Page 1

XZR400 Series

Oxygen Analyzers

User’s Manual

97472 Issue 3

August 2018

Page 2

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

For Michell Instruments' contact information please go to

www.michell.com

© 2018 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

XZR400 Series User’s Manual

Contents

Safety .............................................................................................................................. viii

Electrical Safety ......................................................................................................... viii

Pressure Safety .......................................................................................................... viii

Temperature Safety .................................................................................................... viii

Toxic Materials ........................................................................................................... viii

Repair and Maintenance ............................................................................................. viii

Calibration ................................................................................................................. viii

Safety Conformity ...................................................................................................... viii

Abbreviations ......................................................................................................................ix

Warnings ............................................................................................................................ x

1 INTRODUCTION ................................................................................................1

1.1 Operating Principle .......................................................................................... 2

1.2 The MSRS Technology...................................................................................... 3

2 INSTALLATION ..................................................................................................6

2.1 Unpacking the Analyzer ................................................................................... 6

2.2 Preparation ..................................................................................................... 6

2.3 Dimensions - XZR400A1 ................................................................................... 7

2.3.1 Installing the XZR400A1 .............................................................................. 7

2.4 Dimensions - XZR400A2 ................................................................................... 8

2.4.1 Installing the XZR400A2 .............................................................................. 9

2.5 Dimensions - XZR400A3 ................................................................................. 10

2.6 Dimensions - XZR400A4 ................................................................................. 10

2.7 Operating Requirements ................................................................................ 11

2.7.1 Environmental Requirements ..................................................................... 11

2.7.2 Electrical Requirements ............................................................................. 11

2.7.3 Gas Requirements .................................................................................... 11

2.7.4 Sampling System ...................................................................................... 11

2.8 Connections to the XZR400A1 ........................................................................ 12

2.8.1 Front Panel .............................................................................................. 12

2.8.2 Back Panel ............................................................................................... 12

2.8.3 Gas Inlet, Outlet and Bypass Gas Connections ............................................ 13

2.8.4 Electrical Terminal Block ............................................................................ 14

2.8.5 D-Sub DE9 plug ....................................................................................... 14

2.8.6 Pluggable 8 pins electrical connector ......................................................... 14

2.8.7 Sample Path ............................................................................................ 15

2.8.7.1 Signal Processing Path ........................................................................... 17

2.9 Connections to the XZR400A2 ........................................................................ 18

2.9.1 Gas Sample Inlet and Outlet Fittings .......................................................... 19

2.9.2 Electrical Terminal Block ............................................................................ 20

2.9.3 D-Sub DE9 plug ....................................................................................... 20

2.9.4 D-Sub DA15 plug ...................................................................................... 21

2.9.5 Sample Path ............................................................................................ 21

2.9.6 Signal Processing Path .............................................................................. 22

2.9.7 Alarm Outputs .......................................................................................... 22

2.10 Connections to the XZR400A3 ........................................................................ 23

2.10.1 Front Panel .............................................................................................. 23

2.10.2 Side Panel ................................................................................................ 24

2.10.3 Electrical Terminal Block ............................................................................ 25

2.11 Connections to the XZR400A4-Transportable .................................................... 26

2.11.1 Electrical Terminal Block ............................................................................ 27

2.11.2 D-Sub DE9 Type Plug ................................................................................ 27

iv 97472 Issue 3, August 2018

Page 5

XZR400 Series User’s Manual

2.12 Mains Power Supply - XZR400A1, XZR400A3 & XZR400A4 ................................ 28

2.12.1 Analog Outputs Connections ..................................................................... 29

2.12.2 Alarm Output Connections ........................................................................ 30

2.13 Gas Connection ............................................................................................. 31

3 OPERATION ...................................................................................................32

3.1 General Operational Information ..................................................................... 32

3.2 Powering-up the System ............................................................................... 33

3.3 Warm-Up Period ............................................................................................ 34

3.4 Main Screen .................................................................................................. 36

3.5 Control Parameters Display ............................................................................ 37

3.5.1 Confi guration ........................................................................................... 38

3.5.2 Changing the Access Code ........................................................................ 39

3.6 The Main (Expert) Menu ................................................................................ 41

3.6.1 Analog 1 .................................................................................................. 42

3.6.2 Alarms ..................................................................................................... 43

3.6.3 Auto Adjustment (Optional) ....................................................................... 45

3.6.4 System .................................................................................................... 49

3.6.5 Total Pressure Correction (Optional)........................................................... 51

3.6.6 COMM ..................................................................................................... 52

3.6.6.1 RS232 .................................................................................................. 52

3.6.6.2 RS485 .................................................................................................. 52

3.6.7 Flow ........................................................................................................ 53

4 CALIBRATION ..................................................................................................54

4.1 Defi nitions .................................................................................................... 55

4.1.1 ADJUSTMENT / Calibration Screen Pages 3.2, 3.2.1, 3.2.2 & 3.2.3 ............... 56

4.1.2 Diagnosis of the MSRS Sensor Status - Screen pages 3.2.4 to 3.2.7 ............. 59

5 MAINTENANCE ................................................................................................62

5.1 Troubleshooting Guide / Failure Analysis ......................................................... 62

Tables

Table 1 XZR400 Series MSRS Assembly .....................................................................5

Table 2 RS232 Commands ..................................................................................... 75

Michell Instruments v

Page 6

XZR400 Series User’s Manual

Figures

Figure 1 Zirconia Sensor Operating Principle ..............................................................3

Figure 2 MSRS Sensor..............................................................................................4

Figure 3 MSRS Dimensions .......................................................................................4

Figure 4 MSRS Wiring ..............................................................................................4

Figure 5 XZR400 Series MSRS Assembly ....................................................................5

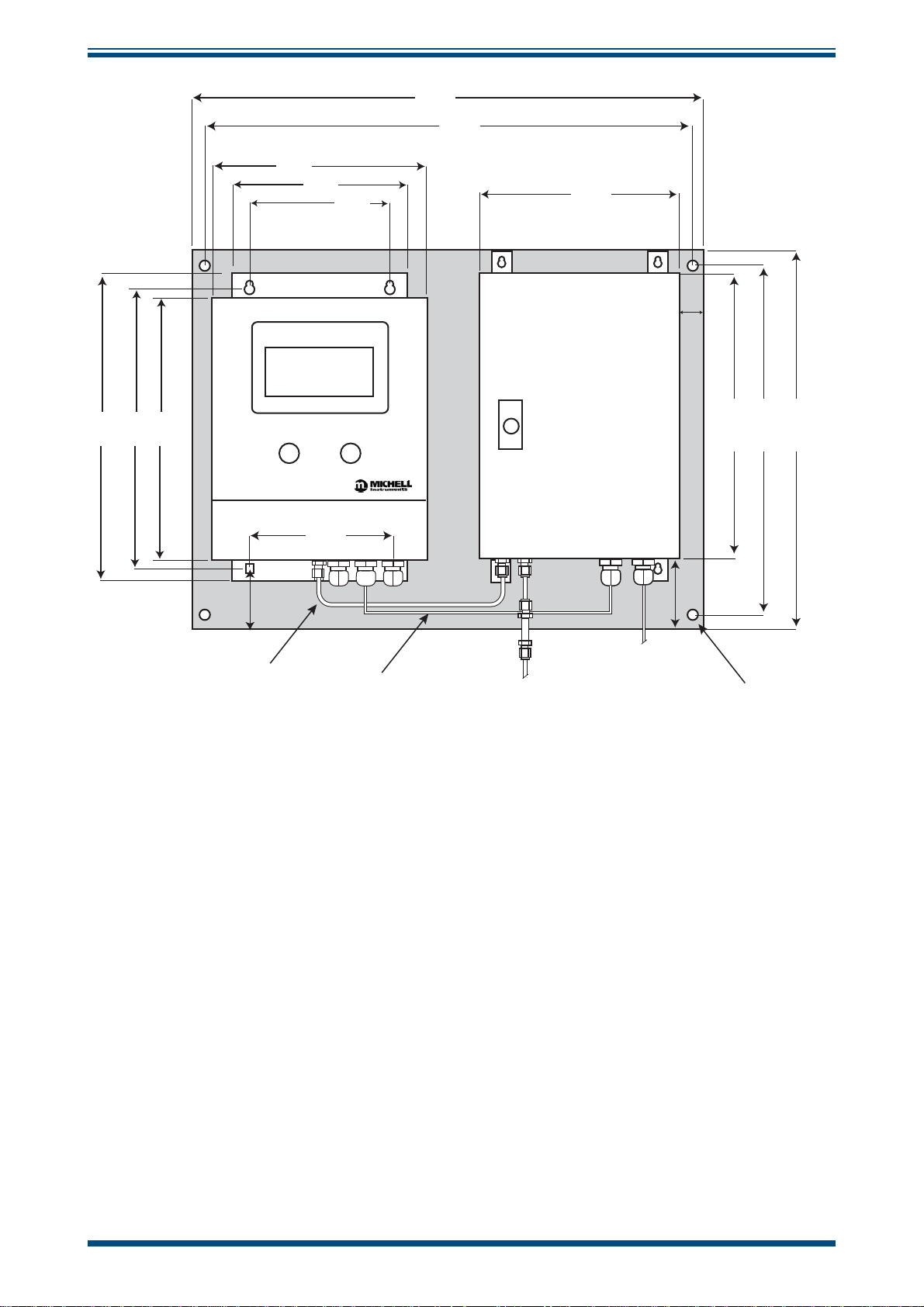

Figure 6 Dimensions - XZR400A1 ..............................................................................7

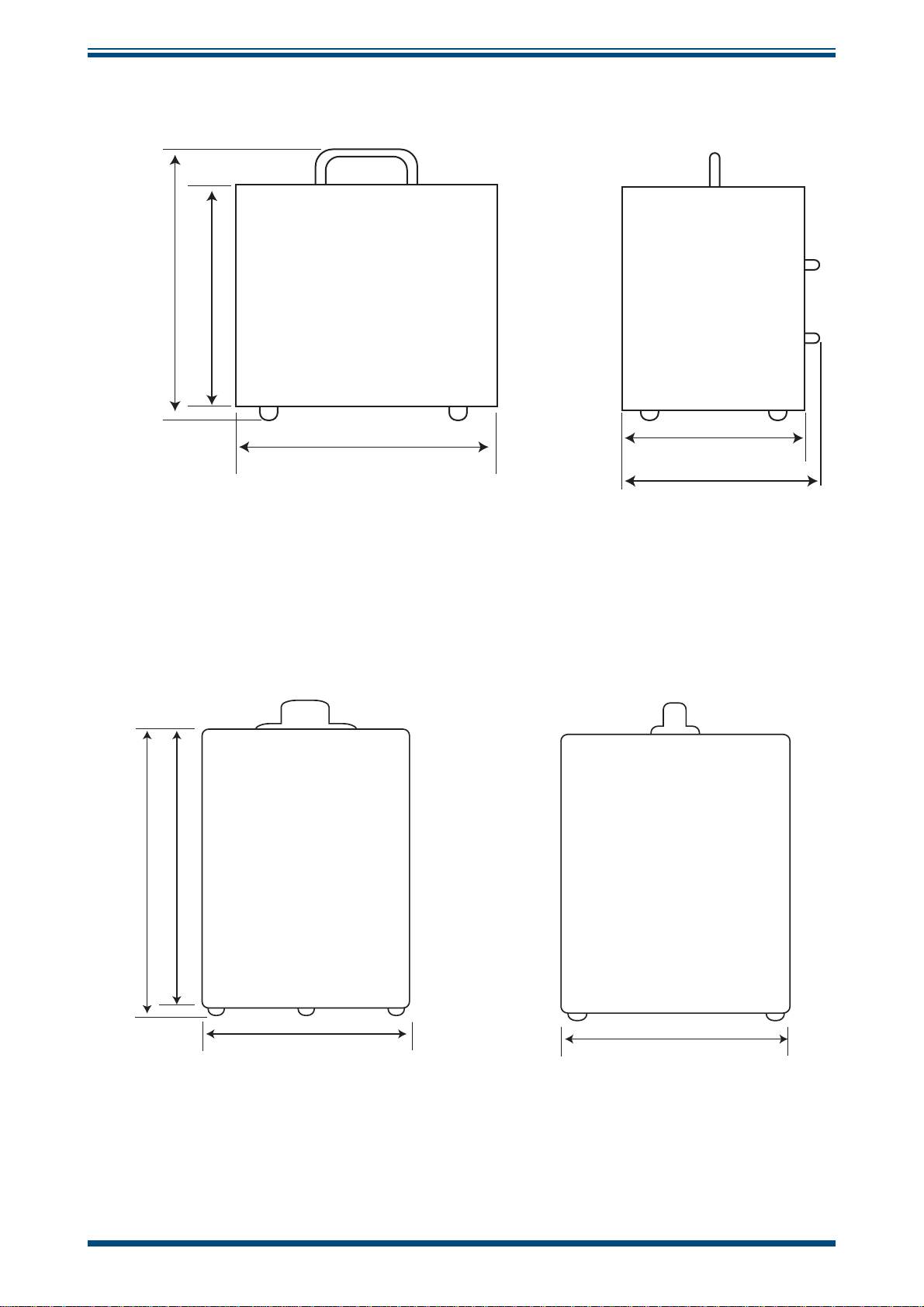

Figure 7 Dimensions - XZR400A2 ..............................................................................8

Figure 8 Dimensions - XZR400A2 with External Pump Option ......................................9

Figure 9 Dimensions - XZR400A3 ............................................................................10

Figure 10 Dimensions - XZR400A4 ............................................................................10

