Page 1

Chilled Mirror Instruments

S8000

Precision Chilled Mirror Hygrometer

A high-precision hygrometer combining straightforward operation with very high sensitivity to

changes in moisture content.

Highlights

• ±0.1°Cdp (±0.18°Fdp) accuracy

• Fundamental, accurate and drift-free measurement

• Simple confi guration and operation via touch screen

interface

• Precision measurements to –60°C (–76°F) dew point

• FAST – guaranteed frost formation below 0°C

(+32°F)

• Measure at pressures up to 2 MPa (20 barg)

• USB, Ethernet, RS485 or RS232 connectivity

• Datalogging to SD card or via digital comms

www.michell.com

Applications

• Standards laboratory reference instrument

• Transformer vacuum drying verifi cation

• Clean/dry room environmental monitoring

• Metallurgical process monitoring

• Reference instrument for commercial calibration

laboratory

• Compressed air dryer R&D

switchgear moisture testing

• SF

6

• Hydrogen fuel cell R&D

Page 2

Chilled Mirror Instruments

S8000

Precision Chilled Mirror Hygrometer

The new S8000 Hygrometer provides a direct measurement

of dew point, temperature and pressure. Dew-point

measurement is based on the proven, fundamental optical

chilled mirror measurement principle, giving long-term

drift-free humidity measurement over the entire operating

range. The S8000 uses this measurement to offer a range

of available measurement units including ppmV, absolute

humidity, relative humidity and ppmW.

To further improve the accuracy of pressure-derived

calculated values (ppm

optional internal pressure transducer can be supplied,

which provides real-time pressure. This allows for continued

humidity measurement stability even during fl uctuations in

sample pressure.

, ppmW, absolute humidity), an

V

The difference in vapor pressure between condensed water

and ice formed on a chilled mirror can introduce dewpoint errors of up to 10% of reading. It is also possible

for intermediate states to exist, where the formation is a

mixture of ice and super-cooled water, making calculated

conversions from one state to the other invalid.

Frost Assurance Technology (FAST)

The S8000 features FAST, the frost assurance technology

which guarantees all dew-point measurements below 0°C

(+32°F) are made over ice. The FAST system works by

detecting whether the mirror is at a temperature where

super cooled water could form, and if so; rapidly cooling the

mirror until a fi lm of ice of predetermined thickness forms.

Once ice has formed, control returns to the instrument and

measurement can begin.

Microscope

A viewing microscope can be supplied with the instrument.

This enables the user to inspect the mirror directly during

the measurement process, and determine whether the

condensation on the surface is water or ice.

