Page 1

MCP3421

1 8 - Bi t A na l o g -t o - D ig i t a l C o n v er t e r

with I2C Interface and On-Board Reference

Features

• 18-bit ΔΣ ADC in a SOT-23-6 package

• Differential input operation

• Self calibration of Internal Offset and Gain per

each conversion

• On-board Voltage Reference:

- Accuracy: 2.048V ± 0.05%

- Drift: 5 ppm/°C

• On-board Programmable Gain Amplifier (PGA):

- Gains of 1,2,4 or 8

• On-board Oscillator

• INL: 10 ppm of FSR (FSR = 4.096V/PGA)

• Programmable Data Rate Options:

- 3.75 SPS (18 bits)

- 15 SPS (16 bits)

- 60 SPS (14 bits)

- 240 SPS (12 bits)

• One-Shot or Continuous Conversion Options

• Low current consumption:

- 145 µA typical

= 3V, Continuous Conversion)

(V

DD

- 39 µA typical

= 3V, One-Shot Conversion with 1 SPS)

(V

DD

• Supports I2C Serial Interface:

- Standard, Fast and High Speed Modes

• Single Supply Operation: 2.7V to 5.5V

• Extended Temperature Range: -40°C to 125°C

Typical Applications

Description

The MCP3421 is a single channel low-noise, high

accuracy ΔΣ A/D converter with differential inputs and

up to 18 bits of resolution in a small SOT-23-6 package.

The on-board precision 2.048V reference voltage

enables an input range of ±2.048V differentially

(Δ voltage = 4.096V). The device uses a two-wire I

compatible serial interface and operates from a single

2.7V to 5.5V power supply.

The MCP3421 device performs conversion at rates of

3.75, 15, 60, or 240 samples per second (SPS)

depending on the user controllable configuration bit

settings using the two-wire I

device has an on-board programmable gain amplifier

(PGA). The user can select the PGA gain of x1, x2, x4,

or x8 before the analog-to-digital conversion takes

place. This allows the MCP3421 device to convert a

smaller input signal with high resolution. The device

has two conversion modes: (a) Continuous mode and

(b) One-Shot mode. In One-Shot mode, the device

enters a low current standby mode automatically after

one conversion. This reduces current consumption

greatly during idle periods.

The MCP3421 device can be used for various high

accuracy analog-to-digital data conversion applications

where design simplicity, low power, and small footprint

are major considerations.

2

C serial interface. This

2

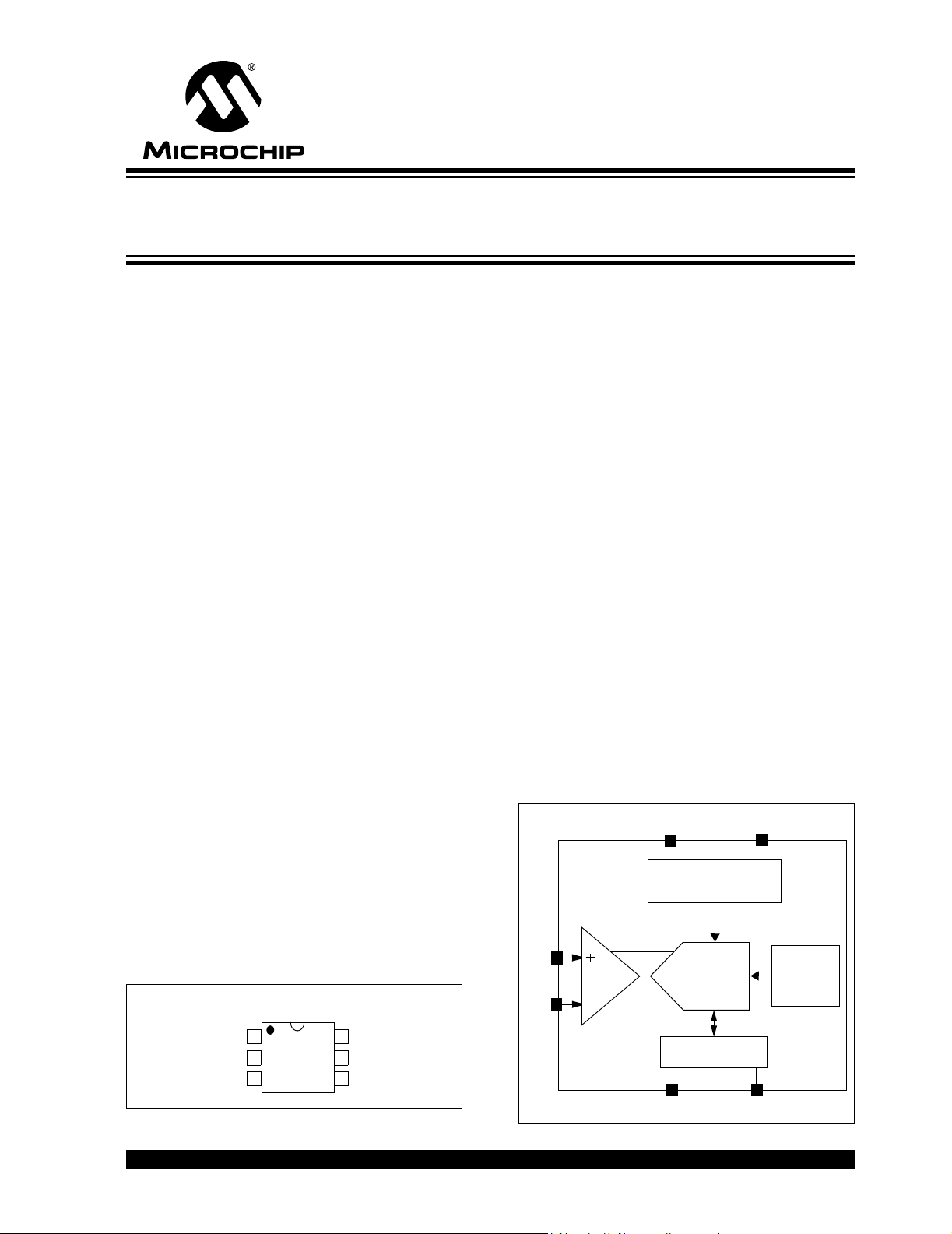

Block Diagram

V

SS

V

DD

C

• Portable Instrumentation

• Weigh Scales and Fuel Gauges

• Temperature Sensing with RTD, Thermistor, and

Thermocouple

• Bridge Sensing for Pressure, Strain, and Force.

Package Types

SS

Top View

1

2

3

6

5

4

V

IN

V

DD

SDA

-

SOT-23-6

VIN+

V

SCL

© 2006 Microchip Technology Inc. DS22003B-page 1

Gain = 1, 2, 4, or 8

VIN+

PGA

VIN-

Voltage Reference

(2.048V)

V

REF

ΔΣ ADC

Converter

2

C Interface

I

SCL

SDA

Clock

Oscillator

Page 2

MCP3421

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings†

VDD...................................................................................7.0V

All inputs and outputs w.r.t V

Differential Input Voltage ...................................... |V

Output Short Circuit Current ................................. Continuous

Current at Input Pins ....................................................±2 mA

Current at Output and Supply Pins ............................±10 mA

Storage Temperature.....................................-65°C to +150°C

Ambient Temp. with power applied ...............-55°C to +125°C

ESD protection on all pins ................ ≥ 6kV HBM, ≥ 400V MM

Maximum Junction Temperature (T

............... –0.3V to VDD+0.3V

SS

) ..........................+150°C

J

DD

- VSS|

†Notice: Stresses above those listed under “Maximum Ratings” may cause permanent damage to the device. This is a

stress rating only and functional operation of the device at

those or any other conditions above those indicated in the

operational listings of this specification is not implied.

Exposure to maximum rating conditions for extended periods

may affect device reliability

.

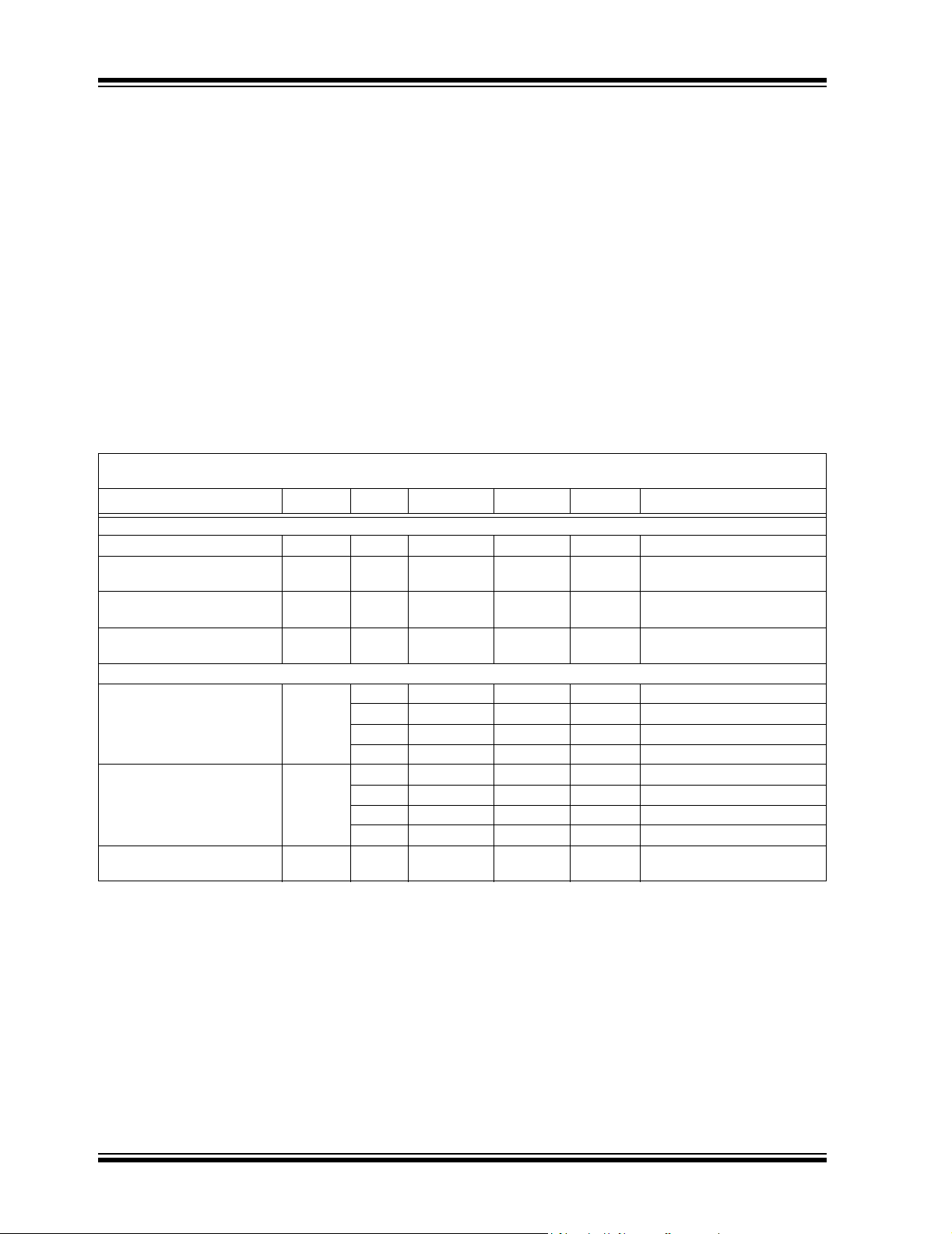

ELECTRICAL CHARACTERISTICS

Electrical Specifications: Unless otherwise specified, all parameters apply for TA = -40°C to +85°C, VDD = +5.0V, VSS = 0V,

V

+ = VIN- = V

IN

Parameters Sym Min Typ Max Units Conditions

Analog Inputs

Differential Input Range — ±2.048/PGA — V V

Common-Mode Voltage Range

(absolute)

Differential Input Impedance

(Note 2)

Common Mode input

Impedance

System Performance

Resolution and No Missing

(Note 8)

Codes

Data Rate

Output Noise — 1.5 — µV

Note 1: Any input voltage below or greater than this voltage causes leakage current through the ESD diodes at the input pins.

