Page 1

QMA601

Process Moisture Analyzer

User’s Manual

97449 Issue 3

June 2018

Page 2

Please fi ll out the form(s) below for each analyzer that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Analyzer

Code

Serial Number

Invoice Date

Location of Analyzer

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Analyzer

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Analyzer

Tag No

Page 3

QMA601

For Michell Instruments' contact information please go to

www.michell.com

© 2018 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

QMA601 User’s Manual

Contents

Safety .............................................................................................................................. viii

Warnings ................................................................................................................... viii

Electrical Safety ......................................................................................................... viii

Pressure Safety .......................................................................................................... viii

Hazardous Materials (WEEE, RoHS2 & REACH) ............................................................. viii

Calibration (Factory Validation) ......................................................................................ix

Repair and Maintenance ...............................................................................................ix

Abbreviations ...................................................................................................................... x

1 INTRODUCTION ................................................................................................1

1.1 General .............................................................................................................. 1

1.2 Theory of Operation ........................................................................................... 2

1.3 Sample Gas Path ................................................................................................ 3

2 INSTALLATION ..................................................................................................4

2.1 Analyzer Storage Instructions .............................................................................. 4

2.2 Unpacking the Analyzer ...................................................................................... 5

2.3 Lifting and Handling ........................................................................................... 5

2.4 Mounting the Analyzer ........................................................................................ 6

2.5 Hazardous Area/Location Safety .......................................................................... 7

2.6 Electrical Safety .................................................................................................. 8

2.6.1 Equipment Ratings and Installation Details ...................................................... 8

2.6.2 Power Connection ....................................................................................... 10

2.6.3 Other Electrical Connections ........................................................................ 11

2.7 Pressure Safety ................................................................................................ 12

2.8 Gas Sample Connections ................................................................................... 13

3 OPERATION ....................................................................................................15

3.1 General Operational Information ........................................................................ 15

3.1.1 First Time Operation .................................................................................... 16

3.1.2 Analyzer Set-Up .......................................................................................... 17

3.2 User Interface .................................................................................................. 18

3.2.1 Interface Controls ....................................................................................... 18

3.2.2 ‘Up/Down Arrow’ Keys ................................................................................. 18

3.2.3 'ENTER’ Key ................................................................................................ 19

3.2.4 ‘ESC’ Key .................................................................................................... 19

3.2.5 Pop Up Keypad ........................................................................................... 19

3.3 Menu Structure ................................................................................................ 20

3.4 Description of Measured Parameters .................................................................. 21

3.5 Main Screen .................................................................................................... 21

3.5.1 Large Display Mode ..................................................................................... 23

3.6 Main Screen Sub Menus .................................................................................... 25

3.6.1 Warning Screen .......................................................................................... 25

3.6.2 Logging Screen ........................................................................................... 26

3.6.3 Alarm Screen .............................................................................................. 27

3.6.4 Field Calibration Screen ............................................................................... 28

3.6.5 Monitor screen ............................................................................................ 32

3.7 Settings Menu ................................................................................................. 33

3.7.1 Measurement Screen ................................................................................... 33

3.7.2 Outputs Screen ........................................................................................... 38

3.7.3 HMI Screen ................................................................................................ 40

3.7.4 Real Time Clock Screen ............................................................................... 42

3.7.5 Software Communications Screen................................................................. 43

3.7.6 Ethernet Screen .......................................................................................... 43

iv 97449 Issue 3, June 2018

Page 5

QMA601 User’s Manual

3.7.7 Field Calibration History ............................................................................... 44

3.7.8 About Screen .............................................................................................. 44

3.8 Sampling Guidelines ......................................................................................... 46

3.9 Measurement Cycle .......................................................................................... 49

3.10 Calibration Cycle ............................................................................................... 51

4 MAINTENANCE ................................................................................................53

4.1 Safety .............................................................................................................. 54

4.2 Removal and Replacement of the Power Supply Fuse .......................................... 54

4.3 Replacing the Optional Contamination Trap ........................................................ 54

4.4 Removal and Replacement of the Desiccant Column ............................................ 55

5 CALIBRATION ..................................................................................................57

5.1 Traceability ...................................................................................................... 57

6 SHIPPING .......................................................................................................59

6.1 Preparation for Shipping and Packing if Not Supplied as a Sample System ............ 59

7 APPLICATION SOFTWARE OVERVIEW ...............................................................60

7.1 System Requirements ....................................................................................... 60

7.2 System Connection ........................................................................................... 60

7.3 Getting Started ................................................................................................. 61

7.3.1 Connection Method (Serial Connection (RS485 or TCP) .................................. 62

7.3.1.1 RS485 Connection ................................................................................. 62

7.3.1.2 Modbus TCP Connection (Ethernet) ....................................................... 62

7.4 Main Window ................................................................................................... 63

7.5 Using the Chart ................................................................................................ 64

7.5.1 Chart Options Window ................................................................................. 65

7.6 Data Logging ................................................................................................... 66

7.6.1 Configuring Logging Start Time .................................................................... 67

7.6.2 Configuring Logging Stop Time .................................................................... 67

7.6.3 Starting the Log .......................................................................................... 67

7.6.4 Viewing a Log ............................................................................................. 67

7.7 Parameters / Field Calibration ............................................................................ 67

7.7.1 Field Calibration .......................................................................................... 68

Michell Instruments v

Page 6

QMA601 User’s Manual

Figures

Figure 1 Measurement System .................................................................................3

Figure 2 Mounting Dimensions .................................................................................6

Figure 3 Earthing Stud And Nut Washer Assembly .....................................................9

Figure 4 24 VDC & 240 V AC Power Unit Connectors ................................................10

Figure 5 Other Electrical Connections ......................................................................11

Figure 6 RJ45 to screw terminal adapter connections ...............................................12

Figure 7 Typical Display .........................................................................................17

Figure 8 User Interface ..........................................................................................18

Figure 9 Up/Down Arrow Keys ................................................................................18

Figure 10 ‘ENTER’ Key .............................................................................................19

Figure 11 ‘ESC’ Key .................................................................................................19

Figure 12 Pop Up Keypad .........................................................................................19

Figure 13 Menu Structure ........................................................................................20

Figure 14 Main Screen .............................................................................................21

Figure 15 Large Display Modes .................................................................................23

Figure 16 Full Screen Graph .....................................................................................24

Figure 17 Warning Screen ........................................................................................25

Figure 18 Logging Screen ........................................................................................26

Figure 19 Alarm Screen ...........................................................................................27

Figure 21 Field Calibration Screen 2 ..........................................................................30

Figure 22 Field Calibration Screen 3 ..........................................................................30

Figure 23 Field Calibration Screen 4 ..........................................................................31

Figure 24 Field Calibration Screen 5 ..........................................................................31

Figure 25 Monitor Screen .........................................................................................32

Figure 26 Settings Menu Screen ...............................................................................33

Figure 27 Measurement Screen ................................................................................34

Figure 28 Carrier Gas Screen ....................................................................................35

Figure 29 Measurement Screen ................................................................................36

Figure 30 External Options .......................................................................................37

Figure 31 Fixed Options ...........................................................................................37

Figure 32 Atmos. Option ..........................................................................................37

Figure 33 User Gas Setup Screen .............................................................................38

Figure 34 Outputs Screen ........................................................................................39

Figure 35 HMI Screen ..............................................................................................40

Figure 36 Real Time Clock Screen .............................................................................42

Figure 37 Software Communications Screen ..............................................................43

Figure 38 Ethernet Screen .......................................................................................43

Figure 39 Calibration History Screen .........................................................................44

Figure 40 About Screen ........................................................................................... 45

Figure 42 Measurement Cycle (Phase 2) Calibration Flow ...........................................50

Figure 43 Calibration Cycle (Phase 1) - Dried Sample Flow .........................................51

Figure 44 Calibration Cycle (Phase 2) - Sample Flow ..................................................52

Figure 45 Typical QMA601 Calibration Certificate .......................................................58

vi 97449 Issue 3, June 2018

Page 7

QMA601 User’s Manual

Tables

Table 1 Pop Up Keypad ..........................................................................................20

Table 2 Main Screen Parameters ............................................................................. 23

Table 3 Large Parameter Display Mode ................................................................... 24

Table 4 Warning Screen ......................................................................................... 27

Table 5 Logging Screen .........................................................................................27

Table 6 Alarm Screen Parameters .......................................................................... 28

Table 7 Calibration Screen Parameters .................................................................... 30

Table 8 Monitor Screen Parameters ....................................................................... 33

Table 9 Measurement Screen ................................................................................. 35

Table 10 Outputs Screen Parameters ....................................................................... 40

Table 11 HMI Setup Screen Parameters ................................................................... 42

Table 12 Real Time Clock Screen Parameters ........................................................... 43

Table 13 Software Communications Screen Parameters..............................................44

Table 15 Calibration History Screen .......................................................................... 45

Table 14 Ethernet Screen Parameters ....................................................................... 45

Table 16 Using the Chart ......................................................................................... 65

Table 17 Chart Options ............................................................................................ 66

Table 18 Modbus Register Map ................................................................................ 83

Appendices

Appendix A Technical Specifi cation ............................................................................... 71

Appendix B Hazardous Area Certifi cation ...................................................................... 74

B.1 Product Standards ....................................................................... 74

B.2 Product Certifi cation .................................................................... 74

B.3 Global Certifi cates/Approvals ........................................................74

B.4 Special Conditions of Use ............................................................. 74

B.5 Maintenance and Installation ........................................................ 75

Appendix C Modbus Holding Register Map ....................................................................77

C.1 Set Points and Ranges ................................................................. 93

C.2 Gases for Gas Correction Values ...................................................94

Appendix D Quality, Recycling, Compliance & Warranty Information ................................ 96

Appendix E Return Document & Decontamination Declaration ........................................ 98

Appendix F Calculating Conversion Factors for Gas Mixes ............................................. 100

Michell Instruments vii

Page 8

QMA601 User’s Manual

!

DANGER

Electric

Shock Risk

Safety

The analyzer is designed to be completely safe when installed and operated correctly in accordance

with the information provided in this manual.

This manual contains all the required information to install, operate and maintain this product. Prior

to installation and use of this product, this entire manual should be read and understood. Installation

and operation of this product should be carried out by suitably competent personnel only. The

installation and operation of this product must be in accordance with the instructions provided and

according to the terms of any associated safety certificates. Incorrect installation and use of this

product other than those described in this manual and other than its intended purpose will render

all warranties void.

This product meets the essential protection requirements of the relevant EU directives. Further

details of applied directives may be found in the product specification.

Electricity and pressurized gas can be dangerous. This product must be installed and operated only

by suitable trained personnel.

Warnings

Where this hazard warning symbol appears in the following sections,

it is used to indicate areas where potentially hazardous operations

need to be carried out and where particular attention to personal and

personnel safety must be observed.

Where this symbol appears in the following sections it is used to

indicate areas of potential risk of electric shock.

Electrical Safety

Ensure electrical safety is complied with by following the directions provided here and observing all

local operation & installation requirements at the intended location of use.

This product is completely safe when using any options and accessories supplied by the manufacturer

of this product for use with it. Refer to Section 2 (Installation) of this manual for further details.

Pressure Safety

For this product to operate satisfactorily, pressurized gas must be connected to it. Observe all the

information contained within this manual and all local operation & installation requirements at the

intended location of use. Refer to Section 2 (Installation) of this manual for further details.

Hazardous Materials (WEEE, RoHS2 & REACH)

This product does not contain or release any prohibited chemicals listed on the SVHC (Substances

of Very High Concern) Candidate List. During the intended normal operation of this product it is not

possible for the user to come into contact with any hazardous materials. This product is designed to

be recyclable except where indicated, see relevant sections in this manual for further details.

viii 97449 Issue 3, June 2018

Page 9

QMA601 User’s Manual

Calibration (Factory Validation)

Prior to shipment, the analyzer undergoes stringent factory calibration to traceable standards. Due

to the inherent stability of the analyzer, regular factory calibration is not required under normal

operating conditions. The analyzer should perform reliably for many years with just basic maintenance,

housekeeping and regular field calibrations from the internal reference (moisture generator) or a

known external reference.

There are, however some consumables that will require periodic replacement.

• Moisture generator - typical lifetime of around 3 years.

• Desiccant column - typical lifetime of around 1 year, but this strongly

depends on the moisture content of the sample gas. The drier the sample

gas, the longer lifetime of the desiccant.

• Optional contamination trap - typical lifetime of around 1 year, a

column of activated charcoal that protects the Desiccant Column from

contamination in applications where the process gas composition contains

heavy hydrocarbon vapors.

Michell Instruments can provide a fully traceable factory calibration service for the analyzer and it is

recommended that this is considered at intervals of every year of the analyzer's life. Please contact

your local Michell Instruments' office or representative for further details (www.michell.com).

Repair and Maintenance

Apart from user-replaceable components required for routine operational maintenance described

above, the analyzer must only be maintained either by the manufacturer or an accredited service

agent. Refer to www.michell.com for details of Michell Instruments’ worldwide offices contact

information.

Michell Instruments ix

Page 10

Abbreviations

The following abbreviations are used in this manual:

AC alternating current

atm pressure unit (atmosphere)

barg pressure unit (=100 kP or 0.987 atm) gauge

°C degrees Celsius

°F degrees Fahrenheit

EU European Union

Hz Hertz

IEC International Electrotechnical Commission

kg kilogram

lb pound

lbs/MMscf pounds per million standard cubic foot

mA milliampere

mV millivolt(s)

mbar millibar

ml/min milliliters per minute

ppm

parts per million (by weight)

W

ppm

parts per million (by volume)

V

psig pound(s) per square inch (gauge)

RH relative humidity

RTU Remote Terminal Unit

V Volts

W Watts

" Inch

QMA601 User’s Manual

x 97449 Issue 3, June 2018

Page 11

QMA601 User’s Manual

1 INTRODUCTION

1.1 General

The QMA601 Moisture Analyzer is designed to provide reliable, fast and accurate

measurement of trace moisture content in a wide variety of process applications where

keeping moisture levels as low as possible is of critical importance.

The high-contrast capacitive button operated LCD display presents all measured data

to the user in a clear and understandable format. The main display incorporates a realtime trend graph and alarm indicators based on the NAMUR 102 standard. A powerful

and intuitive HMI makes control, logging and configuration of analyzer parameters easy.

The analyzer provides two user-configurable analog outputs, and Modbus RTU/TCP

communications, allowing it to interface with a SCADA DCS system, or by a computer

using the dedicated application software. A set of 4 adjustable volt free alarm contacts

allow the QMA601 to be used for direct process control.

Use Your Preferred Communication Media

INTRODUCTION

For greater flexibility, the QMA601 offers:

• Modbus RTU/TCP

• 2 user-configurable analog outputs

• Status and Process Alarms

Minimal & Straightforward Maintenance

Sophisticated analyzers are often complicated and require experience and special care

in use, increasing cost of ownership. The QMA601 differs through its very uncomplicated

approach to field service; the Desiccant Column is easy to replace via its mounting on

the sampling panel. The moisture generator has an average life span of 3 years after

which it can simply be replaced with a calibrated moisture generator supplied by Michell

Instruments.

Automated Calibration for Continued Reliability

The QMA601 incorporates an integrated automatic calibration system for complete

user confidence. Periodic calibration checks of sensor performance can be initiated

on demand, or automatically (at user defined intervals and time of day), providing a

verification of analyzer performance and automatically adjusting out any change. The

moisture generator at the core of this system is supplied with a calibration traceable to

NPL and NIST, but an external calibration reference source can also be used if desired.

During a calibration cycle, the Data Hold function will prevent any interruption of

dependant processes by holding the analog outputs at the same level for the duration

of the calibration.

Michell Instruments 1

Page 12

INTRODUCTION

Full Hazardous Area Certification

The analyzer is ATEX, IECEx and cCSAus certified. The main unit (electronics and

sensing) and associated sampling system may be mounted at a convenient location

next to the pipeline or process, with gas sample and vent connections. The analyzer

is supplied in either a 85-264 V AC version or a 24 V DC version. The product serial

number label will identify the required operating power supply.

Purpose Designed Sample Systems

Sample extraction, handling and conditioning techniques are of critical importance to

assure optimal performance and reliability of all gas analyzers which accurately quantify

specific components within a process gas composition. Three sample systems have

been designed for the most common process moisture analyzer applications:

• Natural Gas Glycol Dehydration & Transmission with an advanced

membrane filter to combat liquid contamination.

• Trace Moisture in High Purity & Petrochemical Gases with protection

against particulates.

QMA601 User’s Manual

• Trace moisture for Asymmetric Cycle variant, includes membrane filter

and 3 way valve for purge gas.

Our QMA601 sample systems facilitate regulation of pressure and flow, and the removal

of contaminants, delivering a properly conditioned sample to the analyzer for reliable

measurements, and trouble-free operation. The integrated bypass system increases

transport speed of the sample while reducing gas wastage. Each high quality sample

system is constructed from 316 stainless steel components, with BS EN 10204 3.1

material certificates available on request.

1.2 Theory of Operation

A pair of frequency-matched quartz crystal oscillators are used for measurement and

are both exposed to the sample gas. The measurement crystal features a hygroscopic

coating to adsorb moisture, whereas the reference crystal is uncoated. As the hygroscopic

coating on the measurement crystal adsorbs moisture from the sample, the overall mass

of the crystal is increased, modifying the oscillation frequency in a precise, repeatable

and measurable manner.

The resulting measurement is highly accurate, and insensitive to changes in background

gas composition.

2 97449 Issue 3, June 2018

Page 13

QMA601 User’s Manual

1.3 Sample Gas Path

The QMA601 measurement system must be supplied with gas at the required pressure

(to match that of its calibration) via the 1/4'' female NPT gas inlet on the flame arrestor.

The flow is controlled automatically.

The sensor cell is located at the end of the sensor block and contains the sensor and

reference oscillators.

Figure 1

HE1 HE2

V1 V2 V3

MG

INTRODUCTION

shows a schematic diagram of this sampling system.

SAMPLE

IN

DD

DD

MFC

QCH

PS

FC1 FC2 FC3

QCH

PS

MFC

Key

Desiccant column

Mass flow controller

Sensor cell

Pressure sensor

Figure 1

MG

V1, V2, V3

HE1, HE2

FC1, FC2, FC3

Measurement System

SAMPLE

Moisture generator

Solenoid valves

Heat exchanger

Flow control

OUT

Michell Instruments 3

Page 14

INSTALLATION

2 INSTALLATION

2.1 Analyzer Storage Instructions

In order for this product to be functional upon installation it should be stored in

accordance with the guidelines below:

• The product must be housed in a sheltered area, out of direct sunlight

and rain.

• The product should be stored to minimize the possibility of sitting in

ground water.

• The temperature within the storage environment should be maintained

between -20 to +60°C (-4 to +140°F).

• The humidity within the storage environment must be non-condensing.

• The storage environment must not expose the analyzer to any corrosive

elements.

QMA601 User’s Manual

• The product should stay assembled with its sample conditioning system

(if supplied).

• All electrical and process connections should remain disconnected and

capped.

• All protective coatings should remain in place until installation.

• For prolonged periods of storage, the lid of the packaging crate should be

removed to allow air to circulate.

• Any documentation supplied with the product should be removed from

the packaging crate and stored elsewhere to protect its integrity.

For the period from installation of the product to commissioning start-up, the following

precautions should be followed:

• The product and associated sampling system (if supplied) must remain

isolated from the process gas, and the enclosure should remain closed to

ensure ingress protection is maintained.

• If supplied, the sampling system enclosure heating/thermostat circuit

should be operated if the climatic temperature might fall below +5°C

(+41°F).

• At time of start-up the procedures contained in the user manuals for both

analyzer and sampling system must be followed.

If the product was previously in service/operation then the following precautions should

be followed before storage:

• Upon isolation from the gas sample the entire system should be purged

with a dry nitrogen gas before powering down of the analyzer.

• All connections and ports (gas and electrical) to the analyzer or sample

system (if provided) should be capped.

• If the product is not removed from its location, the electrical grounding of

the analyzer should remain in place.

4 97449 Issue 3, June 2018

Page 15

QMA601 User’s Manual

!

!

2.2 Unpacking the Analyzer

Open the crate and carefully unpack the analyzer.

The accessories box should contain the following items:

• Traceable calibration certificate

• Application software CD

• Users manual

INSTALLATION

WARNING:

The analyzer weighs 35kg (77lbs) alone,

or 50kg (110lbs) in the crate

If there are any shortages please notify the supplier immediately.

NOTE: Retain the packaging in case the analyzer is returned for factory

calibration or service.

2.3 Lifting and Handling

The QMA601 is not designed as portable or transportable equipment. The product

should be rigidly fixed in position as per the full installation instructions.

The weight of the analyzer is 35kg (77lbs). Therefore, appropriate lifting and handling

techniques should be used during the installation process. Before commencing any lifting

or handling ensure that its intended location is suitable and appropriately prepared.

Make sure that mounting point design considerations have employed locally approved

safety factors.

WARNING:

Personnel must observe suitable lifting and handling

precautions.

When handling and installing this analyzer (particularly after removal from its packaging)

ensure that it is not dropped, impacted or subjected to high levels of vibration or

environmental conditions that may impair its operation.

Michell Instruments 5

Page 16

INSTALLATION

2.4 Mounting the Analyzer

The analyzer is housed in an aluminum Exd enclosure suitable for wall or panel

mounting. Four mounting points are available with M10 clearance holes on fixing

centers of X = 308mm and Y = 312mm.

The enclosure provides environmental ingress protection IP66/NEMA4 and should be

mounted vertically in a location free of any appreciable vibration. It should be placed in

a shaded position to prevent heating effects through sun radiation. The weight of the

analyzer is 35kg (77lbs).

Conduit entries are intended for connection to threaded rigid metal conduit or other

wiring methods in accordance with Article 501 of the National Electrical Code ANSI/

NFPA 70-2005.

335mm

(13.2”)

QMA601 User’s Manual

308mm

(12.1”)

Desiccant

Column

Outlet

335mm

(13.2”)

312mm

Sample In

(12.3”)

TOP VIEW

280mm

131mm

(5.2”)

41mm

(11.0”)

(1.6”)

410mm

Ø

16

(

4 off M10

”)

14

.

66mm

(2.6”)

External Earth Point Marking Label

4 off M20

threaded entries

41mm

(1.6”)

50mm

(2.0”)

97mm

(3.8”)

57mm

(2.2”)

Enclosure

Breather

(do not obstruct)

FRONT VIEW RIGHT VIEW

Figure 2

6 97449 Issue 3, June 2018

Mounting Dimensions

Page 17

QMA601 User’s Manual

!

2.5 Hazardous Area/Location Safety

This product is compliant for installation and use in a Hazardous Area/Location. All

certificates awarded to this product should be fully examined prior to installation and

use.

This product is certified safe for use in an ATEX Zone 1 and

Zone 2 / Class I, Division 1 area only. This product must not

be installed or used within a Zone 0 area.

This product must not be operated within an explosive

atmosphere greater than 1.1 bara (16 psia).

INSTALLATION

WARNING:

WARNING:

WARNING:

This product must not be operated with enriched oxygen

atmospheres (more than 21% oxygen content).

WARNING:

This product must not be operated outside of the

temperature range of +5 to +45°C (+41 to +113°F)

Refer to Appendix B for the Hazardous Area/Location certification details of this product.

Hazardous Area/Location certificates for this product may be downloaded from:

http://www.michell.com.

This product is fitted with a marking label that contains Hazardous Area/Location

information pertinent to the suitable location and installation.

During all installation and operation activities, local regulations and permitted working

routines must be observed. Installation should only be performed by competent

personnel and, where applicable, in accordance with IEC/EN 60079-14:2008 or local

equivalents.

Cable glands/barrier glands/conduit seals shall be installed in accordance with the

manufacturer’s instructions.

Repair and servicing of this equipment must only be carried out by the manufacturer. An

Installation and Maintenance Information Sheet is supplied separately to the manual.

Michell Instruments 7

Page 18

INSTALLATION

DANGER

Electric

Shock Risk

2.6 Electrical Safety

QMA601 User’s Manual

WARNING:

During the installation of this product ensure that all

applicable national and local electrical safety regulations

are observed.

WARNING:

Isolate the power prior to installation.

WARNING:

Always ensure that power is switched off prior to accessing

the product for any purpose other than normal operation, or

prior to disconnecting any cables.

Fuse

This product is provided with an internally mounted fuse located beneath the power

connector.

The fuses are rated at 5 x 20mm anti-surge to IEC60127-2:

Mains 240 V AC 3 A

24 V DC 6.3 A

A replacement fuse can be obtained by contacting Michell Instruments' technical support.

2.6.1 Equipment Ratings and Installation Details

This equipment and all power isolation devices must be installed in a location and

position that allows safe and easy access to their operation and is able to rigidly support

the equipment.

For location and mounting arrangements - refer to the relevant sections of this manual

for further details.

Do not install this equipment in a location that would expose it to impact or high levels

of vibration. Installation of this equipment must include the provision of a suitable and

locally positioned power isolation switch or circuit breaker. Indication of the purpose

of the switch or circuit breaker is strongly recommended. An over-current protection

device should be rated to a maximum of 10 A. Ensure that the power supply is sufficient

to satisfy the instrument's power consumption requirements.

Any power supply terminals and voltages must be suitably separated from the other

input/output requirements of this product.

8 97449 Issue 3, June 2018

Page 19

QMA601 User’s Manual

The product enclosure is supplied with an external protective earthing/grounding

terminal at the lower right hand side as shown in the figure below. As the first step

of the electrical installation - connect this earthing/grounding terminal to plant earth/

ground by a minimum 4mm

comprises of an earth bolt, 2 x plain washers and 1 x spring washer, which are all nickel

plated.

INSTALLATION

2

earth/ground bond strap. The earthing/grounding terminal

Figure 3

Mains Powered Units

As a minimum, the power connection cable should be 3 core over sleeved,

with minimum 0.5mm insulation and rated at 300 V. Cables should have

Live (L), Neutral (N) and Earth [Ground] (E) conductors.

Ensure suitably rated power supply cables and glands are used to ensure that

electrical safety is maintained. Connect each of the Live (L), Neutral (N) and

Earth [Ground] (E) conductors to the similarly marked terminals (L, N, E) on

the Power In connector shown above.

24 V DC Units

The cable should be rated at a minimum of 10 A at 50 V DC with minimum

0.5mm insulation. Connect the +24 V conductor to the terminal marked +

and the 0 V conductor to the terminal marked -.

Before applying power, perform a continuity test to ensure that the power supply cable

and product are effectively connected to the protective earth. A protective earth terminal

is mounted internally and the Earth wire connected to it should never be disconnected.

Earth Bolt And Nut Washer Assembly

Do not remove or exchange any of the cables, electrical components or any other parts

supplied with this product. Doing so will invalidate all warranties.

If installing rigid conduit, a stopping fitting must be installed within 46cm (18") of the

enclosure.

There are no additional or special electrical safety requirements other than those

referred to in this manual.

Michell Instruments 9

Page 20

INSTALLATION

DANGER

Electric

Shock Risk

This product is designed to be safe under the following conditions: between a

temperature range of -40 to +60°C (-40 to +148°F), in maximum 80% relative humidity

for temperatures up to +31°C (+88°F) decreasing linearly to 50% RH at +50°C

(+122°F). Supply voltages of ±10% and transient over voltages up to Overvoltage

Category II. Pollution Degree 2. Altitudes up to 2000m. Outdoor mounting is permitted

using suitably rated glands equivalent to NEMA 4 / IP66. See Appendix A, Technical

Specification, for full operating parameters.

2.6.2 Power Connection

The product is provided with 4 x M20 threaded cable gland entries for customer

connection. Only these gland entry points may be used. The end user/installer is not

permitted to machine additional entries into the enclosure.

This equipment must be supplied with a voltage between the range of 85 to 264 V AC,

47/63 Hz (140 W max) or 24 V DC (140 W max) to function correctly. Cable entry into

the measurement system is made through the bottom of the enclosure.

QMA601 User’s Manual

For an 85/264 V AC powered unit the terminals are marked:

L Live (= IEC Brown)

N Neutral (= IEC Blue)

E Earth/Ground (= IEC Green/Yellow)

For a 24 V DC powered unit, the terminals are marked:

+ 24 V DC

- 0 V DC

All power connections are made via a removable screw terminal connector mounted on

the mains connection PCB shown in

Figure 4.

Figure 4

24 V DC & 240 V AC Power Unit Connectors

All input and output connectors are 2-part pcb mounted type rated @ 300 V 10 A. The

detachable, screw terminal half of each connector is designed to accept 0.5 to 2.5mm2 (24

-12 AWG) stranded or solid conductors. The connector 2-pin for 24 V DC and 3-pin for 240

V AC.

10 97449 Issue 3, June 2018

Page 21

QMA601 User’s Manual

2.6.3 Other Electrical Connections

The power supply (shown below as a silver box) will not be in the 24 V DC version.

INSTALLATION

Figure 5

1 Analog Outputs

21 OP220 OP2+

19 OP118 OP1+

2 External Pressure

17 –

16 +

3 Alarms 3-4

15 COM4 Analyzer Status Alarm

14 NO4

13 NC4

12 COM3

11 NO3

10 NC3

Other Electrical Connections

NO in warning/fault condition

NC no warning/ no fault

4 Alarms 1-2

9 COM2

8 NO2

7 NC2

6 COM1

5 NO1

4 NC1

5 RS485

3G

2B

1A

Michell Instruments 11

Page 22

INSTALLATION

!

!

QMA601 User’s Manual

Pin 1

Pin 8

Figure 6

Pin Signal Name Description Cable Wire Color

1 TX+_D1 Transmit Data+ White with orange stripe

2 TX-_D1 Transmit Data- Orange with white stripe or solid orange

3 RX+_D2 Receive Data+ White with green stripe

4 BI+_D3 Bi-directional+ Blue with white stripe or solid blue

5 BI-_D3 Bi-directional- White with blue stripe

6 RX-_D2 Receive Data- Green with white stripe or solid green

7 BI+_D4 Bi-directional+ White with brown stripe

8 BI-_D4 Bi-directional- Brown with white stripe or solid brown

2.7 Pressure Safety

RJ45 to screw terminal adapter connections

WARNING:

This product is used in conjunction with pressurized gases.

Observe pressurized gas handling precautions.

WARNING:

Pressurized gas is dangerous and should only be handled by

suitably trained personnel.

DO NOT permit pressures greater than the specified safe working pressure to be applied

directly to the analyzer.

12 97449 Issue 3, June 2018

Page 23

QMA601 User’s Manual

!

!

Unless otherwise specified the QMA601 is calibrated at

a sample pressure of 3 barg (43.5 psig) on the gas inlet,

and a back-pressure of 2 barg (29 psig) on the outlet.

Operating the analyzer at a different pressure invalidates

Similarly, gas pressure affects the output of the internal

moisture generator, thereby invalidating further auto

calibrations which use a built-in moisture generator as a

2.8 Gas Sample Connections

The following points should be considered when installing the sample gas supply line:

• PTFE tape is recommended for pipe connections.

• Solvent based pipe thread sealant should not be used, as condensable

components or contaminates can be leached during the curing period.

INSTALLATION

the calibration.

reference.

Care and attention to the position and installation of the tubing will minimize problems

caused by avoidable contamination. The most common issue with of sample flow is the

accumulation of liquid in impulse lines during a shutdown period. If the measurement

system has not been isolated, condensate can be displaced, on re-start, into components

and associated tubework.

WARNING:

Exd enclosure breather must remain open to atmosphere at

all times, without any obstruction - See Figure 2.

Michell Instruments' recommendations are:

• The sampling point from the process line should be taken from the

top of the process line. If a radial probe is used the orifice should face

downstream.

• It is recommended that Viton is used for all O-rings.

• The internal volume of the impulse tubing connecting between the process

line and this product should be as small as possible to minimize response

lag time to changing process conditions.

• Piping should be lagged and/or trace heated if ambient temperatures

could cause the sample gas to fall below its dew-point temperature.

• A drain valve should be placed at the lowest point in the system.

• It should be standard procedure to isolate this product during shutdowns

or when plant problems are being experienced and to adequately purge

the supply lines before restarting.

• The relatively large area of surfaces and internal volume of inline

components can be particularly troublesome if contamination is

experienced.

Michell Instruments 13

Page 24

INSTALLATION

Prolonged purging, or stripping and cleaning, followed by re-purging with

gas may be necessary to remove the contamination.

• Avoid sample gas streams that are already very close to the dew point

or which have dispersed liquid within them. In such cases, sampling

from fast loops and/or from downstream of existing catch pot/coalesce

systems is always preferred.

Failure to observe these recommendations will potentially cause problems of

contamination as well as causing consequential inaccurate, unreliable and inconsistent

monitoring. If a top-entry sample point is not available, extra attention should be given

to the design of the sample line installation to avoid unwanted contamination.

QMA601 User’s Manual

14 97449 Issue 3, June 2018

Page 25

QMA601 User’s Manual

3 OPERATION

This section describes both the general operation of the analyzer and the method of

setting-up and changing the default parameters should this become necessary.

NOTE: Before operating the analyzer read Sections 1 to 3 which explain the

analyzer’s functionality, installation, controls, display functions and screens.

Prior to operation, the analyzer must have been connected to the correct electrical

power supply and the relevant analog and alarm outputs connected to external systems

as required and as described in Section 2. The analyzer must also have been installed

as detailed in Section 2 and connected to a sample gas supply that is representative of

the monitored process.

3.1 General Operational Information

OPERATION

Operation of the QMA601 is completely automated and once set-up requires little or no

operator intervention.

Michell Instruments 15

Page 26

OPERATION

3.1.1 First Time Operation

To commence operation, proceed as follows:

1. Connect the sampling line to the sample system. It is recommended to

heat trace the sample gas line.

2. Switch on the power supply to the analyzer. The Initializing Screen will

appear.

QMA601 User’s Manual

QMA601

Process Moisture Analyzer

Initializing

3. After the initializing period has finished, the following display will appear.

Oven heating to set point, please wait!

Skip

1

2

3

4

4. This heating period lasts about an hour allowing time for the internal

sampling system to be purged with the sample gas.

16 97449 Issue 3, June 2018

Page 27

QMA601 User’s Manual

!

3.1.2 Analyzer Set-Up

During the period when the oven is heating to set point, all functions, except for HMI

adjustments, are disabled until the oven has reached its operating temperature. Press

the

ENTER key to enter the HMI Screen (see Section 3.73) to set up the temperature

and pressure units before operating the analyzer for the first time. Note: Pressing the

ENTER key only takes you to the HMI screen when the oven heating message with

"skip" button is present.

OPERATION

Parameter

1 & 2

Figure 7

Using the inlet pressure regulator adjust the sample pressure until the reading on the

internal sensor pressure readout matches the value on the calibration certificate. The

back-pressure should also be adjusted to the value shown on the calibration certificate.

Unless otherwise specified the QMA601 is calibrated at

a sample pressure of 3 barg (43.5 psig) on the gas inlet,

and a back-pressure of 2 barg (29 psig) on the outlet.

Operating the analyzer at a different pressure invalidates

Similarly, gas pressure affects the output of the internal

moisture generator, thereby invalidating further auto

calibrations which use a built-in moisture generator as a

Typical Display

the calibration.

reference.

Michell Instruments 17

Page 28

OPERATION

3.2 User Interface

The QMA601 features a 7” color display.

3.2.1 Interface Controls

QMA601 User’s Manual

Four capacitive touch keys are used to navigate the menu system.

Key presses are detected through the glass front panel, and are indicated by a blue LED

above the key.

3.2.2 ‘Up/Down Arrow’ Keys

Up () and Down () keys are used to move to required menu items. The

The

selected menu item is surrounded by a black frame.

Figure 8

Figure 9

User Interface

Up/Down Arrow Keys

Numerical options activate a pop up keypad. For more information on the keypad see

Section 3.2.5.

18 97449 Issue 3, June 2018

Page 29

QMA601 User’s Manual

3.2.3 'ENTER’ Key

OPERATION

ENTER

The ENTER key is used to navigate into menus, open keypads, cycle through options,

and accept changes.

For non-data entry options pressing the

3.2.4 ‘ESC’ Key

The ESC key is used to return to the previous menu and is also used to leave keypads

without accepting any changes.

Figure 10

Figure 11

‘ENTER’ Key

ENTER key moves to the next available option.

ESC

‘ESC’ Key

Michell Instruments 19

Page 30

OPERATION

3.2.5 Pop Up Keypad

Allows the user to enter numerical data. The figures below the box indicate the minimum

and maximum limits which can be entered.

QMA601 User’s Manual

000.0

0.0 to 300.0

Figure 12

Key Action Note

ESC

Up () and Down ()

ENTER

Moves cursor to last digit.

Exits to previous page.

Increments or decrements

selected number.

Moves cursor to next digit.

If at last digit, and within

allowable range, updates

value.

Table 1 Pop Up Keypad

Pop Up Keypad

If outside the allowable

range then a message

displays informing the user.

20 97449 Issue 3, June 2018

Page 31

QMA601 User’s Manual

3.3 Menu Structure

LARGE DISPLAY

PARAMETER 1

LARGE DISPLAY

PARAMETER 2

FULL SCREEN

GRAPH

SETTINGS

MEASUREMENT

OUTPUTS

HMI

RTC

SW COMMS

CAL HISTORY

ABOUT

FIRMWARE VER

SERIAL NUMBERS

MAIN SCREEN

WARNINGS

LOGGING

ALARMS

FIELD CAL

MONITOR

CARRIER GAS

DP CALCULATION

PRESSURE INPUT

OUTPUT SELECT

PARAMETER

OUTPUT TYPE

LOW

HIGH

ERROR INDICATION

LANGUAGE

CHART PERIOD

SIGNAL SMOOTHING

TEMP UNIT

PRESSURE UNIT

FLOW UNIT

PARAMETER 1

PARAMETER 2

OVEN TEMP CNTL

ENCLOSURE TEMP

FLOW CONTROL

CELL PRESSURE

EXT PRESSURE

INSTRUMENT DRIFT

BEAT FREQUENCY

PPMV OVER RANGE

LOG PAGE

ALARM SELECTOR

CLEAR LATCH

LATCH

CALIBRATE

ANALOG O/P HOLD

CAL SOURCE

CAL METHOD

SETTLING CYCLES

CALIBRATION CYCLES

MOISTURE CONTENT (PPMV)

BEAT FREQ (HZ)

DELTA FREQ (HZ)

ENCL TEMP (°C)

FLOW RATE (ML/MIN)

CELL PRESSURE (BARG)

EXT PRESSURE (BARG)

MOIST GEN SERVICE

CAL ALARM

OPERATION

OVEN TEMP SENS

OUTPUT 1

OUTPUT 2

OSCILLATOR COM

ETHERNET COM

DRYER SERVICE

PARAMETER

LOW

HIGH

REF SOLENOID

SAMPLE SOLENOID

INT. CAL. SOLENOID

DRYER VOL REMAINIG %

MG REMAINING (DAYS)

SCF

MGF (PPMV)

Parameter

1 & 2

DAY

MONTH

YEAR

SAVE DATE

DATE

INSTRUMENT ID

PROTOCOL

ADDRESS

Figure 13

HOUR

MINUTE

SAVE TIME

TIME

IP ADDRESS

SUBNET MASK

DEFAULT GW

Menu Structure

Michell Instruments 21

Page 32

OPERATION

3.4 Description of Measured Parameters

QMA601 User’s Manual

Moisture content ppm

Moisture content ppm

Moisture content mg/m

Water Vapor Pressure Pa water vapor pressure in pascals

lbs/MMscf pounds of H

Dew point

Oven Temperature Temperature of the internal oven

Flow Gas flow rate

Cell Pressure Pressure measured by the internal pressure transducer

Ext. Pressure

3.5 Main Screen

parts per million of H2O by volume

V

parts per million of H2O by weight

W

3

milligrams of H2O per cubic meter gas

O per million standard cubic feet

2

dew-point temperature of either ideal or natural gas depending

on options set on measurement screen

Pressure measured by an external pressure transducer (if

fitted)

Figure 14

Main Screen

22 97449 Issue 3, June 2018

Page 33

QMA601 User’s Manual

Parameter Description

Parameter 1 & 2

Graph

Alarm 1, 2 & 3

Alarm 4

Internal

Warnings

ΔDP

Live reading of the selected display parameters.

Live graph reading of parameter 1.

The current state of the alarms.

Possible States:

Low – Alarm type is set to Low, and has been triggered because the

selected parameter is below the threshold value.

OK – Alarm has not been triggered.

High – Alarm type is set to High, and has been triggered because

the selected parameter is above the threshold value.

Trip - Alarm has been triggered at some point previously but is now

OK. Only occurs when the alarm is set as 'Latched'

Analyzer Status Alarm Relay

Activated for warning/fault

The parameter selection can be set in the "warnings" menu.

Internal warning alarms.

Possible States: OK, WARNING

Shown as ΔX (where X=the currently selected primary measurement

parameter) – Displays the difference between the minimum and

maximum graph measurements.

Displays the current analyzer mode.

OPERATION

Inst. Mode

Next Mode

Possible States:

Measure – QMA601 is performing a measurement cycle.

Cal Internal – QMA601 is performing a self-calibration using the

internal reference.

Cal External – QMA601 is performing a self-calibration using an

external reference.

Warm up – Oven is still heating to the set-point temperature.

If Inst. Mode = Measure, Next Mode = Next Calibration

If Inst. Mode = Cal Internal/External, Next Mode = Next Measurement

If Inst. Mode = Heating, Next Mode = Oven Temperature

Possible States: Time until the next mode or Manual

Table 2 Main Screen Parameters

Michell Instruments 23

Page 34

OPERATION

3.5.1 Large Display Mode

Parameter 1 & 2

QMA601 User’s Manual

To access the large display mode for Parameter 1 and 2, press the

Main Screen.

Cell Pressure

3.0

1 H2O ppm

2 DP °C

Alarms

3 Cell Pr. barg

4 Warnings

Figure 15

Displays the current gas phase being analyzed

V

OK

OK

OK

OK

Press ESC to exit page

Large Parameter Display Mode

Inst. Mode

Next Calibration

Gas Phase

Next Phase

barg

Measure

Manual

Sample

DOWN key from the

30s

Gas Phase

Next Phase

To return to the Main Screen press the

Possible States: Reference, Calibration, Sample

Refer to Sections 3.9 and 3.10 for a description of the measurement

and calibration cycles.

Shows the countdown in seconds until the current gas phase ends

and the next gas phase begins.

Table 3 Large Parameter Display Mode

ESC key.

24 97449 Issue 3, June 2018

Page 35

QMA601 User’s Manual

Full Screen Graph

This page displays a full screen graph of Parameter 1.

OPERATION

To access the full screen graph, press the

Figure 16

Up () key from the Main Screen.

Full Screen Graph

Michell Instruments 25

Page 36

OPERATION

3.6 Main Screen Sub Menus

The following sub menus can be accessed from the Main Screen:

• Warnings

• Logging

• Alarms

• Field Cal

• Settings

• Monitor

3.6.1 Warning Screen

This page is accessed through the 'Warnings' item on the Main Screen and is used

enable or disable the internal alarms. When an individual alarm is disabled it will not

trigger the internal alarm.

QMA601 User’s Manual

This screen is accessed by pressing the

Navigate between menu items with the

Press the

To return to the Configuration Screen press the

ENTER key to change the required option.

ENTER key from the Configuration Screen.

Up () and Down () keys.

ESC key.

Figure 17

Warning Screen

26 97449 Issue 3, June 2018

Page 37

QMA601 User’s Manual

The state of the internal alarm associated with each of the parameters above is indicated

by the following icons:

Icon Description

Alarm disabled.

x

Alarm enabled. No fault.

Alarm enabled. Fault condition.

OPERATION

3.6.2 Logging Screen

This menu contains a record of the last 280 data points of the 'Log Parameter' value. It

is accessed through the 'Logging' item on the Main screen.

Table 4 Warning Screen

Figure 18

Parameter Description

Log Parameter

Log Page

Michell Instruments 27

Parameter to be recorded in the log file

Opens a keypad to select the page of logged data to view.

Table 5 Logging Screen

Logging Screen

Page 38

OPERATION

3.6.3 Alarm Screen

This menu allows the internal alarm parameters to be set. It is accessed through the

'Alarms' item on the Main screen.

QMA601 User’s Manual

This screen is accessed by pressing the

Navigate between menu items with the

Select the alarm required with the

Press the

activate a pop up keypad. For more information on the keypad see Section 3.2.5.

To return to the Configuration Screen press the

ENTER key to change the required option. Numerical parameter options

ENTER key from the Configuration Screen.

Up () and Down () keys.

ENTER key.

ESC key.

Parameter Description

Selects the required alarm.

Alarm Selector

Available Options: Alarm 1, Alarm 2, Alarm 3, Alarm 4 - Analyzer

Status Alarm only

Clears a latched alarm.

Clear Latch

Available Options: Yes, Cleared

Enables and disables latching of the selected alarm. If latching is

enabled the alarm will enter a 'tripped' state when the cause of the

Latch

Parameter

Low

High

alarm is corrected.

Available Options: YES, NO

Selects the parameter for the selected alarm.

Available Options: Flow ml/min, Cell Pr. barg, Ext. Pr. barg, H

H2O ppmW, H2O mg/m3, WVP Pa, lbs/MMscf, DP °C/°F, Oven °C/°F

Selects the lower limit for the selected alarm.

Selects the uper limit for the selected alarm.

Figure 19

Table 6 Alarm Screen Parameters

Alarm Screen

O ppmV,

2

28 97449 Issue 3, June 2018

Page 39

QMA601 User’s Manual

3.6.4 Field Calibration Screen

This menu allows the field calibration parameters to be set and activated if

necessary. It is accessed through the 'Field Cal' item on the Main screen.

Depending upon the field calibration settings some parameters may become

inactive. In these cases the inactive parameters are automatically hidden

OPERATION

Figure 20

Calibration Screen

Michell Instruments 29

Page 40

OPERATION

Parameter Description

Calibrate

Analog O/P

Hold

QMA601 User’s Manual

Starts a calibration procedure if a manual calibration has been selected.

Toggles data hold mode. This determines whether the last valid

measurement is held while a calibration is carried out.

Available Options: On, Off

If data hold is selected, the user can select how many cycles, after the

calibration, the last measured value is held for.

Toggles between an external calibration source or the internal

calibration source. If an external calibration source is selected the

external reference moisture must be entered in the ext ref setting.

Cal Source

Cal Method

Available Options: External, Internal

External Cal Source - when this is chosen Ext Ref will need to be

entered to show the ppmV value of the external moisture reference.

Internal Cal Source - when this is chosen then the Cal Method can be

set to Manual or Automatic.

Toggles between manual calibration or automatic calibration mode.

Available Options: Automatic, Manual

Manual Cal Method - if this is chosen the Start button must be

pressed in order to initiate the calibration procedure. If this method

is chosen then both the Interval and Hour selection boxes are hidden

and a Start button is displayed.

Automatic Cal Method - if this is chosen then the following parameters

will need to be set and will be displayed on the screen. Calibration will

begin on the time selected using the interval and hour settings.

Interval (Days)

Hour

Settling Cycles

Cal Cycles

Frequency of automatic calibrations in days.

The hour in the day at which an automatic

calibration will start.

Period of time for the QMA401 to stabilize to the

new moisture level (as presented by the internal

moisture generator or external ppm value)

before conducting the actual calibration cycles.

Sets how many calibration cycles are carried out.

Table 7 Calibration Screen Parameters

30 97449 Issue 3, June 2018

Page 41

QMA601 User’s Manual

If Analog O/P Hold is turned off then the ‘Hold Cycles’ selection box is hidden, as shown

below:

OPERATION

Figure 21

Hold Cycles – If Analog O/P Hold is selected, the user can select for how many cycles

after the calibration the last measured value is held for. This is done using the onscreen

keypad which is opened.

If an external calibration source is selected the user must enter the external reference

moisture in the Ext Ref (ppm) setting.

If an internal calibration source is selected then the ‘Ext Ref’ selection box is hidden (as

shown above). If an external calibration is selected then the calibration mode is forced

to manual i.e. an automatic calibration cannot be carried out if the external calibration

source is active. The ‘Cal Method’ selection box is also hidden, as shown below:

Field Calibration Screen 2

Figure 22

If an automatic calibration is selected then calibration will begin on the time selected

using the interval and hour settings. This is done using the onscreen keypad which is

opened.

Field Calibration Screen 3

Michell Instruments 31

Page 42

OPERATION

If a manual calibration is selected then both the ‘Interval’ and ‘Hour’ selection boxes

are hidden, as shown above. If an automatic calibration is selected then the “Calibrate”,

“Cal Source” and “Ext Ref” selection boxes are hidden, as shown below:

QMA601 User’s Manual

Figure 23

• Interval (Days) – This is where the user selects how often in days a

calibration is performed.

• Hour of Day – This is where the user selects the hour within the day at

which the calibration will occur.

• Cal Cycles – This is where the user selects how many calibration cycles

are carried out.

• Settling Cycles – This is where the user selects how many settling cycles

are added after the calibration.

If a field calibration has started all adjustable parameters are hidden. A

control to stop the field calibration is added along with a countdown of the

remaining settling cycles and calibration cycles:

Field Calibration Screen 4

Figure 24

Field Calibration Screen 5

32 97449 Issue 3, June 2018

Page 43

QMA601 User’s Manual

3.6.5 Monitor screen

This screen displays a number of live parameters. No parameter can be changed on this

screen: it is for reference only.

This screen is accessed through the Monitor item on the main screen.

OPERATION

To return to the Main Screen press the

Figure 25

Parameter Description

Moisture Content (ppmV)

Beat Frequency(Hz)

Delta Frequency(Hz)

Enclosure Temperature

(0C)

Flow Rate (ml/min)

Cell pressure (barg)

Ext. pressure (barg)

Ref Solenoid

Sample Solenoid

Internal Cal Solenoid

Dryer vol. remaining %

MG remaining (days)

SCF

MGV

Live moisture reading in ppm

Live beat frequency reading: the frequency difference

between the two crystals.

Live delta frequency reading: the beat frequency difference

between the sample and reference phase.

Live QMA601 enclosure temperature.

Live flow rate reading.

Live internal pressure transducer reading.

Live external pressure reading.

Displays the reference solenoid state.

Displays the sample solenoid state.

Displays the internal calibration solenoid state.

Remaining dryer life in %.

Remaining moisture generator life in days.

Sensor correction factor set during a calibration cycle.

Moisture Generator value.

ESC key.

Monitor Screen

V

Table 8 Monitor Screen Parameters

Michell Instruments 33

Page 44

OPERATION

3.7 Settings Menu

The settings menu is accessed through the Settings item on the main screen.

QMA601 User’s Manual

Allows access to the following sub menus to change instrument settings.

• Measurement

• Outputs

• HMI

• RTC

• SW Comms

• Cal History

• About

3.7.1 Measurement Screen

Figure 26

Settings Menu Screen

This screen is accessed by pressing the ENTER key from the Configuration Screen.

Navigate between menu items with the

Press the

activate a pop up keypad and Carrier Gas parameter options activate a gas options

screen. For more information on the keypad see Section 3.2.5.

To return to the Configuration Screen press the

ENTER key to change the required option. Numerical parameter options

Up () and Down () keys.

ESC key.

34 97449 Issue 3, June 2018

Page 45

QMA601 User’s Manual

OPERATION

Figure 27

Parameter Description

The settings menu is accessed through the Settings item on the main

screen.

Available Options: Air, Ar, CH

Carrier Gas

CO, CO

User 3

User Gas Entry: If a 'User' carrier gas is selected an additional option

to set this gas is added to the menu. See section 3.7.1.1 for more

information.

Selects the dew-point calculation method.

DP Calculation

Available Options:

IGT (IGT Bulletin #8)

ISO (ISO 18453),

Ideal Gas,

Selects the pressure source.

Available Options:

Atmos – Atmospheric pressure.

Fixed – User-settable fixed value.

Pressure Input

When the Fixed option is chosen it enables a fixed value to be entered

(see screen shot below).

External – An externally connected pressure transducer.

When the External option is chosen it enables the choice of the zero

and span range pressure transducer values of 4 or 20mA (see screen

shot below).

Pressure Unit

for indication purposes only but can be changed in the "HMI Menu"

(Section 3.7.3)

Measurement Screen

, C2H2, C2H4, C2H6, C3H6, C3H8, C4H10,

4

, H2, He, Kr, N2, Ne, NH3, NO, N2O, O2, Xe, User 1, User 2,

2

Table 9 Measurement Screen

Michell Instruments 35

Page 46

OPERATION

3.7.1.1 Carrier Gas

Used to select a different carrier gas. When the Carrier Gas option is selected the page

shown below is opened.

QMA601 User’s Manual

Figure 28

There are 20 different preset gases the user can choose from, along with 3 user definable

presets:

• Air

• Argon

• Methane

• Acetylene

• Ethylene

• Ethane

• Propane

• Butane

• Propene

• Carbon Monoxide

Carrier Gas Screen

• Hydrogen

• Helium

• Neon

• Krypton

• Ammonia

• Nitric Oxide

• Nitrous Oxide

• Oxygen

• Xenon

• User 1

• Carbon Dioxide

• Nitrogen

After selecting the carrier gas the user is taken back to the previous page.

• User 2

• User 3

36 97449 Issue 3, June 2018

Page 47

QMA601 User’s Manual

NB. If User 1, 2 or 3 is selected as the carrier gas then a new parameter box

will appear underneath the carrier gas toggle box called ‘User Gas’. This can

be seen below.

OPERATION

When the User Gas option is selected from the carrier gas list, the user can enter the

user gas settings, using the User Gas Setup page which is opened. See Appendix F for

further information on calculating User Flow Correction Factors.

3.7.1.2 DP Calculation Method

Selects the calculation method used for dew point and lbs/MMscf. Options are:

• IGT - as per IGT Bulletin #8

• ISO - as per ISO18453

• Ideal Gas

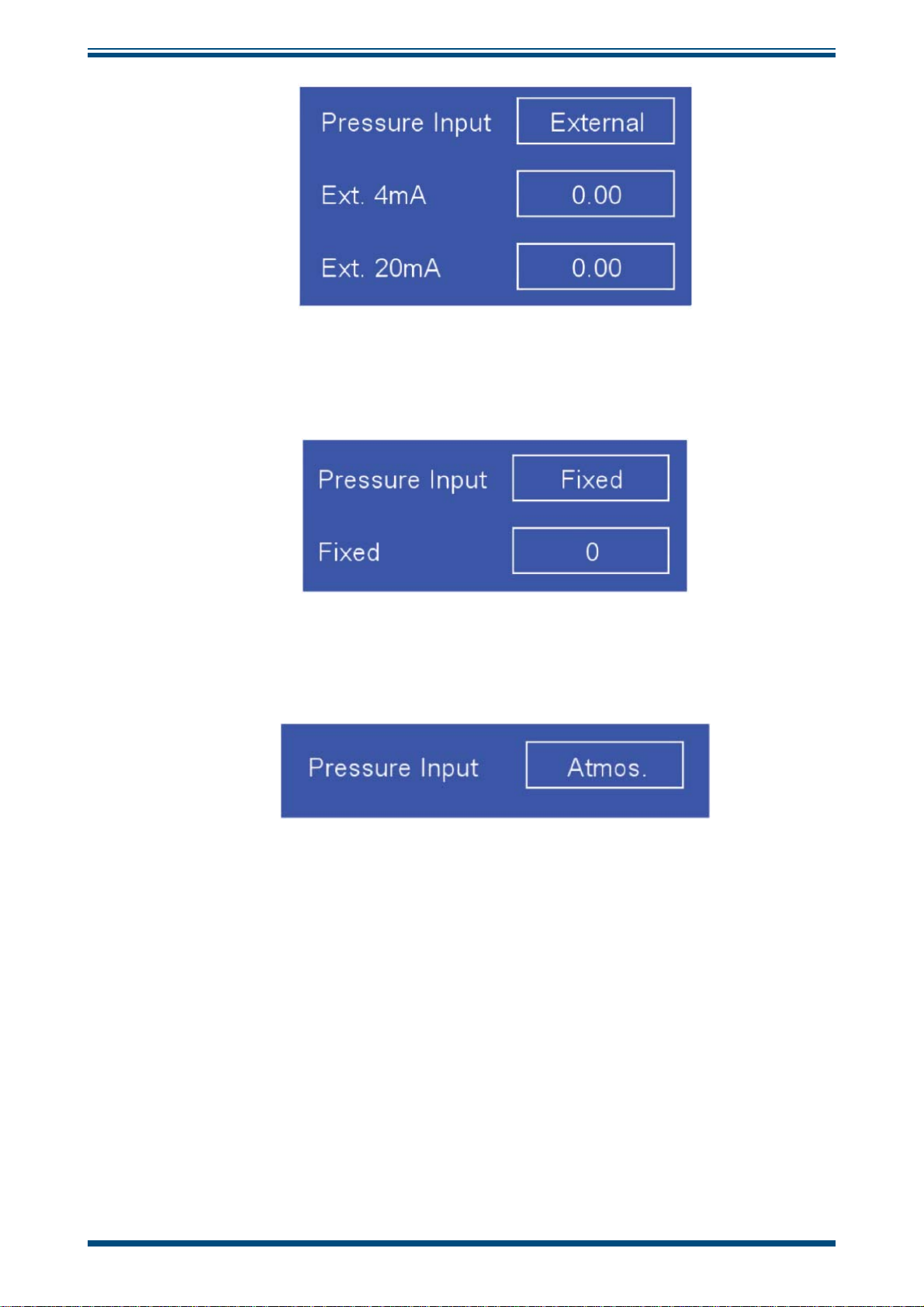

3.7.1.3 Pressure Input

Selects the pressure source. Options are:

• Atmos.

• Fixed

Figure 29

Measurement Screen

• External

If the external option is selected the ‘Fixed’ selection box is hidden and replaced with

the ‘Ext. 4mA’ and ‘Ext. 20mA’ selection boxes as shown below:

Michell Instruments 37

Page 48

OPERATION

QMA601 User’s Manual

Figure 30

If the fixed option is selected the ‘Ext. 4mA’ and ‘Ext. 20mA’ selection boxes are hidden

and replaced with the ‘Fixed’ selection box as shown below:

Figure 31

If the ‘Atmos.’ option is selected the ‘Fixed’, ‘Ext. 4mA’ and ‘Ext. 20mA’ selection boxes

are all hidden as shown below:

External Options

Fixed Options

Figure 32

• Fixed – Allows the user to enter the fixed pressure using the onscreen

keypad.

• Ext. 4mA – Allows the user to enter the pressure at 4mA using the

onscreen keypad.

• Ext. 20mA – Allows the user to enter the pressure at 20mA using the

onscreen keypad.

• Pressure Unit –This displays the current Pressure unit. Please note this

cannot be changed on this page.

Atmos. Option

38 97449 Issue 3, June 2018

Page 49

QMA601 User’s Manual

OPERATION

• Gas – Allows the user to enter a unique name for the gas using the

onscreen keypad.

• Molecular Weight – Allows the user to enter the molecular weight of the

gas using the onscreen keypad.

• FCF – Allows the user to enter the Flow Correction Factor using the onscreen

keypad. See Appendix B for instruction on how to calculate the FCF.

3.7.2 Outputs Screen

The Outputs Screen allows the two analog output channels to be set up. It is accessed

through the 'Outputs' item in the 'Settings menu'.

This screen is accessed by pressing the

Navigate between menu items with the

Select output required with the

Figure 33

ENTER key.

User Gas Setup Screen

ENTER key from the Configuration Screen.

Up () and Down () keys.

Press the

activate a pop up keypad. For more information on the keypad see Section 3.2.5.

To return to the Configuration Screen press the

ENTER key to change the required option. Numerical parameter options

ESC key.

Michell Instruments 39

Page 50

OPERATION

QMA601 User’s Manual

Parameter Description

Output

Selector

Parameter

Selects the output channel to check and modify.

Available Options: Output 1, Output 2

Selects the parameter tracked by the output channel.

Available Options: H2O ppmv, H2O ppmw, mg/m3, WVP Pa, H2O lbs/

MMscf, DP, Oven, Flow, Cell Pr., Ext. Pr.

Selects the signal type of the output.

Output Type

Available Options: 1-5 V, 4-20 mA

Low

High

Error

Indication

Sets the lower output limit for the selected parameter.

Sets the higher output limit for the selected parameter.

Selects the error indication level for the outputs.

Available options:

LOW (3.2 mA / 0.80 V)

HIGH (21.4 mA / 5.35 V)

Figure 34

Outputs Screen

Table 10 Outputs Screen Parameters

40 97449 Issue 3, June 2018

Page 51

QMA601 User’s Manual

3.7.3 HMI Screen

The HMI Screen allows the setting of the display language, parameters and measurement

units. It is accessed from either the HMI item on the Settings menu or directly during

the QMA601 warm up procedure.

OPERATION

This screen is accessed by pressing the

from the Oven heating Screen at start-up. If this screen is entered during start-up -

after any adjustments have been made press the

Screen.

Navigate between menu items with the

required with the

Press the