Page 1

PSD2

Pressure Swing Dryer

User’s Manual

97031 Issue 13.1

September 2018

Page 2

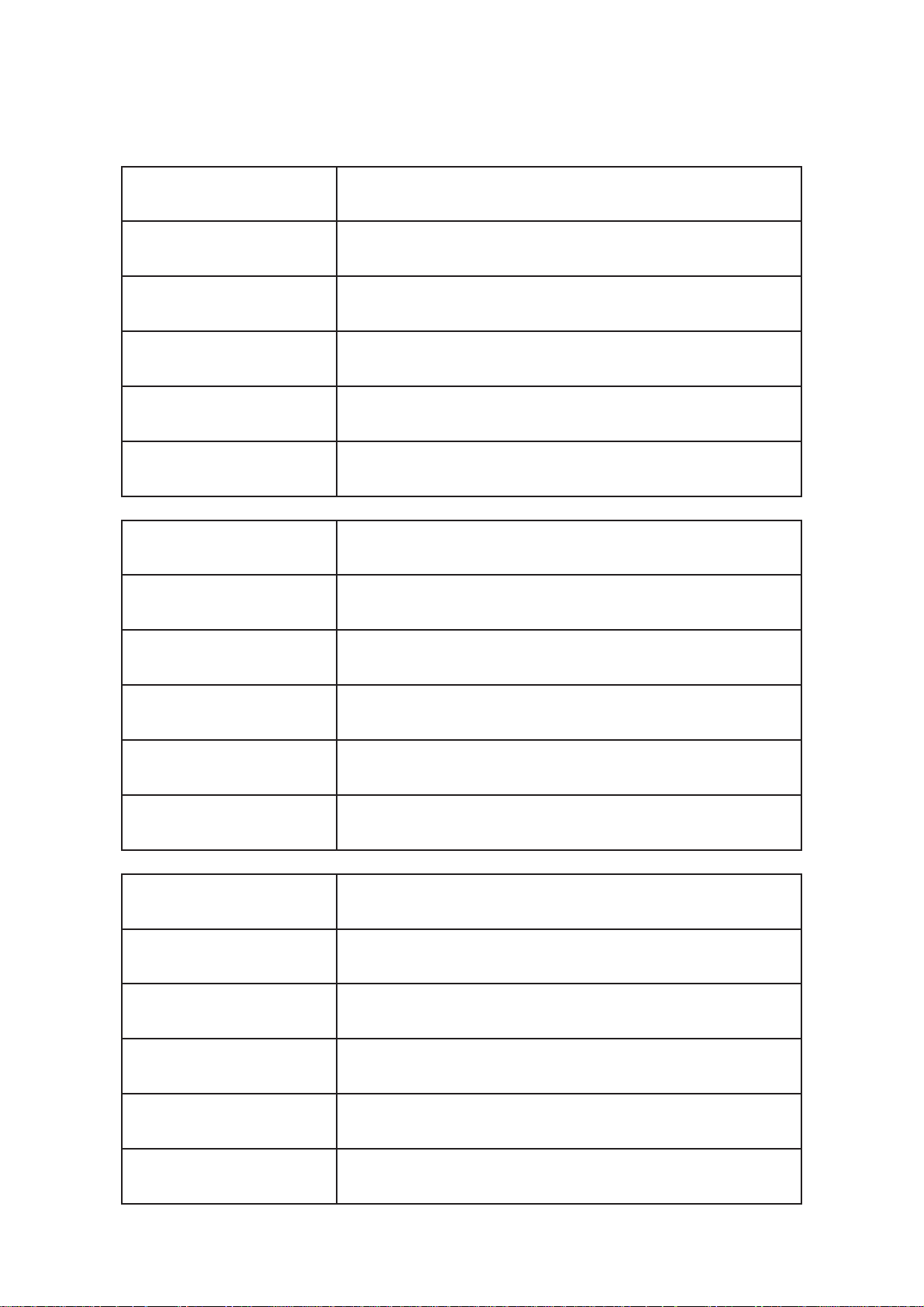

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

PSD2

For Michell Instruments' contact information please go to

www.michell.com

© 2018 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

PSD2 User’s Manual

Contents

Safety ................................................................................................................................ v

