Page 1

SHG-A* Absolute, SHG-TC, SHG-TS & SHG-VS

Linear Encoders

NEWALL MEASUREMENT SYSTEMS LTD

N

Installation Manual

THIS MANUAL SHOULD BE USED IN CONJUNCTION WITH WITH THE

CORRESPONDING PROTOCOL DOCUMENT

Page 2

Newall Measurement Systems

Contents

1

CONTENTS

1.0 Technical Specification..............................................1

1.1 Bracketry ..............................................................................2

1.2 Preparation ..........................................................................2

1.3 Warnings ..............................................................................2

2.0 Encoder Assembly ....................................................3

3.0 Mounting The Reader Head ......................................3

4.0 Mounting The Scale....................................................4

4.1 Double End Mounting ..........................................................4

4.2 Single End Mounting ............................................................6

4.3 Scales in Excess of 2.5 Meters............................................7

5.0 Fitting The Scale Guard ............................................9

6.0 Cable Routing ..........................................................10

7.0 Final Check................................................................10

Appendix A - Scale Bracket Mounting Options ............11

Appendix B - Dimensional Drawing ................................12

Page 3

Introduction

Newall Measurement Systems

2

1.0 INTRODUCTION

This manual will provide connection and mounting instructions for Newall's Absolute, Digital and Distance

Coded linear encoders. It is important that you read and understand this manual prior to commencing the

hardware installation. Electronic specifications can be found in the corresponding integration manual.

If you have any questions relating to this manual or installation contact Newall or your local authorised

Newall representative.

1.1 Bracketry

Due to the variety of machine types and applications, it may be necessary to design, make and fit custom

brackets for the linear encoder assembly. If custom brackets are needed, make certain they are rigid

enough not to allow any flexing or distorting while the machine is in operation. Newall offers a variety of

bracket kits to aid in the installation. Contact Newall or your local authorised representative for details.

1.2 Preparation

Prior to beginning the installation the machine should be studied to determine where the linear encoder(s)

will be fitted.

In order to reduce erroneous readings caused by machine wear, it is recommended that the scale be fitted

as close to the machine lead screw or axial drive shaft as possible.

The actual overall scale length is approximately 258mm (10.1") longer than the stated scale travel on these

SHG encoders (e.g. if SHG travel length is 40", the overall length of the scale will be 50.1").

For SHG-TS and SHG-VS outboard mounting of the scale support brackets will add approximately 20mm

(3/4") to the effective scale travel (Refer to Appendix A).

For a more compact installation, scale travels of 300mm (12") or less may be fitted by supporting one end

of the scale only by use of a single end mounting block (Refer to Figure 6.4 and 6.10).

The moving member of the linear encoder assembly can be either the reader head or the scale.

Cable routing from the reader head should be examined (See Section 8). Each reader head is provided with

either a 3.5 meter (11.5') or 7 meter (22') cable. Extension cables are available in 1 meter (3'), 2 meter

(6.5'), 3.5 meter (11.5'), 5 meter (16.5') and 10 meter (32') lengths. Contact Newall or your local authorised

representative for details.

1.3 Warnings

If for any reason the machine axis travel is greater than the actual scale travel, it is recommended that

‘mechanical stops’ are fitted to the machine to avoid damage caused by over travel. Newall will not accept

responsibility for scale and reader head damage caused by machine over travel.

Both the reader head and the scale are precision made components and it is important that they are

handled with care. By design, the linear encoders can withstand the rigors of the harsh workshop

environment. However, permanent damage can occur through bending or severe impact.

It is important that the scale be kept at least 13mm (0.5") away from any magnetic bases on indicators or

magnetic chucks.