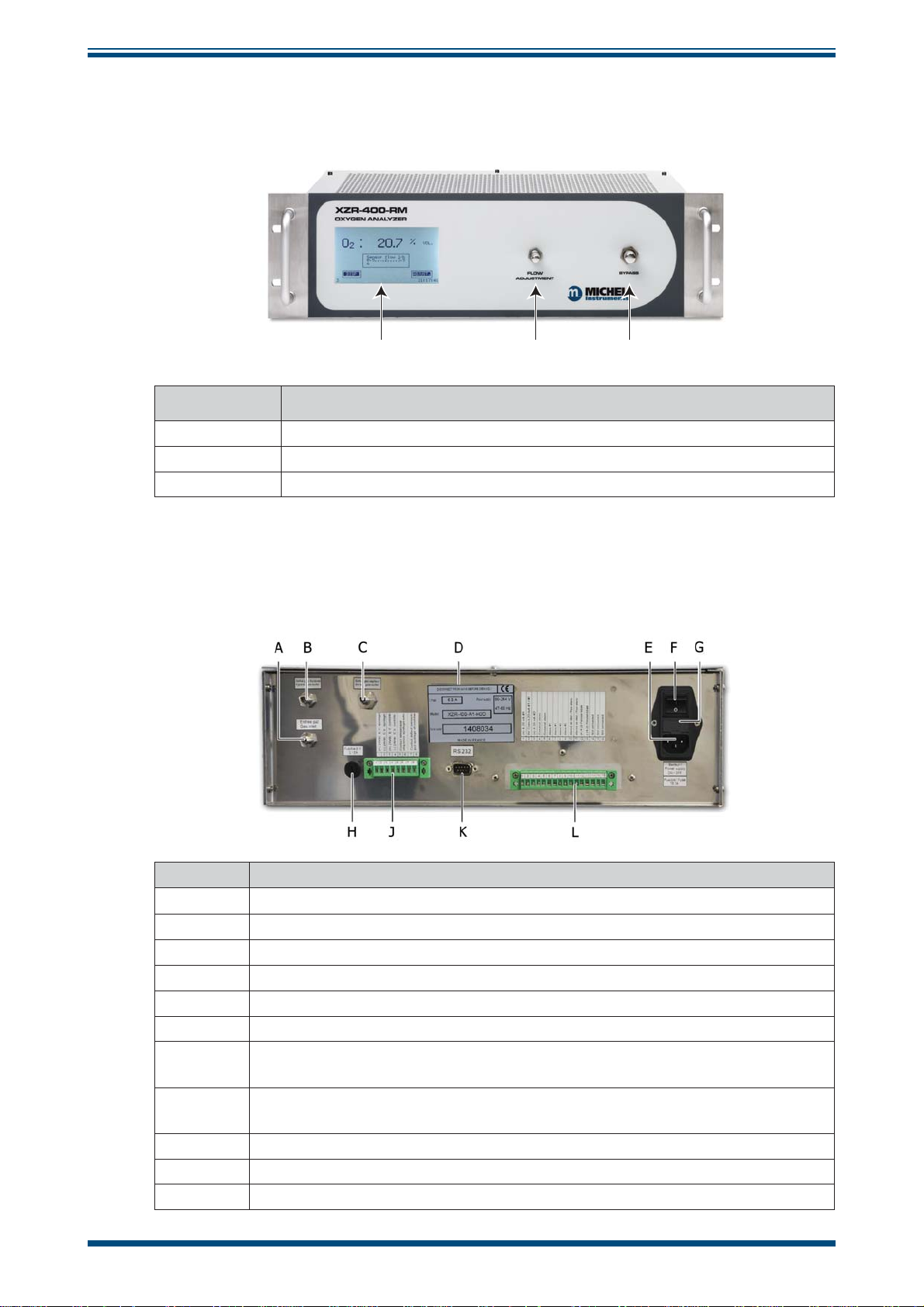

Figure 11 Front Panel XZR400A1 ..............................................................................12

Figure 12 Back Panel XZR400A1 ...............................................................................12

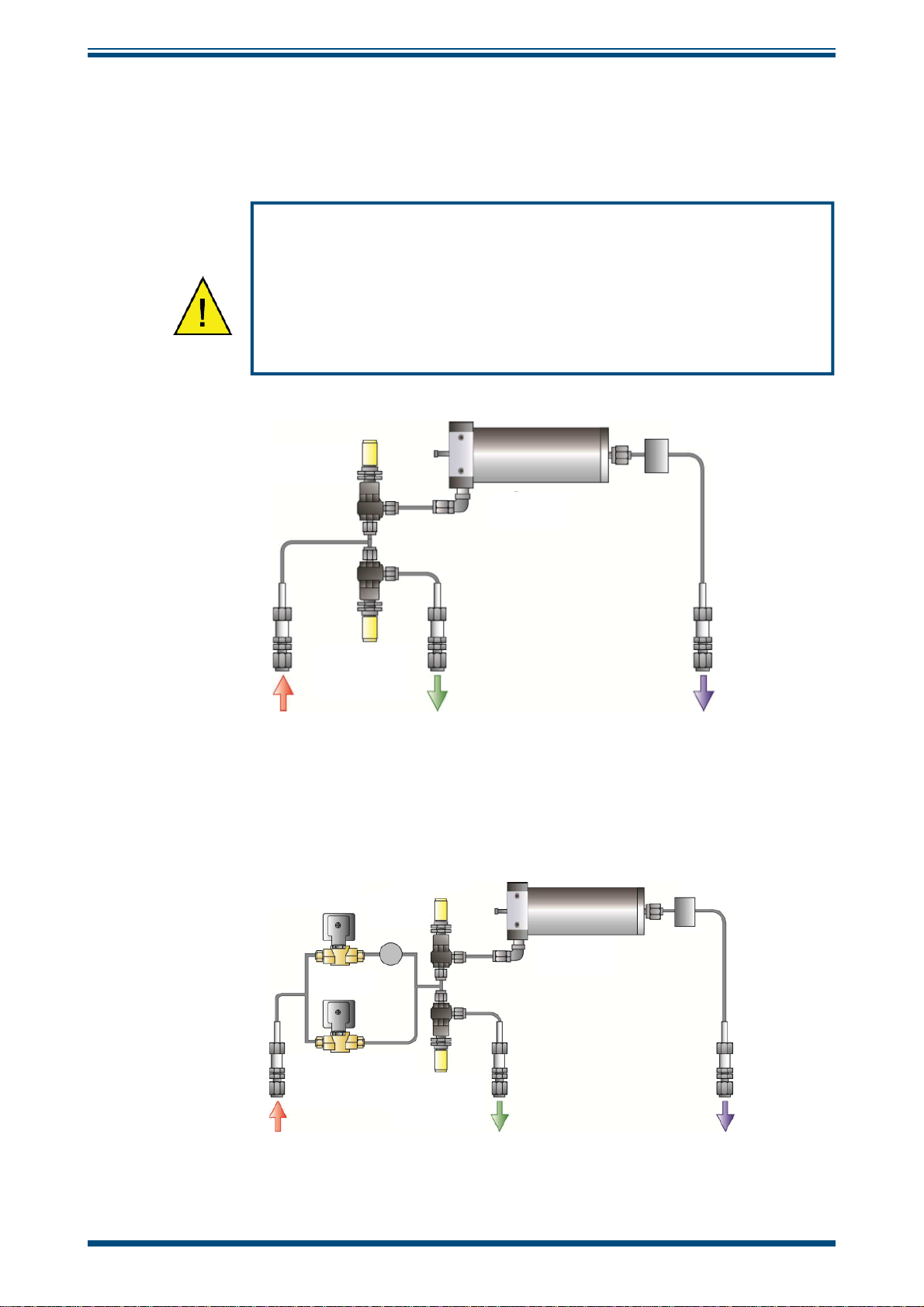

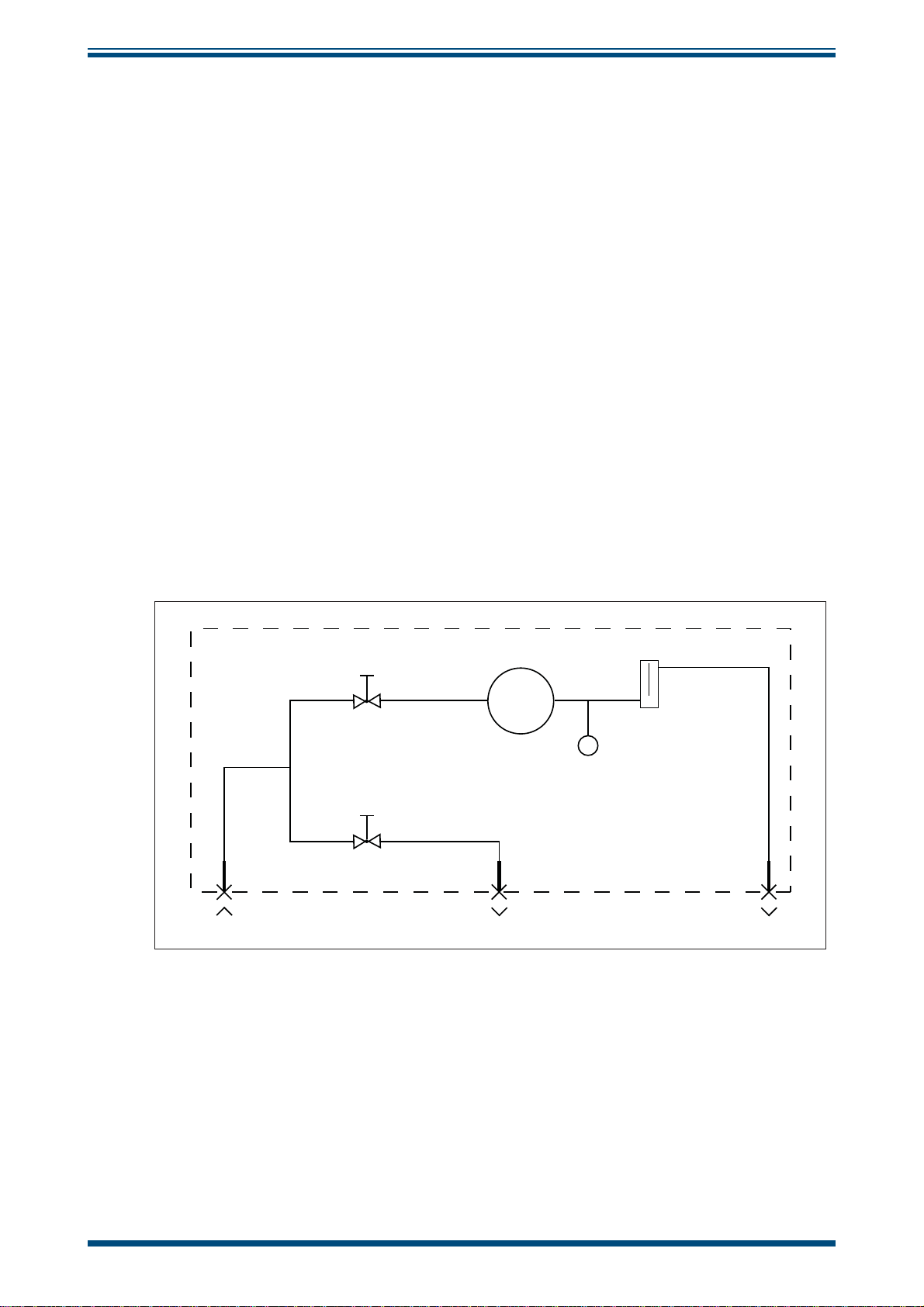

Figure 13 Gas Circuit Diagram for Rack Version .........................................................13

Figure 14 Gas Circuit Diagram for Rack & Pump Version .............................................13

Figure 15 Electrical Terminal Block XZR400A1 ............................................................14

Figure 16 Sample Path XZR400A1 .............................................................................15

Figure 17 Sample Path with Pump Fitted XZR400A1 ...................................................16

Figure 18 Connections XZR400A2 .............................................................................18

Figure 19 Gas Circuit Diagram for XZR400A2 .............................................................19

Figure 20 Electrical Terminal Block XZR400A2 ............................................................20

Figure 21 XZR400A2 Sample Path .............................................................................21

Figure 22 Connections Front Panel - XZR400A3 .........................................................23

Figure 23 Connections Side Panel - XZR400A3 ...........................................................24

Figure 24 Electrical Terminal Block XZR400A3 ............................................................25

Figure 25 Connections Front Panel - XZR400A4 .........................................................26

Figure 26 Electrical Terminal Block XZR400A4 ............................................................27

Figure 27 D-Sub DE9 Plug - XZR400A4 .....................................................................27

Figure 28 Power Input Socket ..................................................................................28

Figure 29 Start-up Screen ........................................................................................34

Figure 30 Oven Temperature Screen .........................................................................34

Figure 31 Sample Flow Adjustment ...........................................................................35

Figure 32 Main Screen .............................................................................................36

Figure 33 Control Parameters Screen ........................................................................37

Figure 34 Main Menu Access Screen .........................................................................38

Figure 35 Main Menu Screen ....................................................................................38

Figure 36 Main Menu Screen ....................................................................................41

Figure 37 Analog Output Screen ...............................................................................42

Figure 38 Alarm Screen (Main) .................................................................................43

Figure 39 Alarm Screen (Alarm 1) .............................................................................44

Figure 40 Auto Adjustment Screen ...........................................................................45

Figure 41 Pressure Correction Screen .......................................................................51

Figure 42 Comm Screen ..........................................................................................52

Figure 43 Flow Correction Screen .............................................................................53

Figure 44 Calibration Procedure with XZR400A1 ........................................................54

Figure 45 Screen Page 3.2 ....................................................................................... 56

Figure 46 Screen Page 3.2.1 ....................................................................................56

Figure 47 Screen Page 3.2.2 ....................................................................................57

Figure 48 Screen Page 3.2.3 ....................................................................................58

Figure 49 Screen Page 3.2.8 ....................................................................................58

Figure 50 Screen Page 3.2.4 ....................................................................................59

Figure 51 Screen Page 3.2.5 ....................................................................................59

Figure 52 Screen Page 3-2-6 ....................................................................................60

Figure 53 Screen Page 3-2-7 ....................................................................................60

Figure 54 Pressure Correction Screen .......................................................................79

vi 97472 Issue 3, August 2018

Page 7

XZR400 Series User’s Manual

Figure 55 Main Page ................................................................................................85

Figure 56 Control Parameters Page ........................................................................... 85

Figure 57 Main Menu ...............................................................................................85

Figure 58 DP Sensor Page ........................................................................................86

Appendices

Appendix A Technical Specifi cations .............................................................................. 67

Appendix B Modbus (RTU) over RS485 ......................................................................... 70

B.1 Port Confi guration ........................................................................ 70

B.2 Hardware Confi guration ............................................................... 70

B.3 RS485 Register Map .....................................................................71

Appendix C RS232 Serial Output .................................................................................. 74

C.1 Port Confi guration ........................................................................ 74

C.2 Hardware Confi guration ............................................................... 74

C.3 RS232 Command List ................................................................... 75

Appendix D Extended Operating Range - (Optional) ...................................................... 77

Appendix E Process Pressure Correction - (Optional) ....................................................79

E.1 Process Pressure Correction Input Connections .............................. 79

Appendix F Flow Fault Contact - (Optional) ................................................................... 81

F.1 Flow Fault Output Connections ..................................................... 81

Appendix G Commutable Scale (Auto-Ranging) .............................................................83

Appendix H Optional moisture sensor ...........................................................................85

Appendix I Quality, Recycling & Warranty Information ...................................................88

Appendix J Analyzer Return Document & Decontamination Declaration ..........................90

Michell Instruments vii

Page 8

XZR400 Series User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

qualifi ed personnel and good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories

supplied by the manufacturer for use with the instrument. The input power supply voltage is 90

to 264 V A C, 47/63 Hz. Refer to labels on instrument or calibration certifi cate.

