SECTION 2

INSTALLATION

SECTION 2

INSTALLATION

WARNING

Do not obstruct the flow of combustion and ventilation air to and from your oven. There must be no

obstructions around or underneath the oven.

CAUTION

For additional installation information, refer to the PS360 Pre-Installation Procedures Manual (Middleby

Marshall P/N 88210-0024) or contact your local Authorized Service Agent.

NOTE

There must be adequate clearance between the oven and combustible construction. Clearance must

also be provided for servicing and for operation.

NOTE

Wiring diagrams are contained in this manual (Section 5, Electrical Schematics) and are also

located inside the Machinery Compartment Access Panel.

NOTE

All aspects of the oven installation, including placement, utility connections, and ventilation requirements, must

conform with any applicable local and national codes. These codes supercede the requirements and guidelines

provided in this manual.

NOTE

In U.S.A., the oven installation must conform with local codes, or in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1. The oven, when installed, must be electrically grounded in accordance with local

codes, or in the absence of local codes, with the National Electrical Code (NEC), or ANSI/NFPA70.

NOTE

In Canada, the oven installation must conform with local codes, or in the absence of local codes, with the Natural

Gas Installation Code, CAN/CGA-B149.1, or the Propane Gas Installation Code, CAN/CGA-B149.2, as applicable.

The oven, when installed, must be electrically grounded in accordance with local codes, or in the absence of local

codes, with the Canadian Electrical Code CSA, C22.2, as applicable.

NOTE

For Australian installation, the oven installation must conform with AGA Code, AG601, and with any requirements of

the appropriate statutory authority.

