Page 1

Promet EExd

Process Moisture Analyzer

User’s Manual

97090 Issue 16

April 2019

Page 2

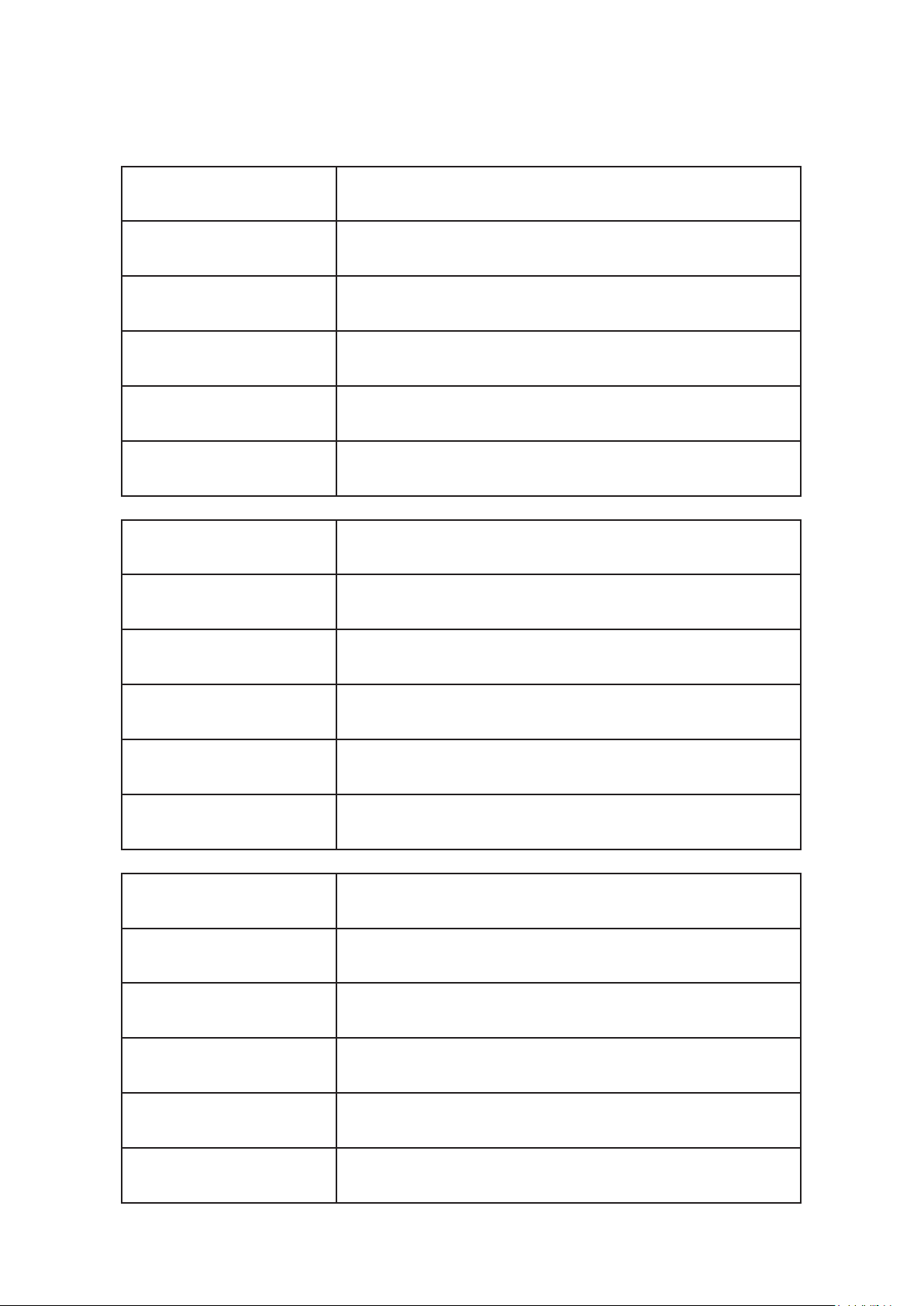

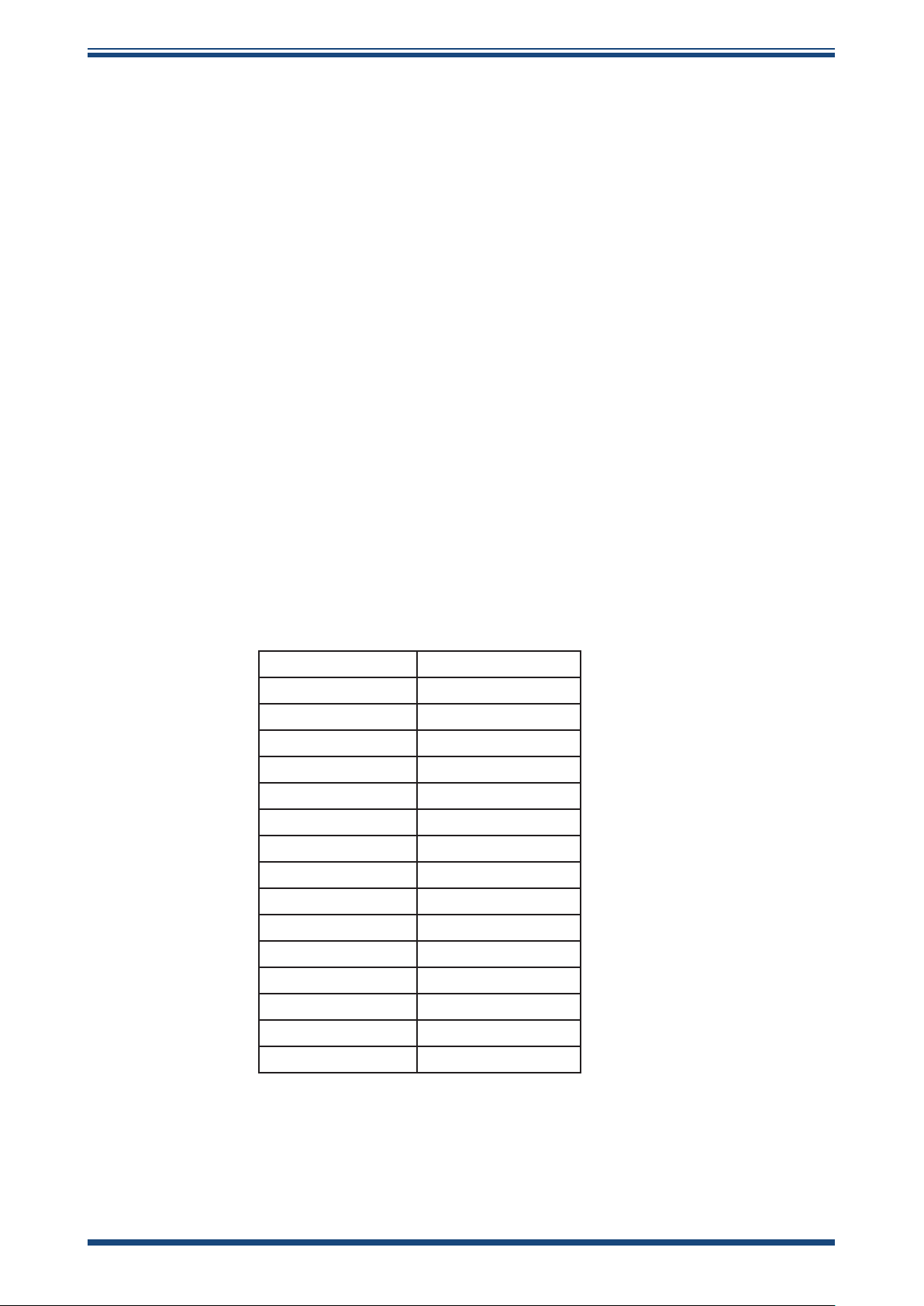

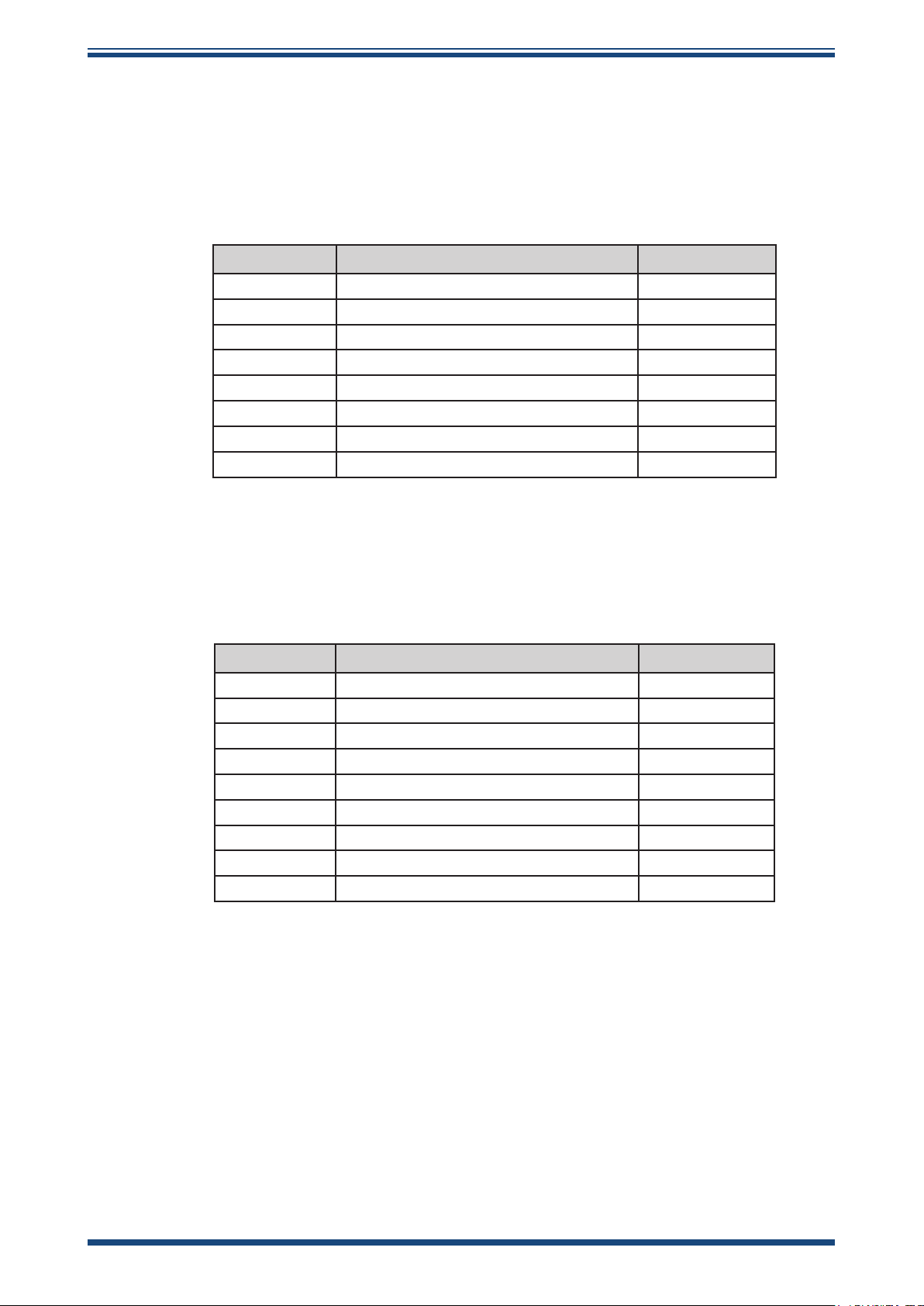

Please ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Analyzer

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

Promet EExd

For Michell Instruments' contact information please go to

www.michell.com

© 2018 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

Promet EExd User’s Manual

Contents

Safety ...............................................................................................................................vii

Electrical Safety ..........................................................................................................vii

Pressure Safety ...........................................................................................................vii

Toxic Materials ............................................................................................................vii

Repair and Maintenance .............................................................................................. vii

Calibration (factory validation) .....................................................................................vii

Safety Conformity .......................................................................................................vii

Abbreviations .................................................................................................................... viii

Warnings .......................................................................................................................... viii

1 INTRODUCTION ................................................................................................1

1.1 General .............................................................................................................. 1

1.2 Sample Gas Path ................................................................................................ 1

1.3 Operating Overview ............................................................................................ 2

1.4 User Display and Interface .................................................................................. 2

1.5 Advanced Sensor Technology .............................................................................. 2

1.6 Measurement Units ............................................................................................. 3

1.7 Elimination of Temperature Effects ....................................................................... 3

1.8 Calibration Maintenance ...................................................................................... 4

1.9 Promet EExd Sampling System ............................................................................ 4

2 INSTALLATION ..................................................................................................5

2.1 Electrical Safety .................................................................................................. 5

2.1.1 Equipment Ratings and Installation Details ...................................................... 5

2.2 Hazardous Area Safety ........................................................................................ 8

2.3 Pressure Safety .................................................................................................. 9

2.4 Lifting and Handling ........................................................................................... 9

2.5 Analyzer System ............................................................................................... 10

2.5.1 Pipework .................................................................................................... 11

2.5.2 Power Connection ...................................................................................... 13

2.5.3 Analog and Digital Communications ............................................................. 14

2.5.4 Process Alarms and Analyzer Status Alarms .................................................. 14

2.6 Promet EExd Start-Up Purge Procedure .............................................................. 15

2.7 Sample Gas Flows ............................................................................................ 16

2.8 Sample Flow Alarms (Optional) .......................................................................... 16

3 OPERATION ....................................................................................................17

3.1 System Operation ............................................................................................. 17

3.2 User Interface .................................................................................................. 17

3.2.1 Interface Controls ....................................................................................... 17

3.2.2 ‘Up/Down Arrow’ Buttons ............................................................................. 18

3.2.3 ‘SELECT’ Button .......................................................................................... 18

3.2.4 ‘MENU/MAIN’ Button ................................................................................... 18

3.3 Menu Structure ................................................................................................ 19

3.4 MAIN MENU Page ............................................................................................. 20

3.5 STATUS Page ................................................................................................... 20

3.6 LOGGING MENU Page ....................................................................................... 21

3.6.1 VIEW LOGGED DATA Page ........................................................................... 21

3.6.2 VIEW STATISTICS Page ............................................................................... 22

3.6.3 VIEW SYSTEM FAULTS Page ........................................................................ 23

3.7 VIEW/ADJ VARIABLES Page .............................................................................. 23

3.7.1 Password .................................................................................................... 23

3.7.2 VARIABLES Pages ....................................................................................... 24

3.7.3 Single Channel Configuration VARIABLES Pages ............................................ 24

iv 97090 Issue 16, April 2019

Page 5

Promet EExd User’s Manual

3.7.4 Dual Channel Configuration VARIABLES Pages .............................................. 25

3.8 SENSOR INFO Page .......................................................................................... 26

3.9 CONTACT INFO Page ....................................................................................... 27

4 MAINTENANCE ................................................................................................28

4.1 Enclosure Cover and User Interface ................................................................... 28

4.2 Replacement of the Moisture Sensor Assembly ................................................... 29

4.3 Replacement of the Flow Switch (if fitted) .......................................................... 31

4.4 Troubleshooting ................................................................................................ 32

4.4.1 Error Messages ........................................................................................... 32

4.4.2 Logged Error Codes ..................................................................................... 33