2: This input impedance is due to 3.2 pF internal input sampling capacitor.

3: The total conversion speed includes auto-calibration of offset and gain.

4: INL is the difference between the endpoints line and the measured code at the center of the quantization band.

5: Includes all errors from on-board PGA and V

6: Full Scale Range (FSR) = 2 x 2.048/PGA = 4.096/PGA.

7: This parameter is ensured by characterization and not 100% tested.

8: This parameter is ensured by design and not 100% tested.

/2. All ppm units use 2*V

REF

(Note 1)

Z

IND

Z

INC

(Note 3)

This parameter is ensured by characterization and not 100% tested.

DR 176 240 328 SPS S1,S0 = ‘00’, (12 bits mode)

as full-scale range.

REF

VSS-0.3 — VDD+0.3 V

(f) — 2.25/PGA — MΩ During normal mode operation

(f) — 25 — MΩ PGA = 1, 2, 4, 8

12 — — Bits DR = 240 SPS

14 — — Bits DR = 60 SPS

16 — — Bits DR = 15 SPS

18 — — Bits DR = 3.75 SPS

44 60 82 SPS S1,S0 = ‘01’, (14 bits mode)

11 15 20.5 SPS S1,S0 = ‘10’, (16 bits mode)

2.75 3.75 5.1 SPS S1,S0 = ‘11’, (18 bits mode)

.

REF

RMSTA

PGA = 1, V

= VIN+ - VIN-

IN

= 25°C, DR = 3.75 SPS,

IN

= 0

DS22003B-page 2 © 2006 Microchip Technology Inc.

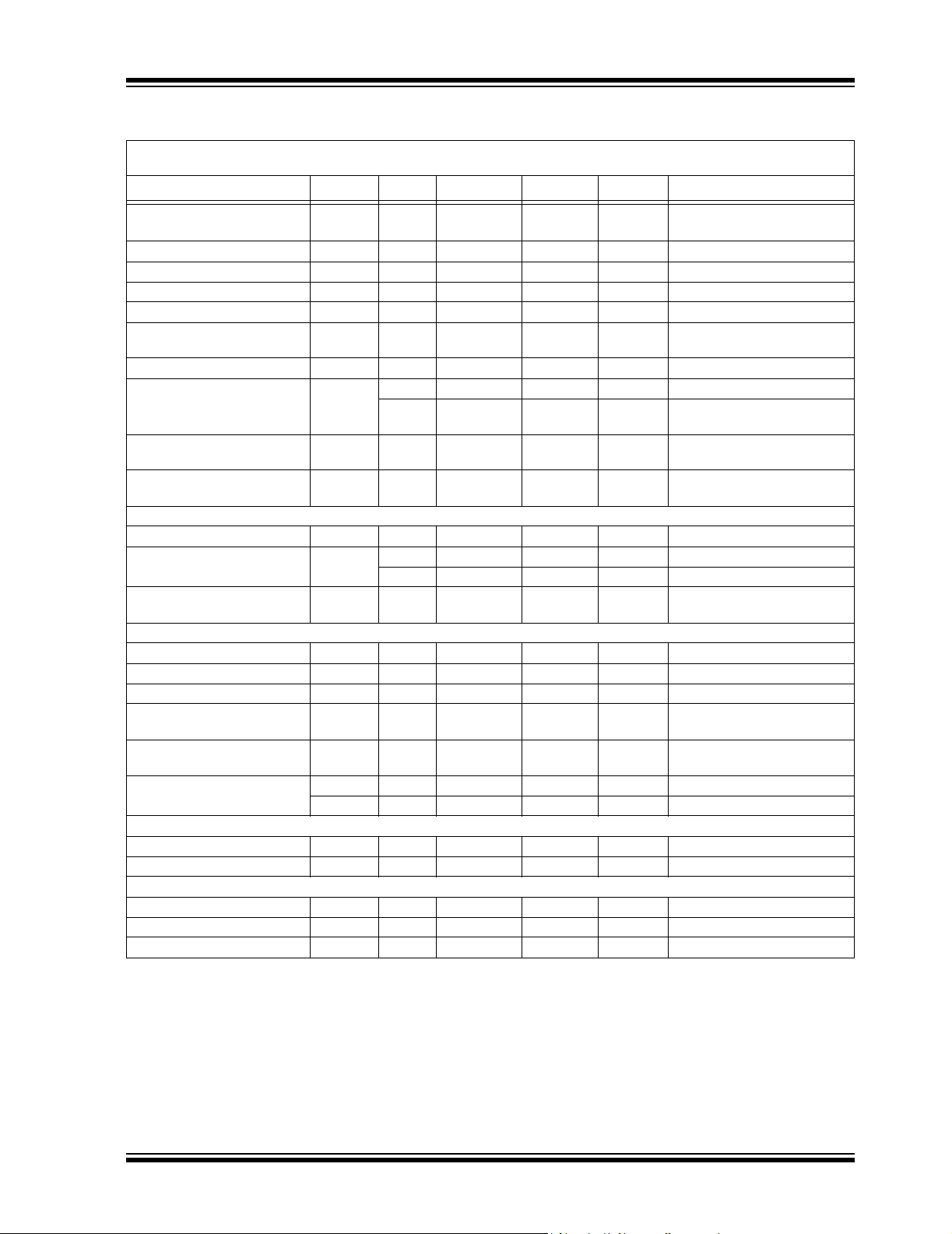

Page 3

MCP3421

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise specified, all parameters apply for TA = -40°C to +85°C, VDD = +5.0V, VSS = 0V,

V

+ = VIN- = V

IN

Parameters Sym Min Typ Max Units Conditions

Integral Nonlinearity

Internal Reference Voltage V

Gain Error

PGA Gain Error Match

Gain Error Drift

Offset Error V

Offset Drift vs. Temperature — 50 — nV/°C V

Common-Mode Rejection — 105 — dB at DC and PGA =1,

Gain vs. V

DD

Power Supply Rejection at DC — 100 — dB T

Power Requirements

Voltage Range V

Supply Current during

Conversion

Supply Current during Standby

Mode

2

C Digital Inputs and Digital Outputs

I

High level input voltage V

Low level input voltage V

Low level output voltage V

Hysteresis of Schmitt Trigger

for inputs

(Note 7)

Supply Current when I

line is active

Input Leakage Current I

Pin Capacitance and I

Pin capacitance C

2

C Bus Capacitance C

I

Thermal Characteristics

Specified Temperature Range T

Operating Temperature Range T

Storage Temperature Range T

Note 1: Any input voltage below or greater than this voltage causes leakage current through the ESD diodes at the input pins.

2: This input impedance is due to 3.2 pF internal input sampling capacitor.

3: The total conversion speed includes auto-calibration of offset and gain.

4: INL is the difference between the endpoints line and the measured code at the center of the quantization band.

5: Includes all errors from on-board PGA and V

6: Full Scale Range (FSR) = 2 x 2.048/PGA = 4.096/PGA.

7: This parameter is ensured by characterization and not 100% tested.

8: This parameter is ensured by design and not 100% tested.

/2. All ppm units use 2*V

REF

(Note 4)

(Note 5)

(Note 5)

(Note 5)

INL — 10 35

REF

OS

as full-scale range.

REF

— 2.048 — V

— 0.05 0.35 % PGA = 1, DR = 3.75 SPS

— 0.1 — % Between any 2 PGA gains

— 5 40 ppm/°C PGA=1, DR=3.75 SPS

— 15 40 µV Tested at PGA = 1

— 110 — dB at DC and PGA =8,

— 5 — ppm/V TA = +25°C, VDD = 2.7V to 5.5V,

2.7 — 5.5 V

— 155 190 µA V

I

DDA

DD

— 145 — µA V

I

DDS

IH

OL

V

HYST

2

C bus

2

C Bus Capacitance

I

DDB

I

ILH

ILL

PIN

IL

b

A

A

A

—0.1 0.5µA

0.7 V

DD

—VDDV

— — 0.3V

—— 0.4VI

0.05V

DD

——Vf

—— 10µA

—— 1 µAV

-1 — — µA VIL = GND

— — 10 pF

— — 400 pF

-40 — +85 °C

-40 — +125 °C

-65 — +150 °C

This parameter is ensured by characterization and not 100% tested.

.

REF

ppm of

FSR

DR = 3.75 SPS

(Note 6)

