Page 1

XTC601

Thermal Conductivity Analyzer

User’s Manual

97400 Issue 2

July 2015

Page 2

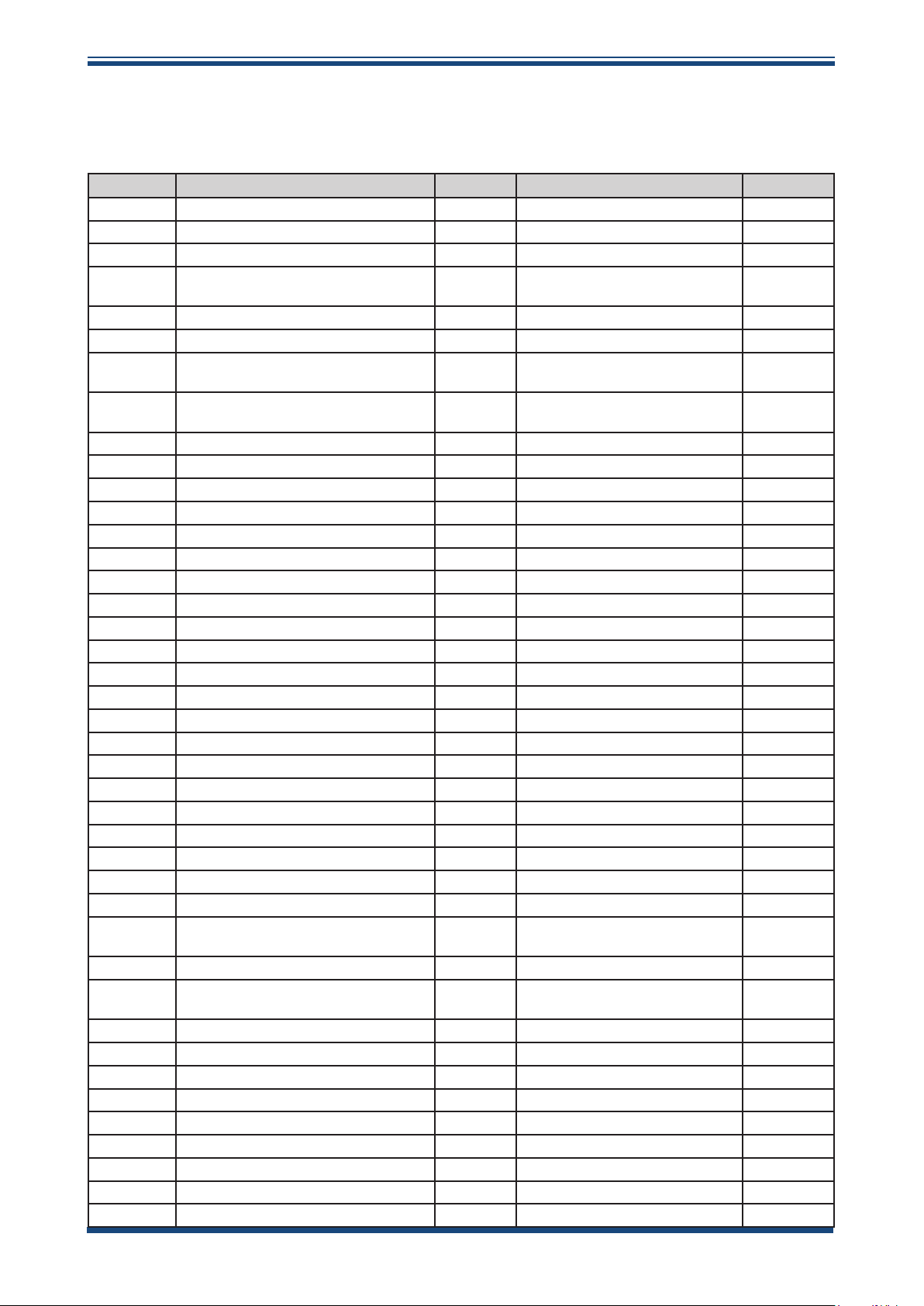

Please ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

XTC601

For Michell Instruments' contact information please go to

www.michell.com

© 2015 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

XTC601 User’s Manual

Contents

Safety ...............................................................................................................................vii

Electrical Safety ..........................................................................................................vii

Hazardous Area Safety .................................................................................................ix

Pressure Safety ............................................................................................................ x

Temperature Safety ...................................................................................................... x

Toxic Materials ............................................................................................................. x

Repair and Maintenance ............................................................................................... x

Calibration ................................................................................................................... x

Safety Conformity ........................................................................................................ x

Abbreviations ......................................................................................................................xi

1 INTRODUCTION ................................................................................................1

1.1 Features ............................................................................................................ 2

1.2 Applications ....................................................................................................... 3

1.3 O-Ring Selection ................................................................................................. 3

2 OPERATION ......................................................................................................4

2.1 Preparation ........................................................................................................ 4

2.2 Powering up the Analyzer .................................................................................... 5

2.3 User Interface .................................................................................................... 6

2.3.1 Interface Controls ......................................................................................... 6

2.3.2 ‘ESC’ Button .................................................................................................. 7

2.3.3 ‘Up/Down Arrow’ Buttons ............................................................................... 7

2.3.4 ‘ENTER’ Button ............................................................................................. 7