4.4.3 Analyzer Status Alarm Relay......................................................................... 34

Figures

Figure 1 Promet EExd Sampling System ....................................................................4

Figure 2 Power Connection Connector .......................................................................5

Figure 3 Earthing Stud And Nut Washer Assembly .....................................................6

Figure 4 Promet EExd Mounting Drawing .................................................................10

Figure 5 Pipework Connections ...............................................................................11

Figure 6 Hook-up Wiring Diagram ...........................................................................13

Figure 7 Minimum Requirements for Start-up Purging ..............................................16

Figure 8 MAIN Page in Single Channel (top) and Dual Channel Modes .......................17

Figure 9 User Interface ..........................................................................................17

Figure 10 Up/Down Arrow Buttons ...........................................................................18

Figure 11 ‘SELECT’ Button ........................................................................................18

Figure 12 ‘MENU/MAIN’ Button .................................................................................18

Figure 13 Menu Structure ........................................................................................19

Figure 14 MAIN MENU Page .....................................................................................20

Figure 15 STATUS Page ...........................................................................................20

Figure 16 LOGGED DATA Page .................................................................................21

Figure 17 STATISTICS Page .....................................................................................22

Figure 18 LOGGED ERROR Page ...............................................................................23

Figure 19 PASSWORD Page ......................................................................................23

Figure 20 VARIABLES Page ......................................................................................24

Figure 21 SENSOR INFO Page ..................................................................................26

Figure 22 CONTACT INFO Page ................................................................................27

Figure 23 Ribbon Cable Connection ..........................................................................29

Figure 24 Moisture Sensor Assembly Replacement .....................................................30

Figure 25 Error Message Line ...................................................................................32

Figure 26 Logged Error Codes ..................................................................................33

Figure 27 Mounting Drawing ....................................................................................38

Figure 28 Pipework Connections ...............................................................................39

Figure 29 System Wiring Diagram .............................................................................40

Figure 30 Calibration Correction Data........................................................................50

Figure 31 Reading Holding Registers State Diagram ...................................................62

Figure 32 Write Single Register State Diagram ...........................................................64

Michell Instruments v

Page 6

Promet EExd User’s Manual

Appendices

Appendix A Technical Specifications ..............................................................................36

A.1 Mounting Drawing ....................................................................... 38

A.2 Pipework Connections ..................................................................39

A.3 System Wiring Diagram ................................................................40

Appendix B Variable Definitions ...................................................................................42

Appendix C Software ................................................................................................... 47

C.1 System Requirements ..................................................................47

Appendix D Modbus RTU Communications .................................................................... 49

D.1 Introduction ................................................................................ 49

D.2 Modbus RTU Basics ...................................................................... 49

D.3 Physical Layer ............................................................................. 49

D.4 Termination Resistor .................................................................... 50

D.5 Register Map ............................................................................... 50

Appendix E Modbus RTU Details ..................................................................................55

E.1 Message Framing .........................................................................55

E.2 Implemented Functions ................................................................56

E.3 Exceptions ..................................................................................60

Appendix F Register Number Formats...........................................................................62

Appendix G Hazardous Area Certification ......................................................................68

G.1 Product Standards .......................................................................68

G.2 Product Certification ....................................................................68

G.3 Global Certificates/Approvals ........................................................ 68

G.4 Special Conditions of Use ............................................................. 69

G.5 Maintenance and Installation ........................................................69

Appendix H Pressure Equipment Directive Compliance Statement ................................... 71

Appendix I Quality, Recycling & Warranty Information ...................................................73

Appendix J Return Document & Decontamination Declaration ........................................75

vi 97090 Issue 16, April 2019

Page 7

Promet EExd User’s Manual

!

Safety

This manual contains all the required information to install, operate and maintain the Promet EExd. Prior

to installation and use of this instrument, this entire manual should be read and understood. Installation

and operation of this product should be carried out by suitably competent personnel only. The operation

of this product must be in accordance with the terms of this manual and associated safety certicates.

Incorrect installation and use of this product for other than its intended purpose will render all warranties

void.

This product is intended for use in a Hazardous Area and is awarded an ATEX, IECEx and CSA Certicate.

The relevant certicates should be fully examined prior to installation or use of this product.

Where this hazard warning symbol appears in the following

sections, it is used to indicate areas where potentially hazardous

operations need to be carried out and where particular attention to

personal and personnel safety must be observed.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied by

the manufacturer for use with the instrument. The input power supply voltage limits are 90 to 260 V AC,

47/63 Hz.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied directly to the instrument.