V

= 5.0V and DR = 3.75 SPS

DD

DD = 5.0V

= +25°C

T

A

PGA = 1

= +25°C, VDD = 2.7V to 5.5V,

A

PGA = 1

= 5.0V

DD

= 3.0V

DD

DD

V

= 3 mA, VDD = +5.0V

OL

= 100 kHz

SCL

= 5.5V

IH

© 2006 Microchip Technology Inc. DS22003B-page 3

Page 4

MCP3421

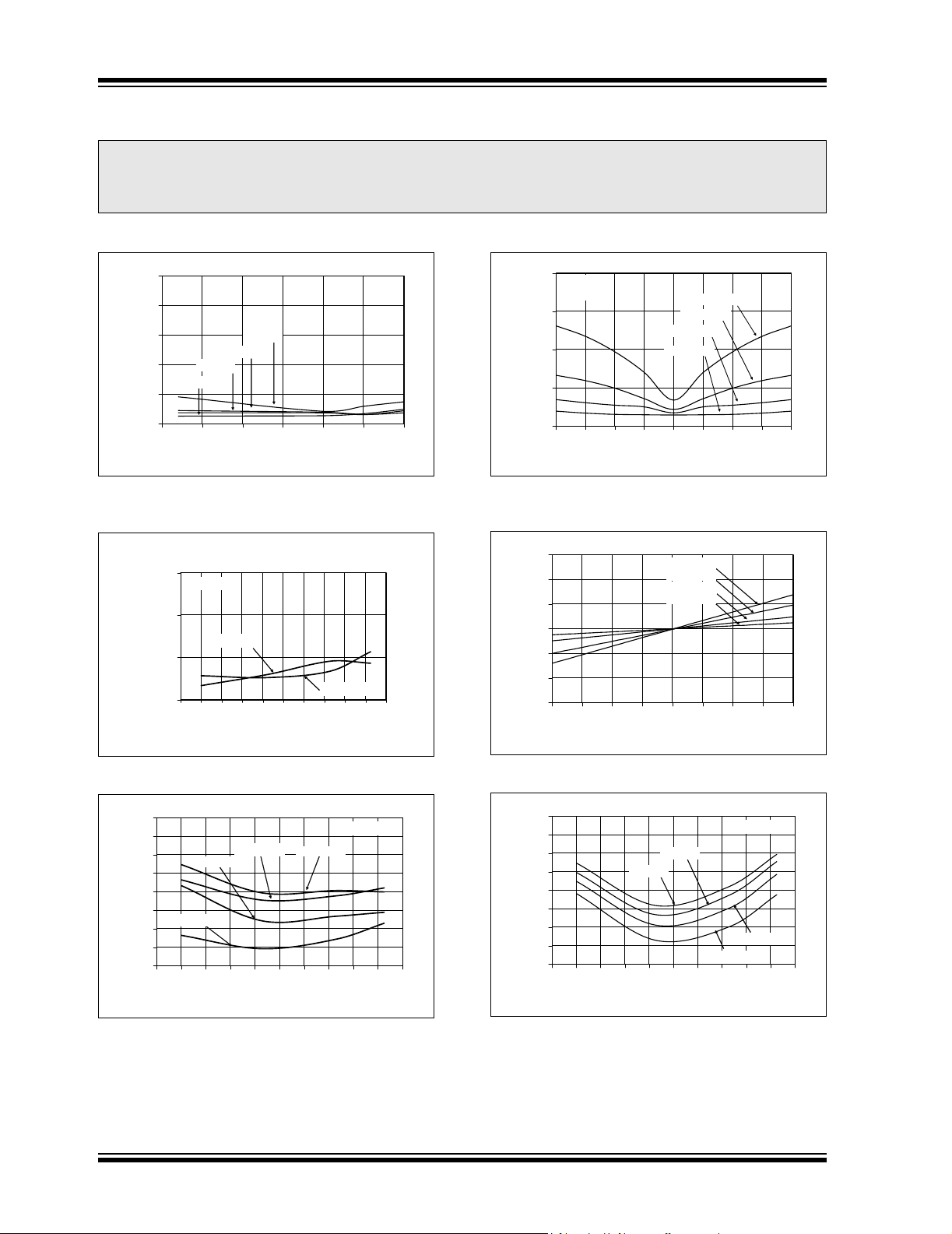

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated, TA = -40°C to +85°C, VDD = +5.0V, VSS = 0V, VIN+ = VIN- = V

.005

.004

.003

.002

.001

.000

Integral Nonlinearity (% of FSR)

PGA = 4

PGA = 1

2.5 3 3.5 4 4.5 5 5.5

PGA = 8

PGA = 2

V

(V)

DD

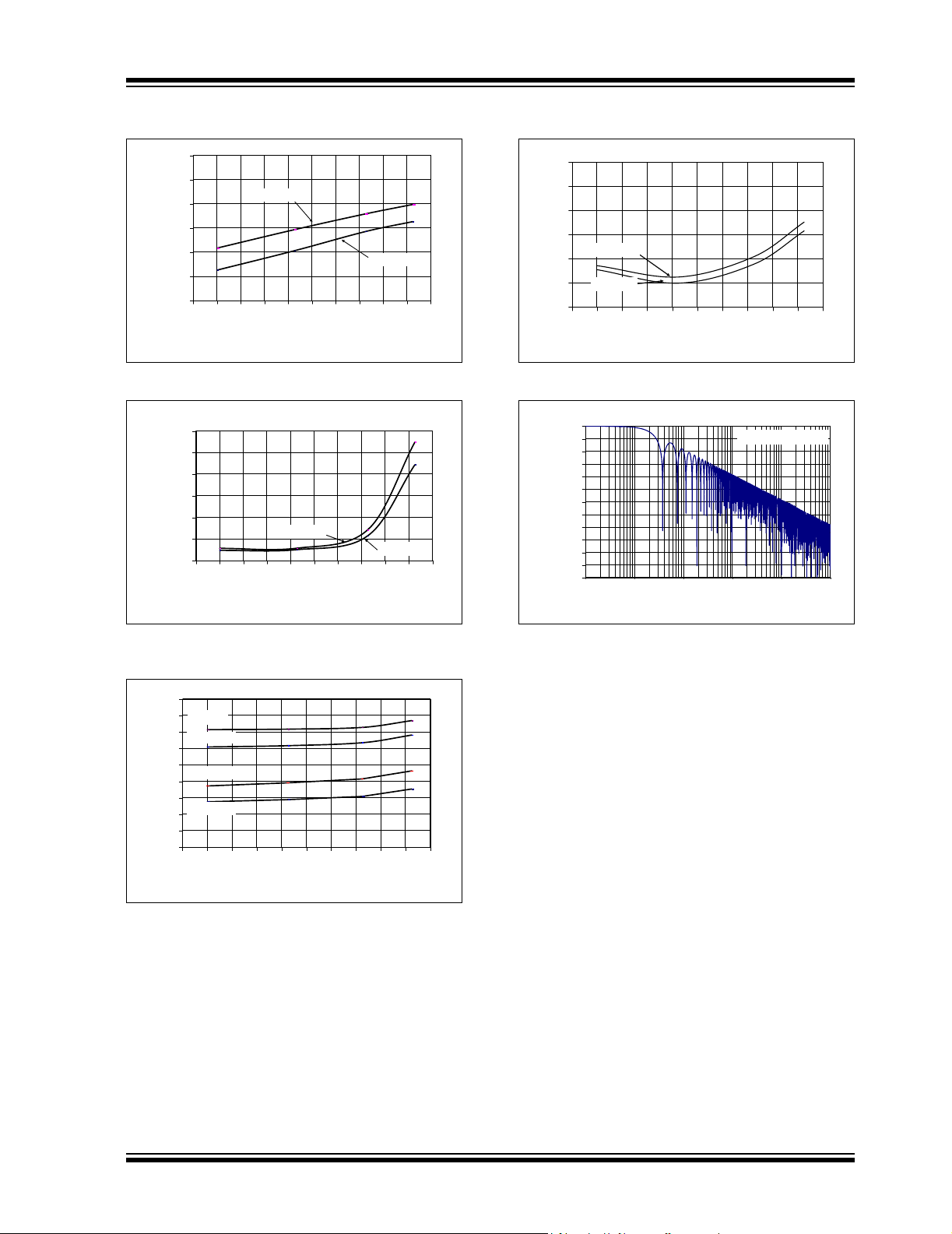

FIGURE 2-1: INL vs. Supply Voltage

(V

).

DD

0.003

PGA = 1

0.002

VDD = 5 V

0.001

(% of FSR)

Integral Nonlinearity

0

-60 -40 -20 0 20 40 60 80 100 120 140

Temperature (oC)

VDD = 2.7V

10.0

TA = +25°C

V

= 5V

DD

7.5

5.0

Noise (µV, rms)

2.5

0.0

-100 -75 -50 -25 0 25 50 75 100

Input Voltage (% of Full-Scale)

PGA = 8

FIGURE 2-4: Noise vs. Input Voltage.

3.0

2.0

1.0

0.0

-1.0

Total Error (mV)

-2.0

-3.0

-100 -75 -50 -25 0 25 50 75 100

Input Voltage (% of Full-Scale)

PGA = 1

PGA = 2

PGA = 4

PGA = 8

REF

PGA = 2

PGA = 4

/2.

PGA = 1

FIGURE 2-2: INL vs. Temperature.

20

15

10

5

0

-5

PGA = 1

-10

Offset Error (µV)

-15

-20

-60 -40 -20 0 20 40 60 80 100 120 140

PGA = 4

PGA = 2

Temperature (°C)

PGA = 8

VDD = 5V

FIGURE 2-3: Offset Error vs. Temperature.

FIGURE 2-5: Total Error vs. Input Voltage.

0.4

0.3

0.2

0.1

0

-0.1

-0.2

Gain Error (% of FSR)

-0.3

-0.4

-60 -40 -20 0 20 40 60 80 100 120 140

PGA = 1

PGA = 2

Temperature (°C)

VDD = 5.0V

PGA = 4

PGA = 8

FIGURE 2-6: Gain Error vs. Temperature.

DS22003B-page 4 © 2006 Microchip Technology Inc.

Page 5

MCP3421

P

Note: Unless otherwise indicated, TA = -40°C to +85°C, VDD = +5.0V, VSS = 0V, VIN+ = VIN- = V

220

200

180

(µA)

160

DDA

I

140

120

100

-60 -40 -20 0 20 40 60 80 100 120 140

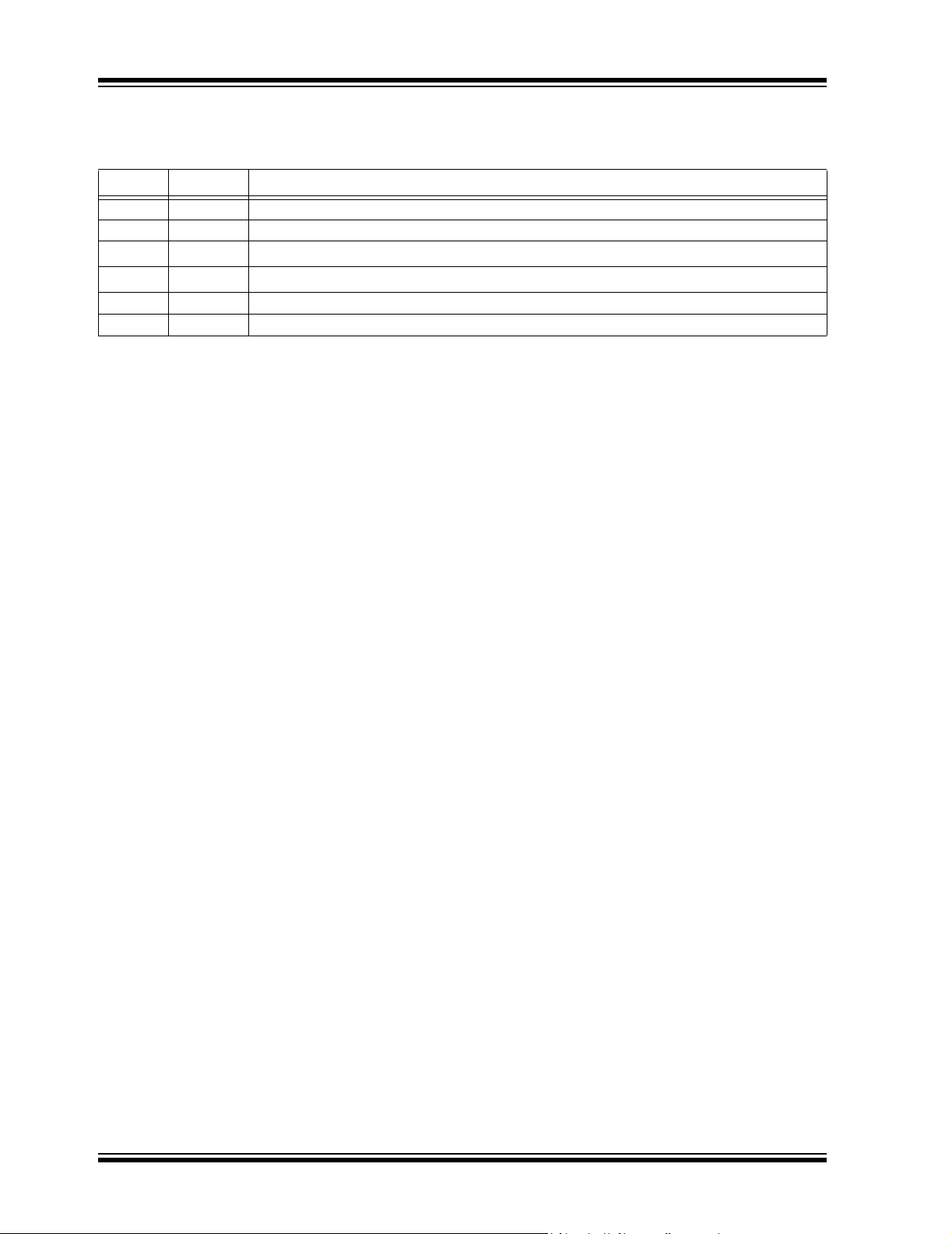

FIGURE 2-7: I

600

500

400

(nA)

300

DDS

I

200

100

0

-60 -40 -20 0 20 40 60 80 100 120 140

VDD = 5V

Temperature (oC)

vs. Temperature.

