Page 1

Promet I.S.

Process Moisture Analyzer

User’s Manual

C

t

c

le

e

S

u

n

e

M

2

L

E

N

N

A

H

C

t

c

e

el

S

u

n

e

M

I.S.

T

E

M

O

PR

4

3

2

1

s

m

r

a

l

A

lay

p

s

i

D

PR

A

y

a

l

p

is

D

HA

C

S.

T I.

E

OM

4

3

2

1

s

m

r

a

l

t

c

le

e

S

u

n

e

M

4

L

NE

N

t

c

e

el

S

u

n

e

M

I.S.

T

E

M

O

PR

4

3

2

1

s

m

r

a

l

A

lay

p

s

i

D

.

S

.

T I

E

OM

PR

4

3

2

1

s

m

r

a

l

A

y

a

l

p

is

D

3

NEL

N

A

H

C

1

EL

N

AN

H

Process Moisture Analyzer

Multi-Channel Control Unit

97221 Issue 5

March 2017

Page 2

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

Promet I.S.

Process Moisture Analyzer

For Michell Instruments' contact information please go to

www.michell.com

© 2017 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

Promet I.S. User’s Manual

Contents

Safety ...............................................................................................................................vii

Electrical Safety ..........................................................................................................vii

Pressure Safety ........................................................................................................... vii

Toxic Materials ............................................................................................................vii

Repair and Maintenance ..............................................................................................vii

Calibration .................................................................................................................. vii

Safety Conformity .......................................................................................................vii

Abbreviations .................................................................................................................... viii

Warnings .......................................................................................................................... viii

1 INTRODUCTION ................................................................................................1

1.1 Performance Features ......................................................................................... 2

1.2 Applications ....................................................................................................... 2

1.3 Theory of Operation ........................................................................................... 3

1.4 System Components ........................................................................................... 4

1.4.1 User Interface ............................................................................................... 5

1.4.2 Power Supply and Input/Output Signal ........................................................... 7

1.5 Sampling System ................................................................................................ 8

2 INSTALLATION ..................................................................................................9

2.1 Unpacking the Analyzer ...................................................................................... 9

2.2 Operating Requirements ................................................................................... 10

2.2.1 Environmental Requirements ....................................................................... 10

2.2.2 Power Requirement ..................................................................................... 10

2.3 Mounting ......................................................................................................... 10

2.3.1 Control Unit Installation ............................................................................... 10

2.3.2 Mounting the Promet I.S. Sensor Assembly into the Sampling System ............. 12

2.3.3 Sampling System Installation ....................................................................... 14

2.4 Wiring ............................................................................................................. 15

2.4.1 Overall Wiring Arrangement ......................................................................... 15

2.4.2 Control Unit Wiring ...................................................................................... 16

2.4.2.1 Power Supply Input Connection.............................................................. 18

2.4.2.2 Sensor Signal Input Connection.............................................................. 20

2.4.2.3 Analog Output Connection ..................................................................... 21

2.4.2.4 Alarm Output Connection....................................................................... 22

2.4.2.5 RS485 Port Connection .......................................................................... 23

2.4.3 Sensor Assembly Wiring .............................................................................. 24

2.4.3.1 Dew-point Transmitter Wiring................................................................. 24

2.4.3.2 Optional Pressure Transmitter Wiring ...................................................... 27

3 OPERATION ....................................................................................................30

3.1 Preparation ...................................................................................................... 30

3.2 Start-Up ........................................................................................................... 30

3.2.1 Function Keys Activation .............................................................................. 30

3.2.2 Powering-up the Analyzer ............................................................................ 31

3.2.2.1 Change Units ........................................................................................ 31

3.2.2.2 Manual Set Pressure Value ..................................................................... 32

3.2.2.3 Display Brightness Adjustment ............................................................... 32

3.2.3 Sample Flow Start-Up .................................................................................. 32

3.3 Menu Structure ................................................................................................ 33

3.4 Main Reading Page ........................................................................................... 35

3.5 Display Set-Up ................................................................................................. 35

3.5.1 Pressure Unit Selection ................................................................................ 35

3.5.2 Settings for the PPMV I (Ideal Gas) Reading ................................................. 36

3.5.3 Setting the Scrolling Interval for a Unit’s Full Name ...................................... 36

3.6 Fault Alarm Set-Up ........................................................................................... 37

iv 97221 Issue 5, March 2017

Page 5

Promet I.S. User’s Manual

3.6.1 Minimum Dew-point Value for the Fault Alarm ............................................... 37

3.6.2 Maximum Dew-point Value for the Fault Alarm .............................................. 38

3.6.3 Minimum Pressure Value for the Fault Alarm ................................................. 38

3.6.4 Maximum Pressure Value for the Fault Alarm ................................................. 39

3.7 Output Set-Up .................................................................................................. 40

3.7.1 Output Source Selection .............................................................................. 40

3.7.2 Output Range ZERO Value Settings .............................................................. 41

3.7.3 Output Range SPAN Value Settings ............................................................... 41

3.8 Alarm Set-Up ................................................................................................... 42

3.8.1 Alarm Set-Point Adjustment ......................................................................... 42

3.8.2 Alarm Type Selection ................................................................................... 42

3.8.3 Alarm Source Selection ................................................................................ 43

Figures

Figure 1 Promet I.S. Control Unit ..............................................................................1

Figure 2 Structure of the Michell Ceramic Moisture Sensor ..........................................3

Figure 3 Major Components of the Promet I.S. ..........................................................4

Figure 4 User Interface ............................................................................................5

Figure 5 Dimensions of the Control Unit ..................................................................10

Figure 6 Rack Mounting Method .............................................................................11

Figure 7 Promet I.S. Sensor Assembly .....................................................................12

Figure 8 Overall Wiring Arrangement ......................................................................15

Figure 9 Control Unit Electrical Connections .............................................................17

Figure 10 POWER INPUT Socket ...............................................................................18

Figure 11 POWER INPUT Connector Block .................................................................19

Figure 12 SENSOR INPUTS Connector Block ..............................................................20

Figure 13 OUTPUT Connector Block .......................................................................... 21

Figure 14 ALARM Connector Block ............................................................................22

Figure 15 Crimped Wires .........................................................................................25

Figure 16 Cut to 5mm .............................................................................................25

Figure 17 Dew-point Transmitter Housing ................................................................25

Figure 18 Pin Assignment Drawing ...........................................................................26

Figure 19 Pressure Transmitter Connector .................................................................27

Figure 20 Removal of Terminal Block ........................................................................28

Figure 21 Pressure Transmitter Wiring Diagram .........................................................29

Figure 22 Units of Measurement Readings in Sequence ..............................................31

Figure 23 Menu Maps ..............................................................................................34

Figure 24 Dimensional Drawings...............................................................................47

Michell Instruments v

Page 6

Promet I.S. User’s Manual

Appendices

Appendix A Technical Specifi cations ..............................................................................46

A.1 Dimensional Drawings .................................................................. 47

Appendix B Serial Communications ............................................................................... 49

Appendix C Modbus RTU Comms .................................................................................54

Appendix D Hazardous Area Certifi cation ...................................................................... 57

D.1 Product Standards .......................................................................57

D.2 Product Certifi cation .................................................................... 57

D.3 Global Certifi cates/Approvals ........................................................ 57

D.4 Terminal Parameters .................................................................... 58

D.5 Special Conditions........................................................................ 58

D.6 Maintenance and Installation ........................................................ 58

Appendix E System Drawings ....................................................................................... 60

E.1 Baseefa Approved System Drawing ............................................... 60

E.2 FM Approved System Drawing ...................................................... 61

E.3 CSA Approved System Drawing ..................................................... 62

Appendix F Quality, Recycling & Warranty Information ...................................................64

Appendix G Return Document & Decontamination Declaration ........................................ 66

vi 97221 Issue 5, March 2017

Page 7

Promet I.S. User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

competent personnel using good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument. The input power supply voltage is 85 to 265 V AC

or 10 to 72 V DC. Refer to labels on instrument or calibration certifi cate.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure, as defi ned in the published

specifi cations. to be applied to the instrument.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Long exposure to, or breathing of, the calibration gases may be dangerous.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide offi ces contact information.

Calibration

The recommended calibration interval for the analyzer is 12 months (6 months or less for agressive

gases) depending on the application in which the instrument is used. Please consult Michell

Instruments for the specifi c calibration interval (refer to www.michell.com for details of Michell

Instruments’ worldwide offi ces contact information).

Safety Conformity

This product meets the essential protection requirements of the relevant EU and US standards

and directives. Further details of applied standards may be found in the Technical Specifi cations in

Appendix A.

Michell Instruments vii

Page 8

Abbreviations

The following abbreviations are used in this manual:

A Ampere

AC alternating current

barg pressure in bar (gauge)

°C degrees Celsius

°F degrees Fahrenheit

DC direct current

dp dew point

Hz Hertz

lb/MMscf pounds per million standard cubic feet

lbf-ft pound force per foot

Promet I.S. User’s Manual

mA milliampere

mg/m

mm millimeters

Nl/min normal liters per minute

ppm

psig pressure in pound(s) per square inch (gauge)

scfh standard cubic feet per hour

T temperature

V Volts

W Watts

” inch(es)

Warnings

The following general warnings listed below are applicable to this instrument. They are

repeated in the text in the appropriate locations.