Refer to the Technical Specications in Appendix A.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During normal

operation it is not possible for the user to come into contact with any hazardous substance which might be

employed in the construction of the instrument. Care should, however, be exercised during maintenance

and the disposal of certain parts.

Repair and Maintenance

The instrument must only be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide oces contact information.

Calibration (factory validation)

Prior to shipment, the analyzer undergoes stringent factory calibration to internationally traceable

standards, NPL (UK) and NIST (USA). Due to the inherent stability of the instrument, only periodic

calibration is required under normal operating conditions.

Michell Instruments recommends that calibration of the sensor should be maintained on a 12 monthly

basis to ensure optimum operation. Michell Instruments oers a calibration exchange program, where

a refurbished and re-certied sensor is supplied as an operational replacement and the original item

returned to Michell to complete the exchange.

NOTE: This interval may need to be reduced if the operation of the sensor is within potentially

aggressive or corrosive sample media (such as sour natural gas). The calibration interval

may therefore need to be shortened to 6 months (or lower in extreme cases) in order to

maintain satisfactory analyzer performance.

Safety Conformity

This product meets the essential protection requirements of the relevant EU directives. Further details of

applied standards may be found in the product specication.

Michell Instruments vii

Page 8

Abbreviations

The following abbreviations are used in this manual:

A Ampere

AC alternating current

barg pressure in bar (gauge)

°C degrees Celsius

°F degrees Fahrenheit

DC direct current

dp dew point

EU European Union

lb pound

lb/MMscf pounds per million standard cubic feet

lbf-ft pound force per foot

kg kilogram

mA milliampere

max maximum

min minute(s)

mg/m3 milligrams per cubic meter

mm millimeters

mV millivolt(s)

N/C normally closed

N/O normally open

Nl/min normal liters per minute

ppmV parts per million by volume

psig pressure in pound(s) per square inch (gauge)

RH relative humidity

scfh standard cubic feet per hour

temp temperature

V Volts

Promet EExd User’s Manual

Warnings

The following general warnings listed below are applicable to this instrument. They are

repeated in the text in the appropriate locations.

Where this hazard warning symbol appears in the following

sections it is used to indicate areas where potentially

hazardous operations need to be carried out.

Where this symbol appears in the following sections it is used

to indicate areas of potential risk of electric shock.

viii 97090 Issue 16, April 2019

Page 9

Promet EExd User’s Manual

1 INTRODUCTION

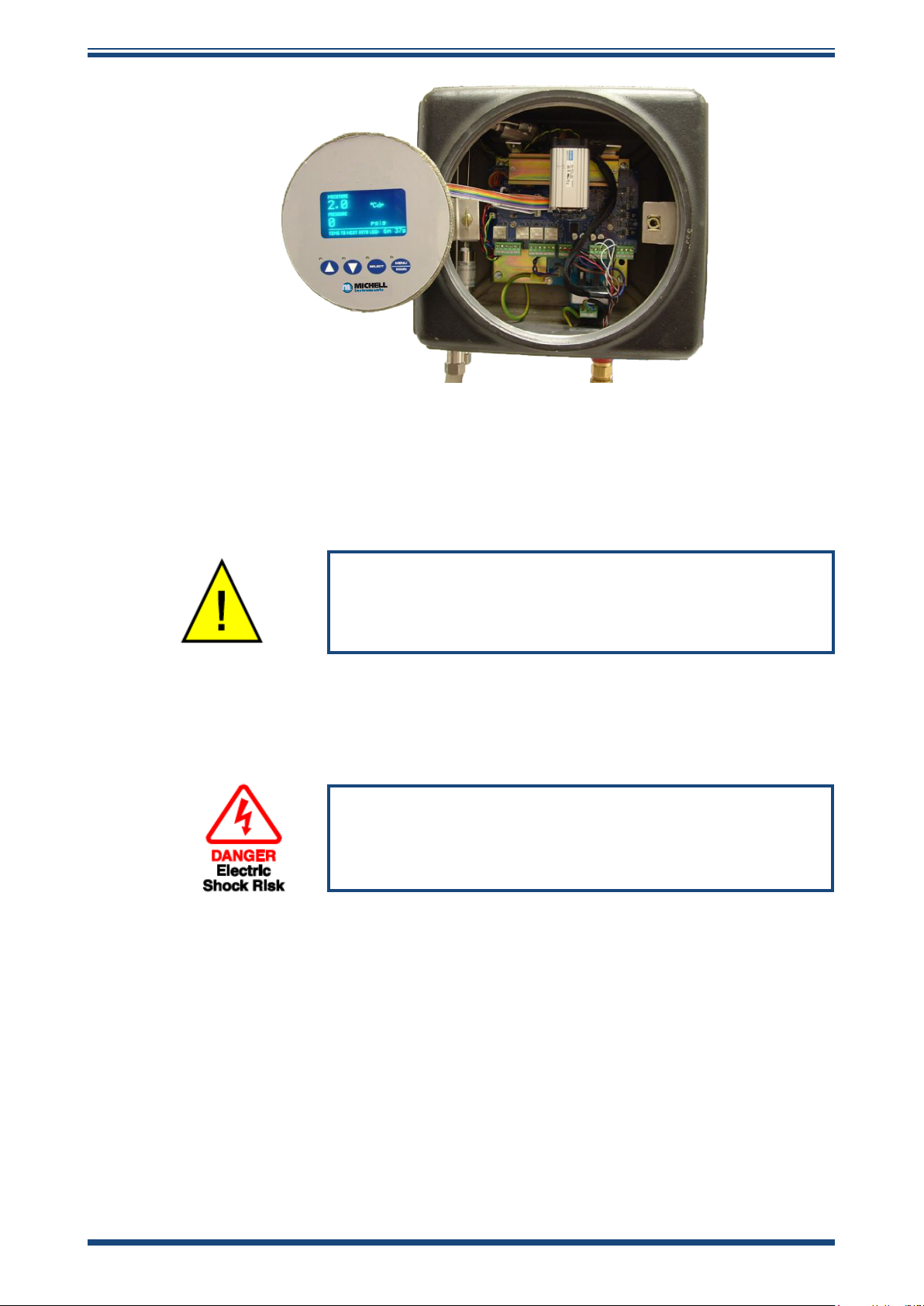

1.1 General

The Promet EExd is designed for continuous, automatic measurement of the moisture

content of processed natural gas, utilizing the Michell Ceramic Moisture Sensor. It is the

result of more than 30 years’ experience in the supply of analyzers to the Worldwide Oil

& Gas Industry.

The analyzer comprises either a single or a dual channel moisture measurement sensor

cell, control electronics and a display interface housed in an Exd enclosure. The analyzer

is ATEX Directive, IECEx or cCSAus compliant for use in a Zone 1 or 2 Hazardous Area

and Class I, Div 1 Hazardous Location. See marking label located on right hand side of

analyzer to identify approvals. An accompanying sample handling panel, designed to be

positioned close to the process sample point to prepare the sample prior to entry into

the Promet EExd, can also be supplied.

The instrument offers several user-selectable display options based on a calibrated

dew-point measurement range of -100 to +20°C (-148 to +68°F), traceable to the

humidity metrology standards of NPL (UK) and NIST (USA). The instrument further

provides indication only in the ranges of +20 to +30°Cdp (+68 to +86°Fdp) and -100 to

-120°Cdp (-148 to -184°F), equating to a moisture measurement capability of <1ppbV

to >30,000 ppmV.

INTRODUCTION

The requirements for operation are a 90 to 260 V AC, 47/63 Hz power supply of 180W

and field communications Modbus RTU and/or 4-20 mA. Refer to the System Wiring

Diagram in Appendix A.

1.2 Sample Gas Path

The Promet EExd analyzer system must be supplied with gas at the required pressure,

via a sample gas handling panel providing suitable pressure, filtration & flow control.

Sample gas entry and exit ports direct the gas through flame arrestors which, along with

the Exd enclosure, provide the explosion proof protection. 1 or 2 separate measurement

channels can be accommodated within the instrument.

The measurement system components are housed within a cast aluminum Exd rated

enclosure. The enclosure has a screw cover incorporating a sealed window. It is

chromate primed, polyester coated in black, and provides environmental protection to

IP66/NEMA 4. An enclosure breather is fitted in the form of an additional flame arrestor.

It is important that no pipe connection is made to this breather and that no restriction

is allowed to occur.

All sample gas-wetted metallic parts are manufactured in AISI 316L stainless steel with

Viton soft parts that comply with the NACE standard MR-01-75 (latest edition). Tube

fittings are twin ferrule compression type. All electrical and gas connections are made

through the base of the enclosure. Refer to the Mounting Drawing in Appendix A.

Channel 1 flow components comprise the following:

• (Optional) Flow Switch 1 (FS1): Provides indication that a flow

is present throughout the moisture measurement stream

• Pressure Transducer 1 (PT1): Provides the measurement of

the sample gas pressure within the moisture measurement cell

Michell Instruments 1

Page 10

INTRODUCTION

Channel 2 flow components comprise the following:

• (Optional) Flow Switch 2 (FS2): Provides indication that a flow

is present throughout the moisture measurement stream

• Pressure Transducer 2 (PT2): Provides the measurement of

the sample gas pressure within the moisture measurement cell

1.3 Operating Overview

The system continuously measures dew point/moisture and pressure in an uninterrupted

gas stream flow. The flow switch, if fitted, will notify the system if the gas flow falls

below the recommended rate.

Moisture and pressure for each channel are logged at a user-defined interval. The logs

are available through the user interface or via the serial communications. Two 4–20 mA

outputs for each channel are available to remotely read the dew point/moisture and

pressure in real time.

Promet EExd User’s Manual

1.4 User Display and Interface

The Promet EExd User Display and Interface Unit is presented via the circular window

of the enclosure. Operation is achieved by a unique system, which allows full control

through the glass of the enclosure cover. The cover is fully detachable for greater

access into the enclosure during the installation and initial set-up of the instrument.

During normal operation of the instrument the cover must remain fully secured.