DDA

VDD = 5V

Temperature (

o

VDD = 2.7V

VDD= 2.7V

C)

5

4

3

2

VDD = 2.7V

1

Oscillator Drift (%)

VDD = 5.0V

0

-1

-60 -40 -20 0 20 40 60 80 100 120 140

Temperature (°C)

FIGURE 2-10: OSC Drift vs. Temperature.

0

-10

-20

-30

-40

-50

-60

-70

-80

Magnitude (dB)

-90

-100

-110

-120

0.1 1 10 100 1000 10000

0.1 1 10 100 1k 10k

Input Signal Frequency (Hz)

/2.

REF

Data Rate = 3.75 SPS

FIGURE 2-8: I

9

8

VDD = 5V

7

VDD = 4.5V

6

A)

5

VDD = 3.3V

(

4

DDB

I

3

VDD = 2.7V

2

1

0

-60 -40 -20 0 20 40 60 80 100 120 140

FIGURE 2-9: I

vs. Temperature.

DDS

Temperature (

vs. Temperature.

DDB

FIGURE 2-11: Frequency Response.

o

C)

© 2006 Microchip Technology Inc. DS22003B-page 5

Page 6

MCP3421

3.0 PIN DESCRIPTIONS

TABLE 3-1: PIN FUNCTION TABLE

Pin No Sym Function

1V

2VSSGround Pin

3SCL

4SDA

5V

6V

+ Non-Inverting Analog Input Pin

IN

Serial Clock Input Pin of the I2C Interface

Bidirectional Serial Data Pin of the I2C Interface

DD

IN

Positive Supply Voltage Pin

- Inverting Analog Input Pin

3.1 Analog Inputs (VIN+, VIN-)

VIN+ and VIN- are differential signal input pins. The

MCP3421 device accepts a fully differential analog

input signal which is connected on the V

+ and VIN-

IN

input pins. The differential voltage that is converted is

defined by V

= (VIN+ - VIN-) where VIN+ is the voltage

IN

applied at the VIN+ pin and VIN- is the voltage applied

at the V

- pin. The input signal level is amplified by the

IN

programmable gain amplifier (PGA) before the

conversion. The differential input voltage should not

exceed an absolute of (2* V

measurement, where V

REF

/PGA) for accurate

REF

is the internal reference

voltage (2.048V) and PGA is the PGA gain setting. The

converter output code will saturate if the input range

exceeds (2* V

REF

/PGA).

The absolute voltage range on each of the differential

input pins is from V

-0.3V to VDD+0.3V. Any voltage

SS

above or below this range will cause leakage currents

through the Electrostatic Discharge (ESD) diodes at

the input pins. This ESD current can cause unexpected

performance of the device. The common mode of the

analog inputs should be chosen such that both the

differential analog input range and the absolute voltage

range on each pin are within the specified operating

range defined in Section 1.0 “Electrical

Characteristics” and Section 4.0 “Description of

Device Operation”.

3.2 Supply Voltage (VDD, VSS)

VDD is the power supply pin for the device. This pin

requires an appropriate bypass capacitor of about

0.1 µF (ceramic) to ground. An additional 10 µF

capacitor (tantalum) in parallel is also recommended

to further attenuate high frequency noise present in

some application boards. The supply voltage (V

must be maintained in the 2.7V to 5.5V range for specified operation.

is the ground pin and the current return path of the

V

SS

device. The user must connect the V

pin to a ground

SS

plane through a low impedance connection. If an

analog ground path is available in the application PCB

(printed circuit board), it is highly recommended that

DD

the V

pin be tied to the analog ground path or

SS

isolated within an analog ground plane of the circuit

board.

3.3 Serial Clock Pin (SCL)

SCL is the serial clock pin of the I2C interface. The

MCP3421 acts only as a slave and the SCL pin

accepts only external serial clocks. The input data

from the Master device is shifted into the SDA pin on

the rising edges of the SCL clock and output from the

MCP3421 occurs at the falling edges of the SCL clock.

The SCL pin is an open-drain N-channel driver.

Therefore, it needs a pull-up resistor from the V

to the SCL pin. Refer to Section 5.3 “I2C Serial Communications” for more details of I

2

C Serial Interface

DD

line

communication.

3.4 Serial Data Pin (SDA)

SDA is the serial data pin of the I2C interface. The SDA

pin is used for input and output data. In read mode, the

conversion result is read from the SDA pin (output). In

write mode, the device configuration bits are written

(input) though the SDA pin. The SDA pin is an opendrain N-channel driver. Therefore, it needs a pull-up

resistor from the V

start and stop conditions, the data on the SDA pin must

be stable during the high period of the clock. The high

or low state of the SDA pin can only change when the

clock signal on the SCL pin is low. Refer to Section 5.3

2

C Serial Communications” for more details of I2C

“I

Serial Interface communication.

)

line to the SDA pin. Except for

DD

DS22003B-page 6 © 2006 Microchip Technology Inc.

Page 7

MCP3421

4.0 DESCRIPTION OF DEVICE OPERATION

4.1 General Overview

The MCP3421 is a low-power, 18-Bit Delta-Sigma A/D

converter with an I2C serial interface. The device

contains an on-board voltage reference (2.048V),

programmable gain amplifier (PGA), and internal

oscillator. The user can select 12, 14, 16, or 18 bit

conversion by setting the configuration register bits.

The device can be operated in Continuous Conversion

or One-Shot Conversion mode. In the Continuous Conversion mode, the device converts the inputs

continuously. While in the One-Shot Conversion mode,

the device converts the input one time and stays in the

low-power standby mode until it receives another

command for a new conversion. During the standby

mode, the device consumes less than 0.1 µA typical.

4.2 Power-On-Reset (POR)

The device contains an internal Power-On-Reset

(POR) circuit that monitors power supply voltage (VDD)

during operation. This circuit ensures correct device

start-up at system power-up and power-down events.

The POR has built-in hysteresis and a timer to give a

high degree of immunity to potential ripples and noises

on the power supply. A 0.1 µF decoupling capacitor

should be mounted as close as possible to the V

for additional transient immunity.

The threshold voltage is set at 2.2V with a tolerance of

approximately ±5%. If the supply voltage falls below

this threshold, the device will be held in a reset

condition. The typical hysteresis value is approximately

200 mV.

The POR circuit is shut-down during the low-power

standby mode. Once a power-up event has occurred,

the device requires additional delay time (approximately 300 µs) before a conversion can take place.

During this time, all internal analog circuitries are

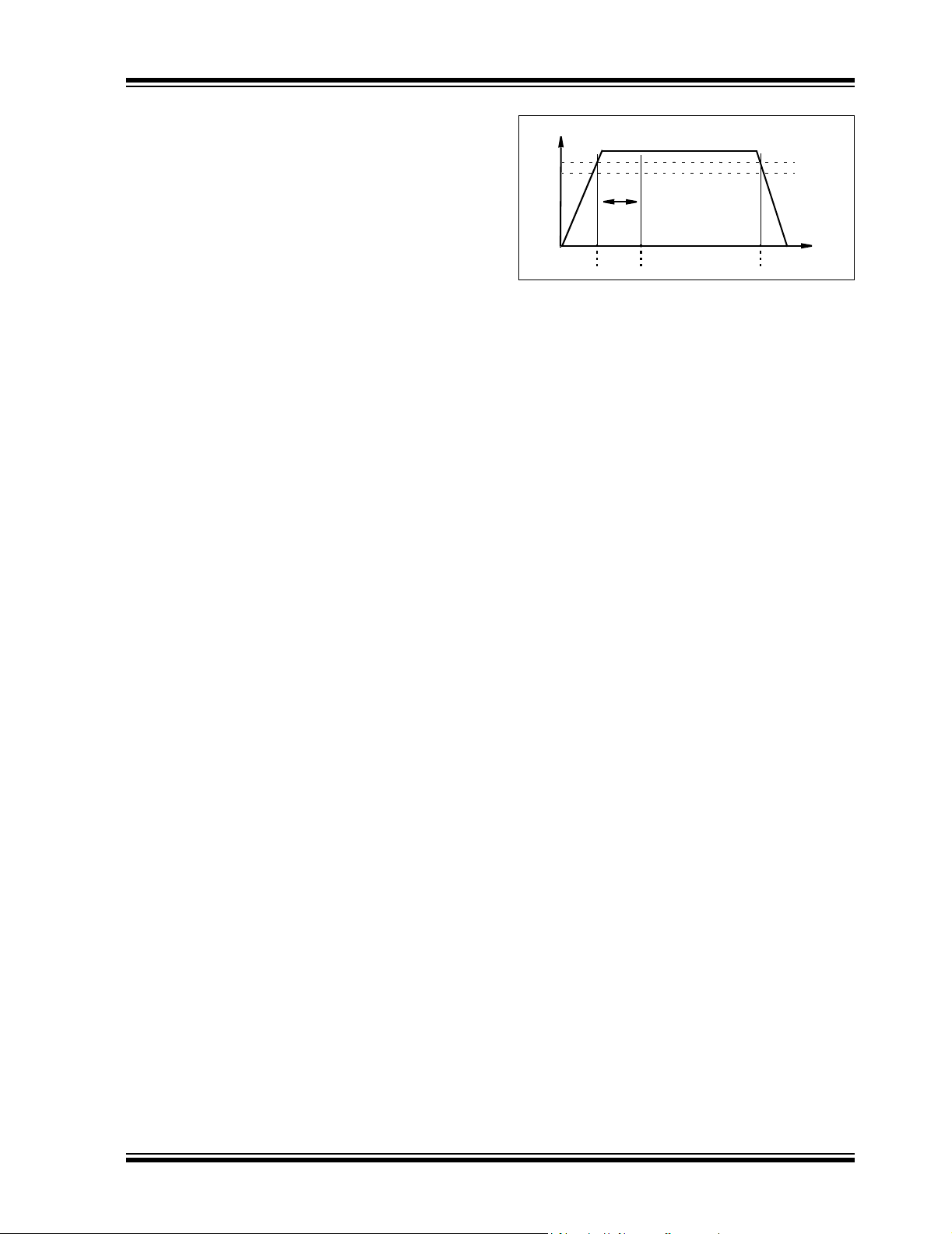

settled before the first conversion occurs. Figure 4-1

illustrates the conditions for power-up and power-down

events under typical start-up conditions.

When the device powers up, it automatically resets

and sets the configuration bits to default settings. The

default configuration bit conditions are a PGA gain of

1 V/V and a conversion speed of 240 SPS in

Continuous Conversion mode. When the device

receives an I

2

C General Call Reset command, it

performs an internal reset similar to a Power-On-Reset

event.