2.4 Menu Structure .................................................................................................. 8

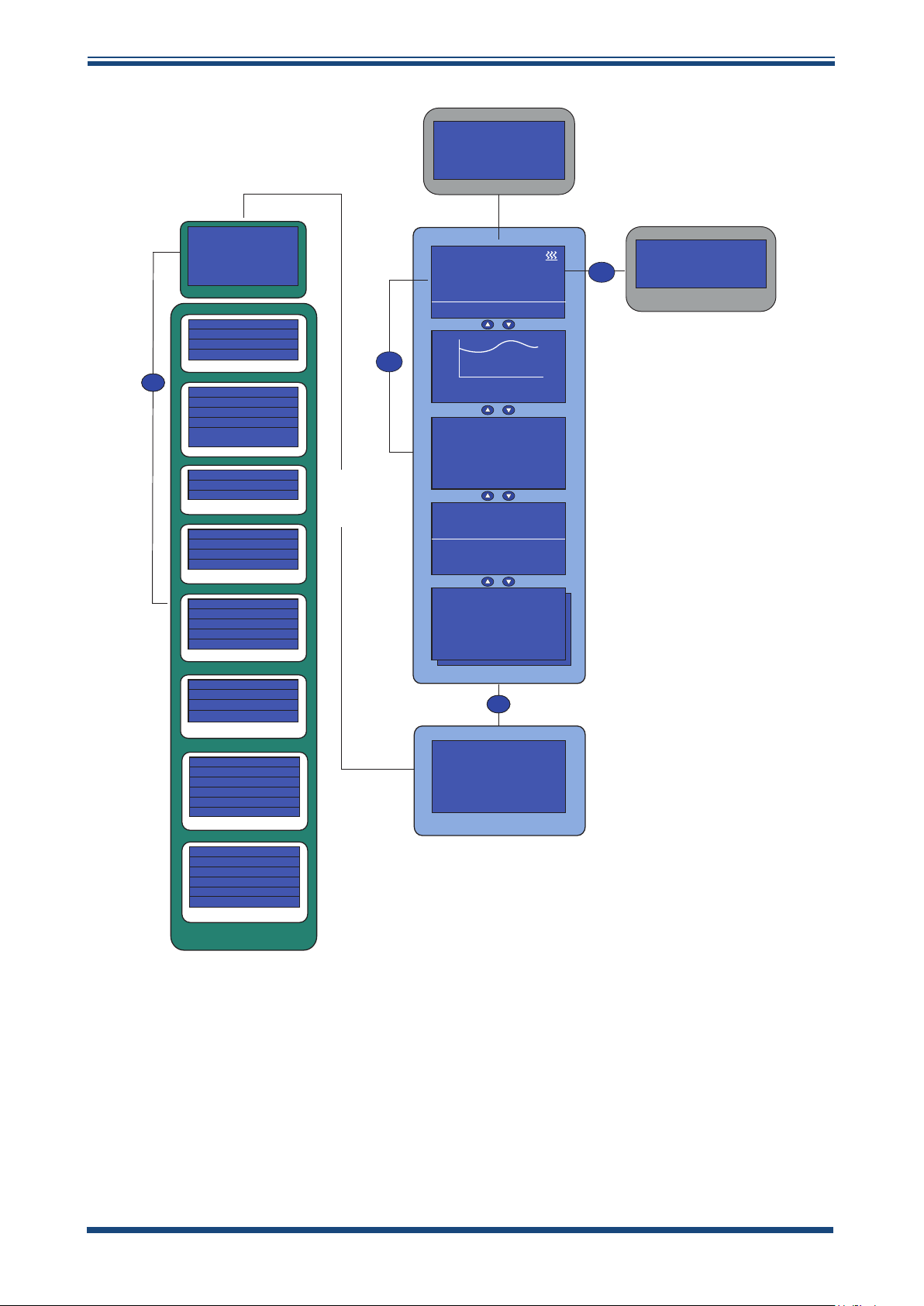

2.4.1 Menu Map .................................................................................................... 9

2.5 Front Pages (No Passcode Required) .................................................................... 9

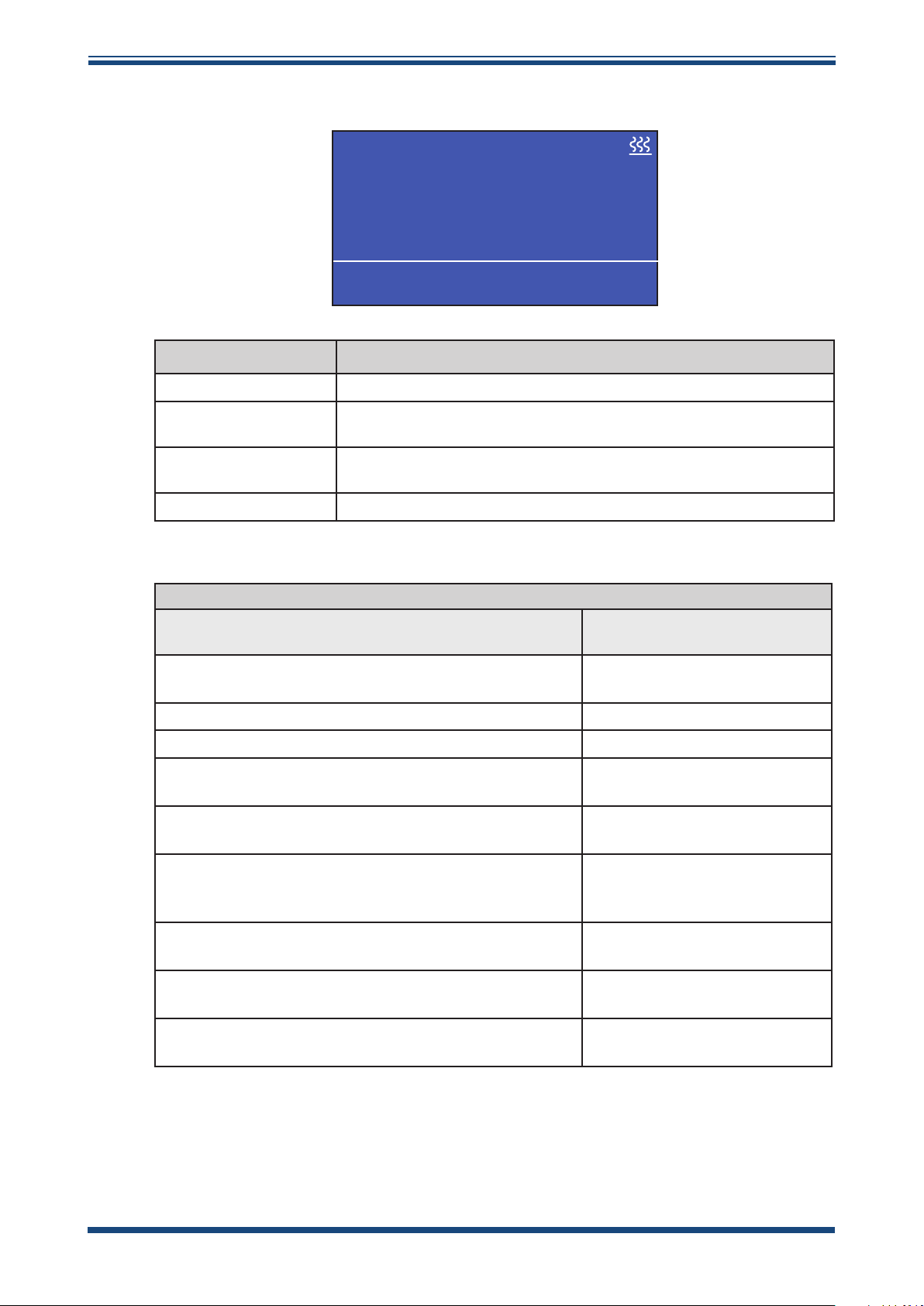

2.5.1 Main Page .................................................................................................. 10

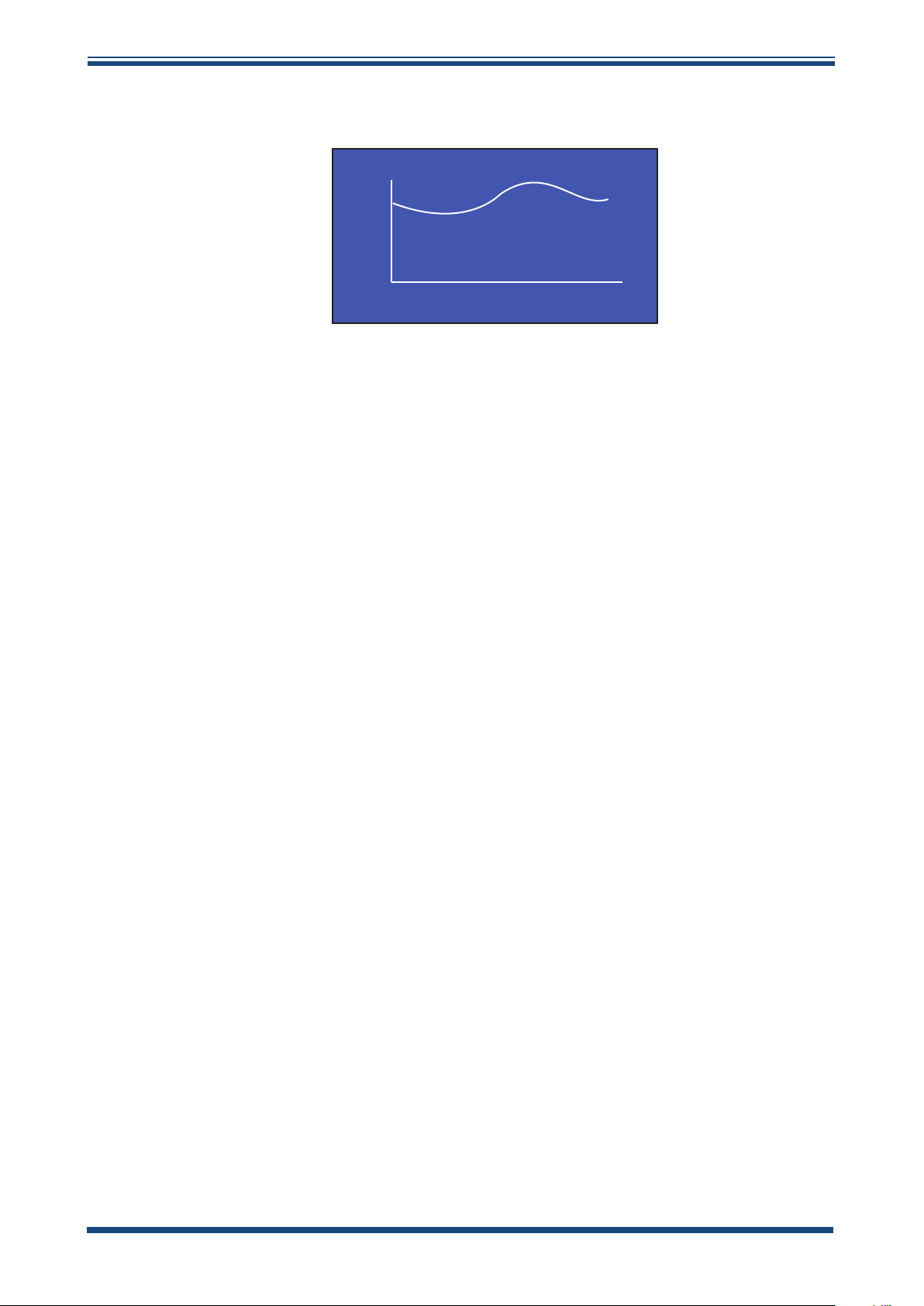

2.5.2 Chart Page ................................................................................................ 11

2.5.3 Secondary Parameters Page ......................................................................... 12

2.5.4 Target Gas Min/Max Page ........................................................................... 12

2.5.5 Alarms Log Pages ....................................................................................... 13

2.6 Info Page ........................................................................................................ 13

2.7 User Set-Up Variables (Passcode Required) ........................................................ 14

2.7.1 Settings Page .............................................................................................. 15

2.7.2 Human Machine Interface (HMI) Page .......................................................... 16

2.7.3 Reset Page ................................................................................................. 16

2.7.4 Outputs Page .............................................................................................. 17

2.7.5 External Compensation Page ........................................................................ 18

2.7.6 External Sensor Page .................................................................................. 19

2.7.7 Clock Page .................................................................................................. 20

2.7.8 Field Cal Page ............................................................................................. 20

2.7.9 Status LED or Light Guide ............................................................................ 21

3 CALIBRATION ..................................................................................................22

3.1 1 Point Calibration ............................................................................................ 23

3.2 2 Point Calibration ........................................................................................... 24

3.3 Field Calibration Reset ...................................................................................... 25

4 INSTALLATION ................................................................................................26

4.1 Unpacking ........................................................................................................ 27

4.2 System Components ......................................................................................... 27

4.2.1 Casing ........................................................................................................ 28

4.3 Set-Up ............................................................................................................. 28

iv 97400 Issue 2, July 2015

Page 5

XTC601 User’s Manual

4.4 Mechanical Installation ...................................................................................... 29

4.4.1 Gas Connection Tape ................................................................................... 30

4.4.2 Sample Gas Requirements ........................................................................... 30

4.4.3 Calibration Gases ........................................................................................ 30

4.5 Electrical Installation ......................................................................................... 31

4.5.1 Power Supply and Input/Output Signal ......................................................... 31

4.5.2 Power Supply (PL9 - Green) ........................................................................ 31

4.5.3 Analog Output ............................................................................................ 31

4.5.4 Serial Output .............................................................................................. 32

4.5.5 Analog (4-20 mA) Outputs and Communications (PL5 - Green) ....................... 32

4.5.6 Alarm Relay Contacts (PL1- Black) ................................................................ 32

4.5.7 Analog (4-20 mA) Inputs and Sensor Excitation Voltage (PL4 - Green) ............ 33

4.5.8 Light Guide ................................................................................................. 33

Figures

Figure 1 XTC601 Thermal Conductivity Analyzer Versions ..........................................1

Figure 2 Initializing Screen .......................................................................................5

Figure 3 Main Page ..................................................................................................5

Figure 5 XTC601 Application Software .......................................................................6

Figure 4 User Interface ............................................................................................6

Figure 6 ESC Button ................................................................................................7

Figure 7 Up/Down Arrow Buttons .............................................................................7

Figure 8 ENTER Button ............................................................................................7

Figure 9 Menu Map ..................................................................................................9

Figure 10 1 Point Calibration Page ............................................................................23

Figure 11 2 Point Calibration Page ............................................................................24

Figure 12 XTC601 Showing Major Components ..........................................................27

Figure 13 XTC601 Lid Removal .................................................................................28

Figure 14 XTC601 Gas Connections and Cable Entries ................................................29

Figure 15 Terminal Block Locations ...........................................................................31

Figure 16 2 Port Dimensional Drawings .....................................................................38

Figure 17 4 Port Dimensional Drawings .....................................................................39

Michell Instruments v

Page 6

XTC601 User’s Manual

Appendices

Appendix A Technical Specifications .............................................................................35

Appendix B Dimensional Drawings...............................................................................38

Appendix C Relative Thermal Conductivity Table ...........................................................41

Appendix D Modbus Register Map ...............................................................................43

Appendix E Hazardous Area Certification .....................................................................50

E.1 Product Standards ...................................................................... 50

E.2 Product Standards ...................................................................... 50

E.3 Global Certicates/Approvals ....................................................... 50

E.4 Special Conditions....................................................................... 50

E.5 Maintenance and Installation .......................................................51

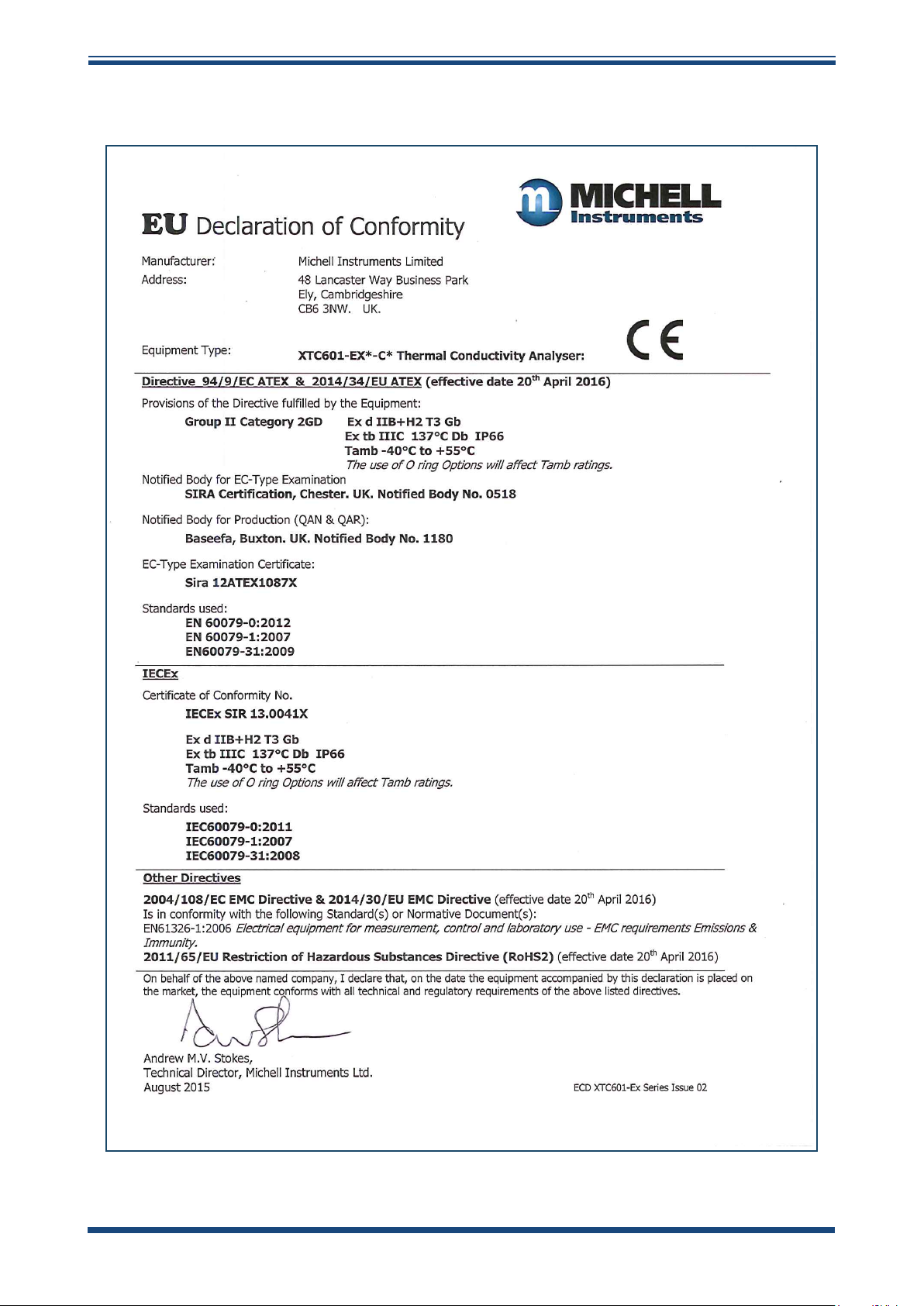

Appendix F EU Declarations ........................................................................................53

F.1 EU Declaration of Conformity - GP Version .................................... 53

F.2 EU Declaration of Conformity - EX Version .................................... 54

Appendix G Quality, Recycling & Warranty Information ..................................................56

G.1 Pressure Equipment Directive (PED) 97/23/EC .............................. 56

G.2 Recycling Policy ......................................................................... 56

G.3 WEEE Compliance ....................................................................... 56

G.4 RoHS2 Compliance .....................................................................57

G.5 Warranty .................................................................................... 57

G.6 REACH Compliance ..................................................................... 58

G.7 Return Policy .............................................................................. 58

G.8 Calibration Facilities ....................................................................59

G.9 Manufacturing Quality ................................................................. 59

G.10 FCC (EMC Requirements for North America) ................................. 59

Appendix H Analyzer Return Document & Decontamination Declaration .........................61

vi 97400 Issue 2, July 2015

Page 7

XTC601 User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

qualified personnel and good engineering practice for all procedures in this manual.

