Page 1

Vapor Delivery System

VDS3

User’s Manual

97433 Issue 1.2

July 2016

Page 2

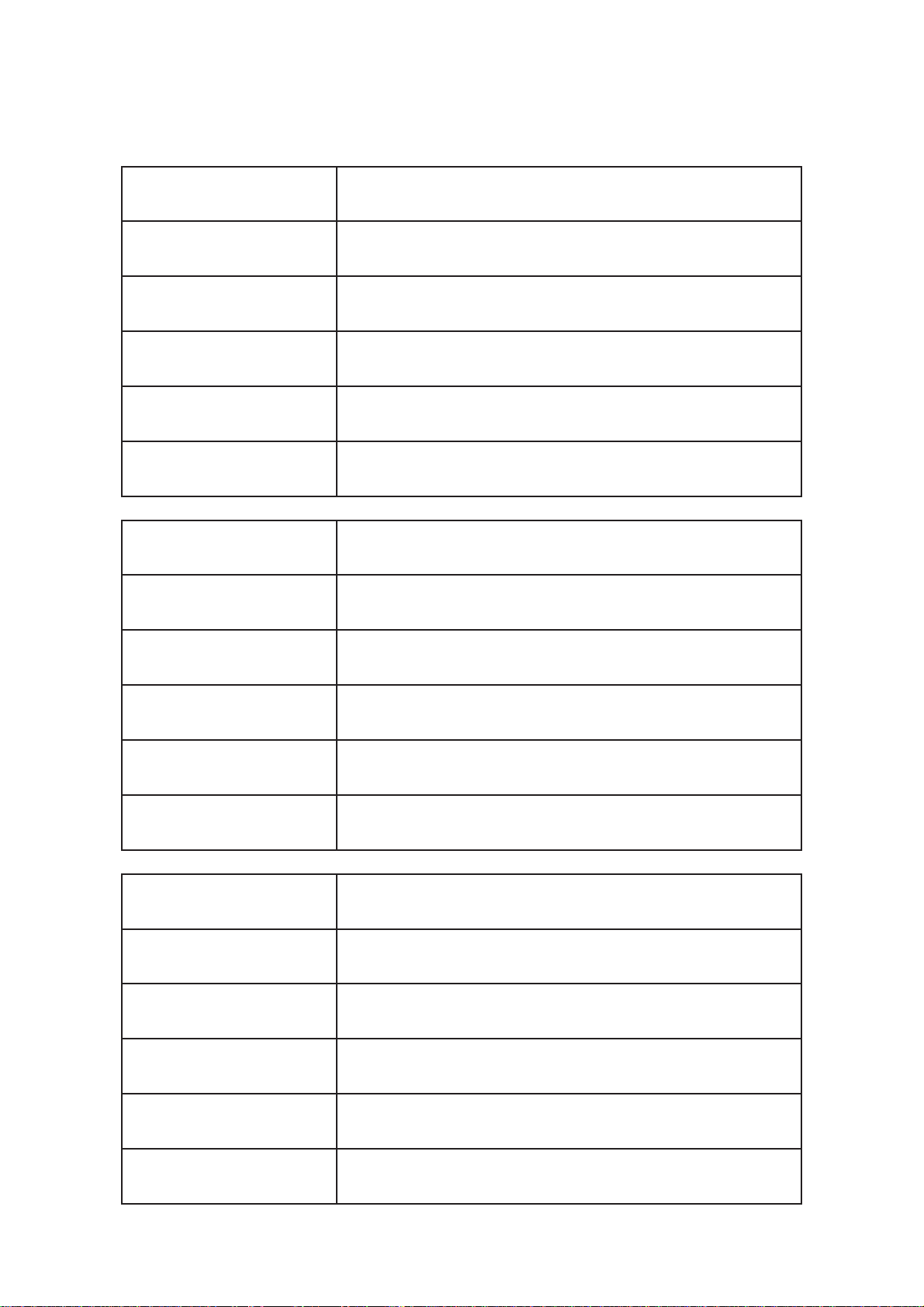

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

VDS3

For Michell Instruments' contact information please go to

www.michell.com

© 2016 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

VDS3 User’s Manual

Contents

Safety ................................................................................................................................vi

Electrical Safety ...........................................................................................................vi

Pressure Safety ............................................................................................................vi

Toxic Materials .............................................................................................................vi

Repair and Maintenance ...............................................................................................vi

Safety Conformity ........................................................................................................vi

Abbreviations .....................................................................................................................vii

Warnings ...........................................................................................................................vii

1 INTRODUCTION ................................................................................................1

1.1 Overview ........................................................................................................... 1

2 INSTALLATION ..................................................................................................2

2.1 Enclosure ...........................................................................................................2

2.2 Gas Connections ................................................................................................. 2

2.2.1 Dry Air Inlet .................................................................................................2

2.2.2 Dew-Point Outlet .......................................................................................... 2

2.2.3 Compressed Air ............................................................................................ 2

2.3 Electrical Connections ......................................................................................... 3

2.3.1 Power Supply ...............................................................................................3

2.3.2 PC Control Connection ................................................................................... 3

3 OPERATION ......................................................................................................4

3.1 Filling the Water Container .................................................................................. 4

3.2 'Start-Up' Procedure ............................................................................................4

