Page 1

SF82

Dew-Point Transmitter

User’s Manual

97576 Issue 1

nbn Austria GmbH

June 2019

Page 2

Please fill out the form(s) below for each analyzer that has been purchased.

Analyzer

Code

Serial Number

Invoice Date

Location of Analyzer

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Analyzer

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Analyzer

Tag No

Use this information when contacting Michell Instruments for service purposes.

Page 3

SF82

For Michell Instruments’ contact information please go to

www.michell.com

© 2019 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or otherwise

reproduced, communicated in any way to third parties, nor stored in any Data Processing System

without the express written authorization of Michell Instruments Ltd.

Page 4

SF82 Transmitter User’s Manual

CONTENTS

Safety ........................................................................................................................ iii

Electrical Safety .......................................................................................................... iii

Pressure Safety ........................................................................................................... iii

Toxic Materials ............................................................................................................ iii

Repair and Maintenance .............................................................................................. iii

Calibration .................................................................................................................. iii

Safety Conformity ....................................................................................................... iv

Abbreviations .............................................................................................................. iv

Warnings .................................................................................................................... iv

1. INTRODUCTION ..................................................................................................... 1

2. INSTALLATION ....................................................................................................... 2

2.1. Unpacking the Instrument ......................................................................................... 2

2.2. Preparation of the Sensor Cable ................................................................................ 3

2.3. Cable Connection ..................................................................................................... 5

2.4. Electrical Schematic .................................................................................................. 5

2.4.1. Electrical Boundaries ........................................................................................... 6

2.4.2. Digital Communications (M12 Version Only) .......................................................... 6

2.5. Transmitter Installatiom ............................................................................................ 6

2.5.1. Sampling Considerations ..................................................................................... 6

2.5.2. Good Measuring Practice ..................................................................................... 9

2.5.3. Transmitter Mounting ....................................................................................... 12

i Michell Instruments

Page 5

SF82 Transmitter User’s Manual

APPENDICES

Appendix A ............................................................................................................... 16

Technical Specifications ................................................................................................. 17

Product Dimensions ...................................................................................................... 19

Appendix B ............................................................................................................... 22

Quality, Recycling & Warranty Information ...................................................................... 23

Appendix C ............................................................................................................... 24

Return Document & Decontamination Declaration ........................................................... 25

Appendix D ............................................................................................................... 26

Modbus Register Map .................................................................................................... 27

Register Address ........................................................................................................... 28

FIGURES

Figure 1 Connector Terminal Block Removal ......................................................................... 3

Figure 2 Wiring Connections ............................................................................................... 3

Figure 3 Sensor Connector Installation ................................................................................. 4

Figure 4 Cable Connections ................................................................................................. 4

Figure 5 Connector Installation ............................................................................................ 5

Figure 6 2-Wire Connection Diagram ................................................................................... 5

Figure 7 Maximum Load of SF82 - Including Cable Resistance................................................ 6

Figure 8 Installation Location .............................................................................................. 7

Figure 9 Installation Location .............................................................................................. 8

Figure 10 Transmitter Mounting - Sensor Block ..................................................................... 9

Figure 11 Material Permeability Comparison ......................................................................... 9

Figure 12 Transmitter Mounting - Pipe or Duct ................................................................... 12

Figure 13 Transmitter Mounting with Adapter ..................................................................... 14

97576 Issue 1, June 2019 ii

Page 6

SF82 Transmitter User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the

safe operation and to maintain the equipment in a safe condition. The safety instructions are

either warnings or cautions issued to protect the user and the equipment from injury or damage.

Use competent personnel using good engineering practice for all procedures in this manual.

Electrical Safety

This instrument is designed to be electrically safe when used with the options and accessories

supplied by Michell Instruments for use with it. This instrument has been independently verified

as complying with the IEC/EN 61010 Standard for Electrical Safety for Europe and for the

equivalent 61010 standards in use in N. America. The instrument is approved for use within the

operating temperature range of -40°C to +60°C, and dependant on version, as being IP66/65.

See Specification section for full details.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied to the instrument.

The specified safe working pressure is 45 MPag (450 barg / 6500 psig). Refer to the Technical

Specifications in Appendix A.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be

exercised during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent.

For Michell Instruments’ contact information please go to www.michell.com.

Calibration

The recommended calibration interval for this instrument is 12 months unless it is to be used in

a mission-critical application or in a dirty or contaminated environment in which case the

calibration interval should be reduced accordingly. The instrument should be returned to the

manufacturer, Michell Instruments Ltd., or one of their accredited service agents for recalibration.

iii Michell Instruments

Page 7

SF82 Transmitter User’s Manual

Where this hazard symbol appears in the following

Safety Conformity

This product meets the essential protection requirements of the relevant EU and US standards

and directives.

Abbreviations

The following abbreviations are used in this manual:

barg pressure unit (=100 kP or 0.987 atm) (bar gauge)

ºC degrees Celsius

ºF degrees Fahrenheit

DC direct current

g grams

in inch(es)

µm micrometer

m/sec meters per second

mA milliampere

mm millimetres

MPa megapascal

Nl/min normal liters per minute

Nm Newton meter

oz ounces

psig pounds per square inch

RH relative humidity

scfh standard cubic feet per hour

fps feet per second

T temperature

V Volts

Ω Ohms

ø diameter

Warnings

The following general warning listed below is applicable to this instrument. It is repeated in the

text in the appropriate locations.

sections it is used to indicate areas where potentially

hazardous operations need to be carried out.

