Page 1

S503

15Vdc

GND

INPUT

VO LT

INPUT

4-20mA

OFF

ON

8 6 3

% RH

SETPOINT

TEMP

RH

10V

5V

1V

mA

INPUT

SELECT

S-503

HUMIDITY GENERATOR

Humidity Calibrator

User’s Manual

97210 Issue 01, April 2011 Michell Instruments

Page 2

Inside front cover (blank)

Page 3

S503 User’s Manual

15Vdc

GND

INPUT

VO LT

INPUT

4-20mA

OFF

ON

8 6 3

% RH

SETPOINT

TEMP

RH

10V

5V

1V

mA

INPUT

SELECT

S-503

HUMIDITY GENERATOR

S503-DIG

© 2011 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or otherwise reproduced,

communicated in any way to third parties, nor stored in any Data Processing System without the express

written authorization of Michell Instruments Ltd.

97210 Issue 01, April 2011 iii Michell Instruments

Page 4

S503 User’s Manual

97210 Issue 01, April 2011 iv Michell Instruments

Contents

Safety .............................................................................................................................................. v

Electrical Safety ......................................................................................................................... v

Toxic Materials .......................................................................................................................... v

Repair and Maintenance............................................................................................................. v

Calibration ................................................................................................................................ v

Safety Conformity ...................................................................................................................... v

Abbreviations ....................................................................................................................................vi

Recycling Policy ................................................................................................................................vii

WEEE and RoHS Compliance .............................................................................................................vii

Calibration Facilities .......................................................................................................................... vii

Manufacturing Quality ...................................................................................................................... viii

Warranty ........................................................................................................................................ viii

Return Policy ................................................................................................................................... viii

1 INTRODUCTION ........................................................................................................................ 1

1.2 Applications .................................................................................................................... 1

1.3 Dimensions .................................................................................................................... 1

1.4 S503 Combinations ......................................................................................................... 2

1.4.1 S503-DIG ................................................................................................................... 2

1.4.2 S503-DIG-OPT ............................................................................................................ 2

1.4.3 S503-DIG-SET ............................................................................................................ 3

1.4.4 S-503-DIG-LC ............................................................................................................. 3

2 OPERATION .............................................................................................................................. 4

2.1 Front Panel Functions ...................................................................................................... 5

2.2 Back Panel Functions ...................................................................................................... 6

2.3 Getting Started ............................................................................................................... 7

2.4 Operating Instructions ..................................................................................................... 8

2.5 Connecting a Transmitter................................................................................................. 8

3 MAINTENANCE .......................................................................................................................... 9

4 TROUBLESHOOTING ................................................................................................................10

5 CALIBRATION ..........................................................................................................................11