3.3 Operating Software.............................................................................................5

3.3.1 Dew-Point Control ......................................................................................... 5

3.3.2 Readings ...................................................................................................... 6

3.3.3 Recording ..................................................................................................... 6

4 MAINTENANCE ..................................................................................................8

4.1 Routine ..............................................................................................................8

iv 97433 Issue 1.2, July 2016

Page 5

VDS3 User’s Manual

Figures

Figure 1 Gas Connections .........................................................................................2

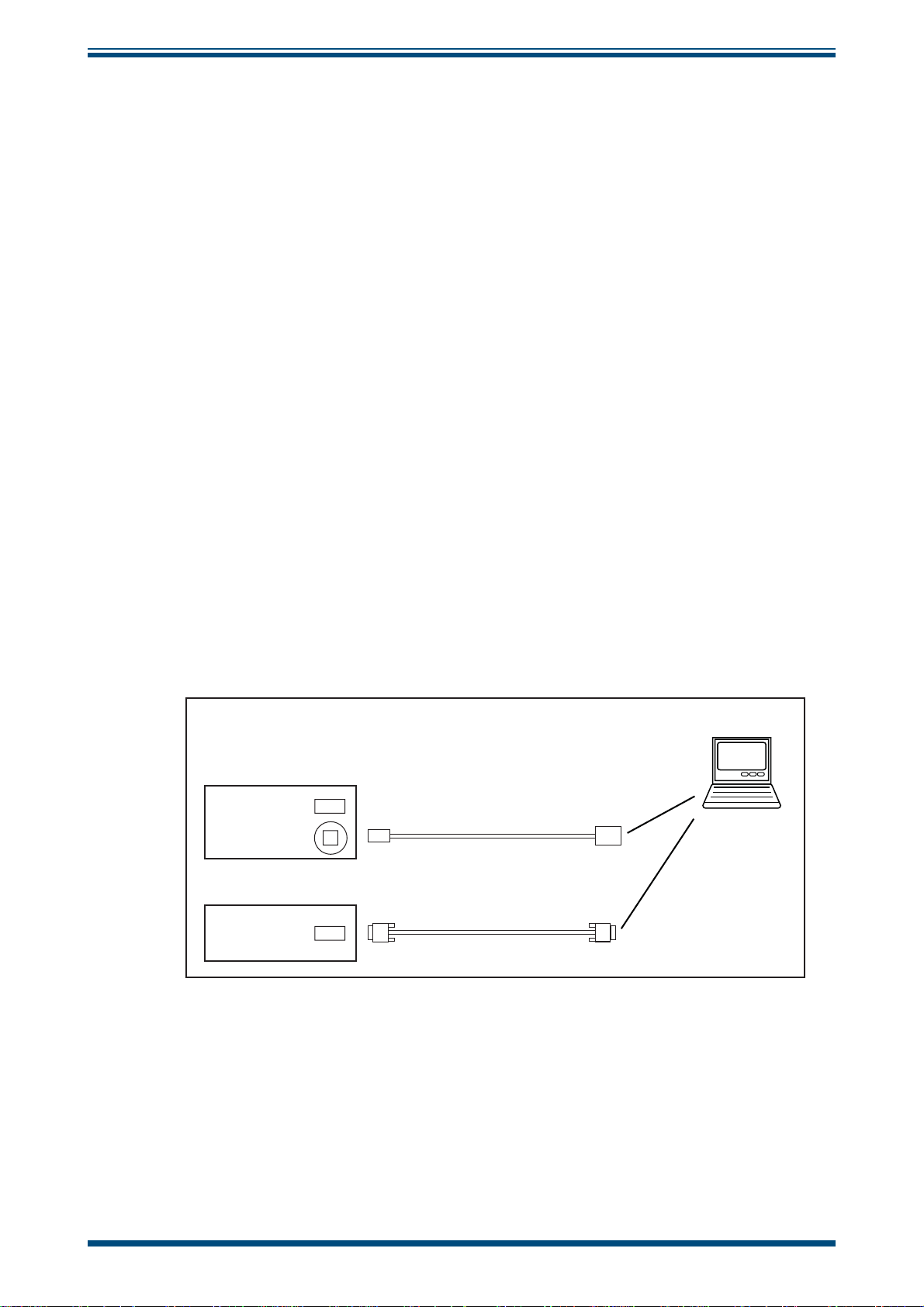

Figure 2 PC Control Connection ................................................................................3

Figure 3 Flow Diagram ...........................................................................................12

Figure 4 Set-Up Connection ....................................................................................14

Appendices

Appendix A Technical Specifi cations ..............................................................................10

A.1 General Arrangement ...................................................................11

A.2 Flow Diagram ..............................................................................12

Appendix B Set-Up Software / Adjustment of Setpoints ..................................................14

B.1 Set-Up Connection .......................................................................14

B.2 About the Software ......................................................................14

B.2.1 Initialization ................................................................................15

B.2.2 Manual Setting of Controllers ........................................................16

B.2.3 Programming the VDS ..................................................................19

Appendix C Quality, Recycling & Warranty Information ...................................................21

C.1 Recycling Policy ...........................................................................21

C.2 WEEE And RoHS Compliance ........................................................21

C.3 Manufacturing Quality ..................................................................21

C.4 Calibration Facilities .....................................................................22

C.5 Return Policy ...............................................................................22

C.6 Warranty .....................................................................................22

Appendix D Return Document & Decontamination Declaration ........................................24

Michell Instruments v

Page 6

VDS3 User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

qualifi ed personnel and good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument. The input power supply voltage limits are 220 to

240 V AC OR 100 to 120 V AC 50/60Hz.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied to the instrument.

The maximum safe inlet pressure is 4.8 barg (70 psig).