97576 Issue 1, June 2019 iv

Page 8

SF82 Transmitter User’s Manual

1. INTRODUCTION

The Michell Instruments SF82 is a loop-powered dew-point transmitter, designed to make dew

point measurements in a flowing sample. The SF82 transmitter is available with 3 different

process connections:

• 5/8” - 18 UNF

• 3/4” – 16 UNF

• G1/2” - BSPP

The SF82 2-wire is available with a choice of electrical connections:

• DIN 43650 Form C

• M12 5-pin

1 Michell Instruments

Page 9

SF82 Transmitter User’s Manual

2. INSTALLATION

2.1. Unpacking the Instrument

On delivery, please check that all the following standard components are in the packing box:

• SF82 Transmitter

• Certificate of Calibration

• Connector (for sensor/cable) for MiniDIN 43650 C version only

It is recommended that all packaging is retained, in case products are returned for service or

calibration. Alternatively, if you choose to dispose of the packaging materials, ensure they are

recycled in accordance with local legislation.

The transmitter will also be supplied with a process seal, which will be fitted to the unit.

Depending on the version, this will either be a bonded seal (5/8” or G1/2” thread versions) or an

o-ring seal (3/4” thread versions).

The transmitter sensing element is protected while in transit by a cover containing a

small desiccant capsule. The connection pins are protected by a red plastic cap. None

of these plastic items are required for the operation of the transmitter. It is

recommended that the MiniDIN 43650 C connector is kept in a safe place until the

transmitter is ready for wiring.

97576 Issue 1, June 2019 2

Page 10

SF82 Transmitter User’s Manual

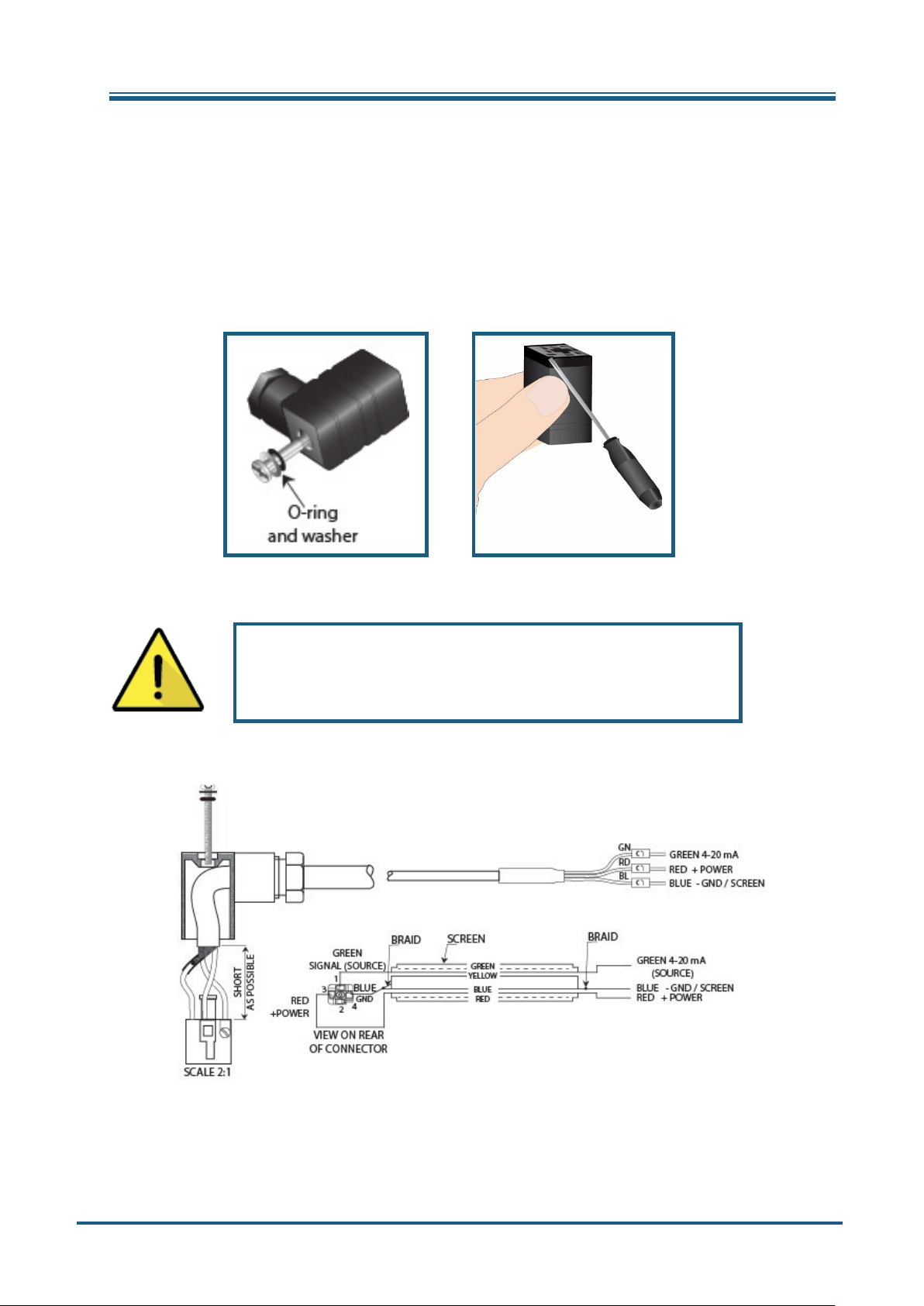

Caution: when removing the central screw ensure that

Figure 2 Wiring Connections

Figure 1 Connector Terminal Block Removal

2.2. Preparation of the Sensor Cable

The sensor cable is NOT supplied as standard. Cables can be obtained by contacting your local

Michell Instruments representative (see www.michell.com for details).

DIN 43650 Version

Cable connections to the SF82 transmitter are made via the removable connector. Removing the

central screw enables the connector terminal block to be removed from the outer housing by

using a small screwdriver to prise it clear.