Figures

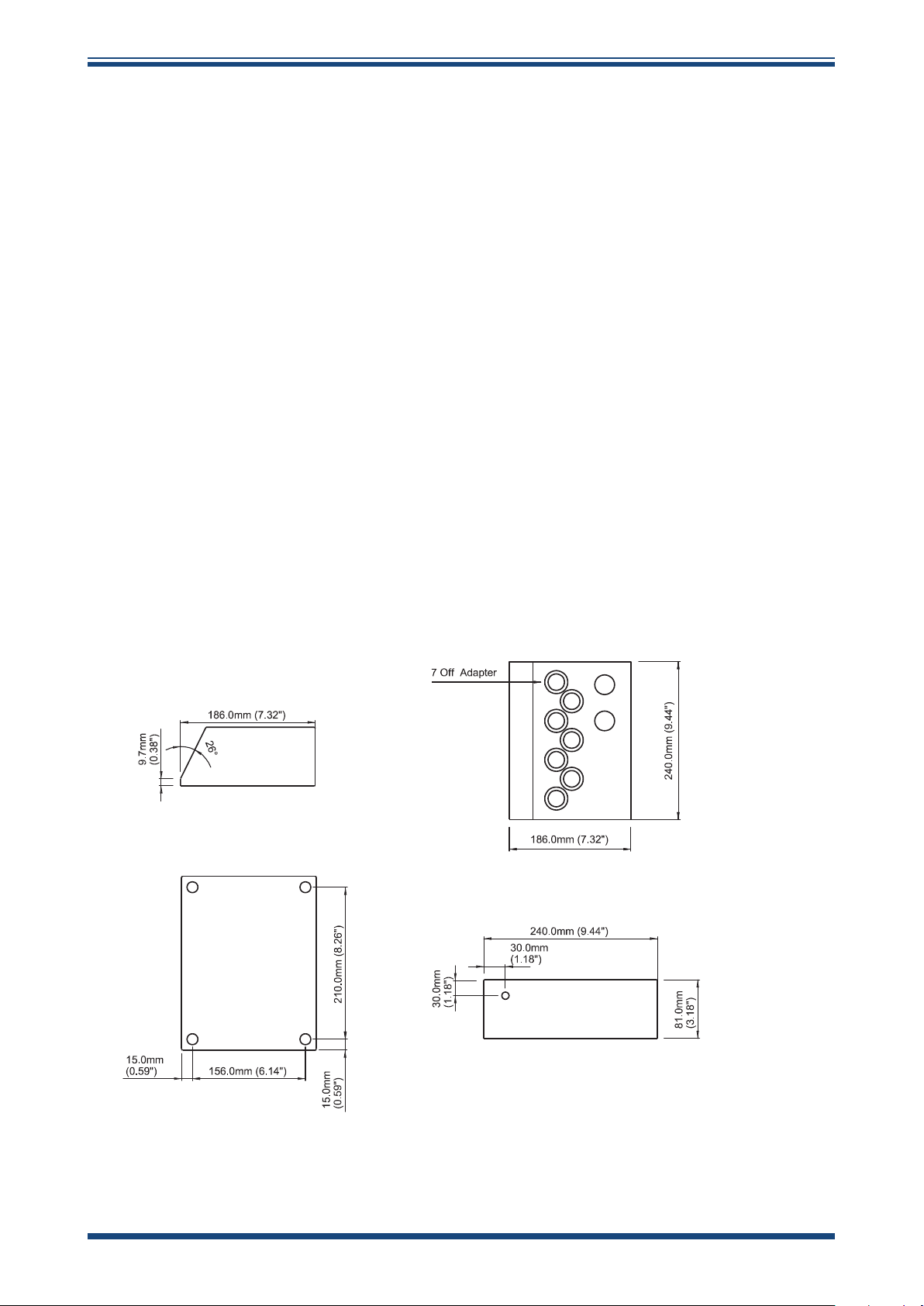

Figure 1.1 S503 dimensions ......................................................................................................1

Figure 1.2 S503-DIG Digital Humidity Generator ........................................................................2

Figure 1.3 S503-DIG-OPT Digital Humidity Generator & Optidew Vision ......................................2

Figure 1.4 S503-DIG-SET Calibration Kit ....................................................................................3

Figure 1.5 S503-DIG-LC S503 with extended chamber ................................................................3

Figure 2.1 Inside the S503 ........................................................................................................4

Figure 2.2 S503 front panel ......................................................................................................5

Figure 2.3 S503 back panel ......................................................................................................6

Figure 2.4 Maximum water level................................................................................................7

Figure 2.5 Sponge inside chamber ............................................................................................7

Appendices

Appendix A Technical Specications ...........................................................................................13

Appendix B Recommended Practices in Humidity Measurements ..................................................15

Appendix C List of Worldwide Michell Instruments’ Ofces ..........................................................20

Page 5

S503 User’s Manual

Michell Instruments v 97210 Issue 01, April 2011

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures detailed in this

manual. The user must not use this equipment for any other purpose than that stated. Do not apply values

greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe operation

and to maintain the equipment in a safe condition. The safety instructions are either warnings or cautions

issued to protect the user and the equipment from injury or damage. Use qualied personnel and good

engineering practice for all procedures in this Manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied by the

manufacturer for use with the instrument.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During normal

operation it is not possible for the user to come into contact with any hazardous substance which might be

employed in the construction of the instrument. Care should, however, be exercised during maintenance and

the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer to

Appendix B for details of Michell Instruments’ worldwide ofces contact information.

Calibration

Under normal ambient conditions (0 to +50ºC (+32 to +122ºF) 0-70% RH) and for accuracy of ±2% RH, an

annual calibration is recommended. For an accuracy ±5% RH a calibration is recommended every ve years.

For environments with airborne chemicals or for high humidity and high temperature conditions more frequent

calibration is recommended.

Safety Conformity

This product meets the essential protection requirements of the relevant EU directives. Further details of

applied standards may be found in Section 5.

Page 6

S503 User’s Manual

97210 Issue 01, April 2011 vi Michell Instruments

Abbreviations

The following abbreviations are used in this manual.

AC alternating current

DC direct current

ºC degrees Celsius

ºF degrees Fahrenheit

g grams

in inches

lbs pounds

kg kilograms

mA milliampere

mm millimetres

oz ounces

% percentage

RH relative humidity

RS232 serial data transmission standard

temp temperature

T temperature

V Volts

Ω Ohms

Warnings

The following general warning listed below is applicable to this instrument. It is repeated in the text in the

appropriate locations.

Where this hazard warning symbol appears in the following

sections, it is used to indicate areas where potentially

hazardous operations need to be carried out.

Page 7

S503 User’s Manual

Michell Instruments vii 97210 Issue 01, April 2011

Recycling Policy

Michell Instruments is concerned with the protection of the environment. It is our commitment to reduce

and eliminate from our operations, wherever possible, the use of substances which may be harmful to the

environment. Similarly, we are increasingly using recyclable and/or recycled material in our business and

products wherever it is practical to do so.

The product that you have purchased may contain recyclable and/or recycled parts and we will be happy to

provide you with information on these components if required.