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide offi ces contact information.

Safety Conformity

This product meets the essential protection requirements of the relevant EU directives.

vi 97433 Issue 1.2, July 2016

Page 7

VDS3 User’s Manual

!

Abbreviations

The following abbreviations are used in this manual:

AC alternating current

atm pressure unit (atmosphere)

barg pressure unit (=100 kP or 0.987 atm) (gauge)

°C degrees Celsius

°F degrees Fahrenheit

dp dew point

EU European Union

Hz Hertz

IEC International Electrotechnical Commission

Nl/min normal liters per minute

mm millimeters

lb pound

psig pound(s) per square inch (gauge)

ppb

scfh standard cubic feet per hour

USB Universal Serial Bus

V Volts

W Watts

" inches

Warnings

The following general warnings listed below are applicable to this instrument. They are

repeated in the text in the appropriate locations.

parts per billion (volume)

V

Where this hazard warning symbol appears in the following

sections, it is used to indicate areas where potentially hazardous

operations need to be carried out.

Michell Instruments vii

Page 8

VDS3 User’s Manual

This page intentionally left blank

viii 97433 Issue 1.2, July 2016

Page 9

VDS3 User’s Manual

1 INTRODUCTION

1.1 Overview

The Michell VDS3 Vapor Delivery System is designed for use as part of a hygrometry

calibration system. It is capable of repeatable generation of set dew-point levels over

the range -100 to +20°C (-148 to +68°F) dew point.

The system is assembled within a small fl oor-mounted 19” equipment rack enclosure

fi tted with castors for ease of movement. The system requires a supply of high quality

dry gas with a moisture content of better than 1 ppbV (-100°C (-148°F) atmospheric

dew point) to enable the maximum range of dew points to be generated. The supply of

high quality dry gas can be provided by a Michell PSD4 Pressure Swing Dryer.

The vapor delivery system divides the dry gas into three controllable gas streams. One

of these streams passes through a controlled evaporator mixer and is then mixed by

volumetric ratios with the other streams to produce different factory pre-set dew point

values over the range -100 to +20°C (-148 to +68°F) (user confi gurable). These dew

points are selected remotely via a PC.

INTRODUCTION

Michell Instruments 1

Page 10

INSTALLATION

2 INSTALLATION

2.1 Enclosure

The instrument enclosure is designed for fl oor mounting (19” equipment mini-rack).

Castors are fi tted for ease of movement.

Access at the front, left hand side and rear is required for operation. Front and side

panels are removable for maintenance & servicing.

2.2 Gas Connections

2.2.1 Dry Air Inlet

The system must be supplied with high quality (oil free) dry compressed air to the same

specifi cation as used during its calibration/setup (< 1ppbV (-100°C (148°F) moisture

content).

The generator was calibrated/set -up using compressed air supplied from a Michell PSD4

Pressure Swing Dryer.

VDS3 User’s Manual

The input gas pressure is further regulated and controlled by an factory set pressure

regulator, located internally. NOTE: This regulator MUST NOT be adjusted!

The gas inlet connection is a stainless steel ¼” Swagelok VCR face seal bulkhead union