Pressure Safety

DO NOT permit pressures exceeding 2 barg (29 psig) to be applied to the instrument. This maximum

pressure applies to all versions of the instrument.

Temperature Safety

During operation some parts of the instrument can be at very high temperatures.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts. Long exposure or breathing of the calibration

gases may be dangerous.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide offi ces contact information.

Calibration

The recommended calibration (or verifi cation) interval for the analyzer is 1 to 3 months depending

on the location and application in which the instrument is used.

Safety Conformity

This product carries the CE mark and meets the requirements of relevant European safety directives.

viii 97472 Issue 3, August 2018

Page 9

XZR400 Series User’s Manual

Abbreviations

The following abbreviations are used in this manual:

AC alternating current

A Ampere

barg pressure unit (=100 kP or 0.987 atm) gauge

°C degrees Celsius

°F degrees Fahrenheit

l/h liters per hour

l/min liters per minute

mA milliampere

min minute

ppm parts per million

psig pound(s) per square inch (gauge)

RS232 Modbus RTU serial data transmission standard

RS485 Modbus RTU serial data transmission standard

T temperature

V Volts

Michell Instruments ix

Page 10

Warnings

The following general warnings listed below are applicable to this instrument. They are

repeated in the text in the appropriate locations.

XZR400 Series User’s Manual

Where this hazard warning symbol appears in the following

sections, it is used to indicate areas where potentially hazardous

operations need to be carried out.

Where this symbol appears in the following sections it is used to

indicate areas of potential risk of electrical shock.

Where this hot surface warning appears in the

following sections it is used to indicate areas where

the surface may potentially be dangerously hot.

x 97472 Issue 3, August 2018

Page 11

XZR400 Series User’s Manual

1 INTRODUCTION

The XZR400 Series Trace Oxygen Analyzer is designed to measure oxygen as an inpurity

in nitrogen, carbon dioxide, argon, helium or other inert gases. Analysis is both quick

and stable, utilizing our metallic sealed reference sensor (MSRS), with no requirement

for reference air.

There are 4 versions of the XZR400 analyzer. All are trace oxygen analyzers designed to

measure oxygen content in gas, between 0.01 ppm and 25% O2 (250,000 ppm).

Michell Instruments can supply the analyzer so that it is suitable for use with enriched

oxygen samples, including pure oxygen which may accidentally be introduced to the

sample. This cleaning service must be ordered at the time of purchase as special

components are required.

Extended operating ranges of 0 to 30% or 0 to 50% O2 can be supplied but will require

the analyzer to be cleaned for oxygen service.

INTRODUCTION

Typical applications include:

Gas purity

Inerting or blanketing specifi c atmospheres

Combustion pre-mixing analysis

Respiratory or medical gas mixtures

Heat treatment

Four models of the XZR400 Series Oxygen Analyzer are available:

• A rack-mount model XZR400A1 (XZR-400-RM)

• A wall-mount model XZR400A2 (XZR-400-WM)

• A bench-mount model XZR400A3 (XZR-400-BM)

• A transportable model XZR400A4 (XZR-400-TP)

NOTE: The rack-mount version can be supplied with a built-in Easidew

sensor for measuring moisture in the range -100 to +20 °C

Sample gases at pressures up to a maximum of 2 barg (29 psig) can be accepted.

Michell Instruments 1

Page 12

INTRODUCTION

The XZR400 Series includes the following front panel mounted items:

• Liquid crystal touchscreen display

• Flow adjustment valve

• Bypass control valve

1.1 Operating Principle

The analyzer operates on the zirconium oxide (zirconia) principle.

A sample of the gas to be measured is connected to the inlet port of the analyzer. The

sample gas fl ows through stainless steel pipework into the oven where the zirconia

oxygen sensor is located.

XZR400 Series User’s Manual

The sample fl ow should be set to between 1 and 3 l/hr using the electronic fl owmeter,

and sample and bypass needle valves on the front of the unit.

The sample gas circulates in the oven, which is heated to temperatures above 600°C,

necessary for the zirconia oxygen sensor to operate properly.

The Michell Metallic Sealed Reference Sensor (MSRS) generates a signal that is

proportional to the logarithm of the ratio of the oxygen partial pressure in the sample

to the oxygen partial pressure contained on the sealed reference side of the MSRS.

The analyzer provides the O2 concentration on the screen and via the 4-20 mA output

(optional on XZR400A3).

The optional Easidew Transmitter utilizes ceramic impeadance technology and further

details can be found on our website.

2 97472 Issue 3, August 2018

Page 13

XZR400 Series User’s Manual

1.2 The MSRS Technology

The zirconium oxide sensors are often referred to as the ‘high temperature’

electrochemical sensors. The principle is based on the Nernst principle [W. H. Nernst

(1864-1941)]. Zirconium oxide sensors use a solid state electrolyte and are stabilized

with yttrium oxide. The zirconium oxide probe is plated on opposing sides with platinum

which serves as the sensor electrodes. For a zirconium oxide sensor to operate properly,

it must be heated to approximately 600°C. At this temperature, on a molecular basis,

the zirconia lattice becomes porous, allowing the movement of oxygen ions from a

higher concentration of oxygen to a lower one, based on the partial pressure of oxygen.

The movement of oxygen ions across the zirconium oxide produces a voltage between

the two electrodes, the magnitude of which is based on the oxygen partial pressure

differential created by the reference and sample gas.

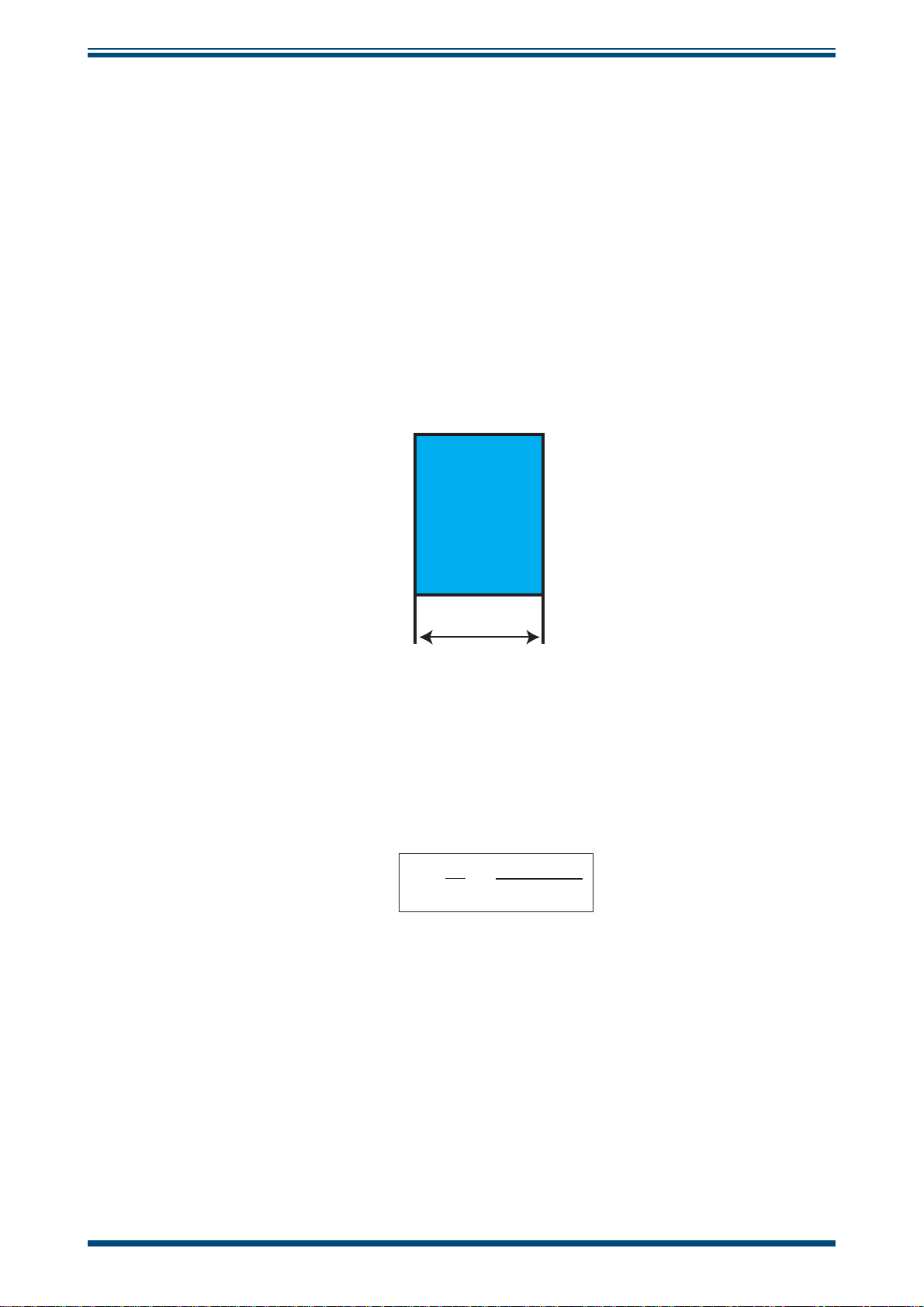

INTRODUCTION

Zirconia

P

P

ref.

(T)

P

P

meas.

E

Figure 1

Within the oven the zirconium oxide MSRS is maintained at a temperature of 634°C.

The MSRS generates a signal that is proportional to the natural logarithm of the partial

pressure of oxygen p (O2).

Zirconia Sensor Operating Principle

p (O

E =

RT

4F

ln

p (O

meas)

2

ref)

2

With a known reference electrode and a constant temperature it is possible to defi ne

the partial pressure of oxygen using the Nernst-equation (see above).

The conductivity of zirconium oxide increases exponentially with temperature. The oxide

ion conductivity is optimized at temperatures above 600°C.

The MSRS technology allows the design of miniaturized zirconium oxide-based oxygen

sensors. The low mass and volume of the MSRS sensors have a positive effect on the

response time, which is one of the best available on the market.

Michell Instruments 3

Page 14

INTRODUCTION

XZR400 Series User’s Manual

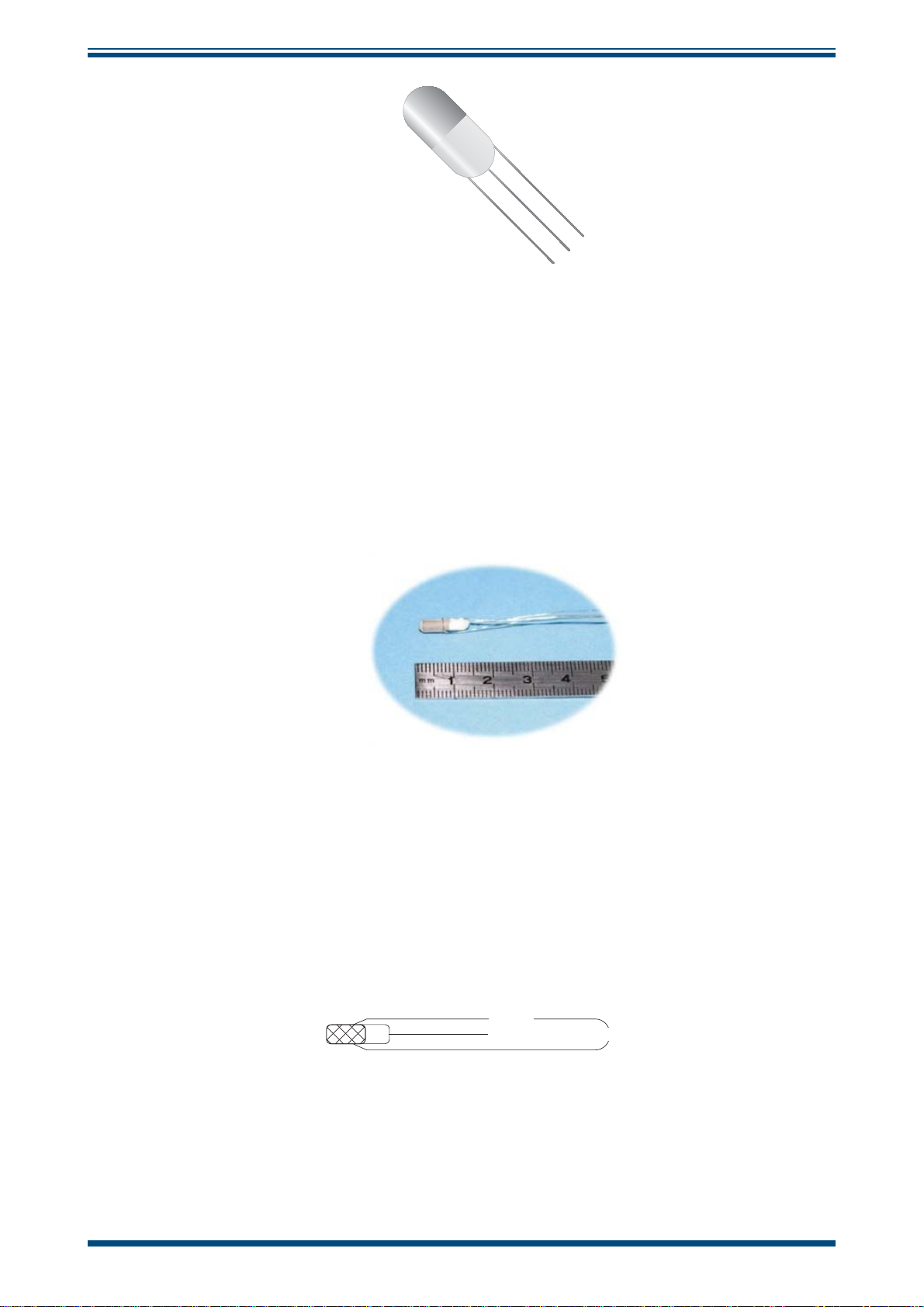

Figure 2

MSRS Sensor

Conventional zirconium oxide sensors require an air reference on one side of the sensor

with the sample on the other. This provides a known constant on one side. The Michell

MSRS does not require an air reference but instead utilizes a metal, and its oxide,

sealed in the zirconium sheath. This allows the sensor operation to be irrespective of

the ambient air quality and negates the requirement for a ‘zero’ calibration gas.

Figure 3

MSRS Dimensions

Temperature is a major component in the Nernst equation and can affect the accuracy

of some sensors. Placing the thermocouple in contact with the small sensor body helps

provide a very accurate temperature measurement. The complete design offers high

accuracy and repeatability.