3

milligrams per cubic meter

parts per million by volume

V

Where this hazard warning symbol appears in the following

sections it is used to indicate areas where potentially hazardous

operations need to be carried out.

Where this symbol appears in the following sections it is used to

indicate areas of potential risk of electric shock.

viii 97221 Issue 5, March 2017

Page 9

Promet I.S. User’s Manual

1 INTRODUCTION

The Promet I.S. Process Moisture Analyzer is a continuous, on-line instrument for the

measurement of absolute moisture content in gas. It is designed to fulfi l a wide range

of applications and provide for the monitoring and/or control of moisture in gas. The

instrument consists of two component parts: the control unit and the sensors’ assembly

(moisture transmitters and optional pressure transmitter). They are individually calibrated

to a single standard allowing for total interchangeability between combinations of

sensors and control units.

The instrument covers the ranges –100 to +20°Cdp ( -148 to +68°Fdp), 0 to 9999

ppm

as well as 0 to 1000 lb/MMscf and g/m3 for natural gas. Selection of the displayed

V

moisture unit of measure is factory-set but may be easily changed by the user. Four

alarm relay contacts are provided which are user-confi gurable both in terms of set-point

and operating mode. Current output is factory set at 4-20 mA.

The Promet I.S. performs moisture content calculations based on the measured dew

point and the analysis pressure. The default setting of the monitor assumes atmospheric

pressure but the customer can set a fi xed value of elevated pressure - for this to be

a valid method, the sensor must be installed at a constant, known analysis pressure.

Alternatively, there is an active pressure compensation option providing a loop-powered

intrinsically-safe pressure transmitter connecting to the second input channel on the

control unit, for dynamic pressure compensation.

INTRODUCTION

The Promet I.S. Control Unit must be placed in a non-hazardous area suitable for

electronic analytical equipment. The moisture transmitter and optional pressure

transmitter can be positioned close to the process sample take-off point in Zone 0, Zone

1 or Zone 2 (Class I, Division 1, Groups A,B,C and D) hazardous area. The control unit

and transmitters are connected via a standard 2-wire instrumentation cable protected

by safety isolation interface units.

Figure 1

Promet I.S. Control Unit

Michell Instruments 1

Page 10

INTRODUCTION

1.1 Performance Features

• State-of-the-art ceramic moisture sensor with chemically inert materials

coupled with physical resilience provides long-term reliability in the most

arduous applications. Robust construction also enables measurement

directly at process / pipeline pressure up to 45 MPa (450 barg/5801 psig).

• High integrity moisture measurement from ambient to ppb level with an

exhaustive list of hygrometric units, including key parameters of natural

gas.

• Two 4-20 mA output with confi gurable units / ranges. RS485 Modbus RTU

communication. Four built-in user-adjustable alarm contacts.

• Assured measurement accuracy with each sensor calibrated across the

entire measurement range and certifi ed traceable to NPL (UK) and NIST

(USA).

• User-programmable or real-time active pressure compensation for

moisture content calculation.

Promet I.S. User’s Manual

• Certifi ed intrinsically safe.

• Replaceable sensor element with Michell Calibration Exchange Service for

professional, scheduled and low cost recalibration to minimize downtime

and cost.

• Up to four independent measurement channels with any combination of

moisture in gas and moisture in liquid measurement at low per-channel

cost.

• Customized sampling systems to meet even the most demanding

applications.

1.2 Applications

• Natural gas production and processing

• Pipeline drying

• Offshore export pipeline natural gas

• Transmission pipeline monitoring

• Fiscal metering/custody transfer of gas

• Gas storage facilities

• Refi nery recycle gas – reformer and platformer

• LNG production processing and receiving terminals

2 97221 Issue 5, March 2017

Page 11

Promet I.S. User’s Manual

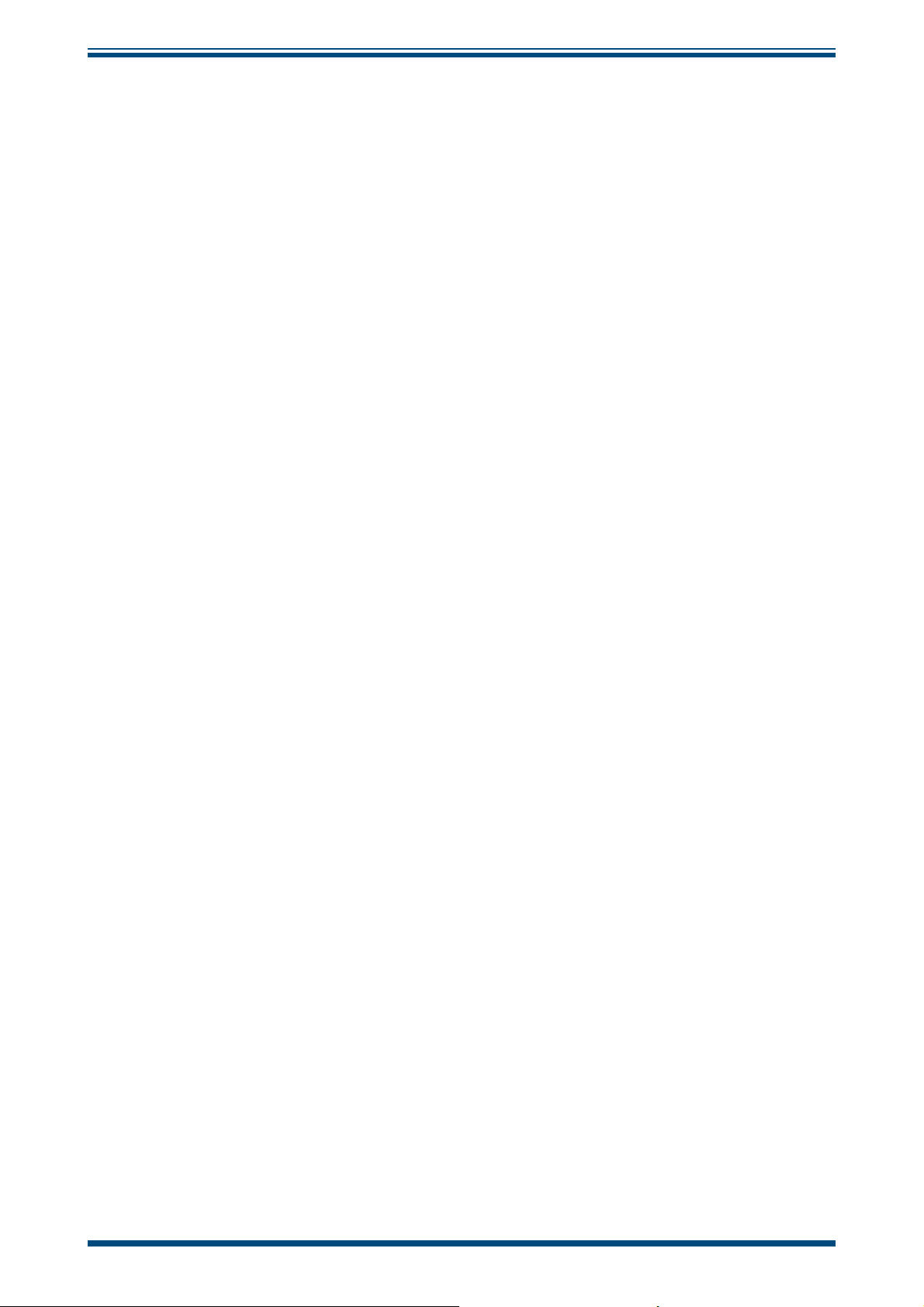

1.3 Theory of Operation

The reliable and robust sensor design is fundamental to achieving accurate measurement

of moisture in process over a long period of time. Proprietary thick- and thin-fi lm

techniques are applied in the Michell Ceramic Moisture Sensor. The inert materials of

the sensor have a high resistance to aggressive media while the inherent strength of

the sensor and the thermal bonded connections to the active device ensures reliable

operation.

INTRODUCTION

Permeable Gold film

g

g

Hygroscopic Mono-layer

Base Electrode

g

Ceramic Substrate

g

Figure 2

Structure of the Michell Ceramic Moisture Sensor

The ceramic sensor responds to the partial pressure of water vapor in the gas being

measured, which is directly related to the dew-point temperature.

Calibration is certifi ed traceable to NPL (UK) and NIST (USA) through the use of dew-

point transfer standards.

The fi rmware of the Promet I.S. incorporates dew point/pressure to moisture content

conversion data for ideal gas and natural gas. The calculation for natural gas uses either

the long established IGT research Bulletin No.8 or the more recently published ISO

18453, depending on the customer’s preference.

