3

N

GREY

CN36

GREY

CN9

XS3

TO BE CONNECTED KJR-12B

BLUE

RED

NC

R S T

COM

NO

COMPRESSOR

OUTDOOR FAN

HIGH PRESSURE SWITCH

T1,T2

K1

H-PRO

XT2

RT3_1

FAN_IN

COMP

KM1,KM2,KM3

XT1

CT1,CT3,CT4

RT2

L-PRO

FAN_OUT

RT1

FAN_O-PRO

CONT ACTOR

INDOOR FAN

TRANSFORMER

CONNECTORS

CONNECTORS

PIPE TEMP.SENSOR

4-WAY TERMINAL

SMALL 5-WAY TERMINAL

LOW PRESSURE SWITCH

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CODE TITLE

K1

H-PRO

XP1-2

XS1-2

RT4

RT2_1

L-PRO

RT1

CONNECTORS

CONNECTORS

OUTDOOR TEMP.SENSOR

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CURR ENT INDU CTOR

RED

RED

RED

WHITE

BLUE

ELECTRICALSOURCE

PROTECTIONRELAY

BLUE

BROWN

GREY

BROWN

GREY

SW3

ON

1

SW3

KJR-12B

MODE

KJR-23B

GREY

BLACK

GREY

BROWN

GREY

BLACK

GREY

BROWN

GREY

CN22

KM2

CN43

R Y CG

XT2

YEL LOW

RED

WHI TE

TOTHEWIREDCONTROLLER

( )