02 Meas.

Ref. S Thermocouple

0

2

Figure 4

MSRS Wiring

4 97472 Issue 3, August 2018

Page 15

XZR400 Series User’s Manual

INTRODUCTION

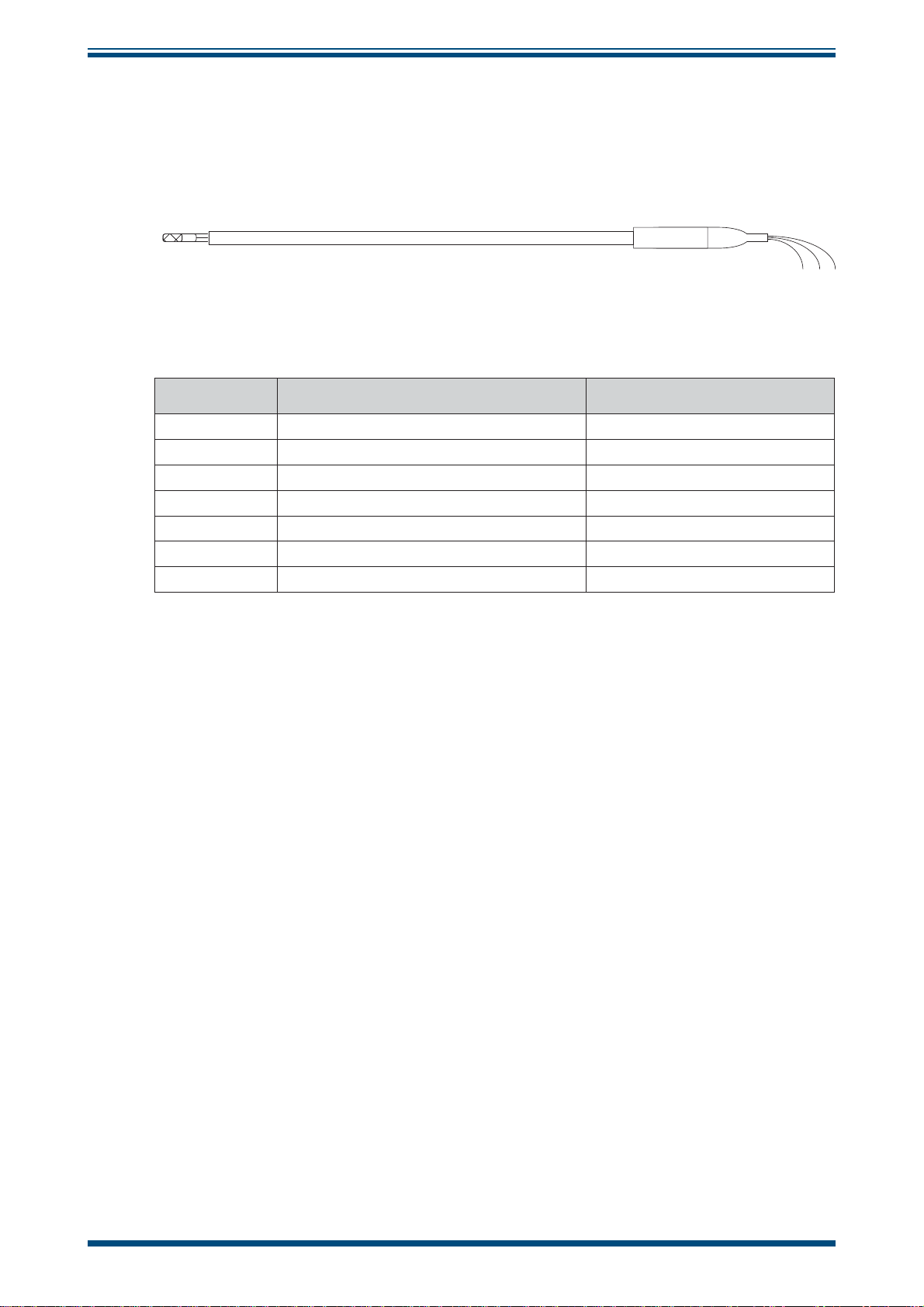

Figure 5

shows the MSRS and its S thermocouple installed in a 4-hole aluminum tube.

This confi guration has the part number XZR400-SMP. Any reference to the MSRS sensor

refers to this complete assembly which is considered solid state and non user-serviceable.

1

2

Figure 5

3

XZR400 Series MSRS Assembly

Item Description Wiring

1 MSRS

2 S-type thermocouple

3 4-hole alumina tube

4 Stainless steel connector

5O

6 Common (O

reference wire blue wire

2

meas. & - TC) white wire

2

7 Positive thermocouple (+TC) orange wire

4

567

Table 1 XZR400 Series MSRS Assembly

Michell Instruments 5

Page 16

INSTALLATION

2 INSTALLATION

It is essential that the installation of the electrical and gas

supplies to this analyzer be undertaken by qualifi ed personnel.

2.1 Unpacking the Analyzer

Open the box and unpack carefully as follows. Save all the packing materials for the

purpose of returning the instrument for any warranty claims.

1. Remove the accessories (if ordered with the analyzer). If no accessories

have been ordered the box should contain the following items:

XZR400 Series User’s Manual

• XZR400 Series Oxygen Analyzer

• Power cable (except XZR400A2 model)

• User’s Manual

• Test result sheet

2. Remove the documentation and packing material.

3. Remove the analyzer and power cable.

2.2 Preparation

Carefully read the following guidelines before installing the analyzer. If you are not sure

about the installation conditions and other important factors please contact a Michell

Instruments’ Application Engineer or a Michell Instruments’ representative prior to the

installation.

The following list will help you to identify the recommended preparation steps:

• The analyzer should be installed at ambient temperatures between 0 and

+55°C (32 to +131°F).

• The location of the installation should allow access to the display.

• The location of the installation should not expose the analyzer to any

vibration.

• The cables should not be exposed to extreme temperatures and mechanical

strain.

6 97472 Issue 3, August 2018

Page 17

XZR400 Series User’s Manual

(

)

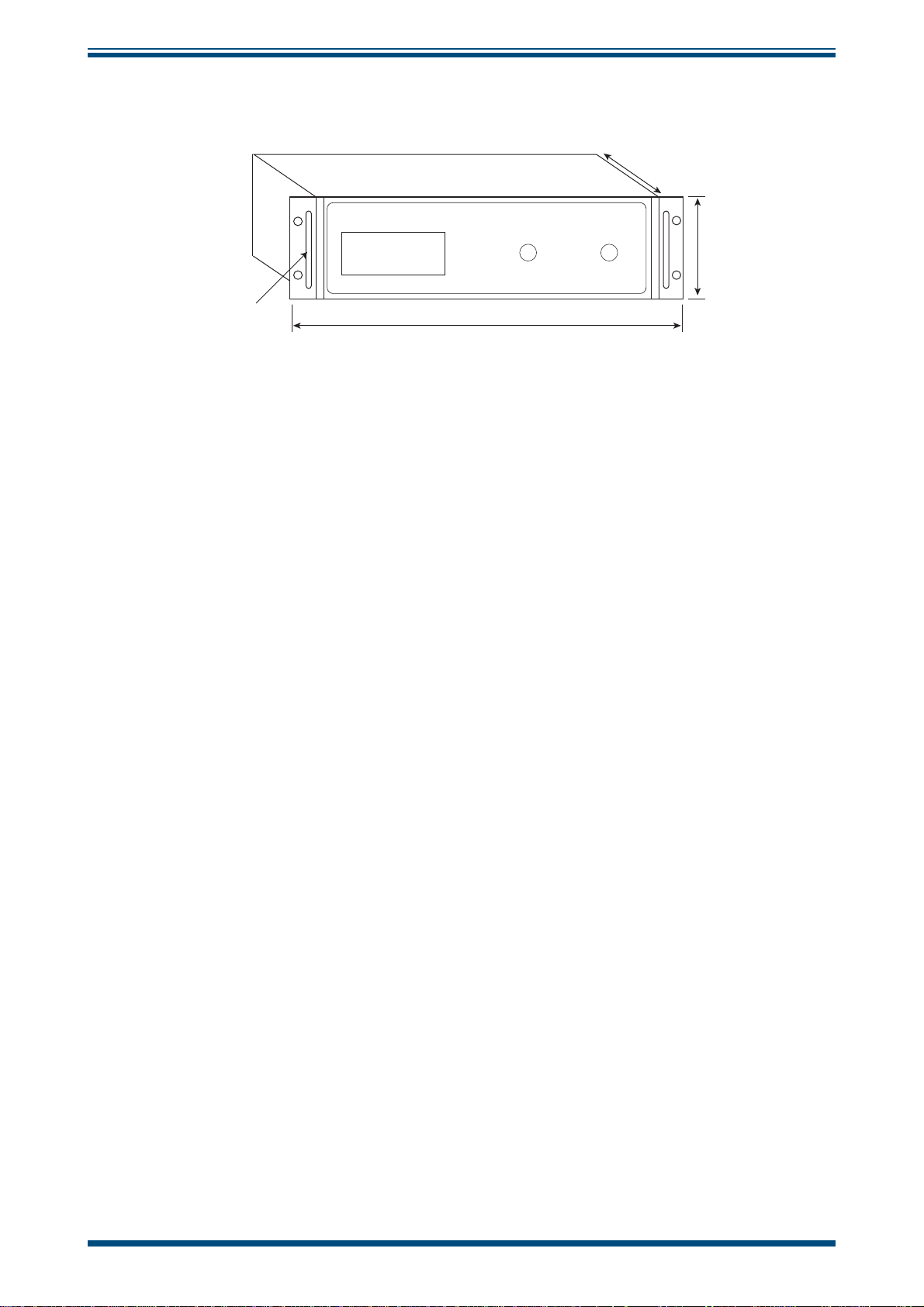

2.3 Dimensions - XZR400A1

XZR-400-RM

OXYGEN ANALYZER

INSTALLATION

362mm + 50mm for cable clearance

(14.25” + 1.96”)

132mm

(5.2”)

3U

Handles protrude

40mm (1.6”)

2.3.1 Installing the XZR400A1

Choose your installation site carefully following the recommendations above. Once

installed into the rack, there should be at least 2U clearance spaces from other equipment

above and below the instrument.

To install, follow the steps below:

1. If necessary, remove any covers from the rack cabinet to gain access to

the rear and side.

2. Slide the instrument into the rack and support its weight while the four

fi xing screws are inserted.

Figure 6

483mm

19”

FLOW

ADJUSTMENT

BYPASS

Dimensions - XZR400A1

3. Ensure that the front panel of the instrument is fl ush and square with the

front of the rack and tighten the fi xing screws.

Michell Instruments 7

Page 18

INSTALLATION

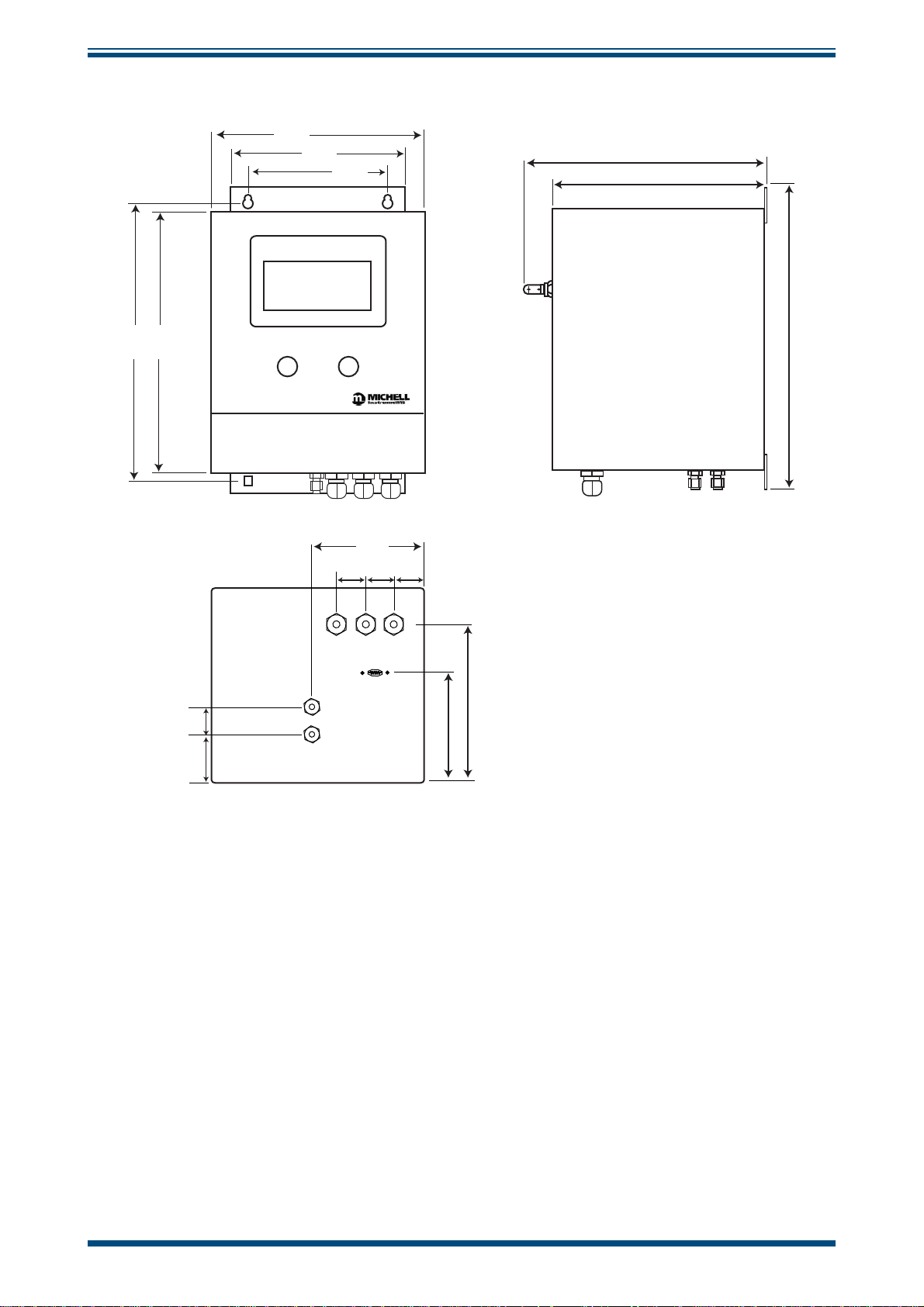

2.4 Dimensions - XZR400A2

220mm

(8.66”)

180mm

(7.09”)

152mm

(5.98”)

XZR400 Series User’s Manual

236mm

(9.29”)

201mm

(7.91”)

274mm

(10.79”)

260mm

(10.24”)

30mm

(1.18”)

42mm

(1.65”)

FLOW

ADJUSTMENT

BYPASS

CONTROL

30mm

(1.18”)

GAS IN

GAS OUT

110mm

(4.33”)

30mm

(1.18”)

30mm

(1.18“)

(4.29”)

109mm

(6.77”)

172mm

(12.01”

305mm

Figure 7

Dimensions - XZR400A2

8 97472 Issue 3, August 2018

Page 19

XZR400 Series User’s Manual

220mm

(8.66”)

180mm

(7.09”)

152mm

(5.98”)

490mm

(19.29”)

(18.50”)

470mm

201mm

(7.91”)

INSTALLATION

20mm

(.79”)

(12”)

305mm

274mm

(10.79”)

260mm

(10.24”)

FLOW

ADJUSTMENT

53mm

(2.09”)

6mm (0.24”) tube

Figure 8

BYPASS

CONTROL

470mm

(18.50”)

Analyzer power supply

Dimensions - XZR400A2 with External Pump Option

2.4.1 Installing the XZR400A2

Choose your installation site carefully following the recommendations above.