Page 4

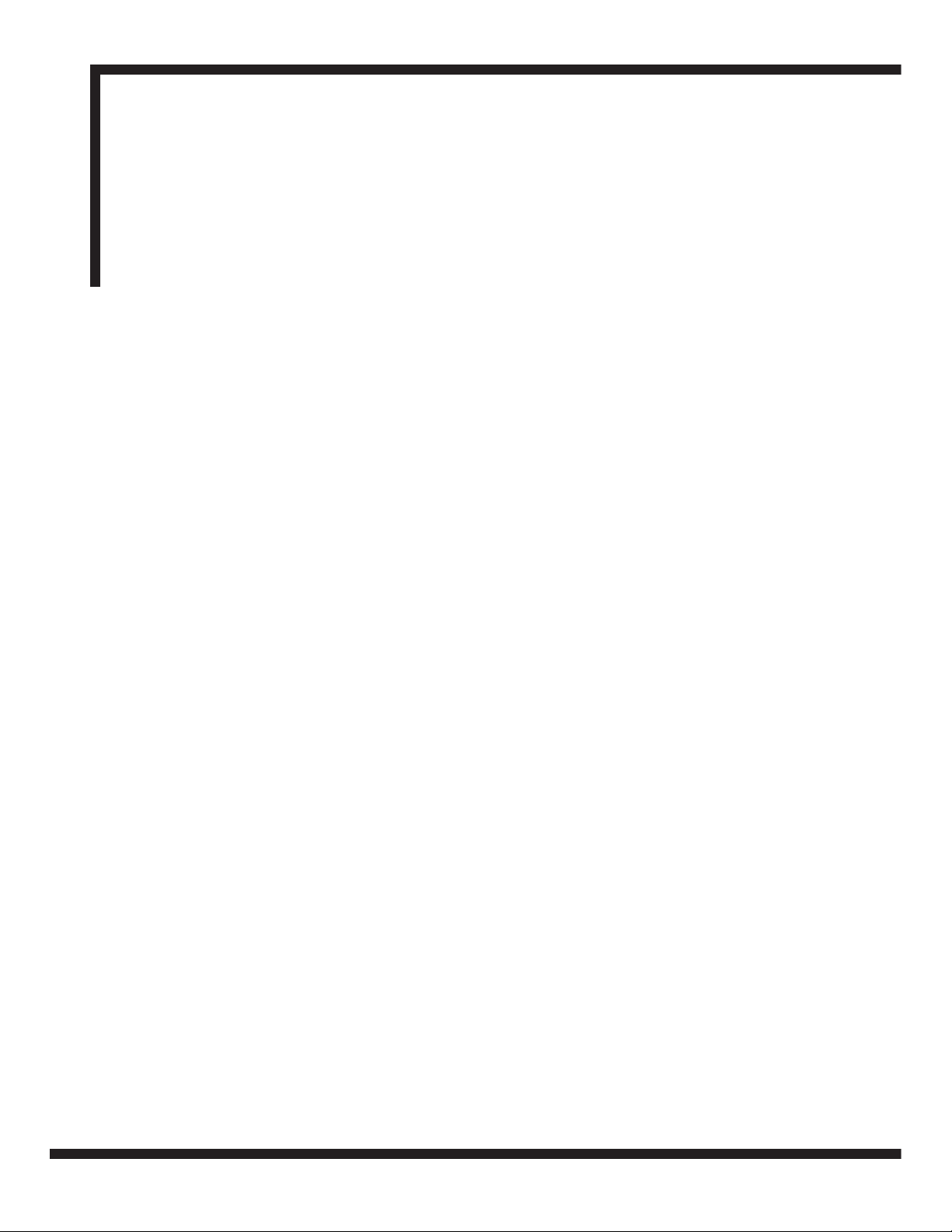

Figure 3.1 - Alignment of the reader head

2.0 ENCODER ASSEMBLY

Item Description

1 Reader Head

2 Scale

3 Scale Support Link

4 Scale Anchor Pin

5 Support Pillar Short

Item Description

6 Support Pillar Long

7 Scale Cover

8 M5 Nut

9 M8 x Socket Button Head

Newall Measurement Systems

3

Encoder Assembly / Mounting the Reader Head

3.0 MOUNTING THE READER HEAD

Mount the reader head together with its bracket(s) to the machine and secure the assembly parallel with axis travel to

within +/-0.05mm (0.002"), (Refer to Figure 3.1).

Final adjustments can be carried out by use of laminated shims, which are included with each transducer assembly.

Each layer of shim is equivalent to 0.05mm (0.002").

