Page 1

July 15, 1999

GFK-1490C

MPORTANT PRODUCT INFORMATION

I

READ THIS INFORMATION FIRST

Product: IC693CPU364 CPU Module with Ethernet Interface

IC693CPU364-AC with Firmware Release 9. 10

Introduction

This document contains information that is not available in any other publication; therefore, we recommend you save it

for future reference. This document discusses the features of the CPU module IC693CPU364. This module provides

two functions in one module: (1) it serves as a High Performance CPU, and (2) it provides Ethernet communications

capability with its embedded (built-in) Ethernet Interface. This release provides Ethernet Global Data (EGD) and

configurable Name Resolution for the 364 module.

CPU364 Feature Highlights (Release 9.10)

CPU Features

Ethernet Global Data and Name Resolution

•

based PLC programming software or version 1.0 or later of the VersaPro Windows-based programming software is

required for configuration of these features. For details, refer to the software online help, the T C P/IP Eth ernet

Communications for the IC69* User's Manual, and th e TCP/IP Ethernet Communications for the IC69* Station

Manager's Manual.

The following features were introduced in release 9.00.

are supported in this release. Version 2.2 or later of the Windows

Software Floating-Point.

•

supported by the CPU352. They are implemented in firmware using floating point emulation in the CPU364.

These Floating-Point math function blocks are described in the IC693 PLC Reference Manual.

User memory totals 240K bytes.

•

and 8K of %AQ memory using the MS-DOS PLC progr a mmin g software, ver s ion 9. 02 or later. These th ree

refer ences are configura bl e u p to 3 2 K in r elease 1.0 of the VersaPro softwar e an d r elease 2. 2 of th e Windows-bas ed

PLC programming software. Configuration instructions for this feature are described in the MS-DOS IC693

Progr amming S oftwa re User’ s M anual, and is includ ed in on-lin e help in both of the Windows PLC P rogramming

Softwa re packages.

Sequential Event Recorder.

•

individual discrete (bit) references. This function block is described in the IC693 PLC Reference Manual and in

online help in the Windows PLC Programming Software.

Break-free SNP.

•

variety of modems.

The SNP protocol no longer r equir es a br ea k t o operate. This allows SNP to work over a wider

The CPU364 supports all of the floating-point function blocks that are currently

%R, %AI, and %AQ references are configurable up to 16K of %R, 8K of %AI

The Sequential Event Recorder can be used to record up to 1024 samples of 32

Ethernet Features

• The CPU364 supports connection to an Ethernet network via either (but not both) of two built-in Ethernet network

ports:

AAUI

1.

2.

: Capability is provided for connection to various types of Ethernet LANs via an external AAUI

transceiver connected to the AAUI port. The IC649AEA103 AAUI transceiver may be used, or the user may

supply a different model that meets AAUI standards.

10Base T:

10BaseT port.

The CPU364 provides direct connection to a 10BaseT (twisted pair) Ethernet LAN from its

MS-DOS and W indows are registered trademarks of Microsoft Corporat ion

Page 2

2 Important Product Information

GFK-1490C

• The CPU364 provides network communications using SRTP (Service Request Transfer Protocol) over standard

TCP/IP (Transmission Control Protocol / Internet Protocol) on an Ethernet Local Area Network (LAN). The

CPU364 supports communications with other IC693 PLCs and/or IC697 PLCs equipped with TCP/IP Ethernet

Interfaces, and with MS-DOS TCP/ I P programmin g softwar e an d applica ti on s which u se the TCP/I P Host

Communications Toolkit (HCT) Software.