2-1

SECTION 2

INSTALLATION

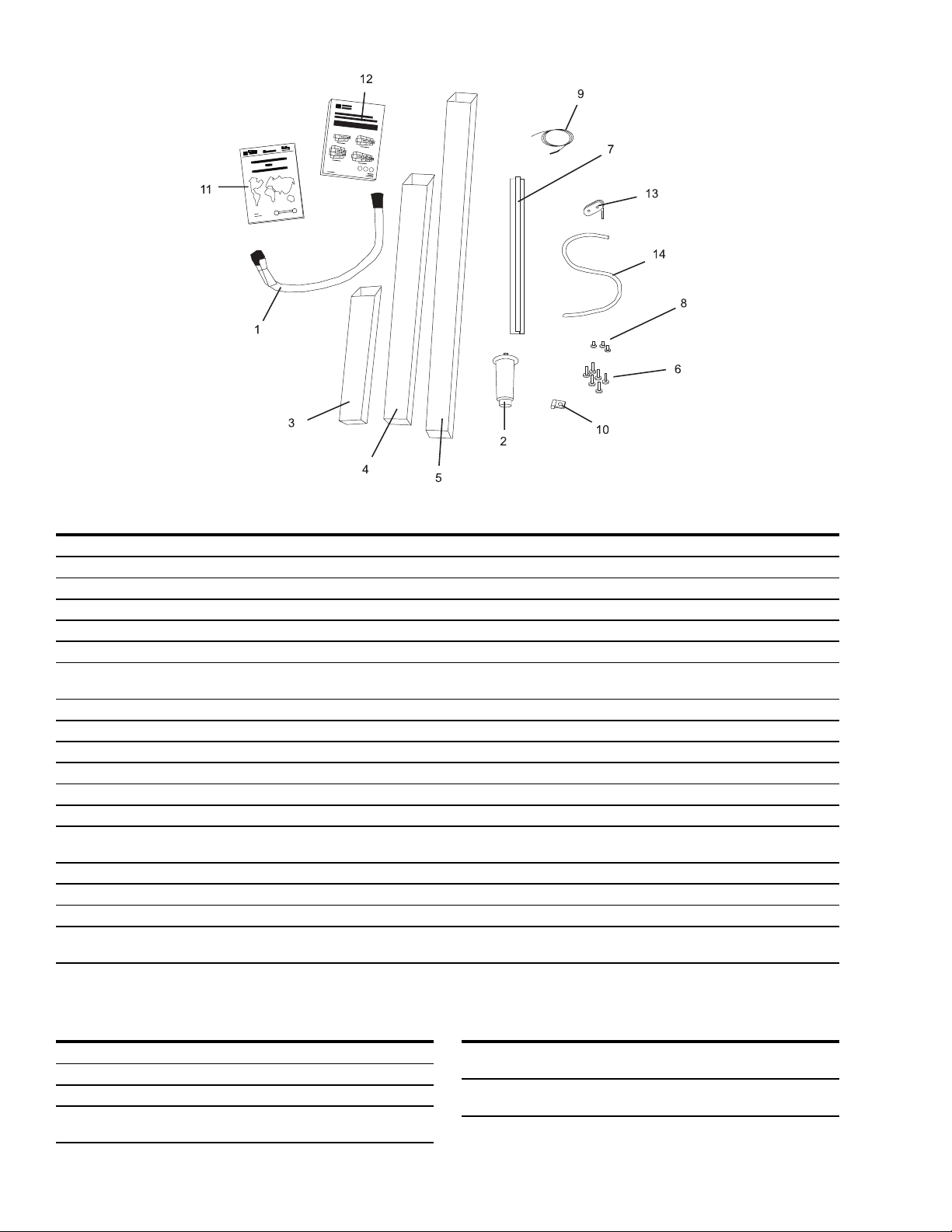

I. INSTALLATION KIT

Fig. 2-1 - Installation Kit

Item Part # Description Tandem Double Tandem Tri Tandem Quad Tandem

1 22361-0001 Flexible Gas Hose 2434

2 22450-0028 Adjustable Legs 8 8 12 16

3 30773 Flue Vent, 14"Lg. 2 - - -

4 30759 Flue Vent, 29-1/2"Lg. - 2 3 4

5 30758 Flue Vent, 50" Lg. - 2 - -

6 21256-0008 Screw, 10-32 x 3/8 A/R A/R A/R A/R

7 35000-1103 Conveyor End Stop - PS360 1 2 - -

35000-1899 Conveyor End Stop - PS360WB

8 21292-0001 Scr, #2PT 10-16 x 3/4 Hx Wsh A/R A/R A/R A/R

9 33984 Thermocouple 2434

10 27276-0001 Cable Clamp 2434

11 1002040 Warranty, Parts & Serv. Dist.List 1111

12 39223 Owners Operating and Installation Manual (English) 1111

13 27126-0238 11 Piece Hex Key Set 1111

14 31389 Silicone Tubing, 36 (914mm) L x 2434

- 35000-1454

- 35000-1456 Front Gasket Spacer 2444

- 35000-1457 Rear Gasket Spacer 2444

- 37200-0013

32483

5/16 (8mm) ID x 7/16 (11mm) OD

Machinery Compartment Trim Strip

Baking Chamber Gasket and Frame - PS360

Baking Chamber Gasket and Frame - PS360WB

1222

1222

II. TRANSITION CHAMBER COMPONENTS (Quad Tandem Ovens Only)

Qty. Part # Description

1 48009-0025 Side Wall

1 35000-1748 Rear Support

2 35000-1749 Front Support

2 37000-0697 Top Support Channel - PS360

32455 Top Support Channel - PS360WB

Qty. Part # Description

1 37000-0696 Floor Panel - PS360

32457 Floor Panel - PS360WB

1 48009-0024 Top Panel - PS360

32456 Top Panel - PS360WB

2-2

III. VENTILATION SYSTEM

IMPORTANT

Where national or local codes require

the installation of fire suppression

equipment or other supplementary

equipment, DO NOT mount the equip-

ment directly to the oven.

MOUNTING SUCH EQUIPMENT ON

THE OVEN MAY:

VOID AGENCY CERTIFICATIONS

RESTRICT SERVICE ACCESS

LEAD TO INCREASED SERVICE

EXPENSES FOR THE OWNER

A. REQUIREMENTS

A mechanically driven ventilation system is required for the

oven.

