Page 1

Calibration Instruments

Pressure Swing Dryers

Pressure Swing dryers provide a source of very dry compressed air for use as a zero

gas in humidity calibration systems, or for general laboratory applications.

PSD2 & PSD4

Pressure Swing Dryers

Air Source Dryer

Humidity

generator

Reference

The Michell PSD Series Pressure Swing Dryers use

two columns fi lled with 4Å molecular sieve desiccant,

which are used alternately on a switching cycle. The

PSD dryers are designed to operate continuously, using

a small proportion of the dried air to regenerate the

offl ine column - generally giving desiccant life in excess

of fi ve years. This type of heatless regeneration uses

signifi cantly less energy than a 'heated' dryer.

The PSD2 is fi tted with inlet and outlet pressure

regulation, and delivers up to 7 Nl/min (14.8 scfh) of

dry air with a moisture content of 1 ppmV or better.

The PSD4 is supplied with stainless steel internals

and larger volume desiccant columns. These factors,

combined with high integrity VCR couplings deliver

an output of up to 90 Nl/min (optional) with a

moisture content better than 14 ppbV.

Issue No: PSD2 and PSD4_97160_V4.1_US_0918

Please note: Michell Instruments adopts a continuous development program which sometimes

necessitates specifi cation changes without notice. Please contact us for latest version.