WEEE and RoHS Compliance

The Waste Electronic and Electrical Equipment (WEEE) Directive, and the Restriction of Hazardous Substances

(RoHS) Directive place rules upon European manufacturers of electrical and electronic equipment. The

directives’ aim is to reduce the impact that electronic devices have on the environment.

Michell products are currently exempt from the RoHS directive, however all future products will be developed

entirely using compliant materials. Furthermore, Michell is taking active steps to remove non-compliant

materials and components from existing products wherever possible.

Michell is in full compliance with the WEEE Directive (Registration No. WEE/JB0235YW). Customers may be

required to return certain instruments for treatment at the end of their working life.

June 2010

Calibration Facilities

Each unit has an internal reference which is calibrated against our working factory standard which is traceable

to ‘VSL’ in The Netherlands and National Physical Laboratory (NPL) in the UK.

Calibration Certicates:

In addition to the normal calibration procedure, each internal reference transmitter can be supplied with its

own VSL or NPL traceable calibration certicate.

Page 8

S503 User’s Manual

97210 Issue 01, April 2011 viii Michell Instruments

Manufacturing Quality

Michell Instruments UK is registered with the British Standards Institute for Quality Assurance to:

BS EN ISO 9001: 2008

Rigorous procedures are performed at every stage of production to ensure that the materials of construction,

manufacturing, calibration and nal test procedures meet the requirements laid down by our BSI approved

Quality System.

Please contact Michell Instruments if the product does not arrive in perfect working order.

Warranty

Unless otherwise agreed, the Supplier warrants that, as from the date of delivery for a period of 12 months

the goods and all their component parts, where applicable, are free from any defects in design, workmanship,

construction or materials.

The Supplier warrants that the services undertaken shall be performed using reasonable skill and care, and of

a quality conforming to generally accepted industry standards and practices.

Except as expressly stated, all warranties, whether express or implied, by operation of law or otherwise, are

hereby excluded in relation to the goods and services to be provided by the Supplier.

All warranty services are provided on a return to base basis. Any transportation costs for the return of a

warranty claim shall reside with the Customer.

Return Policy

If a Michell Instruments’ product malfunctions within the warranty period, the following procedure must be

completed:

Notify a Michell Instruments’ distributor, giving full details of the problem, the model 1.

variant and the serial number of the product.

If the nature of the problem indicates the need for factory service then the instrument 2.

should be returned to Michell Instruments, carriage prepaid, preferably in the original

packaging, with a full description of the fault and the customer contact

information.

Upon receipt, Michell Instruments will evaluate the product to determine the cause of 3.

the malfunction. Then, one of the following courses of action will be taken:

If the fault is covered under the terms of the warranty, the instrument will •

be repaired at no cost to the owner and returned.

If Michell Instruments determines that the fault is not covered under the •

terms of the warranty, or if the warranty has expired, an estimate for the

cost of the repairs, at standard rates, will be provided. Upon receipt of the

owner’s approval to proceed, the product will be repaired and returned.

Page 9

S503 User’s Manual

Michell Instruments 1 97210 Issue 01, April 2011

A

Notes:

Hole A = Power Hole

for adapter

Back view

Top view

Side view

Bottom view

1 INTRODUCTION

The S503 Humidity Generator/Calibrator enables users of humidity sensors, transmitters and read-out devices

to quickly and accurately generate reference humidity conditions at ambient temperatures.

1.1 Features

Generates humidity levels between 10-90% RH•

Highly portable•

Fast stabilization of humidity chamber•

In combination with Michell Instruments’ Optidew Vision, which works on a •

proven, fundamental optical dew-point measurement principle, calibrations

can be done using the most accurate reference (optional).

Multiple sensors can be calibrated at the same time•

1.2 Applications

Calibration and validation of RH transmitters, sensors and data loggers.

1.3 Dimensions

Figure 1.1 S503 dimensions

Page 10

S503 User’s Manual

97210 Issue 01, April 2011 2 Michell Instruments

1.4 S503 Combinations

1.4.1 S503-DIG

The S503-DIG consists of - S503, including 7 user-specied port adapters, power adapter, desiccant and

adapter tool.

1.4.2 S503-DIG-OPT

Figure 1.3 S503-DIG-OPT Digital Humidity Generator & Optidew Vision

Figure 1.2 S503-DIG Digital Humidity Generator

In combination with Michell Instruments’ Optidew Vision, calibrations can be done using the most accurate

reference. The Optidew Vision is traceable to national standards.

The Optidew Vision is a high performance Optical Dew-point Transmitter working on a proven, fundamental

optical dew-point measurement principle and giving unmatched and drift-free long-term performance. It offers

a wide measurement range from -60 to +90°Cdp (-76 to +194°Fdp) (or 0.5 to 100% RH) at temperatures from

-40 to +90°C (-40 to +194°F), and -20 to +130°C (-4 to +266°F) at temperatures from -20 to +130°C (-4 to

+266°F) for the high temperature version.