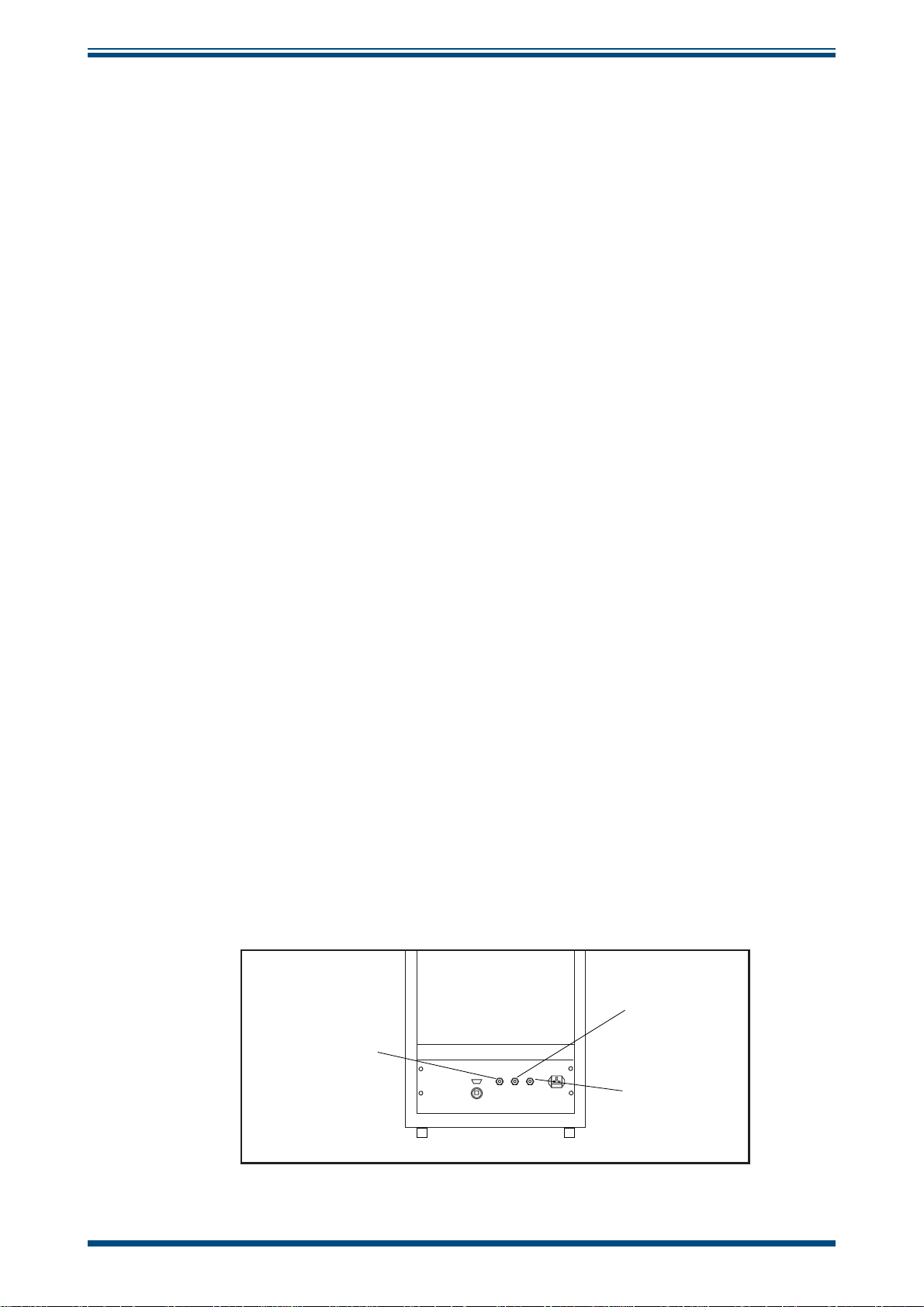

fi tting located on the rear panel of the unit marked

2.2.2 Dew-Point Outlet

The gas outlet connection is a stainless steel ¼” Swagelok VCR face seal bulkhead

union fi tting located on the rear panel of the unit marked

2.2.3 Compressed Air

The system requires a separate supply of oil-free compressed air for operating pneumatic

valves and pressurizing the water supply. The compressed air supply can be a normal

industrial compressed air quality (i.e. 5 to 7 barg (72 to 101 psig) @ -40°Cdp (-40°Fdp).

The compressed air inlet connection is a stainless steel 6mm Swagelok

tube fi tting located on the rear panel of the unit marked COMPRESSED AIR INLET.

GAS INLET.

GAS OUTLET.

®

bulkhead union

GAS OUTLET

(1/4” VCR FACE

COMPRESSED AIR

INLET

(6mm TUBE FITTING)

Figure 1

g

g

g

REAR VIEW

Gas Connections

SEAL FITTING)

GAS INLET

(1/4” VCR FACE

SEAL FITTING)

2 97433 Issue 1.2, July 2016

Page 11

VDS3 User’s Manual

2.3 Electrical Connections

2.3.1 Power Supply

100 to 120 V AC OR 220 to 240 V AC 50/60Hz power supply is required to operate this

instrument. Refer to the yellow label located on the rear panel of the unit for the correct

supply voltage required.

The power supply connection is via the 3-pin IEC fused plug located on the rear panel

of the unit. A 3 core power cable is provided, the free end of which should be wired to

a suitable earthed plug or directly via a fused power spur.

Power cable conductors are colored according to the convention:

Brown L (Live)

Blue N (Neutral)

Green/Yellow E (Earth/Ground)

INSTALLATION

2.3.2 PC Control Connection

Connect the host PC to the VDS via a USB connector located on the rear panel of the

unit marked

PC (CONTROL). A 3 meter USB cable assembly is provided and should be

connected as shown below:

VDS3

RS485 (SET UP)

PC (CONTROL)

S4000 Dewpointmeter

RS232

USB Cable

Serial Cable

Connect to spare

USB port

Host PC

g

g

Connect to spare

COMM Serial port

Figure 2

PC Control Connection

NOTE: Ensure that the S4000 Dewpointmeter is connected to the host PC to

enable the software to read and record dew points. If it is not connected the

software will not operate correctly.

Michell Instruments 3

Page 12

OPERATION

!

3 OPERATION

Before operation, the system needs to be fi lled with distilled water.

3.1 Filling the Water Container

This unit operates under pressure. Safety goggles should be

worn when fi lling the water container.

NOTE: Before attempting fi lling and subsequent top-ups, while the unit is

in operation, ensure that the water container is isolated by turning off the

water pressure valve (¼-turn clockwise) located alongside the display on the

front panel.