GREEN

RT2_2,RT3_2

RESISTANCEOF 10 KILOHMS

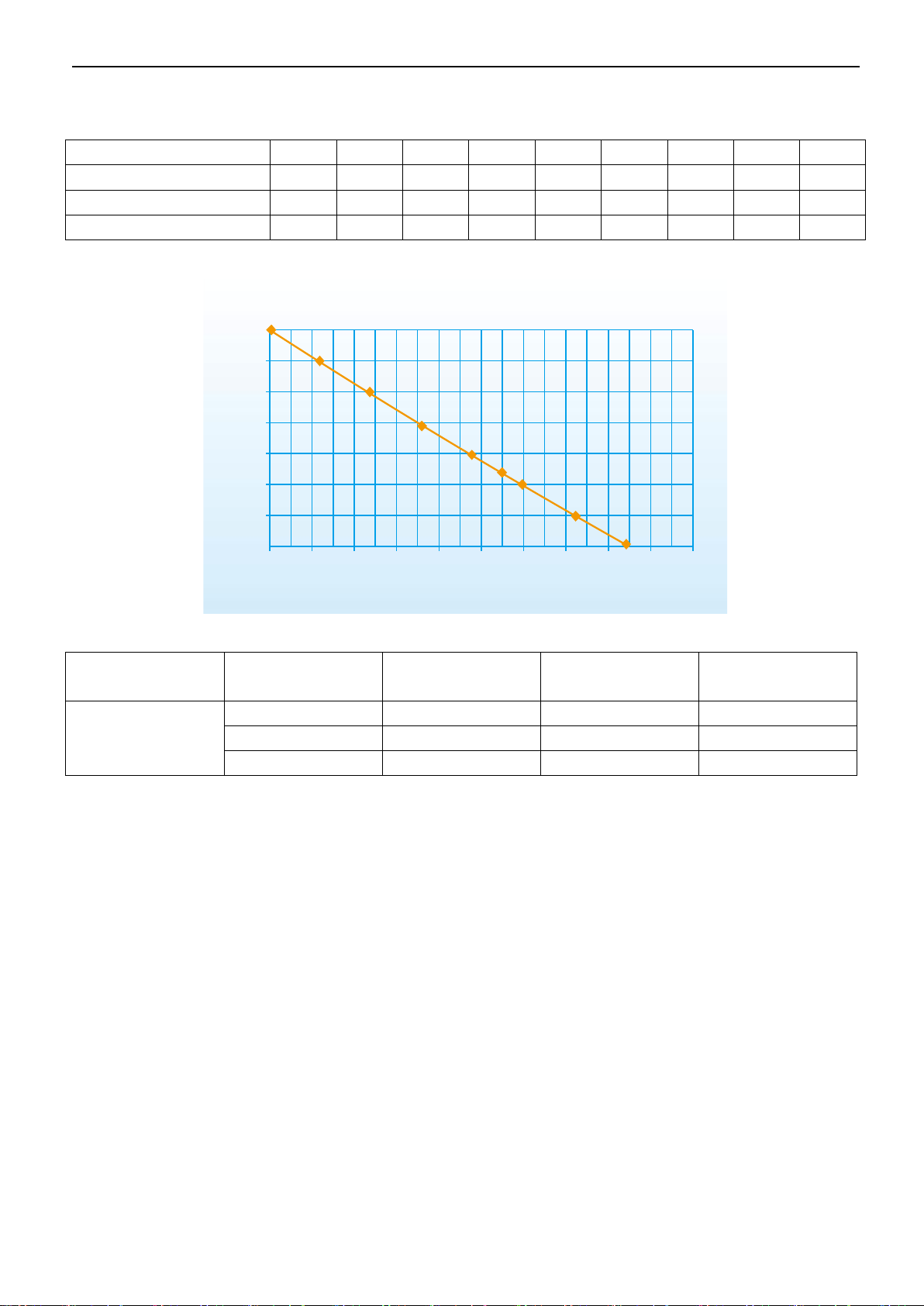

MRBT-085CWN1-D /MRBT-100CWN1-D

27

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

21

22

5

3

1

A2

6

4

2

A1

21

6

22

A2

2

4

5

A1

1

3

21

A2

6224

2

A1

5

3

1

U

W

V

W

COMP

U

V

T3(W )

FAN_IN

T1(U )

T2(V )

FAN_OUT

S2S1

(WHITE)

(B LACK)

CN20

CN12 CN2

CN3

T2

R

T

3

_

1

R

T

4

C

N

4

0

CN13

T 1

MAIN BOARD

B L A C K

BROWN

BL ACK

GREY

G R EY

GR EY

R ED

KM1

KM3

Y / G

Y / G

Y / G

XP1-2

XS1-2

H-PRO K1

L- PRO

CN11 CN1

RT3_2

CN21

RT2_1

CN24

RT1

CN23

RT2_2

CN25

CN7

CN6

YELLOW

G REEN

R Y CG

CT1

CT3

CT4

XT2

YE L L OW

RED

WHITE

202096290109

BRO WN

BLACK

BLUE

GREY

BR OWN

BLA CK

GRE Y

BRO WN

BLACK

GREY

BLACK

TO THE WIRED CONTROLLER

G R EY

( )