Where this symbol appears in the following sections it is used

to indicate areas where potentially hazardous operations need

to be carried out and where particular attention to personal and

personnel safety must be observed.

Electrical Safety

WARNING:

During the installation of this product ensure that all applicable

national and local electrical safety regulations are observed.

WARNING:

Isolate the power prior to installation.

WARNING:

Always ensure that power is switched off prior to accessing the

product for any purpose other than normal operation or prior to

disconnecting any cables.

In compliance with IEC 61010 Electrical Safety Standard the following applies to this product:

Equipment ratings:

This equipment must be supplied with a voltage of 24 V DC, 1.5 A (36 W).

The power is connected via PL9 on the mother board (see Section 4.5).

All input and output connectors are 2-part pcb mounted type.

The detachable, screw terminal half of each connector is designed to accept 24 -12 AWG stranded

or solid conductors.

Michell Instruments vii

Page 8

XTC601 User’s Manual

Ensure suitably rated power supply cables and glands are used to ensure that electrical safety is

maintained. Connect to the POWER IN each of the Live (L), Neutral (N) and Earth [Ground] (E)

conductors to the similarly marked terminals (L, N, E). Ensure the power supply can deliver sufficient

power consumption requirement.

Ensure any power supply terminals and voltages are suitably separated from the other I/O

requirements of this product.

Before applying power, perform a continuity test to ensure that the power supply cable and product

are effectively connected to the protective Earth.

The product enclosure is supplied with an external Earth stud at the lower right hand side. At

installation, connect this Earth stud to plant Earth by a minimum 4mm2 earthing bonding.

Fuse - A replacement fuse can be obtained by contacting Michell Instruments' technical support.

Michell order number - XTP601-26149.

This product is designed to operate, as a minimum, between a temperature range of -5 to +40°C (+23

to +104°F), in maximum 80% relative humidity for temperatures up to +31°C (+87°F) decreasing

linearly to 50% RH at 50°C (122°F). Supply voltages of ±10% and transient over voltages up

to Overvoltage Category II. Pollution Degree 2. Altitudes up to 2,000 mtrs. Outdoor mounting is

permitted using suitably rated glands equivalent to NEMA 4 / IP66. See Technical Specifications

(Appendix A) in this manual for full operating parameters. Do not remove or exchange any of the

cables or electrical components supplied with this product. To do so will invalidate all warranties.

There are no additional or special electrical safety requirements other than those referred to in this

manual.

Location and mounting arrangements. Refer to the relevant sections of this manual for the location

and mounting details.

Installation of this equipment should include the provision of a suitable and locally positioned power

isolation switch or circuit breaker.

Ensure this equipment and all power isolation devices are installed in a location and position that

allows safe and easy access to their operation and is adequate to rigidly support the equipment.

Do not install this equipment in a location that would expose it to impact or high levels of vibration.

Operation of this equipment, other than in a manner as specified by the manufacturer, may impair

the safety protections provided.

The safe installation of this equipment and any system incorporating this equipment is the

responsibility of the installer. Ensure local regulations and requirements are referred to prior to any

installation commencing.

viii 97400 Issue 2, July 2015

Page 9

XTC601 User’s Manual

Hazardous Area Safety

Appendix E of this manual refers to the EX version and the Hazardous Area Certification of this

product.

This product is fitted with a marking label that contains Hazardous Area information pertinent to the

suitable location and installation.

During all installation and operation activities local regulations and permitted working routines must

be observed. Installation should only be performed by competent personnel and in accordance with

IEC/En 60079-14:2008 or local equivalent.

Repair and servicing of this equipment must only be carried out by the manufacturer.

WARNING:

This product is certied safe for use in a Zone 1 and Zone 2 area

only. This product must not be installed or used within a Zone 0

area.

WARNING:

This product must not be operated within an explosive

atmosphere greater than 1.1 bar absolute.

WARNING:

This product must not be operated with oxygen above 21% in a

hazardous area.

WARNING:

This product must not be operated outside of

the temperature range of -20 to +55°C (-4 to +131°F).

Michell Instruments ix

Page 10

XTC601 User’s Manual

Pressure Safety

WARNING:

This product is used in conjunction with pressurized gases.

Observe pressurized gas handling precautions.

WARNING:

Pressurized gas is dangerous.

Pressurized gas should only handled by suitably trained

personnel.

The XTC601 measurement chamber requires pressurized gas to be connected to it. Observe

pressurized gas handling regulations. Suitably trained personnel only should carry out tasks that

include the use of pressurized gas mediums.

DO NOT permit pressures greater than the safe working pressure to be applied to the instrument.

The specified safe working pressure for this instrument is 3 barg (43 psig) max.

Temperature Safety

During operation some internal parts of the instrument may be at high temperature.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Long exposure to, or breathing of the calibration gases, may be dangerous.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. For

Michell Instruments’ worldwide offices contact information go to www.michell.com.

Calibration

The recommended calibration interval for the analyzer is 1 to 3 months.

Safety Conformity

This product carries the CE mark and meets the requirements of relevant European safety directives.

x 97400 Issue 2, July 2015

Page 11

XTC601 User’s Manual

Abbreviations

The following abbreviations are used in this manual:

A Ampere

AC alternating current

bara pressure in bar (absolute)

barg pressure in bar (gauge)

°C degrees Celsius

°F degrees Fahrenheit

DC direct current

kg kilogram

kPa Kilopascal

lb pound

max maximum

mA milliampere

ml/min milliliters per minute

mm millimeters

μm micrometer

ppm parts per million

psig pounds per square inch

scfh standard cubic feet per hour

V Volt

" inches

Ω ohm

% percentage

Michell Instruments xi

Page 12

XTC601 User’s Manual

1 INTRODUCTION

This manual will show how to measure binary or pseudo-binary gases easily using the

XTC601 Thermal Conductivity Analyzer.

The following sections contain information about:

• Analyzer components

• Operating instructions

• Calibration and maintenance of the analyzer

• Installation

Please read this manual carefully and pay special attention to the safety warnings and

notifications.

NOTE: Warnings and important notifications are marked with bold text.

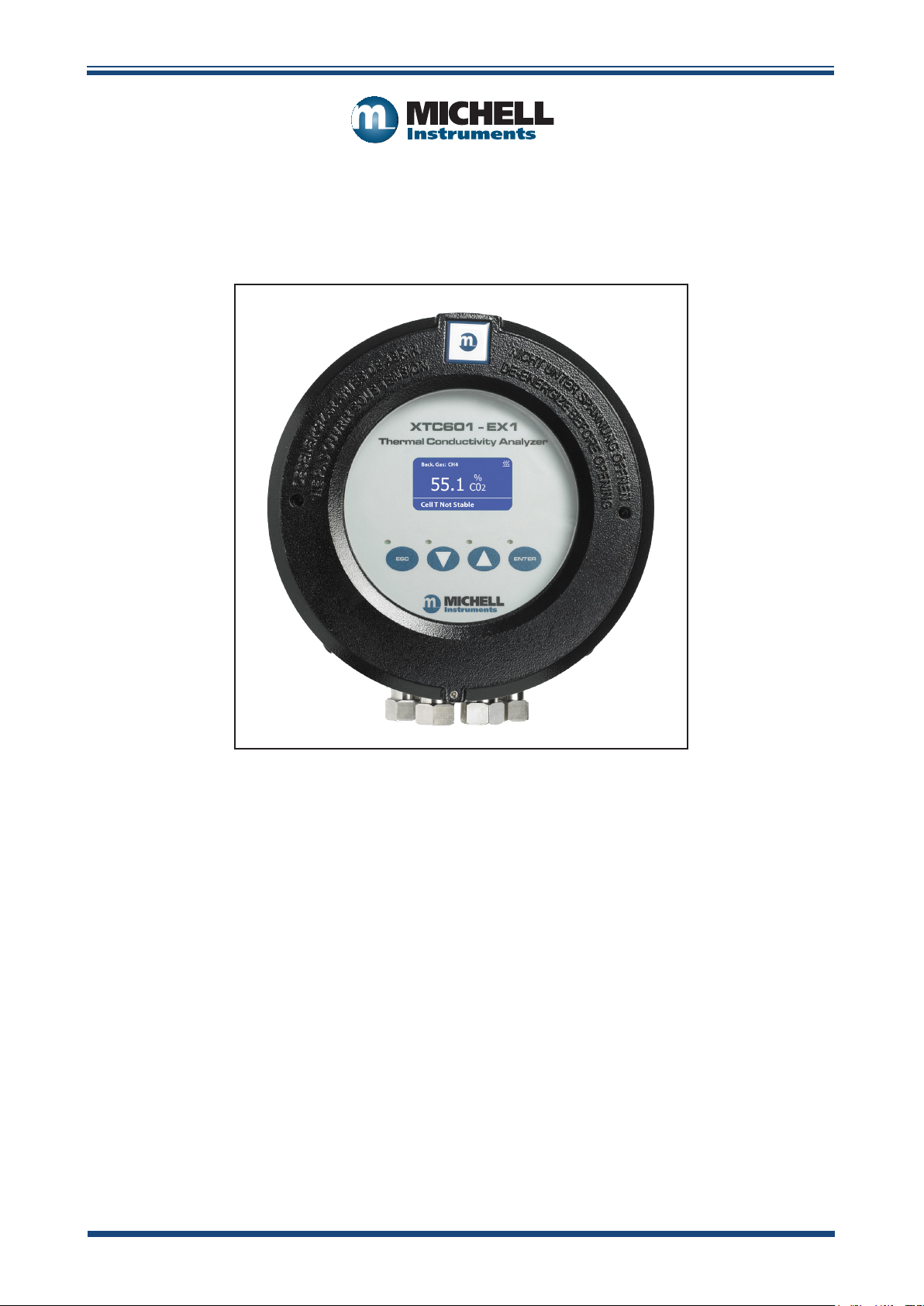

The 4 versions of the XTC601 available (with two or four gas ports) are shown below:

INTRODUCTION

GP1 or EX1 Version GP3 or EX3 Version

Analyzer with touch screen Transmitter

(capacitive buttons)

Back. Gas: CH4

%

55.1 C02

Cell T Not Stable

Figure 1

XTC601 Thermal Conductivity Analyzer Versions

The XTC601 Thermal Conductivity Analyzer is based on Michell Instruments’ advanced

proprietary technology. It measures the percentage levels of a Target Gas in a selection

of background gases, including nitrogen, hydrogen, carbon dioxide, methane and

biogas. The sensor is housed in a weather-proof (GP version) or explosion-proof (EX

version) casing - both IP66 & NEMA 4 rated. It is suitable for a range of applications in

safe or hazardous areas.

Michell Instruments 1

Page 13

INTRODUCTION

1.1 Features

• There are 2 casing versions of the XTC601 available, all of which can be

configured with 2 port (sealed reference) or 4 port (flowing reference):

• The XTC601 provides 2 off 4-20 mA analog output signals that are

proportional to the Target Gas concentration. The primary 4-20

mA output is locked on the calibrated range of the instrument. The

secondary output is user-selectable within the calibrated range.

• Modbus RTU over RS485 protocol serial communications are provided

as standard.

• Accuracy of 2% for standard ranges.

• Zero and span stability of 0.5% of span per month.

XTC601 User’s Manual

Analyzer with display and touch screen (capacitive) buttons

Transmitter

• The sensor used in the XTC601 Thermal Conductivity Analyzer has no

moving parts. This reduces sensitivity to vibration and movement.

• The robust and weather-proof enclosure (IP66 rated) allows the XTC601

to be installed on-site, at the point of measurement. The EX version

is housed in an explosion-proof casing, and is certified to II 2GD Ex d

IIB+H2 T3 Gb, Ex tb IIIC T137°C Db IP66 T amb -40°C to +55°C.

• All of the analyzer functions can be accessed via the touch screen

(capacitive) buttons, or via the Application Software.

• Low cost of ownership due to minimal maintenance. When required,

the casing unscrews to allow for easy access to the sensor, enabling

maintenance to be carried out quickly and easily.

• The XTC601 is certified to ATEX, IECEX, cCSAus & TC TR Ex for use in

hazardous areas.

• 2 x single pole change-over relay alarms for Target Gas concentration,

supplied as standard.

2 97400 Issue 2, July 2015

Page 14

XTC601 User’s Manual

1.2 Applications

The XTC601 binary gas analyzer is designed for use in process environments.