1.5 Advanced Sensor Technology

The Promet EExd utilizes the Michell Ceramic Moisture Sensor, an advanced impedance

sensor technology with more than 1,000 installations in natural gas and petrochemical

applications today. Semiconductor thick- and thin-film technologies combine in metallized

ceramics and achieve a durable sensor with measurement capability from lower than 10

ppbV moisture content and high-pressure capability up to 138 barg (2000 psig).

Unlike older aluminum-oxide technologies, the inherent immunity to pressure shock of

the Ceramic Sensor avoids the risk of sensor failure at commissioning or shut-down.

The inert nature of the sensor gives long-term resistance to chemical attack, even in

extremely sour gas with percentage level H2S concentrations. The Ceramic Sensor

response characteristic is proportional to the partial pressure of water vapor in the gas

being measured, which is directly related to the dew-point temperature.

2 97090 Issue 16, April 2019

Page 11

Promet EExd User’s Manual

1.6 Measurement Units

The Promet EExd offers complete flexibility for the user to select their preference of

hygrometric units. Integral pressure measurement enables unit conversions from dew

point to moisture content, or dew point to dew point for different pressure conditions.

The available units of dew point/moisture content are as follows:

Dew-Point Temperature

• °C or °F dew point

• °C or °F dew point calculated for a set pressure level input by

the user, for either ideal or natural gas

Moisture Content (parts per million)

• ppmV for ideal gas (Ppm(v) IG)

• ppmV for natural gas (Ppm(v) NG)

INTRODUCTION

Moisture Content (pounds per million standard cubic feet)

• lb/MMscf for natural gas (LBMMSCF)

Milligrams per normal cubic meter

• mg/m3 natural gas (mgm-3)

The firmware of the Promet EExd incorporates conversion data for ideal gases and

natural gas. For natural gas the conversions are performed based on the long established

IGT Research Bulletin No. 8 or the recently published ISO 18453, to customer order

preference.

1.7 Elimination of Temperature Effects

To ensure continuous optimum analysis conditions the Promet EExd Main Unit is

temperature controlled (internally) at a stable level. The control temperature level is

selected to suit the climate at the point of installation, being set to the normal maximum

temperature. Such steady state control within the analyzer greatly reduces the effects

of diurnal (day-night) swings in temperature. These temperature changes could induce

transitional adsorption and desorption effects of the flowing sample, resulting in

erroneous measurements.

In addition, the Promet EExd utilizes an advanced temperature compensation algorithm

that automatically maintains best possible measurement accuracy in the event of heater

failure or if the prevailing climate exceeds the set temperature level.

Michell Instruments 3

Page 12

INTRODUCTION

1.8 Calibration Maintenance

Maintenance of calibration is essential to the lifetime performance of all analyzers. To

ensure that all customers worldwide can maintain the performance of their Promet EExd,

the unique Michell Calibration Exchange Service offers freshly calibrated replacement

Ceramic Sensors certified traceable to NPL and NIST. As the calibration characterization

data for each Promet EExd Sensor is programmed into on-board non-volatile memory,

fitment of the Calibration Exchange Sensor refreshes the calibration, returning the

measurement performance to day-one with down-time of only a few minutes while

the interchange is made. No programming or data input is required by the user to

complete this. The calibration exchange is available globally on swift delivery, typically

less than two weeks, and at the same or less then the cost of a traditional ‘return to

manufacturer’ re-calibration service.

The recommended calibration maintenance interval is 12 months for sweet gases and

6 months for sour gases.

Michell recognises that some customers wish to carry out their own calibration

adjustments in the field using either a portable dew-point generator (ATSM D5454),

or against a calibrated reference hygrometer or certified moisture-in-gas cylinders.

The Promet EExd accommodates all such needs within the operating firmware that

offers user-friendly access to the calibration characterization table for re-calibration

adjustments to be made at just one point (for example, using a certified cylinder gas)

or multiple points (using a field generator) across the measurement range.

1.9 Promet EExd Sampling System

Promet EExd User’s Manual

(Optional – see separate manual if you have purchased this item)

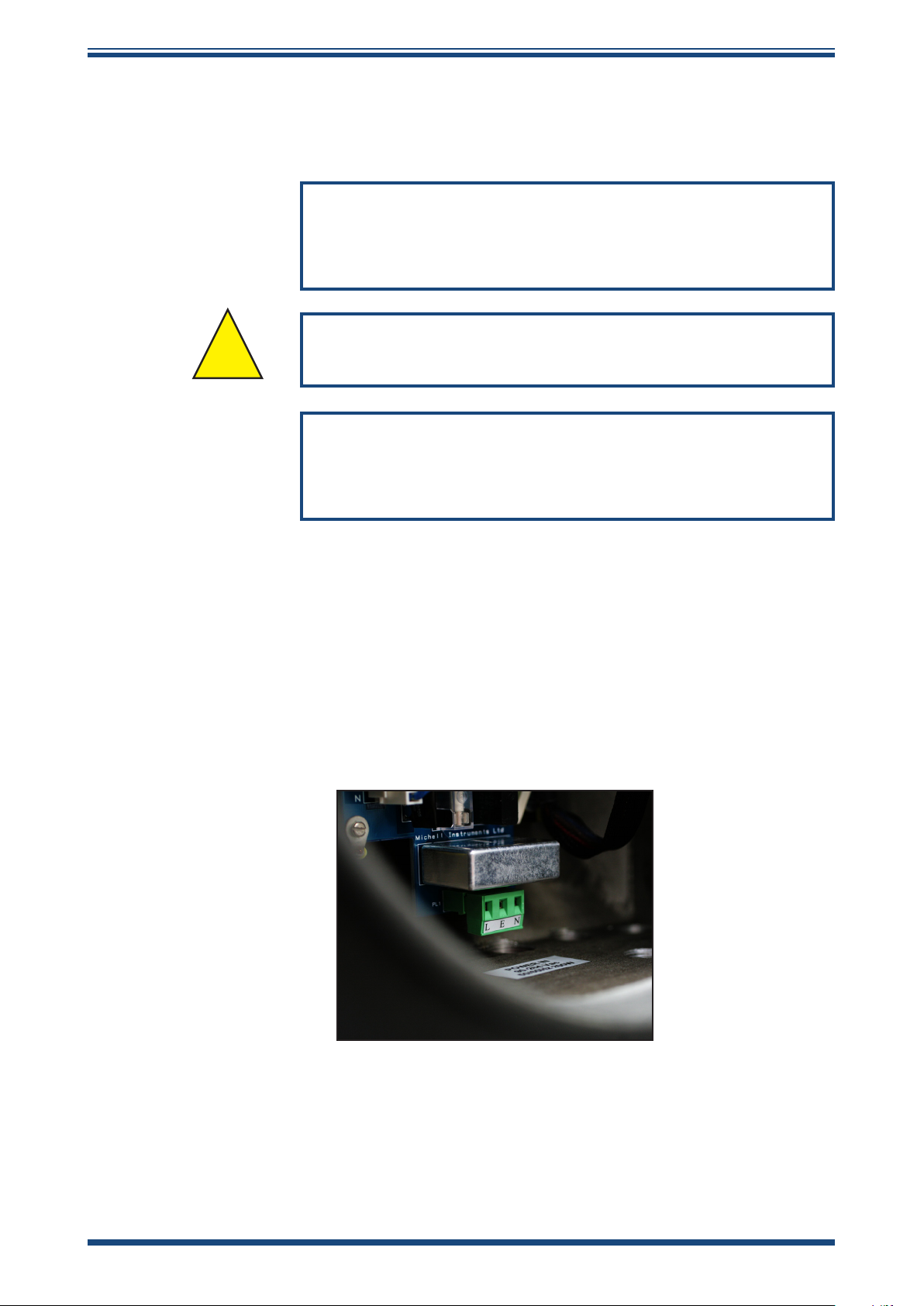

Figure 1

Promet EExd Sampling System

Good sample conditioning and handling is particularly important in the field of moisture

measurement. As the moisture sensor has to be exposed directly to the process liquid

stream in order to detect the dissolved moisture present, key sampling issues such

as the avoidance of particulate contamination are imperative to successful operation.

Michell’s 30 years of expertise in on-line process moisture analyzers are used to optimize

the design of the Promet EExd Sampling Systems.

Contact Michell Instruments for further details: www.michell.com.

4 97090 Issue 16, April 2019

Page 13

Promet EExd User’s Manual

!

2 INSTALLATION

2.1 Electrical Safety

During the installation of this product ensure that all

applicable national and local electrical safety regulations

Always ensure that power is switched off prior to accessing

the product for any purpose other than normal operation or

INSTALLATION

WARNING:

are observed.

WARNING:

Isolate the power prior to installation.

WARNING:

prior to disconnecting any cables.

2.1.1 Equipment Ratings and Installation Details

The following mandatory statements refer to the Ex certified Promet EExd Analyzer only

(not including the sampling system).

This equipment must be supplied with a voltage between the range of 90 to 260 V AC,

47/63 Hz. Maximum power rating is 180 W.