1. Remove the side panel to access the water container.

2. Slowly turn the big blue valve handle (¼-turn anti-clockwise) to release

the air pressure within the container.

VDS3 User’s Manual

3. Fill with clean distilled water to the level of the fi ller port (water capacity

is approximately 1 liter (1 quart).

4. Turn the big blue valve handle back to seal-off the water container.

5. Slowly turn on the water pressure valve (¼-turn anti-clockwise) located

alongside the display on the front panel to repressurize the water container .

NOTE: When fi lling for the fi rst time, or if the water was allowed to

run out, slowly unscrew the tube nut on top of the CEM (Controlled

Evaporation Mixer) to remove any airlock in the system and retighten the nut.

6. Replace the side panel.

3.2 'Start-Up' Procedure

NOTE: If a sequence of dew points is required it is important to start at the

driest and select progressively through the range, moving from dry to wet.

1. Ensure that the water container is fi lled with distilled water as described

above and that the compressed air and dry air supplies are present.

2. Switch on the system via the front panel

panel display should show

fi rmware version and mm/yy is the date) and

POWER on/off switch. The front

VDS Vx.x mm/yy cal mode (where Vx.x is the

Set dewpoint: -100.0.

3. Allow the system to operate for a minimum of 1 hour so that the system

pipework can purge and stabilize.

4. When operating for the fi rst time, or after a long period without use, the

system should be purged for longer, ie a minimum of 8 hours/overnight.

A 5-day purge is required before using the system below -80°Cdp

(-112°Fdp).

NOTE: When the sequence is complete ALWAYS return the unit to the

setting and allow the system to run for several minutes to purge out any

moist gas before shut down.

4 97433 Issue 1.2, July 2016

-100.0

Page 13

VDS3 User’s Manual

3.3 Operating Software

3.3.1 Dew-Point Control

Before starting up the PC, ensure that the dew-point control USB cable and the reference

hygrometer serial cable are both connected to it. Start up the PC and the VDS interface

software will load automatically.

Dew points may be selected manually via a keypad, or a sequence of user-defi ned dew

points (for user-defi ned durations) may be run automatically via a profi le table.

NOTE: The VDS interface software does not control the reference hygrometer

sensor head temperature. The head temperature must be controlled manually.

NOTE: On launch the software will be in manual mode.

Manual Control (keypad):

OPERATION

Click the buttons to select a dew point.

NOTE: The VDS display shows the currently selected

dew point.

Automatic Control (profi le table):

In automatic mode the software will step through the profi le

table starting at position 1 and ending at position 13.

The table is fully customizable. Dew points and durations

may be changed as required.

Table profi les may be saved and loaded.

NOTE: Dew points must be between -100 and +20 in

10 degree steps.

NOTE: If a duration is entered as 0 hours and 0

minutes, the position will be skipped.

Michell Instruments 5

Page 14

OPERATION

3.3.2 Readings

The Readings Section displays both the current set dew point and the actual dew point

as read from the reference hygrometer.

NOTE: The reference hygrometer is read approximately every second.

Readings Section:

Actual dew point as measured by the reference hygrometer.

Set dew point displays the dew point as set through either

manual or automatic dew-point selection.

VDS3 User’s Manual

3.3.3 Recording

The Recording Section contains a real-time chart recorder and a history canvas.

The chart recorder plots both set and actual dew points, plotting new readings

approximately every 5 seconds.

Above the chart are four chart controls, namely;

Plot puts the chart into plot (normal) mode

•

Scroll-X puts the chart into a mode which allows the X axis to be scrolled

•

left and right

Scroll-Y puts the chart into a mode which allows the Y axis to be scrolled

•

up and down

Zoom box puts the chart into a mode which allows zooming in on an area

•

of the chart

To use these modes, click the desired control button then click and drag the mouse on

the chart area.

Plot, Scroll-X, Scroll-Y and Zoom box.

To use the Zoom box, click the left mouse button on the chart area. Keeping the left

mouse button held down, drag a box around the area to be zoomed.

NOTE: After using any mode, click

Plot to resume normal plotting.

6 97433 Issue 1.2, July 2016

Page 15

VDS3 User’s Manual

The history canvas records and displays the following events:

• Any set dew-point changes that take place (either manually or

automatically). Automatic changes are prefi xed with the text (

Manual changes do not have a prefi x.

• When an automatic profi le is started and fi nished.

NOTE: On launch the software will not be recording.

OPERATION

Auto) and

To record, click the

RECORDING button.

Recording Section:

Chart Controls

History Canvas

Chart Area

Recording Controls

START RECORDING button. To stop recording, click the STOP

Michell Instruments 7

Page 16

MAINTENANCE

!

4 MAINTENANCE

4.1 Routine

Routine maintenance of the Michell VDS3 Vapor Delivery System is limited to checking

that the water container is always fi lled with distilled water (refer to Section 3.1).

This should be checked weekly (or more frequently if high dew points are generated for

long periods).

VDS3 User’s Manual

WARNING:

This unit operates under pressure. It is recommended that

safety goggles are worn.