A sample system may be required to ensure that a clean, dry gas with no particles

or oil-mist is delivered to the XTC601. This will ensure the sensor is not damaged or

contaminated by the process. Michell Instruments is able to supply a quotation for such

a system.

Examples of applications include:

• H2 generator cooling systems (Power Generation)

INTRODUCTION

• H

• CO

• CO

in heat treatment furnaces (Metals)

2

in fermentation process (Food)

2

in biogas

2

• Ethylene Oxide sterilization process (Food)

• H

• H

in blast furnace top gas (Steel)

2

in hydrocarbons (Petrochemical)

2

• He recovery (Industrial Gas)

• N

• SF

in CO2 (Industrial Gas)

2

in switchgear

6

1.3 O-Ring Selection

The XTC601 has only one elastomeric seal in the gas path. There are 3 types of O-rings

available to offer greater flexibility with material compatibility. The Viton O-ring is fitted

as standard. The EKRAZ O-ring is available for solvent resistance. For extremely low

temperatures there is a closed cell Silicone O-ring.

To comply with Hazardous Area certification, the material used in the EX1 & EX3 versions

is dependent on the lowest ambient temperature of the area the units are to be installed

in:

Ambient operating range:

-40°C to +55°C (-40°F to +131°F) (for Silicone O-ring)

-15°C to +55°C (+5°F to +131°F) (for Viton O-ring) - Standard

-10°C to +55°C (+14°F to +131°F) (for Ekraz O-ring)

Michell Instruments 3

Page 15

OPERATION

2 OPERATION

This analyzer has been manufactured within our quality procedures and is configured

according to the purchase order. When it is installed and used as per the manufacturer’s

guidelines, it will operate within the stated specification.

Before starting operation it is recommended that the user becomes familiar with this

manual in which all the equipment controls, indicators, the elements of the display and

the overall menu structure are described.

XTC601 User’s Manual

The XTC601 is not certied for use with enriched Oxygen

samples in a hazardous area.

2.1 Preparation

Zero and Span gas cylinders with correct regulation and flow control should be in place

before installing and powering up the analyzer. Commissioning should include a check

with both gases and, if necessary, a field calibration performed.

All analyzers will be calibrated with an inlet pressure of 1 barg (14 psig) with an

atmospheric vent and flow rate of 300 ml/min (0.63 scfh). The calibration gas applied

to the analyzer should be at the same pressure and flow rate as the process gas being

sampled.

• Sample Inlet Pressure: 0 to 3 barg (0 to 43 psig) with atmospheric vent

Before applying power and beginning the ow of gas,

please ensure that the system has been properly installed

following the instructions in Section 4.

Check that the wiring has been completed correctly.

• Sample Flow Rate: 100 to 600 ml/min (0.2 to 1.27 scfh)

4 97400 Issue 2, July 2015

Page 16

XTC601 User’s Manual

2.2 Powering up the Analyzer

After all the preparation work has been done and the

installation and wiring have been checked, turn on the

analyzer and wait for at least 45 minutes (or until

T Not Stable

analyzer to reach its operating temperature of +50°C

(122°F) and protect it from any condensation forming in

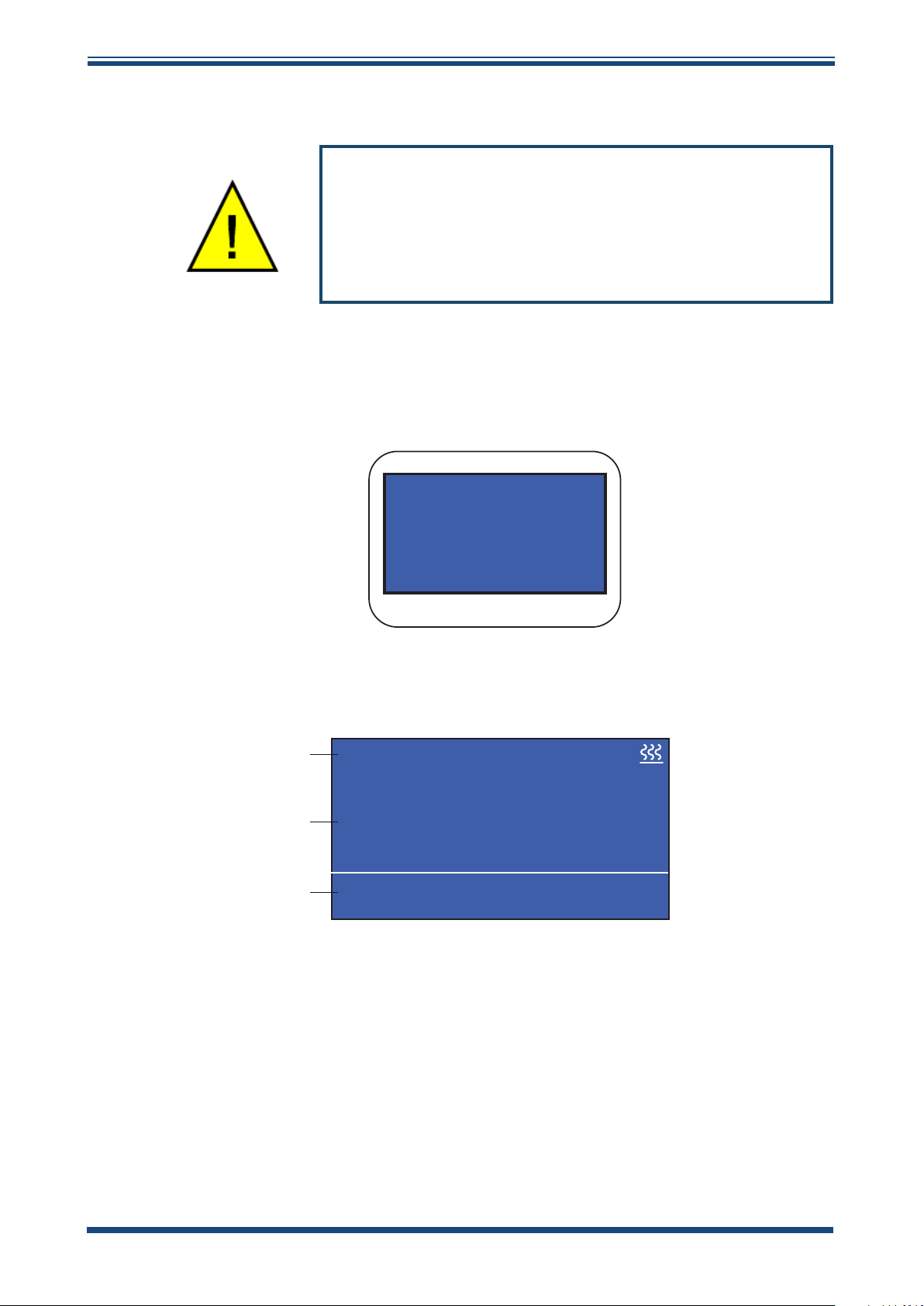

There is no power switch on the XTC601 Thermal Conductivity Analyzer. It is turned on

automatically once a 24 V DC power source is applied. After the analyzer is powered

up, the display will be illuminated. The analyzer takes up to 5 seconds to initialize, and

during this period will display the product type and firmware version number.

OPERATION

Cell

message disappears). This will allow the

the sensor.

Background

Gas

CO2

Concentration

Status Bar

XTC601

Ver. *.**

Figure 2

Back. Gas: CH4

Initializing Screen

55.1 C02

Cell T Not Stable

Figure 3

%

Main Page

Once initialized, the analyzer will show the Main Page which displays the Target Gas

concentration and the background gas that the unit has been calibrated in.

During warm-up (less than 30 minutes) a heating symbol will flash in the top right

hand corner of the page. This symbol will remain for a minimum of 15 minutes until the

temperature has stabilized. The analyzer will be ready for use within 45 minutes from

power-up.

Michell Instruments 5

Page 17

OPERATION

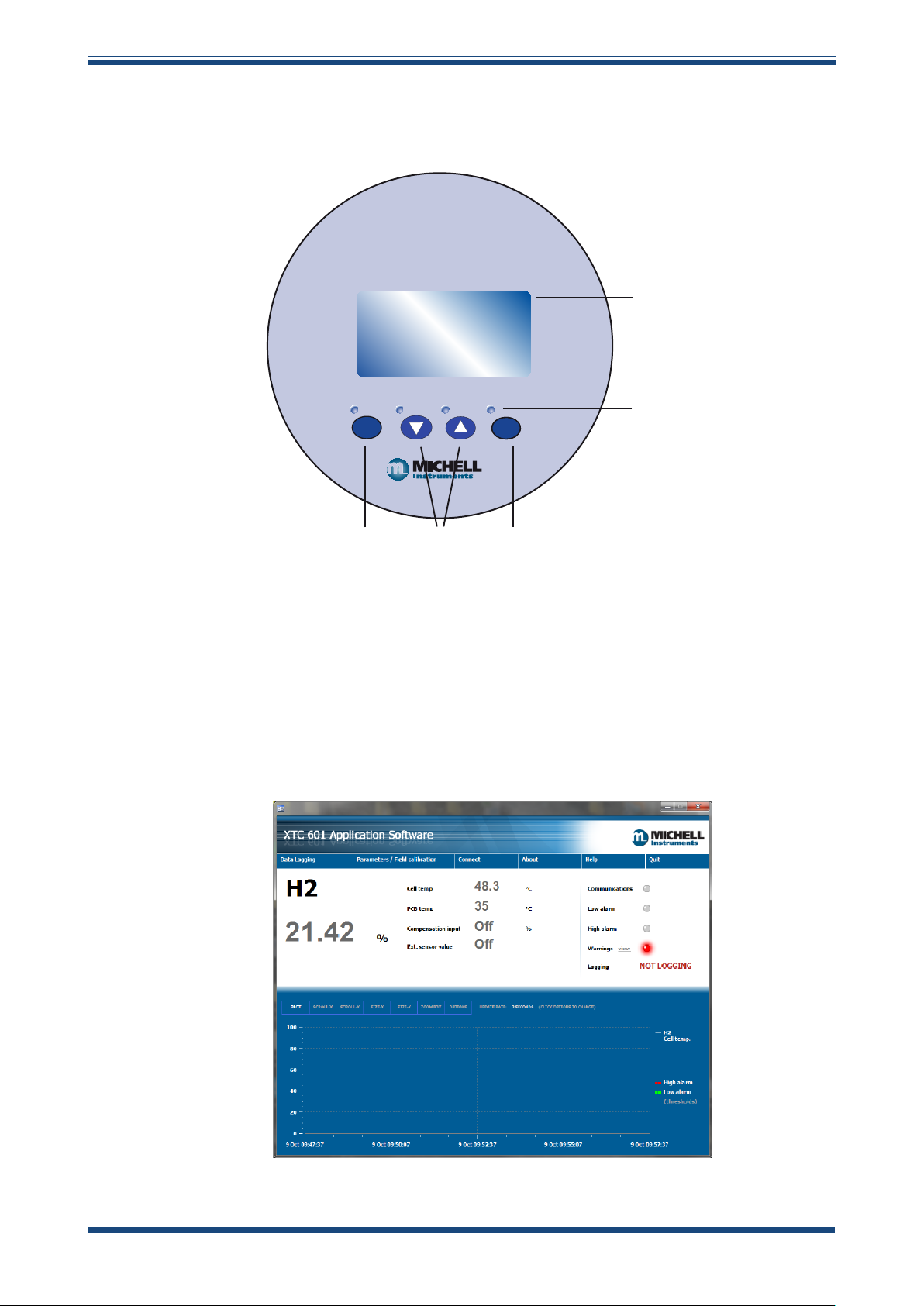

2.3 User Interface

2.3.1 Interface Controls

XTC601-EX1

Thermal Conductivity Analyzer

XTC601 User’s Manual

Backlit LCD

ESC

ESC

Button

Up/Down

Arrow

Buttons

Figure 4

ENTER

ENTER

Button

User Interface

Blue LEDs

The diagram above illustrates the user interface, which consists of a backlit Liquid

Crystal Display and 4 touch-sensitive pads that facilitate user interaction through the

glass of the enclosure.

All versions have Application Software to monitor or adjust parameters.

Figure 5

XTC601 Application Software

6 97400 Issue 2, July 2015

Page 18

XTC601 User’s Manual

2.3.2 ‘ESC’ Button

OPERATION

ESC

The ESC button is used to exit the current menu and to return to the previous menu.

From the Main Page, pressing

2.3.3 ‘Up/Down Arrow’ Buttons

Figure 7

The Up () and Down () buttons are used to change pages, scroll through lists and

adjust values.

Figure 6

ESC Button

ESC will access the Info Page.

Up/Down Arrow Buttons

In the Reset and Field Calibration Menus, pressing the

confirm a selection.