CN36

GREEN

G R E Y

W

BLUE

CN5

XS3

TO BE CONNECTED KJR-12B

B LUE

RED

RED

WHITE

BLUE

B R O W N

G R E Y

BROWN

GREY

SW3

ON

1

SW3

KJR-12B

MODE

KJR-23B

B L A C K

G R E Y

B R O W N

G R E Y

B L A C K

G R E Y

B R O W N

G R E Y

CN22

KM2

Y/G

FAN

_O-PR

O

R S T

COM NONC

RED

WHITE

BLUE

RED

RED

E L E CT RI CA L S OU RC E

P R O TE CT IO N R EL AY

COMP RES SOR

OUTD OOR FAN

HIGH PR ESSURE SWITCH

T1,T 2

K1,K 2

H-PR O

XT2

RT3_ 1

FAN_ IN

COMP

KM1~KM6

XT1

CT1, CT3 ,CT 4

L-PR O

FAN_ OUT

RT1

FAN_O-PRO

CONT ACT OR

INDO OR FAN

TRAN SFO RME R

CONNECTORS

CONNECTORS

PIPE TEMP.SENSOR

4-WAY TERMINAL

SMALL 5-WAY TERMINAL

LOW PRE SSURE SWITCH

TEMP PROTECTION SWITCH

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CODE TITLE

XP1- 2

XS1- 2

RT4

RT2_ 1

CONNECTORS

CONNECTORS

OUTDOOR TEMP.SENSOR

TEMP PROTECTION SWITCH

INDOOR ROOM TEMP.SENSOR

CURR ENT INDUCTOR

F1-F9

THERMAL CUT-OFF

R1-R9 ELECTRICALLY HEATED PIPE

NOTE :TE RMI NAL S X T1 AND XT4 MUST BE SUPPLIED

BY T HE SAM E P OWE R

XT3

XT4 4-WAY TERMINAL

MIDDLE TERMINAL

21

A2

6

22

4

2

A1

5

3

1

21

A2

6

22

4

2

A1

5

3

1

BLUE

21

A2

6

22

4

2

A1

5

3

1

KM4

BLACK

R1

R2

R3

F3

F5

R1

R2

R3

F1

F2

R4

R5

R6

F6

F4

R7

R8

R9

F7

KM5

KM6

BLA CK

BLAC K

BLAC K

F8

F9

WHI TE

WHIT E

WHI TE

X T 4

BLUE

K2

RED

RED

RED

RED

RED

RED

XT3

W

H

I

T

E

BROWN

GRE Y

W

H

I

T

E

W

H

I

T

E

CN9

CN43

BLACK

XT1

L1 L2

L3 N

BLUE

GREY

L3L2L1 N

POWER

Y/G

INDOOR PIPE TEMP.SENSOR

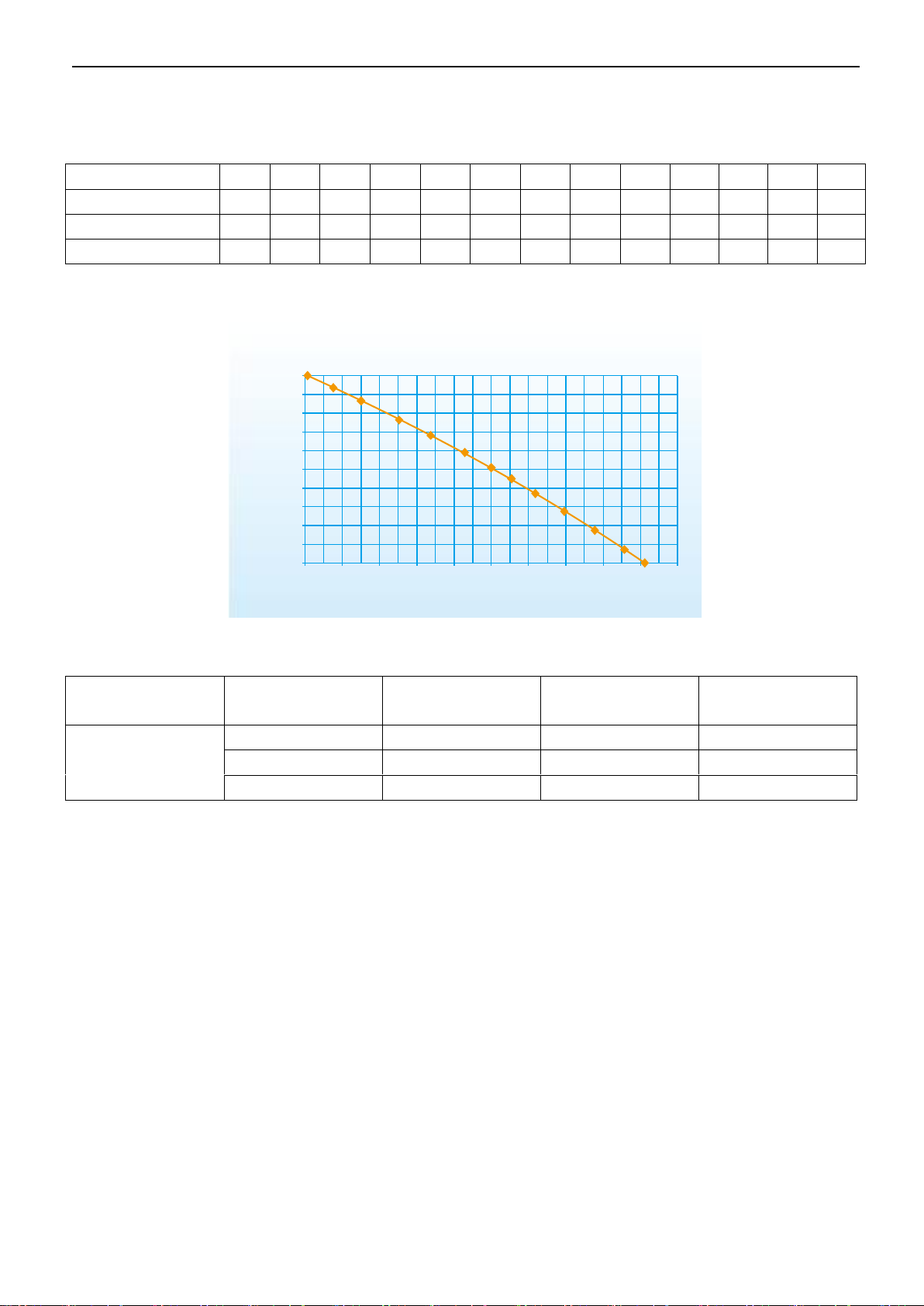

MRCT-085EWN1-D /MRCT-100EWN1-D

28

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

CN5

Y/G

S2S1

(WHITE)

(BLACK)

CN20

C

N12

CN2

T

2

R

T