Less than 2.5m (100”)

Page 5

Mounting the Scale

Newall Measurement Systems

4

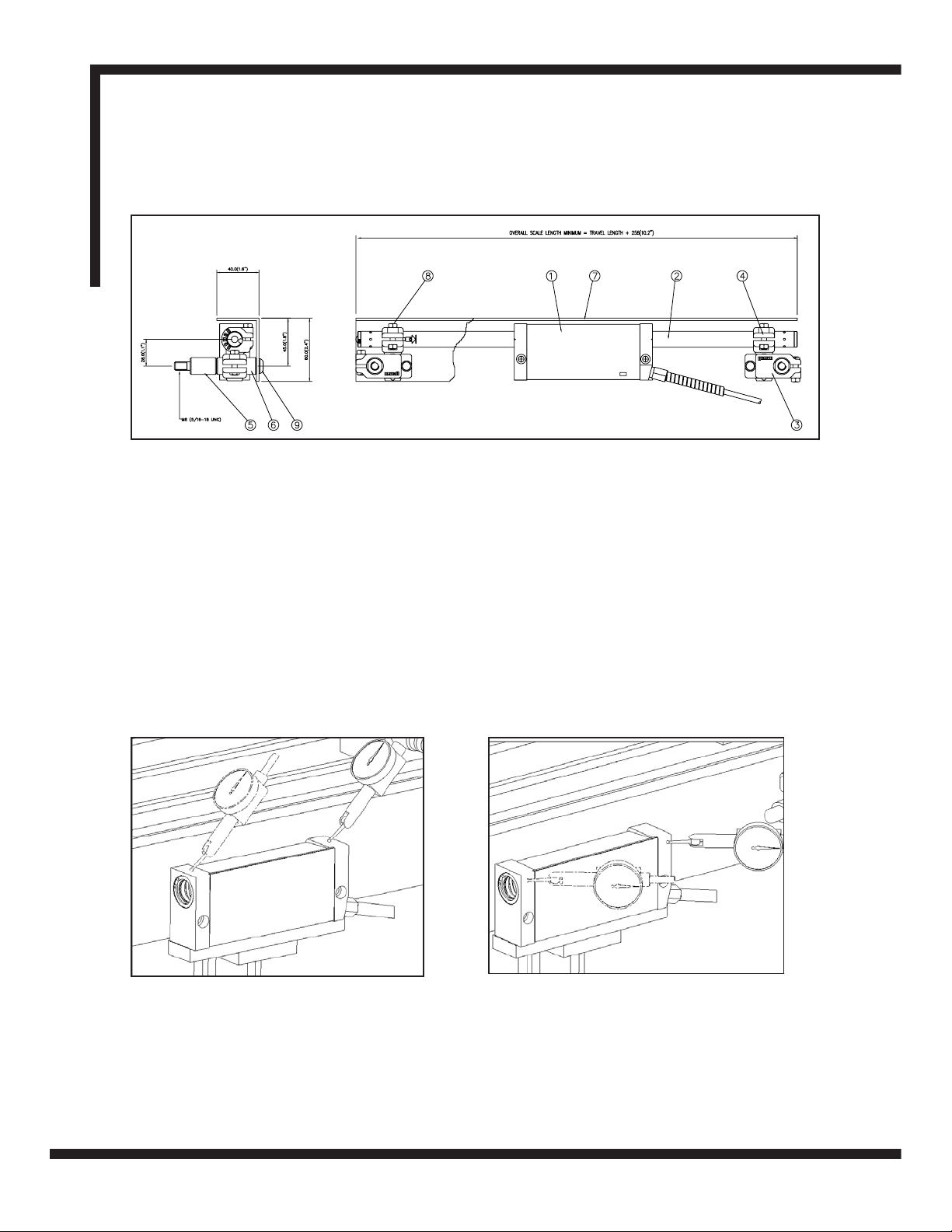

4.0 MOUNTING THE SCALE

4.1 Double End Mounting

Note: Refer to section 4.3 for mounting scales in excess of 2.5 metres.

Each end of the scale is different and can be identified by the “calibration adjustment end” and the “fixed end.

NOTES:

(A) Erroneous readings will occur if the reader head is allowed to travel beyond the effective travel limits

(Refer to Figure 4.1).