Michell Instruments 3

Page 12

INTRODUCTION

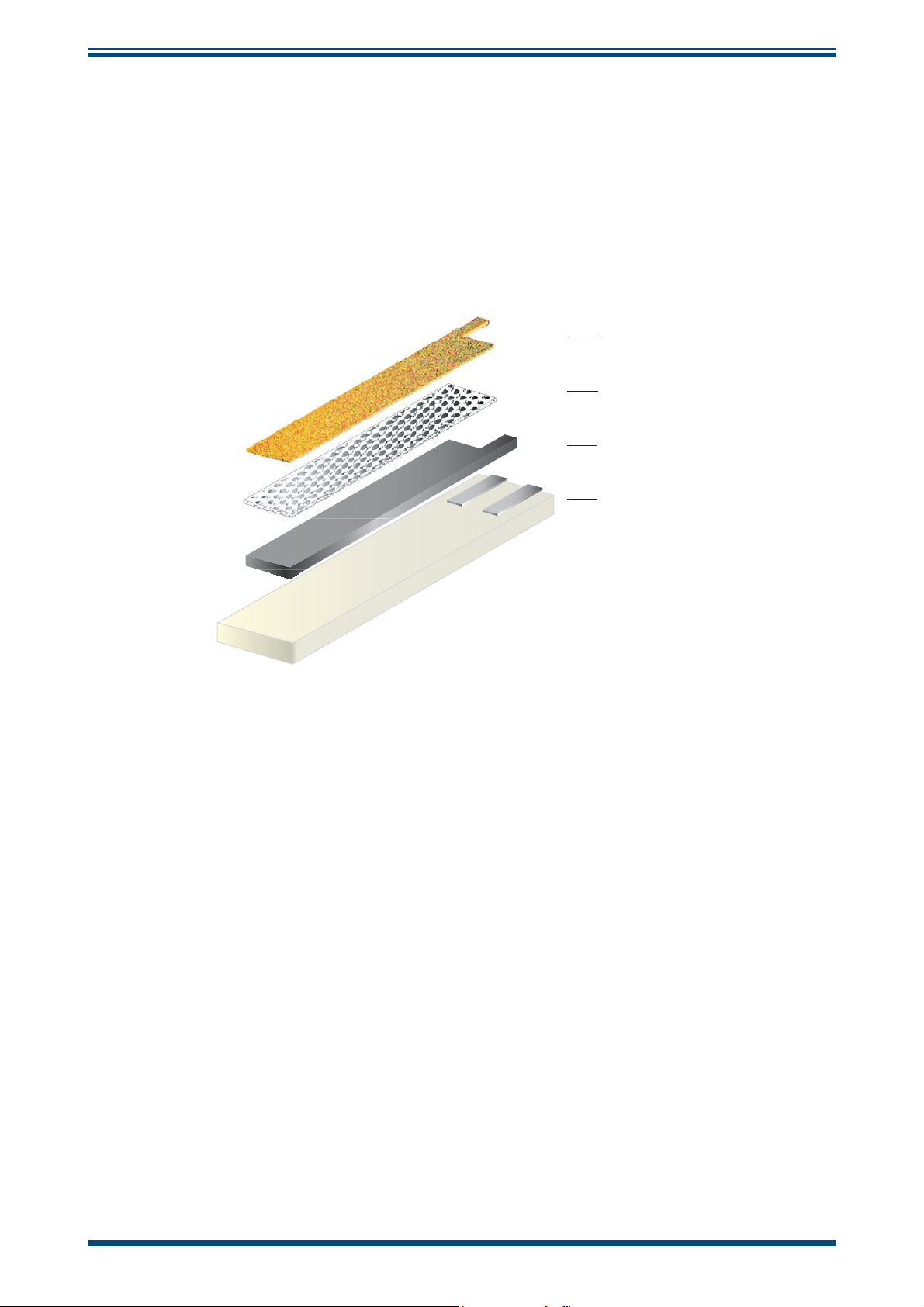

1.4 System Components

The Promet I.S. Process Moisture Analyzer consists of:

• the sensor assembly

• the control unit

c

b

Promet I.S. User’s Manual

a

Sensor Assembly

Control Unit

(Up to four channels can have any combination of Promet I.S. and Liquidew I.S.*)

a Port for optional pressure transmitter

b Sensor block

c Dew-point transmitter

d User interface

e Electrical connections - to hazardous area

f Electrical connections - to non-hazardous area

Figure 3

Major Components of the Promet I.S.

* Liquidew I.S. is a sister product of the Promet I.S. used for moisture in liquid

measurement

4 97221 Issue 5, March 2017

Page 13

Promet I.S. User’s Manual

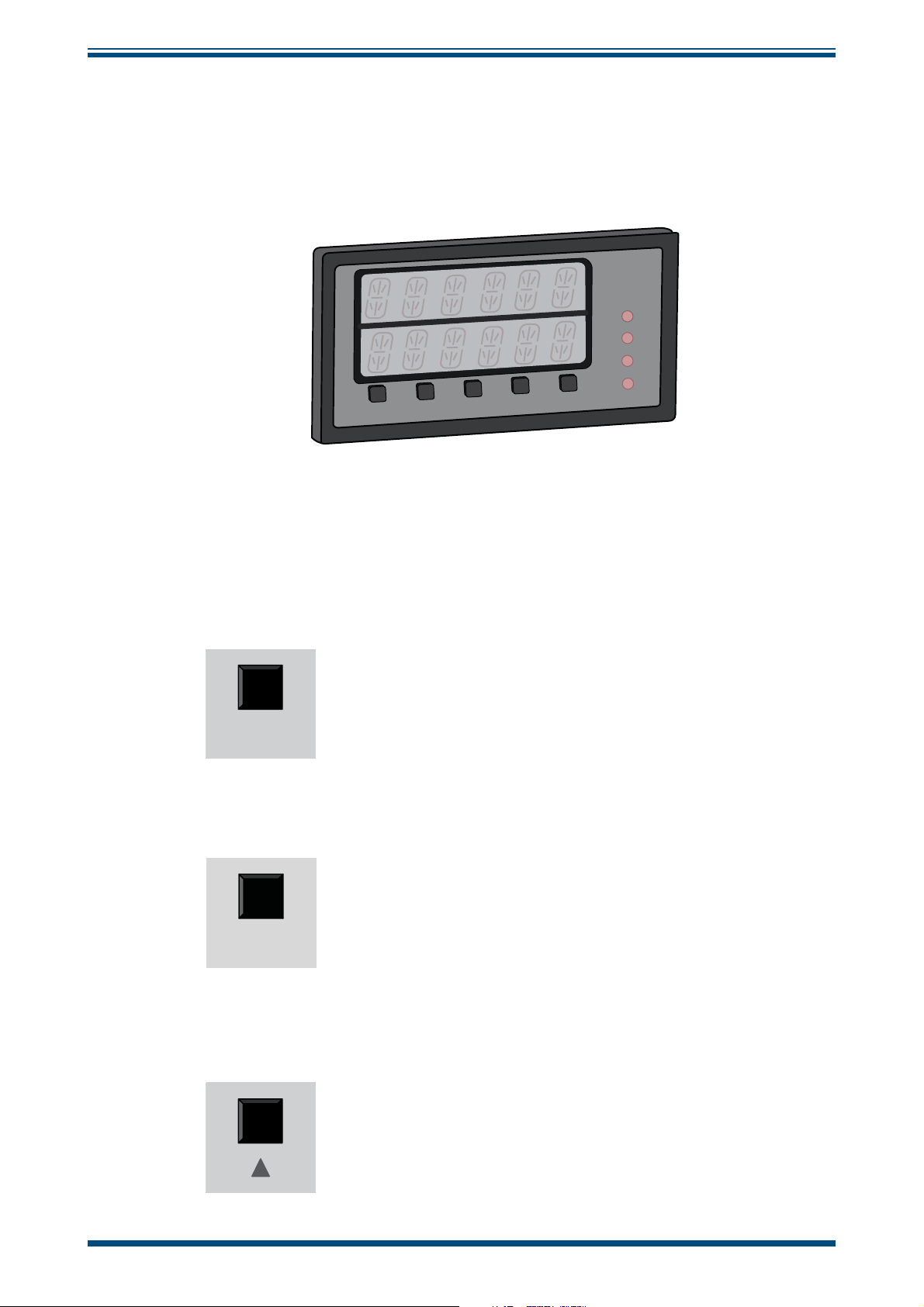

Select

1.4.1 User Interface

The Promet I.S. user interface is located on the control unit. There is a two-line, six digit

(15 segment), LED display and four alarm indicators. Five push-button function keys

facilitate data display, parameter setting and system adjustment.

Me

INTRODUCTION

.

.S

W I

E

D

UI

IQ

L

C

4

.

9

3

C

9

.

1

-

splay

i

D

T

S

ect

el

S

u

n

4

3

2

1

s

rm

a

Al

Figure 4

User Interface

The operation of the function keys are shown below and more information can be found

in Section 3:

•

Menu key:

The Menu key is used to enter and exit the set-up menu.

Menu

•

Menu

Select key:

At any level within the set-up menu, press and hold the

key to return to the default screen.

The Select key is used to enter the sub-menu and to confi rm the

selection.

Michell Instruments 5

• key:

The key is used to scroll up through pages in the top and sublevel menus and to increase values in sub-level menus.

Page 14

INTRODUCTION

• key:

Promet I.S. User’s Manual

The key is used to scroll down through pages in the top and

sub-level menus and to decrease values in sub-level menus.

•

Display key

The Display key is used to change the display unit (see Section

3.2.2).

Display

The four LED alarm indicators will light up when the specifi c alarm relay is activated.

Settings for the alarm relays are explained in Section 3.8.

6 97221 Issue 5, March 2017

Page 15

Promet I.S. User’s Manual

1.4.2 Power Supply and Input/Output Signal

The terminal blocks for the power supply, signal input, signal output and alarm output

are located on the back panel of the control unit (as shown in

• Power Supply

The Promet I.S. requires either 85 to 265 V AC or 10 to 72 V DC power input,

depending on the model ordered.

• Signal Input

There are two 4-20 mA signal input channels from the dew-point and optional

pressure sensors to the control unit. Both input channels are isolated by

built-in galvanic type I.S. barriers.