3

_

1

R

T

4

CN13

H-PRO K2

T1

MAIN BOARD

BROWN

RED

XP1-2

XS1-2

L- PRO

H-PRO K1

L- PRO

CN11 CN1

RT3_2

CN21

RT2_1

CN24

RT1

CN23

RT2_2

CN25

CN6

YELLOW

GRE EN

21

22

531

A2

642

A1

21

6

22

A2

2

4

5

A1

1

3

21

21

6

22

A2

2

4

A2

6224

2

5A11

3

A1

531

U

W

V

W

U

V

KM1

KM4KM3KM2

CT1

CT2

CT3

CT4

21

A2

6

22

4

2

A1

5

3

1

21

A2

6

22

4

2

A1

5

3

1

21

A2

6

22

4

2

A1

5

3

1

KM6

KM7

KM8

POWER

Y/G

XT4

R

Y

C

G

XT2

TO THE WIRE CONTROLLER

( )

W

COMPRESSOR

OUTDOOR FAN

HIGH PRESSURE SWITCH

T1,T2

K1-K3

H-PRO

XT2

RT3_1,RT3_2

FAN_IN

COMP_A,COMP_B

KM1~KM8

XT1

CT1-CT4

L-PRO

FAN_OUT1,2

RT1

FAN_O-PRO1,2

CONTACTOR

IN DO O R FAN

TRANSFORMER

CONNECTORS

CONNECTORS

PIPE TEMP.SENSOR OF UNIT AB

4-WAY TERMINAL

SMALL 5-WAY TERMINAL

LOW PRESSURE SWITCH

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CODE TITLE

XP1-2

XS1-3

RT4

RT2_1,RT2_2

CONNECTORS

CONNECTORS

OUTDOOR TEMP.SENSOR

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CU RR E NT IND UCT OR

F1-F9

THERMAL CUT-OFF

R1-R9 ELECTRICALLY HEATED PIPE

NOTE:TERMINALS XT1 AND XT4MUST BE SUPPLIED

BY THE SAME POWER

L1

L2

L3

CN3

BROWN

BLACK

BLUE

GREY

POWER

XT1

BROWN/RE D

BLACK/ BLACK

B LUE

GREY/WH ITE

L1

L2

L3

N

XT1

BLUE

RE D

CN9

XS3

TO BE CONNECTED KJR-12B

C

N

4

0

R

S T

COM NO NC

SW3

KJR-12B

MODE

BROWN

BLACK

GREY

RED

RED

JP1

CN22

KJR-23B

XT3

XT4 3-WAY TERMINAL

MIDDLE TERMINAL

GREY

ELECTRICAL SOURCE

PROTECTION RELAY

B

A

NOTE:IF

ELECTRICAL SOURCE PROTECTION RELAY IS NOT PRESENT,

WIRE A IS CONNECTED TO WIRE B

NOTE

MRBT-125CWN1-D

29

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

Y/G

S2S1

(WHI TE)

(BLACK)