Electrical Safety ........................................................................................................... v

Pressure Safety ............................................................................................................ v

Toxic Materials ............................................................................................................. v

Repair and Maintenance ............................................................................................... v

Safety Conformity ........................................................................................................ v

Abbreviations ......................................................................................................................vi

Warnings ............................................................................................................................vi

1 INTRODUCTION ................................................................................................1

1.1 Overview ........................................................................................................... 1

1.2 Operating Principle .............................................................................................1

2 INSTALLATION ..................................................................................................2

2.1 Installing the Dryer ............................................................................................. 2

2.2 Electrical Connections .........................................................................................2

2.3 Gas Connections ................................................................................................. 2

3 OPERATION ......................................................................................................3

3.1 Operating the Dryer ............................................................................................ 3

4 MAINTENANCE ..................................................................................................4

4.1 Maintaining the Dryer ........................................................................................4

4.1.1 Desiccant Change .........................................................................................4

4.1.2 Adjusting the Purge Flow ............................................................................... 6

4.2 Fault Diagnosis ................................................................................................... 8

4.2.2 Flow, Pressure and Timing Calibration ............................................................8

Figures

Figure 1 System Layout Drawing ............................................................................13

Figure 2 Schematic Flow Drawing ...........................................................................14

Appendices

Appendix A Technical Specifi cations ..............................................................................11

Appendix B System Drawings .......................................................................................13

B.1 System Layout Drawing ................................................................13

B.2 Schematic Flow Drawing ..............................................................14

Appendix C Quality, Recycling, Compliance & Warranty Information ................................16

Appendix D Return Document & Decontamination Declaration ........................................18

iv 97031 Issue 13, July 2018

Page 5

PSD2 User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

competent personnel using good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied to the instrument.

The specifi ed safe working pressure is 5 to 7 barg (70 to 100 psig).

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide offi ces contact information.

Safety Conformity

This product meets the essential protection requirements of the relevant EU directives. Further

details of applied standards may be found in the product specifi cation.

Michell Instruments v

Page 6

Abbreviations

The following abbreviations are used in this manual:

AC alternating current

atm pressure unit (atmosphere)

bar pressure unit (=100 kP or 0.987 atm)

°C degrees Celsius

°F degrees Fahrenheit

dp dew point

kg kilogram

Hz Hertz

lb pound

l/min liters per minute

max maximum

mm millimeter

ppm

parts per million (by volume)

V

ppb

parts per billion (by volume)

V

scfh standard cubic feet per hour

V Volts

" inch(es)

% percentage

PSD2 User’s Manual

Warnings

The following general warning listed below is applicable to this instrument. It is repeated

in the text in the appropriate locations.

!

Where this hazard warning symbol appears in the following

sections it is used to indicate areas where potentially hazardous

operations need to be carried out.

vi 97031 Issue 13, July 2018

Page 7

PSD2 User’s Manual

1 INTRODUCTION

1.1 Overview

The Michell PSD2 is a Pressure Swing Dryer in a compact rack mounting unit designed

to remove moisture from compressed air down to trace levels of less than 1 part per

million by volume.

The dryer operates by pressure swing regeneration of a desiccant column. Design is

such that, with 2 columns operating in rotation, a constant fl ow of very dry air (or other

inert gas) can be produced for long periods without maintenance.

Heat is not supplied to the desiccant making the unit energy effi cient and extremely

reliable with the typical lifetime of the desiccant being 5 years.

1.2 Operating Principle

INTRODUCTION

The supply pressure is regulated by PR1, and indicated by either gauge PG1 or PG2,

depending which column is active at that moment in time.

The gas then passes through the solenoid valves (SV1 & SV2), which direct it to the

appropriate desiccant column (DC1 or DC2).