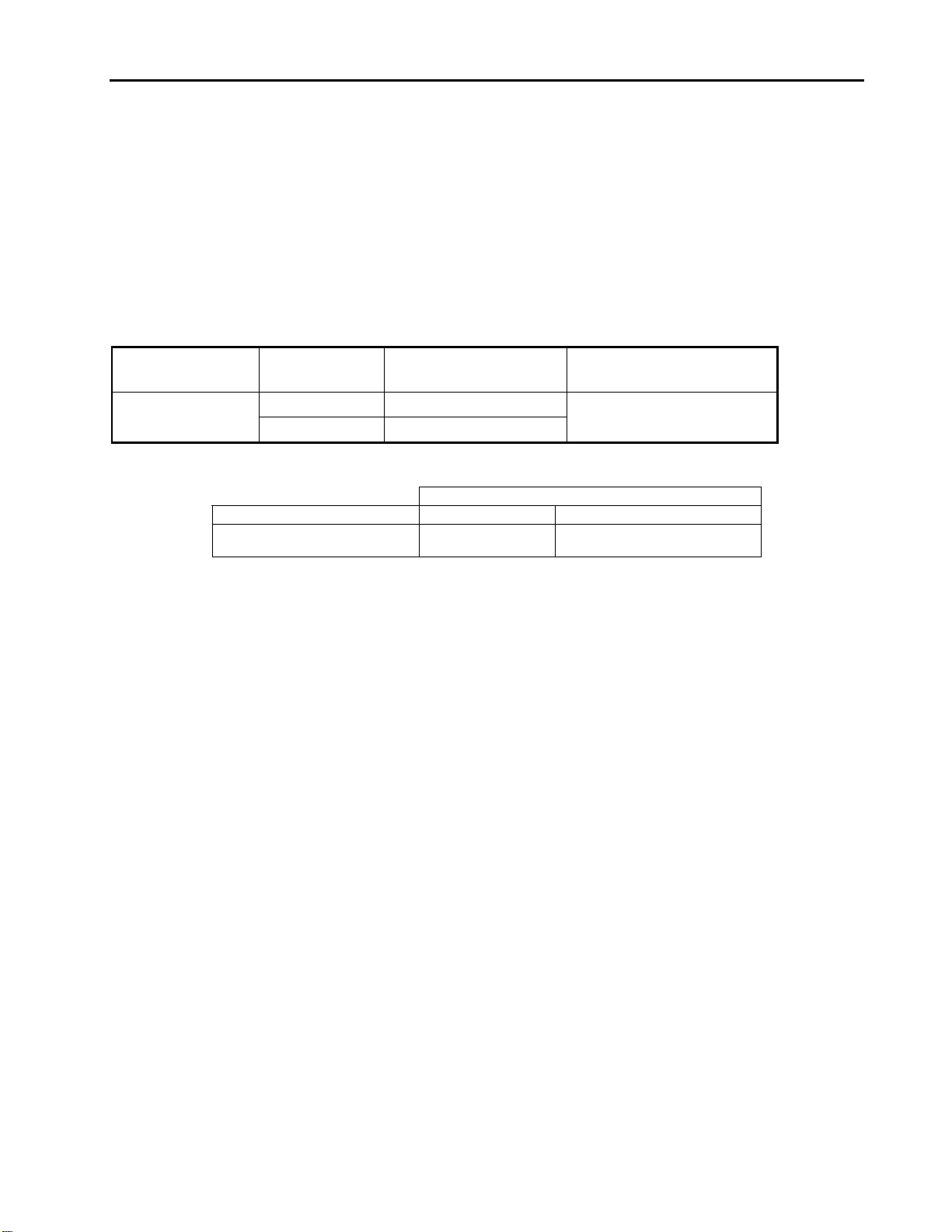

Hardware Identification

The following table shows the revision level of the circuit boards used in this version (-AC) of the IC693CPU364. If

you wish to upgrade an existing CPU364 to firmware version 9.10, you may purchase the kit identified in the following

table. All previous versions are capable of being upgraded.

CPU Model

(Version)

IC693CPU364-AC

Circuit

Board ID Circuit Board Version

CX3A1 (CPU) 44A739579-G01R05 or later

EE3A1 (Ethernet) 44A739599-G01R04 or later

Firmw a re Upgrade Kit

Catalog Number

44A747767-G02

Firmware Identification

Revision

CPU Catalog Number CPU Firmware Daughterboard Firmware

IC693CPU364-AC Main: 9.10 (22A1)

Boot: 9.00 (33A1)

Main: 1.10 (12A1)

Boot: 1.00 (33A1)

Functional Compatibility

• The Windows PLC Programming Software version 2.00 or later must be used to take advantage of C programming

or Sequential Funct i on Chart ( SFC) subr out ines.

• Version 4.00 or later of the C toolkit must be used for C programming.

• The MS-DOS PLC Programming Software Ver sion 9. 02 or later must be used to take advantage of the new features

introduced in firmware release 9.00. These new features are listed in the section “New Features and Functionality

of Firmware Release 9.00.” Note that the CPU363 can be configured with the MS-DOS PLC Programming

Software Version 9.01, but only features prior to firmware release 9.00 are supported in that software version.