CN20

CN1

2

CN2

T

2

R

T

3

_

1

R

T

4

CN13

H- PRO K2

T 1

MAIN BOARD

BROWN

RED

XP1-2

XS1-2

L-PRO

H- PRO K1

L-PRO

CN11 CN1

RT3_2

CN21

RT2_1

CN24

RT1

CN23

RT2_2

CN25

CN6

YELLOW

GREEN

202096390145

WHI TE

21

22

531

A2

642

A1

21

6

22

A2

2

4

5

A1

1

3

21

21

6

22

A2

2

4

A2

6

22

4

2

5A11

3

A1

5

3

1

U

W

COMP_B

V

W

COMP_A

U

V

T3(W)

FAN_IN

T1(U)

T2(V)

FAN_OUT1

RED

WH ITE

BLACK

GREY

GREY

GREY

GREY

KM1

KM5KM3KM2

Y/G

Y/G

Y/G

Y/G

CT1

CT2

CT3

CT4

BROWN

BLACK

GREY

BROWN

BLACK

GREY

RED

BLACK

WHITE

RED

BLACK

WHITE

GR EY

21

6

22

A2

2

4

5

A1

1

3

U

W

V

FAN_OUT2

GREY

KM4

Y/G

BROWN

BLACK

GREY

CN7 CN36

T3(W)

T1(U)

T2(V)

COMPRESSOR

OUTDOOR FAN

HIGH PRESSURE SWITCH

T1,T2

K1,K2

H-PRO

XT2

RT3_1,RT3_2

FAN_IN

COMP_A,COMP_B

KM1~KM5

XT1

CT1-CT4

RT2

L-PRO

FAN_OUT1,2

RT1

FAN_O-PRO1,2

CONTACTOR

INDOORFAN

TRANSFORMER

CONNECTORS

CONNECTORS

PIPETEMP.SENSOROFUNITAB

4-WAYTERMINAL

SMALL5-WAYTERMINAL

LOW PRESSURE SWITCH

TEMPPROTECTIONSWITCH

INDOORPIPETEMP.SENSOR

INDOORROOMTEMP.SENSOR

OUTDOORFANPROTECTIONSWITCH

CODE TITLE

H-PRO

XP1-2

XS1-3

RT4

RT2_1,RT2_2

L-PRO

RT1

CONNECTORS

CONNECTORS

OUTDOORTEMP.SENSOR

TEMPPROTECTIONSWITCH

INDOORPIPETEMP.SENSOR

INDOORROOMTEMP.SENSOR

OUTDOORFANPROTECTIONSWITCH

CURRENTINDUCTOR

HYJ-IV

ELECTRICAL SOURCEPROTECTION RELAY

CN3

BROWN

BLACK

BLUE

GREY

POWER

XT1

BROWN/RED

BLACK/ BLACK

BLUE

GREY/WHI TE

L1L2L3

N

XT1

BLUE

RED

CN9

XS3

TO BE CONNECTED KJR-12B

C

N

4

0

FAN_O-PRO

1

FAN_O-PRO

2

R S T

COM NONC

SW3

ON

1

SW3

KJR-12B

MODE

RED

WHITE

BLUE

RED

RED

JP1

CN22

KJR-23B

RED

WH ITE

BLACK

GR EY

BROWN

GREY

BLACK

GR EY

BROWN

GREY

BLACK

GR EY

BROWN

GREY

BLACK

GR EY

R Y CG

XT2

YEL LOW

RED

WHITE

TOTHEWIREDCONTROLLER

( )

GREEN

GREY

ELECTRICAL SOURCE

PROTECTION RELAY

MRBT-150CWN1-D /MRBT-175CWN1-D

30

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

CN5

Y/G

S2

S1

(WHITE)

(BLACK)

CN20

CN1

2

C

N

2

T

2

R

T

3

_

1

R

T

4

CN13

H-PRO K2

T 1

MAIN BOARD

BR OWN

RED

XP1-2

XS1-2

L-PRO

H-PRO K1L-PRO

CN11 CN1

RT3_2

CN21

RT2_1

CN24

RT1

CN23

RT2_2

CN25

CN6

YELLOW

GREEN

202096390137

WHIT E

21

22

531

A2

642

A1

21

6

22

A2

2

4

5

A1

1

3

21

21

6

22

A2

2

4

A2

6224

2

5A11

3

A1

5

3

1

U

W

COMP_B

V

W

COMP_A

U

V

T3(W)