8 97433 Issue 1.2, July 2016

Page 17

VDS3 User’s Manual

APPENDIX A

Appendix A

Technical Specifi cations

Michell Instruments 9

Page 18

APPENDIX A

VDS3 User’s Manual

Appendix A Technical Specifi cations

General

-100 to +20°C

Dew-Point Range

Output Stability ±0.5ºC (±0.9ºF)

Gas Supply

Gas Output 10 Nl/min @ 0.4 barg

Cable Connection

Water Container

Power Supply 220 to 240 V AC OR 100 to 120 V AC, 50/60Hz

Power Consumption 500 W maximum

Power Connector 3 pin IEC

Power Supply Fuse 3A (F) quick blow

Operating Temperature +10 to +40°C (+50 to +104°F)

Construction Painted diecast aluminum enclosure with smoked glass door

Dimensions 1020 x 555 x 600mm (40 x 21.8 x 23.6") (h x w x d)

Weight 65kg (143lbs) maximum

(factory default pre-set values:

–100, -90, -80, -70, -60, -50, -40, -30, -20, -10, 0, +10 and +20°C)

30 Nl/min @ 4.8 barg (70 psig) pressure and less than 13.8ppb

(-100°C (-148°F) atmospheric dew point) moisture content

USB (type B) for PC Control

RS485 (9 way D plug) for set-up

Material: ABS

Water capacity: 1 liter (1 quart)

V

10 97433 Issue 1.2, July 2016

Page 19

VDS3 User’s Manual

A.1 General Arrangement

APPENDIX A

h

(40.2”)

1020mm

553mm X (600mm depth)

g

(21.7”) X (23.6” depth)

VDS-3

Vapour Delivery System

g

g

g

g

h

WATER PRESSURE

ON/OFF VALVE

POWER ON/OFF

SWITCH

DEW-POINT

SET POINT

DISPLAY

TEMPERATURE

CONTROLLER

(BEHIND PANEL)

COMPRESSED AIR

INLET

(6mm TUBE FITTING)

RS485 CONNECTOR

(9 WAY D TYPE)

PC CONTROL

(USB PORT)

g

FRONT VIEW

g

g

g

g

REAR VIEW

g

g

g

g

CASTORS

WATER

CONTAINER

FILLING PORT

(BEHIND SIDE PANEL)

GAS OUTLET

(1/4” VCR FACE

SEAL FITTING)

GAS INLET

(1/4” VCR FACE

SEAL FITTING)

230 V AC POWER

CONNECTOR

(3 A FUSED)

Michell Instruments 11

Page 20

APPENDIX A

A.2 Flow Diagram

GAS OUTLET

INSTRUMENTS

TO S4000 AND

ON TEST

CV2

VENT

CV1

VENT

EPC2

COIL

4 X 100mm

VDS3 User’s Manual

GFC4

GAUGE

PRESSURE

PORT

FILLER

BALL

EPC1

CEM

LFM GFC1

VALV E

WATER

CONTAINER

BALL

VALV E

PRESSURE

REGULATOR

SOV1

GFC2

MIXING

CHAMBERS

TO CV1

TO CV2

SOV2

GFC3

GFC5

PRESSURE

SWING DRYER

PSD4 PRESSURE

GAS INLET FROM

REGULATOR

Figure 3

PRESSURE

AIR SUPPLY

COMPRESSED

7 BARG & -40ºCdp

REGULATOR

Flow Diagram

12 97433 Issue 1.2, July 2016

Page 21

VDS3 User’s Manual

APPENDIX B

Appendix B

Set-Up Software /

Adjustment of Setpoints

Michell Instruments 13

Page 22

APPENDIX B

VDS3 User’s Manual

Appendix B Set-Up Software / Adjustment of Setpoints

The system is supplied pre-set with 13 setpoints between -100 and +20 at 10 degree

intervals. However, if different setpoints are required, please follow the instructions

below.

B.1 Set-Up Connection

Connect the host PC to the VDS via the 9-way D type connector located on the rear

panel of the unit marked

with a digital interface converter, is provided and should be connected as shown below:

RS485 (SETUP). A 2 meter grey serial cable assembly, along

Host PC

VDS3

RS485 (SET UP)

PC (CONTROL)

B.2 About the Software

Before launching the set-up software, the VDS system must be placed in set-up mode

by following the steps below:

1. Shut down all software(s) running on the host PC.

2. Launch the VDS utility program (found in the host PC desktop VDS folder).

3. Enter

4. Click the

1 as the comm port number and then click the Connect button.

Setup mode button.

Figure 4

Serial Cable

Set-Up Connection

KK-ADE

Converter

RS485

RS232

g

Connect to spare

COMM Serial port

The VDS display should now show

If not, click the

Setup mode button again. When the VDS display shows Setup mode

Setup mode.

close the utility program.

Launch the set-up software through

START > Programs > Michell Instruments >

VDS Setup software > VDS Setup software Vx.x.

The software is used to establish fi xed, repeatable dew points through on-screen,

manual adjustments of all system controllers. Once dew points have been established,

the settings are uploaded to, stored and used by the VDS control unit in dew-point

generation mode.

Up to 13 fi xed dew points may be stored by the VDS control unit, normally –100 to +20

in 10 degree steps.

14 97433 Issue 1.2, July 2016

Page 23

VDS3 User’s Manual

The software provides:

1. A manual settings window

Where individual controller positions & valve states may be set manually in

order to establish dew points.

