Page 1

OptiPEAK TDL600

Process Moisture Analyzer

User’s Manual

97319 Issue 4.2

November 2018

Page 2

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

OptiPEAK TDL600

For Michell Instruments' contact information please go to

www.michell.com

© 2018 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

OptiPEAK TDL600 User’s Manual

Contents

Safety ...............................................................................................................................vii

Electrical Safety ..........................................................................................................vii

Pressure Safety ........................................................................................................... vii

Toxic Materials ............................................................................................................vii

Repair and Maintenance ..............................................................................................vii

Calibration (Factory Validation) ..................................................................................... vii

Safety Conformity .......................................................................................................vii

Abbreviations .................................................................................................................... viii

1 INTRODUCTION ................................................................................................1

1.1 Application ......................................................................................................... 1

1.2 Features ............................................................................................................ 1

1.3 Theory of Operation ........................................................................................... 2

1.3.1 Measurement Using a Laser ........................................................................... 4

2 INSTALLATION ..................................................................................................6

2.1 Unpacking the Instrument ................................................................................... 6

2.2 Lifting and Handling ........................................................................................... 7

2.3 Laser Safety ....................................................................................................... 7

2.4 Hazardous Area Safety ........................................................................................ 8

2.5 Electrical Safety .................................................................................................. 9

2.5.1 Equipment Ratings and Installation Details ...................................................... 9

2.6 Pressure Safety ................................................................................................ 11

2.7 Basic Installation Guidelines .............................................................................. 11

2.8 Electrical Connections ....................................................................................... 15

2.8.1 Power Connection ....................................................................................... 15

2.8.2 Analog Outputs ........................................................................................... 16

2.8.3 Analog Inputs ............................................................................................. 16

2.8.4 Alarm Relays............................................................................................... 16

2.8.5 Modbus RTU / RS485 Connection ................................................................. 17

2.9 Environmental Requirements ............................................................................. 17

2.10 Sample Conditioning Requirements .................................................................... 18

2.10.1 Gas Connections ......................................................................................... 18

2.10.2 Sample Flow Gas Handling Components ....................................................... 18

2.11 Options ............................................................................................................ 21

2.11.1 Enclosure Heater Temperature Control (Outdoor systems ONLY) ..................... 21

2.11.2 Vortex Cooling (Outdoor systems ONLY) ....................................................... 21

2.11.3 Trace Heated Sample Line ........................................................................... 21

3 OPERATION ....................................................................................................22

3.1 Start-Up Procedure ........................................................................................... 22

3.2 Shut Down Procedure ....................................................................................... 23

3.3 User Interface .................................................................................................. 24

3.3.1 Interface Controls ....................................................................................... 24

3.3.2 ‘Up/Down Arrow’ Keys ................................................................................. 24

3.3.3 ‘ENTER’ Key ................................................................................................ 25

3.3.4 ‘ESC’ Key .................................................................................................... 25

3.4 Description of Measured Parameters .................................................................. 25

3.5 Default Settings ................................................................................................ 26

3.5.1 Advanced Menu default settings ................................................................... 26

3.6 Menu Structure ................................................................................................ 27

3.7 Main Menu Screen ............................................................................................ 28

3.7.1 Parameters Screen ...................................................................................... 29

3.7.2 Display Screen ............................................................................................ 30

3.7.3 Log Menu Screen ........................................................................................ 31

3.7.4 About Screen .............................................................................................. 32

3.7.5 Graph Screen .............................................................................................. 32

iv 97319 Issue 4.2, November 2018

Page 5

OptiPEAK TDL600 User’s Manual

3.7.6 Advanced Settings Screen ............................................................................ 33

3.7.6.1 Outputs Screen ..................................................................................... 34

3.7.6.2 Alarms Screen ...................................................................................... 35

3.7.6.3 Inputs Screen ....................................................................................... 38

3.7.6.4 Clock Screen ......................................................................................... 41

3.7.6.5 Modbus Screen ..................................................................................... 42

3.7.6.6 Region Defaults Screen.......................................................................... 43

3.7.6.7 N2-Mode (Measurement Mode) Screen ................................................... 44

3.7.6.8 Safe Mode (Laser Disabled) Screen ........................................................ 44

3.8 Enclosure Cover and User Interface ................................................................... 45

4 MAINTENANCE ................................................................................................46

4.1 Inspection of the Enclosure Cover ...................................................................... 47

4.2 Replacement of the Micro SD Data Logging Card ................................................ 49

4.3 Membrane and Particulate Filter Element Replacement ........................................ 51

4.3.1 Service Intervals ......................................................................................... 51

4.3.2 Installing the Filter Element and Membrane .................................................. 51

4.3.3 Field measurement verifi cation ..................................................................... 53

4.3.4 Long-term maintenance – Laser replacement ................................................ 54

Figures

Figure 1 Beer Lambert Law ......................................................................................3

Figure 2 Laser Scan .................................................................................................4

Figure 3 System Block Schematic ..............................................................................5

Figure 4 Unpacking the TDL600 ................................................................................6

Figure 5 Earthing Stud And Nut Washer Assembly ...................................................10

Figure 6 OptiPEAK Sampling System - Typical Indoor Version ....................................12

Figure 7 OptiPEAK Sampling System - Typical Intdoor Version ...................................12

Figure 8 OptiPEAK Sampling System - Typical Outdoor Version .................................13

Figure 9 OptiPEAK Sampling System - Typical Outdoor Version .................................14

Figure 10 User Interface ..........................................................................................24

Figure 11 Up/Down Arrow Keys ................................................................................24

Figure 12 'ENTER’ Key .............................................................................................25

Figure 13 ‘ESC’ Key .................................................................................................25

Figure 14 Menu Structure ........................................................................................27

Figure 15 Main Menu Screen ....................................................................................28

Figure 16 Parameters Screen ...................................................................................29

Figure 17 Display Setup Screen ................................................................................30

Figure 18 Data Logging Screen ................................................................................31

Figure 19 Contact/About Screen ...............................................................................32

Figure 20 Graph Screen ...........................................................................................32

Figure 21 Advanced Settings Screen .........................................................................33

Figure 22 Output Screens ........................................................................................34

Figure 23 Alarm Screens ..........................................................................................35

Figure 24 Typical Alarm Status Indication on the Run-Mode Screen .............................37

Figure 25 Input Screen ............................................................................................38

Figure 26 Line Pressure Setup Screen .......................................................................39

Figure 27 Spare Input Setup Screen .........................................................................40

Figure 28 Set Date/Time Screen ............................................................................... 41

Figure 29 Modbus Settings Screen ............................................................................42

Figure 30 Region Defaults Screen ............................................................................. 43

Figure 31 N2-Mode (Measurement Mode) Screen ......................................................44

Figure 32 Safe Mode (Laser Disabled) Screen ............................................................45

Figure 33 Dimensional Drawing - Indoor System Enclosure ........................................58

Figure 34 Dimensional Drawing - Outdoor System Enclosure ......................................59

Figure 35 Wiring Diagram Indoor System ..................................................................61

Figure 36 Wiring Diagram Outdoor System ................................................................63

Michell Instruments v

Page 6

OptiPEAK TDL600 User’s Manual

Tables

Table 1 Parameters Screen Parameters ................................................................... 29

Table 2 Display Setup Screen Parameters ................................................................ 30

Table 3 Data Logging Screen Parameters ................................................................ 31

Table 4 Output Screen Parameters .........................................................................34

Table 5 Line Pressure Setup Screen Parameters ....................................................... 39

Table 6 Spare Input Setup Screen Parameters ......................................................... 40

Table 7 Set Date/Time Screen Parameters ..............................................................41

Table 8 Modbus Screen Parameters ........................................................................ 42

Table 9 Region Default Parameters .........................................................................43

Table 10 N2-Mode Parameters ................................................................................. 44

Appendices

Appendix A Technical Specifi cation ...............................................................................55

A.1 Dimensional Drawings .................................................................. 56

A.2 Dimensional Drawings .................................................................. 57

Appendix B Indoor Sampling System Wiring Diagram ....................................................59

Appendix C Outdoor Sampling System Wiring Diagram ..................................................61

Appendix D Flow Diagram ............................................................................................ 63

Appendix E Modbus Holding Register Map ....................................................................65

Appendix F Quality, Recycling, Compliance & Warranty Information ................................ 70

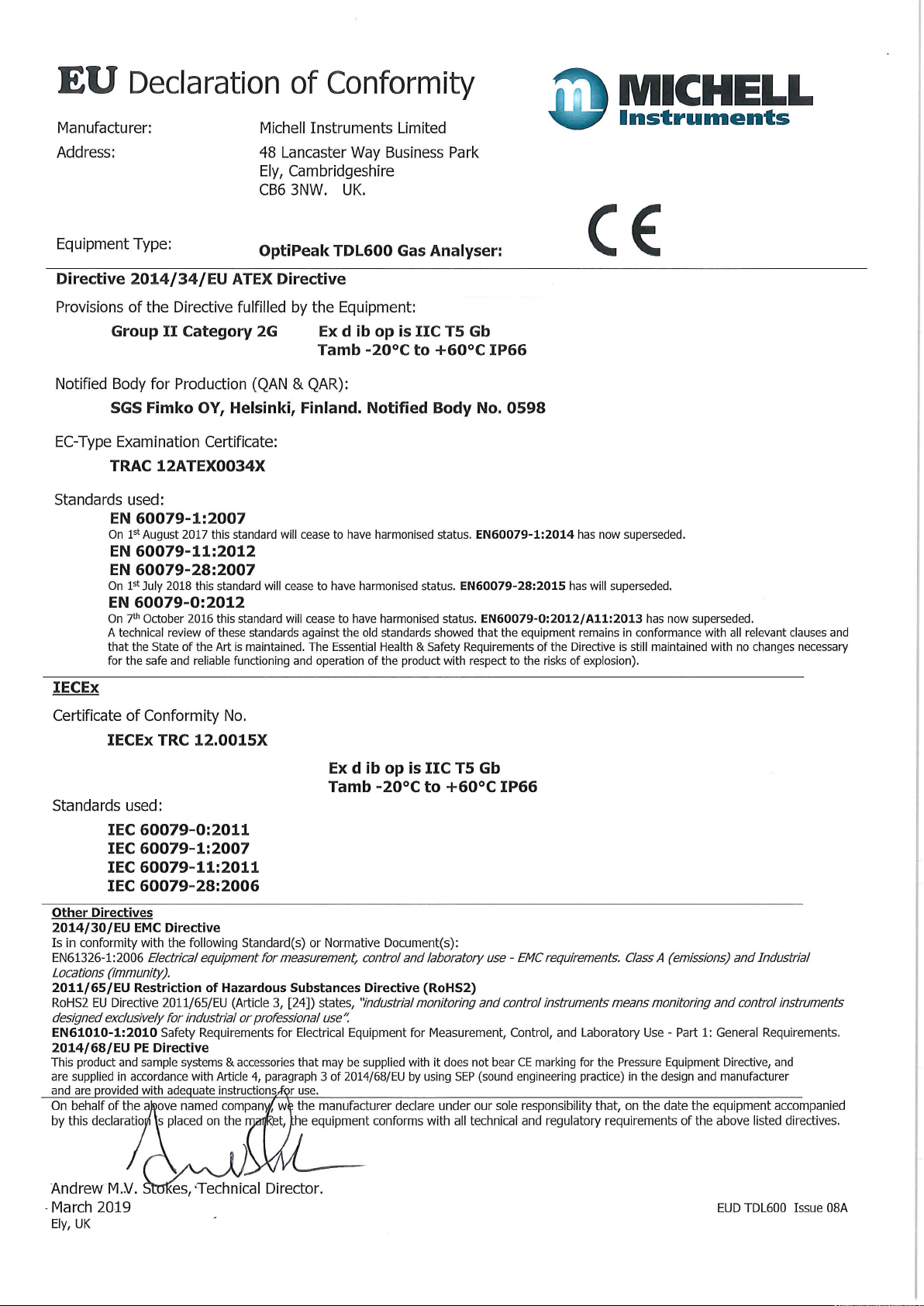

Appendix G Hazardous Area Certifi cation ...................................................................... 71

G.1 Product Standards ....................................................................... 72

G.2 Product Certifi cation ....................................................................72

G.3 Global Certifi cates/Approvals ........................................................72

G.4 Special Conditions of Use .............................................................72

G.5 Maintenance and Installation ........................................................ 73

Appendix H Return Document & Decontamination Declaration ........................................ 75

vi 97319 Issue 4.2, November 2018

Page 7

OptiPEAK TDL600 User’s Manual

!

Safety

This manual contains all the required information to install, operate and maintain the OptiPEAK

TDL600 Process Moisture Analyzer. Prior to installation and use of this product, this entire manual

should be read and understood. Installation and operation of this product should be carried out by

suitably competent personnel only. The operation of this product must be in accordance with the

terms of this manual and associated safety certifi cates. Incorrect installation and use of this product

for other than its intended purpose will render all warranties void.