PROPER VENTILATION OF THE OVEN IS THE

RESPONSIBILITY OF THE OWNER.

B. RECOMMENDATIONS

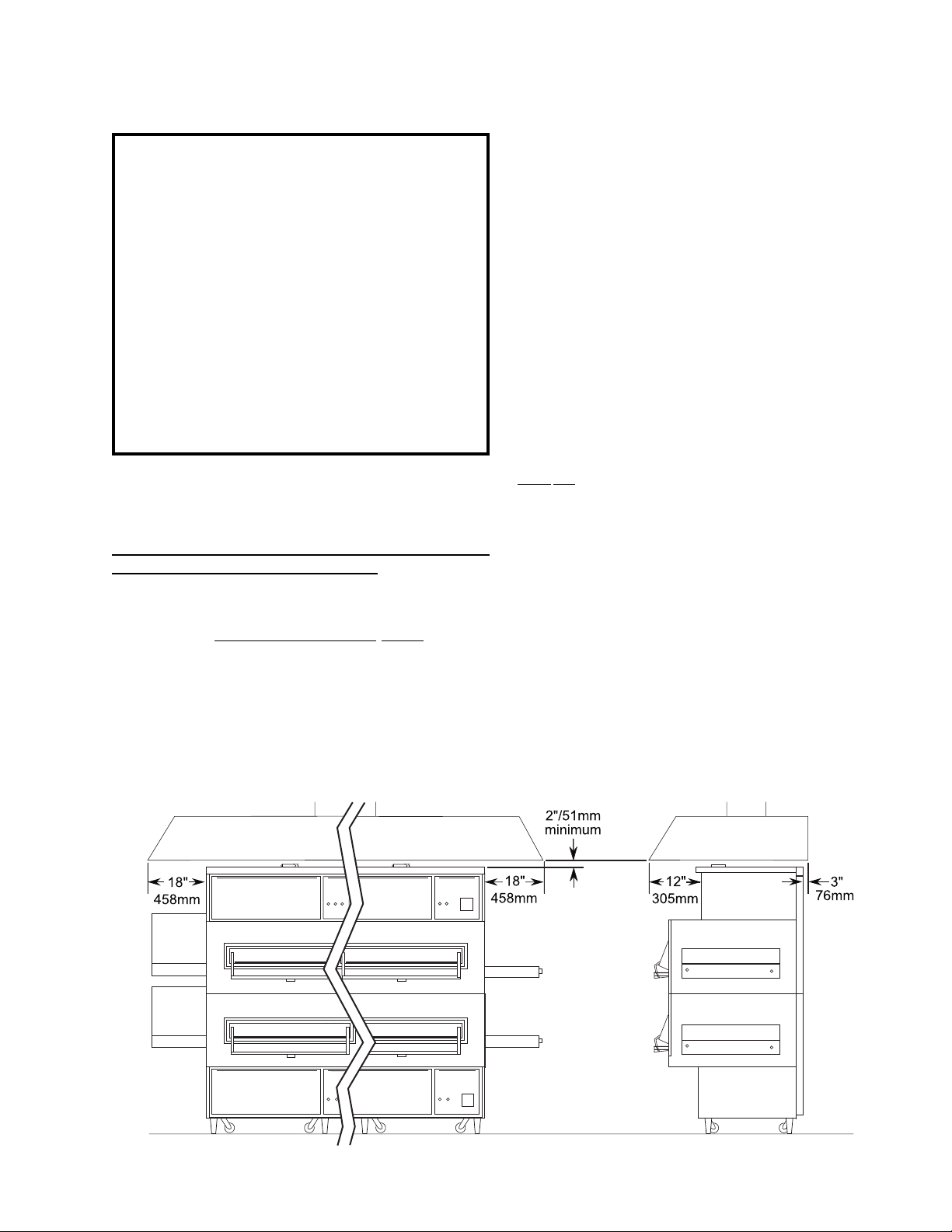

NOTE THAT THE HOOD DIMENSIONS SHOWN IN FIGURE 2-2 ARE RECOMMENDATIONS ONLY. LOCAL

AND NATIONAL CODES WILL VARY, AND MUST BE

FOLLOWED WHEN INSTALLING THE VENTILATION

SYSTEM. ANY APPLICABLE LOCAL AND NATIONAL

CODES SUPERSEDE THE RECOMMENDATIONS

SHOWN IN THIS MANUAL.