The desiccant columns are fi lled with 4 Ångström molecular sieve. The column capacity

is designed so that, as the molecular sieve absorbs water from the gas, the moisture

content at the outlet of the cylinder is reduced to <1ppmV. This output is achievable

regardless of the moisture content of the gas source. the only stipulation is that it must

not contain liquid water.

The dried gas then passes through the non-return valve (NRV1) before reaching the

outlet port.

The life expectancy of the molecular sieve is preserved by continual regeneration of the

active column (purging of accumulated moisture). At the beginning of the regeneration

cycle the bulk of the moisture is removed by rapidly reducing the pressure in the

column, which desorbs moisture from the molecular sieve surface. Following this, the

remainder of the moisture is removed by fl owing a small proportion of the dried gas

from the active column.

Once this cycle is complete, the system switches columns, and begins the cycle again.

This regeneration process operates on 10 minute cycles, to provide uninterrupted dry

gas output.

Michell Instruments 1

Page 8

INSTALLATION

2 INSTALLATION

The PSD2 is supplied with a full accessory package. Please check that you have received

all the items listed on the Packing Check List.

The factory set power supply voltage is indicated on the yellow label located on the rear

panel of the unit. The power supply voltage setting cannot be changed by the user as

this involves replacing internal electro-mechanical parts. Contact Michell Instruments’

Customer Service Department (contact details at www.michell.com) if a change is

needed.

2.1 Installing the Dryer

The PSD2 requires an operating environment of 0 to +50°C (+32 to +122°F), 0 to 90%

RH. Refer to Appendix B for outline dimensions.

The PSD2 case is designed for 19” 6U rack mounting. However, it can be used as a

bench mounted device without any special preparation. When rack mounting, simply

screw the unit front panel to the front of the rack using 4 M6 X 15mm screws and plastic

inserts.

PSD2 User’s Manual

NOTE: A minimum depth behind the PSD2 front panel of 48cm (18.9”) is

required for the unit, pipes and wiring.

2.2 Electrical Connections

Either 220/240 V AC, 50Hz or 100/20 V AC, 60Hz power supply is required to operate

this instrument. Refer to the yellow label located on the rear panel of the unit for the

correct supply voltage required.

The power supply connection is via the 3-pin IEC plug located on the rear panel of

the unit. A 3-core power cable is provided, the free end of which should be wired to a

suitable earthed plug or directly via a fused power spur.

Power cable conductors are colored according to the convention:

Brown L (Live)

Blue N (Neutral)

Green/yellow E (Earth)

2.3 Gas Connections

Gas connections are made via tube fi ttings located on the rear panel of the unit marked

‘GAS INLET’ and ‘GAS OUTLET’.

The gas inlet connection is a Swagelok® stainless steel 6mm bulkhead union tube fi tting.

The gas outlet connection is a Swagelok® stainless steel 6mm bulkhead union face seal

(VCR) fi tting.

Ensure the supply inlet gas is of a suitable pressure - between 5.5 to 7 barg (80 to 100

psig), free of oil and at a dew point of typically <-40ºC (<-40ºF). If the supply inlet gas

does not meet this requirement it will reduce the dryer’s effi ciency and eventually lead

to complete failure.

NOTE: An oil free compressor or bulk inert gas source must be used.

2 97031 Issue 13, July 2018

Page 9

PSD2 User’s Manual

3 OPERATION

There are no external controls for the PSD2 Pressure Swing Dryer, operation is fully

automatic and no internal adjustment is required.

After inlet and outlet gas connections are made tight the unit may be turned on by the

power switch (with integral neon indicator) located on the front panel.

3.1 Operating the Dryer

Two pressure gauges are provided on the front panel, these indicate the pressure in

each drying column. Upon start-up the appropriate pressure gauge should register inlet

line pressure. When inlet line pressure exceeds the PSD2 internally regulated value of

70 psig this regulated value will be shown on the pressure gauge. The other pressure

regulator should register zero. As the changeover point is reached, the second gauge

will rise to the regulated inlet line pressure. Approximately 10 seconds later the fi rst

gauge will show a rapid de pressurization which will be accompanied simultaneously by

a venting of gas from the rear panel mounted purge exhaust port. After a further 50

seconds the next changeover will occur and the reverse process can be observed.