2.3.4 ‘ENTER’ Button

The ENTER button is used to select or de-select the highlighted item in a menu and to

confirm a value.

From the Main Page, pressing

Up () button 3 times will

ENTER

Figure 8

ENTER Button

ENTER will access the Passcode Page.

Michell Instruments 7

Page 19

OPERATION

2.4 Menu Structure

The EX1 and GP1 versions of the XTC601 have front pages that do not require a

passcode but allow the user to scroll through and view Target Gas concentration, recent

trend, internal parameters, minimum & maximum concentration and alarm history.

In order to change any settings on the User Menu pages, the user must enter a passcode.

There is also a separate passcode for service engineers to allow factory setting changes.

XTC601 User’s Manual

To access the User Menu press the

passcode prompt. Use the

each value.

The User Passcode is:

From the Main Page the user can press the ESC button to view the Info Page. This page

shows the firmware version, hours used, last calibration date, calibration pressure and

the received Modbus code.

The user will be able to set up and access all functions of the transmitter versions via

the Application Software supplied. The passcode is the same as with the EX1 and GP1

versions (

The passcode is stored for one minute to allow access back into the User Menu, if

necessary.

1919). The Application Software will be supplied on a CD with the unit.

Up () and Down () buttons and press ENTER after

1919

ENTER button from the Main Page to call up a

8 97400 Issue 2, July 2015

Page 20

XTC601 User’s Manual

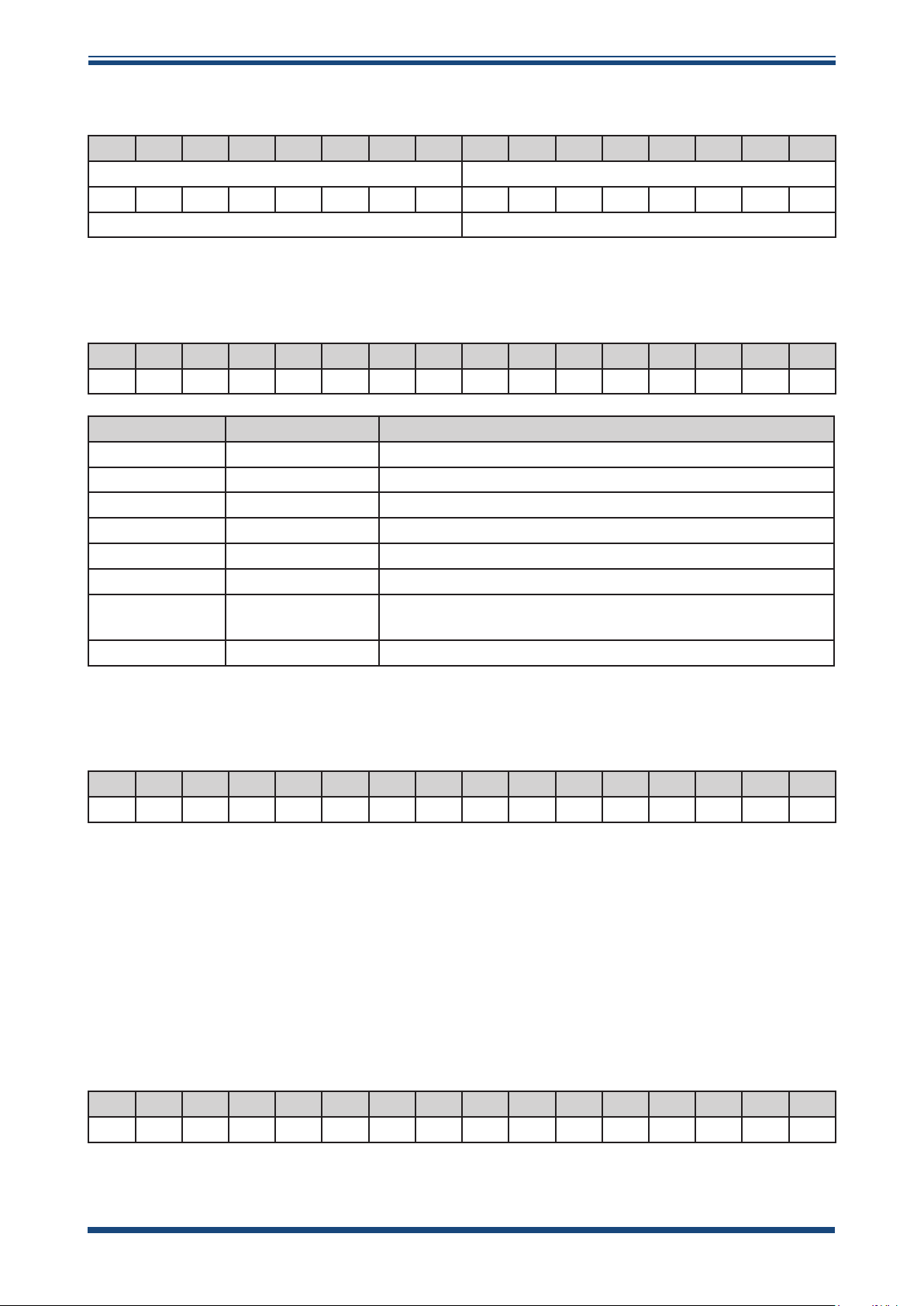

2.4.1 Menu Map

ENTER

FIELD CAL

EXT COMP

LIMIT 0-100%

MODBUS ID

CONTRAST

BRIGHTNESS

TEMPR UNIT

EXT PRESS UNIT

CHART INTVAL

DATE

MIN/MAX

FIELD CAL

LO ALARM SP

HI ALARM SP

CH2 OUT ZERO

CH2 OUT SPAN

COMP 20%

COMP 40%

COMP 60%

COMP 80%

COMP 100%

EXT.SENS PV

EXT.SENS MIN

EXT.SENS MAX

UNIT

HOURS

MINS

DAY

MONTH

YEAR

LIVE CLOCK

CAL TYPE

REF GAS 1

ACTUAL 1

REF GAS 2

ACTUAL 2

LIVE % TG

SETTINGS

HMI

RESET

OUTPUTS

USER SETUP PAGES

EXT COMP.

EXT SENS.

CLOCK

FIELD CAL

USER MENU

ON/OFF

ON/OFF

ON/OFF

1-128

SETTINGS

O-100%

O-100%

C/F/K

psia, bara, kpa

4-60s

US/Non US

HMI

RESET?

DELETE?ALARM LOGS

DELETE?

RESET

0.00-100.00%

0.00-100.00%

0.00-100.00%

0.00-100.00%

OUTPUTS

0.50-2.00

0.50-2.00

0.50-2.00

0.50-2.00

0.50-2.00

EXT COMP

TEMPR, etc

-50.0

100.0

ºC, etc

EXT SENS

00-23

00-59

1-31

1-12

00-99

**:**:**

CLOCK

1/2 POINT

0.00-100.00

0.00-100.00

0.00-100.00

0.00-100.00

FIELD CAL

Passcode

1919

OPERATION

XTC601

Ver: 1.01

INT. SCREEN

Back. Gas: CH4

55.1 C02

Cell T Not Stable

58

ESC

%

52

t-4

CELL T ºC 50.0

PCB TEMP, ºC 28

COMP I/P OFF

EXT I/P OFF

MINIMUM 0.00 %C02

D 12/01 T 19:29:44

MAXIMUM 0.00 %C02

D 12/01 T 19:29:44

ALARM DATE TIME P1

ALARM DATE TIME P1

LOW 02/01 12:50:40

LOW 02/01 12:50:40

HIGH 02/01 11:10:32

HIGH 02/01 11:10:32

LOW 02/01 11:00:29

LOW 02/01 11:00:29

HIGH 02/01 10:20:00

HIGH 02/01 10:20:00

%

or

or

or

or

FRONT PAGES

ENTER

t

ESC

Firmware Ver

Hours Used

Last Cal Date

ModBus Rx Code

INFO PAGE

Enter PassCode

0 0 0 0

PASSCODE PAGE

1.01

125

04:01:14

---

Figure 9

Menu Map

2.5 Front Pages (No Passcode Required)

The EX1 and GP1 versions of the XTC601 have 5 front pages that the user can display

without the need for a passcode. NOTE: These are for display of information only

and there is no way of adjusting any settings on these pages.

From the Main Page (Target Gas concentration) the rest of the front pages can be

accessed using the

() button the required amount of times or press the

Down () button. To return to the Main Page, either press the Up

ESC button.

Michell Instruments 9

Page 21

OPERATION

2.5.1 Main Page

Main Page Description

XTC601 User’s Manual

Back. Gas: CH4

%

55.1 C02

Cell T Not Stable

Background Gas

Target Gas

Heating Symbol

Status Bar

Status Message Table

Message

(Trigger Condition)

Displays the background gas the unit was calibrated in

Target Gas reading in %

Display Resolution = 0.1

This flashes until cell temperature is stable at set point ±0.15°C

for minimum of 15 minutes

Flashes any system warnings and error messages (see below)

Out of range

(beyond calibration range, e.g. 0-25%)

Low alarm ON

High alarm ON

Comp i/p signal error

(input < 3.6 mA or > 21 mA)

Ext sens signal error

(input < 3.6 mA or > 21 mA)

Status LED

N/A

ORANGE1 ON (app s/w only)

ORANGE2 ON (app s/w only)

RED FLASH

(priority2)

RED FLASH

(priority2)

Cell T not stable

(not within ±0.15ºC of set point for continuous period

of 15 minutes)

Cell T sensor error

(cell temp measures <-50 or >+80ºC)

Sensor error

(Vcomp <3400 or >7000)

PCB temp too high

(PCB temp > cell temp set point)

10 97400 Issue 2, July 2015

RED ON

(priority1)

RED ON

(priority1)

RED ON

(priority1)

RED ON

(priority1)

Page 22

XTC601 User’s Manual

2.5.2 Chart Page

• This indicative chart is continuously running at the set Chart Interval (2

to 60 seconds).

• It is auto ranging with an auto range resolution of 1%.

• It is reset if the Chart Interval is changed or the instrument power is

cycled.

25

%

0

t-4

OPERATION

t

• Chart buffer size is 60 values and therefore the chart duration changes

according to interval chosen.

• Chart duration in seconds = (Chart interval * 60).

• Chart data is only stored in volatile memory and therefore is not saved.

Chart interval is saved and available in a Modbus register.

• Chart data is not available via serial comms or in the blind unit as the

Application Software is able to perform more sophisticated charting

functions.

NOTE: This data is not available via the Modbus

Michell Instruments 11

Page 23

OPERATION

2.5.3 Secondary Parameters Page

CELL T, °C 50.0

PCB TEMP, °C 28

COMP I/P OFF

EXT I/P OFF

Parameter Description

XTC601 User’s Manual

CELL T

PCB TEMP

COMP I/P

Sensor cell temperature display in set unit (°C, °F or Kelvin)

Display Resolution = 0.1

Temperature display of Microcontroller in selected temperature unit

This gives an indication of the internal GUB temperature

Display Resolution = 1 unit

Accuracy = ±2ºC

The value of compensation input (mA i/p channel 1) as a %

(4 mA=0% and 20 mA=100%)

OFF displayed instead of value if external compensation is turned off

Value of the external input in the selected parameter and unit

EXT I/P

2.5.4 Target Gas Min/Max Page

(DEWP, TEMPR, PRESS, OTHER or NONE)

OFF displayed instead of value if external compensation parameter is set

to

NONE

MINIMUM 0.00 %CO2

D12/01 T 19:29:44

MAXIMUM 0.00 %CO2

D12/01 T 19:29:44

This indicates the minimum and maximum Target Gas values measured, along with date/

time of occurrence. The value is reset manually via the Reset Page in the User Menu.

This data is not saved in NV memory and is not available via serial communications or

in the blind unit.

12 97400 Issue 2, July 2015

Page 24

XTC601 User’s Manual

2.5.5 Alarms Log Pages

A maximum of 40 High/Low alarms, along with date and time of occurrence, are

recorded in a ring buffer in NV memory. The most recent alarm will overwrite the oldest

alarm when more than 40 alarms are recorded. The data is displayed over a maximum

of 10 pages (with 4 alarms on each page). The latest alarm record is displayed in line

1 of page 1. This data is not available via serial communications or in the blind unit.

The data is reset manually via the Reset Page in the User Menu. The data is saved and

restored when the instrument is restarted.

OPERATION

ALARM DATE TIME P1

LOW 02/01 12:50:40

HIGH 02/01 11:10:32

LOW 02/01 11:00:29

HIGH 02/01 10:20:00

2.6 Info Page

From the Main Page it is possible to get to the Info Page by pressing the ESC button.