(B) The pre-load on the balls are factory set via the set screw at the calibration adjustment end.

Caution: Do not tamper with or adjust the set screw as this will alter the calibration and accuracy

specification of the scale and void the warranty (Refer to Figure 4.1).

(C) When mounting scales in the vertical plane, the calibration adjustment end should be positioned at the top.

Once the reader head is secured and correctly aligned, the scale support brackets can now be fitted. The scale support

brackets consist of the support pin, the support link and the pillar(s).

Traverse the machine to its maximum position toward the non-cable entry side of the reader head. Maximum position

means all available travel, including hand winding past any electrical limits or trip dogs.

Carefully slide the scale or setup tube through the reader head, allowing for a sufficient amount of scale to project from

the reader head in order to fit the scale support brackets. Note: If the scale travel is more then 60" it is recommended

that a setup tube is used for alignment to avoid accidental damage to the actual scale tube.

Assemble the scale support link to the scale support pin leaving approximately 3mm (1/8") gap between the bottom of

the pin shoulder and the top of the link.

Slide the link/pin assembly onto the scale to approximately 5mm (0.2") away from the end of the reader head.

Transfer punch through the support link and into the machine casting. It is important that the support link is kept square

to its mounting surface at all times.

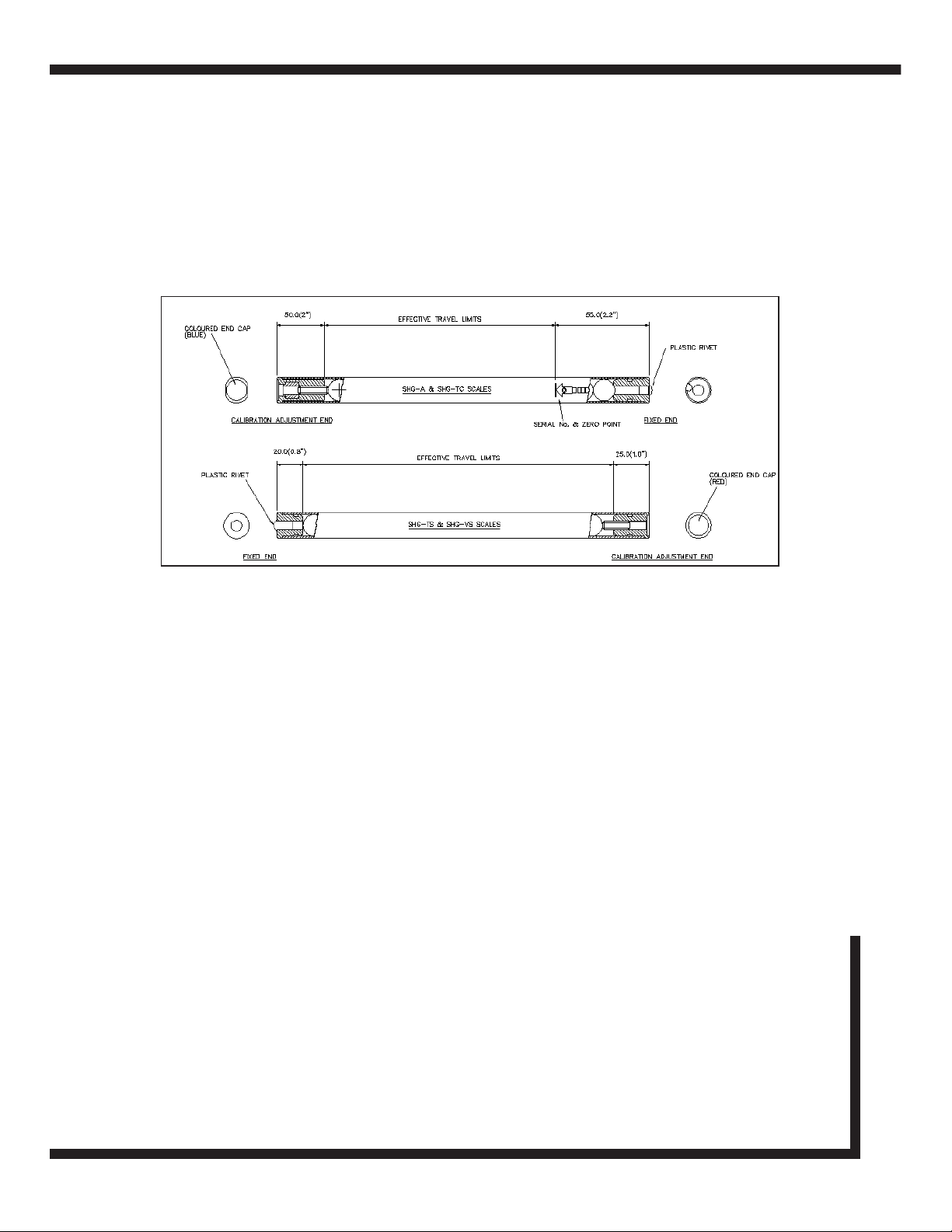

Remove the link/pin assembly and the scale from the reader head. Drill and tap M8 x 18mm deep (USA 5/16 - 18 x 3/4"

deep) into the machine casting as marked by the transfer punch. Fit the pillar(s) to the machine casting by using one of

the methods shown in Figure 4 .3. The pillar should fit square and flush to the machine surface.

Figure 4.1 -Scale

Page 6

Mounting the Scale

A maximum of two support pillars may be screwed together to allow for sufficient adjustment of the scale. If two pillars

are insufficient to enable the scale to be mounted, then additional brackets will be necessary. These brackets must be

sufficiently rigid to eliminate any axial movement of the scale.

Loosely fit the support link/pin assembly onto the pillar and pass the scale through the reader head and into the support

pin. While gently sliding the scale forward and back 25 - 50mm (1 - 2") through the support pin, carefully tighten the hex