This product is intended for use in a Hazardous Area and is awarded an ATEX, IECEx and cQPSus

Certifi cate. These certifi cates should be fully examined prior to installation or use of this product.

Where this hazard warning symbol appears in the following sections,

it is used to indicate areas where potentially hazardous operations

need to be carried out and where particular attention to personal and

personnel safety must be observed.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories

supplied by the manufacturer for use with the instrument. The input power supply voltage limits

are 90 to 264 V AC, 50/60Hz (dependent on chosen options).

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied directly to the

instrument's sample cell. The specifi ed working pressure is 0.7 to 1.4 bara (10 to 20.3 psia). Refer

to the Technical Specifi cations in Appendix A.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide offi ces contact information.

Calibration (Factory Validation)

Prior to shipment, the analyzer undergoes stringent factory calibration to traceable standards. Due to

the inherent stability of the instrument, regular fi eld calibration is not required under normal operating

conditions. The analyzer should perform reliably for many years with just basic maintenance and

housekeeping. Michell can provide a fully traceable factory calibration service for the instrument

when required. Please contact your local Michell offi ce or representative for further details (www.

michell.com).

Safety Conformity

This product meets the essential protection requirements of the relevant EU directives. Further

details of applied standards may be found in the product specifi cation.

Michell Instruments vii

Page 8

Abbreviations

The following abbreviations are used in this manual:

A ampere

AC alternating current

bara pressure unit (=100 kPa or 0.987 atm)

barg pressure unit (=100 kPa or 0.987 atm) gauge

°C degrees Celsius

°F degrees Fahrenheit

EU European Union

ft feet

hr hour

kg kilogram(s)

lbs pound(s)

OptiPEAK TDL600 User’s Manual

lb/MMscf pounds per million standard cubic feet

LCD liquid-crystal display

Nl/min normal liters per minute

m meters

mA milliampere

max maximum

*mg/m3 milligrams per cubic meter

mm millimeters

nm nanometers

NPT(F) National pipe thread (female)

PCB printed circuit board

parts per million by volume

ppm

V

psia pounds per square inch absolute

psig pounds per square inch gauge

RH relative humidity

RS485 serial data transmission standard

scfh standard cubic feet per hour

sec seconds

TDL Tuneable Diode Laser

V Volt

W Watts

% percentage

“ inch(es)

ø diameter

3

* mg/m

refers to standard sm3 (i.e. 15°C at atmospheric pressure)

viii 97319 Issue 4.2, November 2018

Page 9

OptiPEAK TDL600 User’s Manual

1 INTRODUCTION

The OptiPEAK TDL600 Tunable Diode Laser Analyzer employs the latest techniques in laser

absorption spectroscopy and signal processing power to offer a robust high performance

analyzer, designed specifi cally for the measurement of moisture in natural gas. The analyzer is

fully hazardous area certifi ed and delivers class-leading measurement performance, stability

and detection sensitivity.

The complete OptiPEAK TDL600 Analyzer Sampling System can be located close to the gas

sample take-off point in a potentially explosive environment - designated Zone 1 and Zone 2

hazardous area.

The indoor version Sampling System gas handling components are assembled on a 316 Stainless

Steel plate suitable for wall mounting within a temperature controlled analyzer house.

The outdoor version Sampling System is housed within a stainless steel enclosure (304

or 316), with optional thermostatically controlled heating and cooling, for direct fi eld

installation in a 100% shaded location next to the process line (with overall environmental

protection to IP66).

INTRODUCTION

All sample gas wetted metallic parts are in AISI 316L stainless steel with Viton

comply with the NACE standard MR-01-75 (latest edition). Tube fi ttings are type 316 Stainless

Steel. All gas and cable entries are located in the base of the enclosure.

1.1 Application

The measurement of moisture in natural gas streams is an essential and highly critical

analysis for the natural gas industry. Gas companies need to meet specifi c quality

standards for transmission, custody transfer and delivery. High levels of water in the gas

increase the cost of transportation and lower the calorifi c value of the gas. In addition,

excessive moisture content in the gas stream can lead to internal pipe corrosion and

hydrate formation, requiring expensive pipe cleaning or 'pigging'. In severe cases,

pipeline blockage can occur.

Although the analyzer is designed for the measurement of water in transmission quality

natural gas backgrounds it has been confi gured for use with almost any natural gas

stream. This provides full fl exibility if, for example, the analyzer is later re-deployed to

a different application. (See Section 3, Operation, for further details.)

1.2 Features

• High Measurement Sensitivity

®

soft parts that

The OptiPEAK TDL600 features a lower detection limit (LDL) of 1 ppm

water content. This

V

high sensitivity, coupled with the inherent fast response of the TDL optical measurement,

provides an extremely fast, accurate and reliable non-contact gas measurement.

• D-MET – Dynamic Methane Compensation. BioGas Ready

Moisture measurement is virtually independent* of changes in the methane composition

of the natural gas feed and accuracy is not reliant on manual software correction factors

being applied.

The analyzer can be used with a wide range of background gas compositions. With

increasing statutory requirements in many regions for Biomethane to be added to

natural gas streams, the analyzer has been future proofed by being Biomethane ready.

* Over a methane concentration range of 40 - 100% CH

4

Michell Instruments 1

Page 10

INTRODUCTION

• Laser Lock System

Tunable diode lasers can drift. This means that the laser wavelength may slowly change

with time and, eventually, may not precisely match the absorption peak of the water.

This can lead to a reduction in sensitivity and analyzer drift. This inherent property of

diode lasers is overcome in the OptiPEAK TDL600 by the built-in Laser lock system.

This system monitors the optical profi le of the gas absorption peaks to ensure the

laser remains locked to the correct water absorption peak, maintaining a high integrity

measurement at all times.

• Fast Response

Being a non-contact optical measurement, the analyzer offers fast response times,

meaning no long wet-up or dry-down times in contrast to traditional moisture sensors.

None of the sensing components are exposed to the gas stream, protecting them from

any aggressive components or harmful contamination.

OptiPEAK TDL600 User’s Manual

• HMI system

Provides a highly intuitive menu driven interface, utilizing a capacitive touch screen

system, offering stylus-free setup and operation without the need for a 'hot work' permit

to adjust settings or to perform validation checks.

1.3 Theory of Operation

The OptiPEAK TDL600 uses the technique of absorption spectroscopy to measure the

concentration of water vapor in the gas stream. Many gas molecules exhibit very specifi c

resonant vibrations in the infrared region of the electromagnetic spectrum. If infrared

energy, at the same resonant wavelength, is passed through these molecules, some of

this energy will be absorbed. If a suitable detector is used to measure the amount of

received energy, and the gas is contained within a cell of a known path length, then the

gas concentration can be calculated. This can be expressed mathematically and is often

referred to as the Beer-Lambert Law.

A

c =

ε

l

where:

A

= absorbance

ε

= extinction coeffi cient (absorption strength of gas at a specifi c wavelength)

l

= sample cell path length

c

= gas concentration

(l)

This law states that, if the sample cell path length

coeffi cient of the water molecule (

gas absorbs light at a specifi c wavelength) is known, then, if the absorbance of laser

energy by the water molecules is measured (A), the water concentration (c) of the

sample stream can be calculated. This gas law is the basis of all photometric gas

absorption measurement.

ε

- a constant that describes how strongly a particular

is known, and the extinction

2 97319 Issue 4.2, November 2018

Page 11

OptiPEAK TDL600 User’s Manual

Beer Lambert law

concentration (c)

INTRODUCTION

Absorbent

I

O

I

X

Path length (l)

Figure 1

The Michell OptiPEAK TDL600 uses a tunable diode laser source to generate a narrow

and coherent beam of near infrared (NIR) energy at the precise resonant wavelength

of water vapor. Traditionally, infrared analyzers use broadband sources which generate

a wide gamut of wavelengths. To make these analyzers as selective as possible to

moisture only, optical fi lters have to be deployed to 'narrow' the range of wavelengths

that are fi nally passed through the sample. These fi lters do not offer very high selectivity

- they are quite broadband, which can lead to signifi cant spectral interference, as other

gas peaks close to the water absorption peaks are also detected, leading to cross

interference, drift and general degradation in measurement performance.

In contrast, the laser has a bandwidth of less than 0.0001 nanometers. This means the

laser is very selective in detecting only the water and not any other gases present in

the gas stream.

Beer Lambert Law

This optical technique also has the advantage that the analyzer uses a non-contact

method of measurement, i.e. there is no sensing element in contact with the gas

stream. This offers a highly robust and reliable measurement, as only photons of light

pass through the gas. This provides very fast response and no long wet-up or dry-down

times.