• The Windows PLC Programming Software version 2.20 or later or VersaPro version 1.00 or later is required for

configuration of the Ethernet Global Data and configurable Name Resolution features of the 364 PLC.

Operating Notes

User Flash Contents

User informa ti on, con si sting of program, configurat i on, CPU ID (u sed for SNP comm uni ca ti on s), and stat u s ta bles in

RAM memory, will automatically be cleared if the CPU firmware in flash memory is changed. You will need to restore

these if upgrading firmware. A recommended procedure is to first back up your user information from RAM memory

to Flash memory. Then write your new firmware to Flash memory (firmware is stored in a different location in Flash

memory than that used for storing user information such as program, configuration, etc.). Finally, write your user

information back out of Flash into RAM memory. As an alternative, your user information (program, configuration,

etc.) can be restored from a computer-based backup program folder using your PLC programming software. The SNP

ID must be set separately, using the programming software or the Hand-Held Programmer (HHP).

Page 3

Important Product Information 3

GFK-1490C

Firmware Upgrade Procedure

The Model 364 CPU operating firmware is stored in flash memory. The firmware upgrade is provided on a diskette and

must be serially downloaded from a Personal Computer. An IBM AT personal computer or better PC with a minimum

640K of RAM, one 3.5” diskette drive, MS-DOS version 3.3 or later (or Windows 95 or later), and one RS-232 serial

port is required. In addition, two serial cables are required. The following serial cable kit is available:

•

IC690ACC901, Mini Converter Kit with cable (RS-232/RS-485)

This cable can be assembled from the following parts:

IC690ACC900, RS-232 to RS-485/422 Converter Unit

IC693CBL303, 15 Pin RS-485 Serial Cable

IC690CBL705, 25 Pin RS-232 Serial Cable or IC690CBL702, 9 Pin RS-232 Serial Cable (Only one

of th ese cables is r eq uired. Selection depends on PC Serial Port C onnector.)

•

An additional diskette and an additional cable, IC693CBL316, is required to serially download the Ethernet

firmware from the PC to the CPU.

Option Module Revision Requirements

•

All IC693 Ethernet Interface (IC693CMM321) modules used with this CPU should be updated to IC693CMM321

firmware release 1.10 or later. This is also a requirement of the TCP/IP Ethernet version of the MS-DOS

pr ogram mi ng software.

•

FBC version 3 or later is required for this CPU.

Writing Flash Using a Serial Programmer

When wri ting very large progra ms to flash memory, it ma y be necessar y to increas e th e Windows pr ogr amming

software request timeout value to avoid r eceiving a req u es t timeout message. An upper bound of 25 seconds is typically

satisfactory. For further details, see the item “Store of Program or Reference Tables to Flash may Cause Loss of

Ethernet Communications” later in this section.

Power Supply Requirements

The CPU364 requires one of the three following PLC power supplies: IC693PWR321 (Rev. K or later),

IC693PWR322, IC693PWR330, or IC693PWR331. Power consumption of the CPU364 and its supporting devices are

listed below:

•

CPU364 requires 1.1A @ +5VDC (= 5.5 Watts) .

•

If used, the external AAUI transceiver will require a maximum of 400 mA, or 2.0 Watts (limited by the AAUI

standard). Consult the transceiver documentation to obtain its exact power requirements. The IC649AEA103

transceiver requires 380 mA at 5 VDC (=1.9 Watts).

•

If used, the converter in the IC690ACC901 serial cable assembly requires 100 mA at 5 VDC (=0.5 Watts).

•

If used, the IC690ACC900 RS-422/RS-485 to RS-232 converter requires 170 mA at 5 VDC (=0.85 Watts).

Unreliable AAUI 10Base2 Ethernet T ran scei ver (IC649AEA1 01A)

The external AAUI 10Base2 Ethernet transceiver, available as catalog number IC649AEA101A, has been discovered to

operate unreliably under some conditions. This part is no longer offered. Instead, please use catalog number

IC649AEA103.

Configuration via Serial Port is Required Before Using Ethernet Communications

The Ethernet Interface within the CPU module cannot operate on a network until a valid IP address is configured. The

necessary Ethernet addressing information must be configured prior to actual network operation. Two methods are

available:

1. Perform the initial configuration using a PLC Programmer connected through the PLC power supply serial

port.