OPERATION

Upon initial start-up the two desiccant columns will be at equilibrium with ambient air

and therefore drying effi ciency will be quite low. Initially, it is likely that the outlet dew

point will be as high as -20ºC (-4ºF) or -30ºC (-22ºF) dew point although the exact

level depends on the time since its previous use as well as local ambient conditions.

The generator should be operated for a minimum of 24 hours with no fl ow of air being

drawn from the outlet, to allow correct regeneration of the desiccant columns. If the

humidity level fails to reduce below 2 parts per million (-72ºC (-97ºF) dew point)

after 12 hours of no-load operation the desiccant may have been damaged by oil or

other contamination and it may need to be replaced. If this is the case, please consult

Michell Instruments’ Customer Service Department (see www.michell.com for contact

information) for further advice.

NOTE: For optimum performance it is advisable to operate the PSD2

continuously. It is recommended that, when not in use, the dryer is kept in

stand-by condition by operating at a reduced outlet fl ow rate of 1 l/min (2.1

scfh).

Michell Instruments 3

Page 10

MAINTENANCE

4 MAINTENANCE

4.1 Maintaining the Dryer

Other than replacement of the desiccant no other general maintenance is required.

The period between replacement of the desiccant will be determined by the period of

operation and quality of the supply gas.

4.1.1 Desiccant Change

Desiccant Disposal Guidelines

Molecular sieve type 4 Å, 4 - 8 mesh hygroscopic used in this product must be disposed

of in accordance with local regulations.

PSD2 User’s Manual

Handling must be carried out by technically qualifi ed persons familiar with potential

chemical hazards. Personal protective equipment including safety goggles, respirator,

gloves, face shield and/or safety shield must be used while handling molecular sieve.

After any change of desiccant the purge fl ow should always be

!

Proceed as follows:

NOTE: Both cylinders should be renewed with desiccant at the same time.

1. Disconnect power supply, gas inlet and gas outlet tube.

2. Remove the complete dryer from rack unit and place it on a clear work

surface.

3. Remove the top panel.

checked.

4. Isolate the 2 long cylinders from the 4 interconnecting pipes (cylinder

dimensions approximately ø 60mm x 400mm length (ø 2.4” x 15.7”)) and

lay horizontally across the upper portion of the unit.

5. Remove 4 retaining screws and withdraw the 2 cylinders from the unit.

6. On the end of the cylinders there is a blanking plug which can be removed

in order to empty out the old desiccant.

4 97031 Issue 13, July 2018

Page 11

PSD2 User’s Manual

Some of the older units may not have these blanking plugs, in which case

follow the instructions below:

Note: Each cylinder is joined to the other by two angle brackets

- these brackets should be withdrawn with the cylinders still

connected.

Place the cylinders, with angle brackets VERTICALLY on the work surface.

Remove the angle bracket from one end only.

Remove the 8 nuts (4 per cylinder) exposed by the removal of the angle

bracket.

With the cylinders still in the vertical position carefully remove the upper

end caps by fi rmly holding the cylinder tube section and pulling the end

caps away.

MAINTENANCE

Note: Do not pull from the lower end cap and angle bracket

section.

7. The desiccant should be carefully poured out and disposed of.

8. Fill each cylinder with new desiccant.

9. Each cylinder should be fi lled so that when the end caps are

replaced there is no air gap between the desiccant and the end

cap. Banging the cylinder fi rmly on the side will help to distribute the

desicant evenly and allow for more to be squeezed in. It is recommended

to initially over fi ll the cylinders so that the end caps will not push fully

onto the tubes. Remove a small amount of desiccant until the caps fi t in

fully.

10. Re-assemble the PSD2.

11. Reconnect the air supply

12. Check and if required adjust the purge fl ow.

Michell Instruments 5

Page 12

MAINTENANCE

4.1.2 Adjusting the Purge Flow

For correct operation of the PSD2, the purge fl ow needs to be checked annually and

after a descicant change. In order to do this, please follow the steps below:

1. The fi lters on the purge outlets will need to be removed (wear safety

glasses).