Parameter Description

Firmware Ver

Hours used

Last Cal Date

ModBus Rx Code

Firmware Ver

Hours Used

Last Cal Date

ModBus Rx Code

Indicates the firmware version installed in the instrument

Indicates the number of hours that the instrument has been

powered up

The date of the last field or Michell Calibration

Character indicates

The received Modbus function code is flashed here as soon as

a function code is received – this is useful to check the Modbus

communications to ensure that good data is coming through.

If no code is received then ‘

F for Field and M for Michell

1.01

125

04:01:14 M

---

---’ is displayed

Michell Instruments 13

Page 25

OPERATION

2.7 User Set-Up Variables (Passcode Required)

In order to change any settings on the User Menu pages, the user must enter a passcode.

There is also a separate passcode for service engineers to allow factory setting changes.

XTC601 User’s Manual

To access the User Menu press the

passcode prompt. Use the

each value.

The User Passcode is:

Up () and Down () buttons and press ENTER after

1919

SETTINGS

HMI

RESET

OUTPUTS

Use the Up () and Down () buttons to select the sub-menu required. Then press

the

ENTER button. This will give access to one of the following pages.

ENTER button from the Main Page to call up a

EXT COMP.

EXT SENS.

CLOCK

FIELD CAL

14 97400 Issue 2, July 2015

Page 26

XTC601 User’s Manual

2.7.1 Settings Page

OPERATION

FIELD CAL

EXT COMP

LIMIT 0-100%

MODBUS ID

The analyzer is microprocessor-based and, as such, has settings and features accessible

to the user.

Select the parameter required. The options will be highlighted and can be toggled

between by pressing the

which, if only one analyzer is connected to your system, should be set to ‘

Parameter Description/Operation Options

Turns use of field calibration on or off

FIELD CAL

EXT COMP

LIMIT

0-100%

Modbus ID

It is automatically turned off when Michell or field

calibration is being performed

Turn externals sensor compensation on or off

It is automatically turned off when Michell or field

calibration is being performed

Limits the % Target Gas so that any drift below 0.00 and

above 100.00 (for suppressed zero) is not visible

mA outputs also limited accordingly

Unit’s network address for Modbus communications

ENTER button. These are all ON/OFF except for Modbus ID

ON/OFF

ON/OFF

ON/OFF

1/128

1’.

ON/OFF

ON/OFF

ON/OFF

1-128

Michell Instruments 15

Page 27

OPERATION

2.7.2 Human Machine Interface (HMI) Page

XTC601 User’s Manual

CONTRAST

BRIGHTNESS

TEMPR UNIT

EXT PRESS UNIT

CHART INTVAL

DATE

It is possible to change parameters within the HMI, as shown below:

Parameter Description/Operation Options

CONTRAST

BRIGHTNESS

TEMPR UNIT

EXT PRESS UNIT

CHART INTVAL

DATE

LCD contrast setting

LCD backlit setting

Global temperature unit selection

Pressure unit selection (for external

sensor only)

Chart interval

Date on the LCD can be either US

or Non US format

0-100%

0-100%

C/F/K

psia, bara, kpa

2-60s

US/Non US

0-100% in 10% steps

0-100% in 10% steps

psia, bara, kPa

2-60 s in 2 sec steps

US / Non US

ºC, ºF, K

2.7.3 Reset Page

Min/Max and Alarm Logs can be cleared from this menu. See Sections 2.5.4 and 2.5.5

respectively for more information.

This menu can also be used to restore the original calibration settings. For more

information see Section 3.3.

To reset/delete highlight the item use the

the option, then press the

to deselect the option.

MIN/MAX

RESET?

DELETE?ALARM LOGS

FIELD CAL

Up () button 3 times to confirm the change. Press ENTER

DELETE?

Down () button. Press ENTER to select

16 97400 Issue 2, July 2015

Page 28

XTC601 User’s Manual

2.7.4 Outputs Page

OPERATION

LO ALARM SP 0.00-100.00%

HI ALARM SP

CH2 OUT ZERO

CH2 OUT SPAN

The analyzer has two 4-20 mA outputs and 2 concentration alarm relays. The primary

4-20 mA is fixed to the calibrated range of the unit, the second is freely selectable

within this range. The alarm relays are Single Pole Change-Over (SPCO) and are also

freely assignable within the calibrated range. The alarm relays are rated to 250 V, 5 A

maximum.

Parameter Description/Operation Options

LO ALARM SP

HI ALARM SP

% set point for lo alarm relay Range Min to Range Max

% set point for hi alarm relay Range Min to Range Max

0.00-100.00%

0.00-100.00%

0.00-100.00%

CH2 OUT ZERO

CH2 OUT SPAN

% point for 4 mA Range Min to Range Max

% point for 20 mA Range Min to Range Max

Michell Instruments 17

Page 29

OPERATION

2.7.5 External Compensation Page

XTC601 User’s Manual

COMP 20%

COMP 40%

COMP 60%

COMP 80%

COMP 100%

A 4-20 mA sensor may be used to compensate the % Target Gas reading for the effects

of process variables such as line pressure, flow, etc. The table of compensation factors

may be edited for 5 points along the compensation sensor range. The values would be

determined by applying the process variable at each point and noting the effect on the

% of Target Gas.

For example: a compensation is needed for line pressure. A 4-20 mA line pressure

sensor would be ranged over the compensation range. While the instrument reads a

fixed % Target Gas

pressure at 20% of range intervals.

At each point the compensation factor can be set between 0.5 and 2.

value, a table is created (see example below) while varying the

0.50-2.00

0.50-2.00

0.50-2.00

0.50-2.00

0.50-2.00

% of

Pressure

Pressure

TG reading

span

0 0% 20.91 20.91/20.91=1.00 1.00

1 20% 21.65 21.65/20.91=1.04 0.96

2 40% 23.56 1.13 0.88

3 60% 25.99 1.24 0.81

4 80% 29.66 1.42 0.70

5 100% 38.85 1.86 0.54

The compensation factor values are then entered into the External Compensation table

(excluding the 0% point as this will always be assumed to be 1 = no effect).

Below 0% (< 4 mA), the compensation factor is fixed to 1. Above 100% the compensation

factor is extrapolated beyond the last factor.

Effect =

(affected value

/ non affected

value)

Compensation

factor = 1 /

effect

18 97400 Issue 2, July 2015

Page 30

XTC601 User’s Manual

2.7.6 External Sensor Page

OPERATION

EXT.SENS PV

EXT.SENS MIN

EXT.SENS MAX

NONE

N/A

N/A

UNIT = N/A

This page sets up the type and range of the 4-20 mA external sensor signal that may

be connected to the XTC601 for viewing in the Main Page. The range is adjustable

between the MIN and MAX values but is not adjustable for

and 100%).

Parameter Description/Operation Options

The process variable that is being measured by

the external sensor

The options available are:

EXT.SENS PV

EXT.SENS

MIN

EX.SENS

MAX

UNIT

NONE - No external sensor connected

DEWP- Dewpoint

TEMPR - Temperature

PRESS - Pressure

OTHER - User-defined variable

Depends on parameter and unit settings:

Dew point: -100°C, -148°F, 173.0 K

Temperature: -50°C, -58°F, 223.0 K

Pressure: 0.0 psia, 0.0 bara, 0.0 kpa

Other: 0% (non adjustable)

Depends on parameter and unit settings:

Dew point: 20°C, 68°F, 293.0 K

Temperature: 100°C, 212°F, 373.0 K

Pressure: 44.1 psia, 3.0 bara, 304.0 kpa

Other: 100% (non adjustable)

These are related to the type of sensor selected

If

Other is selected, then the unit will be a % of

the overall range

Other setting (fixed at 0%

NONE, DEWP,

TEMPR, PRESS,

OTHER

minimum to

EXT.SENS MAX

EXT.SENS MIN

to maximum

ºC, ºF, K, psia,

kPa, bara, %

Michell Instruments 19

Page 31

OPERATION

2.7.7 Clock Page

XTC601 User’s Manual

HOURS 00-23

MINS

DAY

MONTH

YEAR

LIVE CLOCK

The real time clock and calendar is used to store date/time information for log data,

min/max data and date of calibration. On entering this page all fields are initialized with

the current values.

Parameter Description/Operation Options

HOURS

MINS

DAY

MONTH

YEAR

LIVE CLOCK

NOTE: This can be set via the Application Software and can accept the

computer’s time as the default time and date.

Hours

Minutes

Day

Month

Year

Current Time

00-59

1-31

1-12

00-99

**:**:**

00-23

00-59

1-31

1-12

00-99

**:**:**

2.7.8 Field Cal Page

Parameter Description/Operation

CAL TYPE

REF GAS 1

ACTUAL 1

REF GAS 2

ACTUAL 2

LIVE % TG

CAL TYPE

REF GAS 1

ACTUAL 1

REF GAS 2

ACTUAL 2

LIVE % TG

1 POINT or 2 POINT

Cal reference gas for 1 point cal, lower cal reference gas for 2 point cal

Actual measured TG for REF GAS 1

See Section 3.1

Upper cal reference gas for 2 point cal

Disabled if 1 point cal selected

Actual measured TG for REF GAS 2

See Section 3.2

Disabled if 1 point cal selected

Current TG reading

1/2 POINT

0.00-100.00

0.00-100.00

0.00-100.00

0.00-100.00

0.00-100.00

See Section 3 for field calibration procedure.

20 97400 Issue 2, July 2015

Page 32

XTC601 User’s Manual

2.7.9 Status LED or Light Guide

The Status LED or Light Guide options have identical functionality and take their input

from the same board. Therefore, only one of them can be selected.

For either option the information available is as follows:

Power LED

• Green LED On - indicates instrument power is on.

Status LED

• Red LED flashing - indicates when external compensation input or external

sensor is out of range (if either is selected to

mA or >21 mA (see Status Message Table in Section 2.5.1).

• Red LED On – indicates an internal sensor error or instrument cell

temperature not yet stabilized (see Status Message Table in Section 2.5.1)

– for LED indication this takes priority over external errors.

OPERATION

ON). Out of range is <3.6

These have been designed to follow the NAMUR standard.

Michell Instruments 21

Page 33

CALIBRATION

3 CALIBRATION

Factory Calibration:

The unit is factory calibrated at 5 points to maximize the accuracy over the desired

range. The calibration generally includes Zero & Span points as well as 3 intermediate

points. In the case of suppressed zero ranges the lowest concentration will replace the

Zero Point.

Field Calibration:

Like all process analyzers, the XTC601 will require periodic calibration. The frequency

entirely depends on the location, application and accuracy requirements of the user. The

typical calibration period is expected to be between 1 and 3 months. If the calibration

period is in excess of 1 month Michell recommends a Zero and Span calibration. The

user should establish a calibration frequency to ensure that the reading is within the

specifications required for the process.

XTC601 User’s Manual

NOTE: It is possible to switch off the Field Calibration and revert to the Factory

Calibration. This can be useful for diagnostic purposes if the reading is not

what is expected. The unit is delivered with a factory calibration and, as such,

would not have any field calibration data. As soon as the first field calibration

is performed, the field calibration setting is automatically switched on.

Preparation:

Go to Settings Page (see Section 2.7.1) and make a note of ON/OFF options for all

settings. Re-set these options after calibration.

Zero and Span gas cylinders with correct regulation and flow control should be in place

before installing and powering up the analyzer. Commissioning should include a check

with both gases and, if necessary, a field calibration performed.

All analyzers will be calibrated with an inlet pressure of 1 barg (14 psig) with an

atmospheric vent and flow rate of 300 ml/min (0.63 scfh). The calibration gas applied

to the analyzer should be at the same pressure and flow rate as the process gas being

sampled.

• Sample Inlet Pressure: 0 to 3 barg (0 to 43 psig) with atmospheric vent

• Sample Flow Rate: 100 to 600 ml/min (0.2 to 1.27 scfh)

22 97400 Issue 2, July 2015

Page 34

XTC601 User’s Manual

3.1 1 Point Calibration

This is a single point offset overlaid on top of the factory calibration. It is designed to

correct minor drift and minor changes during transit. This calibration makes the unit

very accurate at the calibration point and improves accuracy throughout the range.

The calibration gas should be of a value that is within the main area of interest, i.e.

if main points of interest for a 0-25% range instrument are around the 6% area then

apply a 6.51% calibration gas.

1. Apply the calibration gas and purge the unit for at least 5 minutes.

View the chart until a flat line shows for 1-2 minutes.

CALIBRATION

21

%

6

t-2

Figure 10

2. Press ENTER to open the Passcode Page - 1919 Passcode. Navigate to

the Field Cal page using the

CAL TYPE and set to 1 POINT. Press

3. Press

(

gas. NOTE: This value only needs to be set when using a new

gas cylinder. Press

4. Ensure the Adjusted value at the bottom of the page has stabilized

NOTE: There will be a ~ symbol next to 'Adjusted' while the

reading is stabilizing. When the ~ symbol disappears the

reading will be stable and the next change can be made.