INTRODUCTION

Figure 9)

.

• Signal Output

There are two 4-20 mA linear signal output channels. The output channel 1 is

used for the dew point, moisture or pressure signal, with confi gurable ranges.

Output channel 2 has a fi xed pressure signal and cannot be confi gured.

There is one RS485 Modbus RTU digital communication port. Refer to

Appendix B.

• Alarm Output

There are four alarm relays. Alarms 1 and 2 are Form C contacts rated 10A

/ 240 V AC or 8A / 24 V DC, non-inductive load. Alarms 3 and 4 are Form

A contacts rated 5A / 240 V AC or 4A / 24 V DC, non-inductive load. The

control actions and set points of these four alarms are user-programmable.

A fault alarm with adjustable set points is also included.

Michell Instruments 7

Page 16

INTRODUCTION

1.5 Sampling System

The Promet I.S. requires a clean sample of the gas mixture that meets the pressure and

fl ow requirements of the transmitter. The design of the sampling system will depend

on the specifi c application.

The requirements for the sample gas going into the sensor block are as follows:

• Temperature: -40 to +60°C (-40 to +140°F)

(-20 to +40°C (-4 to +104°F) recommended for optimum performance)

• Maximum pressure: 45 MPa (450 barg / 5801 psig)

Promet I.S. User’s Manual

• Flow rate: 1 to 5 Nl/min (2.1 to 10.6 scfh)

NOTE: Contact Michell Instruments if you wish to order a specifi c sampling

system.

Please refer to the Promet I.S. Premium Sampling System Instructions if a Michell

sampling system has been ordered with the Promet I.S.

8 97221 Issue 5, March 2017

Page 17

Promet I.S. User’s Manual

2 INSTALLATION

It is essential that the installation of the electrical and gas

supplies to this analyzer be undertaken by suitably qualifi ed

2.1 Unpacking the Analyzer

Unpack carefully as follows:

INSTALLATION

personnel.

a. Remove the accessories (if ordered).

b. If no accessories have been ordered the delivery should contain following

items:

• Promet I.S. control unit

• Promet I.S. sensor assembly (if a sampling system has been

ordered the sensor assembly should already be mounted in the

sampling system)

• User manual

• Certifi cates of calibration and conformity

• Power lead (only for 85 to 265 V AC version)

c. Remove the Promet I.S. sensor assembly from the box.

d. Lift out the control unit together with its end packing pieces.

e. Remove the end packing pieces and set the control unit down at the site

of installation. Save all the packing materials for the purpose of returning

the instrument to the manufacturer for service.

If ordered, the Promet I.S. Premium Sampling System will be shipped in a separate box.

Michell Instruments 9

Page 18

INSTALLATION

2.2 Operating Requirements

2.2.1 Environmental Requirements

The Promet I.S. sensor assembly is intrinsically safe and designed to be installed onsite, indoors or outdoors, directly at the point of measurement within a Hazardous

Area. The sensor assembly is ATEX and IECEx or CSA and FM certifi ed (to be specifi ed

at time of order). To operate correctly, the sensor assembly must be installed within

a suitable sampling system (Michell Instruments can supply standard and custom

designed sampling systems).

The Promet I.S. control unit is NOT designed for use in a Hazardous Area and should

only be installed in a safe area. The control unit is intended for indoor installation only

and operates within environmental limits of 0 to +50°C (+32 to +122°F) and <90%RH.

The control unit contains built-in isolation barriers permitting connection, direct from

the Hazardous Area, of the Promet I.S. sensor assembly.

2.2.2 Power Requirement

The Promet I.S. control unit can be ordered for either of the following electrical supplies:

Promet I.S. User’s Manual

• 85 TO 265 V AC, 47/63 Hz @ 4W max 10W

OR

• 10 to 72 V DC @ 4W max 10W

The Promet I.S. sensor assembly is powered through the 2-wire signal cable directly

from the control unit.

Please refer to the Promet I.S. Premium Sampling System Instructions for the power

requirement of the sampling system.

2.3 Mounting

2.3.1 Control Unit Installation

The Promet I.S. control unit is contained in a 19” sub-rack case (size 3U). It should

be installed in a 19” rack using the mounting holes provided. It should be placed in a

position free from any appreciable vibration and shaded from direct sunlight.

NOTE: The materials and construction of the control unit allow for operation

in an indoor, clean, non-hazardous only, control room environment.

375mm + 100mm for cable clearance

CHANNEL 1

CHANNEL 2

Figure 5

CHANNEL 3

CHANNEL 4

483mm

(19”)

Dimensions of the Control Unit

(14.75” + 3.9”)

132mm

(5.2”)

3U

10 97221 Issue 5, March 2017

Page 19

Promet I.S. User’s Manual

INSTALLATION

Figure 6

Figure 6

standard 19” rack. To fi t the unit proceed as follows:

a. Remove all terminal blocks for the electrical connections.

b. If necessary, remove any covers from the rack cabinet to gain access to

c. Connect up the sensor input, analog and alarm output terminal blocks

d. Slide the instrument into the rack and support its weight while the four

e. Ensure that the front panel of the instrument is fl ush and square with the

f. Insert the terminal blocks into their respective sockets on the rear of the

illustrates the general method for fitting a rack mount instrument into a

the rear and side.

to the internal rack wiring, ensuring that there is suffi cient free cable to

permit withdrawal of the instrument from the rack.

fi xing screws are inserted.

front of the rack and tighten the fi xing screws.

instrument.

Rack Mounting Method

g. Connect the power supply cable and switch the

h. Re-fi t any covers to the rack as necessary.

NOTE: Allow a minimum clearance depth of 100mm (4”) behind the instrument

housing for cables and vents.

ON/OFF switch to ON.

Michell Instruments 11

Page 20

INSTALLATION

2.3.2 Mounting the Promet I.S. Sensor Assembly into the Sampling System

HIGH PRESSURE! High pressure gases are potentially hazardous.

Energy stored in these gases can be released suddenly and with

extreme force. High pressure systems should be assembled and

operated only by people who have been trained in proper safety

practices.

NOTE: If the analyzer has been ordered with a sampling system, the Promet

I.S. sensor assembly will have been installed and tested in the factory. In

that case disregard the following section and go to Section 2.3.3.

Promet I.S. User’s Manual

Figure 7

The Promet I.S. sensor assembly consists of:

1

Dew-point transmitter - Easidew PRO I.S.

2

Pressure transmitter (optional)

Sensor block

3

To assemble, proceed as follows:

a. Remove the protective cap on the dew-point transmitter (Easidew PRO

I.S.) before installation and retain for future use. Take care to prevent any

contamination of the sensor before installation (do not touch or handle

the sintered guard - located on the tip of the Easidew PRO I.S.).

Promet I.S. Sensor Assembly

12 97221 Issue 5, March 2017

Page 21

Promet I.S. User’s Manual

b. The dew-point transmitter has a 5/8” UNF parallel mounting thread which

should be installed directly into the sampling block with the bonded

seal provided. The bonded seal provided should be placed over

the transmitter mounting thread before it is screwed into the

sampling block.

c. Finger tighten the dew-point transmitter by gripping the spanner/wrench

fl ats on the body - NOT the transmitter body cover. Completely tighten

using a spanner/wrench until the bonded seal is fully compressed to a

minimum torque of 30.5 Nm (22.5 lbf-ft).

INSTALLATION

d. The pressure transmitter has a 1/8” NPT thread. It can be installed into

the 1/8” NPTF port on the sensor block. Follow the standard Swagelok

installation instructions to make the connection.

To install the complete Promet I.S. sensor assembly into the sampling system, follow

these steps:

a. Select a location to mount the sensor assembly which has suffi cient

clearance for connecting and disconnecting the inlet/outlet tubing and

cable. The surface should be strong enough to hold the analyzer.

b. Mount the Promet I.S. sensor assembly into the sampling system via its

two mounting holes.

c. Sample gas connections are made via the gas inlet and gas outlet ports as

shown in

ports. Michell recommends using Swagelok® 6mm to 1/8” NPT (ordering

code SS-6M0-1-2) or 1/4” to 1/8” NPT (ordering code SS-400-1-2) male

connectors to connect these two ports to the 6mm or 1/4” sampling

system tubing. Follow standard Swagelok® installation instructions to

make the connections.

Figure 7

. Both the gas inlet and outlet port are 1/8” NPT female

®

d. The sensor assembly will then be supported by the tubings connecting

to it.

Although the operation of the Easidew PRO I.S. dew-point transmitter is not sample

fl ow-rate dependant, it is important to ensure that the fl ow velocity through the sample

line to the sampling block is high enough to avoid long time lags in response to changes

in moisture at the sample source. Michell recommends that a fl ow-rate of 1 to 5 Nl/min

(2.1 to 10.6 scfh) (or equivalent at pressure) be set and that the dew-point transmitter

is mounted as close as practicably possible to the sample source.

Michell Instruments 13

Page 22

INSTALLATION

2.3.3 Sampling System Installation

HIGH PRESSURE! High pressure gases are potentially hazardous.

Energy stored in these gases can be released suddenly and with

extreme force. High pressure systems should be assembled and

operated only by people who have been trained in proper safety

To install the sampling system follow the steps below:

a. Select a location close to the measurement point. The ambient temperature

should be within the range of -20 to 60°C (-4 to +140°F) (preferably 0

to +40°C (+32 to +104°F) for optimum performance). Consult Michell

for special heating or cooling options if the temperature is outside of this

range.