Michell Instruments 3

Page 12

INTRODUCTION

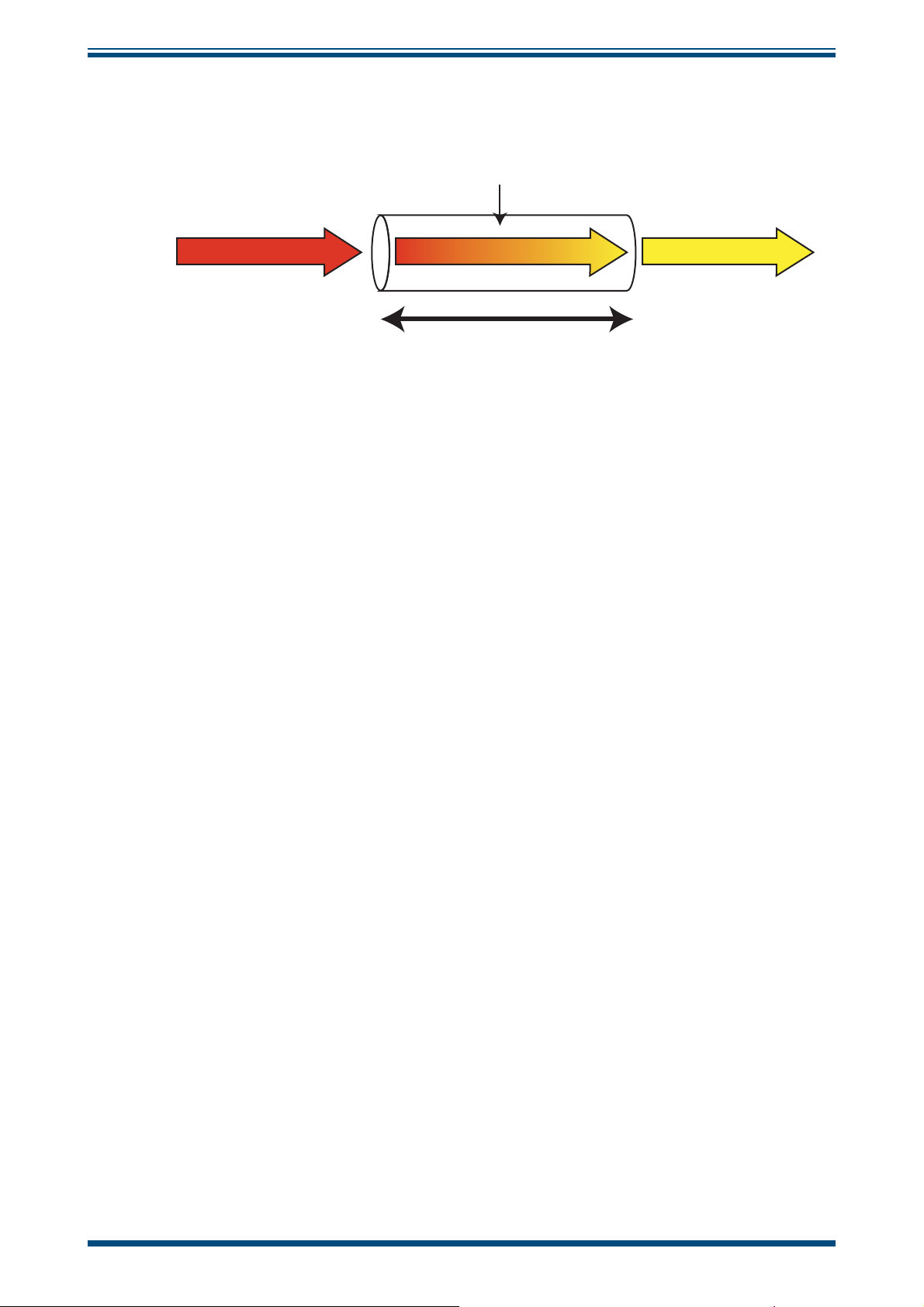

1.3.1 Measurement Using a Laser

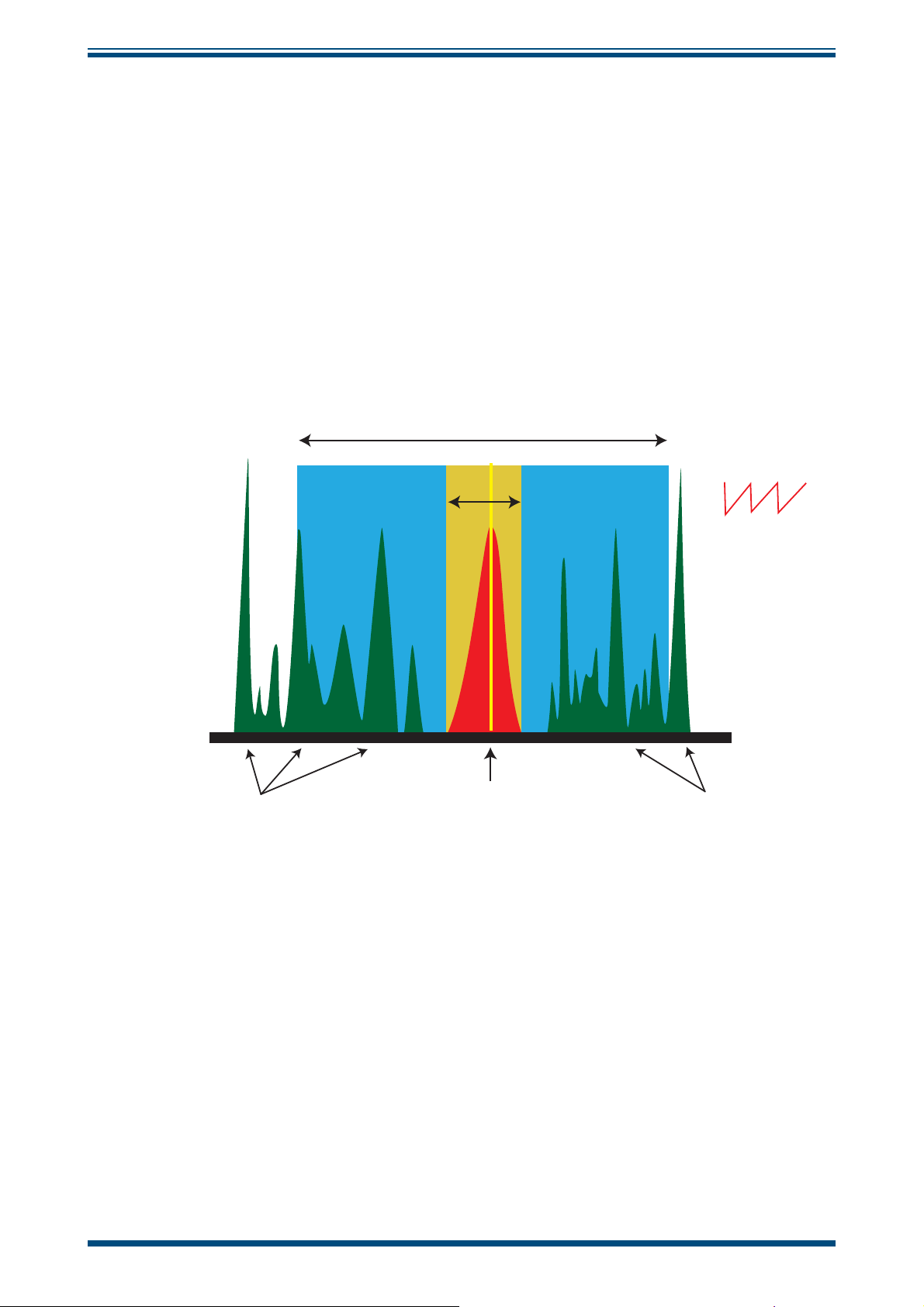

The diagram below illustrates the advantages of using a laser source, compared to a

traditional broadband source.

The water absorption peak is shown in the center of the diagram (red area). The width

of the laser beam is very narrow and is represented by the yellow line.

The laser wavelength is varied in order to scan across the water absorption peak (yellow

area). By scanning the peak in this way, important information can be extracted, such

as changes to the absorption peak caused by variation in the sample gas. This very

precise scan range minimizes any overlap with nearby absorption bands, as would be

the case with conventional broadband infrared sources and optical fi lters (blue area).

Typical broadband source bandwidth

OptiPEAK TDL600 User’s Manual

Scan range

5 Hz ‘sawtooth’

laser scan

Conventional IR

source gives

very broad

transmission

Potential interferant gases Potential interferant gases

Gas absorption

(peak of interest)

Bandwith

approximately 0.05nm

Figure 2

Laser Scan

4 97319 Issue 4.2, November 2018

Page 13

OptiPEAK TDL600 User’s Manual

INTRODUCTION

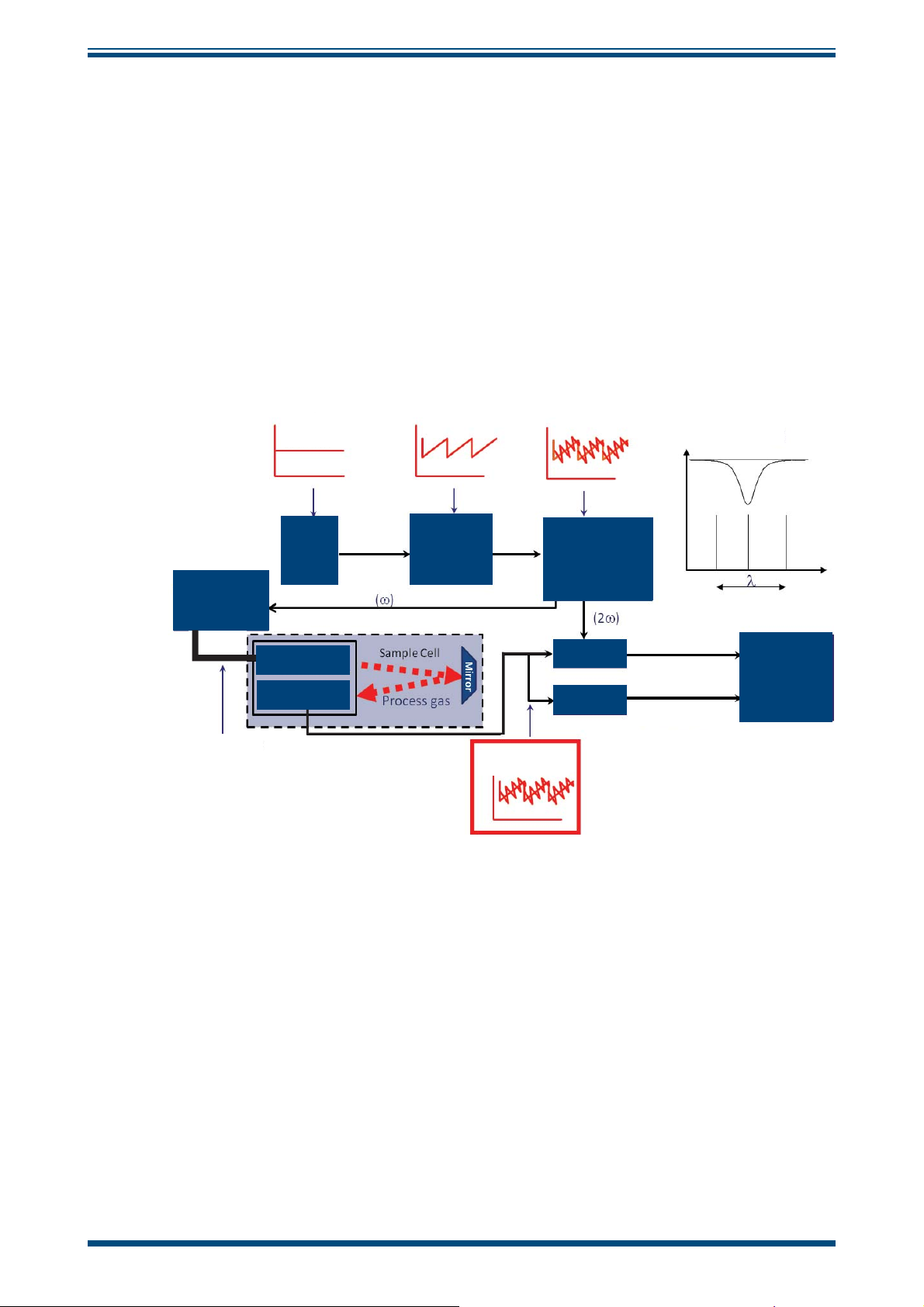

The schematic of the laser measurement system is shown in

Figure 3

below. This

highlights the major control and signal processing sections of the analyzer. The analyzer

uses the WMS (Wavelength Modulation Spectroscopy) technique, in combination with

proprietary signal processing algorithms to provide a selective response and high

sensitivity to moisture.

Here, a single frequency, distributed feedback (DFB) laser diode is tuned by applying

a current ramp to the laser. A further sinusoidal modulation is then applied. Lock-in

detection is applied to the photo-detector signal obtained by passing the tuned laser

radiation through the gas cell. The second harmonic signal from the lock-in detection is

measured to recover the spectroscopic peak of interest. WMS offers a practical method

of recovering weak signal changes from a dilute trace gas sample. WMS is becoming

wide spread within the sector of natural gas monitoring and represents current stateof-the-art technology.

Temperature

controlled

diode laser

Diode

current

Diode

laser

power

Launch head

Detector

Ramp

current

High

frequency

‘carrier’

modulation

Second harmonic

Mixer

Filter

Direct signal

Laser scanning

Signal

processing

Fiber Optic cable

Figure 3

Det. current

System Block Schematic

Michell Instruments 5

Page 14

INSTALLATION

!

2 INSTALLATION

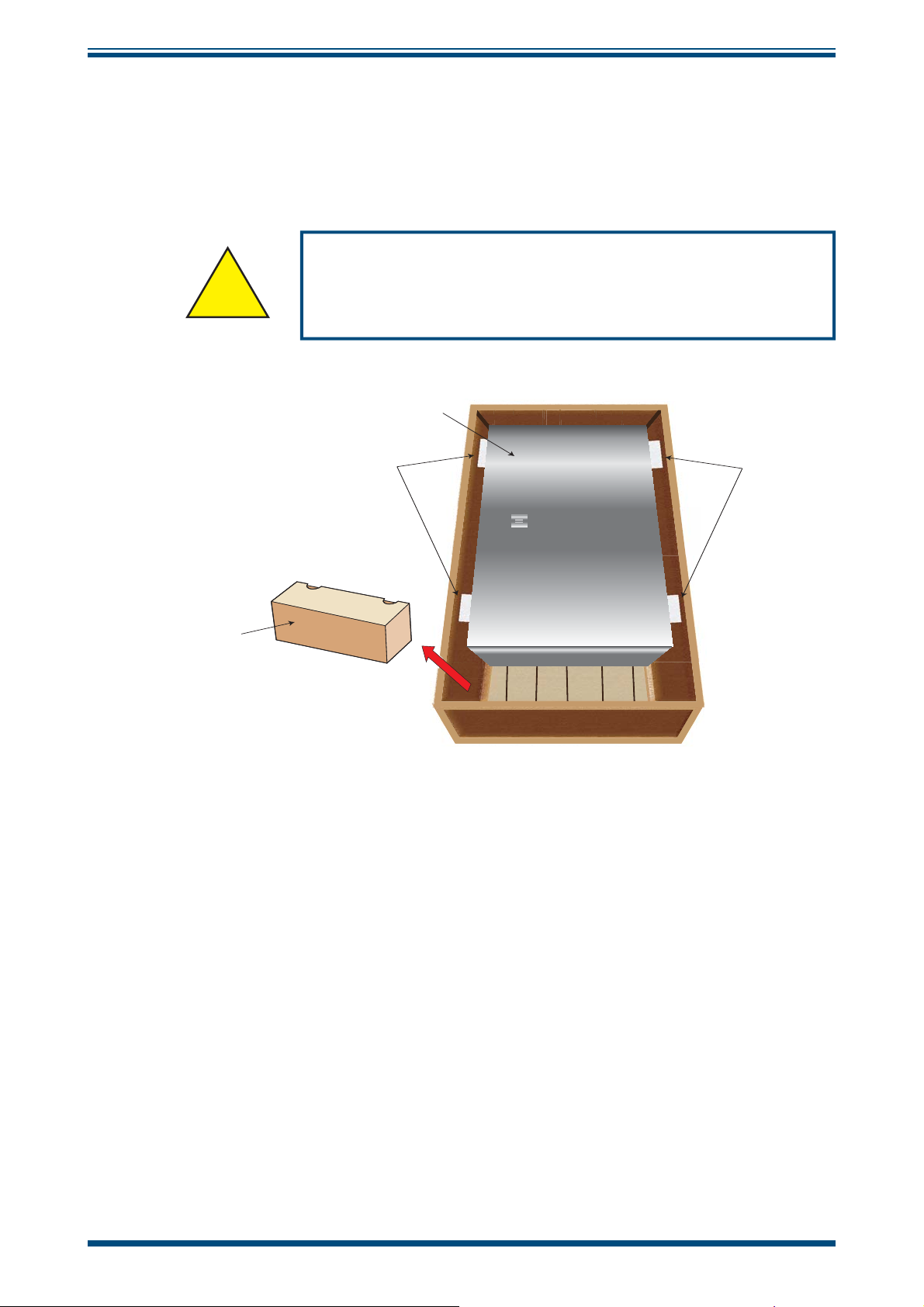

2.1 Unpacking the Instrument

Open the crate and unpack carefully as follows:

The instrument is heavy and should not be lifted alone.