SECTION 2

INSTALLATION

The rate of air flow exhausted through the ventilation

system may vary depending on the oven configuration and

hood design. Consult the hood manufacturer or ventilation

engineer for these specifications.

To avoid a negative pressure condition in the kitchen area,

return air must be brought back to replenish the air that was

exhausted. A negative pressure in the kitchen can cause

heat- related problems to the oven components as if there

were no ventilation at all. The best method of supplying

return air is through the heating, ventilation and air

conditioning (HVAC) system. Through the HVAC system,

the air can be temperature-controlled for summer and

winter. Return air can also be brought in directly from

outside the building, but detrimental effects can result from

extreme seasonal hot and cold temperatures from the

outdoors.

NOTE: Return air from the mechanically driven system

must not blow at the opening of the baking chamber. Poor

oven baking performance will result.

C. OTHER VENTILATION CONCERNS

Special locations, conditions, or problems may re-

quire the services of a ventilation engineer or special-

ist.

Inadequate ventilation can inhibit oven performance.

It is recommended that the ventilation system and

duct work be checked at prevailing intervals as speci-

fied by the hood manufacturer and/or HVAC engineer

or specialist.

Fig. 2-2 - Ventilation System

2-3

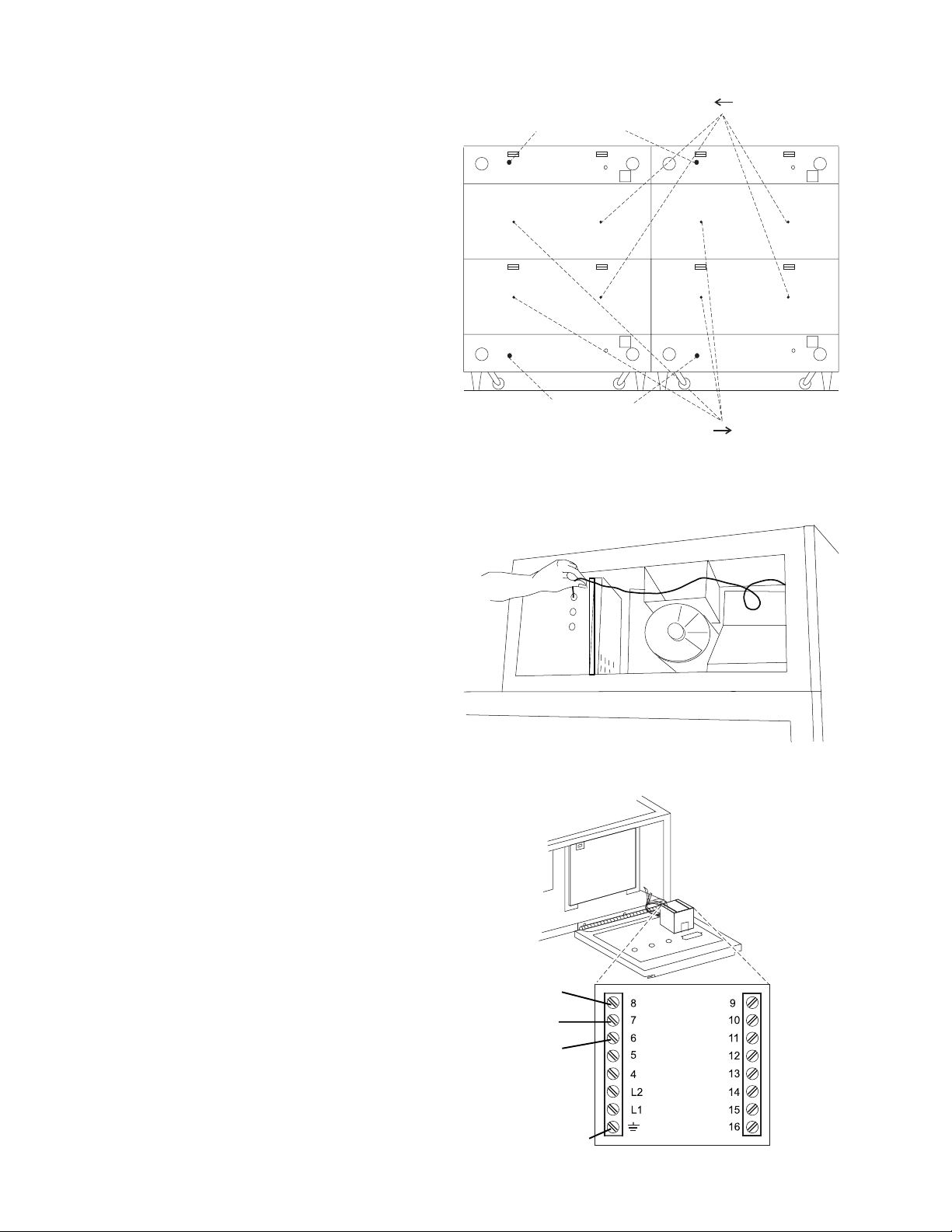

IV.

THERMOCOUPLE

INSTALLATION

1. Install the thermocouple sensing bulb into the correct

hole in the rear of the oven, as shown in Figure 2-3.

2. Thread the thermocouple lead through the grommet

and into the machinery compartment.

Thread lead into

machinery

compartment here

Thread lead into

machinery

compartment here

Use for conveyor

Use for conveyor

Figure 2-3

Thermocouple Installation Locations

3. Remove the right-side access panel of the machinery

compartment.

4. Thread the thermocouple lead through the side of the

machinery compartment as shown in Figure 2-4, and

into the electrical box (at the right-front of the machinery compartment).

5. Connect the thermocouple leads to the temperature

controller as shown in Figure 2-5.

6. Repeat Steps 1-5 for each of the other oven sections in

the installation.