Promet I.S. User’s Manual

practices.

b. Fasten the sampling system to a vertical surface or instrument stand

using the four M8 size mounting holes at each corner.

c. Connect the sample inlet and outlet tubing to the fi ttings of the inlet/outlet

ports on the sampling system. If the sampling system has been ordered

from Michell, the fi tting is a 6mm or 1/4” Swagelok

Follow standard Swagelok® installation instructions for the connection

procedure.

NOTE: The sampling line between the process point and the sampling system

should be as short as possible to minimize the lag time.

®

bulkhead union.

14 97221 Issue 5, March 2017

Page 23

Promet I.S. User’s Manual

2.4 Wiring

These tasks are to be undertaken only by suitably qualifi ed

personnel. All the connections to the rear panel are electrical

connections. Exercise due caution, particularly when connecting

to external alarm circuits which could be at high potential.

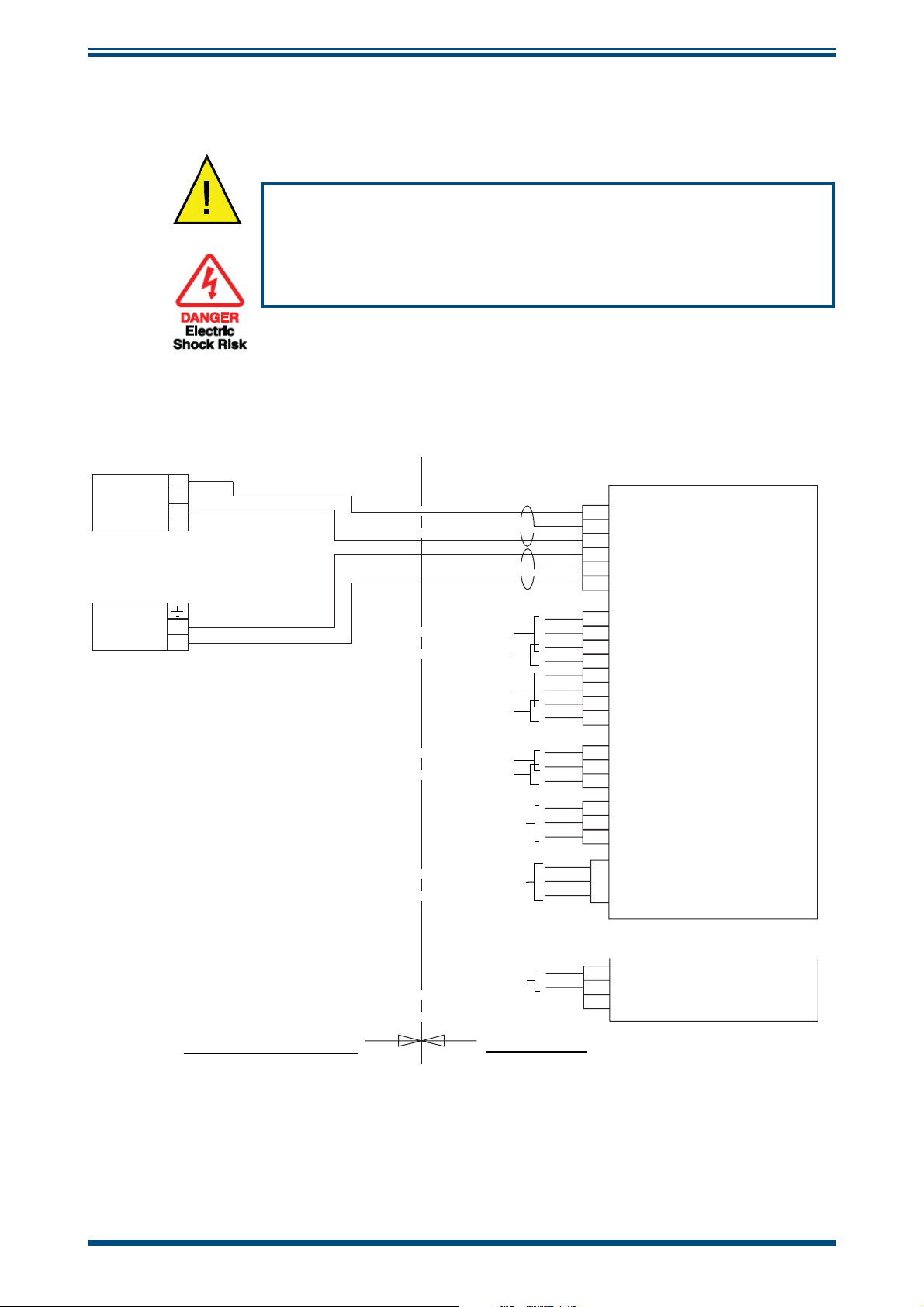

2.4.1 Overall Wiring Arrangement

EASIDEW PRO I.S.

DEW-POINT TX

4

3

2

1

PRESSURE TX

(optional)

CONTROL UNIT

mA

SCN

+V

SENSOR

mA

INPUTS

SCN

+V

INSTALLATION

-

+

HAZARDOUS AREA

ALARM 2

ALARM 4

ALARM 1

ALARM 3

OUTPUT 1

OUTPUT 2

RS 485

90-264 VAC

POWER SUPPLY

(BY OTHERS)

10-72 VDC

POWER SUPPLY

(BY OTHERS)

SAFE AREA

GND

L

N

E

+V

0V

NO

NC

COM

NO

ALARMS

NO

NC

COM

NO

mA

0V

OUTPUT

mA

5

A

B

COMMS

3

2

POWER

SOCKET

24V

POWER

0V

CONNECTOR

Gnd

or

Figure 8

Overall Wiring Arrangement

Michell Instruments 15

Page 24

INSTALLATION

2.4.2 Control Unit Wiring

The electrical connections are located at the rear panel of the control unit. There are

spaces for four individual channels.

The only connections on the control unit which can take cables

Promet I.S. User’s Manual

HAZARDOUS AREA INFORMATION:

from hazardous area are the connectors labelled

SENSOR INPUTS.

ALL OTHER CONNECTORS MUST NOT BE CONNECTED TO CABLES

FROM HAZARDOUS AREA

NOTE: Make sure channels are connected correctly.

Connections for each channel are identical.

The following text will only refer to one channel.

16 97221 Issue 5, March 2017

Page 25

Promet I.S. User’s Manual

SENSOR INPUTS

Dew Point Temp/Pres.

mA +V mA +V

INSTALLATION

Power input

socket and

switch

85 to 265 VAC version

OR

Power input

connector block

10 to 72 VDC version

e

Sensor signal

input

ALARMS

SP2 SP4 SP1 SP3

EASIDEW PRO I S DEWPOINT TRANSMITTER

SYSTEM CERTIFICATE No’s Baseefa07Y0027

Ex ia IIC T4 (-20C TO +60C)

NO NC COM NO NO NC COM NO

OUTPUT

e

COMMS

RS485

mA1 0V mA2

LOCK

OFF ON

Figure 9

HAZARDOUS AREA

CONNECTIONS

e

Alarm output

User interface

key lock

e

Analog

output

e

RS485 port

Control Unit Electrical Connections

Michell Instruments 17

Page 26

INSTALLATION

2.4.2.1 Power Supply Input Connection

85 to 265 V AC

Promet I.S. User’s Manual

The AC power supply connection is a push fi t socket labelled

below.

POWER INPUT

Figure 10

POWER INPUT Socket

Socket

IEC connector

POWER INPUT as shown

The method of connection is as follows:

a. Turn off the AC power. Ensure that both ends of the power cable are

potential free, i.e. not connected to an AC power supply.

b. Check that the

c. Push the IEC connector fi rmly into the

d. Connect the free end of the power cable to a suitable AC power supply

source (voltage range 85 to 265 V AC, 47/63 Hz) and switch on the

AC supply. The instrument may then be switched on, as required, by

pressing the

ON/OFF switch is switched to OFF.

POWER INPUT socket.

ON switch.

18 97221 Issue 5, March 2017

Page 27

Promet I.S. User’s Manual

10 to 72 V DC

If a DC power supply version is ordered it will come with a 3-way push fi t connector

block labelled

POWER INPUT as shown below.

INSTALLATION

POWER INPUT

e

socket

e

+v

Gnd

0V

Figure 11

The method of connection is as follows:

a. Turn off the power. Ensure that both ends of the power cable are potential

free i.e., not connected to a power supply.

b. Remove the terminal block from the

c. Strip back the wires of the power cable, exposing approximately 6mm

(0.2”) - the use of crimps/wire ferrules is recommended.

POWER INPUT Connector Block

POWER INPUT socket.

Terminal block

d. Insert the +24 V DC lead into the

and tighten the screw.

e. Insert the 0V lead into the

tighten the screw.

f. Check that the wiring has been completed correctly.

g. Push the terminal block fi rmly back into the

NOTE: There is no power switch for the DC power supply version;

the analyzer will be turned on automatically as soon as power is

supplied. Connect the free end of the power cable to a suitable DC power

supply source (voltage range 10 to 72 V DC). The instrument may then be

switched on, as required, by the power switch at the source.

+V terminal way on the terminal block

0V terminal way on the terminal block and

POWER INPUT socket.