Mechanical lifting aids may be required for larger systems.

OptiPEAK TDL600 User’s Manual

WARNING:

3

2

1

Figure 4

1. Remove the accessories box (1).

2. Remove the spacer foam (2).

2

Unpacking the TDL600

3. Remove the instrument enclosure (3) and set it down at the site of

installation.

It is recommended to save all the packing materials for the purpose of returning the

instrument for warranty claims.

The accessories box should contain the following items:

• Calibration Certifi cate

• Application Software CD

• User Manual

• CD containing System Documentation

6 97319 Issue 4.2, November 2018

Page 15

OptiPEAK TDL600 User’s Manual

!

!

2.2 Lifting and Handling

This product is in excess of 75kg (165lbs).

Personnel must observe suitable lifting and handling

The TDL600 is not designed as portable or transportable equipment. The product should

be rigidly fi xed in position as per the full installation instructions.

Appropriate lifting and handling techniques should be used during the installation process.

Before commencing any lifting or handling ensure that its intended location is suitable

and appropriately prepared. Make sure that mounting point design considerations have

employed locally approved safety factors.

INSTALLATION

WARNING:

precautions.

When handling and installing this instrument (particularly after removal from its

packaging) ensure that it is not dropped, impacted or subjected to high levels of

vibration or environmental conditions that may impair its operation.

2.3 Laser Safety

This product contains a Diode Laser with an invisible beam, operating in the near

infrared range. The laser as used in this product classifi es it as a CLASS 1 product.

For the purposes of CDRH and FDA Registration the OptiPEAK TDL600 complies with

21CFR1040 with deviations pursuant to Laser Notice 50 and with IEC/EN 60825-1:2007.

WARNING:

This product is a CLASS 1 LASER PRODUCT.

Beware of Laser radiation.

Do not access the Laser.

Do not view the Laser directly.

WARNING:

Use of controls or adjustments, or performance of

procedures other than those specifi ed herein, may result in

hazardous radiation exposure.

Michell Instruments 7

Page 16

INSTALLATION

!

2.4 Hazardous Area Safety

Refer to Appendix G for the Hazardous Area Certifi cation of this product.

This product is fi tted with a marking label that contains Hazardous Area information

pertinent to the suitable location and installation.

During all installation and operation activities, local regulations and permitted working

routines must be observed. Installation should only be performed by competent

personnel and in accordance with IEC 60079-14:2007 and EN 60079-14:2008 or local

equivalent.

Cable glands / conduit seals shall be installed in accordance with the manufacturer’s

instructions.

Conduit seals used should be suitable for a reference pressure of 6.1 bar (89 psi).

Repair and servicing of this equipment must only be carried out by the manufacturer.

OptiPEAK TDL600 User’s Manual

WARNING:

This product is certifi ed safe for use in a Zone 1 and Zone 2

area only. This product must not be installed or used within

a Zone 0 area.

WARNING:

This product must not be operated within an explosive

atmosphere greater than 1.1 bara (16 psia).

WARNING:

This product must not be operated within an enriched

oxygen atmosphere (more than 21% oxygen content).

WARNING:

This product must not be operated outside of the

temperature range of -20 to +55°C (-4 to +131°F)

WARNING:

The analyzer enclosure of this product provides Exd

protection, partly through the threads used for mounting

the lid, stopping plugs and cable gland. At all times effort

should be made to ensure these threads are suitably

protected from damage and that only appropriately rated

mating parts are applied to them, in accordance with the

certifying requirements.

8 97319 Issue 4.2, November 2018

Page 17

OptiPEAK TDL600 User’s Manual

DANGER

Electric

Shock Risk

2.5 Electrical Safety

During the installation of this product, ensure that all

applicable national and local electrical safety regulations are

Always ensure that power is switched off prior to accessing

the product for any purpose other than normal operation, or

prior to disconnecting any cables.

INSTALLATION

WARNING:

observed.

WARNING:

2.5.1 Equipment Ratings and Installation Details

The following mandatory statements refer to the Ex certified TDL600 Analyzer and

sampling system.

This equipment must be supplied with a voltage in the range of 90 to 264 V AC, 50/60

Hz. Maximum power rating depends on chosen standard options, 80W to 250W.

All electrical connections to the analyzer are made through junction boxes, mounted on

the panel of the sample system in accordance with Section 2.8.

Any power cable should be 3 core over sleeved, with minimum 0.5mm insulation

and rated at 300 V. Cables should have Live (L), Neutral (N) and Earth [Ground] (E)

conductors. Ensure suitably rated power supply cables and glands are used to ensure

that electrical safety is maintained. Ensure the power supply can deliver suffi cient power

to meet the consumption requirements.

Any power supply terminals and voltages must be suitably separated from the other I/O

requirements to this product.

Before applying power, perform a continuity test to ensure that the power supply cable

and the TDL600 are effectively connected to the protective Earth.

Michell Instruments 9

Page 18

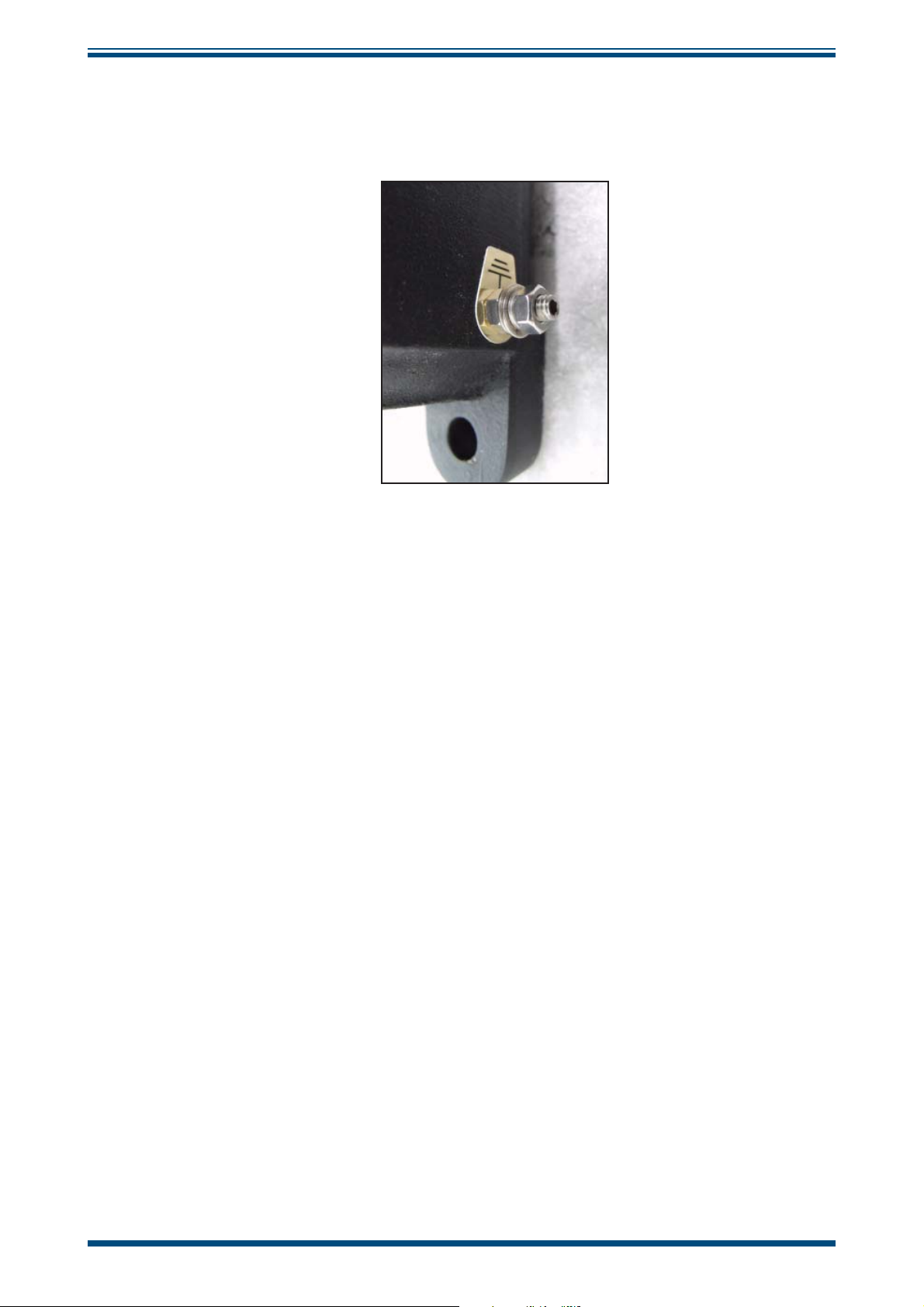

INSTALLATION

The protective Earth terminal is mounted internally and the Earth wire connected to it

should never be disconnected. The analyzer enclosure is supplied with an external earth

stud at the lower right hand side. This earth stud is connected to the sampling system

earth using 4mm2 minimum earthing bonding.

OptiPEAK TDL600 User’s Manual

Figure 5

Fuse: A replacement fuse can be obtained by contacting Michell Instruments' technical

support. Fuse rating = 5 x 20mm 2.5 A anti-surge to IEC 60127-2.

This measuring product is designed, where applicable and possible, to be in compliance

with EN/BS/IEC61010 safety requirements or electrical equipment or measurement,

control, and laboratory use. This product is designed to be safe at least under the

following conditions: between a temperature range of -40 to +60°C (-40 to +148°F),

in maximum 80% relative humidity for temperatures up to +31°C (+88°F) decreasing

linearly to 50% RH at +50°C (+122°F). Supply voltages of ±10% and transient over

voltages up to Overvoltage Category II. Pollution Degree 2. Altitudes up to 2000m.

Outdoor mounting is permitted using suitably rated glands equivalent to NEMA 4 / IP66.

See Appendix A, Technical Specifi cation, for full operating parameters.

NOTE: Do not remove or exchange any of the cables or electrical components

supplied with this product. Doing so will invalidate all warranties.

There are no additional or special electrical safety requirements other than those

referred to in this manual.

For location and mounting arrangements please refer to the relevant sections of this

manual.

Earthing Stud And Nut Washer Assembly

Installation of this equipment must include the provision of a suitable and locally

positioned power isolation switch or circuit breaker. Indication of the purpose of the

switch or circuit breaker is strongly recommended. An over-current protection device

should be rated to a maximum of 3 A.

This equipment and all power isolation devices must be installed in a location and

position that allows safe and easy access to their operation and is able to rigidly support

the equipment.

10 97319 Issue 4.2, November 2018

Page 19

OptiPEAK TDL600 User’s Manual

!

Do not install this equipment in a location that would expose it to impact or high levels

of vibration.

Operation of this equipment, other than in a manner specifi ed by the manufacturer, may

impair the safety protections provided.

The safe installation of this equipment and any system incorporating this equipment is

the responsibility of the installer. Ensure local regulations and requirements are referred

to prior to any installation commencing.

2.6 Pressure Safety

This product is used in conjunction with pressurized gases.

Pressurized gas should only be handled by suitably trained

Observe pressurized gas handling precautions.

INSTALLATION

WARNING:

personnel.

The TDL600 measurement chamber requires pressurized gas to be connected to it.

Observe pressurized gas handling regulations. Only suitably trained personnel should

carry out tasks that include the use of pressurized gas media.

The TDL600 measurement cell accepts a maximum sample pressure of 1.4 bara (20.3 psia).

2.7 Basic Installation Guidelines

The OptiPEAK TDL600 Moisture Analyzer Sampling System gas handling components

are assembled onto a stainless steel mounting plate suitable for wall mounting.

The outdoor version Sampling System provides environmental ingress protection to IP66

and should be mounted vertically, free of any appreciable vibration, in a permanently

shaded position to prevent heating effects through sun radiation. The Sampling System

enclosure can be specifi ed with optional thermostatically controlled heating (fi xed set

point). Optional enclosure cooling, using a compressed-air-driven vortex tube and

fi xed set point thermostat, is recommended for installation in hot climates (>+45°C

(>+113°F)).

NOTE: Any TDL being installed within a plant where it cannot vent to open

atmosphere needs a fl are line connection that runs to the highest point and

enters the fl are system from a topside connection. This is to prevent liquids

present in the fl are stack from draining back into the analyzer system.