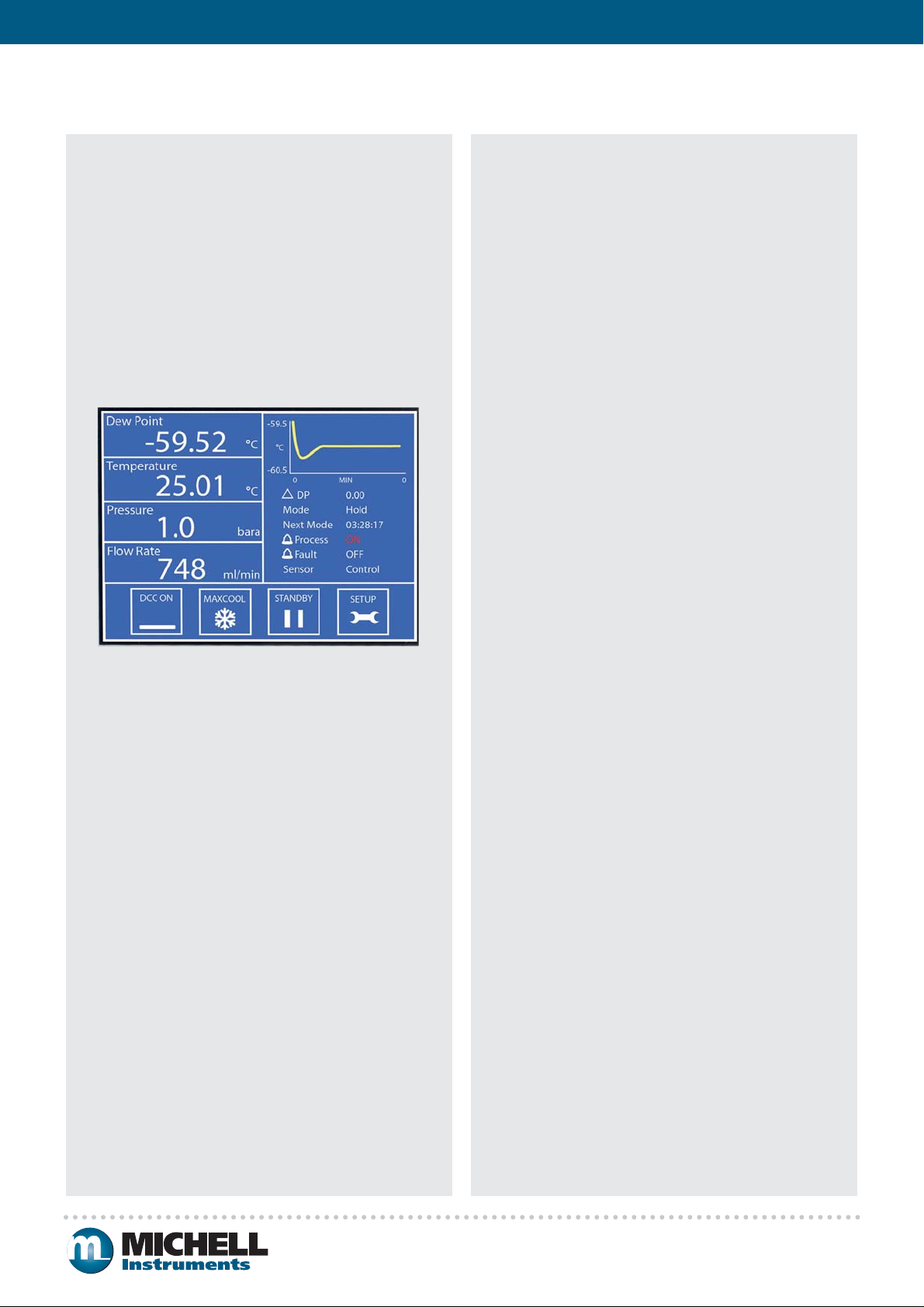

Use your Preferred Communications

Media

For greater fl exibility:

A pair of adjustable isolated alarm contacts allow the S8000

Chilled Mirror Hygrometer to be used for direct process

control. A high-contrast touch screen LCD display provides

entirely customizable local indication of the measured values,

along with a trend graph and fault warnings.

RRS Triple Optics for Increased

Sensitivity

The rate of frost formation on the surface of a chilled mirror

is slower at lower frost points. This is due to the very low

quantity of water molecules which are present – it takes

time for enough molecules to pass the mirror to form a layer

of frost. An accurate and reliable measurement with a nonfundamental hygrometer can be diffi cult to perform.

The S8000 utilizes the RRS Optical System to detect very

small changes in the quantity of moisture condensed on

the mirror surface, resulting in very high sensitivity and fast

response to changes in frost point, even at low levels of

moisture.

Confi dence of Seeing your Measurement

In carefully controlled laboratory conditions, super-cooled

water can exist in temperatures as low as –48°C (–54°F).

However, when using a chilled mirror instrument it only

occurs on the mirror at temperatures down to around –30°C

(–22°F).

• Modbus TCP over Ethernet

• Modbus RTU over: USB, RS232, RS485

• Datalogging to SD Card or via application software

• 3 user-confi gurable analog outputs

• Status and process alarms

DCC for Increased Reliability

The S8000 utilizes a system called DCC (Dynamic

Contamination Correction). The DCC system is intuitive and

adapts the instrument control to the operating conditions to

achieve optimum measurement performance at all times by

periodically re-balancing the optics to compensate for any

reduction in light intensity caused by contamination of the

components in the optical path. Although the DCC system is

fully automatic it can be confi gured by the user for individual

applications.

Application Software

Flexible application software is provided with the S8000,

allowing the operator to control all the functions of the

instrument directly from a PC. A parameter display shows

all measured and calculated parameters, and a customizable

graph is provided to display any combination of parameters

against a time base.

Data logging functionality is provided, allowing log fi les to be

created and saved directly on the host PC.

www.michell.com

Page 3

Technology:

Chilled Mirror

Michell’s chilled mirror dew-point hygrometers

are precision instruments for critical

measurement and control applications.

Chilled mirror sensors measure a primary

RRS

This means that chilled mirror instruments:

• Have no drift: the temperature at which condensation forms

is measured directly so there are no calculated variables that

could shift over time.

characteristic of moisture – the temperature at

which condensation forms on a surface.

Chilled Mirror Instruments

Experts in Chilled Mirror Technology

The S8000 is the result of 40 years’ experience of developing

chilled mirror technology.

As the world’s largest producer of high-quality dew-point

sensors, we use the S8000, along with other instruments in

the chilled mirror range, as the secondary references and

the working standards of our manufacturing and calibration

operations.

• Are inherently repeatable, giving reliable results every time.

These parameters mean that chilled mirrors are widely accepted

as the default choice for use as humidity calibration references.