Highlights

• Excellent long term stability

• Maintenance free except for a desiccant change

• Completely self-contained

• Low power consumption

2

once every 5 years

www.michell.com

Page 2

Technical Specifi cations

Calibration Instruments

Pressure Swing Dryers

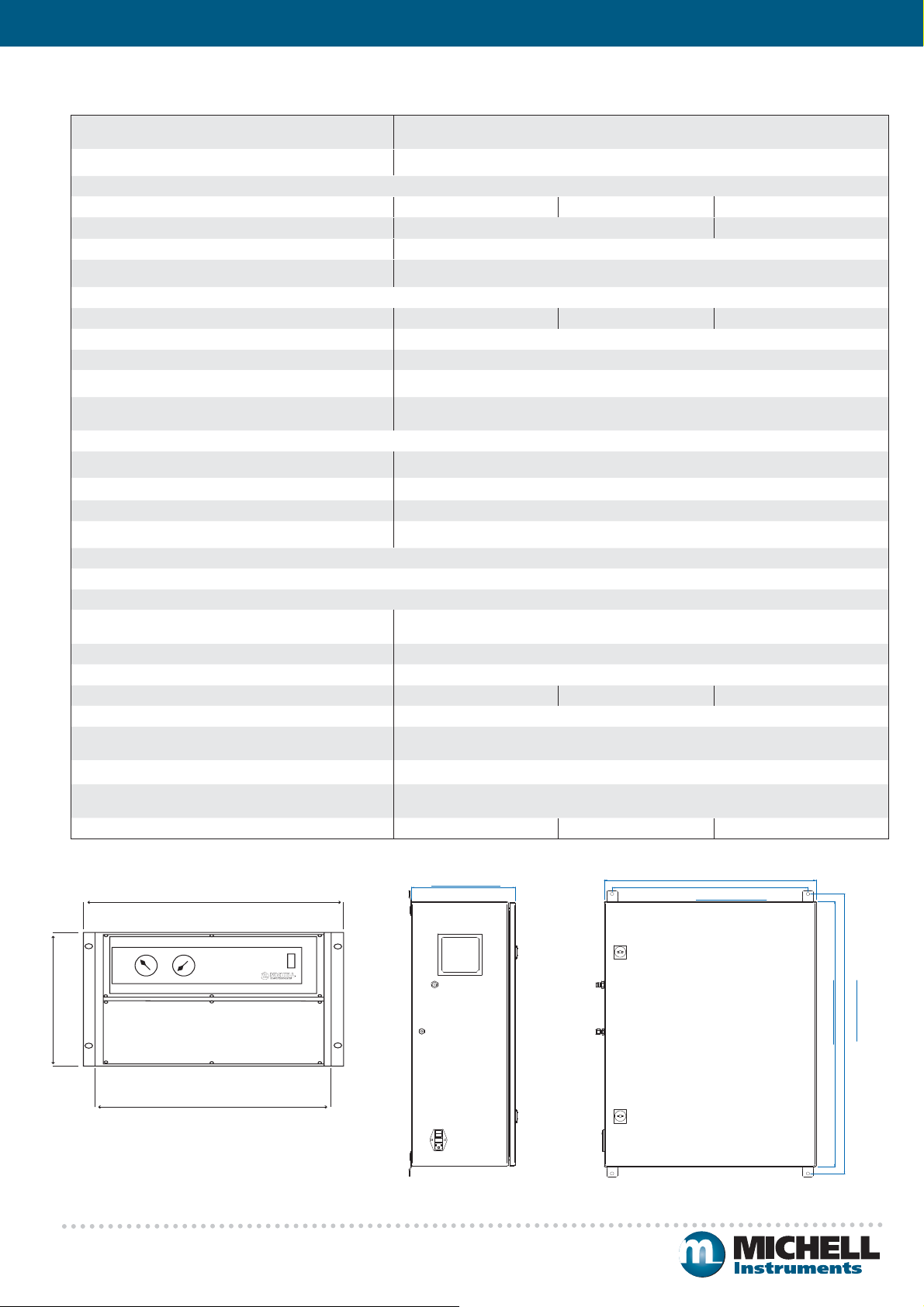

Model PSD2 PSD4-STD

(Standard)

PSD4-HFV

(High fl ow volume)

PSD4-HPO

(High pressure output)

Performance

Gas output

Flow 7 Nl/min (14.8 scfh) 30 Nl/min (63.6 scfh) 90 Nl/min (109.7 scfh) 30 Nl/min (63.6 scfh)

Pressure 0.5 barg (7 psig) User-settable up 8 barg (116 psig)

Moisture content <1ppm

V

<13.8 ppb

V

Input Requirements

Gas supply

Flow 10 Nl/min (21.2 scfh) 30 Nl/min (63.6 scfh) 90 Nl/min (109.7 scfh) 30 Nl/min (63.6 scfh)

Pressure 5 to 7 barg (70 to 100 psig) 6 to 10 barg (87 to 145 psig)

Moisture content Oil and liquid water-free <16ppm

V

Electrical Input

Power 100 to 115 OR 220 to 240

VAC, 50/60Hz

Power Connection IEC socket

100 to 240VAC 50/60Hz

Environmental Conditions

Operating temperature +5 to +35°C (+41 to +95°F) +10 to +40°C (+50 to +104°F)

Storage temperature -40 to +35°C (-40 to +95°F) -40 to +50°C (-40 to +122°F)

Mechanical Specifi cations

Type Twin column desiccant, pressure swing

Desiccant 4 Ångström Molecular sieve bead (4-8 mesh)

Amount required (approx.) 2 kg 3.5 kg

Timer Mechanical cam Programmable relay

Gas connections

Inlet Swagelok® ¼" ¼" VCR Swagelok

Outlet Swagelok® ¼" ¼" VCR Swagelok

Outlet None Millipore Wafergard IIF Micro Inline (sealed type) with PTFE membrane element rated at >99.999%

Vent None Bonded glass microfi ber rated at >99.999% retention of 0.1μm particles

Construction Rack mount: 19" x 6U x

324mm (12.8")

Weight 12.5kg (27.5lbs) 30Kg (66lb) 35Kg (77lb) 32Kg (70lb)

304 stainless steel wall mounting enclosure: 800x600x300mm (31.5x24x12”)

Dimensions - PSD2

300mm 12"

®

½" VCR Swagelok

Filters

retention of 0.003μm particles

Dimensions - PSD4

482mm

®

®

600mm 24"

555mm 22"

¼" VCR Swagelok

266mm

®

800mm 31"

845mm 33"

440mm

Depth: 324mm

Please note: Michell Instruments adopts a continuous development program which sometimes

necessitates specifi cation changes without notice. Please contact us for latest version.

© Michell Instruments 2018

Front View

3

Loading...

Loading...