screws on the support link, ensuring that the scale slides smoothly through the reader head and into the support pin. If

any interference is detected then fully loosen the hex screws on the support link and repeat this step.

Note: Do not force the scale through the Support Pin.

IMPORTANT WARNING:

THE CENTER LINE BORE OF THE READER HEAD MUST BE IN DIRECT ALIGNMENT WITH THE

CENTER LINE BORE OF THE SUPPORT PIN. PERMANENT DAMAGE TO SCALE AND/OR

ERRONEOUS READINGS WILL OCCUR IF THIS WARNING IS NOT FOLLOWED (REFER TO FIGURE 4.2).

Remove the scale from the reader head and traverse the machine to its full extent in the opposite direction.

Full extent means hand winding past electrical limits.

Assemble the scale support link to the scale support pin leaving approximately 3mm (1/8") gap between the bottom of

the pin shoulder and the top of the link.

Slide the link/pin assembly onto the scale making certain that there is sufficient clearance between the reader head and

the support link to prevent damage to the reader head cable. Do not secure the support pin to the scale at this time.

Transfer punch through the support link and into the machine casting. It is important that the support link be kept square

to its mounting surface at all times.

Figure 4.2 - Reader head and bracket alignment

Newall Measurement Systems

5

Page 7

Mounting the Scale

Newall Measurement Systems

6

Remove the link/pin assembly and the scale from the reader head. Drill and tap M8 x 18mm deep (USA 5/16" -18 x 3/4"

deep) into the machine casting as marked by the transfer punch. Fit the pillar(s) to the machine casting by using one of

the methods shown in Figure 4.3. The pillar shoulder fit square and flush to the machine surface.

A maximum of two support pillars may be screwed together to allow for sufficient adjustment of the scale. If two pillars

are insufficient to enable the scale to be mounted, then additional brackets will be necessary. These brackets must be

sufficiently rigid to eliminate any axial or radial movement of the scale.

Loosely fit the support link/pin assembly onto the pillar and pass the scale through the reader head and into the support

pin. While gently sliding the scale forward and back 25 - 50mm (1 - 2") through the support pin, carefully tighten the hex

screws on the support link, ensuring that the scale slides smoothly through the reader head and into the support pin. If

any interference is detected then fully loosen the hex screws on the support link and repeat this step.