PSD2 User’s Manual

2. Connect sample tubing for attaching a fl owmeter (scaled 0-10 NL/min).

3. When the PSD-2 switches from one desiccant cylinder to the other then is

a sudden depressurisation of one cylinder (do not connect the fl ow meter

yet) as this produces a high fl ow at the exhaust. Note the connection

thread is M5.

4. About 10 seconds later the fl ow should have dropped to a measurable

value of about 5-6 l/m, connect the fl ow meter now.

5. This fl ow will continue to drop slightly during the next 40 seconds, until

it suddenly stops when the unit changes cylinders again. At the point just

before the fl ow stops, the fl ow must be between 4-5 l/m.

6. Both exhausts must be checked, so repeat the procedure with the other

vent.

7. There should not be a fl ow difference of greater than 0.5 l/m. If there is

the non-retun valves need to be checked and replace if necessary.

8. If the value is less than 4l/min then the fl ow should be adjusted.

6 97031 Issue 13, July 2018

Page 13

PSD2 User’s Manual

9. Removing the lower front panel of the PSD 2.

10. Loosen the lock nut off fi rst (and then tighten up afterwards).

11. Increase or decrease the fl ow via the adjuster knob.

MAINTENANCE

12. Replace front cover and gold fi lters on outlets.

Michell Instruments 7

Page 14

MAINTENANCE

4.2 Fault Diagnosis

The PSD2 is a factory set unit which should not need any further adjustment.

If a fault occurs, other than a blown fuse, it is recommended that the unit be returned

to Michell Instruments (see www.michell.com for contact details) or to your local Michell

agent for repair or desiccant column refi lling.

The table below details some likely faults and recommended actions.

SYMPTOM POSSIBLE CAUSE ACTION

PSD2 User’s Manual

Power neon will not

illuminate

Neon lights but no

column changeover

Dryer will not

produce 1ppm

less

If any internal components (pressure regulators, fl ow valves etc.) are replaced then the

following calibration procedure should be followed:

4.2.2 Flow, Pressure and Timing Calibration

or

V

AVOID CONTACT WITH COMPONENTS AND CABLES WHICH ARE

!

Fuse blown Replace fuse 5A in IEC connector

Mains power fault Check at source

Cam timer fault Replace cam timer

Solenoid valve failure Replace solenoid valve

Incorrect purge fl ow Check purge fl ow setting

Desiccant saturated

Desiccant contaminated

Low inlet pressure Increase pressure

Excess load Reduce outlet fl ow

WHILE UNDERTAKING THIS WORK TAKE EXTREME CARE TO

CARRYING HIGH VOLTAGE (MAINS POWER).

Reduce fl ow to 1 l/min (2.1 scfh)

and purge for 24 hours

If low fl ow purge not successful,

replace desiccant

Calibrated test equipment required:

a. Pressure gauge, 0 to 1 barg (0 to 15 psig)

b. Flow meter, 0.4 to 6 l/min

c. Flow control valve

d. On/off control valve

1. Remove the lower front 3U panel to gain access to internal components.

2. Connect a 6.9 barg (100 psig) airline to the GAS IN port on the rear panel

(right hand side viewed from the rear). Connect an on/off valve to the

GAS OUT port (rear panel) and close the valve. Turn the air line on.

3. Connect the PSD2 to the appropriate power supply and switch it on.

Adjust the inlet pressure regulator to give 4.8 barg (70 psig) on either of

8 97031 Issue 13, July 2018

Page 15

PSD2 User’s Manual

the two front panel pressure gauges. While under pressure, check all pipe

joints for leaks using a soap/water solution.

4. Check that the timer cam is rotating and the micro switches operating. By

adjusting the position of the cams, set the overlap period to between 8

and 12 seconds (the time during which both front panel pressure gauges

indicate pressure together) as follows:

a. Column 1 pressurized, column 2 rising, adjust cam 1 relative to cam

2, T = 8 to 12 seconds.

b. Column 2 pressurized, column 1 rising, adjust cam 2 relative to cam

1, T = 8 to 12 seconds.