Michell Instruments 19

Page 28

INSTALLATION

2.4.2.2 Sensor Signal Input Connection

HAZARDOUS AREA INFORMATION

Cables from transmitters mounted in hazardous areas can be

connected directly to the

are built-in Galvanic I.S. barriers for all connections made to this

Refer to ATEX/CSA/FM/IECEx certifi cates for the dew-point and

optional pressure transmitters’ connection cable requirements

which stipulate maximum permissible mutual capacitance and

All wiring procedures should be in accordance with local

Two input ports are provided for signals from the dew-point transmitter and the optional

pressure transmitter respectively. They are connected via a single 6-way push fi t

connector block labelled

SENSOR INPUTS as shown below.

Promet I.S. User’s Manual

SENSOR INPUTS connector block. There

connector block.

inductance to resistance ratio.

electrical codes.

Figure 12

The method of connection is as follows:

a. Remove the terminal block from the

b. Strip back the wires of the dew-point transmitter signal cable, exposing

approximately 6mm (0.2”) - the use of crimps/wire ferrules is recommended.

c. Insert the + 4-20 mA lead into the

terminal block and tighten the screw.

d. Insert the – 4-20 mA lead into

terminal block and tighten the screw.

e. Strip back the wires of the pressure transmitter signal cable, exposing

approximately 6mm (0.2”) - the use of crimps/wire ferrules is

recommended.

f. Insert the + 4-20 mA lead into the

the terminal block and tighten the screw.

g. Insert the – 4-20 mA lead into the

the terminal block and tighten the screw.

h. Check that the wiring has been completed correctly.

SENSOR INPUTS Connector Block

SENSOR INPUTS socket.

Dew Point +V terminal way on the

Dew Point mA terminal way on the

Temp./Press. +V terminal way on

Temp./Press. mA terminal way on

i. Push the terminal block fi rmly back into the

SENSOR INPUTS socket.

20 97221 Issue 5, March 2017

Page 29

Promet I.S. User’s Manual

2.4.2.3 Analog Output Connection

Two analog output ports are provided for moisture content signal and pressure signal

respectively. They are connected via a single 3-way push fi t connector block labelled

OUTPUT as shown below.

INSTALLATION

OUTPUT

e

socket

e

mA1

mA2

0V

Figure 13

The method of connection is as follows:

a. Remove the terminal block from the

b. Strip back the wires of the moisture content signal cable, exposing

approximately 6mm (0.2”) - the use of crimps/wire ferrules is recommended.

c. Insert the + 4-20 mA lead into the

block and tighten the screw.

d. Insert the – 4-20 mA lead into the

and tighten the screw.

e. Strip back the wires of the pressure signal cable, exposing approximately

6mm (0.2”) - the use of crimps/wire ferrules is recommended.

OUTPUT Connector Block

OUTPUT socket.

mA1 terminal way on the terminal

0V terminal way on the terminal block

Terminal block

f. Insert the + 4-20 mA lead into the

block and tighten the screw.

g. Insert the – 4-20 mA lead into the

and tighten the screw.

h. Check that the wiring has been completed correctly.

i. Push the terminal block fi rmly back into the

mA2 terminal way on the terminal

0V terminal way on the terminal block

OUTPUT socket.

Michell Instruments 21

Page 30

INSTALLATION

2.4.2.4 Alarm Output Connection

Four alarm output ports are provided and are connected to the instrument via a single

8-way push fi t connector block labelled

Promet I.S. User’s Manual

ALARMS as shown below.

e

e

NO

SP1

COM

NO

NC

SP3

ALARM Connector Block

COM

NC

NO

SP2

NO

SP4

Figure 14

Alarm 1 (connection labelled as SP1) and Alarm 2 (connection labelled as SP2) are Form

C (single pole, double throw) relays.

The method of connection is as follows:

a. Remove the terminal block from the ALARMS socket.

socket

Terminal block

ALARMS

b. Strip back the wires of the Alarm 1 cable, exposing approximately

6mm (0.2”) - the use of crimps/wire ferrules is recommended.

c. Insert the

N/O connection lead into the SP1 NO terminal

way on the terminal block and tighten the screw.

d. Insert the

N/C connection lead into the SP1 NC terminal way on the

terminal block and tighten the screw.

e. Insert the common lead into the

SP1 COM terminal way on the terminal

block and tighten the screw.

f. Repeat operations b. to e. for connecting the Alarm 2 cable to the SP2

terminals.

22 97221 Issue 5, March 2017

Page 31

Promet I.S. User’s Manual

Alarm 3 (connection labelled as SP3) and Alarm 4 (connection labelled as SP4) are Form

A (single pole, single throw, normally open) relays.

The method of connection is as follows:

INSTALLATION

a. Strip back the wires of the Alarm 3 cable, exposing approximately

6mm (0.2”) - the use of crimps/wire ferrules is recommended.

b. Insert the

on the terminal block and tighten the screw.

c. Insert the common lead into the

block and tighten the screw.

d. Repeat operations a. to c. for connecting the Alarm 4 cable to the SP4

terminals.

e. Check that the wiring has been completed correctly.

f. Push the terminal block fi rmly back into the

2.4.2.5 RS485 Port Connection

N/O connection lead into the SP3 NO terminal way

NOCOM

SP3 COM terminal way on the terminal

ALARMS socket.

The RS485 connection is a push-fi t socket labelled COMMS as shown in

The method of connection is as follows:

Pin Number Function

2B

3A

50V

a. Check the orientation of the RS485 connector and gently push it into the

socket.

b. Tighten the two screws on the connector.

Figure 9

.

Michell Instruments 23

Page 32

INSTALLATION

2.4.3 Sensor Assembly Wiring

NOTE: If the analyzer has been ordered with a sampling system, the Promet

I.S. sensor assembly will be wired-up in the factory to the junction box. In

that case disregard the following instructions and go to Section 3.

2.4.3.1 Dew-point Transmitter Wiring

HAZARDOUS AREA INFORMATION

The dew-point transmitter (Easidew PRO I.S.) is certifi ed

intrinsically safe for use in hazardous areas.

Before using the Easidew PRO I.S. in any hazardous environment

ensure that personnel are completely familiar with the above

standards relating to the certifi cation of this instrument and

also with the further information relating to intrinsically

safe apparatus to be found in standard EN60079-14:1997 or

equivalent, and up-to-date codes of practice in the country of

Installation of the Easidew PRO I.S. MUST be as per system

drawing in order to comply with the intrinsic safety regulations.

Promet I.S. User’s Manual

installation.

Refer to ATEX/CSA/FM/IECEx certifi cates for the dew-point and

optional pressure transmitters’ connection cable requirements

which stipulate maximum permissible mutual capacitance and

inductance to resistance ratio.

24 97221 Issue 5, March 2017

Page 33

Promet I.S. User’s Manual

Preparation of the Sensor Cable

In order to comply with hazardous area certifi cation of the

product it is essential that the crimps/wire ferrules supplied

must be attached on to any cable installed into the connector.

INSTALLATION

a. As shown in

Figure 15

below, the crimps/wire ferrules should be applied

so that there is no possibility of a conductor strand of a core becoming

free.

When the crimp/wire ferrules are applied they should have a minimum of

two positions of crimping. After the crimp/wire ferrules are applied they

should be trimmed to a length of 5mm (0.2”) (see

Figure 16)

.

10

Figure 15

Crimped Wires

Figure 16

mm

Cut to 5mm

b. Cable connection to the dew-point transmitter is made via the terminal

block (4) (see

4

Figure 17)

j

Figure 17

. Remove the terminal housing lid (2) to access.

1

j j

51

j

j

2

j

j

3

Dew-point Transmitter Housing

Michell Instruments 25

Page 34

INSTALLATION

c. Ensure that the outer diameter of the selected cable is matched to an EExe

M20 cable gland (5). Unscrew the cable gland (5) and slide the cable

through the cable gland (5) and into the terminal housing (1) through the

cable entry (3).

d. Remove the terminal block (4) from the PCB for easier operation. Connect

the signal cable leads with the crimps/wire ferrules to the screw terminals

on the terminal block (4) in accordance with the following pin-assignment

drawing.

Promet I.S. User’s Manual

HAZARDOUS AREA

1 2 3 4

NOTE: Connect cable screen to cable gland

Figure 18

12 V Min, 28 V max

+ 4-20mA lead

- 4-20mA lead

4-20mA

Pin Assignment Drawing

SENSOR INPUTS Block

Dew Point

mA

Temp

+V

Always connect the 4-20mA return signal to a suitable load (in

this case, back into the control unit) before the power is applied.

Without this connection the transmitter may be damaged if

allowed to operate for prolonged periods. The maximum load is

500 Ω at 24 V or 250 Ω at 12 V.

When the crimps/wire ferrules are installed into the connector

terminal block ensure that they are inserted completely. When

all wire connections are made, ensure that there is a minimum

clearance distance of 2mm (0.008”) between each terminal.

e. Press the terminal block (4) back into its socket fi rmly.

f. Tighten the cable gland (5) around the cable. Ensure that the sealing is

not damaged and that the cable gland and seals are assembled correctly

in order to ensure ingress protection.

g. Install and tighten the terminal housing lid (2).

26 97221 Issue 5, March 2017

Page 35

Promet I.S. User’s Manual

2.4.3.2 Optional Pressure Transmitter Wiring

HAZARDOUS AREA INFORMATION

The pressure transmitter is certifi ed intrinsically safe for use

in hazardous areas by Baseefa and is covered by EC-type

examination certifi cate BAS01ATEX1125X. The instrument

conforms to the standards specifi ed in EN 50014:1997 + Amds 1

& 2, EN 50020:1994 and EN 50284:1999 with certifi cation code

Ex ia IIB T4 (-20°C≤Ta≤75°C).