DD

pin

V

DD

2.2V

2.0V

300 µS

Reset

Start-up

Normal Operation

Reset

Time

FIGURE 4-1: POR Operation.

4.3 Internal Voltage Reference

The device contains an on-board 2.048V voltage

reference. This reference voltage is for internal use

only and not directly measurable. The specifications of

the reference voltage are part of the device’s gain and

drift specifications. Therefore, there is no separate

specification for the on-board reference.

4.4 Analog Input Channel

The differential analog input channel has a switched

capacitor structure. The internal sampling capacitor

(3.2 pF) is charged and discharged to process a

conversion. The charging and discharging of the input

sampling capacitor creates dynamic input currents at

the V

+ and VIN- input pins, which is inversely

IN

proportional to the internal sampling capacitor and

internal frequency. The current is also a function of the

differential input voltages. Care must be taken in setting

the common-mode voltage and input voltage ranges so

that the input limits do not exceed the ranges specified

in Section 1.0 “Electrical Characteristics”.

4.5 Digital Output Code

The digital output code produced by the MCP3421 is a

function of PGA gain, input signal, and internal

reference voltage. In a fixed setting, the digital output

code is proportional to the voltage difference between

the two analog inputs.

The output data format is a binary two’s complement.

With this code scheme, the MSB can be considered a

sign indicator. When the MSB is a logic ‘0’, it indicates

a positive value. When the MSB is a logic ‘1’, it

indicates a negative value. The following is an example

of the output code:

(a) for a negative full-scale input voltage: 100...000

(b) for a zero differential input voltage: 000...000

(c) for a positive full-scale input voltage: 011...111.

The MSB is always transmitted first through the serial

port. The number of data bits for each conversion is 18,

16, 14, or 12 bits depending on the conversion mode

selection.

© 2006 Microchip Technology Inc. DS22003B-page 7

Page 8

MCP3421

The output codes will not roll-over if the input voltage

exceeds the maximum input range. In this case, the

code will be locked at 0111...11 for all voltages

greater than +(V

voltages less than -V

of output codes of various input levels using 18 bit

conversion mode. Ta bl e 4 -3 shows an example of

minimum and maximum codes for each data rate

option.

The output code is given by:

- 1 LSB) and 1000...00 for

REF

. Ta ble 4 - 2 shows an example

REF

EQUATION 4-1:

VIN+VIN-–()

Output Code Max Code 1+()

The LSB of the code is given by:

---------------------------------------

×=

2.048V

EQUATION 4-2:

×

LSB

Where:

N = the number of bits

2 2.048V

--------------------------=

N

2

TABLE 4-1: LSB SIZE OF VARIOUS BIT

CONVERSION MODES

Bit Resolutions LSB (V)

12 bits 1 mV

14 bits 250 µV

16 bits 62.5 µV

18 bits 15.625 µV

TABLE 4-2: EXAMPLE OF OUTPUT CODE

FOR 18 BITS

Input Voltage (V) Digital Code

≥ V

REF

V

- 1 LSB 011111111111111111

REF

2LSB 000000000000000010

1LSB 000000000000000001

0 000000000000000000

-1 LSB 111111111111111111

-2 LSB 111111111111111110

- V

REF

< -V

REF

011111111111111111

100000000000000000

100000000000000000

TABLE 4-3: MINIMUM AND MAXIMUM

CODES

Number

of Bits

12 240 SPS -2048 2047

14 60 SPS -8192 8191

16 15 SPS -32768 32767

18 3.75 SPS -131072 131071

Note: Maximum n-bit code = 2

Data Rate

Minimum n-bit code = -1 x 2

Minimum

Code

n-1

- 1

Maximum

Code

n-1

4.6 Self-Calibration

The device performs a self-calibration of offset and

gain for each conversion. This provides reliable

conversion results from conversion-to-conversion over

variations in temperature as well as power supply

fluctuations.

4.7 Input Impedance

The MCP3421 uses a switched-capacitor input stage

using a 3.2 pF sampling capacitor. This capacitor is

switched (charged and discharged) at a rate of the

sampling frequency that is generated by the on-board

clock. The differential mode impedance varies with the

PGA settings. The typical differential input impedance

during a normal mode operation is given by:

ZIN(f) = 2.25 MΩ/PGA

Since the sampling capacitor is only switching to the

input pins during a conversion process, the above input

impedance is only valid during conversion periods. In a

low power standby mode, the above impedance is not

presented at the input pins. Therefore, only a leakage

current due to ESD diode is presented at the input pins.

The conversion accuracy can be affected by the input

signal source impedance when any external circuit is

connected to the input pins. The source impedance

adds to the internal impedance and directly affects the

time required to charge the internal sampling capacitor.

Therefore, a large input source impedance connected

to the input pins can increase the system performance

errors such as offset, gain, and integral nonlinearity

(INL) errors. Ideally, the input source impedance

should be zero. This can be achievable by using an

operational amplifier with a closed-loop output

impedance of tens of ohms.

DS22003B-page 8 © 2006 Microchip Technology Inc.

Page 9

4.8 Aliasing and Anti-aliasing Filter

Aliasing occurs when the input signal contains timevarying signal components with frequency greater than

half the sample rate. In the aliasing conditions, the

device can output unexpected output codes. For

applications that are operating in electrical noise

environments, the time-varying signal noise or high

frequency interference components can be easily

added to the input signals and cause aliasing. Although

the MCP3421 device has an internal first order sinc

filter, its’ filter response may not give enough

attenuation to all aliasing signal components. To avoid

the aliasing, an external anti-aliasing filter, which can

be accomplished with a simple RC low-pass filter, is

typically used at the input pins. The low-pass filter cuts

off the high frequency noise components and provides

a band-limited input signal to the MCP3421 input pins.

MCP3421

© 2006 Microchip Technology Inc. DS22003B-page 9

Page 10

MCP3421

5.0 USING THE MCP3421 DEVICE

5.1 Operating Modes

The user operates the device by setting up the device

configuration register and reads the conversion data

using serial I2C interface commands. The MCP3421

operates in two modes: (a) Continuous Conversion

Mode or (b) One-Shot Conversion Mode (single

conversion). The selection is made by setting the O

bit in the Configuration Register. Refer to Section 5.2

“Configuration Register” for more information.

5.1.1 CONTINUOUS CONVERSION

MODE (O

The MCP3421 device performs a Continuous

Conversion if the O

conversion is completed, the result is placed at the

output data register. The device immediately begins

another conversion and overwrites the output data

register with the most recent data.

The device also clears the data ready flag (RDY

when the conversion is completed. The device sets the

ready flag bit (RDY

result has been read by the Master.

/C BIT = 1)

/C bit is set to logic “high”. Once the

bit = 1), if the latest conversion

/C

bit = 0)

5.1.2 ONE-SHOT CONVERSION MODE

(O

/C BIT = 0)

Once the One-Shot Conversion (single conversion)

Mode is selected, the device performs a conversion,

updates the Output Data register, clears the data ready

flag (RDY

mode. A new One-Shot Conversion is started again

when the device receives a new write command with

RDY

This One-Shot Conversion Mode is recommended for

low power operating applications. During the low

current standby mode, the device consumes less than

1 µA typical. For example, if user collects 18 bit

conversion data once a second in One-Shot Conversion mode, the device draws only about one fourth of

its total operating current. In this example, the device

consumes approximately 39 µA (= ~145 µA/3.75 SPS),

if the device performs only one conversion per second

(1 SPS) in 18-bit conversion mode with 3V power

supply.

= 0), and then enters a low power standby

= 1.

DS22003B-page 10 © 2006 Microchip Technology Inc.

Page 11

MCP3421

5.2 Configuration Register

The MCP3421 has an 8-bit wide configuration register

to select for: PGA gain, conversion rate, and conversion mode. This register allows the user to change the

operating condition of the device and check the status

of the device operation. The user can rewrite the

configuration byte any time during the device

operation. Register 5-1 shows the configuration

register bits.

REGISTER 5-1: CONFIGURATION REGISTER

R/W-1 R/W-0 R/W-0 R/W-1 R/W-0 R/W-0 R/W-0 R/W-0

RDY C1 C0 O/C S1 S0 G1 G0

1 * 0 * 0 * 1 * 0 * 0 * 0 * 0 *

bit 7 bit 0

* Default Configuration after Power-On Reset

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 RDY

bit 6-5 C1-C0: Channel Selection Bits

bit 4 O

bit 3-2 S1-S0: Sample Rate Selection Bit

bit 1-0 G1-G0: PGA Gain Selector Bits

: Ready Bit

This bit is the data ready flag. In read mode, this bit indicates if the output register has been updated

with a new conversion. In One-Shot Conversion mode, writing this bit to “1” initiates a new conversion.

Reading RDY bit with the read command:

1 = Output register has not been updated.

0 = Output register has been updated with the latest conversion data.

Writing

Continuous Conversion mode: No effect

One-Shot Conversion mode:

1 = Initiate a new conversion.

0 = No effect.

These are the Channel Selection bits, but not used in the MCP3421 device.

1 = Continuous Conversion Mode. Once this bit is selected, the device performs data conversions

0 = One-Shot Conversion Mode. The device performs a single conversion and enters a low power

00 = 240 SPS (12 bits),

01 = 60 SPS (14 bits),

10 = 15 SPS (16 bits),

11 = 3.75 SPS (18 bits)

00 = 1 V/V,

01 = 2 V/V,

10 = 4 V/V,

11 = 8 V/V

RDY bit with the write command:

/C: Conversion Mode Bit

continuously.

standby mode until it receives another write/read command.

© 2006 Microchip Technology Inc. DS22003B-page 11

Page 12

MCP3421

In read mode, the RDY bit in the configuration byte

indicates the state of the conversion: (a) RDY = 1

indicates that the data bytes that have just been read

were not updated from the previous conversion. (b)

= 0 indicates that the data bytes that have just

RDY

been read were updated.