\

the small sealing O-ring and the washer are retained on

the screw and are present during re-installation

The sensor cables are terminated as per the following diagram:

Note: The cable screen (see figure 2) should only be connected to a ground point at

either the transmitter installation side, or at the receiving equipment. Failure to

observe this precaution can result in ground loops and equipment malfunction.

3 Michell Instruments

Page 11

SF82 Transmitter User’s Manual

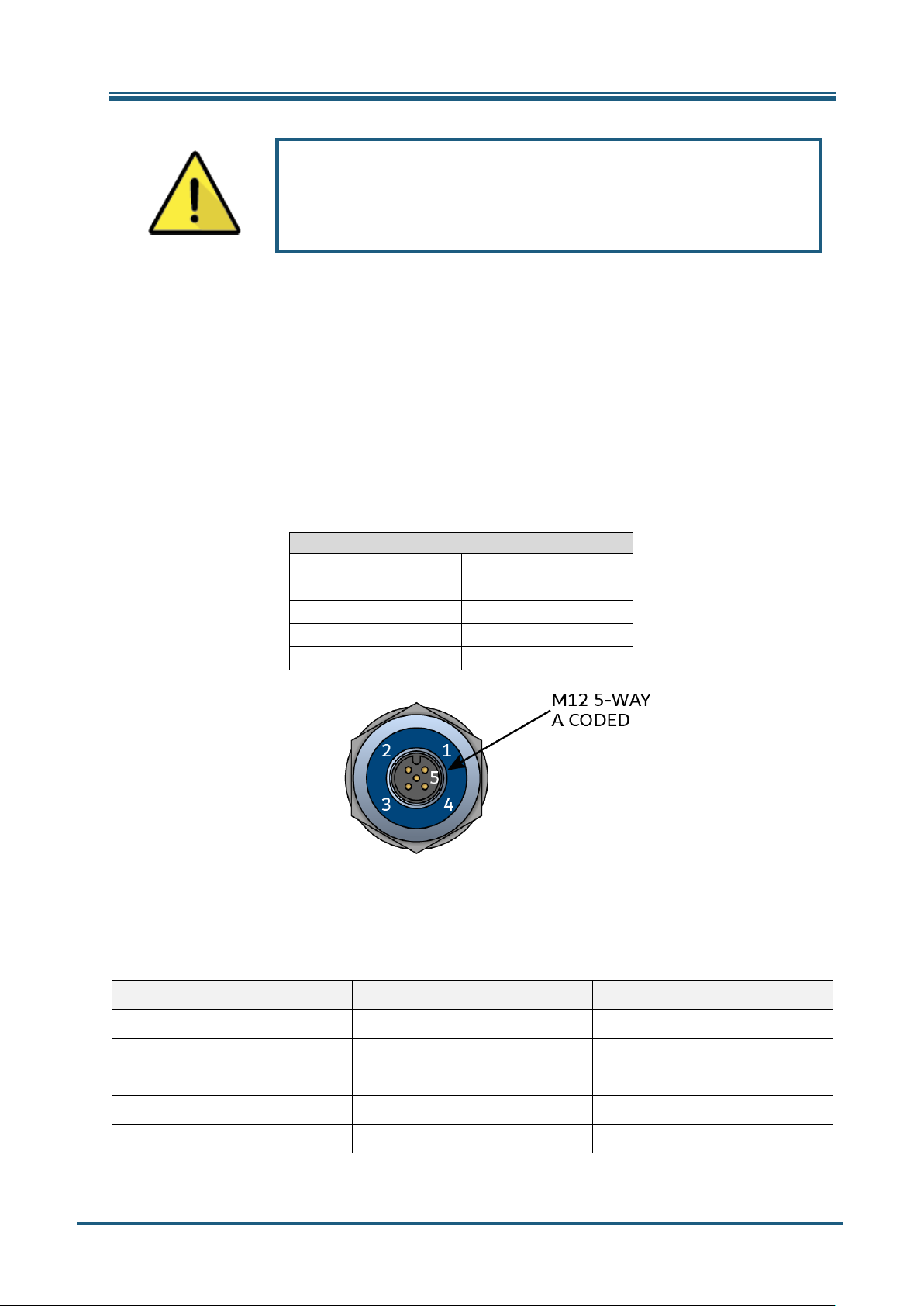

Always connect the 4-20 m return signal to a suitable load

4-20 mA 2-wire

PIN 1

Modbus A

PIN 2

Modbus B

PIN 3

4-20 mA

PIN 4

Power Supply

PIN 5

0 V

Function

Pin

Wire Colour

Modbus A

1

Brown

Modbus B

2

White

4 -20 mA

3

Blue

Power Supply

4

Black

0 v

5

Grey

Figure 3 Sensor Connector Installation

(see figure 3) before the power is applied. Without this

connection, the transmitter may be damaged if allowed to

operate for prolonged periods.

M12 5-Pin Version

Cables with moulded M12 connectors are available from Michell Instruments in the following

lengths:

• 0.8 m

• 2 m

• 5 m

• 10 m

The other end of the sensor cable is unterminated, for straightforward connection into the

desired monitoring system.