NOTE: The actual detailed confi guration will be shown in the as-built drawings

provided with the shipped analyzer.

For start-up instructions refer to Section 3.

Michell Instruments 11

Page 20

INSTALLATION

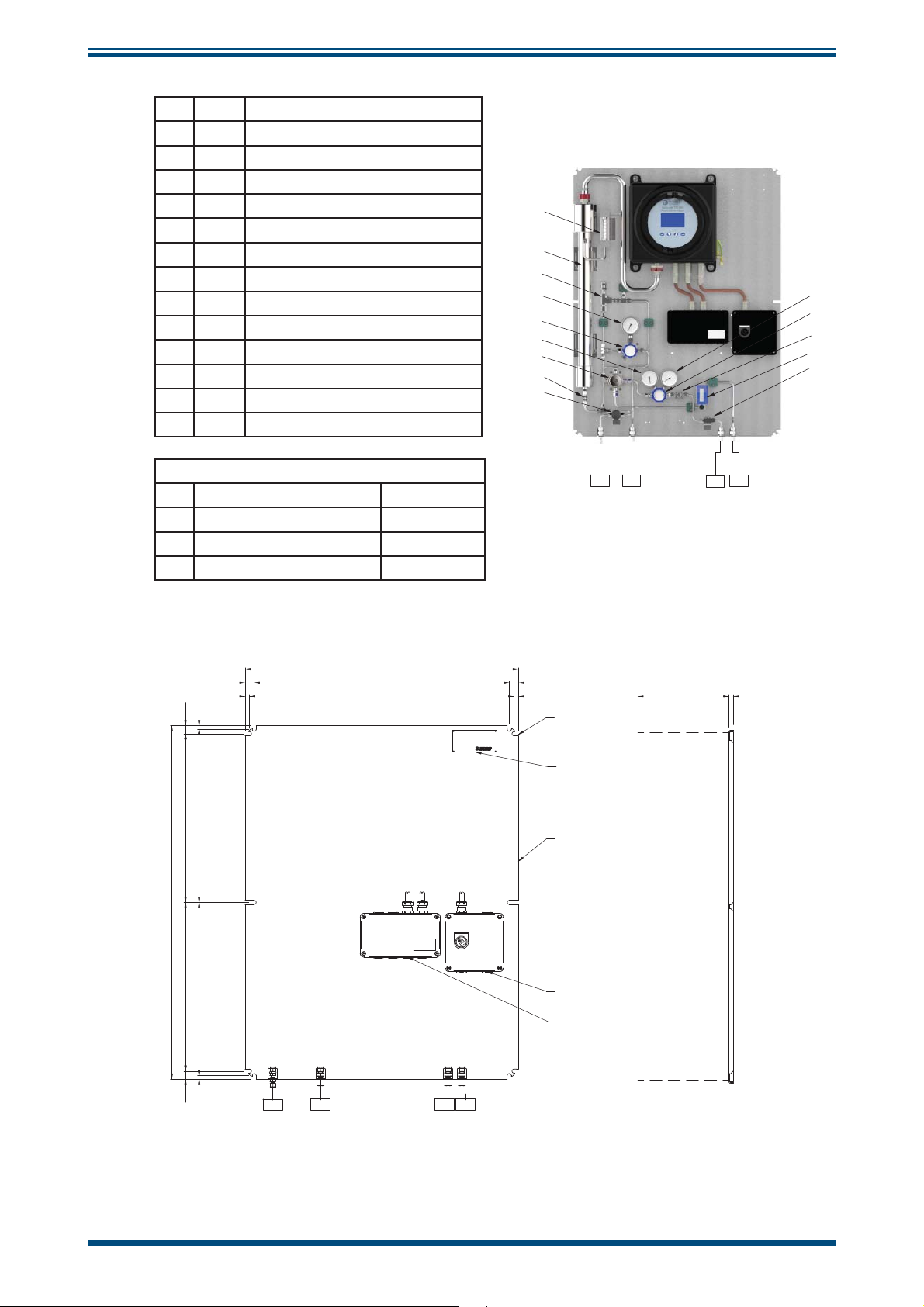

1 BV1 Ball Valve

2 F2 Particulate Filter

3 PR1 Pressure Regulator

4 PG1 Pressure Gauge

5 PR2 Pressure Gauge

6 F2 Coalescing & Membrane Filter

7 PR2 Pressure Regulator

8 PG3 Pressure Gauge

9 PRV1 Pressure Relief Valve

10 FM1 Flowmeter

11 AN1 Moisture Analyzer

12 MV1 Metering Valve

13 NV1 Needle Valve

14 FM2 Flowmeter

TP1 Sample Gas Inlet 1/4” NPT (F)

TP2 Sample Gas Outlet 1/4” NPT (F)

TP3 Bypass Flow Gas Outlet 1/4” NPT (F)

TP4 Letdown Gas Vent/Drain 1/4” NPT (F)

TP Connections

OptiPEAK TDL600 User’s Manual

10

11

9

8

7

5

6

12

13

TP2TP4

TP1

TP3

4

3

2

14

1

Figure 6

25.0 700.0 CRS 25.0

12.0 726.0 CRS 12.0

970.0

463.0 CRS 463.0 CRS

475.0 CRS 475.0 CRS

OptiPEAK Sampling System - Typical Indoor Version

750.0

250.0

MIN. CLEARANCE

MOUNTING HOLES

(10x

MODEL: OPTIPEAK TD L600

TYPE: PROCESS MOISTURE ANALYZER

SERIAL NUMBER : nnnn nn /2017

WO NUMBER : BC4556 5

www.michell.com

11mm)

316SS NAMEPLATE

316SS MOUNTING

PLATE

POWER INLET

CABLE ENTRY

(M20)

SIGNAL OUTPUTS

CABLE ENTRIES

(2 x M20)

12.0

22.0 22.0

10.0 10.0

TP04

TP02

TP01 TP03

Figure 7

12 97319 Issue 4.2, November 2018

OptiPEAK Sampling System - Typical Indoor Version

Page 21

OptiPEAK TDL600 User’s Manual

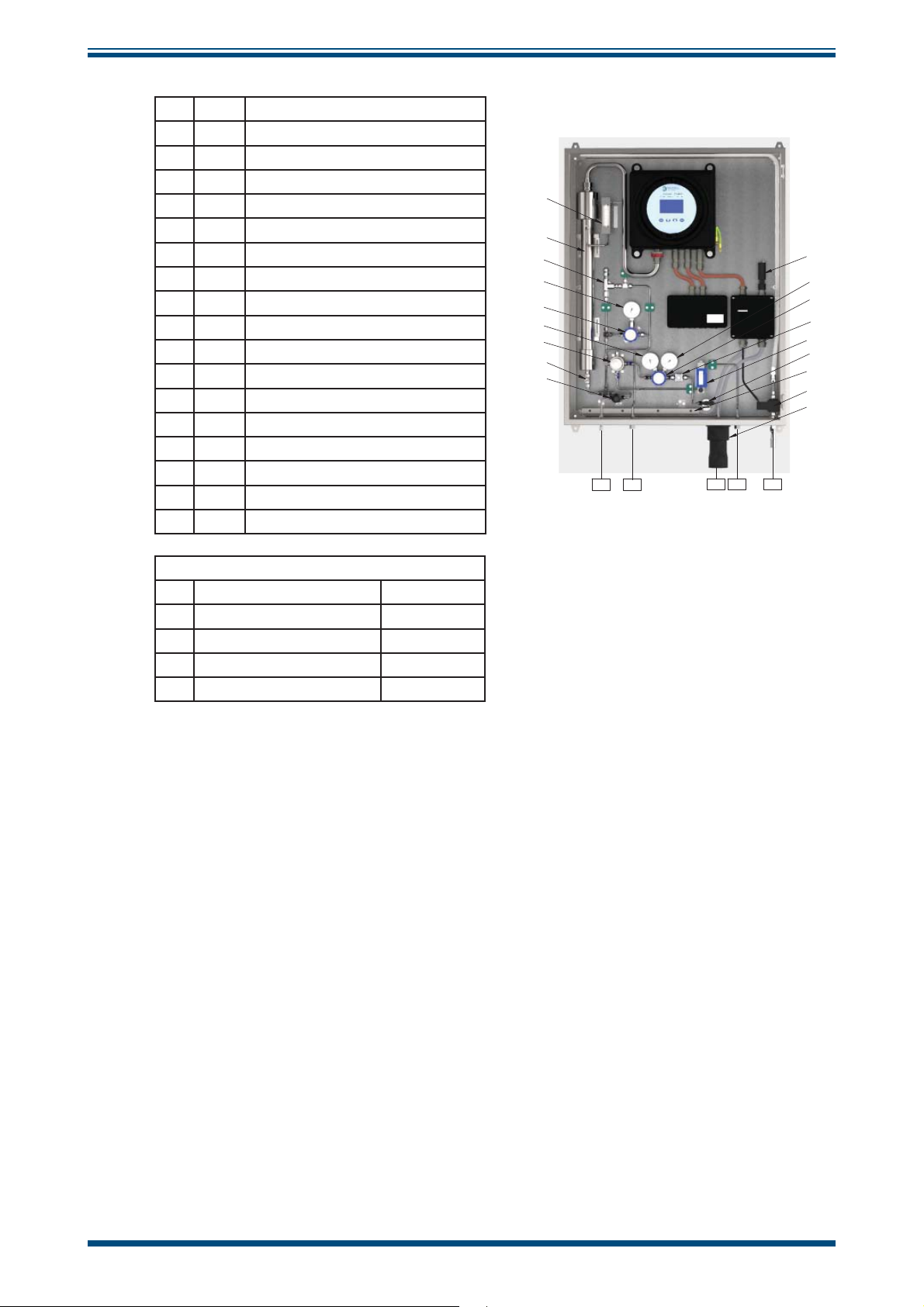

1 BV1 Ball Valve

2 F2 Particulate Filter

3 PR1 Pressure Regulator

4 PG1 Pressure Gauge

5 PG2 Pressure Gauge

6 F2 Coalescing & Membrane Filter

7 PR2 Pressure Regulator

8 AN1 Pressure Gauge

9 FM1 Pressure Relief Valve

10 PRV1 Flowmeter

TS1

11

12 MV1 Metering Valve

13 FM2 Needle Valve

14 NV1 Flowmeter

15

16

SOV1

17

18

Moisture Analyzer

HT

Enclosure Heater

TS1

Thermostat

Solenoid Valve

TH

Trace Heating

INSTALLATION

10

11

9

8

7

5

6

12

13

TP4 TP3

TP2

TP1

16

4

3

2

14

1

15

17

18

TP5

TP Connections

TP1 Sample Gas Inlet 1/4” NPT (F)

TP2 Sample Gas Outlet 1/4” NPT (F)

TP3 Bypass Flow Gas Outlet 1/4” NPT (F)

TP4 Letdown Gas Vent/Drain 1/4” NPT (F)

TP5 Vortex Cooler Inlet 1/4" NPT (F)