Carefully slide the scale through the support pin, through the reader head and into the opposite support pin. FULLY

TIGHTEN THE SUPPORT PIN HEX SCREW AT THE FIXED END OF THE SCALE, BUT ONLY “SNUG UP” THE HEX

SCREW ON SUPPORT PIN AT THE CALIBRATION ADJUSTMENT END.

4.2 Single End Mounting

Note: The maximum total length of the scale must not exceed 610mm (24") when using a single end

mounting kit. The single end mounting kit is sold separately, UK part number 600-63610, USA part number 294-

23010.

For SHG-A* and SHG-TC remove the nylon pan head screw from the end of the scale to access the tapped hole. For

SHG-TS and SHG-VS, remove the red end cap fromt he end of the scale to access the tapped hole.

After the reader head has been installed, slide the scale through the reader head and insert the end of the scale into

the single end mounting block (Refer to Figure 4.4).

Once the position for the single end mounting block has been determined mark the machine casting using the slot in the

mounting block as the guide. Drill and tap M6 x 12mm deep (USA 1/4 - 20 x 1/2"). Fit the mounting block using the M6

(USA 1/4 - 20") socket head cap screw and washer.

Check the alignment by gently sliding the scale through the head and in and out of the mounting block. A djustments

may be carried out by adjusting the M5 jacking screws. When the alignment is complete secure the scale by inserting

the M5 screw and washer through the mounting block and into the calibration adjustment end of the scale.

Figure 4.3 - Support pillars

Page 8

Mounting the Scale

4.3 Scales in Excess of 2.5 Meters

Traverse the machine to fullest extent of travel including hand winding past any electrical limits or trip dogs.

Insert the set up tube into the reader head, allowing for a sufficient amount of scale to project from the reader head in

order to fit the scale mounting brackets.