The chilled mirror sensor consists of a temperature-controlled

mirror and the advanced RRS optical detection system. A beam

of light from an LED (4) is focused on the mirror surface (2) with

a fi xed intensity. As the mirror is cooled less light is refl ected due

to the scattering effect of the condensate formed on the mirror

surface. The level of light refl ected from the mirror surface

is measured by photo-detector 5, whereas photo-detector 6

measures light which is scattered by the condensate. The third

reference photo-detector (3) measures the intensity of light

from the LED, and compensates for changes in temperature

conditions.

The signals from this optical system are used to precisely

control the drive to a solid state thermoelectric cooler (TEC)

(1), which heats or cools the mirror surface. The mirror

surface is then controlled in an equilibrium state whereby

evaporation and condensation are occurring at the same rate.

In this condition the temperature of the mirror, measured by a

platinum resistance thermometer (7), is equal to the dew point

temperature of the gas.

Our chilled mirror instruments prove their reliability on

a daily basis in our production processes and service

centres, as well as in our UKAS-accredited calibration

laboratory.

5

4

3

6

2

7

1

www.michell.com

Page 4

Chilled Mirror Instruments

Technical Specifi cations

Dew-Point Sensor Performance

Measurement technology Chilled Mirror

Accuracy* ±0.1°C (±0.18°F)

Reproducibility ±0.05°C (±0.09°F)

Measurement range –60 to +40°Cdp (–76 to +104°Fdp)

Operating pressure

Low pressure version

High pressure version

Sample fl ow rate 0.1 to 1 Nl/min (0.2 to 2.1 scfh)

Detection system RRS Triple Detection

Remote PRT Probe (Optional)

Temperature

measurement

Measurement accuracy ±0.1°C (±0.18°F)

Cable length 2m (6.6’) (250m (820’) max)

Flow Sensor

Measurement accuracy Typical ±5% uncalibrated

Measurement range 0 to 1000 ml/min

Integrated Pressure Sensor (Optional)

Measurement range 0 to 25 bara (0 to 377 psia)

Measurement accuracy* 0.25% Full Scale

Measurement units psia, bara, KPa or MPag

Monitor

Resolution User-selectable to 0.001 dependant on

Measurement units °C and °F for dew point and temperature

Outputs

Analog

Digital

HMI 5.7” LCD with touchscreen, white on blue

Data logging SD Card (512Mb supplied) and USB interface

Environmental

conditions

0 to 1 barg / 14.5 psig

0 to 20 barg / 290 psig

4 wire Pt100, 1/10 DIN class B

parameter

3

%RH, g/m

calculated humidities

3 channels, user-selectable 4–20 mA,

0–20 mA or 0–1 V

Modbus RTU over USB, and optional Modbus

RTU over RS232, RS485 or Modbus TCP over

Ethernet

Alarm

Two volt-free changeover contacts, one

process alarm, one fault alarm; 1 A @ 30 V

DC

graphics

SD Card (FAT-32) — 32Gb max. that allows 24

million logs or 560 days, logging at 2 second

intervals

–20 to +40°C (–4 to +104°F)

, g/kg, ppmV , ppmW (SF6), for

Power supply 85 to 264 V AC, 47/63 Hz

Power consumption 100 V A

EMC - Class A Emissions

Industrial Location

Immunity

Complies with EN61236:1997 (+A1/A2/A3)

Mechanical Specifi cations

Dimensions 187 x 440 x 343mm (7.36 x 17.32 x 13.5”)

Weight 11.4kg (25.1lb)

h x w x d

General

Process connections 6mm Swagelok® or 1/4” Swagelok

Storage temperature –20 to +50°C (–40 to +122°F)

Calibration 3-point traceable in-house calibration as

standard

UKAS accredited calibrations optional —

please consult Michell

* Measurement accuracy means maximum deviation between instrument under

test and corrected reference. To this must be added the uncertainties associated

with the calibration system and the environmental conditions during testing or

subsequent use.

®

Dimensions

186.9 mm

7.358 ins

178.5 mm

7.028 ins

34 mm

1.337 ins

440.0 mm

17.323 ins

342.9 mm

13.498 ins

46.0 mm

1.811 ins

177.0 mm

7.0 ins

144.5 mm

5.689 ins

Related Products

S8000 RS

High Precision Hygrometer

Michell Instruments 48 Lancaster Way Business Park, Ely, Cambridgeshire, CB6 3NW

Tel: +44 (0)1353 658000, Fax: +44 (0)1353 658199, Email: info@michell.com, Web: www.michell.com/uk

Michell Instruments adopts a continuous development programme which sometimes necessitates specifi cation changes without notice.

Issue no: S8000_97509_V2_UK_Datasheet_0618

S8000 Remote

Remote High Precision

Hygrometer

Optidew Vision

Precision Dew-Point

Hygrometer

S4000 TRS

Precision Dew-Point

Hygrometer

© 2018 Michell Instruments

Loading...

Loading...