Page 4

4 Important Product Information

GFK-1490C

2. Connect a serial terminal to the station manager port (port 1) of the CPU364. Then use the CHSOSW

comman d to enter a temporary IP ad dress. The Ethernet Int erface can then be accessed over the network (s u ch

as by an Ethernet PLC Programmer). See TCP/IP Ethernet Communications for the IC69* Station Manager

Manual for details.

Proper IP Addressing is Always Essential

The CPU364’s embedded Ethernet Interface must be configured with the correct IP Address for proper operation in a

TCP/IP Ethernet network. Use of incorrect IP addresses can disrupt network operation. Refer to TCP/IP Eth ernet

Communications for the IC69* User’s Manual for important information on IP addressing.

AAUI Cable Attach ment

Power to the PLC must be turned off whenever the transceiver (AAUI) ca ble is conn ected or dis connected at the

CPU364 or at the transceiver. Sudden changes in power supply loading caused by connecting or disconnecting the

transceiver with power on may result in unexpected operation of the CPU364 or other modules.

Connecting th e tr ansceiver with power on may also blow the protect ive Ethernet interface fuse. A blo wn fuse can be

repla ced in the fi el d. Refer to TCP/IP Ethernet Communications for the IC69* User’s Manual for instructions.

SQE Enable

The Ethernet Interface within the CPU364 requires that the SQE test signal be enabled on the transceiver connecting it

to the Ethernet LA N. If you are using an external tr ansceiver , make sure your trans cei ver has SQE enabled.

COMMREQ Operation

The CPU364 receives E thernet Communications Requ est (COMMREQ) funct ion blocks at a uni que Rack /Slot and Ta s k

address. Each COMMREQ sent to the CPU364 must be addressed to SYSID = 0001 (= Rack 00 / Slot 01, the location

of the CPU364) and to TASK = 21 decimal (Note: TASK = 0 is used in COMMREQs sent to the IC693CMM321

Ethernet module). Please refer to the TCP/IP Ethernet Communications for the IC69* User’s Manual for furth er

COMMREQ function block deta ils.

Serial Load/Store of Register Table Causes Loss of Comm unications to Ethernet Programmers

A load or s tore of the PLC Register (% R) ta ble from a PLC P rogrammer connected th rough the CPU serial p ort (using

the connector on the PLC Power Supply) can cause Ethernet applications that use the PLC programmer communications

window to lose communications. This condition occurs when the load/store operation requires more than 10 seconds to

complete (called a “timeout”). For example, transferring a large %R table to the CPU (even at 19,200 baud) may cause

a timeout. If this occurs, the Ethernet Interface will post two or more PLC faults with the text “LAN system-software

fault; resuming”, and fault-specific data starting with 080008 and/or 080042. In addition, faults with text “Bad remote

application request; discarded request” (1B0021) and “Local request to send rejected; discarded request” (110005) may

occur. When these faults occur, the STAT LED on the CPU364 will be turned off to indicate posting of faults to the

PLC fault tables. Normal operation will resume once the transfer completes. The STAT LED can be reset using the

Station Manager OK command.

Ethernet Programmer May Briefly Lose Communications When Configuration Stored

Storing a PLC configuration containing Ethernet configuration values may require the Ethernet Interface to restart itself

in order to use any chan ged config ur ation values. When th e Ethernet In terface r estarts, an Ethernet PLC Programm er

will briefly report a loss of communications. PLC faults similar to those listed under “Serial Load/Store of Register

Table Causes Loss of Communications to Ethernet Programmers” above will occur; and the STAT LED on the CPU364

will be turned off to indicate posting of faults to the PLC fault tables. In some cases, a ten second delay may occur

before loss of communications is detected. Normal operation will resume once the Ethernet Interface restarts. The

STAT LED can be reset using the Station Manager OK comman d.

Page 5

Important Product Information 5

GFK-1490C

When the PLC configuration is stored from an Ethernet PLC Programmer, the communications loss occurs immediately

after s u cces sful comp l etion of the store. Attempts to st ore configur ation plus logic and/or r eference t ables in on e

operation can fail. However, storing configuration separately from logic or reference tables will always succeed.

Store of Program or Reference Tables to Flash May Cause Loss of Ethernet Communications

While storing the PLC program, configuration, and/or reference tables from PLC RAM memory into Flash memory,

Ethernet data communicat ions may be lost . Normal da ta transfer s are temporarily suspended during the Fla sh store

operation. Ethernet data transfers (such as used by an Ethernet PLC Programmer connection) during a Flash store

operation will fail when the Flash store exceeds the 10-second maximum period allowed for completion. Upon

completion of the store to Flash operation, normal operation will resume.