Before using the pressure transmitter in any hazardous

environment ensure that personnel are completely familiar

with the above standards relating to the certifi cation of

this instrument and also with the intrinsically safe system

information in the BAS01ATEX1125X certifi cate or equivalent

codes of practice in the country of installation.

If the pressure transmitter is not ordered together with the

analyzer, it is the user’s responsibility to make sure that the

pressure transmitter is compatible with the I.S. barrier in the

INSTALLATION

control unit.

Refer to ATEX/CSA/IECEx certifi cates for the dew-point and

optional pressure transmitters’ connection cable requirements

which stipulate maximum permissible mutual capacitance and

inductance to resistance ratio.

NOTE: A pressure transmitter will only be provided if the model with active

pressure compensation (order code:

active pressure compensation (order code:

a. The cable connection to the pressure transmitter is made via the removable

connector. Loosen the central screw (1) to remove the connector from the

transmitter.

P1/P2) is ordered. For the model without

G), skip this section.

Figure 19

Pressure Transmitter Connector

Michell Instruments 27

Page 36

INSTALLATION

b. When the connector is unplugged from the transmitter, remove the central

screw (1)

(Figure 19)

Promet I.S. User’s Manual

completely.

c. Remove the gasket (8)

d. Using a small screwdriver in the mounting hole (7), lever the terminal

block (6) out of the outer housing (5)

5

Figure 20

(Figure 19)

6

from the connector.

(Figure 20)

.

Removal of Terminal Block

7

e. Ensure that the outer diameter of the cable selected matches the outer

housing’s cable gland. To ensure that full ingress protection is achieved,

the sensor cable used must have a minimum diameter of 4.6mm (0.18”).

Slide the cable through the cable gland nut (2), washer (3), gland seal (4)

and outer housing (5)

f. Apply crimps/wire ferrules to the fl ying leads of the cable. Connect these

leads to the screw terminals on the terminal block (6) in accordance

with the following pin-assignment drawing. Pin designations are marked

adjacent to each pin.

CAUTION: In order to comply with Hazardous Area Certifi cation

of the product it is essential that the crimps/wire ferrules

supplied must be attached on to any cable installed into the

(Figure 19)

.

connector.

28 97221 Issue 5, March 2017

Page 37

Promet I.S. User’s Manual

pply

INSTALLATION

3

2

Figure 21

+ 4-20mA lead

– 4-20mA lead

1

Pressure Transmitter Wiring Diagram

Su

4-20 mA

CAUTION: Always connect the 4-20 mA return signal to a

suitable load (in this case, back into the control unit) before the

power is applied. Without this connection, the transmitter may

be damaged if allowed to operate for prolonged periods.

CAUTION: When the crimps/wire ferrules are installed into the

connector terminal block ensure they are completely inserted.

When all wire connections are made, ensure that there is a

minimum clearance distance of 2mm between each terminal.

g. Press the terminal block (6) back into the outer housing (5) fi rmly

20)

, until a ‘click’ sound is heard.

h. Tighten the cable gland (2)

(Figure 19)

around the cable. Ensure that the

(Figure

sealing is not damaged and that the cable gland and seals are assembled

correctly in order to ensure ingress protection.

i. Slide the terminal block (6) onto the connection pins on the transmitter.

NOTE: There is only one orientation by which the terminal block

can be plugged onto the transmitter.

Michell Instruments 29

Page 38

OPERATION

3 OPERATION

3.1 Preparation

Ensure that personnel are familiar with Sections 1, 2 and 3 of this manual in which the

equipment controls, indicators, elements of the display and overall menu structure are

described before starting operation.

Prior to operation, the instrument must be connected to the correct electrical power

supply, sensor signal input, relevant analog and alarm outputs as described in Section 2.

Promet I.S. User’s Manual

Before applying power and beginning sample fl ow ensure that

the system has been properly installed following the instructions

in Section 2 and that all sample connections are tight and leak

free. Check that the wiring has been correctly completed.

On delivery, the instrument will have been set-up with a standard set of default

parameters defi ning the operation of the analyzer. These parameters can be changed

as required by means of the Set-up menus.

3.2 Start-Up

3.2.1 Function Keys Activation

There are fi ve push-button function keys on the user interface of the control unit. They

can be locked to prevent unauthorized operation or accidental pressing. The lock switch

is located on the back panel of the control unit (see

OFF position to activate the function keys.

the

NOTE: Remember to lock the function keys after each operation.

Figure 9)

. It must be switched to

30 97221 Issue 5, March 2017

Page 39

Promet I.S. User’s Manual

3.2.2 Powering-up the Analyzer

For the AC power supply version of the Promet I.S., turning on the power switch on the

back panel of the control unit will power-up the control unit and the two transmitters

for each channel connected. There is no power switch for the DC power supply version.

It is turned on automatically once 24 V DC power source is applied.

After turning on the analyzer the display will be illuminated. The default Main Reading

Page displays sample dew point (°C) and sample pressure (barg).

NOTE. Depending on your order, the pressure value can be real-time readings

from the pressure transmitter if the model with active pressure compensation

(order code: P1/P2) is ordered, or manual set value if the model without active

pressure compensation (order code: G) is ordered (see Section 3.2.2.2).

3.2.2.1 Change Units

From the Main Reading Page, press the Display key to change the units of measurement

readings in sequence as shown below:

OPERATION

Default

DEG C

DEG F

PPMV I

LBMMCF

MG/M3

d

6 5. 0 B

- 2 2. 1 C

Display

d

6 5. 0 B

- 7. 9 F

Display

d

6 5. 0 B

1 2. 4 7

Display

d

6 5. 0 B

1. 1 5

Display

d

6 5. 0 B

1 9. 6 1

Pressure

Dew point oC

Pressure

Dew point o F

Pressure

ppm

ideal gas

V

Pressure

Lbmmscf natural gas

Pressure

mg/m3 natural gas

Display

d

PPMV N

Figure 22

6 5. 0 B

2 5. 7 4

Display

Pressure

ppmV natural gas

Units of Measurement Readings in Sequence

Michell Instruments 31

Page 40

OPERATION

At the Main Reading Page, the full description of the currently selected unit for the

moisture measurement will scroll across the display on the bottom line at set intervals

(set in the

Promet I.S. User’s Manual

DISP – display settings sub-menu).

NOTE: Unit for the sample pressure reading / set value can be set in the

– display settings sub-menu.

NOTE: After the display units are set, they will remain the same even after

the analyzer power is turned off and on again.

3.2.2.2 Manual Set Pressure Value

If the model without active pressure compensation (order code: G) is ordered, press

the and keys from the Main Reading Page to manually set the required pressure.

3.2.2.3 Display Brightness Adjustment

The brightness of the display can be adjusted. From the Main Reading Page, press and

hold the

Select key then press the key to enter the brightness adjustment page.

DISP

2

a. Use the and keys to adjust the display brightness.

b. Press the

return to the Main Reading Page.

3.2.3 Sample Flow Start-Up

Follow the Promet I.S. Premium Sampling System Instructions to establish the sample

fl ow of:

1 to 5 Nl/min (2.1 to 10.6 scfh).

Select key to confi rm the adjustment. The display will then

BRI

32 97221 Issue 5, March 2017

Page 41

Promet I.S. User’s Manual

DDIINN

3.3 Menu Structure

The Promet I.S. main menu has a two level menu structure. There are three sub-menus

DISP, FAU LT and OUTPUT. The ALARM SETTINGS are not in the main menu and are

accessed separately. These are described in detail in following sections. Below is the

complete menu structure:

OPERATION

NOTE:

Menu

h

Menu

h

Menu

h

represents the Main Reading Page

h

MAIN

READING

Display

Select

+

MANUAL SET PRESSURE VALUE

h

CHANGE DISPLAY BRIGHTNESS

h

PAGE

+

Menu

Select

h

CHANGE ALARM SETTINGS

h

Menu

Select

Pressure

h

Unit

PPMV I

Resolution

Scroll

Interval

Select

SKIP

DISP

h

h

ENTER

DISP

h

h

Menu

Select

h

Min

DP

Max

DP

Min

Pressure

Max

Pressure

Select

SKIP

FAULT

h

h

ENTER

FAULT

h

h

Menu

Select

h

Source

Zero

Span

OUTPUT

Select

SKIP

h

h

ENTER

OUTPUT

h

h

CHANGE UNITS

See Section 3.2.2.1

See Section 3.2.2.2

See Section 3.2.2.3

See Section 3.8

Menu

Select

h

h

h

h

h

h

h

Select

Select

Select

Select

Select

Select

Select

Select

Select

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

h

h

h

h

h

h

h

h

h

h

Michell Instruments 33

Page 42

OPERATION

IIN

N

Promet I.S. User’s Manual

MAIN

READING

PAGE

Menu

h

CHANGE

MAIN MENU

SETTINGS

Display

Select

Select

+

+

SP_1

SP_2

SP_3

SP_4

h

h

h

h

SPC_1

h

MANUAL SET PRESSURE VALUE

h

CHANGE UNITS

See Section 3.2.2.1

See Section 3.2.2.2

h

Select

Select

Select

Select

010

Select

ALARM SETTING MENU

h

h

h

BRI

See Section 3.8

Source

BRIGHTNESS ADJUSTMENT

See Section 3.2.2.3

Select

h

Select

000-high 100-low

Select Select

h

000-high 100-low

Select Select

h

000-high 100-low

Select Select

h

000-high 100-low

Select Select

h

h

SPC_2

h

SPC_3

h

SPC_4

h

010

h

010

h

010

h

Select

Select

Select

h

h

h

Source

Select

Source

Select

Source

Select

- Main Reading Page

Figure 23

Menu Maps

34 97221 Issue 5, March 2017

Page 43

Promet I.S. User’s Manual

3.4 Main Reading Page

The Main Reading Page is the default screen shown after turning the instrument on. It

will display the units of measurement selected by the user (see Section 3.2.2.1).