Figure 4 Cable Connections

97576 Issue 1, June 2019 4

Page 12

SF82 Transmitter User’s Manual

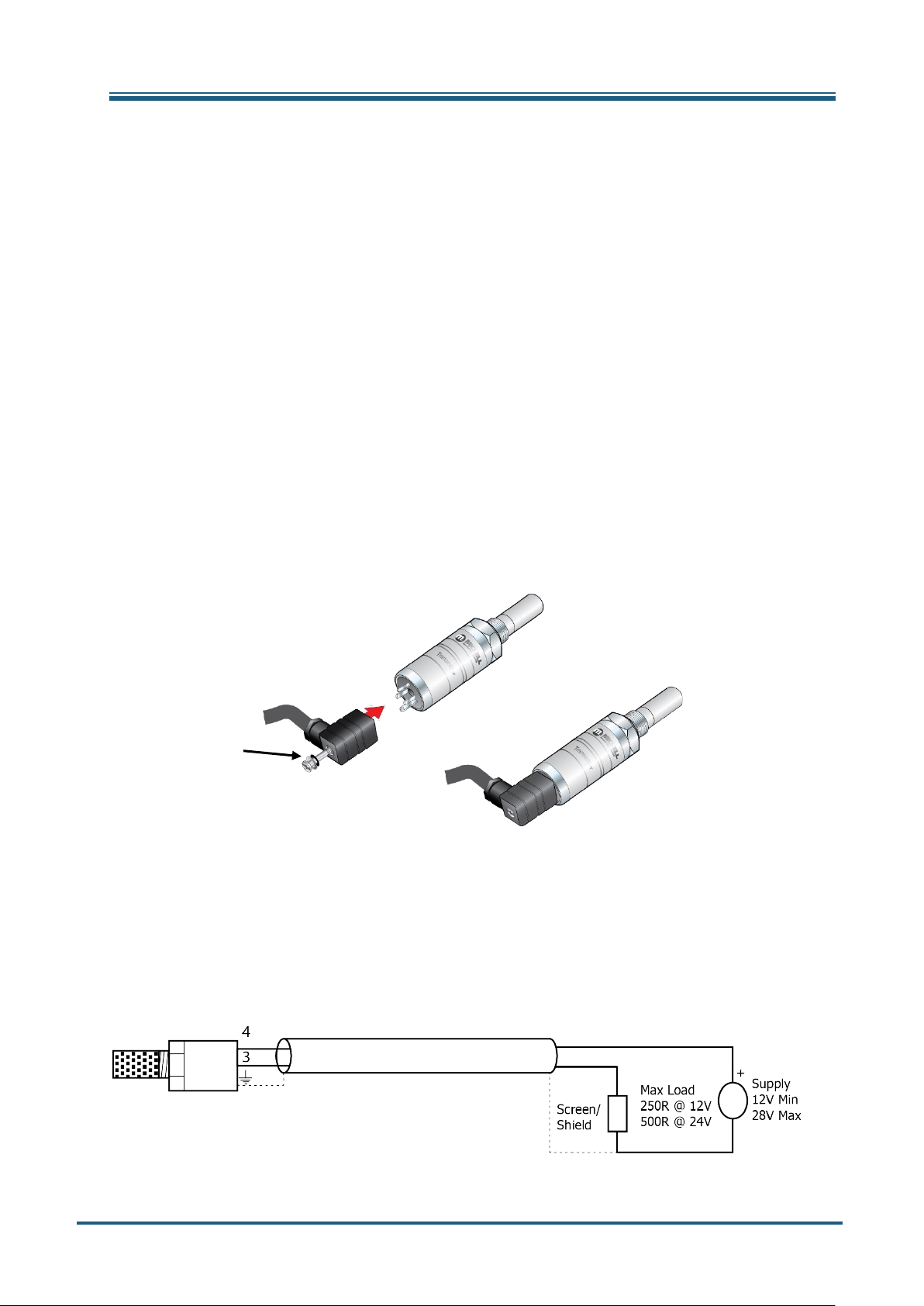

Figure 5 Connector Installation

Figure 6 2-Wire Connection Diagram

O-ring and

washer

If longer cable runs are required, off the shelf 5-pin M12 cables can be connected between the

SF82 transmitter and the cable provided by Michell Instruments.

Note: The cable screen should only be connected to ground point at either the

transmitter installation side or at the receiving equipment. Failure to observe this

precaution can result in ground loops and equipment malfunction.

2.3. Cable Connection

DIN 43650 Version

To ensure the specified ingress protection is achieved, when installing the connector, the securing

screw (with the O-ring and washer) must be tightened to a minimum torque of 3.4 Nm (2.5 ftlbs). The sensor cable used must be a minimum diameter of 4.6 mm (0.2”).

M12 5-Pin Version

The connector should be installed by aligning the locating pin on the transmitter with the slot

on the cable. The connector can then be pushed into place and rotated until finger tight.

2.4. Electrical Schematic

Note: The cable screen should only be connected to a ground point at either the

transmitter installation side, or at the receiving equipment. Failure to observe this

precaution can result in ground loops and equipment malfunction.

5 Michell Instruments

Page 13

Figure 7 Maximum Load of SF82 - Including Cable Resistance

2.4.1. Electrical Boundaries

SF82 Transmitter User’s Manual

2.4.2. Digital Communications (M12 Version Only)

Modbus RTU over RS485 communication is available on the SF82 M12, and can be used

simultaneously with the 2-wire current output. Section 2.2 describes the electrical connections to

the transmitter.

The Modbus register map can be found at the end of this manual.

2.5. Transmitter Installatiom

2.5.1. Sampling Considerations

There are two basic methods of measuring a sample with the SF82 Transmitter:

In-situ measurements are made by placing the transmitter inside the environment to be

measured.

Extractive measurements are made by installing the sensor into a block within a sample handling

system and flowing the sample outside of the environment to be measured through this system.

Extractive measurements are recommended when the conditions in the environment to be

measured are not conducive to making reliable measurements with the product.

Examples of such conditional limitations are:

• Excessive flow rate

• Presence of particulates matter

• Presence of entrained liquids

• Excessive sample temperature

97576 Issue 1, June 2019 6

Page 14

SF82 Transmitter User’s Manual

Figure 8 Installation Location

The basic considerations for each measurement type are as follows:

In-Situ

1. Dew-Point Sensor Position – will the sensor see an area of the environment that is

representative of what you want to measure?