For more information on the Optidew Vision please contact Michell Instruments or your local distributor (see

contact details in Appendix B).

The S503-DIG-OPT consists of - S503, with 5 user-specied port adapters, 2 Optidew adapters (A000272

(stainless steel port adapter) and A000273 (polymer housing port adapter ø18.5mm (0.73”) to ø3mm (0.19”)),

power adapter, desiccant and adapter tool.

Page 11

S503 User’s Manual

Michell Instruments 3 97210 Issue 01, April 2011

1.4.3 S503-DIG-SET

Figure 1.4 S503-DIG-SET Calibration Kit

The S503-DIG-SET consists of - S503, including hand meter and probe (with calibration certicate),

7 user-specied port adapters, power adapter, desiccant, distilled water bottle (water not included), adapter

tool and carrying case.

1.4.4 S-503-DIG-LC

Figure 1.5 S503-DIG-LC S503 with extended chamber

The S503-DIG-LC has an extended chamber (0.54 liter extra)

Page 12

S503 User’s Manual

97210 Issue 01, April 2011 4 Michell Instruments

2 OPERATION

Desiccant

chamber

Water

chamber

Power supply

12 V DC

Calibration chamber

Figure 2.1 Inside the S503

A vapor saturator and desiccant chamber are coupled to the calibration chamber. Saturated or dry air is

pumped into the chamber to achieve the set point. The electronics assure fast ramping to the actual calibration

point. An LCD displays the actual chamber humidity, as well as the actual chamber temperature.

The S503 utilizes a high accuracy reference sensor which has been calibrated to a traceable reference. The

overall accuracy between 20 and 80% RH is ±2% RH. Although the internal reference is accurate and

stable, an external reference probe, either a traceable RH indicator or a chilled mirror dew-point probe, is

recommended as the calibrated reference.

Page 13

S503 User’s Manual

Michell Instruments 5 97210 Issue 01, April 2011

2.1 Front Panel Functions

15Vdc

GND

INPUT

VO LT

INPUT

4-20mA

OFF

ON

8 6 3

% RH

SETPOINT

TEMP

RH

10V

5V

1V

mA

INPUT

SELECT

S-503

HUMIDITY GENERATOR

2 3 4 5 6 7

1

11

12

13

14

108 9

Figure 2.2 S503 front panel

Display Screen1.

Input Select

Temp 2. Shows the actual calibration chamber temperature

RH 3. Shows the actual calibration chamber relative humidity

10 V 4. Shows the actual output of a transmitter in the calibration

chamber with an output of 0-10 V.

Display reads from 0-100%RH / 0 to +100ºC

5 V5. Shows the actual output of a transmitter in the calibration

chamber with an output of 0-5 V.

Display reads from 0-100%RH / 0 to +100ºC

1 V 6. Shows the actual output of a transmitter in the calibration

chamber with an output of 0-1 V.

Display reads from 0-100%RH / 0 to +100ºC

mA 7. Shows the actual output of a transmitter in the calibration

chamber with an output of 4-20 mA.

Display reads from 0-100%RH / 0 to +100ºC

Set point 8. Selects the desired relative humidity: 10-90% RH in steps of

0.1% RH

Humidify 9. When lit, indicates that the vapor saturator is activated

De-Humidify 10. When lit, indicates that the desiccant chamber is activated

15 V DC 11. +15 V DC supply for a transmitter in the calibration

chamber

Input Volt12. Connect to v+ transmitter signal in the calibration chamber

with voltage output (0-1, 0-5 or 0-10 V)

Input mA13. Connect to + signal of transmitter in the calibration chamber

Gnd 14. Common ground for v- transmitter signal and power supply

with current output (2-wire 4-20 mA)

Page 14

S503 User’s Manual

97210 Issue 01, April 2011 6 Michell Instruments

Power Supply

Socket

2.2 Back Panel Functions

Figure 2.3 S503 back panel

The power supply cable comes with a country-specic plug attached.

The input is 12 V (850 mA).

Page 15

S503 User’s Manual

Michell Instruments 7 97210 Issue 01, April 2011

2.3 Getting Started

Stabilize the unit to room temperature before use.

Always close the calibration chamber ports before use.

Remove the cover from the desiccant chamber (see •

of new desiccant.

Remove the cover and the blue sponge (see •

(see

Figure 2.1)

Maximum water level

(shown with cover removed)

and ll with water to BELOW the maximum water level.

Do not overll as the water can ow directly to the calibration

Figure 2.1)

Figure 2.5)

from the water chamber

and ll with 25g

Figure 2.4 Maximum water level

chamber, causing the generator to malfunction.

IMPORTANT: THE CALIBRATOR SHOULD NOT BE TRANSPORTED

WHEN FILLED WITH WATER. ALL WATER MUST BE DRAINED

BEFORE MOVING THE UNIT (SEE SECTION 3 FOR DETAILS)

Place the blue sponge back into the water chamber - this sponge prevents •

water from entering the grey tube and water droplets getting into the humidity

chamber.

Figure 2.5 Sponge inside chamber

Page 16

S503 User’s Manual

97210 Issue 01, April 2011 8 Michell Instruments

2.4 Operating Instructions

The unit must be used at normal room temperature (approximately +20ºC 1.

(+68ºF)) and must be stabilized for a minimum of 1 hour, if used for different

temperature environments.

Power the unit with 12 V DC (connection at the rear of the instrument). 2.

A 100 - 240 V AC adapter is included.

Make sure the calibration ports are closed.3.

Switch the unit to ‘RH’ and choose the desired humidity.4.

Install the humidity transmitter to be calibrated (without lter) into the 5.

calibration chamber.

If applicable, connect the transmitter to the built-in power supply and read out. 6.

See Section 2.5 for further information.

Press ‘ON’. The unit will now start to dry or humidify, depending on the humidity 7.

set, until it reaches its set point.

If the humidity probe is connected to the built-in power supply and read out, 8.

switch to the corresponding input sensitivity.

If the transmitter has an output:

of 0-10 V, switch to ‘10 V’•

of 0-5 V, switch to ‘5 V’•

of 0-1 V, switch to ‘1 V’ •

of 4-20mA switch to ‘mA’ •

The display shows the actual output of the transmitter under calibration.

2.5 Connecting a Transmitter

The S503 Humidity Generator/Calibrator accepts any probe with a diameter varying from 5mm to a maximum

of 25mm.

The S503 has a built-in power supply of 15 V DC for transmitters under calibration.

For example, if the transmitter under calibration has a 0-10 V output, the output signal should be connected

to the voltage input and the input select switch should be set to 10 V. The actual reading of the transmitter

is shown on the display from 0-100% RH. To see the actual relative humidity in the chamber the input select

switch should be set to ‘RH’.

Before placing the transmitter in the calibration chamber,

remove the dust lters. Use slotted caps only - this will reduce

the stabilization time of the transmitter under calibration.

Page 17

S503 User’s Manual

Michell Instruments 9 97210 Issue 01, April 2011

3 MAINTENANCE

WATER

Only add distilled water to the water compartment.

Do not shake or turn over the instrument as water may ow

into the calibration chamber or internal electronics.

Do not overll as the water can ow directly to the calibration

chamber, causing the generator to malfunction.

IMPORTANT: THE CALIBRATOR SHOULD NOT BE

TRANSPORTED WHEN FILLED WITH WATER. ALL WATER

To remove water (either when exchanging the water or removing before transportation):

Remove the cover and sponge from the water chamber.•

Use a syringe to remove the water from the chamber.•

Replace the sponge and the cover. •

MUST BE DRAINED BEFORE MOVING THE UNIT.

DESICCANT

Replace desiccant when colorless. Use only dark blue or orange, ultra dry desiccant.

The desiccant can be regenerated by heating it to +150ºC for 1-2 hours.

NOTE: Remove water before removing desiccant.

To remove desiccant:

Firstly, remove water by following the above instructions.•

Remove the cap from the desiccant chamber.•

Turn the S503 upside-down to remove the desiccant.•

Use only genuine desiccant to rell.•

Page 18

S503 User’s Manual

97210 Issue 01, April 2011 10 Michell Instruments

4 TROUBLESHOOTING

UNIT DOES NOT DRY

Desiccant may be saturated (transparent color) •

Replace with fresh ultra dry desiccant following the instructions in Section 3.

Condensation or water may be on the wall of the calibration •

chamber

Remove the ports and open the chamber. Wipe carefully with a dry cloth and

allow to dry for approximately 15 minutes.

Calibration chamber may contain standing water •

Remove the water and allow the unit to dry for 2 days with all the ports open

or with the top plate removed.

UNIT IS TOO MOIST OR TOO DRY

Chamber temperature could be extremely cold or hot•

Stabilize to room temperature.

Cover is open or there is leakage through the cover•

Unscrew and remove the top plate of the instrument and check the seals around

the chambers (see

Figure 2.1)

.

LARGE DEVIATIONS IN CALIBRATION

Large calibration deviations when starting up are usually a result of a •

difference in temperature between the transmitter under calibration

and the actual chamber temperature.

Allow to stabilize for at least 1 hour.

Page 19

S503 User’s Manual

Michell Instruments 11 97210 Issue 01, April 2011

5 CALIBRATION

Calibration Interval Time:

Under normal ambient conditions (0 to +50ºC (+32 to +122ºF) 0-70% RH) and for

an accuracy of ±2% RH, we recommend an annual calibration.

For an accuracy of ±5% RH we recommend calibration every ve years.

For environments with airborne chemicals or for high humidity and high temperature

conditions we recommend more frequent calibration.

EMC Compatibility:

The series S503 Humidity Generators/Calibrators are designed to meet the following

European standards:

EN 61326 (1997) + A1 (1998) + A2 (2001)

Emission: Class B

Immunity: Industrial

EN 61000-3-2 (1995) + A1 (1998) + A2 (1998)

EN 61000-3-3 (1995)

Page 20

S503 User’s Manual

97210 Issue 01, April 2011 12 Michell Instruments

Appendix A

Technical Specications

Page 21

S503 User’s Manual

Michell Instruments 13 97210 Issue 01, April 2011

Appendix A Technical Specications

Humidity

Generation range 10-90% RH in steps of 0.1% RH

Accuracy ±2% RH or better (5-95% RH)

Stability chamber Better than ±0.5%

Stabilization time to set point <10 minutes

Temperature

Temperature accuracy ±0.3ºC (±0.54ºF) - internal reference

Operating temperature (ambient) +15 to +35ºC (+59 to +95ºF)

Sensor Under Calibration

Voltage read out 0-1, 0-5, 0-10 V

Current read out 4-20 mA

Voltage supply 15 V DC, ±10% at 30 mA max

General

Probe ports 7 off sensor body diameters 5 to 25mm (0.2 to 0.98”)

accommodated by port adapters

Desiccant chamber 25g (0.88oz) capacity

Saturation chamber 25ml capacity, distilled water

Display 3½ digit LCD, 13mm (0.5”) characters

Supply 12 V DC (100 - 240 V AC adapter included)

Weight 1.85kg (4.08lb)

Page 22

S503 User’s Manual

97210 Issue 01, April 2011 14 Michell Instruments

Appendix B

Recommended Practices

in Humidity Measurements

Page 23

S503 User’s Manual

Michell Instruments 15 97210 Issue 01, April 2011

Appendix B Recommended Practices in Humidity Measurements

The following text is reproduced with kind permission from the National Physical Laboratory. It is originally

published in the booklet,

Denition of Relative Humidity

Relative Humidity – The ratio of the actual vapor pressure to the saturation vapor pressure over a plane

liquid water surface at the same temperature, expressed as a percentage. This is commonly understood when

the term ‘X percent relative humidity’ is used.

A Guide to the Measurement of Humidity.

For actual vapor pressure, e, and saturation vapor pressure, e

s

e

relative humidity (in %) = ––– x 100

e

s

USAGE: The phrase ‘relative humidity’ is commonly abbreviated RH although this is not a recognized

abbreviation. Values of relative humidity are commonly expressed in units of percent relative humidity (%

RH).

Recommended practices in humidity measurements

General practical recommendations

Where relative humidity is of interest, a direct measurement of relative humidity is usually best. Where an •

absolute measure of humidity is needed, choose dew point, vapor pressure or similar measurements.

Establish the measurement requirements at the purchasing stage in order to have the right instrument for •

the job.

Allow hygrometers to equilibrate in any new environment. This is particularly necessary after changes in •

temperature due to transportation or storage. Depending on the instrument and on how great the change

in conditions, this may require from only a few minutes to many hours.

Follow Michell Instruments’ care instructions for the instrument. Some instruments need routine cleaning •

or other maintenance. Before using any solvent cleaner, check with Michell Instruments that this will not

harm the sensor or other materials of construction.

Wherever possible, ensure that hygrometers are calibrated under the conditions of use, i.e. at similar values •

of humidity and temperature, and (if relevant) in similar conditions of pressure, airow, etc.

Keep a record of calibrations and any adjustments to the hygrometer. This will show the long-term stability •

of the instrument and allow the associated uncertainty to be assessed.

Check instruments, if possible, at intervals between calibrations, by comparison with another (stable) •

instrument, to monitor for long-term drift. Routine checks are also useful before and after subjecting an

instrument to transportation or other stress, which might lead to a shift in its performance. Where the

check is against two (or more) instruments this is even better: not only does this add condence, but in the

event of one instrument drifting among a set of three, it can be seen which reading is most suspect.

Cleanliness of the environment will affect different hygrometers in different ways. Dust and airborne droplets •

should be avoided or ltered out if possible. Contaminants can come from the most surprising sources,

ordinary urban pollution, for example.

Page 24

S503 User’s Manual

97210 Issue 01, April 2011 16 Michell Instruments

The readings given by some types of hygrometer are sensitive to gas type. For any Instrument which •

reads in terms of mass per unit volume, e.g. in grams per cubic metre, it must be conrmed whether the

calibration is valid for the gas in use.

Avoid using instruments in direct sunlight or near any other source of heat, unless they are suitably shielded •

to prevent measurement errors.

Sampling in general

Relative humidity measurements should be carried out at a representative temperature. •

Failure to allow temperature equilibration will lead to a false indication of the relative humidity.

Variations in vapor pressure from place to place can occur where an environment is subject to any •

addition or removal of water. If so, care must be taken over where to make a measurement in order to

obtain a representative result.

Sources and sinks of water vapor should be avoided in any sampling system. Invasion of stray water can be •

minimised by attention to leaks, hygroscopic materials, droplets and condensation. The lower the humidity,

the more critical these precautions are.

Hygroscopic materials should be avoided. Many materials contain moisture as part of their structure, •

particularly organic materials (whether natural or synthetic), salts (or anything which contains them), and

anything which has small pores. Temperature changes can increase the tendency of these materials to

affect the humidity of the surrounding air.

Condensation in a sampling process can invalidate humidity measurements by reducing the water content •

of the gas being measured. What is more, condensed liquid may alter the humidity elsewhere by dripping

or running to other locations and evaporating there. In these circumstances, measurement results may be

misleading if hygrometer location is not considered carefully.

Water droplets or mist must be avoided. These can result in overestimates of the humidity of the air between •

the droplets. Such results may exceed 100% RH, or may be impossible to interpret meaningfully. Droplets of

liquid also damage some electrical types of humidity sensor. Filtering the air sample can eliminate droplets.

If pumps are used for sampling gas, these should be located after the hygrometer, to avoid contaminating •

the measurement environment. Where possible, oil free pumps should be used, or lters employed.

Oscillations in pressure due to pumping can sometimes be reduced or buffered using a needle valve or a

reservoir of large volume.

Special treatments such as ltration can change the amount of moisture in a gas. Some drying agents take •

out other gases, too

When sealing any sensor or probe into a port or manifold in a duct or chamber, leaks through the probe •

or electrical cable should be considered. These are not always sealed against passage of ambient air.

Where sampling involves a step change in temperature, pressure or gas ow rate, relative to the process •

being sampled, results may need to be converted or interpreted. For example ‘pressure dew point’ will differ

from the value found after expanding the gas sample to atmospheric pressure. Care should be taken to

distinguish between ‘gauge’ and absolute values of pressure.

Dew point in general

The measuring environment and all parts of the sampling pathway must be kept above the dew point •

if condensation is to be avoided. Electrical trace heating or other heating methods should be used if

necessary. An excess temperature of 10°C above the dew point is usually a safe margin.

For measurements in the region below 0°C it must be clear whether the condensate is dew or frost. Failure •

to distinguish between these can result in errors of about 1°C for every 10°C below zero.

Page 25

S503 User’s Manual

Michell Instruments 17 97210 Issue 01, April 2011

Relative humidity in general

Due care must be taken of temperature. The effect of temperature on humidity is highly signicant. Failure •

to take this into account can sometimes lead to errors so large that the measurement is meaningless.

In many situations, the largest single source of uncertainty in a humidity measurement is the effect of

temperature differences from place to place in the process, room or chamber. The importance of considering

the temperature effects carefully cannot be overstated when relative humidity is the parameter of interest.

Care must be taken when expressing uncertainties, changes or fractional differences in relative humidity. •

For example, the difference between 50% RH and 52% RH is 2% RH. This can also be expressed as a

difference of 4% of value. It is important to distinguish clearly between these two kinds of statement.

Recommendations specic to ranges of measurements

Ambient humidity• - Avoid using hygrometers near the body, which is a source of heat and moisture. Do not

breathe close to the measurement.

High humidity, above the ambient range -• Ample lines should be maintained above the dew point of the gas

being measured, to avoid condensation. Electrical trace heating is often the most practical method.

Low humidity, and very dry gases -• If possible, prepare for measurements by ushing sample lines and

hygrometers with dry gas, or by evacuating to low pressure. Drive off stray residual water by baking

assemblies if possible (but not instruments – unless designed for this!). The lower the moisture content to

be measured, the more dramatically the required drying time multiplies.

Avoid hygroscopic materials. At low humidity (anything much below a dew point of 0°C) the amounts of •

water given off by organic and porous materials can dramatically affect the value of humidity. The lower

the level of moisture, the more signicant the effects.

Choose impermeable materials, to avoid inward diffusion of moisture through sampling tubes and enclosures. •

Steel and other metals are practically impermeable. PTFE (‘Teon’) is only slightly permeable and will

usually be satisfactory for dew points above -20°C, and sometimes below this level. Materials such as PVC

and rubber are relatively permeable and so totally unsuitable at low humidity, and not really satisfactory in

any humidity range.

Surface nish of pipework is important for very dry gases. Even the tiny quantities of water adsorbed on •

the surfaces of non-hygroscopic materials can have signicant effect. Polished or electropolished steel is

recommended for the best results.

Clean environments are always best for humidity measurements, but this is especially critical at very •

low humidity. Even ngerprints harbour water. High purity cleaning agents are recommended: Analytical

Reagent (AR) quality solvents for oil-based contaminants, and puried water (distilled or de-ionised) for

salts. Cleaning should be followed by thorough drying by a clean method.

Sample tubing should be as short in length as possible. The surface area should be minimised by using the •

narrowest tubing that the ow conditions will permit.

Avoid leaks. Minimising the number of connections (elbows, tees, valves, etc.) helps with this.•

Adequate ow of the gas sample should be ensured, to minimise the inuence of sources of stray water in •

the ow path.

‘Dead ends’ should be avoided, as they cannot easily be ushed.•

Back-diffusion of moisture should be minimised, e.g. by fast ow rates of gas, long exhaust tubes after the •

sensor, or by valves which isolate the low-humidity region from ambient air.

Page 26

S503 User’s Manual

97210 Issue 01, April 2011 18 Michell Instruments

Practical recommendations for specic types of hygrometer

Relative humidity capacitive sensor

Care should be taken to avoid mechanical shock (impact) or thermal shock (sudden temperature changes). •

Sensors should be protected from steam or water sprays, and from direct sunlight.

Where a sensor is at risk of exposure to dust, droplets, or the occasional knock during handling, the •

appropriate guard or lters for the sensor head should be used.

Any temptation to breathe on the sensor, or to wave it over cups of tea, etc. should be resisted. Filters and •

saturation guarding may protect the sensor, but these actions carry a risk of damage by condensation or

other contamination.

Protective lters can slow the response time of sensors. This can be avoided by removing any lter, but the •

benet must be weighed against the risk of damage to the sensor.

Sensors should not normally be submerged in liquids. In the case of a resistive (electrolytic) sensor, water •

or other liquids would certainly damage the sensor beyond repair.

Salt solutions are especially commonly used for calibration of electrical sensors, and should be provided •

with traceability directly or via a calibrated hygrometer. Protection of sensors from direct contact with salt

or solution is most important as contamination would destroy or seriously impair the sensing element.

Page 27

S503 User’s Manual

Michell Instruments 19 97210 Issue 01, April 2011

Appendix C

List of Worldwide

Michell Instruments’ Ofces

Page 28

S503 User’s Manual

97210 Issue 01, April 2011 20 Michell Instruments

Appendix C List of Worldwide Michell Instruments’ Ofces

Asia

Michell Asia

PO Box 3149

Joondalup

WA 6027

Australia

Tel: +61 893 046587

E-mail: au.info@michell.com

Web: www.michell.com/au

China

Michell Instruments (Shanghai) Ltd

Room 505, Qilai Building

889 Yishan Road

Shanghai, 200233

P R China

Tel: +86 21 5401 2255

Fax: +86 21 5401 2085

E-mail:

cn.info@michell.com

Web: www.michell.com/cn

Germany, Austria, Switzerland

Michell Instruments GmbH

Industriestrasse 27

D-61381 Friedrichsdorf

Germany

Tel: +49 6172 591700

Fax: +49 6172 591799

E-mail:

de.info@michell.com

Web: www.michell.com/de

Benelux

Michell Instruments Benelux BV

Krombraak 11

4906 CR Oosterhout

The Netherlands

Tel: +31 162 680 471

Fax: +31 162 437 566

E-mail: nl.info@michell.com

Web:

www.michell.com/nl

France

Michell Instruments SAS

2-4, rue Jean Desparmet

69008 Lyon

France

Tel: +33 437 53 88 20

Fax: +33 437 53 88 21

E-mail: fr.info@michell.com

Web: www.michell.com/fr

Italy

Michell Italia Srl

Via Capecelatro, 10

20148 Milano

Italy

Tel: +39 02 4047194

Fax: + 39 02 40010565

E-mail: it.info@michell.com

Web: www.michell.com/it

Japan

Michell Japan KK

Musashino Center Building

1-19-18 Nakacho, Musashino

Tokyo 180-0006

Japan

Tel: +81 422 502600

Fax: +81 422 521700

E-mail: info@michell-japan.co.jp

Web: www.michell-japan.co.jp

North America

Michell Instruments Inc

319 Newburyport Turnpike, Suite 207

Rowley, MA 01969

USA

Tel: +01 978 484 0005

Fax: +01 978 843 7669

E-mail:

us.info@michell.com

Web: www.michell.com/us

Middle East

Michell Instruments Middle East

P-06, #097

Sharjah Airport Int’l free zone

Sharjah,

United Arab Emirates

Tel: +971 6 5575028

+971 6 5575029

Fax:

E-mail: me.info@michell.com

United Kingdom

Michell Instruments Ltd

48 Lancaster Way Business Park

Ely, CB6 3NW

Cambridgeshire

England

Tel: +44 1353 658000

Fax: +44 1353 658199

E-mail: info@michell.com

Web: www.michell.com/uk

Page 29

S503 User’s Manual

Michell Instruments 21 97210 Issue 01, April 2011

NOTES:

Page 30

S503 User’s Manual

97210 Issue 01, April 2011 22 Michell Instruments

NOTES:

Page 31

S503 User’s Manual

Michell Instruments 23 97210 Issue 01, April 2011

NOTES:

Page 32

http://www.michell.com

Loading...

Loading...