NOTE: It is vital that both overlap times are the same.

4. Connect the 0 to 1 b a rg (0 to 1 5 psig) pressure gauge to the GAS OUT on/

off valve and open the valve.

5. By adjustment of the output pressure regulator set the output pressure

to between 0.7 and 0.8 barg (10 and 12 psig). Lock the regulator shaft

by tightening the lock nuts.

APPENDIX A

6. Replace the 0 to 1 barg (0 to 15 psig) pressure gauge by the fl ow control

valve and connect the fl ow meter on the outlet of the fl ow control valve.

Set the output fl ow rate to about 6 l/min as indicated on the fl ow meter .

7. Check that the internal non-return valves are not rattling i.e. that the

operation is quiet. Allow the dryer to cycle during this test. After this test

shut the on/off valve on the GAS OUT port.

8. Remove both sintered guard fi lters from the back-fl ow outlets on the

PSD2 rear panel.

9. Connect the fl ow meter to one outlet using

the air fl ow is constant then adjust the small valve (located at the ‘cross

roads’ of the non-return valves) to give a back fl ow-rate of 4 l/min. Repeat

this operation on the other outlet.

10. Repeat until both 4 l/min readings are within 0.2 l/min at the lowest fl ow

level i.e. just before switch-over. Remove the fl ow meter from the back-

fl ow outlet and replace both of the sintered fi lters.

11. Connect the fl ow meter to the fl ow control valve (already connected to

the GAS OUT port of the PSD2).

12. Connect a Michell Instruments’ hygrometer (calibrated down to -75ºC

(-103ºF) dew point) to the outlet of the fl ow meter. By adjustment of

the fl ow control valve set the PSD2 gas fl ow rate to 2 l/min. Leave the

system operating until a hygrometer reading of -70ºC (-94ºF) dew point

or drier is achieved (-70ºC (-94ºF) dew point should be achieved within

24 hours).

a suitable adapter. Wait until

13. Fit the lower front 3U panel back in position.

The PSD2 is now ready for use.

Michell Instruments 9

Page 16

APPENDIX A

PSD2 User’s Manual

Appendix A

Technical Specifi cations

10 97031 Issue 13, July 2018

Page 17

PSD2 User’s Manual

APPENDIX A

Appendix A Technical Specifi cations

General

Type Twin column desiccant, pressure swing

Desiccant 4 Ångström molecular sieve bead (approx. 2 kg required)

Timer Motorized cam

Gauges Bourdon type

Gas Ports 6mm compression fi ttings

Exhuasts Sintered bronze silencers

Gas Inlet 10 l/min (21 scfh) @ 5 to 7 barg (70 to 100 psig)

(Oil and liquid water free)

Gas Outlet 7 l/min (14.8 scfh) max. at stp less than 1 ppm

(= less than -75ºC dew point)

Outlet pressure 0.7 barg (10 psig)

Power 100/120 or 220/240 V AC, 50/60Hz

Operating Temperature +5 to +35ºC (+41 to +95ºF)

Storage Temperature -40 to +50ºC (-40 to +122ºF)

Construction Aluminum case, 19” sub-rack 6U x 350mm (13.7”) deep

Weight 12.5kg (27.5lb) approximately

V

Michell Instruments 11

Page 18

APPENDIX B

PSD2 User’s Manual

Appendix B

System Drawings

12 97031 Issue 13, July 2018

Page 19

PSD2 User’s Manual

Appendix B System Drawings

B.1 System Layout Drawing

APPENDIX B

266mm

(10.5”)

482mm

(18.9”)

PRESSURE GAUGES (PG1, PG2)

440mm

(17.3”)

44mm

POWER

SWITCH

GAS INLET

CONNECTION

6mm OD TUBE

(1.7”)

286mm

(11.3”)