ENTER to highlight REF GAS 1 and use the Up () and Down

) buttons to match the value of the concentration of the calibration

ENTER to de-select.

t

1 Point Calibration Page

Up () button. Press ENTER to highlight

7

%

6

t-2

ENTER to de-select.

t

5. Press

button 3 times. Ensure that the ACTUAL 1 value is now equal to the

Adjusted value (±0.01%). Press

return to the Main Menu.

6. The Adjusted reading will now be the same as that displayed on the

Main Page and be equal to the calibration gas.

7. The calibration process is complete. Return to sampling the process

gas.

NOTE: On entering the field calibration page (whether or not a change has

been made), the Pressure Compensation is switched off. After calibration go

to the Settings Page (see Section 2.7.1) and re-set any feature that may have

been turned off during the calibration process.

ENTER to highlight ACTUAL 1 value and press the Up ()

ENTER to de-select. Press ESC to

Michell Instruments 23

Page 35

CALIBRATION

3.2 2 Point Calibration

This is a 2 point adjustment that is overlaid on top of the factory calibration. It is

designed to correct minor drift and minor changes during transit. This calibration makes

the unit more accurate throughout the range than the single point calibration.

1. Apply the lower calibration gas and purge the unit for at least 5 minutes.

View the chart until a flat line shows for 1-2 minutes.

XTC601 User’s Manual

21

%

6

t-2

Figure 11

2. Press ENTER to highlight CAL TYPE and set to 2 POINTS. Press ENTER

to de-select.

3. Press

(

calibration gas. NOTE: This value only needs to be set when

using a new gas cylinder. Press

4. Ensure the Adjusted value at the bottom of the page has stabilized

NOTE: There will be a ~ symbol next to 'Adjusted' while the

reading is stabilizing. When the ~ symbol disappears the

reading will be stable and the next change can be made.

ENTER to highlight REF GAS 1 and use the Up () and Down

) buttons to match the value of the concentration of the lower

t

2 Point Calibration Page

7

%

6

t-2

ENTER to de-select.

t

5. Press

6. Apply the upper calibration gas and purge the unit for at least 5

7. Press

8. Ensure that the Adjusted value at the bottom of the page has stabilized.

9. Press

ENTER to highlight ACTUAL 1 value and press the Up ( ) button

3 times. Ensure that the ACTUAL 1 value is now equal to the Adjusted

value (±0.01%). Press

minutes. View the chart until a flat line shows for 1-2 minutes (see

above).

ENTER to de-select.

ENTER to highlight REF GAS 2 and use the Up () and Down

) buttons to match the value of the concentration of the upper

(

calibration gas. NOTE: This value only needs to be set when

using a new gas cylinder. Press

ENTER to de-select.

ENTER to highlight ACTUAL 2 value and press the Up ()

button 3 times. Ensure that the ACTUAL 2 value is now equal to the

Adjusted value (±0.01%). Press

return to the Main Menu.

ENTER to de-select. Press ESC to

24 97400 Issue 2, July 2015

Page 36

XTC601 User’s Manual

10. The Adjusted reading will now be the same as that displayed on the

Main Page and be equal to the upper calibration gas.

11. The calibration process is complete. Return to sampling the process

gas.

NOTE: On entering the field calibration page (whether or not a change has

been made), the Pressure Compensation is switched off. After calibration go

to the Settings Page (see Section 2.7.1) and re-set any feature that may have

been turned off during the calibration process.

NOTE: The Live % TG reading will now be the same as that displayed on the

Main Page and be equal to the upper calibration gas.

3.3 Field Calibration Reset

If the analyzer is displaying a different value to the expected reading, it is possible to

restore the unit to the original calibration settings it left the factory with. The analyzer

will still require calibration, but this will be made easier as the reading will be forced

back into the correct range.

CALIBRATION

This feature is accessed by selecting the Reset Page (see below).

MIN/MAX

RESET?

DELETE?ALARM LOGS

FIELD CAL

Select Field Calibration and press ENTER to highlight DELETE?, then press the Up ()

button 3 times to confirm the change. Press

DELETE?

ENTER to deselect the option.

Michell Instruments 25

Page 37

INSTALLATION

4 INSTALLATION

Before installing the analyzer, read through this manual carefully and take note of all

warnings.

XTC601 User’s Manual

Do not open the casing while powered-up in a hazardous

area.

Special care must be taken when the analyzer is

energized.

The XTC601-EX versions must only be installed by

suitably qualied personnel and in accordance with the

instructions provided and the terms of the applicable

product certicates.

Maintenance and servicing of the product must only be

carried out by suitably trained personnel or returned to an

approved Michell Instruments’ Service Center.

Before the cover is retted, the amepath/threaded joint

between the cover and body must be thoroughly wiped

clean of dirt, grit or other foreign substances and then a

thin coating of an approved form of non-setting grease

applied to joint/threads. Ensure gasket is free from

damage.

Threaded covers must be screwed down until fully tight

(at least 7 full turns) and then locked in position with the

hex key provided.

26 97400 Issue 2, July 2015

Page 38

XTC601 User’s Manual

4.1 Unpacking

If sold separately (not part of a sampling system), the XTC601 will be supplied in a

custom box which should be retained for future use (such as service return). The box

contains a small carton containing 2 lid keys and 1 hex key (for the grub screw). Any

cable glands supplied will also be in the smaller carton. The manual will be loose in the

main box.

Contents:

• XTC601 Thermal Conductivity Analyzer

• XTC601 97400 user’s manual

• Test result sheet

• Carton (containing: 2 x lid keys and 1 x hex key)

• Cable entry options (if ordered)

• Application software CD

INSTALLATION

4.2 System Components

The XTC601 Thermal Conductivity Analyzer benefits from a modular construction, with

the major parts of the analyzer shown below:

G

F

E

D

C

B

A

Figure 12

XTC601 Showing Major Components

A Instrument case

B Flowing reference gas inlet and outlet (if fitted)

C Sample gas inlet and outlet

D Measuring cell

E Quick release mechanism for display PCB

F Motherboard

G Power supply (24 V DC) connector (PL9)

Michell Instruments 27

Page 39

INSTALLATION

4.2.1 Casing

• General Purpose (GP) IP66 weather-proof

• Explosion Proof (EX) for installations in hazardous areas, certified to:

XTC601 User’s Manual

II 2 G Ex d IIB+H2 T3 Gb

II 2 D Ex tb IIIC T137°C Db IP66 T amb -40°C to +55°C

cCSAus - Class I, Division 1, Groups B, C, D

TC TR Ex-Cert - 1Exd IIB+H2 T3 Gb

4.3 Set-Up

• The XTC601 is designed to be panel or wall mounted. There are 2 bolt

holes and 2 lugs (1 per corner) see

be found in Appendix B. Mount the analyzer before attempting to remove

the lid.

WARNING: This unit is 24 V DC powered only!

• The EXd thread is greased and therefore it may be advisable to wear latex

gloves.

Figure 11

. Dimensional drawings can

• Ensure that the grub screw is loose, using the hex key (supplied), to

prevent scoring on the casing.

• Connect the earthing strap to the earth point on the right hand side of

the case.

• Remove the lid, using the lid keys (supplied). The lid will require a firm

grip to loosen.

Figure 13

XTC601 Lid Removal

M5 Locking Grub Screw

• If fitted, remove the display / status pcb via the two ¼ turn quick-connect

fittings.

• Disconnect the ribbon / interconnecting cable from the loose pcb.

28 97400 Issue 2, July 2015

Page 40

XTC601 User’s Manual

WARNING: Prior to connecting power, ensure the unit is

correctly earthed via the earth point on the right hand side

• Connect to the power and outputs (see Section 4.5).

• After making all necessary connections, reconnect the display / status pcb

via the ribbon/interconnecting cable & quick-connect fittings and replace

and screw down the lid until fully tight (at least 7 full turns).

• Use the hex key (supplied) to tighten the grub screw. NOTE: This is

necessary in order to adhere to the hazardous area certification

requirements.

• For operating instructions refer to Section 2.

4.4 Mechanical Installation

INSTALLATION

of the case.

WARNING: Unused cable entries must be appropriately

blanked to maintain the integrity of the Exd casing.

There are 3 cable entries on the bottom surface, towards the rear, that can be utilized

by the customer in a variety of manners. The following standard options are available:

Cable Gland, Conduit Entry, Blanking Plug or Light Guide.

Inlet Inlet

Outlet Outlet

Gas

Connections

Cable

Entries

Earthing

Point

Figure 14

XTC601 Gas Connections and Cable Entries

Michell Instruments 29

Page 41

INSTALLATION

4.4.1 Gas Connection Tape

The gas connections are on the bottom surface towards the front of the unit. The

standard fittings are ¼” NPT to ¼” tube. Optional ¼” NPT to 6mm tube adaptors are

available.

concentration is classed as enriched (>21% O2) any

PTFE tape used must be unsintered. This is to prevent

an explosion due to conventional PTFE tape acting as a

Unsintered PTFE tape is available as an accessory from Michell Instruments (PTFETAPE-02).

4.4.2 Sample Gas Requirements

Samples must have a dew point at least 10°C less than the cell temperature (so as not

to condense), be free from oil-mist and with particle size < 3µm. NOTE: There is NO

filtration inside the analyzer.

XTC601 User’s Manual

For Safe Area applications where the oxygen

potential fuel source.

• Sample Inlet Pressure: 0 to 3 barg (0 to 43 psig) with atmospheric vent

• Sample Flow Rate: 100 to 600 ml/min (0.2 to 1.27 scfh)

4.4.3 Calibration Gases

Cylinders of the appropriate Zero and Span gases should be available for installation

and commissioning. Dependent on the specific duty of the analyzer, these gases may

have a lead time of several weeks.

See Section 3 for more information. Contact your local Michell representative for

information on finding a local gas supplier.

30 97400 Issue 2, July 2015

Page 42

XTC601 User’s Manual

4.5 Electrical Installation

4.5.1 Power Supply and Input/Output Signal

The XTC601 requires 24 V DC power input at a maximum start-up current of 1.5 A.

All versions will use a braid screened multi-core cable. Ideally, one cable for signals

(PL4, PL5) and another cable for power (PL9) / relay contacts (PL1). Braid of cables

must be well terminated at the cable glands. Wire sizes should be between 28 to 16

AWG.

The terminal blocks for the power supply, input signal and output signal are located

underneath the lower PCB. NOTE: The terminal blocks are color co-ordinated to

match the connectors - make sure this color coding is adhered to.

Pin1 Pin1

Pin1

PL9 PL4

INSTALLATION

PL5

JMP3

Figure 15

4.5.2 Power Supply (PL9 - Green)

PIN 3 PIN 2 PIN 1

0 V N/C 24 V ±4 V

JMP4

Terminal Block Locations

Pin1

Relays

PL1

4.5.3 Analog Output

Two 4-20mA analog outputs are available. Both are for Thermal Conductivity

concentration. One is fixed on the calibrated range of the unit and the second can

be configured in the menu. NOTE: When the instrument is warming up (cell

temperature not stabilized) these outputs are set to 3.5 mA to indicate that

the instrument is not ready.

• The maximum mA output is approximately 25 mA

• The minimum mA output is approximately 0 mA

Michell Instruments 31

Page 43

INSTALLATION

XTC601 User’s Manual

4.5.4 Serial Output

The analyzer has Modbus RTU communications over RS485 protocol; please see

Application Software CD for more details.

• Type: Modbus RTU over RS485

• RS485: 2 wire (plus ground), half duplex

• Baud Rate: 9600

• Parity: None

• Data bits: 8

• Stop bits: 1

4.5.5 Analog (4-20 mA) Outputs and Communications (PL5 - Green)

PIN 7 PIN 6 PIN 5 PIN 4 PIN 3 PIN 2 PIN 1

RS485

GND

RS485

B

RS485

A

Ch2

O/P

-

Ch2

O/P

+

Ch1

O/P

Ch1

O/P

-

+

NOTE 1: Channel 1 is fixed range output over instrument range and Channel

2 is adjustable within instrument range.

NOTE 2: For long cable lengths, a termination resistor of 120Ω is provided to

aid in impedance matching of the communications cable. This is selectable

via JMP3. A terminating resistor is simply a resistor placed at the extreme

end or ends of a cable on an RS485 network to reduce effects of impedance

mismatch. Impedance mismatch can cause reflections of data as it passes

down the cable and the reflections could be large enough to cause data errors.