If the configuration byte is read repeatedly by clocking

continuously after the first read (i.e., after the 5th byte

in the 18-bit conversion mode), the state of the RDY

indicates whether the device is ready with new

conversion data. See Figure 5-2. For example,

= 0 means new conversion data is ready for read-

RDY

ing. In this case, the user can send a stop bit to exit the

current read operation and send a new read command

to read out updated conversion data. See Figures 5-2

and 5-3 for reading conversion data. The user can

rewrite the configuration byte any time for a new

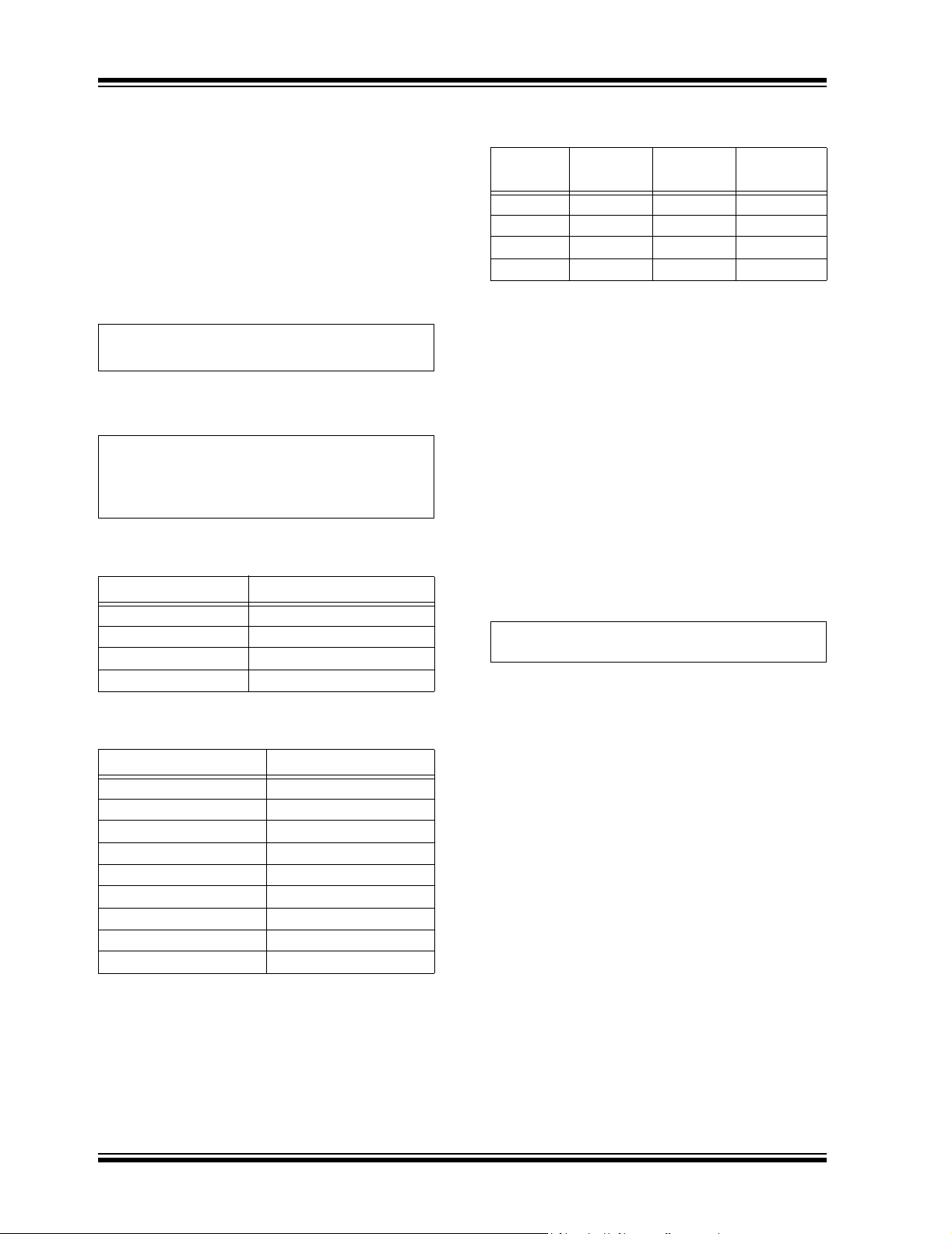

setting. Tables 5-1 and 5-2 show the examples of the

configuration bit operation.

TABLE 5-1: CONFIGURATION BITS FOR

bit

WRITING

R/W O/C RDY Operation

0 0 0 No effect if all other bits remain

the same - operation continues

with the previous settings

0 0 1 Initiate One-Shot Conversion

0 1 0 Initiate Continuous Conversion

0 1 1 Initiate Continuous Conversion

TABLE 5-2: CONFIGURATION BITS FOR

READING

R/W O/C RDY Operation

1 0 0 New conversion data in One-

Shot conversion mode has been

just read. The RDY

low until set by a new write

command.

1 0 1 One-Shot Conversion is in

progress, The conversion data is

not updated yet. The RDY

stays high.

1 1 0 New conversion data in Continu-

ous Conversion mode has been

just read. The RDY

to high after this read.

1 1 1 The conversion data in Continu-

ous Conversion mode was

already read. The latest conver-

sion data is not ready. The RDY

bit stays high until a new

conversion is completed.

bit remains

bit

bit changes

5.3 I2C Serial Communications

The MCP3421 device communicates with Master

(microcontroller) through a serial I

Circuit) interface and supports standard

(100 kbits/sec), fast (400 kbits/sec) and high-speed

(3.4 Mbits/sec) modes. The serial I

2-wire data bus communication protocol using opendrain SCL and SDA lines.

The MCP3421 can only be addressed as a slave. Once

addressed, it can receive configuration bits or transmit

the latest conversion results. The serial clock pin (SCL)

is an input only and the serial data pin (SDA) is

bidirectional. An example of a hardware connection

diagram is shown in Figure 6-1.

The Master starts communication by sending a START

bit and terminates the communication by sending a

STOP bit. The first byte after the START bit is always

the address byte of the device, which includes the

device code, the address bits, and the R/W

device code for the MCP3421 device is 1101. The

address bits (A2, A1, A0) are pre-programmed at the

factory. In general, the address bits are specified by the

customer when they order the device. The three

address bits are programmed to “000” at the factory, if

they are not specified by the customer. Figure 5-1

shows the details of the MCP3421 address byte.

During a low power standby mode, SDA and SCL pins

remain at a floating condition.

2

More details of the I

in Section 5.6 “I

C bus characteristic is described

2

C Bus Characteristics”.

5.3.1 DEVICE ADDRESSING

The address byte is the first byte received following the

START condition from the Master device. The

MCP3421 device code is 1101. The device code is

followed by three address bits (A2, A1, A0) which are

programmed at the factory. The three address bits

allow up to eight MCP3421 devices on the same data

bus line. The (R/W

wants to read the conversion data or write to the

Configuration register. If the (R/W

mode), the MCP3421 outputs the conversion data in

the following clocks. If the (R/W

mode), the MCP3421 expects a configuration byte in

the following clocks. When the MCP3421 receives the

correct address byte, it outputs an acknowledge bit

after the R/W

address byte. See Figures 5-2 and 5-3 for the read and

write operations of the device.

) bit determines if the Master device

bit. Figure 5-1 shows the MCP3421

2

C (Inter-Integrated

2

C is a bidirectional

bit. The

) bit is set (read

) bit is cleared (write

DS22003B-page 12 © 2006 Microchip Technology Inc.

Page 13

MCP3421

Acknowledge bit

Start bit

Address

Address Byte

Address

Device Code Address Bits

1

Note 1: Specified by customer and programmed at the

0

1

factory. If not specified by the customer,

programmed to ‘

1

X

000’.

Read/Write

X

bit

(Note 1)

X

R/W

ACK

FIGURE 5-1: MCP3421 Address Byte.

5.3.2 READING DATA FROM THE DEVICE

When the Master sends a read command (R/W = 1),

the MCP3421 outputs the conversion data bytes and

configuration byte. Each byte consists of 8 bits with

one acknowledge (ACK) bit. The ACK bit after the

address byte is issued by the MCP3421 and the ACK

bits after each conversion data bytes are issued by the

Master.

When the device is configured for 18-bit conversion

mode, the device outputs three data bytes followed by

a configuration byte. The first 7 data bits in the first

data byte are the MSB of the conversion data. The

user can ignore the first 6 data bits, and take the 7th

data bit (D17) as the MSB of the conversion data. The

LSB of the 3rd data byte is the LSB of the conversion

data (D0).

If the device is configured for 12, 14, or 16 bit-mode, the

device outputs two data bytes followed by a

configuration byte. In 16 bit-conversion mode, the MSB

of the first data byte is the MSB (D15) of the conversion

data. In 14-bit conversion mode, the first two bits in the

first data byte can be ignored (they are the MSB of the

conversion data), and the 3rd bit (D13) is the MSB of

the conversion data. In 12-bit conversion mode, the

first four bits can be ignored (they are the MSB of the

conversion data), and the 5th bit (D11) of the byte

represents the MSB of the conversion data. Table 5-3

shows an example of the conversion data output of

each conversion mode.

The configuration byte follows the output data byte.

The device outputs the configuration byte as long as

the SCL pulses are received. The device terminates

the current outputs when it receives a Not-Acknowledge (NAK), a repeated start or a stop bit at any time

during the output bit stream. It is not required to read

the configuration byte. However, the user may read the

configuration byte to check the RDY

bit condition to

confirm whether the just received data bytes are

updated conversion data. The user may continuously

send clock (SCL) to repeatedly read the configuration

bytes to check the RDY

bit status.

Figures 5-2 and 5-3 show the timing diagrams of the

reading.

5.3.3 WRITING A CONFIGURATION BYTE

TO THE DEVICE

When the Master sends an address byte with the R/W

bit low (R/W = 0), the MCP3421 expects one

configuration byte following the address. Any byte sent

after this second byte will be ignored. The user can

change the operating mode of the device by writing the

configuration register bits.

If the device receives a write command with a new

configuration setting, the device immediately begins a

new conversion and updates the conversion data.

TABLE 5-3: EXAMPLE OF CONVERSION DATA OUTPUT OF EACH CONVERSION MODE

Conversion

Mode

18-bits MMMMMMMD16 (1st data byte) - D15 ~ D8 (2nd data byte) - D7 ~ D0 (3rd data byte) - Configuration

byte

16-bits MD14~D8 (1st data byte) - D7 ~ D0 (2nd data byte) - Configuration byte

14-bits MMMD12~D8 (1st data byte) - D7 ~ D0 (2nd data byte) - Configuration byte

12-bits MMMMMD10D9D8 (1st data byte) - D7 ~ D0 (2nd data byte) - Configuration byte

Note: M is MSB of the data byte.

© 2006 Microchip Technology Inc. DS22003B-page 13

Conversion Data Output

Page 14

MCP3421

9

G

G

S

S

C

C

1

D

D

D

D

D

D

D

D

9

D

D

D

D

D

D

D

191

9

7

D

D

D

Master

ACK by

0

1

0

1

O/C

5th Byte

0

1

RDY

Master

ACK by

0

1

2

3

4

5

6

7

Master

ACK by

8

9

10

11

12

13

14

15

Master

ACK by

16

17

Configuration Byte

4th Byte

Lower Data Byte

3rd Byte

Middle Data Byte

(Optional)

Master

9

1

Stop Bit by

0

G

G

S

S

C

C

Master

NAK by

1

0

1

O/C

0

1

RDY

(Optional)

Configuration Byte

Nth Repeated Byte:

2nd Byte

can be ignored)

Upper Data Byte

(Data on Clocks 1-6th

1

9

1

SCL

Repeat of D17 (MSB)

ACK by

MCP3421

R/W

1st Byte

Start Bit by

MCP3421 Address Byte

– Address Bits A2- A0 = 000 are programmed at the factory unless customer requests specific codes.

– Stop bit or NAK bit can be issued any time during reading.

– Data bits on clocks 1 - 6th in 2nd byte are repeated MSB and can be ignored.

Master

Note: – MCP3421 device code is 1101.

1 1 0 1 A2 A1 A0

SDA

FIGURE 5-2: Timing Diagram For Reading From The MCP3421 With 18-Bit Mode.

DS22003B-page 14 © 2006 Microchip Technology Inc.