For example, if the sensor is to be mounted into a glove box, there are three different positions

in which it could be installed – each giving a different measurement:

• Position A is on the purge inlet. In this position the sensor will confirm the dew point of the

gas entering the glove box but will not detect any leaks in the glove box itself, or any moisture

released from the work piece.

• Position B is on the gas outlet. In this position the sensor will be exposed to the gas leaving

the glove box and will therefore be detecting any moisture which has entered into the system

(e.g. ingress/leaks) or has been released by the work piece.

• Position C is in the glovebox itself, in this position the sensor will be only detecting any moisture

in its immediate vicinity. Leaks not in close proximity to the measurement point may not be

detected as this moisture could be drawn directly to the outlet.

If the transmitter is to be mounted directly into a pipe or duct, then consider that the installation

point should not be too close to the bottom of a bend where oil or other condensate may collect.

7 Michell Instruments

Page 15

SF82 Transmitter User’s Manual

Figure 9 Installation Location

2. Gas speed – if you are planning on installing the sensor in a duct, consider how fast the

sample gas is moving through it.

• If the gas speed is very low, or occasionally static, then the moisture content through the

length (and width, if it is more than a few cm across) of the duct is unlikely to be uniform.

• Extremely high gas speeds can cause damage to the sensor. Direct insertion is not

recommended in gas speeds in excess of 10m/s (32.8ft/s).

3. Particulates – Particulates travelling at speed can cause severe and irreversible damage to

the sensor. At low velocity they can cling to the sensor, reducing its’ surface area, and

therefore response speed.

The sensor is provided with a basic level of particulate protection in the form of a sintered guard;

either HMWPE (10μm pore size) or Stainless Steel (80μm pore size). If the sample stream

contains smaller particulates than this, or generally large amounts of dust; extractive

measurement is recommended to accommodate proper in-line filtration.

4. Sample Temperature – Although the sensor can be operated at sample temperatures up

to 60°C, it is advisable to keep the sample temperature as close to ambient, and as stable as

possible to keep adsorption & desorption characteristics as consistent as possible (see section

2.5.2 Sampling Hints for more information).

Extractive

If the sensor is to be mounted into a sample conditioning system, then the above points are still

of relevance, but it is important to consider the extraction point itself – make sure that the chosen

extraction point is representative of the process, i.e. that the sample of interest is flowing past

the extraction point, and it is not being pulled from a dead volume.

97576 Issue 1, June 2019 8

Page 16

SF82 Transmitter User’s Manual

Figure 10 Transmitter Mounting - Sensor Block

Figure 11 Material Permeability Comparison

2.5.2. Good Measuring Practice

Ensuring reliable and accurate moisture measurements requires the correct sampling techniques,

and a basic understanding of how water vapour behaves. This section aims to explain the

common mistakes and how to avoid them.

Sampling Materials – Permeation and Diffusion

All materials are permeable to water vapour since water molecules are extremely small compared

to the structure of solids, even including the crystalline structure of metals. The graph above

demonstrates this effect by showing the increase in dew point temperature seen when passing

very dry gas through tubing of different materials, where the exterior of the tubing is in the

ambient environment. If the partial water vapour pressure exerted on the outside of a

compressed air line is higher than on the inside, the atmospheric water vapour will naturally push

through the porous medium causing water to migrate into the pressurised air line. This effect

is called transpiration.

9 Michell Instruments

Page 17

SF82 Transmitter User’s Manual

What this demonstrates is the dramatic effect that different tubing materials have on the humidity

levels of a gas passed through them. Many materials contain moisture as part of their structure

and when these are used as tubing for a dry gas the gas will absorb some of the moisture. Always

avoid using organic materials (e.g. rubber), materials containing salts and anything which has

small pores which can easily trap moisture (e.g. nylon).

As well as trapping moisture, porous sampling materials will also allow moisture vapour to ingress

into the sample line from outside. This effect is called diffusion and occurs when the partial water

vapour pressure exerted on the outside of a sample tube is higher than on the inside. Remember

that water molecules are very small so in this case the term ‘porous’ applies to materials that

would be considered impermeable in an everyday sense – such as polyethylene or PTFE. Stainless

steel and other metals can be considered as practically impermeable and it is surface finish of

pipework that becomes the dominant factor. Electropolished stainless steel gives the best results

over the shortest time period.

Take into consideration the gas you are measuring, and then choose materials appropriate to

the results you need. The effects of diffusion or moisture trapped in materials are more significant

when measuring very dry gases than when measuring a sample with a high level of humidity.

Temperature and Pressure effects

As the temperature or pressure of the environment fluctuates, water molecules are adsorbed and

desorbed from the internal surfaces of the sample tubing, causing small fluctuations in the

measured dew point.

Adsorption is the adhesion of atoms, ions, or molecules from a gas, liquid, or dissolved solid to

the surface of a material, creating a film. The rate of adsorption is increased at higher pressures

and lower temperatures.

Desorption is the release of a substance from or through the surface of a material. In constant

environmental conditions, an adsorbed substance will remain on a surface almost indefinitely.

However, as the temperature rises, so does the likelihood of desorption occurring.

Ensuring the temperature of the sampling components is kept at consistent levels is important

to prevent temperature fluctuation (i.e. through diurnal changes) continually varying the rates of

adsorption and desorption. This effect will manifest through a measured value which increases

during the day (as desorption peaks), then decreasing at night as more moisture is adsorbed into

the sampling equipment.

If temperatures drop below the sample dew point, water may condense in sample tubing and

affect the accuracy of measurements.

97576 Issue 1, June 2019 10

Page 18

SF82 Transmitter User’s Manual

Maintaining the temperature of the sample system tubing above the dew point of the sample is

vital to prevent condensation. Any condensation invalidates the sampling process as it reduces

the water vapour content of the gas being measured. Condensed liquid can also alter the humidity

elsewhere by dripping or running to other locations where it may re-evaporate.