RUN Mode Pro g ram Store

A stor e of a fol d er conta in ing large (greater th an 14kb) program blocks fr om a P LC Programm er con nected through th e

Ethernet port on the CPU364, or through an IC693CMM321 Ethernet module, may fail and result in momentary loss of

communications. This condition has been observed only when attempting to store a large program to a PLC which is in

RUN mode, and which is configured to use a limited communications window. These conditions cause the store

operation to take the maximum possible period to complete. The failure may occur if this period exceeds 10 secon d s for

an individual program block. If this problem does occur, one of the following options may be used to complete the

store operati on s u cces sfully:

1. Change the PLC configuration to use Run-to-Completion mode instead of a Limited Communications Window for

the st ore operati on.

2. Change the PLC from RUN to STOP mode to complete the store.

3. Str uctur e the folder being st ored to el iminat e larg e progra m blocks or subr outin e block s. This will min imiz e the

chance that any single block will take longer than the maximum 10-second period allowed for storage of that block.

Store of Large Program Blocks from Older Ethernet Programmers

If an attempt is made to store a folder which contains large (greater than 14kb) program blocks or subroutine blocks

using the IC693 MS-DOS programming software, Ethernet Version 6.6 or earlier, the store attempt may fail with the

message “(S83) Program size too large for PLC or invalid user program” displayed. If this problem is observed, the

following options may be used to complete the store operation successfully:

1. Update the IC693 MS- DOS pr ogra mm ing softwar e, Eth ern et Ver sion , to a mor e r ecen t ver sion tha t can be r un in a

DOS box under the Microsoft Windows NT/95 operating system. IC693 MS-DOS programming software,

Ethernet Version 9.02 or later is recommended. (Note: In order to configure the CPU364, Version 9.02 or later is

req uired. ) This opt ion req uire s Micros oft Win dows NT or Micr osoft Win dows 95 to be in stall ed on th e PC that

executes the pr ogramming software.

2. If the ladder contains large (greater than 14kb) program blocks or subroutine blocks, then restructure the ladder to

use sm alle r blocks , eith er by sim plif ying th e progra m or by ma king u se of mor e su broutin e block s th at ar e each

smaller than 14kb in size.

3. If neither of the previous options is practical, the following work-around for the problem may be successful.

Modify the CONFIG.SYS fil e on the MS-DOS programmer PC to decrease the maximum TCP segment si ze used

by the Beame & Whiteside driver. This may be accomplished by changing the values used on the line containing

the following:

DEVICE=C:\BWTCP\TC PI P. SYS 1 460 2920 20

Change the value 1460 to 1024, and change the value 2920 to 2048.

Managing Channels and TCP Connections

In certain conditions, the supply of TCP connections can be totally exhausted. When you issue a COMMREQ to

establish a read or write channel, a TCP connection is created, the transfer(s) are made, then upon completion of all the

Page 6

6 Important Product Information

GFK-1490C

transfers, the TCP connection is terminated. If an application is constructed so that it rapidly and repeatedly establishes

a channel with only one repetition (one transfer), the available TCP connections for the Ethernet Interface may be

totally exhausted.

Specifically, if your ladder program for issu ing COMMREQs is constructed so it does the followin g , all available TCP

connections can quickly be used up: The number of repetitions (Word 9) in an Establish Read or Write Channel

COMMREQ is set to 1, and a new COMMREQ is issued repeatedly and immedia t el y upon completi on of the prior one.

It is recommended you use “Channel Re-tasking” to avoid exhausting TCP connections. Re-tasking is described in the

TCP/IP Ethernet Communications for the IC69* User’s Manual.

Documentation

Instructions for using the IC693CPU364 module can be found in the latest version of the following manuals:

General Configuration Instructions:

Ladder Logic Programming:

Ethernet-Spe ci fic Instr ucti ons:

TCP/IP Ethernet Communications for the IC69* Station Manager Manual

IC693 PLC Reference Manual.

IC693 PLC Programming Software User’s Manual.