3.5 Display Set-Up

The display preference of the Main Reading Page can be confi gured under DISP –

display settings sub-menu.

OPERATION

From the Main Reading Page, press the

setting option is:

The top line shows the navigation command. Press the key to change the navigation

command from

Press the Select key to confi rm the navigation command and either skip to the next

sub-menu or enter this display setting sub-menu. The fi rst setting parameter under the

display settings sub-menu is the unit for pressure reading / set value.

3.5.1 Pressure Unit Selection

SKIP to ENTER.

Menu key to enter the main menu. The fi rst

SKI P

DI SP

ENTER

DI SP

BARG

PRESS

Either BARG or psiG can be selected as the unit for the pressure reading / set value.

a. Change the selection by scrolling through these two options using the

and keys.

b. When the desired unit is shown on the display, press the

confi rm. The display will then change to the next setting parameter which

PPMV I readings.

is for

NOTE: The pressure reading / set value at the Main Reading Page will then

change to the selected unit.

Select key to

Michell Instruments 35

Page 44

OPERATION

• For the model with active pressure compensation (P1/P2), the

pressure reading value will be automatically converted based on

the new unit selected.

Promet I.S. User’s Manual

• For the model without active pressure compensation (

manually set pressure value will NOT be automatically converted

based on the new unit selected. The value must be manually

changed. For example - if the pressure is set at 60 barg - when the

pressure unit is changed to

60 psig. This must be manually changed to 870 psig.

NOTE: The pressure fault alarm set point under

sub-menu - will also switch to the selected unit. The value will be automatically

converted based on the new unit selected.

3.5.2 Settings for the PPMV I (Ideal Gas) Reading

psiG, the value of the pressure setting will be

0. 1 2 3

PPM V_I

The resolution of PPMV I (ideal gas) readings can be adjusted between one decimal

point to three decimal points, based on the user’s preference. It will not change the

resolutions of readings with other units.

G), the

FAU LT – fault alarm settings

a. Increase or decrease the resolution by pressing the and keys.

b. When the desired resolution is on the display, press the

display will change to the next setting parameter which is for setting the

scrolling intervals of the unit’s full name on the Main Reading Page.

The PPMV I (ideal gas) readings at the Main Reading Page, if selected, will then

change to the set resolution.

3.5.3 Setting the Scrolling Interval for a Unit’s Full Name

At the Main Reading Page, the full description of the currently selected unit will scroll

across the display on the bottom line at set intervals. This interval can be set to the

user’s preference.

10.0

SCR OL L

a. Increase or decrease the scrolling interval (in seconds) by pressing the

and keys.

Select key. The

b. When the desired value is on the display, press the

will then change to the next sub-menu

FAU LT – fault alarm settings.

Select key. The display

36 97221 Issue 5, March 2017

Page 45

Promet I.S. User’s Manual

3.6 Fault Alarm Set-Up

There are four conditions for the system’s fault alarm which can be confi gured in the

FAU LT – fault alarm settings sub-menu.

OPERATION

From the Main Reading Page, press

to scroll to the

FAULT option.

Menu to enter the main menu. Use the Select key

SKI P

FAULT

The top line shows the navigation command. Press the key to change the navigation

command from

SKIP to ENTER.

ENTER

FAULT

Press the Select key to confi rm the navigation command and to either skip to the next

sub-menu or enter the

The fi rst setting parameter under this sub-menu is for the minimum dew-point fault

alarm set-point.

FAU LT – fault alarm settings sub-menu.

3.6.1 Minimum Dew-point Value for the Fault Alarm

-100.0C

MI N_ DP

This is the minimum dew point below which the fault alarm will be activated.

a. Increase or decrease the value by pressing the and keys.

b. When the desired set-point is on the display press the

confi rm. The display will then change to the next setting parameter - the

maximum dew-point fault alarm set-point.

NOTE: This fault alarm set-point can only be set in °Cdp, no matter what unit

has been selected for the Main Reading Page.

Select key to

Michell Instruments 37

Page 46

OPERATION

3.6.2 Maximum Dew-point Value for the Fault Alarm

20.0C

MAX_ DP

This is the maximum dew-point above which the fault alarm will be activated.

a. Increase or decrease the value by pressing the and keys.

Promet I.S. User’s Manual

b. When the desired set-point is on the display press the

confi rm. The display will then change to the next setting parameter - the

minimum pressure fault alarm set-point.

NOTE: This fault alarm set-point can only be set in °Cdp, no matter what unit

has been selected for the Main Reading Page.

3.6.3 Minimum Pressure Value for the Fault Alarm

0. 0 8

MI N_ B

This is the minimum pressure below which the fault alarm will be activated.

Select key to

a. Increase or decrease the value by pressing the and keys.

b. When the desired set-point is on the display press the

confi rm the choice. The display will then change to the next setting

parameter - the maximum pressure fault alarm set-point.

NOTE: The unit could be either barg (B) or psig (P), depending on the choice

of pressure unit in

The value will be automatically converted if a new unit is selected.

DISP – display settings sub-menu (refer to Section 3.5.1).

Select key to

38 97221 Issue 5, March 2017

Page 47

Promet I.S. User’s Manual

3.6.4 Maximum Pressure Value for the Fault Alarm

68.98

MAX_ B

This is the maximum pressure above which the fault alarm will be activated.

a. Increase or decrease the value by pressing the and keys.

OPERATION

b. When the desired set-point is on the display press the

confi rm. The display will then change to the next sub-menu

output settings.

NOTE: The unit could be either barg (B) or psig (P), depending on the choice

of pressure unit in

The value will be automatically converted if a new unit is selected.

DISP – display settings sub-menu (refer to Section 3.5.1).

Select key to

OUTPUT –

Michell Instruments 39

Page 48

OPERATION

3.7 Output Set-Up

The source and scale of the 4-20 mA output can be confi gured in OUTPUT – output

settings sub menu.

Promet I.S. User’s Manual

From the Main Reading Page, press

to scroll to the

The top line shows the navigation command. Press the key to change the navigation

command from

Press the Select key to confi rm the navigation command and either skip to the Main

Reading Page or enter the output settings sub-menu. The fi rst setting parameter under

this sub-menu is the output source selection.

3.7.1 Output Source Selection

OUTPUT option.

SKIP to ENTER.

Menu to enter the main menu. Use the Select key

SKI P

OUTPUT

ENTER

OUTPUT

MOI ST

SOURCE

The following list shows the options for the output source:

PPMV_N – moisture content in ppmV natural gas

MG/M3 – moisture content in mg/m3 natural gas

LBMMCF – moisture content in lb/MMscf natural gas

PPMV_I – moisture content in ppmV ideal gas

DP_F – °F dew point

psiG – pressure in psig

DP_C – °C dew point

BARG – pressure in barg

a. Change the selection by scrolling through these options using the and

keys.

b. When the desired source is on the display, press the

The 4-20 mA output will then switch to the selected source. The display

will change to the

ZERO value for the output range set-point.

Select key to confi rm.

40 97221 Issue 5, March 2017

Page 49

Promet I.S. User’s Manual

3.7.2 Output Range ZERO Value Settings

ZERO

a. Use the and keys to adjust the ZERO value.

OPERATION

0. 0 0

b. Press the

Select key to confi rm the input. The display will change to the

SPAN value of the output range set-point.

NOTE: The output range

the specifi c source selected in Section 3.7.1. The

range will not change accordingly when a new output source is selected. The

range should be checked and manually adjusted after changing the output

source.

3.7.3 Output Range SPAN Value Settings

ZERO value could be in different units, depending on

SPAN

ZERO value of the output

20.00

a. Use the and keys to adjust the SPAN value.

b. Press the

output settings sub-menu and return to the Main Reading Page.

NOTE: The output range

the specifi c source selected in Section 3.7.1. The

range will not change accordingly when a new output source selected. The

range should be checked and manually adjusted after changing the output

source.

Select key to confi rm the input. The display will leave the

SPAN value could be in different units, depending on

SPAN value of the output

Michell Instruments 41

Page 50

OPERATION

3.8 Alarm Set-Up

There are 4 built-in alarm relays. They can be confi gured independently in the menu.

From the Main Reading Page, press and hold the

enter the

3.8.1 Alarm Set-Point Adjustment

The fi rst page in ALARM is for adjusting the set-point of the Alarm Relay 1.

a. Use the and keys to adjust the set-point.

ALARM page.

Promet I.S. User’s Manual

Select key then press the key to

0. 0 C

SP _1

b. Press the

the alarm set-point for Alarm Relay 2.

c. Repeat the same operation to adjust the set-point for Alarm Relay 2, and

then Alarm Relay 3 and Alarm Relay 4 accordingly.

d. After Alarm Set Point SP_4 for Alarm Relay 4 has been set, press the