Particulate

filter

Gas Inlet

6mm

230 V AC

50 Hz

60mm

(2.4”)

305mm

370mm

(12.01”)

4 x Ø 8.4

(14.57”)

390mm

(15.35”)

Follow the steps below:

1. Identify a clean and fl at surface on a wall or other vertical location e.g.

an instrument panel that is suitable to hold the analyzer.

2. Prepare the mounting site by drilling 4 holes in appropriate locations

corresponding to the dimension and location of the fastening holes at the

back of the analyzer enclosure.

3. Fix the analyzer vertically to the installation surface using suitable screws.

The gas connections and the electrical connections should be on the

bottom.

Michell Instruments 9

Page 20

INSTALLATION

2.5 Dimensions - XZR400A3

(11.4”)

290mm

(8.6”)

220mm

XZR400 Series User’s Manual

260mm

(10.2”)

Figure 9

2.6 Dimensions - XZR400A4

(16.5”)

420mm

(17.7”)

450mm

203mm

(7.9”)

236mm

(9.3”)

Dimensions - XZR400A3

300mm

(11.8”)

Figure 10

Dimensions - XZR400A4

350mm

(13.8”)

10 97472 Issue 3, August 2018

Page 21

XZR400 Series User’s Manual

2.7 Operating Requirements

2.7.1 Environmental Requirements

The XZR400 Series should be installed in a clean, dust free environment. The

recommended ambient temperature is +20 to +25°C (+68 to +77°F) although the

instrument will operate, within specifi cation, inside the temperature band of 0 to +55°C

(32 to +131°F). It must be installed indoors in a non-condensing atmosphere.

2.7.2 Electrical Requirements

The analyzer requires the following electrical supply:

90 to 264 V AC, 47/63 Hz

There are 2 concentration alarm relays. The output contacts are normally open and

potential free. The relay switching capability is 10 W max (up to 100 V or up to 0.5 A).

INSTALLATION

2.7.3 Gas Requirements

To ensure that the sample gas is properly conditioned a

Contact Michell Instruments if you wish to order a suitable

The gas must be clean, dry and oil mist free with the pressure up to a maximum of 2

barg (29 psig) and with particle size < 3 m.

The analyzer is not suitable for samples with hydrocarbons

present. These will combust on the cell and consume oxygen

2.7.4 Sampling System

Depending upon the application a sampling system may be used to cope with high

pressure samples, samples with contamination or outdoor installations. The sampling

system may include components such as fi lters, pressure gauges, by-pass loops,

calibration inlet, pressure regulators and sample pumps - all installed on a panel, or in

an enclosure.

It is recommended that a stainless steel construction is used for all parts that will be in

contact with the gas.

sampling system might be required.

sampling system.

molecules.

Please consult Michell Instruments if a sampling system is required. Install the sampling

system as close as possible to the XZR400 Series analyzer to ensure the best possible

measurement results.

NOTE: Michell Instruments can provide a suitable sampling system when

delivering the analyzer. Contact a Michell Instruments’ Application Engineer

for more information.

Michell Instruments 11

Page 22

INSTALLATION

2.8 Connections to the XZR400A1

2.8.1 Front Panel

ABC

Item Description

A Touchscreen LCD

B Flow adjustment needle valve

C Bypass control needle valve

XZR400 Series User’s Manual

2.8.2 Back Panel

An electrical connection terminal is provided for signal and alarm connections.

Item Description

A Inlet fi tting for gas sample to be analyzed.

B Outlet fi tting for gas sample output bypass.

C Outlet fi tting for gas sample to be analyzed.

D Manufacturer's plate.

E Mains socket (90-132 / 187-264 V AC, 47/63 Hz).

F On/Off button.

G Housing for analyzer's 2 x electrical protection fuses

H Housing for solenoid valve's electrical protection fuses (250 V AC, 3.15 A).

J Optional connector for the automatic setting option.

K Optional D-sub DE9 male plug (RS232 port).

L Electrical connector.

Figure 11

(250 V AC, 6.3 A)

Only fi tted on the rack with automatic setting option.

Front Panel XZR400A1

Figure 12

Back Panel XZR400A1

12 97472 Issue 3, August 2018

Page 23

XZR400 Series User’s Manual

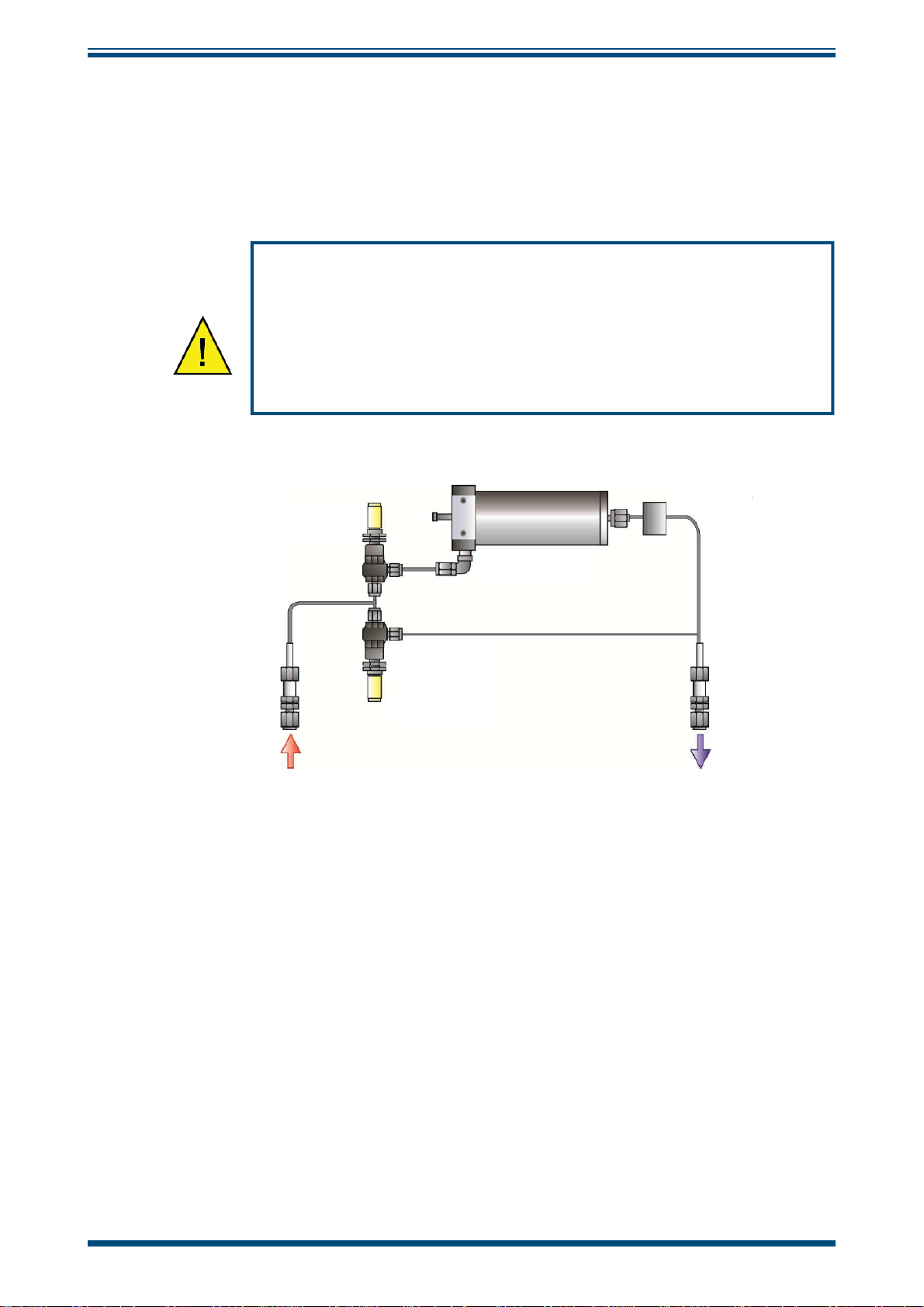

2.8.3 Gas Inlet, Outlet and Bypass Gas Connections

The fl uidic system comprises 2 fl ow control valves (sensor fl ow and by-pass fl ow), an

electronic fl ow meter and a sensor. The gas connections are stainless steel Swagelok

1/8" quick connecting couplers, which guarantee a perfect seal and easy removal.

The evacuation of the analyzed sample must be carried out at

atmospheric pressure, otherwise the total pressure adjustment

option is required.

The measurement of hazardous gas samples require the

analyzer's outlet to be outside the analysis area and must be in

accordance with local regulations.