TCP/IP Ethernet Communications for the IC69* PLC User’s Manual. Also see the

Page 7

Important Product Information 7

GFK-1490C

Problems Resolved in Firmware Version 9.10 (Ethernet Version 1.10)

AI & AQ Above Default Values

Release 9.00 provided support for configuring %AI and %AQ above their default values. These new references would

previously only work as extra program memory, and could not be used as actual inputs or outputs on physical modules

in the configuration. Thi s has been corrected in rel ease 9.10 so th a t these high er referen ces n ow w ork the sam e as the

lowe r ref ere nce s.

Load File of Size 1528 Bytes

Loads of a user program where the file was of this specific size would fail. This has been corrected in release 9.10.

C Program with Code Area Greater Than 64K Bytes

Before release 9.10, C Program blocks with code areas greater than 64k bytes would not store. In release 9.10 and later,

‘C’ program blocks code sizes are limited only by available memory.

Ethernet Status Bits

If the Ethernet portion of the 364 module had a watchdog or flash checksum failure, its status bits would be held in the

previous state. In release 9.10 the status bits are cleared in this case.

Handling of heavy network loading conditions

Handling of three types of network errors under temporary heavy network load conditions has been improved.

Error Condition Recorded as MAC Tally Exception Log Event

Lost Carrier LostCarr event c, entry 2 = 102H

Maxim u m Ret r ies Exceeded Frtry event c, entry 2 = 10aH

Late Collision LateColl event c, entry 2 = 10bH

For all these errors, the LLC wi ll tolerat e u p to four consecu tive occurrences of an error before restarting th e LLC.

During an LLC restart, the Ethernet Interface cannot communicate on the network, so fewer LLC restarts result in less

disruption to communications.

Also, the Maximum Ret r ies Exceeded condition is now logg ed in the Eth ernet Interface’s excep t ion log an d the PLC’s

fault table only after a fourth consecutive occurrence, th u s r ed ucing nuisance faul t r eports.

SRTP channel management

An SRTP Channel will now be properly retasked while in the AWAIT_DRSP or AWAIT_CRSP states.

Large PING

PINGing the Ethernet Interface with more than 32739 data bytes no longer causes the Interface to restart.

Time of day clock

The time of day clock maintained by the Ethernet Interface no longer runs about 15 seconds fast per day

%S32 & %S20 in Periodic Subroutine

These status bits could be changed if used in a periodic subroutine. This has been corrected in release 9.10.

Update Mode

When the Ethernet (daughterboard) firmware is in update mode, no fault is logged on the PLC to indicate this. The

firmware update mode is indicated by the flashing of the EOK, LAN, and STAT LEDs. The LEDs flash in unison.

Page 8

8 Important Product Information

GFK-1490C

Problems Resolved in Firmware Version 9.01

SNP Master mode on CPU Ports

With some very large configur at i on s and versi on 9.00 firm ware, after a power -cycle, CPU ports set up for SNP Master

would need to have their configurat ion re-stored for the pr otocol to accept COMM_ RE Qs. This is corrected in versi on

9.01.

Online Changes to Reference Tables

Making online changes with the programmer to reference tables could result in a watchdog timeout. This has been

corr ected in version 9.01.

Read from Flash

In version 9.00, reading a folder from flash memory could result in the PLC going into a faulted state. This is corrected

in version 9.01.

CPU364 Restri ctions and Open Problems

Multiple Log Events

The Ethernet Interface sometimes generates multiple exception log events and PLC Fault Table entries when a single

error condition occurs. Under repetitive error conditions, the exception log and/or PLC Fault Table can be completely

filled with repetitive error messages.

DDP2 Name Not Used

In systems u s ing mor e th an 75 Ethernet Global Data exchanges, th e Eth er net Interface may n ot in itialize with the u s erconfigured DDP name (i f any), but rather use the default DDP name. Attempts by remote st a ti on s to communicate with

the Interface using the user-configured name will fail. Possible workarounds include:

1. Reconfigure the application to use less than 75 exchanges, or

2. Have remote stations refer to the Interface by its default DDP name

Same IP Address

Use of the same IP Address by the CPU364 and by another device on the same network results in the PLC Fault Table

message “Bad remote application request; discarded request”. This condition should be identified more precisely.

Trace LZ

While a local Stat ion Manager “TRACE LZ” tr ou bl eshooting comman d i s in effect at an Ethernet In terface, d o n ot is su e

Station Manager “REM <node> TEST” commands to it from a remote Interface. Doing so can cause errant behavior,

including module lockup and loss-of-module in the PLC fault table.