FAN_IN

T1 ( U)

T2 ( V)

FAN_OUT1

RE D

WH I TE

BL A CK

GREY

GREY

GREY

GRE Y

KM1

KM5

KM3KM2

Y/ G

Y/ G

Y/ G

Y/ G

CT1

CT2

CT3

CT4

BROWN

BLACK

GREY

BROWN

BLACK

GREY

RED

BLACK

WHIT E

RED

BLACK

WHITE

GR E Y

21

6

22

A2

2

4

5A11

3

U

W

V

FAN_OUT2

GRE Y

KM4

Y/ G

BROWN

BLACK

GREY

21

A2

6

22

4

2

A1

5

3

1

21

A2

6

22

4

2

A1

5

3

1

BLUE

21

A2

6

22

4

2

A1

5

3

1

KM6

BLA CK

F3

F5

F1

F2

F6

F4

F7

KM7

KM8

POWER

Y/G

BLA CK

BLA CK

BLA CK

F8

F9

WHI TE

WHI TE

WHI TE

X T 4

CN7

R Y CG

XT2

YE L L OW

RED

WHI TE

TO T HE WIRED CONTROLLER

CN36

( )

GR E E N

BLUE

W

T3(W)

T1 ( U)

T2 ( V)

BLUE

K3

WH I TE

RED

RED

RED

RED

RED

RED

COMP RES SOR

OUTD OOR FAN

HIGH PRESSURE SWITCH

T1,T 2

K1-K 3

H-PR O

XT2

RT3_ 1,R T3_2

FAN_ IN

COMP_A,COMP_B

KM1~KM8

XT1

CT1- CT4

L-PR O

FAN_ OUT 1,2

RT1

FAN_O-PRO1,2

CONT ACT OR

INDO OR FAN

TRAN SFO RMER

CONNECTORS

CONNECTORS

PIPE TEMP.SENSOR OF UNIT AB

4-WAY TERMINAL

SMALL 5-WAY TERMINAL

LOW PRESSURE S WIT CH

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CODE TITLE

XP1- 2

XS1- 3

RT4

RT2_ 1,R T2_2

CONNECTORS

CONNECTORS

OUTDOOR TEMP.SENSOR

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CURR ENT INDUCTOR

F1-F9

THERMAL CUT-OFF

R1-R9 ELECTRICALLY HEATED PIPE

NOTE :TE RMI NAL S XT1 AND XT4 MUST BE SUPPLIED

BY T HE SAME POWER

L1L2

L3

WH I TE

XT3

WHITE

CN3

BR OWN

BLACK

BLUE

GREY

POWER

XT1

BROWN /RED

BLA CK/BLACK

BLUE

GRE Y/WHITE

L1L2L3

N

XT1

BLUE

RE D

CN9

XS3

TO BE CONNECTED KJR-12B

C

N

4

0

FAN_O

-

PRO

1

FAN_O

-

P

RO2

R S T

COM NONC

SW3

ON

1

SW3

KJR-12B

MODE

RED

WHITE

BLUE

RED

RED

JP1

CN22

KJR-23B

BROWN

GREY

RE D

WH I TE

BL A CK

GR E Y

BR O WN

GR E Y

BL A CK

GR E Y

BR O WN

GR E Y

BL A CK

GR E Y

GR E Y

BL A CK

GR E Y

XT3

XT4 3-WAY TERMINAL

MIDDLE TERMINAL

GREY

E L E CT RI CA L S O UR CE

P R O TE CT IO N R E LA Y

BR O WN

R1

R2

R3

R4

R5

R6

R7

R8

R9

MRCT-150EWN1-D /MRCT-175EWN1-D

31

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

Y/G

S2S1

(WHI TE)

(BLACK)

CN20

CN1

2

CN2

T

2

R

T

3

_

1

R

T

4

CN13

H-PRO K2

T 1

MAIN BOARD

BROWN

RED

XP1-2

XS1-2

L-PRO

H-PRO K1

L-PRO

CN11 CN1

RT3_2

CN21

RT2_1

CN24

RT1

CN23

RT2_2

CN25

CN6

YELLOW

GREEN

202096490097

WHI TE

21

22

531

A2

642

A1

21

6

22

A2

2

4

5

A1

1

3

21

21

6

22

A2

2

4

A2

6224

2

5A11

3

A1

5

3

1

U

W

COMP_B

V

W

COMP_A

U

V

T3(W)