Figure 2-4

Placing the Thermocouple Leads

Figure 2-5

Thermocouple Lead

Connections

8=White=Positive

7=Red=Negative

R=No Connection

Ground=Shielded cable

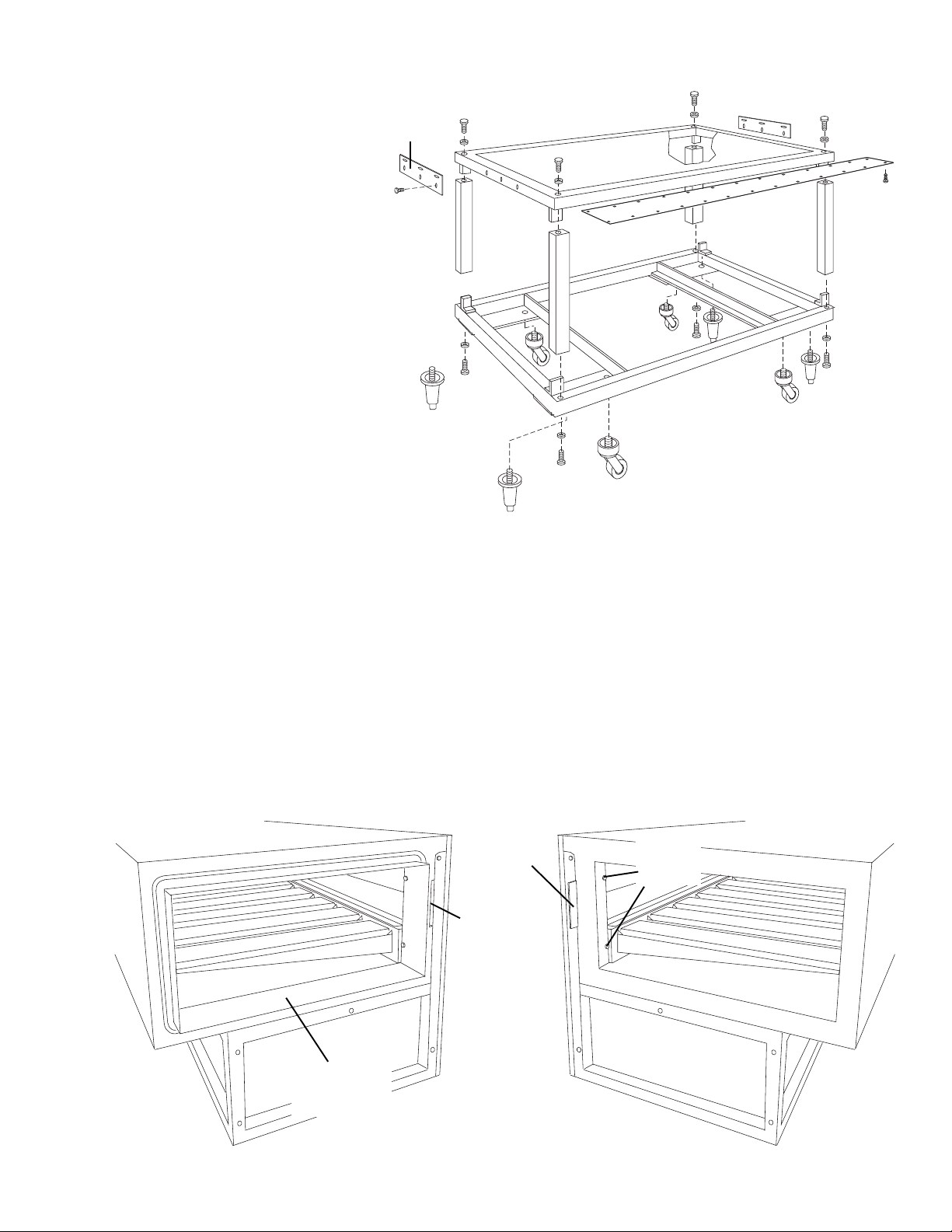

V. ASSEMBLY

A. OVEN STAND

If the installation includes upper ovens

mounted atop lower ovens, the ovens

must be stacked before joining the

tandem ovens together.

If the installation includes ovens that

are to be mounted on stands, assemble

the ovens to the stands before joining

the ovens together. An exploded view

of the stand is shown in Figure 2-6.

B. JOINING THE OVEN BODIES

Attachment

plates inc. w/

upper oven

Figure 2-6

Exploded View -

Oven Stand

For TANDEM and DOUBLE TANDEM installations, perform

Steps 1-8 in this section to join the ovens.

For TRI TANDEM installations, perform Steps 1-8 to join

two of the ovens together, and ensure that they are level;

then, repeat Steps 1-8 to join the third oven to the two that

have already been assembled.

For QUAD TANDEM installations, perform Steps 1-8 for

1. Determine the proper position of the ovens by referring

to Figure 2-7. Then, move the ovens to their approximate

final locations.

2. Check that the top and bottom air finger retaining

screws are present on all mating ends of the oven

sections. See Figure 2-7. The screws prevent the air

fingers from sliding in between the oven sections.

EACH PAIR of ovens, producing two sets of two joined

ovens. Do not assemble the center bridge section at this

time.

Figure 2-7

LEFT OVEN RIGHT OVEN

Oven Positioning and Alignment

Alignment

plate

Slot for

alignment

plate

Air finger

retaining

screws

Sealing gasket

assembly (pre-

mounted)

NOTE: The Sealing Gasket Assembly may be

pre-mounted to EITHER of the two ovens.

Loading...

Loading...