2. A system diagram window

Where manual controller settings (targets) and actual controller settings

(read back from the controllers) may be viewed simultaneously (useful for

diagnostic purposes).

3. A system settings window

This window has 3 purposes, namely:

i. It contains the table of settings stored within the control

unit (these settings are stored in a text fi le at c:/Massfl ow.

dat) and may be saved / loaded at any time.

ii. Settings may be transferred from the table into the manual

settings window.

APPENDIX B

iii. The control unit is programmed with the table of settings

through this window.

B.2.1 Initialization

On launching the software, a communications port input box appears as shown below:

Enter 1 (for COMM port number 1) and click OK.

Michell Instruments 15

Page 24

APPENDIX B

B.2.2 Manual Setting of Controllers

Use the Control panel window to manually set all gas, pressure and liquid fl ow controller

inputs.

This enables a specifi c dew point to be generated if required, e.g. to generate -25°C,

load the -30°C preset and adjust the values as appropriate.

Position the scroll bars to the desired

levels and set the valves to on/off by

toggling the valve buttons.

Combinations of valve positions make up

3 stages (Stage 1, 2 and 3) as shown

next to the buttons.

VDS3 User’s Manual

Once the desired settings are made,

click the Program button to upload

the settings to the VDS controller. The

software will prompt for programming

confi rmation.

NOTE: These are live settings only

and are NOT stored by the VDS

control unit.

After a few seconds, the status bar at the bottom of the screen should indicate that the

VDS control unit has been programmed successfully. Also, the S

will appear showing the manually set values next to each controller.

NOTE: The VDS front panel display will show

while manual settings are being made.

Set dewpoint: USER on the display

ystem Diagram window

16 97433 Issue 1.2, July 2016

Page 25

VDS3 User’s Manual

APPENDIX B

Status Bar

A success message on the bottom of the

screen shows that the controller inputs have

been set as per the manual settings.

To read back from the controller's outputs, tick the

box (bottom left of the system diagram window). The controller readings will update

every few seconds.

NOTE: This is a useful visual tool for diagnostics purposes of the system,

confi rming that all components of the system are functioning properly.

System Diagram Window

T arget values map the manually-set values in

the control panel. Both the system diagram

and the Controller input are updated with

these values by clicking the

in the Control panel window.

Program button

Continuously read system check

Michell Instruments 17

Page 26

APPENDIX B

VDS3 User’s Manual

Feedback

Values alongside

correctly, these values should match the target values.

(The screen shot shows random numbers for illustration purposes only).

NOTE: If the target EPC is set to 0 then a slight deviation may be observed due

to back-pressure in the system.

Reads text are values being read back from the controllers. If functioning

18 97433 Issue 1.2, July 2016

Page 27

VDS3 User’s Manual

B.2.3 Programming the VDS

NOTE: The settings have been factory set at Michell Instruments prior to

shipment. However, if you want to change them proceed as follows:

Once all dew points have been established, the controller settings must be entered into

the System settings table and then programmed into the control unit.

The screen shot below is an example of a full 13 point table from –100 to +20 in 10°C

steps.

APPENDIX B

System Settings

The table shows example dew points and associated controller

settings by row.

Values may be edited by clicking on a cell and typing. Use backspace to erase digits.

Toggle valve states by double-clicking the valve cells.

Click

Save to save the table to disk or Load to load it from disk. The fi le is located at:

c:/Massfl ow.dat.

To program the VDS with the table, click

a minute. (The software will inform whether the programming has been successful or

not). Once programmed, the VDS control unit is ready to run in calibration mode on

next power down / power up.

The dew points are mapped in order as per the settings table, i.e. a binary value of 0000

on the D.C.L. input will select the dew point at position 1 (-100 in the above example),

0001 at position 2 (-90) to 1101 at position 13 (+20) and so on.

NOTE: Adjusting the values in this table will not change the keypad labels

shown in Section 3.3.1, but will change the generated dew-points.

Program Eeprom. This process takes about

Michell Instruments 19

Page 28

APPENDIX C

VDS3 User’s Manual

Appendix C

Quality, Recycling

& Warranty

Information

20 97433 Issue 1.2, July 2016

Page 29

VDS3 User’s Manual

Appendix C Quality, Recycling & Warranty Information

C.1 Recycling Policy

Michell Instruments is concerned with the protection of the environment. It is our

commitment to reduce and eliminate from our operations, wherever possible, the use

of substances which may be harmful to the environment. Similarly, we are increasingly

using recyclable and/or recycled material in our business and products wherever it is

practical to do so.

To protect natural resources and to promote material reuse, please separate batteries

from other types of waste and recycle responsibly. If batteries are not properly disposed

of, these substances can cause harm to human health and the environment

The product that you have purchased may contain recyclable and/or recycled parts and

we will be happy to provide you with information on these components if required.

APPENDIX C

C.2 WEEE And RoHS Compliance

The Waste Electronic and Electrical Equipment (WEEE) Directive, and the Restriction

of Hazardous Substances (RoHS) Directive place rules upon European manufacturers

of electrical and electronic equipment. The directives’ aim is to reduce the impact that

electronic devices have on the environment.