Page 15

MCP3421

9

G

G

S

S

C

C

1

9

D

D

D

D

D

D

D

1

1

99

9

D

D

D

D

D

D

D

D

D

Master

ACK by

0

1

0

1

0

1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

O/C

RDY

Master

ACK by

Master

ACK by

ACK by

MCP3421

4th Byte

(Optional)

Configuration Byte

9

G

G

S

S

3rd Byte

Lower Data Byte

1

2nd Byte

Middle Data Byte

C

C

Master

Stop Bit by

0

Master

NAK by

1

0

1

O/C

0

1

RDY

(Optional)

Configuration Byte

Nth Repeated Byte:

R/W

1st Byte

MCP3421 Address Byte

1

SCL

1101A2A1A0

SDA

Start Bit by

– Address Bits A2- A0 = 000 are programmed at the factory unless customer requests specific codes.

– Stop bit or NAK bit can be issued any time during reading.

– In 14 - bit mode: D15 and D14 are repeated MSB and can be ignored.

– In 12 - bit mode: D15 - D12 are repeated MSB and can be ignored.

Master

Note: – MCP3421 device code is 1101.

FIGURE 5-3: Timing Diagram For Reading From The MCP3421 With 12-Bit to 16-Bit Modes.

© 2006 Microchip Technology Inc. DS22003B-page 15

Page 16

MCP3421

1

SCL

1

9

9

SDA

Start Bit by

Master

1101A2A1

R/W

A0

ACK by

MCP3421

C1 C0

RDY

O/C

1st Byte:

MCP3421 Address Byte

with Write command

2nd Byte:

Configuration Byte

Note: – Stop bit can be issued any time during writing.

– MCP3421 device code is 1101.

– Address Bits A2- A0 = 000 are programmed at factory unless customer requests different codes.

FIGURE 5-4: Timing Diagram For Writing To The MCP3421.

5.4 General Call

The MCP3421 acknowledges the general call address

(0x00 in the first byte). The meaning of the general call

address is always specified in the second byte. Refer

0

to Figure 5-5. The MCP3421 supports the following

general calls:

5.4.1 GENERAL CALL RESET

The general call reset occurs if the second byte is

‘00000110’ (06h). At the acknowledgement of this

byte, the device will abort current conversion and

perform an internal reset similar to a power-on-reset

(POR).

5.4.2 GENERAL CALL CONVERSION

The general call conversion occurs if the second byte

is ‘00001000’ (08h). All devices on the bus initiate a

conversion simultaneously. For the MCP3421 device,

the configuration will be set to the One-Shot Conversion mode and a single conversion will be performed.

The PGA and data rate settings are unchanged with

this general call.

Note: The I2C specification does not allow to use

“00000000” (00h) in the second byte.

0 0 0 0 0 0 0

(General Call Address)

FIGURE 5-5: General Call Address Format.

For more information on the general call, or other I2C

modes, please refer to the Phillips I

S1 S0 G1 G0

ACK by

MCP3421

First Byte

Stop Bit by

Master

ACK

x

A Axxxxxx x

Second Byte

2

C specification.

ACK

LSB

DS22003B-page 16 © 2006 Microchip Technology Inc.

Page 17

MCP3421

5.5 High-Speed (HS) Mode

The I2C specification requires that a high-speed mode

device must be ‘activated’ to operate in high-speed

mode. This is done by sending a special address byte

of 00001XXX following the START bit. The XXX bits are

unique to the High-Speed (HS) mode Master. This byte

is referred to as the High-Speed (HS) Master Mode

Code (HSMMC). The MCP3421 device does not

acknowledge this byte. However, upon receiving this

code, the MCP3421 switches on its HS mode filters

and communicates up to 3.4 MHz on SDA and SCL.

The device will switch out of the HS mode on the next

STOP condition.

For more information on the HS mode, or other I

modes, please refer to the Phillips I

2

C specification.

2

5.6 I2C Bus Characteristics

The I2C specification defines the following bus

protocol:

• Data transfer may be initiated only when the bus

is not busy.

• During data transfer, the data line must remain

stable whenever the clock line is HIGH. Changes

in the data line while the clock line is HIGH will be

interpreted as a START or STOP condition.

Accordingly, the following bus conditions have been

defined using Figure 5-6.

5.6.1 BUS NOT BUSY (A)

Both data and clock lines remain HIGH.

5.6.2 START DATA TRANSFER (B)

A HIGH to LOW transition of the SDA line while the

clock (SCL) is HIGH determines a START condition. All

commands must be preceded by a START condition.

5.6.3 STOP DATA TRANSFER (C)

A LOW to HIGH transition of the SDA line while the

clock (SCL) is HIGH determines a STOP condition. All

operations can be ended with a STOP condition.

5.6.4 DATA VALID (D)

The state of the data line represents valid data when,

after a START condition, the data line is stable for the

duration of the HIGH period of the clock signal.

The data on the line must be changed during the LOW

period of the clock signal. There is one clock pulse per

bit of data.

Each data transfer is initiated with a START condition

and terminated with a STOP condition.

5.6.5 ACKNOWLEDGE

The Master (microcontroller) and the slave (MCP3421)

C

use an acknowledge pulse as a hand shake of

communication for each byte. The ninth clock pulse of

each byte is used for the acknowledgement. The

acknowledgement is achieved by pulling-down the

SDA line “LOW” during the 9th clock pulse. The clock

pulse is always provided by the Master (microcontroller) and the acknowledgement is issued by the

receiving device of the byte (Note: The transmitting

device must release the SDA line (“HIGH”) during the

acknowledge pulse.). For example, the slave

(MCP3421) issues the acknowledgement (bring down

the SDA line “LOW”) after the end of each receiving

byte, and the master (microcontroller) issues the

acknowledgement when it reads data from the Slave

(MCP3421).

When the MCP3421 is addressed, it generates an

acknowledge after receiving each byte successfully.

The Master device (microcontroller) must provide an

extra clock pulse (9th pulse of each byte) for the

acknowledgement from the MCP3421 (slave).

The MCP3421 (slave) pulls-down the SDA line during

the acknowledge clock pulse in such a way that the

SDA line is stable low during the high period of the

acknowledge clock pulse.

During reads, the Master (microcontroller) can

terminate the current read operation by not providing

an acknowledge bit on the last byte that has been

clocked out from the MCP3421. In this case, the

MCP3421 releases the SDA line to allow the master

(microcontroller) to generate a STOP or repeated

START condition.

(A) (B) (D) (D) (A)(C)

SCL

SDA

START

CONDITION

ADDRESS OR

ACKNOWLEDGE

VAL ID

DATA

ALLOWED

TO CHANGE

STOP

CONDITION

FIGURE 5-6: Data Transfer Sequence on the Serial Bus.

© 2006 Microchip Technology Inc. DS22003B-page 17

Page 18

MCP3421

TABLE 5-4: I2C SERIAL TIMING SPECIFICATIONS

Electrical Specifications: Unless otherwise specified, all limits are specified for TA = -40 to +85°C, VDD = +2.7V, +3.3V or +5.0V,

V

= 0V, VIN+ = VIN- = V

SS

Parameters Sym Min Typ Max Units Conditions

Standard Mode

Clock frequency f

Clock high time

Clock low time

SDA and SCL rise time

SDA and SCL fall time

START condition hold time T

Repeated START condition

setup time

Data hold time

(Note 3)

Data input setup time

STOP condition setup time

STOP condition hold time

Output valid from clock

(Notes 2 and 3)

Bus free time

Fast Mode

Clock frequency

Clock high time

Clock low time

SDA and SCL rise time

SDA and SCL fall time

START condition hold time T

Repeated START condition

setup time

Data hold time

(Note 4)

Data input setup time

STOP condition setup time

STOP condition hold time

Output valid from clock

(Notes 2 and 3)

Bus free time

Input filter spike suppression

(Note 5)

Note 1: This parameter is ensured by characterization and not 100% tested.

2: This specification is not a part of the I

plus SDA Fall (or rise) time:

3: If this parameter is too short, it can create an unintended Start or Stop condition to other devices on the bus line. If this

parameter is too long, Clock Low time (T

4: For Data Input: This parameter must be longer than t

Clock Low time (T

For Data Output: This parameter is characterized, and tested indirectly by testing T

5: This parameter is ensured by characterization and not 100% tested. This parameter is not available for Standard Mode.

REF

(Note 1)

(Note 1)

(Note 1)

(Note 1)

/2.

SCL

T

HIGH

T

LOW

T

R

T

F

HD:STA

T

SU:STA

T

HD:DAT

T

SU:DAT

T

SU:STO

T

HD:STD

T

AA

T

BUF

T

SCL

T

HIGH

T

LOW

T

R

T

F

HD:STA

T

SU:STA

T

HD:DAT

T

SU:DAT

T

SU:STO

T

HD:STD

T

AA

T

BUF

T

SP

T

) can be affected.

LOW

0 — 100 kHz

4000 — — ns

4700 — — ns

— — 1000 ns From VIL to V

— — 300 ns From VIH to V

4000 — — ns After this period, the first clock

pulse is generated.

4700 — — ns Only relevant for repeated Start

condition

0 — 3450 ns

250 — — ns

4000 — — ns

4000 — — ns

0 — 3750 ns

4700 — — ns Time between START and STOP

conditions.

0 — 400 kHz

600 — — ns

1300 — — ns

20 + 0.1Cb — 300 ns From VIL to V

20 + 0.1Cb — 300 ns From VIH to V

600 — — ns After this period, the first clock

pulse is generated

600 — — ns Only relevant for repeated Start

condition

0 — 900 ns

100 — — ns

600 — — ns

600 — — ns

0 — 1200 ns

1300 — — ns Time between START and STOP

conditions.

0 — 50 ns SDA and SCL pins

2

C specification. This specification is equivalent to the Data Hold Time (T

AA

= T

HD:DAT

LOW

+ TF (OR TR).

) can be affected.

. If this parameter is too long, the Data Input Setup (T

SP

parameter.

AA

IH

IL

IH

IL

HD:DAT

SU:DAT

)

) or

DS22003B-page 18 © 2006 Microchip Technology Inc.

Page 19

MCP3421

TABLE 5-4: I2C SERIAL TIMING SPECIFICATIONS (CONTINUED)

Electrical Specifications: Unless otherwise specified, all limits are specified for TA = -40 to +85°C, VDD = +2.7V, +3.3V or +5.0V,

V

= 0V, VIN+ = VIN- = V

SS

Parameters Sym Min Typ Max Units Conditions

High Speed Mode

Clock frequency f

Clock high time

Clock low time

SCL rise time

SCL fall time

SDA rise time

SDA fall time

(Note 1)

(Note 1)

(Note 1)

(Note 1)

START condition hold time

Repeated START condition

setup time

Data hold time

(Note 4)

Data input setup time

STOP condition setup time

STOP condition hold time

Output valid from clock

(Notes 2 and 3)

Bus free time

Input filter spike suppression

(Note 5)

Note 1: This parameter is ensured by characterization and not 100% tested.

2: This specification is not a part of the I

plus SDA Fall (or rise) time:

3: If this parameter is too short, it can create an unintended Start or Stop condition to other devices on the bus line. If this

parameter is too long, Clock Low time (T

4: For Data Input: This parameter must be longer than t

Clock Low time (T

For Data Output: This parameter is characterized, and tested indirectly by testing T

5: This parameter is ensured by characterization and not 100% tested. This parameter is not available for Standard Mode.

/2.

REF

) can be affected.