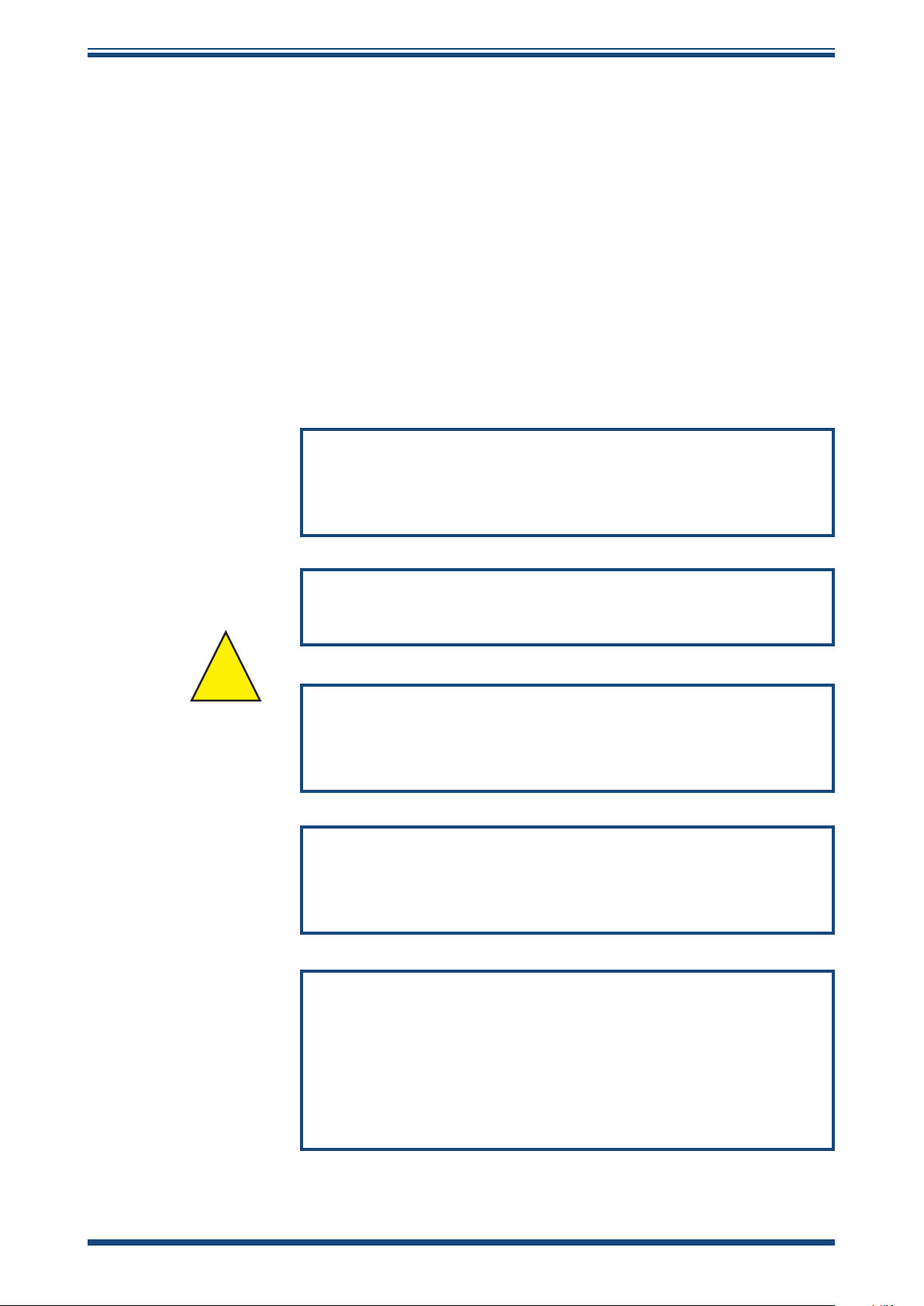

The power is connected via PL1 on the mains connector PCB.

Figure 2

All input and output connectors are 2-part PCB mounted type, rated at 300 V 10 A.

The detachable, screw terminal half of each connector is designed to accept 0.5 to

2.5mm2 [24 -12 AWG] stranded or solid conductors.

Power Connection Connector

Michell Instruments 5

Page 14

INSTALLATION

Any power connection cable should be 3 core over sleeved, with minimum 0.5mm

insulation and rated at 300 V. Cables should have Live (L), Neutral (N) and Earth

[Ground] (E) conductors. Ensure suitably rated power supply cables and glands are

used to ensure that electrical safety is maintained. Connect each of the Live (L), Neutral

(N) and Earth [Ground] (E) conductors to the similarly marked terminals (L, N, E) on

the Power In connector shown in Figure 3 above. Ensure the power supply can deliver

sufficient power consumption requirement.

Any power supply terminals and voltages must be suitably separated from the other I/O

requirements of this product.

Before applying power, perform a continuity test to ensure that the power supply cable

and product are effectively connected to the protective Earth.

The Protective Earth terminal is mounted internally and the Earth wire connected to it

should never be disconnected. The product enclosure is supplied with an external earth

stud at the lower right hand side. At installation, connect this earth stud to plant earth

by a minimum 4mm2 earthing bonding. M6 stud and 2 off M6 nuts and washers, all

nickel plated.

Promet EExd User’s Manual

Figure 3

Fuse: A replacement fuse can be obtained by contacting Michell Instruments' technical

support. Fuse rating = 5 x 20mm 2.5 A anti-surge to IEC 60127-2.

This product is designed to be safe at least under the following conditions: between a

temperature range of -40 to +60°C (-40 to +148°F), in maximum 80% relative humidity

for temperatures up to +31°C (+88°F) decreasing linearly to 50% RH at +50°C

(+122°F). Supply voltages of ±10% and transient over voltages up to Overvoltage

Category II. Pollution Degree 2. Altitudes up to 2000m. Outdoor mounting is permitted

using suitably rated glands equivalent to NEMA 4 / IP66. See Appendix A, Technical

Specification, for full operating parameters.

Do not remove or exchange any of the cables or electrical components supplied with

this product. Doing so will invalidate all warranties.

There are no additional or special electrical safety requirements other than those

referred to in this manual.

Earthing Stud And Nut Washer Assembly

6 97090 Issue 16, April 2019

Page 15

Promet EExd User’s Manual

Location and mounting arrangements - refer to the relevant sections of this manual for

the location and mounting details.

Installation of this equipment must include the provision of a suitable and locally

positioned power isolation switch or circuit breaker. Indication of the purpose of the

switch or circuit breaker is strongly recommended. An over-current protection device

should be rated to a maximum of 10 A.

This equipment and all power isolation devices must be installed in a location and

position that allows safe and easy access to their operation and is able to rigidly support

the equipment.

Do not install this equipment in a location that would expose it to impact or high levels

of vibration.

Operation of this equipment, other than in a manner specified by the manufacturer, may

impair the safety protections provided.

The safe installation of this equipment and any system incorporating this equipment is

the responsibility of the installer. Ensure local regulations and requirements are referred

to prior to any installation commencing.

INSTALLATION

Michell Instruments 7

Page 16

INSTALLATION

!

2.2 Hazardous Area Safety

Refer to Appendix G for the Hazardous Area Certification of this product.

This product is fitted with a marking label that contains Hazardous Area information

pertinent to the suitable location and installation.

During all installation and operation activities, local regulations and permitted working

routines must be observed. Installation should only be performed by competent personnel

and in accordance with the latest version of IEC/EN60079-14 or local equivalent.

Repair and servicing of this equipment must only be carried out by the manufacturer.

An Installation and Maintenance Information Sheet is supplied separately to the manual.

This product is certified safe for use in a Zone 1 and Zone 2

area only. This product must not be installed or used within

Promet EExd User’s Manual

WARNING:

a Zone 0 area.

WARNING:

This product must not be operated within an explosive

atmosphere greater than 1.1 bara.

WARNING:

This product must not be operated with enriched oxygen

gas samples (more than 21% oxygen content).

WARNING:

This product must not be operated outside of the

temperature range of -40 to +60°C

WARNING:

The enclosure of this product provides Exd protection, partly

through the threads used for mounting the lid, stopping

plugs and cable gland. At all times effort should be made to

ensure these threads are suitably protected from damage

and that only appropriately rated mating parts are applied

to them, in accordance with the certifying requirements.

8 97090 Issue 16, April 2019

Page 17

Promet EExd User’s Manual

!

!

!

2.3 Pressure Safety

This product is used in conjunction with pressurized gases.

Observe pressurized gas handling precautions.

Pressurized gas should only handled by suitably trained personnel.

INSTALLATION

WARNING:

WARNING:

Pressurized gas is dangerous.

This product requires pressurized gas to be connected to it. Observe pressurized gas

handling regulations. Only suitably trained personnel should carry out tasks that include

the use of pressurized gas mediums.

2.4 Lifting and Handling

Personnel must observe suitable lifting and handling precautions.

This product is not designed as portable or transportable equipment. It should be rigidly

fixed in position as per the full installation instructions.

The weight of the analyzer is in excess of 18kg. Therefore, appropriate lifting and

handling techniques should be used during the installation process. Before commencing

any lifting or handling ensure that its intended location is suitable and appropriately

prepared. Make sure that mounting point design considerations have employed locally

approved safety factors.

WARNING:

This instrument is in excess of 18kg.

When handling and installing this product (particularly after removal from its packaging)

ensure that it is not dropped, impacted or subjected to high levels of vibration or

environmental conditions that may impair its operation.