Michell products are currently exempt from the RoHS directive, however all future

products will be developed entirely using compliant materials. Furthermore, Michell is

taking active steps to remove non-compliant materials and components from existing

products wherever possible.

Michell is in full compliance with the WEEE Directive (Registration No . WEE/JB0235YW).

Customers may be required to return certain instruments for treatment at the end of

their working life.

June 2010

C.3 Manufacturing Quality

Michell Instruments is registered with the British Standards Institute for Quality

Assurance to:

BS EN ISO 9001: 2008

Rigorous procedures are performed at every stage of production to ensure that the

materials of construction, manufacturing, calibration and fi nal test procedures meet the

requirements laid down by our BSI approved Quality System.

Please contact Michell Instruments (www.michell.com) if the product does not arrive in

perfect working order.

Michell Instruments 21

Page 30

APPENDIX C

C.4 Calibration Facilities

Michell Instruments’ calibration facilities are among the most sophisticated in the world

and have been recognized for their excellence.

Traceability to the National Physical Laboratory (NPL) UK is achieved through our UKAS

Accreditation (Number 0179). This covers dew point over the range -90 to +90°C (-130

to +194°F) and also Relative Humidity.

Dew-point calibrations are also traceable to the National Institute for Standards &

Technology (NIST) USA over the range -75 to +20°C (-103 to +68°F).

NOTE: Standard traceable calibration certifi cates for instruments and sensors are not

issued under our UKAS accreditation. UKAS certifi cates are usually to special order and

are clearly identifi ed.

C.5 Return Policy

If a Michell Instruments’ product malfunctions within the warranty period, the following

procedure must be completed:

VDS3 User’s Manual

1. Notify a Michell Instruments’ distributor, giving full details of the problem,

the model variant and the serial number of the product.

2. If the nature of the problem indicates the need for factory service then the

instrument should be returned to Michell Instruments, carriage prepaid,

preferably in the original packaging, with a full description of the fault

and the customer contact information.

3. Upon receipt, Michell Instruments will evaluate the product to determine

the cause of the malfunction. Then, one of the following courses of action

will be taken:

• If the fault is covered under the terms of the warranty, the

• If Michell Instruments determines that the fault is not covered

C.6 Warranty

Unless otherwise agreed, the Supplier warrants that as from the date of delivery for a

period of 12 months the goods and all their component parts, where applicable, are free

from any defects in design, workmanship, construction or materials.

instrument will be repaired at no cost to the owner and returned.

under the terms of the warranty, or if the warranty has expired,

an estimate for the cost of the repairs, at standard rates, will be

provided. Upon receipt of the owner’s approval to proceed, the

product will be repaired and returned.

The Supplier warrants that the services undertaken shall be performed using reasonable

skill and care, and of a quality conforming to generally accepted industry standards and

practices.

Except as expressly stated all warranties whether express or implied, by operation

of law or otherwise, are hereby excluded in relation to the goods and services to be

provided by the Supplier.

All warranty services are provided on a return to base basis. Any transportation costs

for the return of a warranty claim shall reside with the Customer.

22 97433 Issue 1.2, July 2016

Page 31

VDS3 User’s Manual

APPENDIX D

Appendix D

Return Document

&

Decontamination Declaration

Michell Instruments 23

Page 32

APPENDIX D

VDS3 User’s Manual

Appendix D Return Document & Decontamination Declaration

'HFRQWDPLQDWLRQ&HUWL¿FDWH

IMPORTANT NOTE: Please complete this form prior to this instrument, or any components, leaving your

site and being returned to us, or, where applicable, prior to any work being carried out by a Michell

engineer at your site.

Instrument Serial Number

Warranty Repair? YES NO Original PO #

Company Name Contact Name

Address

Telephone # E-mail address

Reason for Return /Description of Fault:

Has this equipment been exposed (internally or externally) to any of the following?

Please circle (YES/NO) as applicable and provide details below

Biohazards YES NO

Biological agents YES NO

Hazardous chemicals YES NO

Radioactive substances YES NO

Other hazards YES NO

Please provide details of any hazardous materials used with this equipment as indicated above (use continuation sheet

if necessary)

Your method of cleaning/decontamination

Has the equipment been cleaned and decontaminated? YES NOT NECESSARY

Michell Instruments will not accept instruments that have been exposed to toxins, radio-activity or bio-hazardous

PDWHULDOV)RUPRVWDSSOLFDWLRQVLQYROYLQJVROYHQWVDFLGLFEDVLFÀDPPDEOHRUWR[LFJDVHVD VLPSOHSXUJHZLWKGU\

JDVGHZSRLQW&RYHUKRXUVVKRXOGEHVXI¿FLHQWWRGHFRQWDPLQDWHWKHXQLWSULRUWRUHWXUQ

Work will not be carried out on any unit that does not have a completed decontamination declaration.

Decontamination Declaration

I declare that the information above is true and complete to the best of my knowledge, and it is safe for Michell

personnel to service or repair the returned instrument.

Name (Print) Position

Signature Date

F0121, Issue 2, December 2011

24 97433 Issue 1.2, July 2016

Page 33

VDS3 User’s Manual

NOTES:

Michell Instruments 25

Page 34

http://www.michell.com

Loading...

Loading...