Sensor flow

adjustment

INSTALLATION

Electronic

flow meter

Inlet for gas

to be

analyzed

Figure 13

Solenoid

Bypass flow

adjustment

NC

valve

Sensor

Gas outlet

bypass

sample

Gas Circuit Diagram for Rack Version

Sensor flow

adjustment

Sensor

Analyzed

gas

outlet

Electronic

flow meter

Pump

NO

Solenoid

valve

Inlet for gas

to be

analyzed

Figure 14

Bypass flow

adjustment

Gas outlet

bypass

sample

Analyzed

Gas Circuit Diagram for Rack & Pump Version

gas

outlet

Michell Instruments 13

Page 24

INSTALLATION

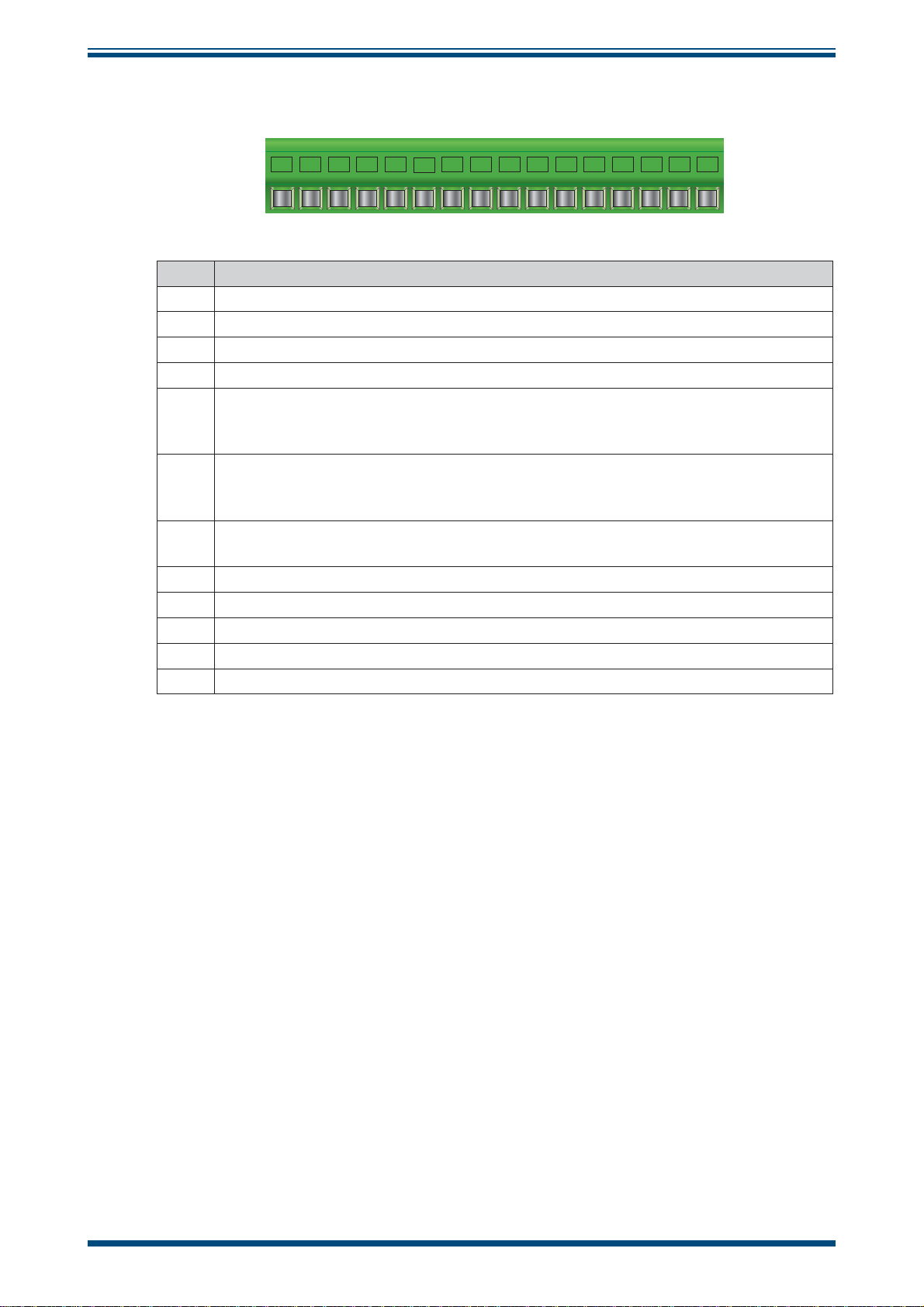

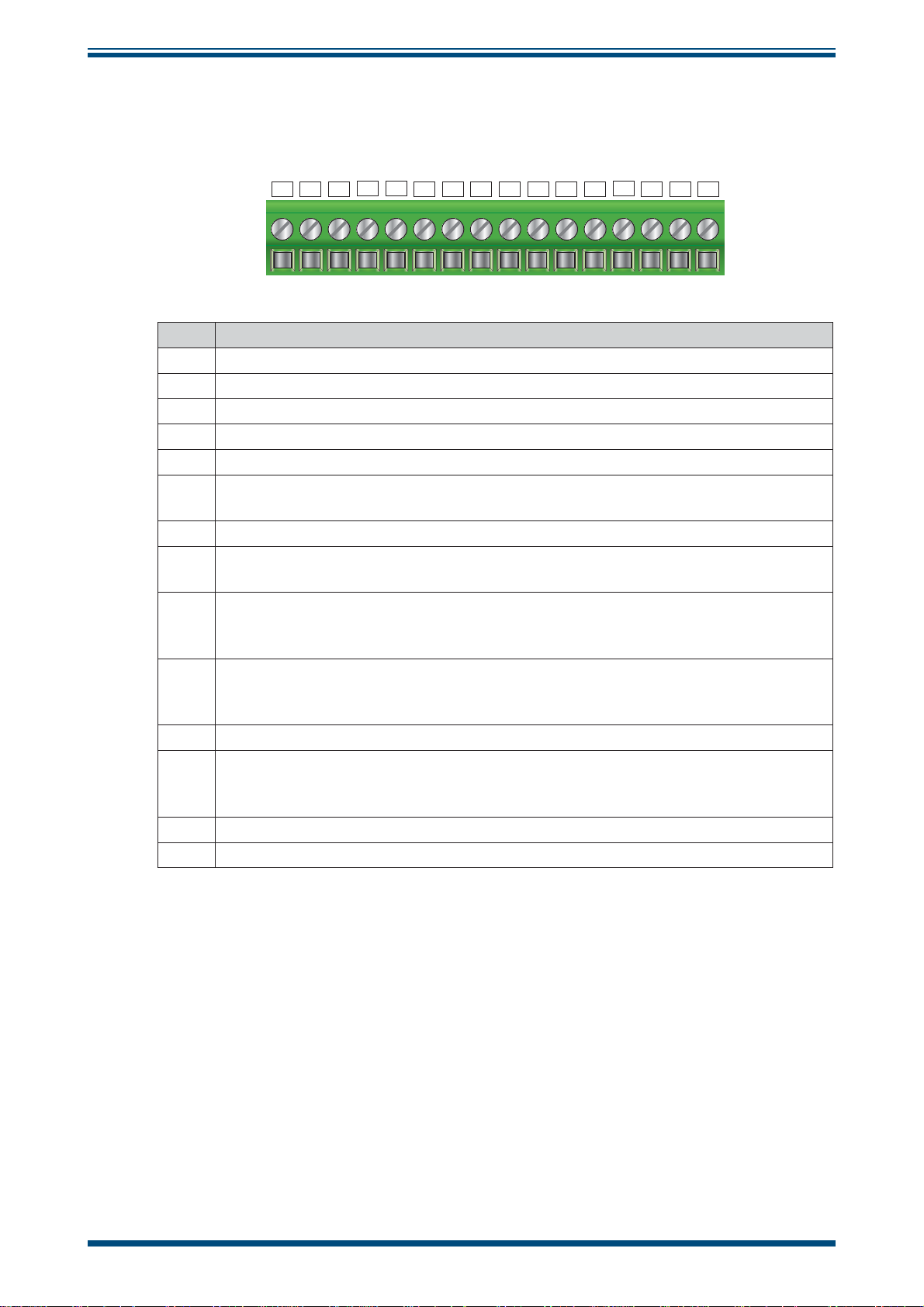

2.8.4 Electrical Terminal Block

1 2 3 4 5 6 7 8 9 10111213141516

Item Function

1 (+) 4-20 mA Output No 1. Measurement proportional to the chosen O

2 0 V from the 4-20 mA Output No 1 & 2.

3 (+) 4-20 mA Output No. 2. Measurement proportional to the chosen 0

4-5 General fault alarm dry contact (250 V AC, 2 A or 30 V DC, 2 A on resistive load.

6-7 Alarm No. 1 dry contact terminal (250 V AC, 2 A or 30 V DC, 2 A resistive load).

Function mode (positive, normal) and hysteresis can be confi gured by setting the

parameters.

8-9 Alarm No. 2 dry contact terminal (250 V AC, 2A or 30 V DC, 2A resistive load).

Function mode (positive, normal) and hysteresis can be confi gured by setting the

parameters.

10-11 Dry contact terminal for fl ow alarm option (250 V AC, 2 A or 30 V DC, 2 A on

resistive load).

12 (+) 4-20 mA input. Option process pressure correction input.

13 (0V) 4-20 mA input. Option process pressure correction input.

14 RS485 Data +/A.

15 RS485 Data -/B.

16 RS485 0 V.

XZR400 Series User’s Manual

scale.

2

scale.

2

Figure 15

Electrical Terminal Block XZR400A1

2.8.5 D-Sub DE9 plug

This optional D-Sub DE9 type male plug (9 pin) is used to connect an RS232 port.

2.8.6 Pluggable 8 pins electrical connector

This optional connector allows the connection of terminals for automatic analyzer

calibration.

14 97472 Issue 3, August 2018

Page 25

XZR400 Series User’s Manual

2.8.7 Sample Path

The MSRS sensor is placed inside an oven in which the gases to be analyzed are

circulated. The oven consists of a gas inlet head and a outlet plate. 3 Viton O-rings

ensure the sealing of this device (2 for the inlet and 1 for the outlet).

The internal sample path consists of:

• 2 fl ow control valves: sensor fl ow and by-pass fl ow

• 1 sealing head

• 1 outlet plate

• 1 oven tube

• 1 electronic fl ow meter

INSTALLATION

• 1 MSRS sensor

• 3 Swagelok 6mm stainless steel bulkhead unions (1 gas inlet and 2

gas outlets) - on the rear panel

XZR400A1

Sensor flow adjustment valve

O2 sensor

Barometric pressure sensor

By-pass flow adjustment valve

Ɨ” bulkhead union Ɨ” bulkhead unionƗ” bulkhead union

Sampling gas inlet

Electronic flowmeter 0-12 l/h

Sampling gas outletSampling gas outlet

Figure 16

Sample Path XZR400A1

Michell Instruments 15

Page 26

INSTALLATION

XZR400A1 WITH INTERNAL PUMP:

• 3 Swagelok 6mm stainless steel bulkhead unions (1 gas inlet and 2

gas outlets) - on the rear panel

• 1 sampling pump (3 l/min)

• 2 electrovalves

XZR400 Series User’s Manual

XZR400A1

Ɨ” bulkhead union Ɨ” bulkhead unionƗ” bulkhead union

Sampling gas inlet

N.C. Solenoid valve

Sampling pump

N.O. Solenoid valve

Figure 17

Sensor flow adjustment valve

P

By-pass flow adjustment valve

O2 sensor

Barometric pressure sensor

Electronic flowmeter 0-12 l/h

Sample Path with Pump Fitted XZR400A1

Sampling gas outletSampling gas outlet

16 97472 Issue 3, August 2018

Page 27

XZR400 Series User’s Manual

2.8.7.1 Signal Processing Path

The values of oxygen concentration and fl ow passing through the sensor are displayed

continuously.

On specifi c screen pages the following control parameters are displayed:

• Oven temperature

• Ambient temperature (corresponding to the thermocouple junction

temperature)

INSTALLATION

• O

• MSRS sensor voltage

• Barometric pressure (standard) or process pressure (optional)

• Flow passing through the sensor

Analog Outputs:

• 2 x 4-20 mA analog outputs proportional to user-defi ned scales. The

Standard Alarms:

• General fault alarm

• 2 concentration alarms with user-confi gurable high/low thresholds and

concentration

2

wiring connector is on the rear side

hysteresis

Optional Alarm:

• An optional fl ow alarm is available

Michell Instruments 17

Page 28

INSTALLATION

2.9 Connections to the XZR400A2

The connections are shown below.

A

B

C

D

E

F

XZR400 Series User’s Manual

G

H

Item Description

A Graphic touch screen - displays measurement and menus.

B Multi-turn knurled knob for fi ne adjustment of the gas fl ow.

C Multi-turn knurled knob for basic adjustment of the gas fl ow (bypass).

D Removable plate for access to electrical terminal block and mains fuse.

E Three cable glands are provided for the electrical connections.

F Optional D-Sub DE9 male plug (RS485 or RS232 port).

G Inlet fi tting for the gas sample to be analyzed (for 6mm tube).

H Outlet fi tting for the analyzed gas sample (for 6mm tube).

Figure 18

Connections XZR400A2

18 97472 Issue 3, August 2018

Page 29

XZR400 Series User’s Manual

2.9.1 Gas Sample Inlet and Outlet Fittings

The gas path consists of 2 fl ow control valves (sensor fl ow and by-pass fl ow), a sensor

and an electronic fl owmeter. For the gas inlet and the outlet connections, Swagelok

stainless steel 6mm bulkhead unions are used, which guarantees perfect sealing and

easy removal.

The evacuation of the analyzed sample must be carried out at

atmospheric pressure, otherwise the total pressure adjustment

The measurement of hazardous gas samples require the

analyzer's outlet to be outside the analysis area and must be in

accordance with local regulations.

INSTALLATION

option is required.

Sensor flow

adjustment

Inlet for gas

to be

analyzed

Figure 19

Electronic

flow meter

Sensor

Bypass flow

adjustment

Analyzed

gas

outlet

Gas Circuit Diagram for XZR400A2

Michell Instruments 19

Page 30

INSTALLATION

2.9.2 Electrical Terminal Block

The terminal block is located by removing the front panel cover.

1 2 3 4 5 6 7 8 9 10111213141516

Item Function

1 Connection to the MSRS cell; system reserved (TC+ – orange).

2 Connection to the MSRS cell; system reserved (common – white).

3 Connection to the MSRS cell; system reserved (reference – blue).

4 Oven connection, system reserved.

5 Oven connection, system reserved (see paragraph 15.2).

6 (+) 4-20 mA output measurement proportional to the chosen O

4-20 mA output is available as an option.

7 4-20 mA (0 V).

8-9 Optional. Dry contact alarm for fl ow rate setting (250 V AC, 30 V DC or 2 A, 2 A

resistive load). Direction of action.

10-11 Threshold alarm No. 1 dry contact terminal (250 V AC , 2 A or 30 V DC, 2 A on

resistive load). Function mode (positive, normal) and hysteresis can be confi gured

by setting the parameters.

12 Threshold alarm No. 1 dry contact terminal (250 V AC , 2 A or 30 V DC, 2 A on

resistive load). Function mode (positive, normal) and hysteresis can be confi gured

by setting the parameters.

13 Shared contact for alarms No.1 and No. 2.

14 Threshold alarm No. 2 dry contact terminal (250 VAC , 5A or 30 VDC, 5A on

resistive load). Function mode (positive, normal) and hysteresis can be confi gured

by setting the parameters.

15 Mains supply phase.

16 Mains supply neutral.

XZR400 Series User’s Manual

scale. A second

2

The equipment is protected by a T2 A - 250 V AC timed fuse (5 x 20 mm) located near

the terminal block

Figure 20

Electrical Terminal Block XZR400A2

2.9.3 D-Sub DE9 plug

This optional D-Sub DE9 type male plug (9 pin) is used to connect an RS485 or RS232

port.

20 97472 Issue 3, August 2018

Page 31

XZR400 Series User’s Manual

2.9.4 D-Sub DA15 plug

This optional D-Sub DA15 male plug (15 pin) is used to connect a second 4-20 mA

output, a total pressure adjustment inlet, and the analyzer's auto adjustment terminals,

as well as automatic scale switching operations.

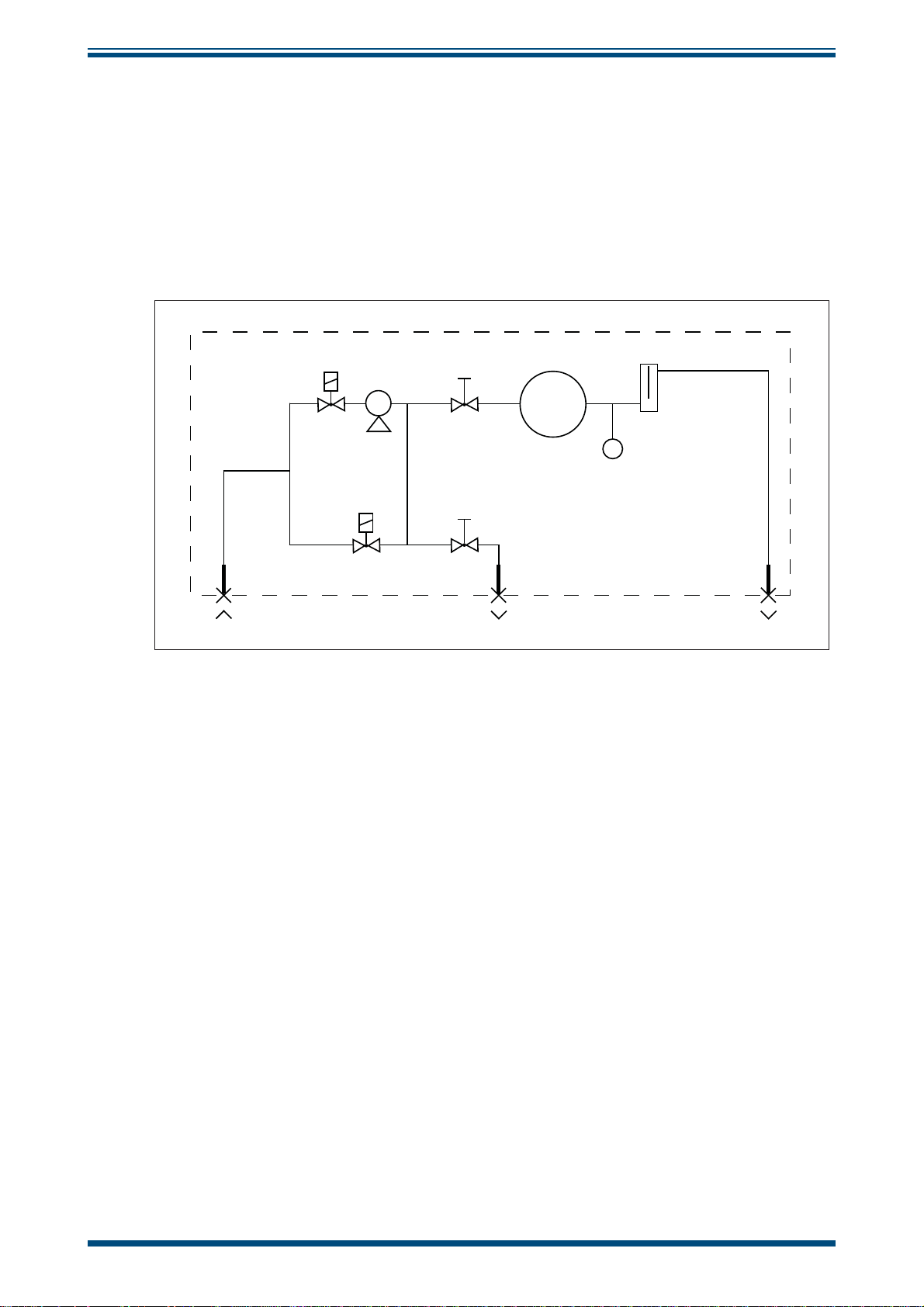

2.9.5 Sample Path

The MSRS sensor is placed inside an oven in which the gases to be analyzed are

circulated. The oven consists of a gas inlet head and a outlet plate. 3 Viton O-rings

ensure the sealing of this device (2 for the inlet and 1 for the outlet).