Michell Instruments 9

Page 18

INSTALLATION

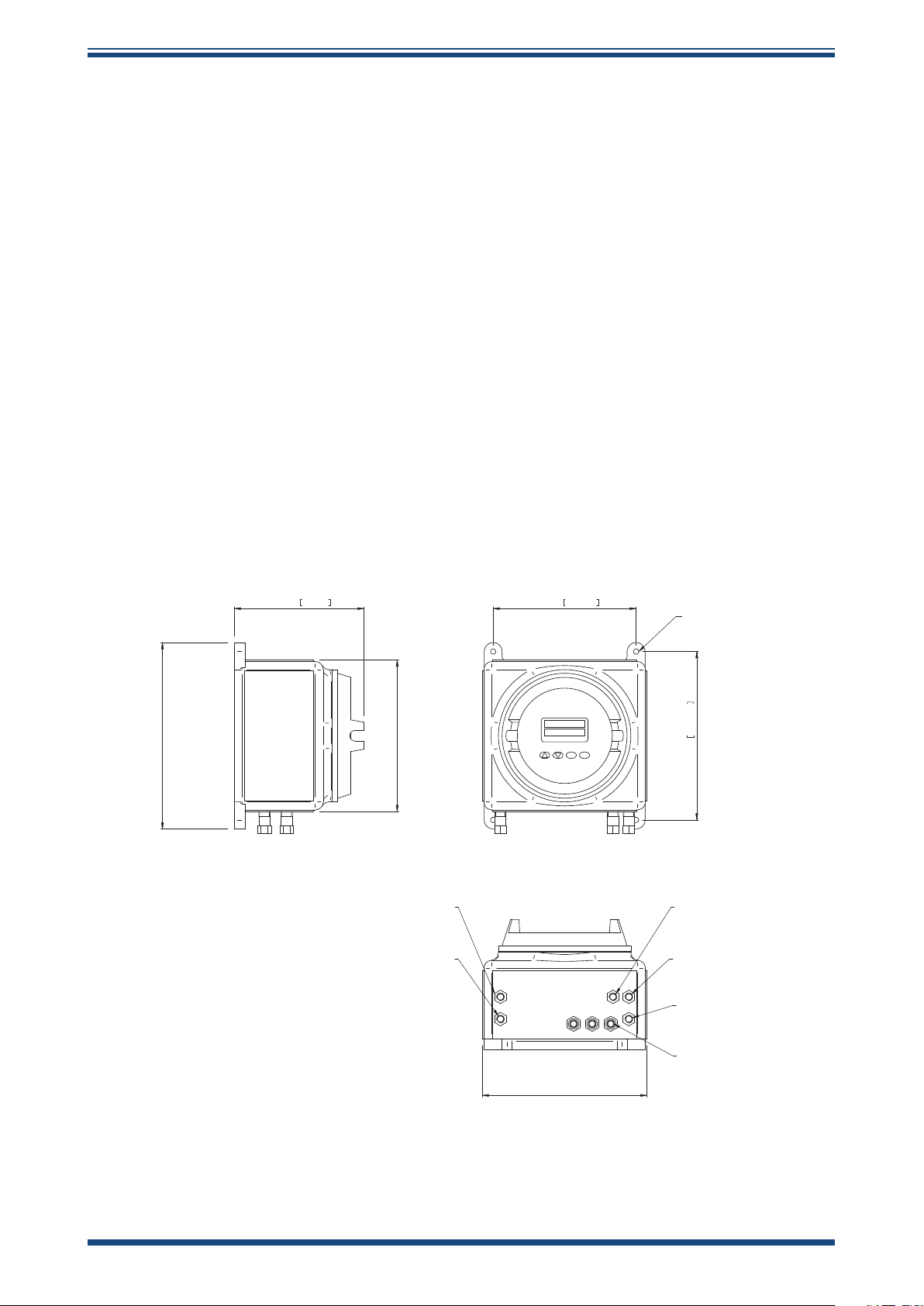

2.5 Analyzer System

Refer to the Installation & Maintenance Information sheet (supplied separately) and the

System Drawings in Appendix A.

The instrument is housed in an aluminum EExd enclosure suitable for wall or panel

mounting. Four mounting points are available with M12 clearance holes on fixing

centres of X = 270mm x Y = 318mm.

Height: 355mm (13.9”)

500mm (19.68”) including installation clearance

Width: 310mm (12.20”)

500mm (19.68”) including installation clearance

Depth: 245mm (9.64”)

The enclosure provides environmental ingress protection IP66 and should be mounted

vertically in a location free of any appreciable vibration. It should be placed in a shaded

position to prevent heating effects through sun radiation.

Promet EExd User’s Manual

The weight of the analyzer is 21kg (46lbs).

245mm 9.65"

355mm [13.9"]

Sample out - Channel 1

1/8" NPT Female (ATEX/IECEx/CSA)

Sample in - Channel 1

1/8" NPT Female (ATEX/IECEx/CSA)

290mm [11.41"]

Flame Arrestor

Flame Arrestor

270mm 10.63"

4 o M12 (1/2")

Clearance

318mm 12.52"

Enclosure Breather

Flame Arrestor

Do NOT obscure

Sample Out - Channel 2 (Optional)

Flame Arrestor

1/8" NPT Female (ATEX/IECEx/CSA)

Sample In - Channel 2 (Optional)

Flame Arrestor

1/8" NPT Female (ATEX/IECEx/CSA)

Cable Entry Glands

3 o M20 (ATEX)

3 o 1/2" NPT (CSA)

Figure 4

310mm [12.20"]

Promet EExd Mounting Drawing

10 97090 Issue 16, April 2019

Page 19

Promet EExd User’s Manual

2.5.1 Pipework

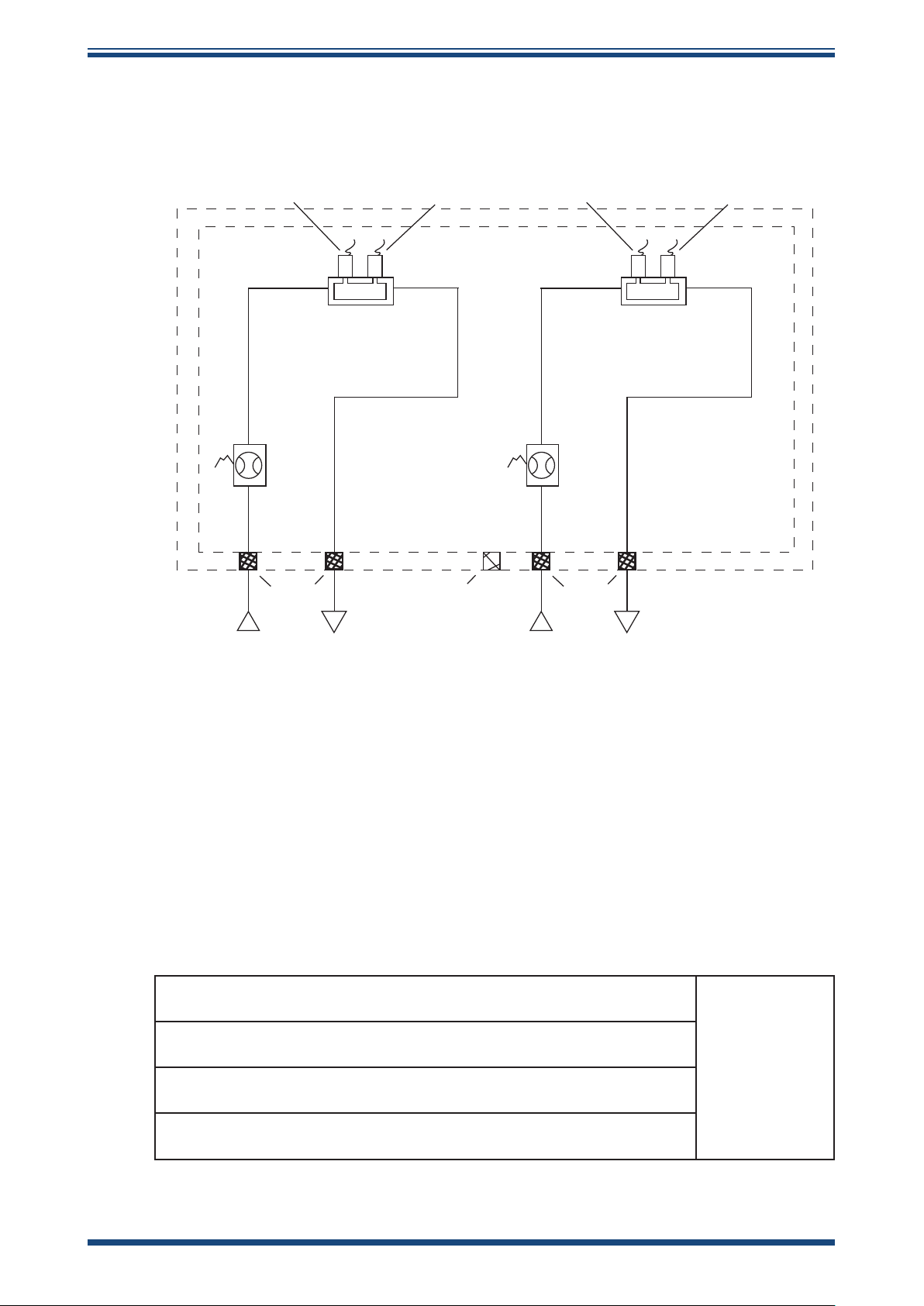

CHANNEL 1 CHANNEL 2

MICHELL MOISTURE

SENSOR

PRESSURE

TRANSMITTER

MICHELL MOISTURE

SENSOR

INSTALLATION

PRESSURE

TRANSMITTER

GAS SAMPLING BLOCK

FLOW

SWITCH

(optional)

ARRESTORS

GAS IN GAS OUT

FLAME

FLAME

ARRESTOR

BREATHER

GAS SAMPLING BLOCK

FLOW

SWITCH

(optional)

ARRESTORS

GAS IN GAS OUT

FLAME

Figure 5

Pipework Connections

Note: Ensure that the process sample gas supply line is well flushed through

to clear any liquids and debris present prior to connection to the instrument. A

sample handling system must prepare the gas in terms of pressure regulation

and filtration before entering into the measurement system.

In accordance with the Certification requirements, the Promet EExd must have, as a

minimum, the components described in Figure 7.

The pipework connections are as follows:

Water dew-point Channel 1 Gas Sample inlet

(Maximum pressure of 138 barg (2000 psig))

Water dew-point Channel 1 Gas Sample outlet

(Vent to atmosphere or low pressure are line)

1/8” NPT(F)

Water dew-point Channel 2 Gas Sample inlet

(Maximum pressure of 138 barg (2000 psig))

Water dew-point Channel 2 Gas Sample outlet

(Vent to atmosphere or low pressure are line)

Michell Instruments 11

Page 20

INSTALLATION

The following points should be considered when installing the sample gas supply line:

PTFE tape is recommended for pipe connections. Solvent based pipe thread sealant

should not be used, as condensable components or contaminates can be leached during

the curing period.

It is recommended that Viton is used for all O-rings.

Care and attention to the position and installation of the piping will minimize problems

caused by avoidable contamination of the measurement system. The most common

cause of difficulty is the accumulation of liquid in impulse lines during a shutdown

period. If the measurement system has not been isolated on restart-up, condensate

can be displaced into components and associated pipe work within the measurement

system.