EGD status code

The status code of an EGD exchange is not updated to “16” while performing Name Resolution as described in the

manual. The first status code update occurs when the Name Resolution is complete, either “0” if successful or “4 ” if

unsuccessful.

Write Channel Retasking Error

When retasking a Write Channel, the Ethernet Interface may very intermittently generate exception log event 1c, entry

2 = 5. The channel stops with status code 9590 (= internal error). The application program may issue another Write

Channel COMMREQ to start thi s channel.

Page 9

Important Product Information 9

GFK-1490C

Intermittent SNTP Loss Of Synchronization

Under moderately heavy EGD traffic load, the Ethernet Interface may occasionally lose synchronization with its SNTP

time server and generate exception log event 29, entry 2=bH.

Timing Issue With ALG220/221 Modules May Result i n Incorrect %AI Values Read by CPU

A problem was found with the IC693ALG220/221 where the actual %AI values reported by the card may exhibit erratic

behavior (ca t alog m odule revisions F and earli er may show this pr oblem; revi s ion G has fix e d this problem). Ce rtain

current or voltage levels within the input range applied to the card could cause the %AI values to report incorrectly.

The problem stems from the use of particular optocouplers, which may exhibit timing issues with these CPU35x/36x

modules.

CPUs 341, 331, 321, 313, and 311 have not exhibited this timing problem reading %AI values.

Page 10

10 Important Product Information

GFK-1490C

IC693CPU364 Data

a47501

CPU Type

Total Basepl ates per System

Load Required from Power Supply

Processo r Sp eed

Processor Type

Ethernet fuse, replaceable

Opera ting temperatu re

Typical Scan Rate

User Memory (total)

Discre te Inp ut Poi n ts - %I

Discrete Output Poi n ts - %Q

Discrete Global Memory - %G

Internal Coils - %M

Output (Temporary) Coils - %T

System Status References - %S

Register Memory - %R

Analog Inputs - %AI

Analog Outputs - %AQ

System Registers

viewing only; cannot be referenced in user

logi c progra m)

(

for reference table

Timers/Counters

Shift Registers

Built-in Serial Ports

Communications

Override

Battery Back ed Clock

Interrupt Support

Type of Memory Storage

PCM/CCM Compatibility

Floating Point Math Support

Note: On so m e m o dules the LE D labeled “ PS PORT” ma y sa y “ SN P” instead; ot h erwise, t he mo dules ar e

identical.

Single slot CPU module with embedded Ethernet Interface

8 (CP U basepl ate + 7 ex pansi on and/or remote)

1.1 Amps from +5 VDC supply

25 MegaHertz

80386EX

2.69x2.69x6.1 mm, 125V, 1A, slow acting

0 to 60 degrees C (32 to 140 degrees F) ambient

.22 mi lliseconds per 1K of logic ( B oolean contacts)

240K (245,760) Bytes. Note: Actual size of available user

program memory depends on the amounts configured for the

%R, %AI, and %AQ configurable word memory types

(described below).

2,048

2,048

1,280 bits

4,096 bits

256 bits

128 bits (%S, %SA, %SB, %SC - 32 bits each)

Configurable in 128 word increments, from 128 to 16,384

words with DOS programmer, and from 128 to 32,640 words

with Window s progr ammer Ver. 2.2 or Ver saPro versi on 1.0.

Configurable in 128 word increments, from 128 to 8,192

words with DOS programmer, and from 128 to 32,640 words

wit h Windows programmer Ver 2.2 wh en availabl e.

Configurable in 128 word increments, from 128 to 8,192

words with DOS programmer, and from 128 to 32,640 words

wit h Windows programmer Ver. 2. 2 w hen availabl e.

28 words (%SR)

>2,000 (depends on available user memory)

Yes

1 (uses connector on PLC Power Supply). Supports

SNP/SNPX. Requires option modules for RTU and CCM.

Ethernet

(internal) – AAUI or 10Base T. AAUI requires

external transceiver . 10 B ase T is di rect.

Ethernet

LAN

(additional) – Supports Ethernet option modules.

– Requi res op tion mod ules for Genius, Pr of ibus, FIP.

Yes

Yes

Supports the periodic subroutine feature.

RAM and Flash

Yes

Yes, firmware-based

EOK

LAN

STAT

CPU 364

CPU 364

ON

ETHERNET

RESTART

PORT 1

RS-232

AAUI

10BASE T

FRAME

PS

SNP

PORT

OFF

Loading...

Loading...