110 V OR 240 V AC

POWER SUPPLY

CONNECTION

(3 PIN IEC PLUG)

PURGE EXHAUST

PORTS

(SINTERED VENTS)

REAR VIEW

GAS OUTLET

CONNECTION

6mm OD TUBE

Figure 1

System Layout Drawing

Michell Instruments 13

Page 20

APPENDIX B

B.2 Schematic Flow Drawing

PSD2 User’s Manual

GAS OUT

PG1

PR2

NRV3

X

NRV4

X

FV1

NRV1

DC1

X

X

NRV2

DC2

FLOW DIAGRAM REFERENCE

DC DRYER CYLINDERS

FV METERING BLEED VALUE

NRV NON RETURN VALVES

PG PRESSURE GAUGES

PR PRESSURE REGULATORS

SV SOLENOID VALVES

PG2

SV1

X

X

SV2

X

X

PR1

TO SV1

TO SV2

DELAY

X

10 SECONDS

GAS IN

SV1

FUNCTION

SV2

ELECTRICAL FUNCTION/TIME DELAY GRAPH

Figure 2

Schematic Flow Drawing

14 97031 Issue 13, July 2018

Page 21

PSD2 User’s Manual

APPENDIX C

Appendix C

Quality, Recycling

& Warranty

Information

Michell Instruments 15

Page 22

APPENDIX C

PSD2 User’s Manual

Appendix C Quality, Recycling, Compliance & Warranty Information

Michell Instruments is dedicated to complying to all relevant legislation and directives.

Full information can be found on our website at:

www.michell.com/uk/aboutus/compliance

This page contains information on the following directives:

• ATEX Directive

• Calibration Facilities

• Confl ict Minerals

• FCC Statement

• Manufacturing Quality

• Modern Salvery Statement

• Pressure Equipment Directive

• REACH

• RoHS2

• WEEE2

• Recycling Policy

• Warranty and Returns

This information is also available in pdf format.

16 97031 Issue 13, July 2018

Page 23

PSD2 User’s Manual

APPENDIX D

Appendix D

Return Document &

Decontamination Declaration

Michell Instruments 17

Page 24

APPENDIX D

PSD2 User’s Manual

Appendix D Return Document & Decontamination Declaration

'HFRQWDPLQDWLRQ&HUWL¿FDWH

IMPORTANT NOTE: Please complete this form prior to this instrument, or any components, leaving your

site and being returned to us, or, where applicable, prior to any work being carried out by a Michell

engineer at your site.

Instrument Serial Number

Warranty Repair? YES NO Original PO #

Company Name Contact Name

Address

Telephone # E-mail address

Reason for Return /Description of Fault:

Has this equipment been exposed (internally or externally) to any of the following?

Please circle (YES/NO) as applicable and provide details below

Biohazards YES NO

Biological agents YES NO

Hazardous chemicals YES NO

Radioactive substances YES NO

Other hazards YES NO

Please provide details of any hazardous materials used with this equipment as indicated above (use continuation sheet

if necessary)

Your method of cleaning/decontamination

Has the equipment been cleaned and decontaminated? YES NOT NECESSARY

Michell Instruments will not accept instruments that have been exposed to toxins, radio-activity or bio-hazardous

PDWHULDOV)RUPRVWDSSOLFDWLRQVLQYROYLQJVROYHQWVDFLGLFEDVLFÀDPPDEOHRUWR[LFJDVHVDVLPSOHSXUJHZLWK GU\

JDVGHZSRLQW&RYHUKRXUVVKRXOGEHVXI¿FLHQWWRGHFRQWDPLQDWHWKHXQLWSULRUWRUHWXUQ

Work will not be carried out on any unit that does not have a completed decontamination declaration.

Decontamination Declaration

I declare that the information above is true and complete to the best of my knowledge, and it is safe for Michell

personnel to service or repair the returned instrument.

Name (Print) Position

Signature Date

F0121, Issue 2, December 2011

18 97031 Issue 13, July 2018

Page 25

Page 26

http://www.michell.com

Loading...

Loading...