Although ambient pressure does not change drastically in a single location, the gas sample

pressure does need to be kept constant to avoid inconsistencies introduced by adsorption or

desorption. The integrity of all connections is also an important consideration, especially when

sampling low dew points at an elevated pressure. If a small leak occurs in a high-pressure line,

gas will leak out, however, vortices at the leak point and a negative vapour pressure differential

will also allow water vapour to contaminate the flow.

Theoretically flow rate has no direct effect on the measured moisture content, but in practice it

can have unanticipated effects on response speed and accuracy. An inadequate flow rate may:

• Accentuate adsorption and desorption effects on the gas passing through the sampling system.

• Allow pockets of wet gas to remain undisturbed in a complex sampling system, which will then

gradually be released into the sample flow.

• Increase the chance of contamination from back diffusion. Ambient air that is wetter than the

sample can flow from the exhaust back into the system. A longer exhaust tube can help

alleviate this problem.

• Slow the response of the sensor to changes in moisture content.

An excessively high flow rate can:

• Introduce back pressure, causing slower response times and unpredictable changes in dew

point

• Result in a reduction in depression capabilities in chilled mirror instruments by having a cooling

effect on the mirror. This is most apparent with gases that have a high thermal conductivity

such as hydrogen and helium.

System design for fastest response times

The more complicated the sample system, the more areas there are for trapped moisture to hide.

The key pitfalls to look out for here are the length of the sample tubing and dead volumes.

The sample point should always be as close as possible to the critical measurement point to

obtain a truly representative measurement. The length of the sample line to the sensor or

instrument should be as short as possible. Interconnection points and valves trap moisture, so

using the simplest sampling arrangement possible will reduce the time it takes for the sample

system to dry out when purged with dry gas.

Over a long tubing run, water will inevitably migrate into any line, and the effects of adsorption

and desorption will become more apparent.

11 Michell Instruments

Page 19

SF82 Transmitter User’s Manual

Figure 12 Transmitter Mounting - Pipe or Duct

Dead volumes (areas which are not in a direct flow path) in sample lines, hold onto water

molecules which are slowly released into the passing gas. This results in increased purge and

response times, and wetter than expected readings. Hygroscopic materials in filters, valves (e.g.

rubber from pressure regulators) or any other parts of the system can also trap moisture.

Plan your sampling system to ensure that the sample tap point and the measurement point are

as close as possible to avoid long runs of tubing and dead volumes.

Filtration

All trace moisture measurement instruments and sensors are by their nature sensitive devices.

Many processes contain dust, dirt or liquid droplets. Particulate filters are used for removing dirt,

rust, scale and any other solids that may be in a sample stream. For protection against liquids, a

coalescing or membrane filter should be used. The membrane provides protection from liquid

droplets and can even stop flow to the analyser completely when a large slug of liquid is

encountered, saving the sensor from potentially irreparable damage.

2.5.3. Transmitter Mounting

Once an installation location has been chosen, this point will require a thread to match the

transmitter thread. Fixing dimensions are shown in Figure 6. For circular pipework, to ensure the

integrity of a gas tight seal, a mounting flange will be required on the pipework in order to provide

a flat surface to seal against.

97576 Issue 1, June 2019 12

Page 20

SF82 Transmitter User’s Manual

5/8” 18 UNF Version

1. Remove the protective cover and desiccant capsule from the transmitter and retain for future

use

2. Prevent any contamination of the sensor before installation by handling the transmitter by

the main body only, avoiding contact with the sensor guard.

3. Pass the bonded seal over the 5/8”- 18 UNF mounting thread.

4. Screw the transmitter into the sampling location or sample block by hand using the wrench

flats only. DO NOT grip and twist the sensor cover when installing the sensor.

5. When installed, fully tighten using a wrench to a torque setting of 30.5 Nm (22.5 ft-lbs)

3/4” - 16 UNF Version

1. Remove the protective cover and desiccant capsule from the transmitter and retain for future

use.

2. Prevent any contamination of the sensor before installation by handling the transmitter by

the main body only, avoiding contact with the sensor guard.

3. Ensure that the O-ring is seated in the recess at the top of the transmitter body.

4. Screw the transmitter into the sampling location or sample block by hand using the wrench

flats only. DO NOT grip and twist the sensor cover when installing the sensor.

5. When installed, fully tighten using a wrench to a torque setting of 40 Nm (29.5 ft-lbs).

G1/2" BSPP Version

1. Remove the protective cover and desiccant capsule from the transmitter and retain for future

use

2. Prevent any contamination of the sensor before installation by handling the transmitter by

the main body only, avoiding contact with the sensor guard.

3. Pass the bonded seal over the G1/2" mounting thread.

4. Screw the transmitter into the sampling location or sample block by hand using the wrench

flats only. DO NOT grip and twist the sensor cover when installing the sensor.

5. When installed, fully tighten using a wrench to a torque setting of 30.5 Nm (22.5 ft-lbs)

13 Michell Instruments

Page 21

SF82 Transmitter User’s Manual

Figure 13 Transmitter Mounting with Adapter

Installation using Additional Thread Adaptor

1. Remove the protective cover and desiccant capsule from the transmitter and retain for future

use

2. Prevent any contamination of the sensor before installation by handling the transmitter by

the main body only, avoiding contact with the sensor guard.