LOW

SCL

T

HIGH

T

LOW

T

T

T

R: DAT

T

F: DATA

T

HD:STA

T

SU:STA

T

HD:DAT

T

SU:DAT

T

SU:STO

T

HD:STD

T

T

BUF

T

AA

SP

0—3.4

1.7

60

——ns

120

160

——nsC

320

R

F

——4080ns From VIL to VIH,Cb = 100 pF

——4080ns From VIH to VIL,Cb = 100 pF

——80

160

——80

160

MHz

Cb = 100 pF

MHz

C

= 400 pF

b

Cb = 100 pF

ns

C

= 400 pF

b

= 100 pF

b

C

= 400 pF

b

C

= 400 pF

b

C

= 400 pF

b

ns From VIL to VIH,Cb = 100 pF

C

= 400 pF

b

ns From VIH to VIL,Cb = 100 pF

C

= 400 pF

b

160 — — ns After this period, the first clock

pulse is generated

160 — — ns Only relevant for repeated Start

condition

0

0

—70

150

ns Cb = 100 pF

C

= 400 pF

b

10 — — ns

160 — — ns

160 — — ns

— — 150

310

ns Cb = 100 pF

C

= 400 pF

b

160 — — ns Time between START and STOP

conditions.

0 — 10 ns SDA and SCL pins

2

C specification. This specification is equivalent to the Data Hold Time (T

T

AA

= T

HD:DAT

LOW

+ TF (OR TR).

) can be affected.

. If this parameter is too long, the Data Input Setup (T

SP

parameter.

AA

HD:DAT

SU:DAT

)

) or

© 2006 Microchip Technology Inc. DS22003B-page 19

Page 20

MCP3421

T

F

T

T

SU:STA

SP

T

HD:STA

T

LOW

SCL

SDA

FIGURE 5-7: I2C Bus Timing Data.

T

HIGH

T

HD:DAT

T

R

T

T

SU:DAT

T

AA

SU:STO

T

BUF

DS22003B-page 20 © 2006 Microchip Technology Inc.

Page 21

MCP3421

6.0 BASIC APPLICATION

CONFIGURATION

The MCP3421 device can be used for various precision

analog-to-digital converter applications. The device

operates with very simple connections to the

application circuit. The following sections discuss the

examples of the device connections and applications.

6.1 Connecting to the Application

Circuits

6.1.1 INPUT VOLTAGE RANGE

The fully differential input signals can be connected to

+ and VIN- input pins. The input range should be

the V

IN

within absolute common mode input voltage range:

VSS- 0.3V to VDD + 0.3V. Outside this limit, the ESD

protection diode at the input pin begins to conduct and

the error due to input leakage current increases rapidly.

Within this limit, the differential input V

is boosted by the PGA before a conversion takes place.

The MCP3421 can not accept negative input voltages

on the input pins. Figures 6-1 and 6-2 show typical connection examples for differential inputs and a singleended input, respectively. For the single-ended input,

the input signal is applied

(typically connected to the V

to one of the input pins

+ pin) while the other

IN

input pin (typically VIN- pin) is grounded. The input

signal range of the single-ended configuration is from

0V to 2.048V. All device characteristics hold for the

single-ended configuration, but this configuration loses

one bit resolution because the input can only stand in

positive half scale.

Characteristics”

.

Refer to

Section 1.0 “Electrical

6.1.2 BYPASS CAPACITORS ON VDD PIN

For accurate measurement, the application circuit

needs a clean supply voltage and must block any noise

signal to the MCP3421 device. Figure 6-1 shows an

example of using two bypass capacitors (a 10 µF

tantalum capacitor and a 0.1 µF ceramic capacitor) in

parallel on the V

line. These capacitors are helpful to

DD

filter out any high frequency noises on the V

also provide the momentary bursts of extra currents

when the device needs from the supply. These

capacitors should be placed as close to the V

possible (within one inch). If the application circuit has

separate digital and analog power supplies, the V

and VSS of the MCP3421 should reside on the analog

plane.

6.1.3 CONNECTING TO I2C BUS USING

PULL-UP RESISTORS

The SCL and SDA pins of the MCP3421 are open-drain

configurations. These pins require a pull-up resistor as

shown in Figure 6-1. The value of these pull-up resistors depends on the operating speed (standard, fast,

and high speed) and loading capacitance of the I

(= VIN+-VIN-)

IN

line and

DD

DD

pin as

DD

2

C bus

line. Higher value of pull-up resistor consumes less

power, but increases the signal transition time (higher

RC time constant) on the bus. Therefore, it can limit the

bus operating speed. The lower value of resistor, on the

other hand, consumes higher power, but allows higher

operating speed. If the bus line has higher capacitance

due to long bus line or high number of devices

connected to the bus, a smaller pull-up resistor is

needed to compensate the long RC time constant. The

pull-up resistor is typically chosen between 1 kΩ and

10 kΩ ranges for standard and fast modes, and less

than 1 kΩ for high speed mode in high loading

capacitance environments.

V

Input Signals

MCP3421

-

V

V

SDL

IN

DD

6

5

4

V

+

1

IN

V

2

SS

3

SCL

Note: R is the pull-up resistor.

DD

V

DD

R

10 µF0.1 µF

R

TO MCU

(MASTER)

FIGURE 6-1: Typical Connection Example for Differential Inputs.

V

Input Signals

MCP3421

-

V

V

SDL

IN

DD

6

5

4

+

V

1

IN

V

2

SS

3

SCL

Note: R is the pull-up resistor.

DD

V

DD

R

10 µF0.1 µF

R

TO MCU

(MASTER)

FIGURE 6-2: Typical Connection Example for Single-Ended Input.

The number of devices connected to the bus is limited

only by the maximum bus capacitance of 400 pF. The

bus loading capacitance affects on the bus operating

speed. For example, the highest bus operating speed

for the 400 pF bus capacitance is 1.7 MHz, and

3.4 MHz for 100 pF. Figure 6-3 shows an example of

multiple device connections.

© 2006 Microchip Technology Inc. DS22003B-page 21

Page 22

MCP3421

Microcontroller

(PIC16F876)

MCP3421

SDA SCL

EEPROM

(24LC01)

NPP301

V

DD

V

DD

V

DD

Temperature

Sensor

(TC74)

FIGURE 6-3: Example of Multiple Device

Connection on I

2

C Bus.

6.2 Device Connection Test

The user can test the presence of the MCP3421 on the

I2C bus line without performing an input data conversion. This test can be achieved by checking an

acknowledge response from the MCP3421 after sending a read or write command. Here is an example using

Figure 6-4:

(a) Set the R/W

(b) The MCP3421 will then acknowledge by pulling

SDA bus LOW during the ACK clock and then release

the bus back to the I

(c) A STOP or repeated START bit can then be issued

from the Master and I

bit “HIGH” in the address byte.

2

C Master.

2

C communication can continue.

Address Byte

MCP3421

-

V

V

+

1

IN

V

2

SS

3

SCL SDL

6

IN

V

5

DD

4

R

10 µF0.1 µF

R

TO MCU

(MASTER)

FIGURE 6-5: Example of Pressure Measurement.

In this circuit example, the sensor full scale range is

±7.5 mV with a common mode input voltage of V

This configuration will provide a full 14-bit resolution

across the sensor output range. The alternative circuit

for this amount of accuracy would involve an analog

gain stage prior to a 16-bit ADC.

Figure 6-6 shows an example of temperature measure-

ment using a thermistor. This example can achieve a

linear response over a 50°C temperature range. This

can be implemented using a standard resistor with 1%

tolerance in series with the thermistor. The value of the

resistor is selected to be equal to the thermistor value

at the mid-point of the desired temperature range.

DD

/ 2.

SCL

SDA

123456789

1

Start

Bit

1

Device bits

1A2A1A0

0

Address bits

1

R/W

ACK

Start

Bit

10 kΩ

Resistor

10 kΩ

Thermistor

V

DD

V

DD

V

DD

MCP3421

Response

FIGURE 6-4: I2C Bus Connection Test.

6.3 Application Examples

V

1

V

2

3

SCL

MCP3421

+

IN

SS

V

V

SDL

IN

DD

-

6

5

4

R

10 µF0.1 µF

R

The MCP3421 device can be used in a broad range of

sensor and data acquisition applications. Figure 6-5,

shows an example of interfacing with a bridge sensor

for pressure measurement.

TO MCU

(MASTER)

FIGURE 6-6: Example of Temperature Measurement.

DS22003B-page 22 © 2006 Microchip Technology Inc.

Page 23

7.0 PACKAGING INFORMATION

7.1 Package Marking Information

MCP3421

6-Lead SOT-23

5

XXNN

64

Example

2

13

5

CA25

64

2

13

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

3

e

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designator ( )

can be found on the outer packaging for this package.

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

© 2006 Microchip Technology Inc. DS22003B-page 23

3

e

Page 24

MCP3421

6-Lead Plastic Small Outline Transistor (OT) (SOT-23)

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E

E1

B

n

c

β

Number of Pins

Pitch

Outside lead pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

*

Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .005" (0.127mm) per side.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

See ASME Y14.5M

JEITA (formerly EIAJ) equivalent: SC-74A

Drawing No. C04-120

L

Units

n

p

p1

φ

c

α

β

p1

D

1

α

φ

A

A1

A2

*

MILLIMETERSINCHES

MAXNOMMINMAXNOMMINDimension Limits

66

0.95 BSC.038 BSC

1.90 BSC.075 BSC

1.451.180.90.057.046.035AOverall Height

1.301.100.90.051.043.035A2Molded Package Thickness

0.150.080.00.006.003.000A1Standoff

3.002.802.60.118.110.102EOverall Width

1.751.631.50.069.064.059E1Molded Package Width

3.102.952.80.122.116.110DOverall Length

0.550.450.35.022.018.014LFoot Length

10501050

0.200.150.09.008.006.004

0.500.430.35.020.017.014BLead Width

10501050

10501050

Revised 09-12-05

DS22003B-page 24 © 2006 Microchip Technology Inc.

Page 25

APPENDIX A: REVISION HISTORY

Revision B (December 2006)

• Changes to Electrical Characteristics tables

• Added characterization data

• Changes to I

• Change to Figure 5-7.

Revision A (August 2006)

• Original Release of this Document.

2

C Serial Timing Specification table

MCP3421

© 2006 Microchip Technology Inc. DS22003B-page 27

Page 26

MCP3421

NOTES:

DS22003B-page 28 © 2006 Microchip Technology Inc.

Page 27

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. XXX

Device

Device: MCP3421T: Single Channel ΔΣ A/D Converter

Address Options: XX A2 A1 A0

Address Temperature

Options

Range

(Tape and Reel)

A0 *=000

A1=001

A2=010

A3=011

A4=100

A5=101

A6=110

A7=111

* Default option. Contact Microchip factory for other

address options

/XX

Package

Examples:

a) MCP3421A0T-E/OT: Tape and Reel,

MCP3421

Single Channel ΔΣ A/D

Converter,

package.

SOT-23-6

Temperature Range: E = -40°C to +125°C

Package: OT = Plastic Small Outline Transistor (SOT-23-6),

6-lead

© 2006 Microchip Technology Inc. DS22003B-page 29

Page 28

MCP3421

NOTES:

DS22003B-page 30 © 2006 Microchip Technology Inc.

Page 29

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Linear Active

Thermistor, Mindi, MiWi, MPASM, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

8-bit MCUs, KEELOQ

microperipherals, nonvolatile memory and analog products. In addition,

Microchip’s quality system for the design and manufacture of

development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial EEPROMs,

© 2006 Microchip Technology Inc. DS22003B-page 31

®

Page 30

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu