Page 1

Process Analyzers

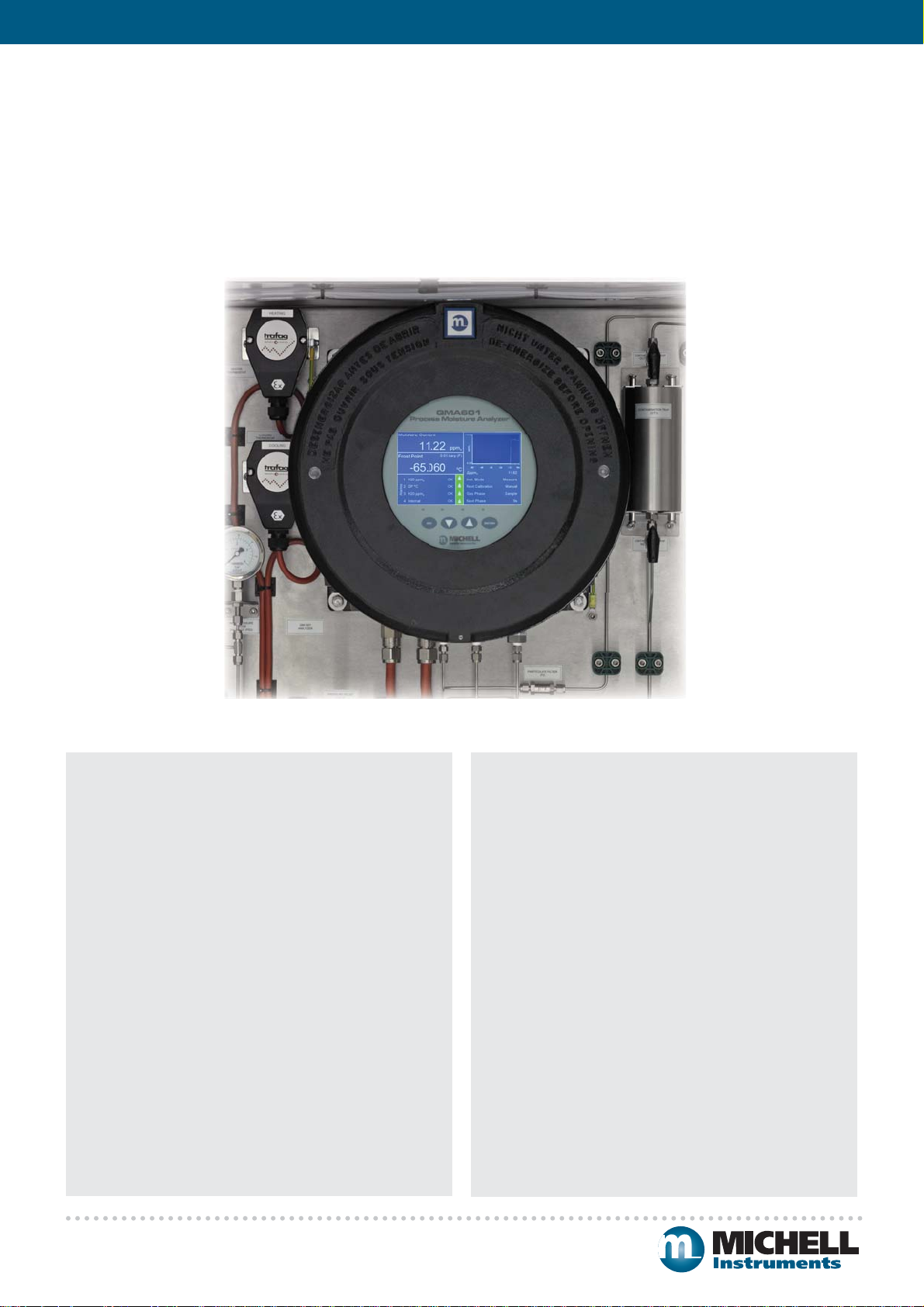

QMA601

Process Moisture Analyzer

Fast, high-precision moisture measurements for hazardous areas.

The next generation Advanced Quartz Crystal Microbalance analyzer from Michell Instruments

is designed to provide reliable, fast and accurate measurement of trace moisture content in a

wide variety of process applications where keeping moisture levels as low as possible is of critical

importance.

Highlights

• Fast and reliable measurement from 0.1 to

2000ppm

• Accuracy of ±0.1ppmV at <1ppmV and 10% of

reading from 1 to 2000ppm

• Maintenance-free for 3 years

• Built-in verification of customer process gas

• IECEx, ATEX, TC-TR Ex certified for Exd flameproof,

CSA

• Intuitive, color HMI with touch-screen keypad; no

‘hot work’ permit required

• 14 internal alarms

• 21 predefined carrier gases and 3 user-defined

gases

• Proven Michell Instruments quality: 40 years of

expertise in moisture measurement built into the

design

V

V

US certified for explosion proof

Applications

• Glycol dehydration of natural gas

• Molecular sieve dehydration of natural gas

• Natural Gas transmission and storage

• Refinery catalytic reforming — recycle gas

monitoring

• Ethylene and propylene production

• LNG production / revaporization

www.michell.com

Page 2

Process Analyzers

40 Years of Experience with Moisture Measurement

The control of moisture is critical for the operational safety and efficiency of the plant equipment in upstream through to

downstream processes. We at Michell Instruments have been developing expert moisture-sensing instruments and systems for

40 years. Over this time, we have developed the world’s largest range of moisture and hydrocarbon dew-point analyzers for the

oil, natural gas, refining and power industries. We have gained extensive knowledge of applications in these industries, with

thousands of installations in sites across the globe.

Introducing the QMA601

Process Moisture Analyzer

Precision Measurement

• High accuracy with lower detection limit of 0.1 ppm

• Wide range of 0.1 to 2000ppm

• Sensitivity of 0.01ppm

The QMA601 is the result of Michell Instruments’ continuous

effort to improve Quartz Crystal Microbalance technology. The

new analyzer utilizes a new generation of precision crystal

oscillators guaranteeing a highly accurate measurement

which is completely insensitive to changes in background

gas composition.

While other moisture technologies are being stretched at

sub-ppm trace moisture levels, the new QMA601 can offer

reliability, simplicity and greatly reduced cost of ownership

from trusted and proven Quartz Crystal technology.

v

v

Reliability

For maximum stability, all critical components of the QMA601

— the moisture generator, sensor and flow control devices

— are precisely temperature controlled. This ensures that

fluctuations in sample gas or environmental temperature

have no influence on the measurement.

The analyzer utilizes a mass flow controller to ensure precise

control of the sample and reference gas flows to ±0.1 ml/

min. Coupled with a pressure transducer, this system ensures

continued accuracy of measured and calculated parameters

even during fluctuations in sample pressure.

Simplicity

Human Machine Interface (HMI)

The QMA601 provides a highly intuitive, menu driven color

interface, utilizing a capacitive touch-screen keypad. This

powerful HMI makes control, logging and configuration of

analyzer parameters very simple. The main display also

incorporates real-time trend graphing and alarm indicators

based on the NAMUR 102 standard. This allows operation

and interrogation of the analyzer in the field with no need

for a ‘hot work’ permit.

v

Easy Integration into Existing Control Systems

The QMA601 is equipped with two analog outputs,

configurable for either current or voltage scaling. It also

provides both Modbus RTU Protocol over RS485 and Modbus

TCP for easy connection to a SCADA or other user-defined

data acquisition system.

Dedicated remote application software is also available.

Integrated Sampling System

The instrument can be supplied with a high quality, in-house

designed, sample conditioning system that is optimized

for the application, as well as for the requirements of the

analyzer.

Reduced Cost of Ownership

Minimum Maintenance

Sophisticated instruments are often complicated and

require experience and special care in use, increasing

cost of ownership. The QMA601 differs through its very

uncomplicated approach to field service; the desiccant dryer

is easy to replace via its mounting on the sampling panel.

The moisture generator has an average life span of 3 years

before replacement is required. The analyzer will therefore

perform reliably for many years with just basic maintenance

and housekeeping.

Automated Verification

The QMA601 incorporates an automatic or manual

verification system that can use either the internal traceable

moisture generator or an external reference supplied by the

user. Carried out on the process gas flow, these periodic

validation-checks of sensor performance can be initiated on

demand, or automatically (at user-defined intervals and time

of day), providing a verification of analyzer performance

and automatically adjusting out any change. The moisture

generator at the core of the system is supplied with a

calibration traceable to NPL and NIST.

Ease of Installation

Available with a choice of either AC or DC powered versions.*

No barrier unit or safety earth are required, saving the user

both cost and inconvenience.

*CSAUS version 24V DC only

www.michell.com

Page 3

Technology:

Quartz Crystal Microbalance

The Quartz Crystal Microbalance (QCM) technology for moisture measurement is

based on monitoring the frequency modulation of a hygroscopic-coated quartz

crystal with specific sensitivity to water vapor.

Bulk adsorption of water vapor onto the coated crystal causes an increase in

effective mass. This change in mass modifies the oscillation frequency in a very

precise and repeatable manner and the frequency change is in direct proportion

to the water vapor pressure. The moisture concentration can therefore be

measured as a change in the oscillation frequency, with respect to a reference

crystal.

The sorption process is fully reversible with no long-term drift effect, giving a

highly reliable and repeatable measurement.

Process Analyzers

Pole

Quartz Crystal Polyamide

Our products are also backed up

by global service and support. With

locations on 6 continents and 56

countries, Michell Instruments offers

an extensive network of factory

trained application engineers ready to

analyze your application and deliver

the solution. This allows us to assure

customer satisfaction throughout the

product’s lifetime.

If you can’t find a product to fit your

application contact your local Michell

Instruments office, or visit our website

www.michell.com/uk - we’re here to

help.

Polymer Coating

Gold Electrode

The QMA601 Process Moisture Analyzer is designed to provide highly reliable,

fast and accurate measurement of moisture content in a wide variety of

carrier gases. Utilizing Quartz Crystal Microbalance technology, the analyzer

incorporates automatic (or manual) verification using an integrated moisture

generator reference source and, with its intuitive touch-screen operated color

HMI, provides easy operation.

The Moisture Specialists:

We have the solution for your moisture sensing needs

With 5 proprietary moisture sensing technologies, Michell Instruments will tailor

our solutions to best fit the specifics of the your application, as well as the project

budget.

Capacitive humidity sensors:

For quick and easy pipeline integrity measurement in low pressure town gas.

Michell Ceramic Sensor technology:

3rd generation of metal oxide for natural gas applications at high pressure (CNG)

and economical, easy gas processing applications.

Chilled Mirror:

For precise reference measurements at highest accuracy and NPL or NIST

traceability.

www.michell.com

Quartz Crystal Microbalance:

For fast, precise measurement at low ranges in changing backgrounds.

TDLAS:

For fast, precise and low maintenance measurement in both sweet and sour gases

from 1000ppm

to 1ppmv.

v

Page 4

Process Analyzers

Technical Specifications

Measuring technology Fast Response Quartz Crystal Microbalance

Calibrated range* 0.1 to 700ppm

Measurement range 0.1 to 2000ppm

Accuracy ±10% of reading from 1 to 2000ppm

Repeatability ±5% of the reading from 1 to 2000ppm

Limit of detection

Available units ppmV, ppmW, mg/Nm3, vapor pressure (Pa), dew

Response speed

Automatic calibration Internal moisture generator source calibrated

Sensitivity

Electrical Specifications

Supply voltage 85 to 264 V AC, 47/63Hz or 24 V DC (ATEX /

Alarms 1 x system alarm, volt-free change-over (FORM

Analog signals 2 x 4–20 mA or 1–5 V (selectable)

Digital communications

Data logging Available on analyzer (Limited number of values)

Local interface

Electrical connections M20 entries for cable glands

*Applies only to standard 30-30 second cycle variant. Contact Michell

Instruments for further details

±0.1ppmV between 0.1 & 1ppm

±0.1ppmV between 0.1 & 1ppm

0.1ppm

point (°C/°F), lb/MMscf

T63 <2 mins to step change in either direction

T95 <5 mins to step change in either direction*

traceable to NPL & NIST

0.01ppm

IECEx)

24 V DC only (CSAUS)

C)

3 x process alarms, selectable for various

parameters, volt-free changeover

(FORM C)

Maximum load resistance 500 Ω for 4–20 mA

and minimum load of 1M Ω for 1–5 V

RS485 ModBus RTU

Modbus TCP

or via Application Software

7” colour LCD with intuitive HMI

V

V

V

V

V

V

V

or 1% of reading, whichever is greater

V

Operating Conditions

Inlet pressure 3 barg (43.5 psig)

Outlet pressure 2 barg (29 psig)

Sample flow 300ml/min total flow

Sample gas temperature 0 to +100°C (+32 to +212°F)

Operating environment

Mechanical Specifications

Type GUB Flameproof Exd

Enclosure

Gas connections 1/8” NPT

Weight 35kg (77lb) without sampling system

Sample system enclosure 316L stainless steel

Certifications

Hazardous area

certifications

Analyzer only

Analyzer in sampling

system

Lid & body

Glass window

ATEX

IECEx

CSAc

CSAUS

TC-TR

+5 to +45°C (+41 to +113°F) up to

90% RH

–20 to +55°C (–4 to +131°F) up to 95% RH

(fitted with heater/thermostat and/or enclosure

cooling as appropriate to maintain +5 to +45°C

(+41 to +113°F) internal temperature)

Cast copper-free aluminum LM25

(EN AC-42000), less than 0.6 magnesium

Heat resistant, explosion proof, polyester coated,

IP66, NEMA 4

II 2 GD Ex d IIB+H2 T6 Gb, Ex tb IIIC T85°C

Db, Tamb -40°C to +60°C

Ex d IIB+H2 T6 Gb, Ex tb IIIC T85°C Db, Tamb

-40°C to +60°C

Class I, ZONES, Ex d IIB+H2 T6 Gb, Tamb -20°C

to +55°C

Class I, Div 1, Group BCD T6, Tamb -25°C to

+55°C

1Ex d IIB+H2 T4 Gb X, 1Ex tb IIIC 130°C Db X

and

1Ex d IIB+H2 T3 Gb X, 1Ex tb IIIC 195°C Db X

Michell Instruments Ltd 48 Lancaster Way Business Park, Ely, Cambridgeshire, CB6 3NW

Tel: +44 (0) 1353 658000, Fax: +44 (0) 1353 658199, Email: uk.info@michell.com, Web: www.michell.com/uk

Michell Instruments adopts a continuous development programme which sometimes necessitates specification changes without notice.

Issue no: QMA601_97490_V4_UK_Datasheet_0518

© 2018 Michell Instruments

Loading...

Loading...