If this event follows a period when process lines may have been contaminated by nonhydrocarbons, e.g. glycol, corrosion inhibitors, etc., the problem is magnified. Similarly,

difficulty will be encountered in sample gases carrying liquids, including hydrocarbon

liquids.

Promet EExd User’s Manual

Our recommendations are:

• The sampling point on the process line should be on the top of the pipe. If

a radial probe is used, the orifice should face downstream. Sample should

be taken from middle 1/3 pipe internal diameter.

• The internal volume of the impulse tubing between the process line and

any sampling system should be as low as possible (sample lines should

be kept as short as possible) to minimize response lag time to changing

process conditions.

• Piping should be lagged and/or trace heated if ambient temperatures

could cause the sample gas to fall below its dew-point temperature.

• A drain valve should be placed at the low point (if any) in the system.

• It should be standard procedure to isolate the measurement system

during shutdowns or when plant problems are being experienced. The

supply lines must be fully purged before restarting.

• The relatively large area of surfaces and internal volume of pressure

regulators can be particularly troublesome if contamination is experienced.

Prolonged purging with gas may be necessary to remove the contamination.

Stripping and cleaning, followed by purging of the system, is preferred.

• Avoid sample gas streams that are already very close to the dew point

or which have dispersed liquid (not necessarily hydrocarbon) burden. In

such cases, sampling from fast loops and/or from downstream of existing

catch pot/coalesce systems is always preferred.

NOTE: Failure to observe these recommendations will potentially cause

problems of contamination as well as causing consequential inaccurate,

unreliable and inconsistent monitoring. If a top-entry sample point

is not available, extra attention should be given to the design of the

sample line installation to avoid unwanted contamination.

12 97090 Issue 16, April 2019

Page 21

Promet EExd User’s Manual

2.5.2 Power Connection

A single-phase AC power connection is required.

The power supply can accommodate voltages from 90 to 260 V AC, 47/63 Hz. The unit

requires a maximum of 180 W to function correctly.

The connection is made via a two-part connector mounted at the base of the unit. See

Appendix A.

Cable entry into the measurement system is made through the bottom of the enclosure.

• For ATEX/IECEx compliant versions of the product 3 off ISO M20 tapped

holes are provided

• For cCSAus compliant version of the product 3 off ½” NPT entries are

provided

INSTALLATION

NOTE: For ATEX/IECEx installations EExd Stopping Glands MUST be used

when installing. Refer to the separate Installation & Maintenance Information

sheet supplied.

The terminals are marked:

L = Live

N = Neutral

E = Earth

AL3AL2AL1 AL4 COMMS Channel 1 Channel 2

mA1+

mA1-

mA2+

NC C NO NC C NO

1 2 3 4 5 6

NC C NO NC C NO

PL16

7 8 9 10 11

B A GND

12

PL20 PL15 PL14 PL19

13 14 15

16 17 18 19 20 21 22 23

mA2-

mA3+

mA3-

mA4+

mA4-

L E N

Enclosure wall

Gland

Cable screen

Figure 6

Hook-up Wiring Diagram

Michell Instruments 13

Page 22

INSTALLATION

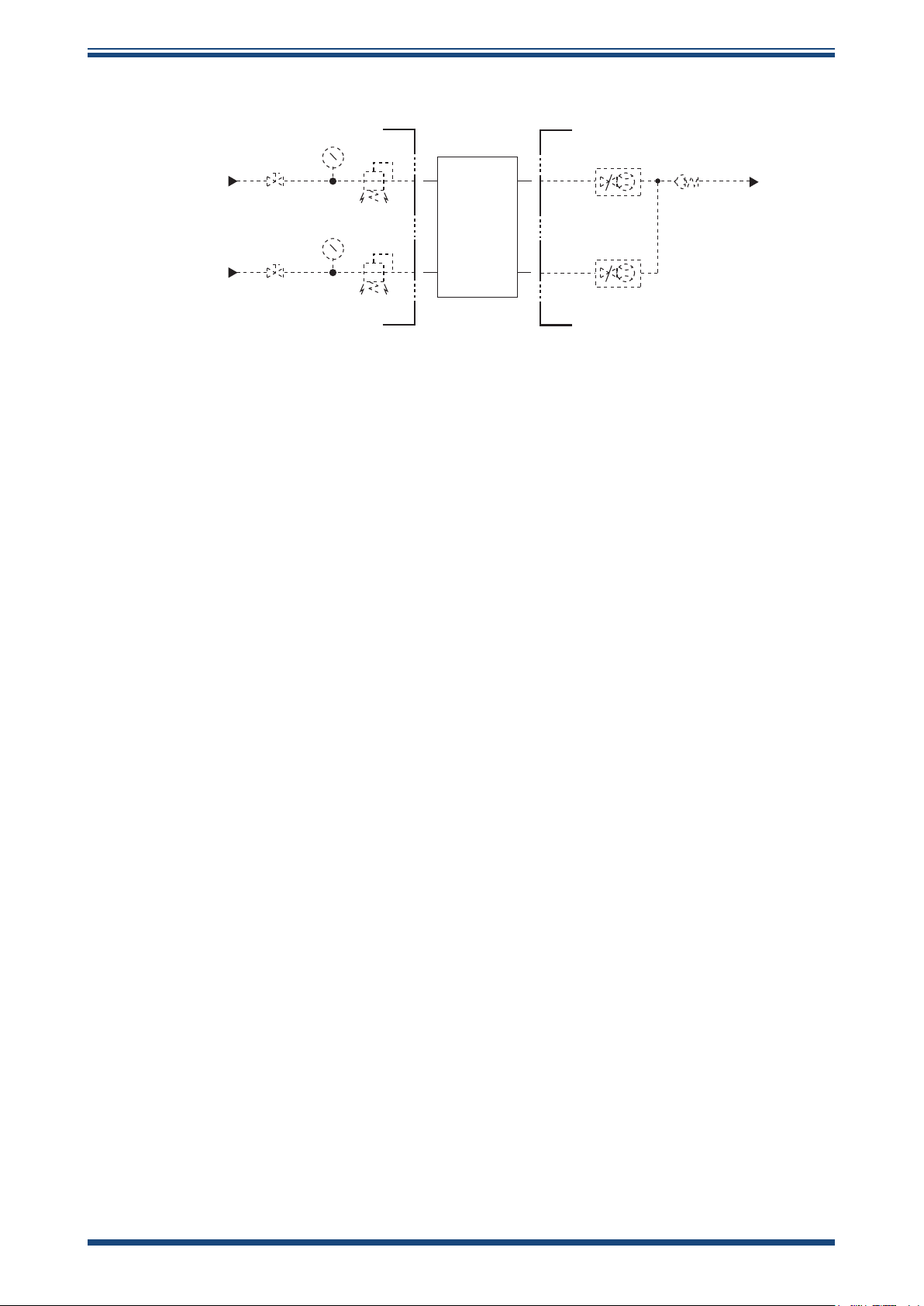

2.5.3 Analog and Digital Communications

Two active 4-20 mA outputs and a Modbus RS485 digital interface (see Appendix F for

details) are provided with the Promet EExd. mA1 and mA3 output the moisture values.

mA2 and mA4 output the pressure values of Channels 1 & 2 respectively.

NOTE: The maximum output resistance for the 4-20 mA outputs is 500Ω.

See Section 3.7 for setting the 4-20 mA outputs via the user interface and Appendix F

for setting the outputs via the Modbus interface.

Refer to Figure 6 for cable wiring.

2.5.4 Process Alarms and Analyzer Status Alarms

Promet EExd User’s Manual

Each channel has an associated process and fault alarm, as shown below:

AL1: Channel 1 process alarm

AL2: Channel 1 fault alarm

AL3: Channel 2 process alarm

AL4: Channel 2 fault alarm

Each alarm relay features Normally Open (N/O), Normally Closed (N/C) and Common

(C) contacts.

The process alarm contacts change state when the moisture value is greater than the

alarm set point.

The fault alarm contacts change state when an error associated with the channel occurs,

or when there is a supply failure.

14 97090 Issue 16, April 2019

Page 23

Promet EExd User’s Manual

2.6 Promet EExd Start-Up Purge Procedure

This is a mandatory procedure stipulated in the ATEX/

IECEx certification of the product. The procedure must be

fully carried out prior to the Promet EExd having any power

or signal connections applied. It must also be fully carried

out after the Promet EExd and associated gas handling

equipment has been installed and leak checked. Always

refer to Appendix G.4 - Special Conditions of Safe Use.

This procedure must be carried out at any time following

service or maintenance periods that cause any of the Promet

EExd or associated gas handling equipment pipe work to be

disconnected.

INSTALLATION

It is not necessary to carry out this procedure if power or

signal connections only have been disconnected.

1. Before start-up, ensure that all power and signal connections to the

Promet EExd are fully isolated

2. Ensure that all Inlet & Outlet gas connections to the Promet EExd are

made correctly and are leak tight checked.

3. Fully open the flow control valve of the flow meter of each channel.

4. Fully open the sample gas inlet isolation valves.

5. Adjust open the pressure regulators until full scale flow is observed on

each of the water dew-point channels.

6. Allow the sample gas to purge the system for the period of time indicated

in the table below:

TOTAL PURGE TIME

must be a minimum of 1 minute at 1 Nl/min (2.1 scfh)

Assumes total system pipe length is 3m (9.8’) and internal pipe bore is

the recommended 4mm (0.16”) internal bore.

For every additional 1m (3.3’) of pipe work, continue the Gas Purge for

an additional 15 seconds at 1 Nl/min (2.1 scfh).

7. After the appropriate purge duration, close the gas inlet isolation valve.

8. Ensure the window is replaced and fully secured before applying the

power.