Figure 8

OptiPEAK Sampling System - Typical Outdoor Version

Michell Instruments 13

Page 22

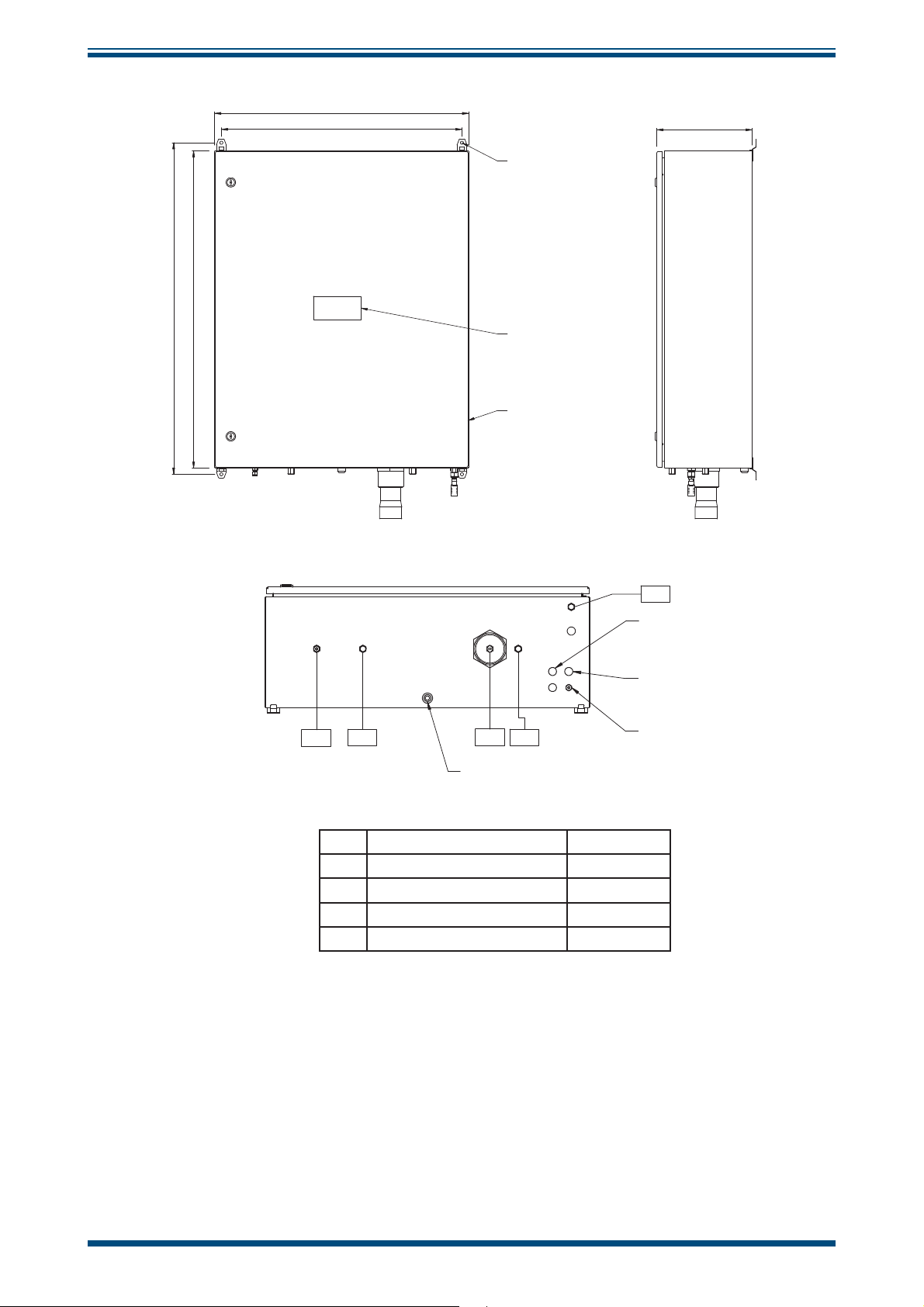

INSTALLATION

1045

1000

800

758

OptiPEAK TDL600 User’s Manual

300.0

MOUNTING HOLES

10mm)

(4x

316SS NAMEPLATE

ENCLOSURE (NOTE 1)

TP05

SIGNAL OUTPUTS

CABLE ENTRIES

(2 x M20)

POWER INLET

CABLE ENTRY

(M20)

TP04

TP02

TP01

TP03

BREATHER/DRAIN

EARTH STUD

TP1 Sample Gas Inlet 1/4” NPT (F)

TP2 Sample Gas Outlet 1/4” NPT (F)

TP3 Bypass Flow Gas Outlet 1/4” NPT (F)

TP4 Letdown Gas Vent/Drain 1/4” NPT (F)

TP5 Vortex Cooler Inlet 1/4" NPT (F)

Figure 9

OptiPEAK Sampling System - Typical Outdoor Version

14 97319 Issue 4.2, November 2018

Page 23

OptiPEAK TDL600 User’s Manual

!

2.8 Electrical Connections

All electrical connections to the TDL600 are made through junction boxes JB1 & JB2

(ATEX, IECEx and NEC500 Class I, Division 2 versions only).

INSTALLATION

WARNING:

Once the mains power connections are made to JB1 the

heaters and vortex cooling solenoid (if fi tted) will be

energized.

This includes:

• Power Connection

• Analog Outputs

• Analog Inputs (line pressure transmitter)

• Alarm Relays

• Modbus RTU / RS485 Connection

For the wiring diagram, consult the appropriate Appendix, depending on whether the

TDL600 was supplied with the indoor sample system, or the outdoor sample system:

Indoor Sample System Appendix B

Outdoor Sample System Appendix C

2.8.1 Power Connection

A single-phase AC mains power supply is required to operate the Analyzer and Sampling

System. The analyzer power supply can accommodate voltages from 90 to 264 V AC, 50/60

Hz. If enclosure heating or cooling options are selected, these will have defi ned voltage and

wattage requirements.

The factory-set power supply voltage is indicated on a yellow label located on the rear panel.

NOTE: The user cannot change the specifi ed power supply voltage.

Cable connections are made onto terminals within the Power Circuits junction box. Cable

entry into the junction box is provide via M20 threaded holes (fi tted with certifi ed stopping

plugs). Suitably certifi ed cable glands should be used (not supplied).

The power connection is made through JB1 (ATEX, IECEx and NEC500 Class I, Division

2 versions only) – refer to the appropriate Appendix.

Michell Instruments 15

Page 24

INSTALLATION

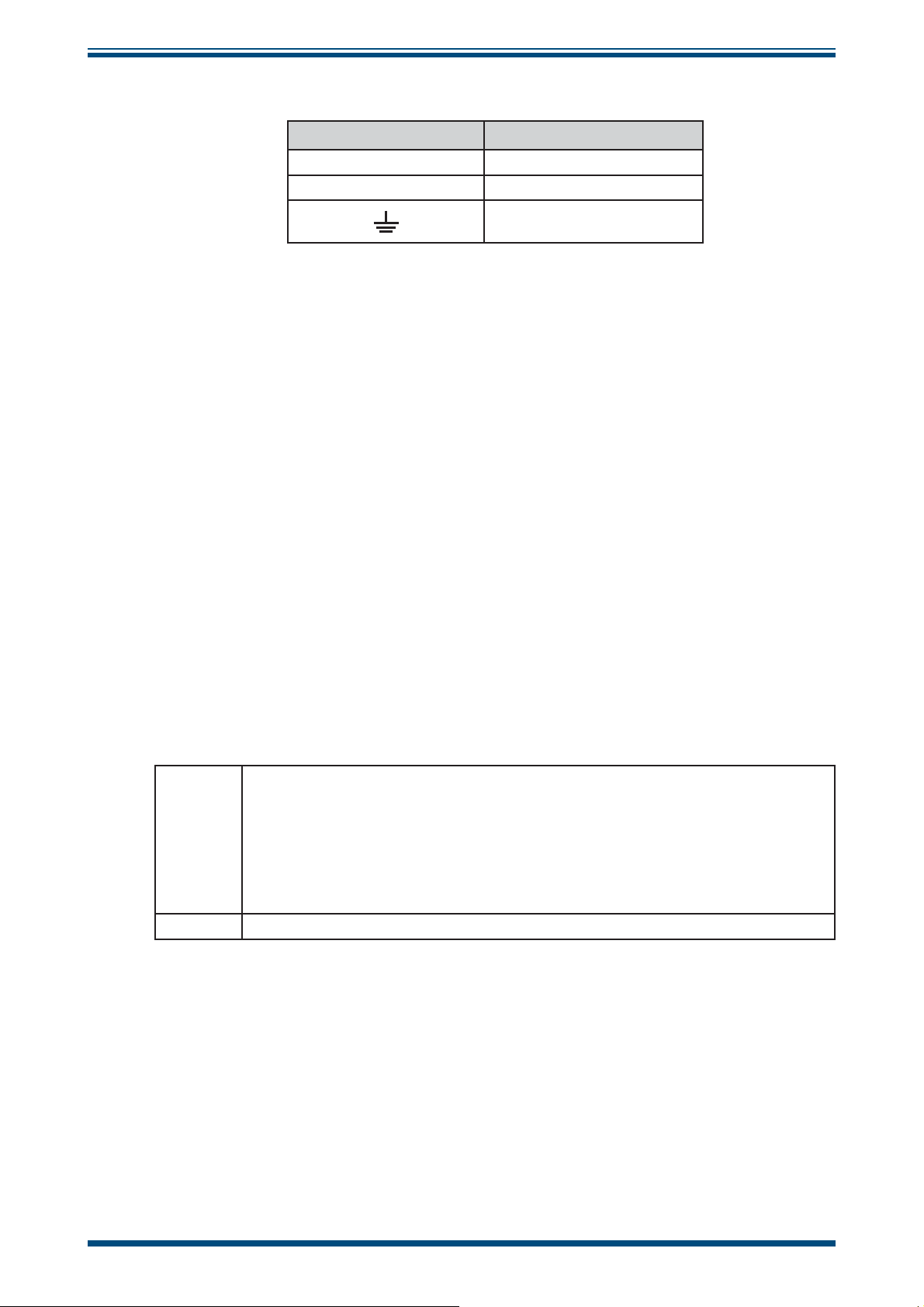

Terminals are marked:

NOTE: An earth stud is provided in the base of the enclosure. This must be

used to earth bond the Sampling System.

A power isolator switch is provided on the Power Circuits junction box for local power

isolation of the OptiPEAK TDL600 Moisture Analyzer (Main Unit only) for maintenance or

servicing. NOTE: This switch isolates the analyzer but does not isolate power

from ancillaries such as the heating/cooling circuits where fi tted.

2.8.2 Analog Outputs

OptiPEAK TDL600 User’s Manual

Terminal No. Power Supply

1 Live

5 Neutral

Earth

Three 2-wire analog outputs are provided that can be confi gured to represent any of

the directly measured or calculated output parameters. These outputs are active, selfpowered from the analyzer and can be set as either 0-20mA or 4-20mA.

For an overview of the analog output menu, refer to Section 3.7.6.1.

The analog output connections are made through JB2 (ATEX, IECEx and NEC500

Class I, Division 2 versions only) – refer to the appropriate Appendix.

2.8.3 Analog Inputs

Connection for process line pressure transmitter (optional).

Enables dynamic pressure compensation for calculation of moisture content

units.

Input 1

Input 2 No function

12 V DC excitation power provision for loop powered 4-20mA, 2-wire

transmitter. Transmitter must be able to function from 12 V DC excitation,

such as typical devices requiring 8 - 30 V DC.

Internal sensing resistor 100 Ω.

2.8.4 Alarm Relays

Three alarm relays are provided that can be triggered by any of the directly measured

or calculated output parameters. Each alarm relay has Common (CO), Normally Open

(NO) and Normally Closed (NC) contacts.

For detailed information on the alarms refer to Section 3.7.6.2.

The alarm relay connections are made through JB2 (ATEX, IECEx and NEC500 Class

I, Division 2 versions only) – refer to the appropriate Appendix.

16 97319 Issue 4.2, November 2018

Page 25

OptiPEAK TDL600 User’s Manual

2.8.5 Modbus RTU / RS485 Connection

The TDL600 features an RS485 port for digital communication, and uses a subset of the

Modbus RTU protocol. The RS485 connection should be confi gured with the following

parameters:

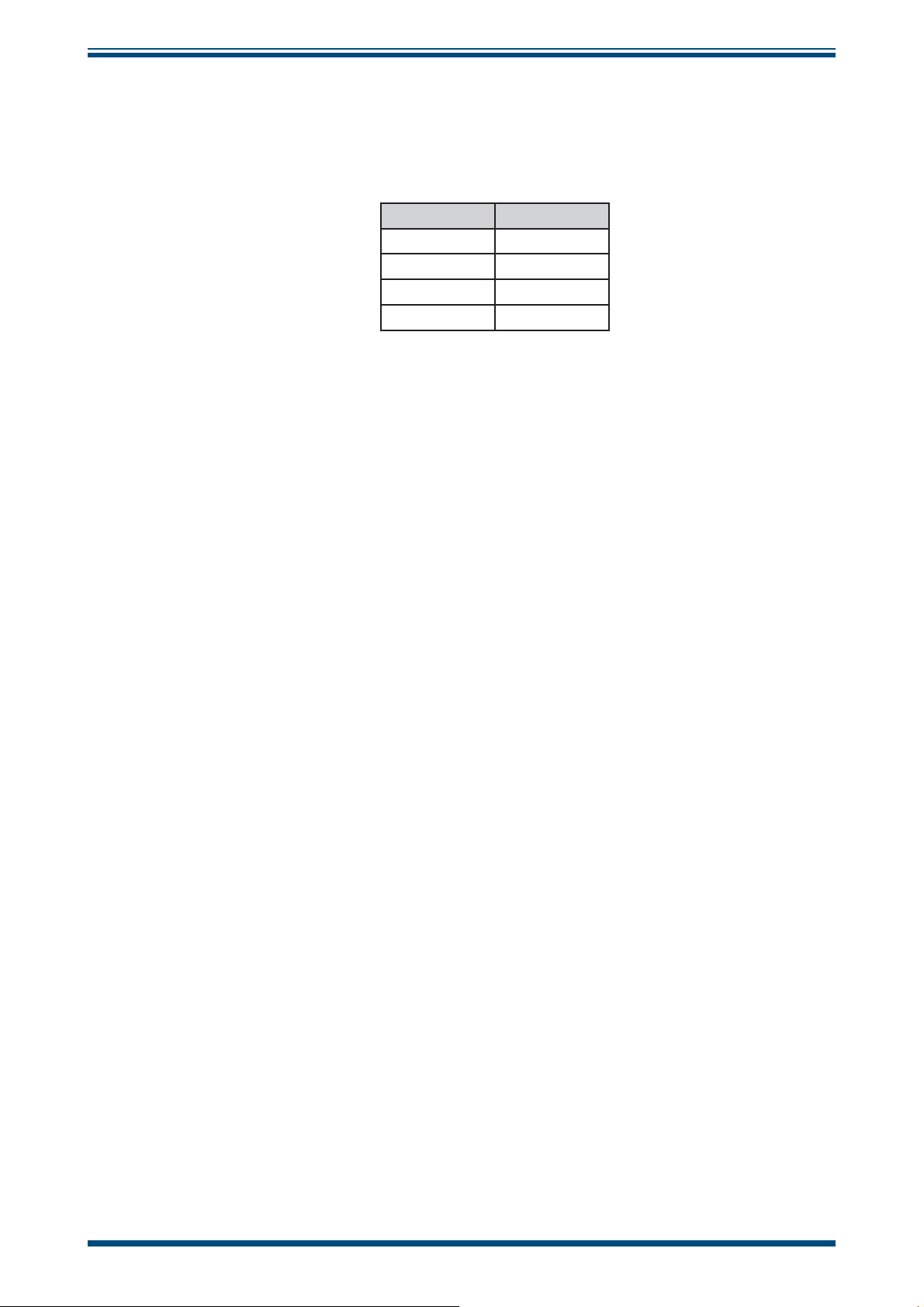

Parameter Value

Baud Rate 9600bps

Data Bits 8

Parity None

Stop Bits 2

A full list of Modbus registers can be found in Appendix E.