The internal sample path consists of:

• 2 fl ow control valves: sensor fl ow and by-pass fl ow

• 1 sealing head

INSTALLATION

• 1 outlet plate

• 1 oven tube

• 1 electronic fl ow meter

• 1 MSRS sensor

• 2 Swagelok 6mm stainless steel bulkhead unions (gases inlet and outlet)

- under the analyzer

XZR400A2

Sensor flow adjustment valve

By-pass flow adjustment valve

O2 sensor

Barometric pressure sensor

Electronic flowmeter 0-12 l/h

6mm bulkhead union 6mm bulkhead union

Sampling gas inlet

Figure 21

XZR400A2 Sample Path

Sampling gas outlet

Michell Instruments 21

Page 32

INSTALLATION

2.9.6 Signal Processing Path

The values of oxygen concentration and fl ow passing through the sensor are displayed

continuously.

On specifi c screen pages the following control parameters are displayed:

• Oven temperature

• Ambient temperature (corresponding to the thermocouple junction

temperature)

XZR400 Series User’s Manual

• O

• MSRS sensor voltage

• Barometric pressure (standard) or process pressure (optional)

• Flow passing through the sensor

Analog Outputs:

The analog output can be confi gured to represent the measured oxygen parameters and

is provided as a 2-wire signal. It can be set-up as a current loop signal 4-20 mA. The

confi guration of the output can be set via the

The analog output is proportional to user-defined scale. The connection is inside the

enclosure, behind the removable panel on the front of the unit. An optional second

4-20 mA output is available.

2.9.7 Alarm Outputs

Standard Alarms:

• general fault alarm

concentration

2

Main Menu.

• 2 concentration alarms with user-confi gurable high/low thresholds and

hysteresis

Two alarm relays are provided. They are connected to the instrument via the terminal

block inside the XZR400A2 Analyzer.

Under the

pre-set parameter threshold level is exceeded (refer to Section 3.6.2). The direction of

the activation, as well as the hysteresis can be confi gured.

The fault alarm is a non-confi gurable alarm which continuously monitors the status of

the analyzer. During normal operating conditions the alarm is off. The alarm will be

triggered and both relay contacts will open if:

• the oven temperature is low

• the thermocouple breaks

• a fault with the memory occurs

Optional Alarm:

• an optional fl ow alarm is available

Main Menu, the two concentration alarms can be set-up to operate when a

22 97472 Issue 3, August 2018

Page 33

XZR400 Series User’s Manual

2.10 Connections to the XZR400A3

2.10.1 Front Panel

The front panel features are shown below:

A

B

INSTALLATION

C

D

E

Item Description

A Carrying handle.

B Multi-turn knurled knob for basic adjustment of the gas fl ow (bypass).

C Graphic touch screen - displays measurement and menus.

D Multi-turn knurled knob for fi ne adjustment of the gas fl ow.

E Access plate to the MSRS sensor.

Figure 22

Connections Front Panel - XZR400A3

Michell Instruments 23

Page 34

INSTALLATION

2.10.2 Side Panel

The side panel connections are shown below:

XZR400 Series User’s Manual

A

B

C

D

Item Description

A ON/OFF button.

B Mains socket (90-132/187-264 VA, automatic range switching, 47/63 Hz).

C Inlet fi tting for the gas sample to be analyzed (for 6mm tube).

D Manufacturer's plate.

E Optional Sub-D DE9 male connector; RS232 or RS485 output.

F Optional Sub-D DA15 male connector

G Outlet fi tting for the gas sample to be analyzed (for 6mm tube).

E

F

G

Figure 23

Connections Side Panel - XZR400A3

24 97472 Issue 3, August 2018

Page 35

XZR400 Series User’s Manual

2.10.3 Electrical Terminal Block

1 2 3 4 5 6 7 8 9 10111213141516

Item Function

1 Connection to the MSRS cell; system reserved (TC+ – orange).

2 Connection to the MSRS cell; system reserved (common – white).

3 Connection to the MSRS cell; system reserved (reference – blue).

4-5 Oven connection, system reserved.

6 Optional (+) 4-20 mA output. Measurement proportional to the chosen O

A second 4-20 mA output is available as an option.

7 Optional 4-20 mA (0 V).

8-9 Optional Dry contact alarm for fl ow rate setting (250 V AC, 30 V DC or 2 A, 2 A

resistive load). Direction of action (positive, normal).

10-11 Optional General alarm dry contact terminal (250 V AC, 2 A or 30 V DC, 2 A on

resistive load). Direction of action (positive, normal).

12 Optional Threshold alarm No. 1 dry contact terminal (250 V AC , 2 A or 30 V DC,

2 A on resistive load). Function mode (positive, normal) and hysteresis can be

confi gured by setting the parameters.

13 Optional Shared contact for alarms No.1 and No. 2.

14 Optional Threshold alarm No. 2 dry contact terminal (250 V AC, 5 A or 30 V DC,

5 A on resistive load). Function mode (positive, normal) and hysteresis can be

confi gured by setting the parameters.

15-16 Not connected.

INSTALLATION

scale.

2

Figure 24

Electrical Terminal Block XZR400A3

Michell Instruments 25

Page 36

INSTALLATION

XZR400 Series User’s Manual

2.11 Connections to the XZR400A4-Transportable

A

B

C

F

D

E

Item Description

A Graphic touch screen - displays measurement and menus.

B Multi-turn knurled knob for fi ne adjustment of the gas fl ow.

C Multi-turn knurled knob for basic adjustment of the gas fl ow (bypass).

D Mains socket (90 - 264 V AC, 47/63 Hz)

On/Off button.

Analyzer housing for 2 electrical protection fuses (250 V AC - T2A or 250 V

AC - T6.3A).

E D-Sub DE9 female connector.

F Manufacturer's plate.

G Inlet fi tting for the gas sample to be analyzed (for 6mm tube)

H Outlet fi tting for the analyzed gas sample (for 6mm tube).

G

H

Figure 25

Connections Front Panel - XZR400A4

26 97472 Issue 3, August 2018

Page 37

XZR400 Series User’s Manual

2.11.1 Electrical Terminal Block

INSTALLATION

1

9 15

Item Function

1-2 General alarm contact.

2 Alarm No.1 contact terminal.

3 Shared contact for Alarm No.1 and Alarm No.2.

4 Alarm No.2 contact terminal.

5 Not connected.

7-8 Optional Flow alarm.

9 Optional 4-20 mA output #1 positive (+).

10 Optional 4-20 mA output #1 ground (-).

11 Optional 4-20 mA output #2 positive (+).

12 Optional 4-20 mA output #2 ground (-).

13-15 Not connected.

8

Figure 26

2.11.2 D-Sub DE9 Type Plug

Pin No. Function

1-2 General alarm contact.

3 Shared contact for Alarm No 1 and Alarm No 2.

4 Alarm No. 1 contact terminal.

5 Alarm No. 2 contact terminal.

6 + 4-20 mA measurement.

7 0 V of the 4-20 mA.

8 Optional.

9 Optional.

Electrical Terminal Block XZR400A4

5

96

1

Figure 27

D-Sub DE9 Plug - XZR400A4

Michell Instruments 27

Page 38

INSTALLATION

XZR400 Series User’s Manual

2.12 Mains Power Supply - XZR400A1, XZR400A3 & XZR400A4

The AC power supply is a push fi t into a power input socket as shown below. The

method of connection is as follows:

Figure 28

1. Ensure that both ends of the power cable are potential free i.e. not

connected to an AC power supply.

2. Check that the

3. Push the IEC connector fi rmly into the power input socket.

l/0 switch on the power supply connector is switched to 0.

POWER INPUT

Socket

IEC connector

Power Input Socket

28 97472 Issue 3, August 2018

Page 39

XZR400 Series User’s Manual

2.12.1 Analog Outputs Connections

The analyzer is supplied with 1 or 2 off 4-20 mA outputs.

The signal outputs will be connected to external systems that can

potentially infl uence the operation of the process.

The alarm level signals could also be at mains potential so it is

essential that, before connecting these signal lines, checks are

made to ensure that these inputs are not live and that it is safe to

The output connection can be wired directly to the terminal block on the back panel of

the analyzer. Use screened cable.

INSTALLATION

handle them.

The method of connection is as follows:

Always use screened cable to connect the output to the external

device.

1. Strip back the wire for the positive output lead, exposing approximately

6mm (0.25") wire and clamp into the screw port labelled

Do not overtighten the screw.

2. Strip back the wire for the negative output lead, exposing approximately

6mm (0.25") wire and clamp into the screw port labelled

Do not overtighten the screw.

3. Connect the screen to the ground port.

4-20 mA +.

4-20 mA –.

Michell Instruments 29

Page 40

INSTALLATION

2.12.2 Alarm Output Connections

Two alarm relays are provided and are connected to the instrument via the terminal

block on the back panel of the analyzer.

The signal outputs will be connected to external systems that can

potentially infl uence the operation of the process.

The alarm level signals could also be at mains potential so it is

essential that, before connecting these signal lines, checks are

made to ensure that these inputs are not live and that it is safe to

Alarms 1 and 2 are concentration alarms. The direction of the activation N/O or N/C, as

well as the hysteresis, can be confi gured.

XZR400 Series User’s Manual

handle them.

The output contacts are normally open and potential free. The relay switching capability

is 10 W max (up to 100 V or up to 0.5 A).

The method of connection is as follows:

Always use screened cable to connect the output to the external

device.

Alarm 1

1. Strip back the two wires for the alarm 1 output leads, exposing

approximately 6mm (0.25") wire and clamp them into the two screw ports

labelled as

2. Connect the screen to the ground port.

Alarm 2

Alarm 1. Do not overtighten the screw.

1. Strip back the two wires for the alarm 2 output leads, exposing

approximately 6mm (0.25") wire and clamp them into the two screw ports

labelled as

2. Connect the screen to the ground port.

Alarm 2. Do not overtighten the screw.

30 97472 Issue 3, August 2018

Page 41

XZR400 Series User’s Manual

2.13 Gas Connection

To ensure that the sample gas is properly

conditioned a sampling system might be

Contact Michell Instruments if you wish to order

a suitable sampling system.

Sample gas connections are made via the gas input and gas output ports located on

the back panel (XZR400A1), bottom panel (XZR400A2), side panel (XZR400A3) or front

panel (XZR400A4) of the analyzer.

Both the input and output gas connections are 1/8” stainless steel Swagelok® couplings.

NOTE: To facilitate ease of connection to the port, at least 75mm (3") of the

tubing coming out of the gas inlet port must be straight.

INSTALLATION

required.

The method of connecting to the gas inlet and gas outlet ports is as follows:

1. Connect the gas source from the sample system to the Swagelok® fi tting

at the inlet port on the instrument using 1/8” stainless steel tubing.

Tighten the fi tting as much as possible by hand and tighten again with a

7/16” fl at wrench (approximately 1¼ turns).

2. Connect the gas outlet port in a similar manner to that described in

Step 1 using 1/8” stainless steel tubing.

If you undo the fi tting again and reconnect it, fi rst tighten up by

hand and then tighten using a 7/16” fl at wrench with no more

than a 1/8 turn.

DO NOT OVER-TIGHTEN.

NOTE: Maximum sample pressure is 2 barg (29 psig).

NOTE: Sample is vented to atmosphere. Depending on the location of the

analyzer it may require a vent line to a safe location that is freely ventilated.

Michell Instruments 31

Page 42

OPERATION

3 OPERATION

It is recommended that the user becomes familiar with Section 2 of this manual in which

all the equipment controls, indicators, the elements of the display and the overall menu

structure are described.

Prior to operation, the analyzer must have been connected to the correct electrical

power supply and the relevant analog and alarm outputs connected to external systems

as described in Section 2.

On delivery, the instrument will have been set-up with a standard set of default

parameters defi ning the operation of the analyzer. These parameters can be changed

as required by means of the

3.1 General Operational Information

Main Menu.

XZR400 Series User’s Manual

The input gas must be at a pressure of less than 2 barg (29 psig). A pressure regulator

is recommended when above 2 barg (29 psig) for better fl ow control. The outlet of the

system must be at atmospheric pressure.

NOTE: If the outlet is at higher pressure than atmospheric an optional process

pressure correction is necessary. Please consult Michell Instruments in this

case.

The instrument is designed to operate with a gas fl ow of 2 l/h ±1 l/h.

NOTE: For best results ensure that the sampling system is as close as possible

to the XZR400 Series Analyzer.

For all applications the sample gas is taken into the instrument via the gas inlet port

located on the bottom panel of the analyzer, from where it passes into an oven chamber.

The gas fl ow rate is then measured on the outlet side of the sample chamber, prior to

being exhausted from the instrument via the gas outlet port.

The fl ow, necessary for the sample gas circulation, is generated by the sensor oven

which utilizes the heat convection principle. The hot sample gas from the sensor oven is

pushed by the hot oven gases, which are still in the oven. On the way out of the oven

the sample gas cools, passing through the gas outlet port, and is carried away by the

main gas fl ow.

The XZR400 Series Analyzers are suitable for the measurement of oxygen in a wide

variety of clean and dry gases. It will not contaminate high purity gases and is safe for

use in critical semiconductor and fi bre optic manufacturing applications.

It is possible to continuously visualize the oxygen concentration in the range between

0.01 ppm and 25% oxygen. If required, the analyzer can display the MSRS voltage, the

oven temperature and the temperature of the cold junction in the thermocouple.

32 97472 Issue 3, August 2018

Page 43

XZR400 Series User’s Manual

3.2 Powering-up the System

Carefully check the electrical connection before applying the power.

Switch the external disconnecting device supplying power

Wall Mount Version

to the analyzer. This device does not have a built-in on/off

switch.

OPERATION

Portable and Rack

Versions

Power-up the system. Observe all normal safety precautions during the powering-up

procedure.

Never allow sample gas to enter the analyzer when it is switched

In the case of power breakdown for more than 1 hour it is

necessary to purge the analyzer with Nitrogen or instrument air

This will prevent any condensation due to the oven being off.

Switch the built-in on/off switch to the

off.

dew point < -40.

Maintain the fl ow rate at 2 l/h ±1 l/h.

ON position

Michell Instruments 33

Page 44

OPERATION

3.3 Warm-Up Period

Upon power up, the screen appears as shown below. The analyzer performs a series of

internal checks for about 5 seconds.