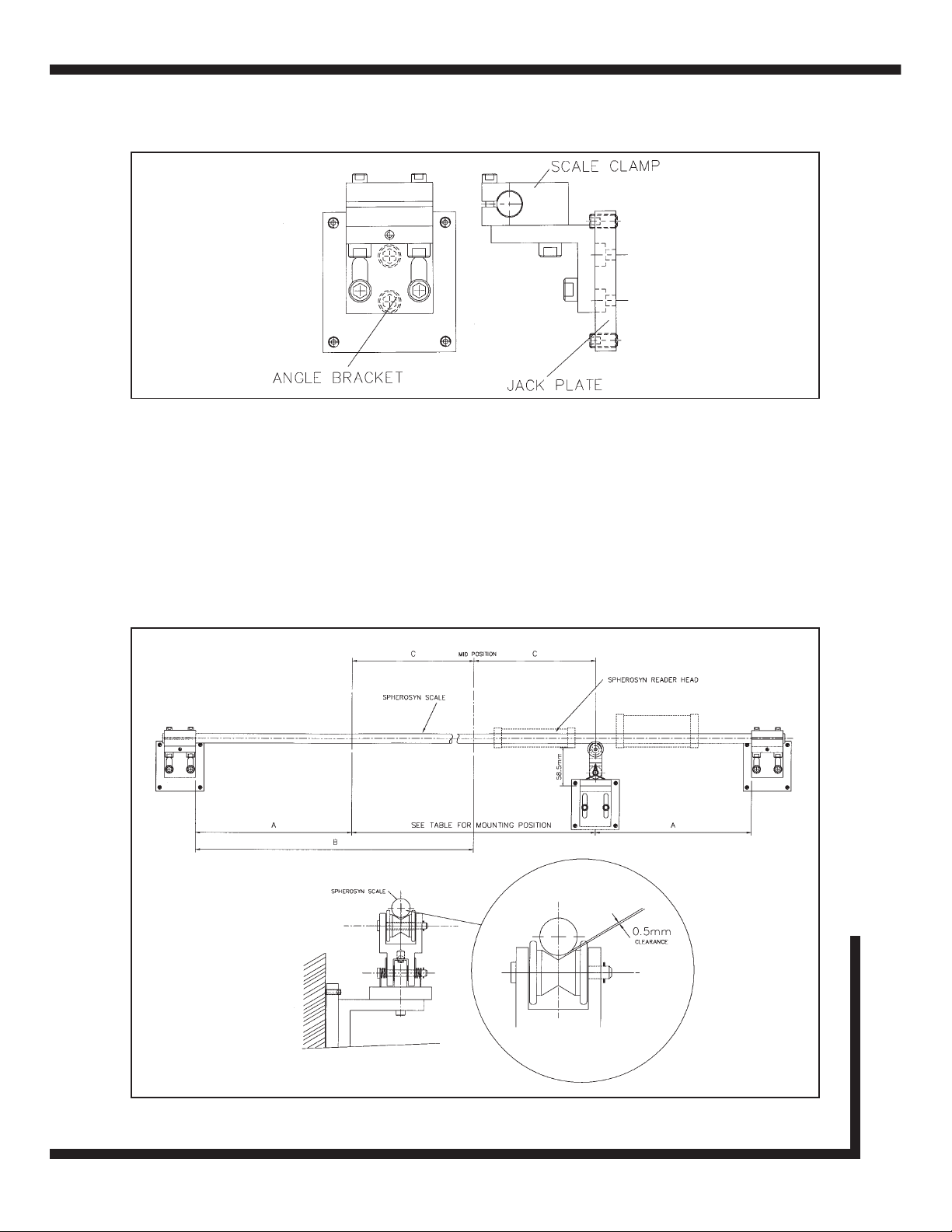

Assemble the angle bracket to the scale clamp (Refer to Figure 4.5). The jack plate is included in each bracket kit and

will only be required if the machine mounting face is not a machined surface. Slide the assembly onto the scale,

allowing approximately 10mm clearance from the end of the reader head.

Mark the position of the jack plate (if required) or the angle support bracket. Drill and tap the necessary fixing holes and

assemble the bracket to the machine.

Remove the blank tube and the bracket assembly from the reader head. Drill and tap M8 x 18mm (USA 5/16 - 18 x

3/4") fixing holes. Fit the jack plate (if required) and secure to the machine. Assemble the scale clamp and the angle

bracket to the jack plate but do not secure. Traverse the reader head as near to the bracket assembly as possible.

Slide the set-up tube through the reader head into the scale clamp. Adjust the brackets into position and carefully

tighten the screws. Check that the set-up tube slides through the reader head and into the scale clamp smoothly

without any fouling or interruption.

Remove the set-up tube and traverse the machine to the full extent in the opposite direction. Remember the “full extent”

is the absolute maximum travel up to the mechanical “dead stops.”

Check the overall length of the actual scale and measure from the outside edge of the scale clamp already fitted to the

machine and mark the position of the scale on to the machine.

Slide the set-up tube into the reader head, assemble the remaining scale bracket assembly including the jacking plate

(if required) and slide onto the tube.

Set the outside edge of the scale clamp level with the mark that indicates the overall length of the scale and mark the

fixing position for the bracket assembly.

58.00

SINGLE END MOUNTING BLOCK

30.00

10.00

25.40

FIXING SLOT FOR M6 SCREW

JACKING SCREWS M5

Figure 4.4 - Single end mounting

Newall Measurement Systems

7

Page 9

Newall Measurement Systems

8

Mounting the Scale

For scales which are mounted in the horizontal position, spring loaded scale supports are included and should be

positioned according to Table 1.

Once the locations for the supports have been determined, the reader head should be positioned in the location where

the first support is to be fitted. Assemble the support unit, including the jack plate if required. Mark the position for the

fixing screws, drill and tap (M8 for the jack plate or M6 for the angle bracket). Ensure that the angle bracket has

sufficient movement utilizing the two slots to allow for adjustment in the vertical plane. It is important that the top face

of the angle bracket is set to 58.5mm (2.3") from the bottom machined face on the reader head.