4.5.6 Alarm Relay Contacts (PL1- Black)

PIN 6 PIN 5 PIN 4 PIN 3 PIN 2 PIN 1

Hi Alarm

C

Hi Alarm

NO

Hi Alarm

NC

• Type: SPCO (NO, NC and C)

• Contact Rating, Max: 5 A, 250 V

• Hysteresis is 0.03%

Low Alarm

C

Low Alarm

NO

Low Alarm

NC

• AL1 and AL2 can be configured as OFF, LOW or HIGH

• A low alarm switches on when % O

is below the set point and switches

2

off when % O2 is above the set point + Hysteresis

• A high alarm switches on when % O

is above the set point and switches

2

off when % O2 is below the set point - Hysteresis

• When the instrument is warming up (cell temperature not stabilized) both

relays are OFF

32 97400 Issue 2, July 2015

Page 44

XTC601 User’s Manual

4.5.7 Analog (4-20 mA) Inputs and Sensor Excitation Voltage (PL4 - Green)

PIN 6 PIN 5 PIN 4 PIN 3 PIN 2 PIN 1

Ch2

I/P

-

The XTC601 features 2 input channels for 4-20 mA signal from external instruments such

as pressure transmitters or other devices to compensate for pressure or background gas

influence.

CH2

I/P

+

Ch2

Exc.V

Ch1

I/P

-

INSTALLATION

Ch1

I/P

+

Ch1

Exc.V

The input configured as

Parameters Page under the heading

NOTE 1: Channel 1 is External Compensation input and Channel 2 is External

Sensor input.

NOTE 2: Excitation voltage = Same as power supply ±1 V if JMP4 connected

across top 2 pins and 15 ±0.5 V (max 100 mA per channel) if JMP4 connected

across bottom 2 pins.

4.5.8 Light Guide

The optional light guide can be fitted to the left hand cable entry. If this is required for

the Hazardous Area version of the analyzer this must be specified at time of purchase

order. Only one light guide can be fitted to each analyzer.

EXT SENS (External Sensor) can be viewed on the Secondary

EXT I/P (External Input).

If tted in a Hazardous Area version of the XTC601-EX the

light guide MUST NOT be removed by the user. As part of

the certication it is individually pressure tested at the

factory.

Removal and re-tting will invalidate the certication.

Michell Instruments 33

Page 45

APPENDIX A

XTC601 User’s Manual

Appendix A

Technical Specications

34 97400 Issue 2, July 2015

Page 46

XTC601 User’s Manual

Appendix A Technical Specications

Performance

Measurement Technology Thermal Conductivity sensor

Measured Gases CO

Gas Requirements Non-condensing sample with particles <3μm

Measurement Range Selectable from 0-5 up to 0-100%

Display Resolution 0.1%

Display Type Backlit LCD

Intrinsic Error (Accuracy) < ±2% of span *

Response Time (T90) Standard < 20 seconds *

Repeatability ±0.2% of span

Linearity ±1% span

Zero Stability ±0.5% of span per month

Span Stability ±0.5% of span per month

, CH4, Ar, He, N2, H2 or Air

2

APPENDIX A

Sample Flow Rate 100 to 600 ml/min (0.2 to 1.27 scfh) with atmospheric vent

Sample Flow Effect

(cal at 300 ml/min (0.64 scfh))

Sample Pressure 0 to 3 barg (0 to 43 psig)

Sample Temperature 0 to 45°C (+32 to +113°F) max

Sample Cell Temperature Standard +50°C (+122°F)

< 1% of span for flows: 100 to 600 ml/min (0.2 to 1.27 scfh)

Electrical Specications

2 off 4-20 mA inputs

Analog Inputs

Analog Outputs 2 off 4-20 mA outputs (isolated)

Output Ranges

Alarms

Datalogging

Digital Communications Modbus RTU over RS485 Protocol

Power Supply 24 V DC; 1.5 A max

One for an external sensor that can be displayed on the screen

One to act as an active compensation for the process conditions

Primary range is set to the calibrated range of the instrument

The second is user selectable within the primary range

2 off single pole changeover (SPCO) relays for concentration

(250 V, 5 A max)

The user can use the digital communications to log the output

from the analyzer

The unit will store 40 alarm points and the min/max concentrations

with date and time stamp

Operating Conditions

Ambient Temperature

-20 to +55°C (+4 to +131°F)

(dependent on configuration)

Michell Instruments 35

Page 47

APPENDIX A

XTC601 User’s Manual

Mechanical Specication

Warm Up Time < 25 minutes

Stabilization Time 5 minutes

Dimensions 234 x 234 x 172mm (9.2 x 9.2 x 6.7”) (w x d x h)

Weight 9.7kg (21.4lbs)

Wetted Materials 316 stainless steel, boroscillicate glass, platinum, (plus O-ring)

O-Ring Materials Viton, Silicone or Ekraz

Gas Connection

1/4” NPT to 1/4” tube (standard)

1/4” NPT to 6mm tube (optional)

Ingress Protection IP66, NEMA 4

Hazardous Area Classication

ATEX II 2GD Ex d IIB+H2 T3 Gb

Certification Codes

IECEx Ex d IIB+H2 T3 Gb

ITC TR Ex 1Ex d IIB+H2 T3 Gb

cCSAus Class I, Division 1, Groups B C D,

Temperature Ranges for

ATEX and IECEx as per

O-ring type

Silicon: Ta = -40°C to +55°C

Viton: Ta = -15°C to +55°C

Ekraz: Ta = -10°C to +55°C

* The standard intrinsic error and response time will be as above. Certain gas combinations and/or

ranges may have different specifications. Please consult Michell Instruments for specific cases. For

example, CO

/ N2 would be < 50 seconds for T90.

2

NOTE: If the 4 port version is selected then a reference gas with a flow rate of 300ml/

min is required.

Ex tb IIIC T137°C Db IP66

Ex tb IIIC T137°C Db IP66

36 97400 Issue 2, July 2015

Page 48

XTC601 User’s Manual

APPENDIX B

Appendix B

Dimensional Drawings

Michell Instruments 37

Page 49

APPENDIX B

Appendix B Dimensional Drawings

234.0

O

11.5

172.0

O

XTC601 User’s Manual

9.0

172.0

11.5

172.0

195.0

12.0

171.0

195.0

82.5

12.0171.0

15.0

50.5

70.0

93.0

70.5

39.0

35.0

35.0

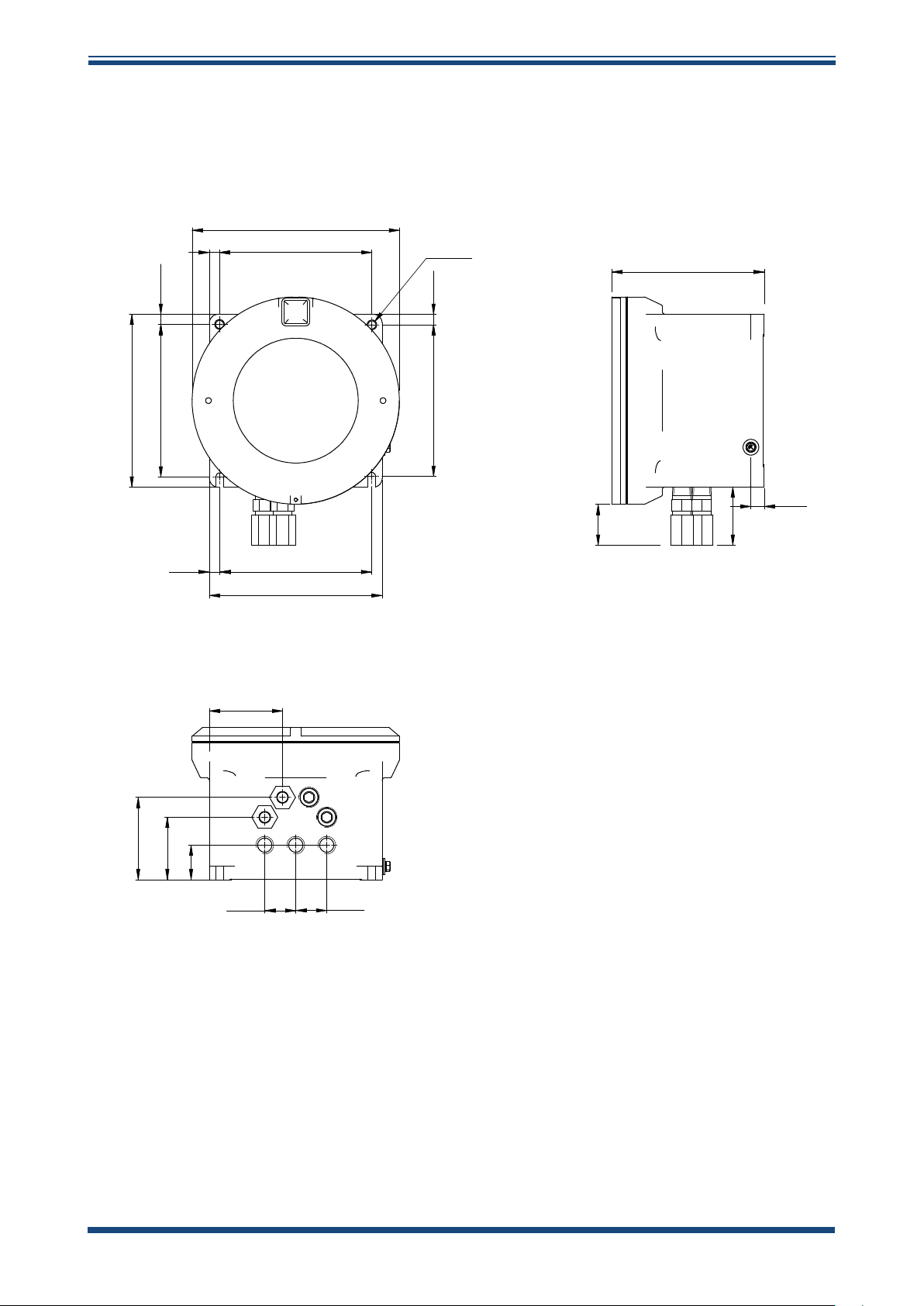

Figure 16

2 Port Dimensional Drawings

NOTE: Fixing mounts are NOT symmetrical.

This is to ensure correct orientation.

38 97400 Issue 2, July 2015

Page 50

XTC601 User’s Manual

234.0

O

11.5

11.5

172.0

APPENDIX B

O

9.0

12.0

172.0

172.0

195.0

171.012.0

195.0

20.0 30.0 20.0

93.0

70.5

39.0

35.0

35.0

171.0

15.0

50.5

70.0

Figure 17

4 Port Dimensional Drawings

NOTE: Fixing mounts are NOT symmetrical.

This is to ensure correct orientation.

Michell Instruments 39

Page 51

APPENDIX C

XTC601 User’s Manual

Appendix C

Relative Thermal

Conductivity Table

40 97400 Issue 2, July 2015

Page 52

XTC601 User’s Manual

APPENDIX C

Appendix C Relative Thermal Conductivity Table

Gas Temperature=0°C (32°F) Temperature=100°C (212°F)

Commonly Used

Helium, He 5.970 5.530

Hydrogen, H2 6.968 6.803

Water Vapor, H2O 0.755 0.771

Air, N2/O2 1.000 1.000

Nitrogen, N2 1.000 0.989

Oxygen, O2 1.018 1.028

Argon, Ar 0.677 0.665

Carbon Dioxide, CO2 0.603 0.704

Methane, CH4 1.250 1.450

Other Options

1,3 Butadiene, C4H6 0.441 0.642

Acetone, C3H6O 0.406 0.557

Acetylene, C2H2 0.770 0.900

Ammonia, NH3 0.897 1.040

Carbon Monoxide, CO 0.962 0.958

Chlorine, Cl2 0.323 0.340

Cyclohexane, C6H12 0.375 0.576

Ethane, C2H6 0.750 0.970

Ethyl Alcohol, C2H5OH 0.590 0.685

Ethyl Chloride, C2H5Cl 0.391 0.540

Ethylene Oxide, C2H4O 0.469 0.620

Ethylene, C2H4 0.720 0.980

Freon-11, CCl3F 0.286 0.368

Freon-113, C2Cl3F3 0.277 0.369

Freon-12, CCl2F2 0.344 0.442

Freon-22, CHClF2 0.388 0.474

Hydrogen Chloride, HCl 0.520 0.517

Hydrogen Sulfide, H2S 0.538 0.562

Isobutane, C4H10 0.569 0.776

Isopentane, C5H12 0.515 0.702

Isopropyl Alcohol, C3H7OH 0.492 0.644

Methyl Chloride, CH3Cl 0.377 0.530

n-Butane, C4H10 0.552 0.744

Neon, Ne 1.900 1.840