The RS485 connection is made through JB2 (ATEX, IECEx and NEC500 Class I,

Division 2 versions only) – refer to the appropriate Appendix.

INSTALLATION

2.9 Environmental Requirements

The environmental requirements of the analyzer (complete with sampling system) are

as follows:

Temperature

Indoor version +10 to +45°C (+50 to +113°F)

Outdoor version -20 to +45°C (-4 to +113°F)

Outdoor version with enclosure cooling option -20 to +55°C (-4 to +131°F)

Temperature (Storage) -30 to +60°C (-22 to +140°F)

Relative Humidity Less than 90% RH

If installed outside, the analyzer must be in a shaded position to prevent heating effects

through sun radiation.

Michell Instruments 17

Page 26

INSTALLATION

2.10 Sample Conditioning Requirements

Sample extraction, handling and conditioning techniques are of critical importance to assure

optimal performance and reliability of all gas analyzers that accurately quantify specifi c

components within a process gas composition. Michell Instruments' recommendations

and requirements in relation to the OptiPEAK TDL600 are outlined below.

Michell Instruments offers a range of sample extraction probes and sample conditioning

systems that have been selected and designed to exceed these minimum requirements.

For further information and advice please contact your local Michell offi ce or distributor

– refer to contact details on www.michell.com.

2.10.1 Gas Connections

Ensure that the process sample gas supply line is well fl ushed

through to clear any liquids and debris present, prior to

connection to the Sampling System.

OptiPEAK TDL600 User’s Manual

Connections are as follows - refer to Flow Diagram in Appendix D:

• TP1 Sample Gas Inlet

• TP2 Sample Gas Outlet

• TP3 Bypass Outlet

• TP4 System Vent/Drain

TP1 to TP3 are 1/4” NPT(F), TP4 is 1/4" OD.

2.10.2 Sample Flow Gas Handling Components

The sample fl ow gas handling components are as follows:

• Gas Inlet Isolation Valve (BV1):

Allows user to manually isolate the system from the process sample gas

supply line for maintenance or servicing.

• Particulate Filter (F1):

Provides protection to regulator from particulates

• Line Pressure Gauge (PG1):

Indicates the sample gas line pressure.

• Pressure Regulator 0-35 Bar (PR1):

Allows the user to manually set the sample gas analysis pressure for moisture

measurement. 1st stage pressure regulation.

• Regulated Pressure Gauge (PG2)

Indicates pressure set on PR1.

18 97319 Issue 4.2, November 2018

Page 27

OptiPEAK TDL600 User’s Manual

• Particulate/Coalescing Filter (F2):

Provides system protection from contamination of entrained liquids and

particulates using membrane fi ltration.

• Pressure Regulator 0-4 Bar (PR2):

2nd stage pressure regulation for moisture measurement.

• Input Pressure Gauge (PG3):

Indicates cell input pressure as set at PR2.

• Insert Pressure Relief Valve (PRV1)

Protects AN1 from over pressure

• Metering Valve (MV1):

Allows the user to manually set the sample gas fl owrate into the TDL gas

cell.

INSTALLATION

• Moisture Analyzer (AN1):

TDL600 Process Moisture Analyzer

• Flowmeter (FM1):

Provides indication of the sample gas fl ow rate through the TDL gas cell.

• System Drain Needle Valve (NV1):

Allows the user to manually letdown the sample gas pressure trapped in the

system for maintenance or servicing.

The bypass fl ow gas handling components are as follows:

• Bypass Flowmeter & Valve (FM2):

Allows the user to manually set and provide indication of the bypass gas fl ow

rate across the membrane fi lter.

Sample Extraction and Impulse Tubing

An insertion probe, with tip positioned within the central one-third of the crosssectional area of the pipe, should be used to extract a sample with a composition that

is representative of the majority of gas fl owing within the pipeline. Attention should

be given to the installation of impulse tubing connecting from the sample probe to the

analyzer sample conditioning system. Analytical grade acid-etched stainless steel tubing

should be used, which has a low moisture sorption capacity. Tube size should be 1/8"

or 3mm diameter, or 1/4” or 6mm as a maximum, to ensure that sample transportation

delay time is kept to a minimum. Likewise, to ensure the best dynamic response of

the complete installed analyzer system, the positioning of the analyzer with sample

conditioning system should be as close to the sample extraction probe as possible.

Michell Instruments 19

Page 28

INSTALLATION

To avoid any risk of condensation forming during transportation to the analyzer, and so

ensure that the integrity of the sample gas is maintained, the temperature of the sample

impulse tubing must be maintained at a temperature above the highest envisaged water

dew point. It is recommended that the sample tubing temperature is maintained at least

5°C (10°F) above the maximum water dew point at the prevailing pressure, as a suitable

‘safety’ margin. Self-limiting heating cable should be applied to the complete length of

the impulse tube, enclosed within suitable insulation. Trace heated tube bundle is a

factory fi tted option for Michell-produced sample conditioning systems.

Sample Conditioning System

The Michell designed sample conditioning system addresses the needs for filtration,

pressure reduction and sample flow control. To maintain cleanliness of the analyzer's

optical detection system, the process sample flow is filtered to eliminate entrained

liquids and particles. To provide protection against hydrocarbon condensates and

compressor oils that may be present in process natural gas, we use a micro-porous

membrane filtration with an oleophobic element specifically intended to reject such

low-surface tension liquids. Pressure reduction and sample flow control can achieve

0.5 Nl/min (1 scfh) sample flow at atmospheric pressure. Flow control is achieved by

a fine metering valve operating with a low upstream pressure and located at the inlet

to the analyzer optical cell. Flow indication on the outlet of the analyzer optical cell

is achieved with a variable area flow meter without a flow valve so as to avoid any

significant back-pressure.

OptiPEAK TDL600 User’s Manual

The sample gas exhaust should vent freely to atmosphere to avoid any signifi cant back

pressure to the analyzer optical cell. A suitable fl ame arrestor can be installed at the

fi nal vent point, which should be selected in accordance with site safety requirements

governing such atmospheric release of gas. The bypass fl ow from the membrane fi lter

could be taken to the site fl are system, as back-pressure is less critical in that case

(maximum 3 barg).

The enclosure for outdoor installed systems must be located within 100% shade from

direct sun, by the addition of an effective sun canopy, if necessary.

Combined Sample Extraction Probe with Integral Membrane Filter and

Pressure Reduction

It is possible to simplify the sample extraction and sample conditioning requirements

by use of an insertion sample probe that incorporates membrane fi ltration with sample

pressure reduction. The design of such combination probes has both the membrane

fi lter element and the pressure regulation control device at the tip of the probe, so

within the process pipeline fl ow. Final fi ltration and sample pressure reduction should

still be provided within the analyzer sampling system.

20 97319 Issue 4.2, November 2018

Page 29

OptiPEAK TDL600 User’s Manual

INSTALLATION

2.11 Options

2.11.1 Enclosure Heater Temperature Control (Outdoor systems ONLY)

Sampling systems fi tted within enclosures are temperature controlled to maintain a

constant temperature environment of at least 10°C (18°F) above the highest envisaged

dew-point temperature, independent of surrounding temperature variations. The

temperature control system consists of a heater controlled by a fi xed preset thermostat

to provide internal ambient air temperature control of +20°C (>+68°F).

2.11.2 Vortex Cooling (Outdoor systems ONLY)

A sampling system enclosure cooling kit can be fi tted to the stainless steel enclosure.

The cooling device is a Vortex tube driven by instrument grade (liquid and particulate

free) compressed air. A fi xed thermostat maintains an internal ambient <+40°C

(104°F) controlling a solenoid valve permitting the fl ow of compressed air through the

Vortex tube. A manifold (clear plastic pipe) positioned around the internal

walls of the enclosure distributes the cooling air throughout.

2.11.3 Trace Heated Sample Line

As an option, a trace heated sample line can be supplied with the Sampling System. This

ensures that the sample gas temperature from the process take-off point to the analyzer

is maintained at a constant temperature, independent of surrounding temperature

variations.

The trace heated tubing bundle consists of 6mm or ¼” OD 316L stainless steel seamless

tube and BSX™ self-regulating heating cable with non-hygroscopic glass fi ber insulation

and polymer outer jacket.

The self-regulating heat output of BSX™ cable varies in response to the surrounding

conditions along the entire length of a circuit. Whenever the heat loss increases (as

the ambient temperature drops), the heat output of the cable increases. Conversely

when the heat loss decreases (as the ambient temperature rises), the cable reacts by

reducing its heat output.

Operation of the trace heated sample line is fully automatic. Once a mains power supply

is provided then no further adjustment is required.

The trace heated sample line is connected directly onto the

(via the bulkhead entry seal gland, when fi tted to an enclosure) within the Sampling

System and the heating cable is terminated onto terminals within the Power Circuits

junction box. Cable entry into the junction box is via an EExe cable gland (supplied).

Gas Inlet Isolation Valve

See wiring diagram for termination details (Appendix C).

Michell Instruments 21

Page 30

OPERATION

!

!

3 OPERATION

Operation of the OptiPEAK TDL600 Sampling System should be carried out in conjunction

with, and referring to, this manual, prior to commencing the System Start-Up Procedure

(Section 3.1).

Before commencing the start-up procedure it is essential to ensure that the installation

conforms to the correct hazardous area and local plant standards.

Before any gas pressure is applied, check that all gas inlet & outlet connections are fully

tightened up and that all valves and regulators are in the closed position.

Additionally, for the outdoor version, the heater/thermostat circuit will need to achieve

the set-point temperature.

OptiPEAK TDL600 User’s Manual

BEFORE power is applied to the Sampling System check that the

OptiPEAK TDL600 Power Isolator switch (JB1) is set to the

position.

OFF

Check that all customer supplied cables are according to certifi cated approved

specifi cations and, as a minimum, are as described below:

Recommended Customer Cable Requirements

Power Cable 3 core, 0.75mm

Communications Cable

3.1 Start-Up Procedure

See Flow Diagram in Appendix D.

If the unit is left in storage for an extended period prior to

installation, it is recommended that the system be run on

2

conductor area (6A)

For use with 4-20 mA only or Modbus only

1 pair individually screened 0.5mm

overall screen (BS5308 or equivalent)

For use with 4-20 mA and Modbus

2 pair individually screened 0.5mm

overall screen (BS5308 or equivalent)

the sample gas for up to 24 hours before use to allow for

proper system dry down.

2

(min) conductors with an

2

(min) conductors with an

1. Switch on the analyzer power using the Power Isolator Switch (JB1).

WARNING:

Once the mains connections are made to JB1 the heaters

and vortex cooling solenoid (if fi tted) will be energized.

22 97319 Issue 4.2, November 2018

Page 31

OptiPEAK TDL600 User’s Manual

2. Ensure the System Drain Needle Valve (NV1) is CLOSED.

3. Ensure the Measurement Cell Pressure Regulators (PR1 & PR2) and

Bypass Flow Metering Valve (FM2) are fully CLOSED.

4. Ensure the Measurement Cell Metering Valve (MV1) is fully CLOSED.

5. Slowly OPEN the Gas Inlet Isolation Valve (BV1) to allow sample gas to

enter the Sampling System.

6. Perform leak tests using snoop (or equivalent leak test fl uid) on any new

system gas connections.

7. Set Pressure Regulator (PR1) to 20 barg, indicated on PG2 and then

adjust the Measurement Cell Pressure Regulator (PR2) to show 2 barg on

Pressure Gauge (PG3).