Figure 4.6 - Long scale mounting and support details

Figure 4.5 - Long scale support bracket assembly

Page 10

Mounting the Scale / Fitting the Scale Guard

Length

2500mm

3000mm

3500mm

4000mm

4500mm

5000mm

5500mm

6000mm

6500mm

7000mm

7500mm

8000mm

8500mm

9000mm

9500mm

10000mm

10500mm

11000mm

No. of Scale

Supports

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

6

6

6

Left Side (A)

850mm

1100mm

1350mm

1500mm

1125mm

1250mm

1350mm

1500mm

1300mm

1400mm

1500mm

1600mm

1410mm

1500mm

1580mm

1420mm & 2840mm

1500mm & 3000mm

1570mm & 3140mm

Right Side (B)

850mm

1100mm

1350mm

1500mm

1125mm

1250mm

1350mm

1500mm

1300mm

1400mm

1500mm

1600mm

1410mm

1500mm

1580mm

1420mm & 2840mm

1500mm & 3000mm

1570mm & 3140mm

Mid Position

of Travel (B)

-

-

-

-

2250mm

2500mm

2750mm

3000mm

-

-

-

-

4250mm

4500mm

4750mm

-

-

-

Left Side Position

of Travel (C)

-

-

-

-

-

-

-

-

650mm

700mm

750mm

800mm

1410mm

1500mm

1580mm

710mm

750mm

785mm

Right Side Position

of Travel (C)

-

-

-

-

-

-

-

-

650mm

700mm

750mm

800mm

1410mm

1500mm

1580mm

710mm

750mm

785mm

FROM FIXING BRACKET

Table 1

Newall Measurement Systems

9

5.0 FITTING THE SCALE GUARD

Each encoder includes a protective guard. This aluminium guard is intended to protect the scale from impact damage.

The guard can be attached to the machine casting or by means of the scale support pillars (Refer to Figure 5.1).

To fit the guard to the support pillars, measure and mark off the distance between the center of each pillar. For SHG,

drill two 8.5mm (3/8") holes at either end of the guard. The guard can be attached to the pillars by using the button

head screws provided. After the guard is attached, move the machine axis to both extents of its travel ensuring that the

guard does not interfere with or rub against the reader head.

Figure 5.1 - Fitting the scale guard (example shown using a Spherosyn™ scale)

Page 11

Newall Measurement Systems

10

Cable Routing / Final Check

6.0 CABLE ROUTING

The most important and the most over looked aspect of fitting the linear encoder is proper cable routing. Dangling and

loose cables can be snagged or broken causing irreparable damage. Care should be taken in order to ensure that the

cables are secured to the machine and that cable loops do not interfere with any part of the machine or the linear

encoder movements. “P” clips and thread forming screws are provided to route the cables from the reader head.

Note: The armored cable is an integral part of the reader head. If the cable becomes damaged, then it would

have to be replaced complete with the reader head.

If extension cables are used, do not allow the plug and socket junction to lie in the swarf tray or in the direct flow of

coolant or oil. Optional IP67 rated submergible connectors are available if required.

In order to avoid problems associated with electrical noise and interference, do not allow the cables to lie across

electrical motors, fuse boxes or electrical pumps.

7.0 FINAL CHECK

Prior to putting the linear encoder into operation, slowly traverse the machine axis to both extents of its travel checking

at all times that the cables are secure and that machine over travel cannot occur. Newall will not accept responsibility

for linear encoder malfunction caused by over travel or damaged cables.

Page 12

Appendix A

Newall Measurement Systems

11

Appendix A - SCALE BRACKET MOUNTING OPTIONS

Outboard scale support mounting

Scale supports inverted

Page 13

Appendix B

Newall Measurement Systems

12

Appendix B - DIMENSIONAL DRAWING

Page 14

Appendix B (cont’d)

Newall Measurement Systems

13

Appendix B - DIMENSIONAL DRAWING

Page 15

Notes

Newall Measurement Systems

14

Page 16

NEWALL MEASUREMENT SYSTEMS LTD

HEAD OFFICE

Newall Measurement Systems Ltd.

Technology Gateway, Cornwall Road

South Wigston

Leicester LE18 4XH

United Kingdom

Telephone: +44 (0)116 264 2730

Facsimile: +44 (0)116 264 2731

Email: sales@newall.co.uk

Web: www.newall.co.uk

Newall Electronics, Inc.

1778 Dividend Drive

Columbus, OH 43228

Telephone: +1 614 771 0213

Toll Free: 800.229.4376

Facsimile: +1 614 771 0219

Email: sales@newall.com

Web: www.newall.com

023-80620/03-UK . Oct 2006

Loading...

Loading...