FAN_IN

T1(U)

T2(V)

FAN_OUT1

BLACK

GREY

GREY

GREY

GREY

KM1

KM5KM3KM2

Y/G

Y/G

Y/G

Y/G

CT1

CT2

CT3

CT4

BROWN

BLACK

GREY

BROWN

BLACK

GREY

BLACK

BLACK

GREY

21

6

22

A2

2

4

5

A1

1

3

U

W

V

FAN_OUT2

GREY

KM4

Y/G

BROWN

BLACK

GREY

CN7 CN36

T3(W)

T1(U)

T2(V)

COMPRESSOR

OUTDOOR FAN

HIGH PRESSURE SWITCH

T1,T2

K1,K2

H-PRO

XT2

RT3_1,RT3_2

FAN_IN

COMP_A,COMP_B

KM1~KM5

XT1

CT1-CT4

RT2

L-PRO

FAN_OUT1,2

RT1

FAN_O-PRO1,2

CONTACTOR

INDOORFAN

TRANSFORMER

CONNECTORS

CONNECTORS

PIPETEMP.SENSOROFUNITAB

4-WAYTERMINAL

SMALL5-WAYTERMINAL

LOW PRESSURE SWITCH

TEMPPROTECTIONSWITCH

INDOORPIPETEMP.SENSOR

INDOORROOMTEMP.SENSOR

OUTDOORFANPROTECTIONSWITCH

CODE TITLE

H-PRO

XP1-2

XS1-3

RT4

RT2_1,RT2_2

L-PRO

RT1

CONNECTORS

CONNECTORS

OUTDOORTEMP.SENSOR

TEMPPROTECTIONSWITCH

INDOORPIPETEMP.SENSOR

INDOORROOMTEMP.SENSOR

OUTDOORFANPROTECTIONSWITCH

CURRENTINDUCTOR

HYJ-IV ELECTRICAL SOURCE PROTECTION RELAY

CN3

BROWN

BLACK

BLUE

GREY

POWER

XT1

BROWN

BLACK

BLUE

GREY

L1L2L3

N

XT1

BLUE

RED

CN9

XS3

TO BE CONNECTED KJR-12B

C

N

4

0

FAN_O-P

RO1

FAN_O

-

P

RO2

R S T

COM NO

NC

SW3

ON

1

SW3

KJR-12B

MODE

RED

WHITE

BLUE

RED

RED

JP1

CN22

KJR-23B

BLACK

GREY

BROWN

GR EY

BLACK

GREY

BR OWN

GR EY

BLACK

GREY

BR OWN

GR EY

BLACK

GREY

R Y CG

XT2

YEL LOW

RED

WHITE

TOTHEWIREDCONTROLLER

( )

GREEN

GREY

ELECTRICAL SOURCE

PROTECTION RELAY

CN43 CN44

BR OWN

BR OWN

GR EYGR EY

BROWN

BROWN

GREY

GREY

BLACK

BLACK

MRBT-200CWN1-D

32

MCAC-RTSM-2015-01 60Hz R410A ClimaMaster Tropical Rooftop Package Unit

CN5

Y/G

S2S1

(WHITE)

(BLACK)

CN20

C

N

1

2

C

N

2

T

2

R

T

3

_

1

R

T

4

CN13

H-PRO K2

T 1

MAIN BOARD

BROWN

RED

XP1-2

XS1-2

L-PRO

H-PRO K1L-PRO

CN11 CN1

RT3_2

CN21

RT2_1

CN24

RT1

CN23

RT2_2

CN25

CN6

YE LLOW

GREE N

202096490100

WHITE

21

22

531

A2

6

4

2

A1

21

6

22

A2

2

4

5

A1

1

3

21

21

6

22

A2

2

4

A2

6224

2

5

A1

1

3

A1

5

3

1

U

W

COMP_B

V

W

COMP_A

U

V

T3(W)