3. Pass the bonded seal over the 5/8”- 18 UNF mounting thread.

4. Screw the transmitter into the adaptor, and tighten to 30.5 Nm (22.5 ft-lbs)

5. NOTE: Use the flats of the hexagonal nut and not the sensor body.

6. Screw the transmitter (1) with its seal (3) and adapter (4) into the sampling location block

(and fully tighten using a wrench to the following torque settings:

• G 1/2” BSP 56 Nm (41.3 ft-lbs)

• 3/4” - 16 UNF 40 Nm (29.5 ft-lbs)

97576 Issue 1, June 2019 14

Page 22

SF82 Transmitter User’s Manual

Figure 14 Replacement HMWPE Guard

Handle, using

Calibration

Annual recalibration of the SF82 is recommended to maintain the performance. Calibration

services traceable to the UK National Physical Laboratory (NPL) and the US National Institute of

Standards and Technology (NIST) are provided by Michell Instruments.

Michell Instruments offers a variety of re-calibration and exchange sensor schemes to suit specific

needs. A Michell representative can provide detailed, custom advice (for Michell Instruments’

contact information go to www.michell.com).

Sensor Guard Replacement

The sensor is supplied with a white HMWPE guard (standard) or a stainless steel guard (if

specified at time or order).

The sensor guard should be replaced if the surface shows any damage or signs of discolouration.

When replacing a guard, make sure to wear clean disposable gloves, and handle by the threaded

base section only.

Replacement HMWPE or stainless steel guards can be ordered from your Michell Instruments

representative.

gloves, by white

knurled part only

Bonded Seal

If the supplied bonded seal is damaged or lost, a pack of 5 replacement bonded seals can be

obtained by contacting your Michell Instruments representative.

O-ring Seal

If the supplied O-ring seal is damaged or lost a pack of 5 replacement O-ring seals

can be obtained by contacting your Michell Instruments representative.

15 Michell Instruments

Page 23

SF82 Transmitter User’s Manual

APPENDIX A

Technical Specifications

97576 Issue 1, June 2019 16

Page 24

SF82 Transmitter User’s Manual

Measurement Range (Dew

Point)

63% at room temperature at 1 bara

-20 ºC to -60 ºC dew point: 40 s

User configurable over range;

communications

-60 °C to +60 °C dew point

Analog only 23 mA max,

digital only 6 mA max

IEC61010-1, UL61010-1 &

EN50121-3-2 Rail EMC/RFI

Technical Specifications

Performance

Product

SF82 MiniDIN 43650 SF82 M12

-60 ºC to +60 ºC dew point

Accuracy (Dew Point)

Response Time

-60 ºC to -20 ºC dew point: 6 s

±2 °C dew point*

Repeatability 0.5 ºC dew point

Calibration 9-point calibration certificate traceable to national standards

Electrical Specifications

Output Signal

User configurable over range;

4-20 mA (2 wire connection,

current source)

4-20 mA (2 wire connection,

current source) Modbus RTU

over RS485 digital

Moisture Output Dew point or moisture content

Temperature Output Not available Data via Modbus RTU

Analog output scaled range

4-20 mA (Dew point)

Analog output scaled range

4-20 mA (Moisture content

in gas)

Supply Voltage 6.5 to 28 V DC 5 to 28 V DC

Load Resistance Max 250 Ω @ 12 V (500 Ω @ 24 V)

Current consumption 23 mA max

Electrical Safety

17 Michell Instruments

-50 °C to +50 °C dew point

-50 °C to +30 °C dew point

-80 °C to +20 °C dew point

-20 °C to +50 °C dew point

(Non standard ranges available on request)

0 to 24000 ppm

(Non standard ranges available on request)

IEC61010-1, UL61010-1 &

CAN/CSA C22.2 No. 61010

v

CAN/CSA C22.2 No. 61010

EN61373 Rail Rolling Stock

Page 25

SF82 Transmitter User’s Manual

Compensated temperature

Maximum Operating

IP66 in accordance with BS EN

(current version)

L = 133 mm x ø45 mm

(with connector cable)

L = 156 mm x ø45 mm

(with connector cable)

Standard: HMWPE <10 µm

Optional: 316 stainless steel sintered guard <80 µm

5/8” - 18 UNF

Mating connector supplied as

available

Sensor fault: 23 mA

Over-range dew point: mA

Operating Specifications

Operating temperature

range

Storage Temperature

Pressure

Pressure Safety Rating

Flow rate

10 MPag (100 barg) maximum

45 MPag (450 barg) maximum

1 to 5 Nl/min mounted in standard sampling block; 0 to 10

-20 °C to +60 °C

-20 °C to +50 °C

-40 °C to +60 °C

m/sec direct insertion

Mechanical Specifications

60529 (current version):

Ingress protection

NEMA 4 ingress protection in

accordance with NEMA 250

Housing material 316 stainless steel

IP65

Dimensions

Filter (sensor protection)

Process connection

3/4” - 16 UNF

G1/2” - BSP

Weight 150 g (excluding connector cable)

Electrical connections MiniDIN 43650 form C M12 5 pin (A coded)

Optional 0.8 , 2, 5, 10 meter

M12 A coded

connector/cable available

Mating Electrical

Connectors

Diagnostic conditions

standard

Optional 0.8, 2, 5, 10 metre

MiniDIN connector/cable

Under-range dew point: mA

(factory programmed)

NOTES: * Over Compensated Temperature Range

97576 Issue 1, June 2019 18

Page 26

SF82 Transmitter User’s Manual

M12, 5/8” UNF

M12, G1/2

M12, 3/4" UNF

Product Dimensions

19 Michell Instruments

Page 27

SF82 Transmitter User’s Manual

MiniDIN, 5/8” UNF

MiniDIN, G1/2

MiniDIN, 3/4” UNF

97576 Issue 1, June 2019 20

Page 28

SF82 Transmitter User’s Manual

5/8” UNF

G1/2

Quick Connect

3/4” UNF

21 Michell Instruments

Page 29

SF82 Transmitter User’s Manual

APPENDIX B

Quality, Recycling &

Warranty Information

97576 Issue 1, June 2019 22

Page 30

SF82 Transmitter User’s Manual

Quality, Recycling & Warranty Information

Michell Instruments is dedicated to complying to all relevant legislation and directives. Full

information can be found on our website at:

www.michell.com/compliance

This page contains information on the following directives:

• ATEX Directive

• Calibration Facilities

• Conflict Minerals

• FCC Statement

• Manufacturing Quality

• Modern Slavery Statement

• Pressure Equipment Directive

• REACH

• RoHS2

• WEEE2

• Recycling Policy

• Warranty and Returns

23 Michell Instruments

Page 31

SF82 Transmitter User’s Manual

APPENDIX C

Return Document &

Contamination Declaration

97576 Issue 1, June 2019 24

Page 32

SF82 Transmitter User’s Manual

Return Document & Decontamination Declaration

25 Michell Instruments

Page 33

SF82 Transmitter User’s Manual

APPENDIX D

Modbus Register Map

97576 Issue 1, June 2019 26

Page 34

SF82 Transmitter User’s Manual

16-bit unsigned integer, can contain options list e.g. 0 = Dew Point, 1 =

Temperature.

http://www.simplymodbus.ca/FAQ.htm is an excellent

be found in the sidebar.

https://www.scadacore.com/tools/programming-

Modbus Register Map

All the data values relating to the SF82 are stored in 16-bit wide holding registers. Registers can

contain either measured or calculated values (dew-point, temperature, etc.), or configuration

data (output settings).

Modbus RTU Implementation

This is a partial implementation of the Modbus RTU Standard with the following codes

implemented:

Function Code Description

3 Read Holding Register

6 Write Holding Register

16 Write Multiple Holding Registers

Register Types

Data Type Description

uint16

int16 16-bit signed integer.

int32 32-bit signed integer, stored across 2 16-bit registers.

float IEEE754 single precision floating pint, stored across 2 16-bit registers

Serial Port Settings (RS485)

9600 Baud Rate, 8 Data Bits, No Parity, 1 Stop Bit, No Flow Control

resource covering the basics of the Modbus protocol. Full

descriptions of the function codes (FC03/FC06/FC16) can

calculators/online-hex-converter/ is an excellent resource

for determining register types/byte order issues in raw

received Modbus data.

27 Michell Instruments

Page 35

Dec

Hex

Access

Data

Type

Description

Comment

Instrument Modbus

Address

1

01 R uint16

Instrument ID

Batch 0xA123

A123-001

3

03 R uint16

Sensor Serial Number

4

04 R uint16

Firmware Version

Divide by 1000, ie 12003 = V12.003

5

05 R uint16

Register Map Version

Divide by 1000, ie 12003 = V12.003

6

06 R uint16

Year of Calibration

7 07 R uint16

Month of Calibration

8 08 R uint16

Day of Calibration

… …

bit0 = Dew-point Sensor Short

bit15 = Hardware Fault

… …

17

11 R float

Dew Point (High Word)

18

12

Dew Point (Low Word)

19

13 R float

Temperature (High

Word)

20

14

Temperature (Low

Word)

Register Address

SF82 Transmitter User’s Manual

0 00 R uint16

2 02 R uint16 Sensor Batch Number

Serial 0x0001

Complete sensor serial would be

14 0E R special Status

bit1 = Dew-point Sensor Open

bit2 = Temperature Sensor Short

bit3 = Temperature Sensor Open

bit4 = Analogue Output UnderRange

bit5 = Analogue Output Over-Range

bit6 = Analogue Output Out-OfRange

...

bit14 = Memory Fault

97576 Issue 1, June 2019 28

Page 36

SF82 Transmitter User’s Manual

21

15 R float

ppmV Ideal Gas (High

Word)

22

16

ppmV Ideal Gas (Low

Word)

… …

101

65

R/W

float

Pressure Value (High

Word)

Used for ppmV Ideal Gas calculation

102

66

Pressure Value (Low

Word)

… …

110

6E

R/W

uint16

Analogue Output

0 = Off

3 = ppmV Ideal Gas

111

6F

R/W

float

Analogue Output Range

This value is clipped when

parameter ranges below

112

70

Analogue Output Range

Low (Low Word)

113

71

R/W

float

Analogue Output Range

This value is clipped when

parameter ranges below

114

72

Analogue Output Range

High (Low Word)

… …

R/W

uint16

Analogue Output,

R/W

uint16

Analogue Output, OverRange Output

R/W

uint16

Analogue Output, DewPoint Sensor Fault

R/W

uint16

Analogue Output,

Fault

120 78

Parameter

Low (High Word)

High (High Word)

Under-Range Output

1 = Dew Point

2 = Temperature

parameter is changed. See

parameter is changed. See

0 = None

1 = Low Alarm (3.5ma)

121 79

122 7A

123 7B

29 Michell Instruments

Temperature Sensor

2 = High Alarm (23ma)

3 = Minimum Scale (4ma)

4 = Maximum Scale (20ma)

5 = Namur Low Alarm (3.7ma)

6 = Namur High Alarm (20.5ma)

Page 37

Parameter Ranges

Min

Max

Dew Point

-150

250

Temperature

-150

250

ppmV

0

30000

SF82 Transmitter User’s Manual

97576 Issue 1, June 2019 30

Page 38

http://www.michell.com

Aufgrund laufender Weiterentwicklungen sind Änderungen der Spezikationen vorbehalten. Alle Angaben vorbehaltlich Satz- und Druckfehler.

nbn Austria GmbH

nbn @ nbn. at | www. nbn. atTel. +43 316 40 28 05 | Fax +43 316 40 25 06 Riesstraße 146, 8010 Graz

Loading...

Loading...