8. Adjust the Bypass Flow Metering Valve (FM2) to indicate a gas fl ow rate

of approximately 3 Nl/min (6.5 scfh).

9. Adjust the Measurement Cell Flow Metering Valve (MV1) to indicate

a sample gas fl ow rate of approximately 0.5 Nl/min (1 scfh) on the

Measurement Cell Flow Meter (FM1).

OPERATION

10. Close the enclosure door and allow the system temperature to stabilise.

3.2 Shut Down Procedure

1. Isolate the Sampling System from the sample gas supply line by CLOSING

the Gas Inlet Isolation Valve (BV1).

2. Allow approximately 2 minutes for the Sampling System to begin to

depressurize. Fully depressurize the Sampling System by CLOSING the

Bypass Flow Metering Valve (FM2) and OPENING the System Drain

Needle Valve (NV1).

3. Ensure the Power Isolator switch (JB1) is in the OFF position.

4. After approximately 2 minutes close the System Drain Needle Valve (NV1).

Michell Instruments 23

Page 32

OPERATION

3.3 User Interface

The OptiPEAK features a 4.3” color display.

3.3.1 Interface Controls

OptiPEAK TDL600 User’s Manual

OptiPEAK TDL600

Process Moisture Analyzer

ALARM!

ppm

V

21.4

Dewpoint ISO at Line Pressure Line Pressure

-17.5 °C 61.2 barg

No faults

1

2

3

Alarms

ppm

V

>20

Dewpt

>-10

RTD Temp

<5, >50

TRIPPED

OK

Four capacitive touch keys are used to navigate the menu system.

Key presses are detected through the glass front panel, and are indicated by a blue LED

above the key.

3.3.2 ‘Up/Down Arrow’ Keys

ESC ENTER

Figure 10

User Interface

Figure 11

Up/Down Arrow Keys

Up () and Down () keys are used to change pages, scroll through lists and

The

adjust values.

Some parameters, such as the output and alarm minimum and maximum values activate

the numerical entry screen. On this screen, the

the

Up () key changes the value of the currently selected digit.

Down () key selects the next digit and

24 97319 Issue 4.2, November 2018

Page 33

OptiPEAK TDL600 User’s Manual

3.3.3 ‘ENTER’ Key

OPERATION

ENTER

The ENTER key is used to select or de-select a highlighted item in a menu list.

Some parameters, such as the output and alarm minimum and maximum values activate

the numerical entry screen. On this screen, the

and returns to the previous screen.

3.3.4 ‘ESC’ Key

The ESC key is used to return to the previous menu, Run-Mode Screen, Main Menu or

Advanced Settings Screen.

Some parameters, such as the output and alarm minimum and maximum values activate

the numerical entry screen. On this screen, the

returns to the previous screen.

Figure 12

Figure 13

'ENTER’ Key

ENTER key accepts the displayed value

ESC

‘ESC’ Key

ESC key discards the new value and

3.4 Description of Measured Parameters

ppm

V

lb/MMscf

Pw

Dewpoint ISO

Dewpoint IGT

DP Ideal

mg/m3

Line Pressure*

Spare Input*

parts per million of H2O by volume

pounds H2O per million standard cubic feet (20°C, 101.325KPa)

partial vapor pressure of H2O in kilopascals

dew-point temperature (with respect to ice below 0°C), natural gas

(ISO18453)

dew-point temperature (with respect to ice below 0°C), natural gas

(IGT Bulletin 8)

dew-point temperature

milligrams H2O per cubic meter (15°C, 101.325 kPa)

Line pressure from current (mA) input

Spare current loop input for a user-connected device

* Available as secondary or tertiary parameter only

Michell Instruments 25

Page 34

OPERATION

3.5 Default Settings

On initial start up, the TDL600 Regional Setting is set to EU and metric units (i.e. Dew

Point to ISO 18453 and ºC) are selected. The Regional Setting can be changed to US

(see section 3.7.6.6), this is applies US standard units (i.e. lb/MMscf and ºF). The

default settings are shown here:

Top level menu - EU region Top level menu - US region

Parameters

Primary: ppm

Secondary: Dew-point ISO Secondary: lb/MMscf

Tertiary: mg/m

Display

Pressure units: barg Pressure units: psig

Temperature units: ºC Temperature units: ºF

Resolution (dp): 1 Resolution (dp): 1

Brightness (%): 100 Brightness (%): 100

Log menu

Logging disabled as default Logging disabled as default

V

3

OptiPEAK TDL600 User’s Manual

Primary: ppm

Tertiary: Dew-point ISO

V

3.5.1 Advanced Menu default settings

Outputs

Output 1 Output 2 Output 3

Parameter: ppm

V

Parameter: ppm

Type: 4-20 mA Type: 4-20 mA Type: 4-20 mA

Minimum: 0 Minimum: 0 Minimum: 0

Maximum: 1000 Maximum: 0 Maximum: 0

Alarms

All alarms disabled as default

Inputs

All inputs disabled as default

Modbus

Device Address: 1

Baud: 9k6

V

Parameter: ppm

V

26 97319 Issue 4.2, November 2018

Page 35

OptiPEAK TDL600 User’s Manual

3.6 Menu Structure

OPERATION

Run-Mode Screen

ESC

Main Menu

ENTER

Outputs

Outputs 1, 2, 3

Parameter

Type

Minimum

Maximum

Parameters

Primary

Secondary

Tertiary

Alarms

Alarms 1, 2, 3

Parameter

Type

Latching

Minimum

Maximum

Display Log Menu About Graph

Pressure

Unit

Temperature

Unit

Resolution

Log Period

Log #

Start Log

Contact &

Firmware Info

Measurement

Brightness

Clock Modbus

Date/

Time

Device

Address

Baud

Rate

Line

Pressure

Dewpoint

Source

Fixed

Pressure

Minimum

Maximum

Units

Inputs

Spare

Input

ppm

No

access

Minimum

Maximum

Enable

Selected

Primary

Parameter

Info

Region

Unit

Presets

Advanced

Settings

Password

7316

ENTER

N2-Mode

N2

Mode

Safe Mode

Not for

customer

use

Hysteresis

Enable

KEY

Press Up/Down keys

to change pages, scroll through

lists & adjust values.

Max/Min values activate the numerical

entry screen. Press Down key to select digit

& Up key to change value of selected digit.

ESC

Press ESC key to get back to Main Menu,

Advanced Menu or Run Mode Screen

depending on location.

Max/Min values activate the numerical

entry screen. Press ESC key to discard new

value & return to previous screen.

Figure 14

Menu Structure

ENTER

Press ENTER key to select or de-select a

highlighted item in a menu list.

Max/Min values activate the numerical

entry screen. Press ENTER key to accept the

displayed value & return to previous screen.

Michell Instruments 27

Page 36

OPERATION

3.7 Main Menu Screen

All instrument operating parameters, logging information, and advanced settings for

outputs, alarms and pressure are available through this screen.

This screen is accessed by pressing the ESC key from the Run-Mode Screen.

OptiPEAK TDL600 User’s Manual

Use the

ENTER key to access.

Press the

Up () and Down () keys to highlight the page of interest and press the

ESC key to return to the Run-Mode Screen.

Main Menu

Parameters

Display

Log Menu

About

Graph

Advanced Settings

Figure 15

Main Menu Screen

28 97319 Issue 4.2, November 2018

Page 37

OptiPEAK TDL600 User’s Manual

3.7.1 Parameters Screen

The Parameters Screen controls which measured or calculated parameters are shown

on the Run-Mode Screen.

OPERATION

This screen is accessed by pressing the

Use the

the

required and press the

Press the

Up () and Down () keys to highlight the parameter of interest and press

ENTER key to access. Use the Up () and Down () keys to choose the option

ENTER key to accept.

ESC key to return to the Main Menu Screen.

ENTER key from the Main Menu Screen.

Parameters

Primary: ppm

V

Secondary: Dew Point IGT

Tertiary: Line Pressure

Figure 16

Parameter Description

Parameter shown on large, top left pane of Run-Mode Screen

Primary

Available Options: ppm

ISO, Pw, mg/m3, lb/MMscf

Parameter shown on the leftmost smaller pane of Run-Mode

Screen

Secondary

Available Options: ppm

Ideal, Dewpoint IGT, Dewpoint ISO, Pw, mg/m3, lb/MMscf

Parameter shown on the rightmost smaller panel of Run-Mode

Screen

Tertiary

Available Options: ppm

Ideal, Dewpoint IGT, Dewpoint ISO, Pw, mg/m3, lb/MMscf

Table 1 Parameters Screen Parameters

Parameters Screen

, DP Ideal, Dewpoint IGT, Dewpoint

V

, Line Pressure, Spare Input, DP

V

, Line Pressure, Spare Input, DP

V

Michell Instruments 29

Page 38

OPERATION

3.7.2 Display Screen

The Display Setup Screen controls which units are used for temperature and pressure

on the display, alarm, and analog output screens. It also enables the brightness and

display resolution to be set.

OptiPEAK TDL600 User’s Manual

This screen is accessed by pressing the

Use the

the

required and press the

Press the

Up () and Down () keys to highlight the parameter of interest and press

ENTER key to access. Use the Up () and Down () keys to choose the option

ENTER key to accept.

ESC key to return to the Main Menu Screen.

ENTER key from the Main Menu Screen.

Display Setup

Pressure Units: kPa

Temperature Units: °C

Resolution (dp): 2

Brightness (%): 100

Figure 17

Parameter Description

Pressure unit used for cell pressure

Pressure Units

Available Options: psig, psia, MPa, kPa, barg, bara

Temperature

Units

Resolution (dp)

Brightness (%)

Table 2 Display Setup Screen Parameters

Temperature units used for dew point and temperature

Available Options: °C, °F

Number of decimal places used for display units

Available Options: 0, 1, 2

Brightness of display backlight

Available Options: 20 to 100%

Display Setup Screen

30 97319 Issue 4.2, November 2018

Page 39

OptiPEAK TDL600 User’s Manual

3.7.3 Log Menu Screen

The Data Logging Screen allows data-logging to the SD card, which is fi tted to the rear

of the display PCB. Refer to Section 4.2 for instructions on fi tting and removing the SD

card.

OPERATION

When logging is active it will be indicated by a disc icon

This screen is accessed by pressing the

Use the

the

required and press the

Press the

Up () and Down () keys to highlight the parameter of interest and press

ENTER key to access. Use the Up () and Down () keys to choose the option

ENTER key to accept.

ESC key to return to the Run Mode Screen.

ENTER key from the Main Menu Screen.

on the Run-Mode Screen.

Data Logging

Log Period: 15s

Log#: 0

Stop Log: No

Figure 18

Parameter Description

Sets the interval at which data is recorded in the log fi le

Log Period

Available Options: 15s, 1min, 5min, 30min, 1hr, 4hrs, 24hrs

Log #

Stop Log

Table 3 Data Logging Screen Parameters

0 - 9

Yes/No

Data Logging Screen

Michell Instruments 31

Page 40

OPERATION

3.7.4 About Screen

The Contact/About Screen shows the current fi rmware version and company contact

information.

OptiPEAK TDL600 User’s Manual

This screen is accessed by pressing the

Press the

ESC key to return to the Run Mode Screen.

Contact/About

Michell Instruments

Web: www.michell.com

Firmware Part no: 36219

Firmware ver: 01.09

Hw Serial No: 123123

Figure 19

ENTER key from the Main Menu Screen.

Contact/About Screen

3.7.5 Graph Screen

The Graph screen shows a graph of primary measurement parameter over time.

This screen is accessed by pressing the

Down () key changes the scale of the selected primary measurement parameter

The

axis. The

Press the

Up () key changes the scale of the time axis.

ESC key to return to the Run Mode Screen.

ENTER key from the Main Menu Screen.

300

250

200

150

100

50

V

ppm

0

0hrs-1-2-3-4-5-6-7

Figure 20

Graph Screen

32 97319 Issue 4.2, November 2018

Page 41

OptiPEAK TDL600 User’s Manual

3.7.6 Advanced Settings Screen

This screen is accessed by pressing the ENTER key from the Main Menu Screen.

Passcode

To safeguard against unauthorized adjustment of Advanced Settings options, an entry

lock is provided.

OPERATION

The user must fi rst input the access code

The Down () key selects the digit and the Up () key changes the value of the

currently selected digit. Press the

Screen.

After the passcode is entered use the

required and press the

Screen.

ENTER key or press the ESC key to return to the Run-Mode

ENTER key to access the Advanced Settings Options

7316.

Up () and Down () keys to choose the option

Advanced Settings

Outputs

Alarms

Inputs

Region

N2-Mode

Safe Mode

Clock

Modbus

Figure 21

Advanced Settings Screen Options

• Outputs

• Alarms

• Inputs

• Clock

• Modbus

• Region

• N2-Mode

• Safe Mode