FAN_IN

T1 ( U)

T2 ( V)

FAN_OUT1

BR O WN

GR E Y

BL AC K

BLUE

BLUE

BLUE

BLUE

KM1

KM5

KM3KM2

Y/ G

Y/ G

Y/ G

Y/ G

CT1

CT2

CT3

CT4

BRO WN

BLA CK

GRE Y

BROWN

BLACK

GREY

BRO WN

BLA CK

GREY

BRO WN

BLA CK

GREY

BL UE

21

6

22

A2

2

4

5

A1

1

3

U

W

V

FAN_OUT2

BLUE

KM4

Y/ G

BROWN

BLACK

GREY

21

A2

6

22

4

2

A1

5

3

1

21

A2

6

22

4

2

A1

5

3

1

BLUE

21

A2

6

22

4

2

A1

5

3

1

KM6

F3

F5

F1

F2

F6

F4

F7

KM7

KM8

Y/G

BLAC K

BLAC K

BLA CK

F8

F9

WHIT E

WHIT E

WHIT E

CN7

R Y CG

XT2

YE L LO W

RED

WHITE

TO THE WIRED CONTROLL ER

CN36

( )

GR E E N

BLUE

W

T3(W)

T1 ( U)

T2 ( V)

BLUE

K3

WH IT E

RED

RED

RED

RED

RED

RED

COMP RES SOR

OUTD OOR FAN

HIGH PRE SSURE SWITC H

T1,T 2

K1-K 3

H-PR O

XT2

RT3_ 1,R T3_2

FAN_ IN

COMP_A,COMP_B

KM1

~

KM8

XT1

CT1- CT4

RT2

L-PR O

FAN_ OUT 1,2

RT1

FAN_O-PRO1,2

CONT ACT OR

INDO OR FAN

TRAN SFO RMER

CONNECTORS

CONNECTORS

PIPE TEMP.SENSOR OF UNIT AB

4-WAY TERMINAL

SMALL 5-WAY TERMINAL

LOW PRES SURE SWITC H

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CODE TITLE

H-PR O

XP1- 2

XS1- 3

RT4

RT2_ 1,R T2_2

L-PR O

RT1

CONNECTORS

CONNECTORS

OUTDOOR TEMP.SENSOR

TEMP PROTECTION SWITCH

INDOOR PIPE TEMP.SENSOR

INDOOR ROOM TEMP.SENSOR

OUTDOOR FAN PROTECTION SWITCH

CURR ENT INDUCT OR

F1-F9

THERMAL CUT-OFF

R1-R9 ELECTRICALLY HEATED PIPE

NOTE :TE RMINALS XT1 A ND XT4 MUST BE SU PPL IED

BY T HE SAME POWER

WH I TE

XT3

WHITE

CN3

BROWN

BLA CK

BLU E

GREY

POWE R

XT 1

BROWN

BLACK

BL UE

GR EY

L1L2

L3 N

XT 1

BLUE

RED

CN9

XS3

TO BE CONNECTED KJR-12B

C

N

4

0

F

AN_O-

P

RO1

FAN

_

O

-PRO2

R S

T

COM NONC

SW3

ON

1

SW3

KJR-12B

MODE

RED

WHITE

BLUE

RED

RED

JP1

CN22

KJR-23B

BR O WN

GR E Y

BL AC K

BL UE

BR O WN

GR E Y

BL AC K

BL UE

BR O WN

GR E Y

BL AC K

BL UE

BR O WN

GR E Y

BL AC K

BL UE

XT3 MIDDLE TERMINAL

EL EC T RI C AL SOU R CE

PR OT E CT I ON REL A Y

CN44 CN43

BLACK

BLACK

BLACK

POWER

X T 4

L1L2

L3

RED

WHI TE

XT4

4-WAY TERMINAL

3-WAY TERMINAL

R1

R2

R3

R4

R5

R6

R7

R8

R9

MRCT-200EWN1-D

33

60Hz R410A ClimaMaster Tropical Rooftop Package Unit MCAC-RTSM-2015-01

Ambient Temperature(℉)

Air Flow

CFM

1800

Ent DB

(℉)

75

80

85

90

75

Entering Wet Bulb(℉)

61