NOTE: Touch the French or English area to display the menu in the required

language.

XZR400 Series User’s Manual

Software version V0.1.7.ver

1

French

Figure 29

English

Start-up Screen

Wait about 15 minutes until the oven temperature reaches 634°C, indicated by the oven

temperature line.

The low temperature alarm is displayed digitally throughout the rise in oven temperature;

the general alarm contact is activated.

NOTE: A fl ow greater than 3.5 l/h prevents the correct rise in oven temperature.

Oven

Flow

48.8ºC

7.5 l/h

Low temperature alarm

Figure 30

Oven Temperature Screen

34 97472 Issue 3, August 2018

Page 45

XZR400 Series User’s Manual

If required, adjust the gas sample fl ow by operating the by-pass valve (B) and then the

end fl ow valve (A) to obtain a 2 ±1 l/h fl ow rate (C).

NOTE: For optional measurement do not fully close the by-pass valve.

OPERATION

AB

Flow l/h

O

: 19.3 %

2

View

Figure 31

C

Pump

0,5....2....3,5

U

Adjustment

20:09:43

Sample Flow Adjustment

AB

3

NO

Michell Instruments 35

Page 46

OPERATION

3.4 Main Screen

Once the temperature has been reached, the screen displays:

XZR400 Series User’s Manual

C

A

B

Pump

O

: 19.3 %

2

Flow l/h

View

D

Measured oxygen concentration between 0.01 ppm and 25%. The maximum

measurement precision can only be obtained following an adjustment

A

B

C Screen number

D

E Message display area

F Sample gas fl ow between 0.5 and 3.5 l/h, shown by the cursor position

G

H Current time

performed after a minimum of 3 hours of operation. However, upon receipt

of the analyzer, this adjustment will have been performed in the factory as

shown in the manufacturing check and adjustment sheet.

Pump

The

Touch-sensitive

Touch sensitive

Used to adjust the MSRS cell after changing the cell or the oven

ON/OFF button available on A1 or A4 models.

PUMP signal fl ashes when the pump is operating

View area

Adjustment area

0,5....2....3,5

Figure 32

U

E

F

Main Screen

Adjustment

20:09:43

G

3

NO

H

36 97472 Issue 3, August 2018

Page 47

XZR400 Series User’s Manual

3.5 Control Parameters Display

On the Measurement Display Screen (3) touch the VIEW area

The Control Parameters Screen (3.1) will appear.

Control parameters

Sensor Voltage

O2 27.35 ppm

Adjustment

Oven

Room temp

Atm pressure

Flow

CO

Adjustment

634.0ºC

30.7ºC

-122.76 mV

1036 mBar

2.5 L/h

0.00

Maintenance

OPERATION

3.1

Figure 33

Control Parameters Screen

This displays the following information about the analyzer.

Current temperature of the hot joint of the thermocouple

Oven

corresponding to oven temperature. This must be 634°C.

Temperatures 30°C below the reference and 50°C above the

reference trigger a general alarm.

Room Temperature

Measure taken on the motherboard. This measurement is only

used to compensate for the cold solder joint of the thermocouple.

Measurement in mV of the voltage supplied by the measuring

Sensor Voltage

cell, which must be between -300 and +250 mV. A value greater

than the upper limit generates a MSRS fault alarm.

The pressure at the analyzer outlet must be near atmospheric

pressure (between 800 and 1750 mbar). A value above 1200

Atm pressure

mbar and under 800 mbar generates an oxygen measurement

error. NOTE: If the pressure is greater than 1750 mbar,

the atmospheric pressure sensor can be damaged

irreversibly.

The sample's fl ow in l/hour must be 2 ±1 l/h. A fl ow value

Flow

below 0.5 or greater than 3.5 l/h generates a general fault alarm

displaying a Flow fault.

O2 Measured oxygen percentage

Return to Main Screen 3. The display returns to the Main Screen

automatically if the touch screen is not used for 2 minutes.

Adjust Displays the adjustment screen to calibrate the analyzer.

Maintenance

Displays the analyzer's parameter setting screen (access code,

outputs, alarm limits, time-stamp, RS485, fl ow corrections).

Michell Instruments 37

Page 48

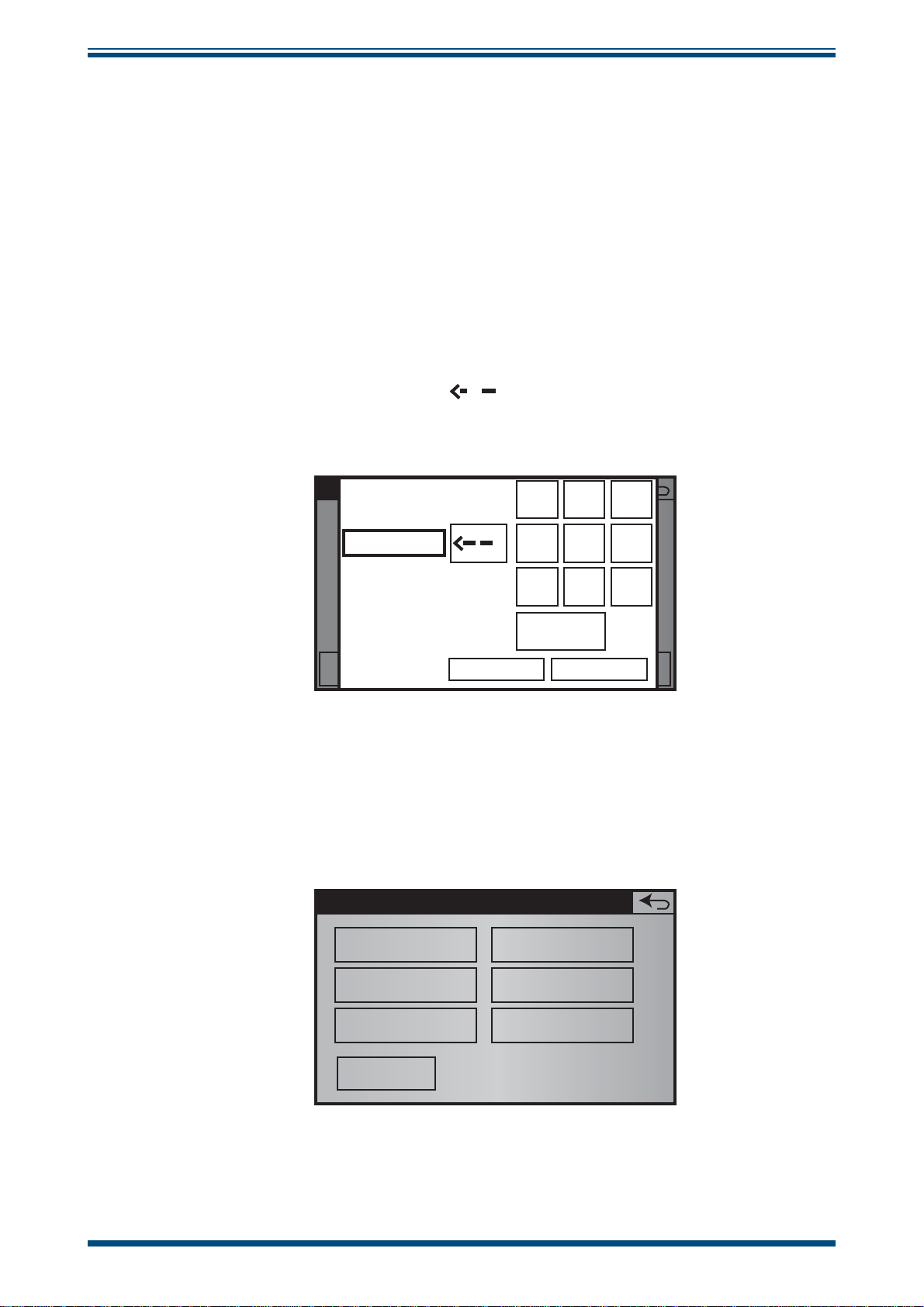

OPERATION

3.5.1 Confi guration

To reach the Main Menu Screen enter the access code as follows.

XZR400 Series User’s Manual

• Touch the

VIEW area of Screen 3. The Control Parameters Screen is

displayed.

• Touch the

NOTE: To leave this screen touch

Maintenance area.

Cancel area.

• Touch the box labelled 0____

• Enter the access code on the keyboard. The default access code is 0.

• To correct an entry error press

• Touch the OK area.

Control parameters

Access code

Oven

0___

Min = 0

Max = 9999

O2 27.35 ppm

Adjustment

Room temp

Sensor Voltage

Atm pressure

Flow

CO

Cancel

Adjustment

789

680.3C

30.7C

456

-122.76 mV

1036 mBar

1

2.5 L/h

0.00

23

0

Maintenance

3.1

OK

Figure 34

Main Menu Access Screen

If the access code is incorrect the screen goes back to Screen 3.1.

If the access code is correct the Main Menu Screen is displayed (5).

Main menu

5

Analog output Alarms

Auto adjustment System

Pressure

Flow

Figure 35

Main Menu Screen

Comm

38 97472 Issue 3, August 2018

Page 49

XZR400 Series User’s Manual

3.5.2 Changing the Access Code

The default access code is 0000. To change this code proceed as follows:

OPERATION

NOTE: To leave a screen, touch

• Touch the

VIEW area of Screen 3. The Control Parameters Screen is

displayed.

Control parameters

Sensor Voltage

Atm pressure

O2 27.35 ppm

Adjustment

• Touch the Maintenance area.

Main menu

.

Oven

Room temp

Flow

CO

Adjustment

634.0ºC

30.7ºC

-122.76 mV

1036 mBar

2.5 L/h

0.00

Maintenance

3.1

Analog output Alarms

Auto adjustment System

Flow

• Touch the System area.

System

Hour Misc.

Tue 18/02/2014 15:48:54

Pressure

Comm

++ + ++

-- - --

5

5.5

• Touch the Misc tab

Michell Instruments 39

Page 50

OPERATION

XZR400 Series User’s Manual

System

Hour

Misc.

Setpoint

Language

New access code

• Touch the New Access code area

System

Access code

Hour Misc.

0___

Min = 0

Max = 9999

New access code

Setpoint

English

5.5

634ºC

English

****

789

5.5

456

1

634ºC

23

English

0

****

• Enter the new access code

• To correct an entry error, press the

• Press the

OK area

Cancel

OK

area

40 97472 Issue 3, August 2018

Page 51

XZR400 Series User’s Manual

3.6 The Main (Expert) Menu

This menu accesses all of the confi guration functions of the analyzer. Press the

corresponding area to display the required screen.

Main menu

Analog output Alarms

Auto adjustment System

OPERATION

5

Pressure

Flow

Figure 36

Main Menu Screen

Comm

Area Function Section

Analog output

Confi gures the 4-20 mA analog output 1 3.6.1

Disables the 3 alarms (during adjustment and/or during

Alarms

normal operation) and sets the threshold and the function

3.6.2

mode for alarm 1 and 2

Confi gures the automatic cyclical adjustment (adjust) of

Auto adjustment

the analyzer

3.6.3

Optional

Confi gures the analyzer timestamp function, oven

System

temperature, menu display language, Expert access

code and RS output confi guration (ModBus address with

3.6.4

RS485 or frame period with RS232).

Pressure

Confi gures the process pressure correction

Optional for all models

3.6.5

Returns to the Measurement Display Screen (3)

Sets the frequency of the frame transmission

COM 232

Optional

3.6.6

Cannot coexist with the RS485

Sets the ModBus address of the analyzer and displays

COM 485

the message frames received by the analyzer via the

RS485 interface

3.6.6

Cannot coexist with the RS232

Flow

Confi gures the gas sample fl ow correction based on its

density

3.6.7

Michell Instruments 41

Page 52

OPERATION

3.6.1 Analog 1

The Analog Output 1 screen (5.1) sets the parameters for the 0/4-20 mA output.

• Touch the area to select it and change it.

• Enter the new numeric value on the virtual keypad.

XZR400 Series User’s Manual

• Click

OK to confi rm or Cancel to discard the changes.

Analog output

Analog 1

Area Function

Confi guration of the 0/4-20 mA analog output No 1.

LIN: the output voltage must be linearly proportional to the oxygen

measurement value.

LOG: the output voltage must be a logarithmic function with respect to

the oxygen measurement value. Use this option when the signal span is

greater than 3 decimal counts.

4-20 mA

A current of 3.80 mA (4-20 mA output confi gured) or 21 mA is

automatically generated when there is a general fault if:

Analog 2

4-20 mA

Start of scale

Unit

End of scale

Range

Figure 37

Analog Output Screen

5.1

O2 Linear

0.10%

%

10.00%

0-20 mA

Start of scale

Unit

End of scale

Range

Analog 2

• oven temperature is lower than 30°C or higher than 50°C

from the setpoint

• thermocouple rupture

• fl ow less than 0.5 and greater than 3.5 l/h

• internal wiring fault

Confi guring the concentration for the low scale and the measurement

unit. Select a value and a unit corresponding to the concentration to be

measured.

Confi guration of the unit in which the value is expressed (% or ppm).

Confi guring the high scale concentration and the measurement unit.

Select a value and a unit corresponding to the concentration to be

measured.

NOTE: the difference between the low scale and high scale value

is limited to three decimal places to ensure correct resolution.

This limitation only applies to a linear output type.

Confi guration of the analog output (0-20 or 4-20 mA).

Returns to the Main Menu screen.

The information is similar to that of the Analog 1 menu and can be reached by touching

the Analog 2 area. When this option is not available, the display shows

Option not

available.

42 97472 Issue 3, August 2018

Page 53

XZR400 Series User’s Manual

3.6.2 Alarms

The Main Tab

The Alarms Screen sets the general behaviour for alarms 1 and 2.

• Touch the area to select it and change it.

OPERATION

• Click

Area Function

OK to confi rm or Cancel to discard the changes.

Alarms

Enable when adj

Sets the behaviour for alarms 1 and 2 exclusively during auto adjust

operations or manual.

•

Enable when adj

•

Sets the current behaviour for alarms 1 and 2 and that of the General

fault exclusively in normal mode of operation (excluding adjustment).

•

Disabled

Alarm 1 tab

Alarm 2 tab

•

NOTE: Operating with alarms disabled must only be done

temporarily, particularly during adjustments.

Touch the area to display the alarm 1 threshold change screen.

Touch the area to display the alarm 2 threshold change screen.

Returns to the Main Menu Screen.

Alarm 1

Disabled

Figure 38

Alarm 2Main

Alarm Screen (Main)

5.3

No

No

No: exceeding the alarm threshold will not trigger the

relay for alarms 1 and 2 during adjustment operations, or

when alarm set off is confi gured by the user.