Michell Instruments 15

Page 24

INSTALLATION

Promet EExd User’s Manual

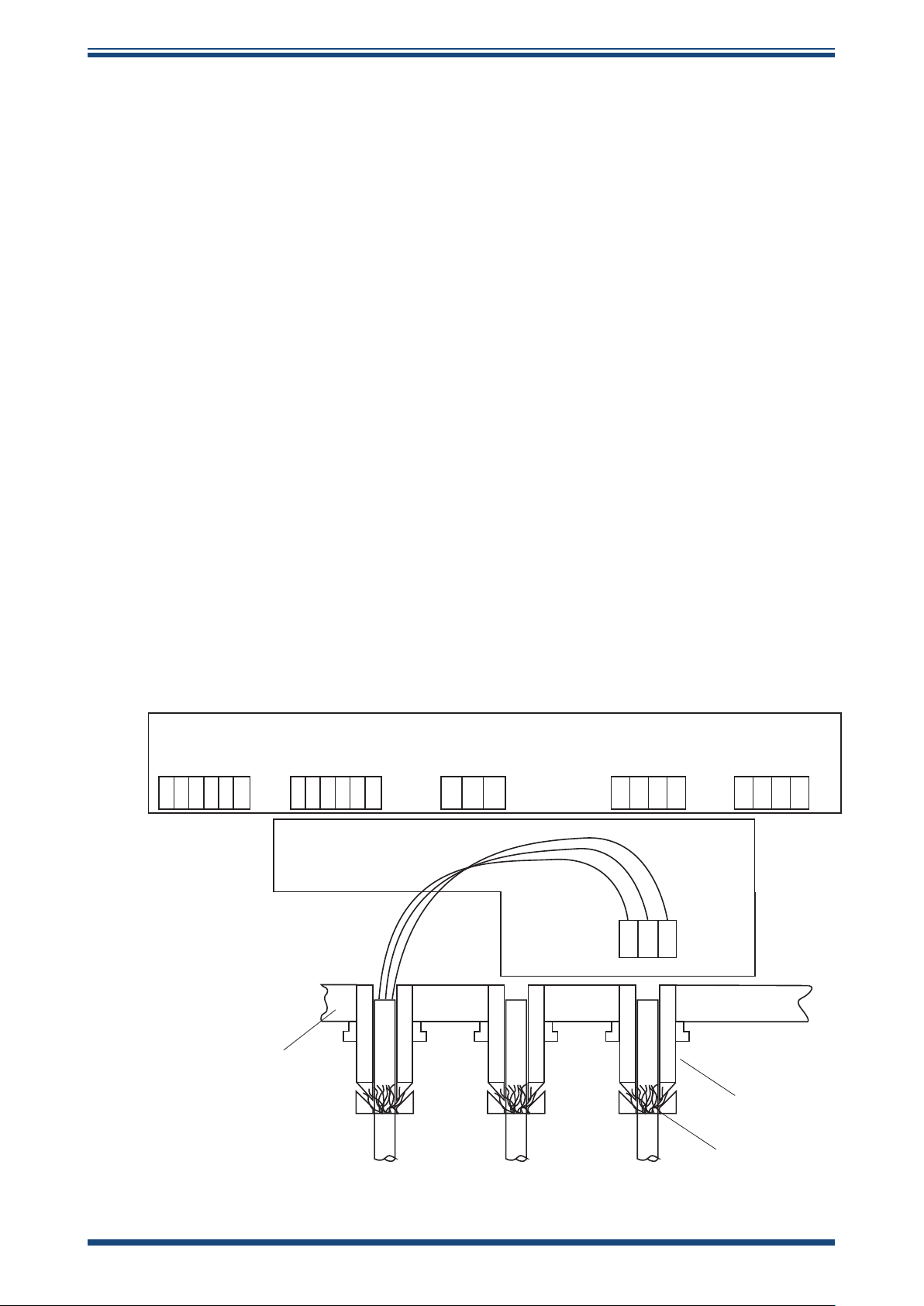

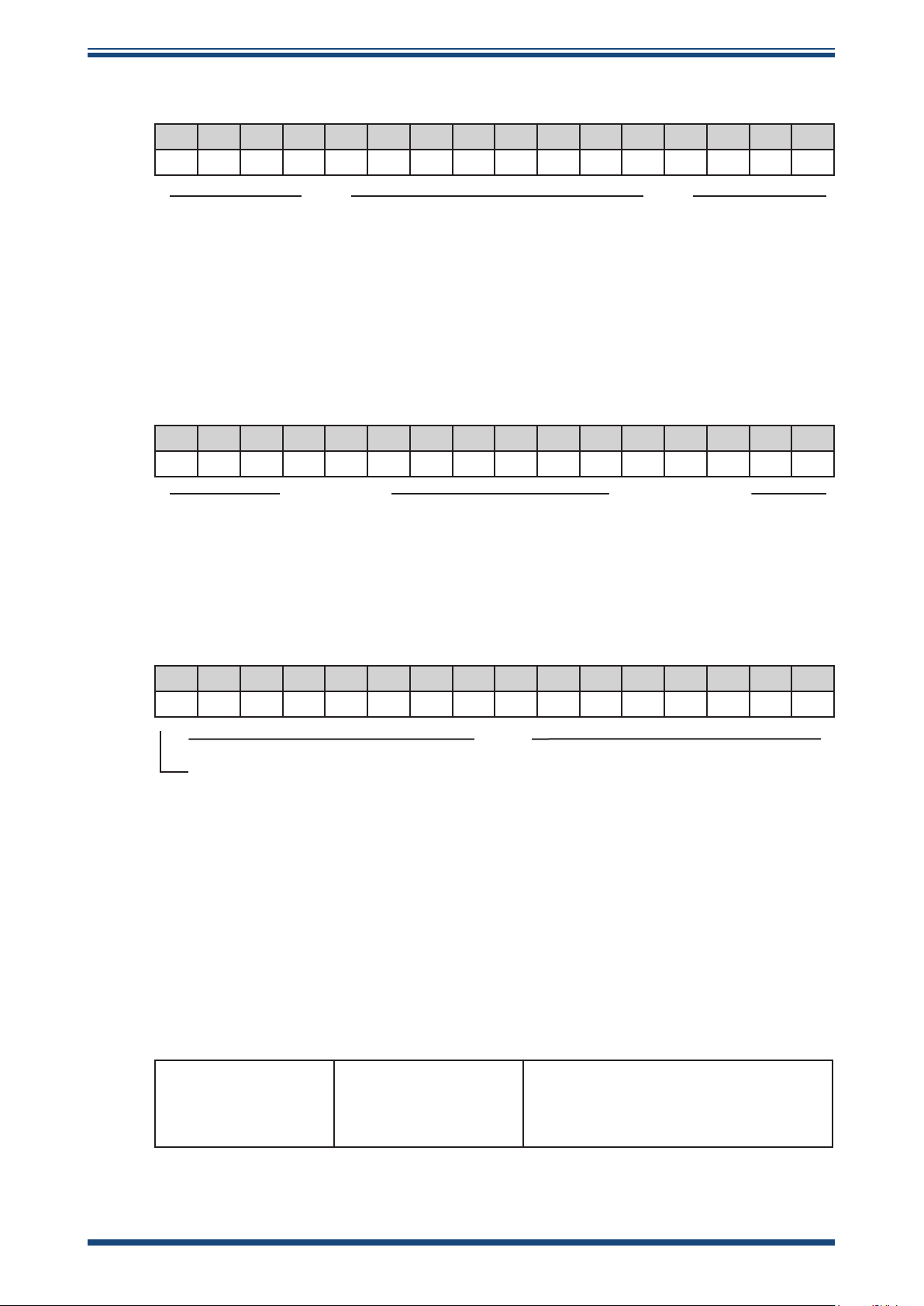

MINIMUM REQUIREMENTS FOR START UP PURGING

PRESSURE

GAS INLET

GAS INLET

GAS INLET

ISOLATION VALVE

GAS INLET

ISOLATION VALVE

NOTE:

CONNECTING PIPEWORK TO BE 4mm I/D BORE, 316L STAINLESS STEEL TUBE

PRESSURE

Figure 7

2.7 Sample Gas Flows

The flow through each channel should be set at approximately 2 Nl/min (4.2 scfh). This

flow setting figure is not required to be precise. Its purpose is only to ensure that a

representative sample of gas is presented to the measurement sensor.

GAUGE

GAUGE

PRESSURE

REGULATOR

PRESSURE

REGULATOR

WATER DEW-POINT

CHANNEL-1

GAS IN GAS OUT

PROMET EExd

GAS IN GAS OUT

WATER DEW-POINT

CHANNEL-2

FLOWMETER

FLOWMETER

Minimum Requirements for Start-up Purging

NON-RETURN

VALVE

GAS OUTLET

To increase the speed of response of the measurement of the main process gas it is

highly recommended that a fast bypass loop be installed into the gas sampling system.

The recommended flow through the bypass loop should be approximately 3 times that

of the measurement channel. Therefore, typically, the bypass gas flow should be set to

approximately 6 Nl/min (12.7 scfh).

2.8 Sample Flow Alarms (Optional)

The optional flow switches are supplied to alert the user to either severely reduced

or discontinuation of the sample gas flow through the system. An alarm state will be

indicated on the error message line at the bottom of the MAIN Page. See Section 4.4 on

troubleshooting for further details.

When the flow of sample gas is set correctly, the alarm states will be indicated when

the gas flows have lowered into a range deemed unsuitable for effective measurements

to be made.

The flow switches are adjusted during factory test to activate the alarm when the

flow falls below approximately 10 to 20% of the normal recommended sample flow

setting (see Section 2.7). During the factory setting procedure the gas pressure that

is applied represents the most common application analysis conditions for water dewpoint sensors {68 barg (986 psig)}. The operation of these variable area flow switches

are influenced by pressure. For increased pressure the flow alarm activation point will

be at a higher flow rate and conversely, for reduced pressure, the activation point will

be at a lower rate. These devices exhibit a hysteresis that may require a flow of greater

than 100% of the recommended flow setting for a brief period in order to clear the

alarm condition.

NOTE: If the Promet EExd is going to be operating with significantly different

analysis pressures to those used during factory testing then fine re-adjustment

of the flow switches may be beneficial to suit the application conditions. If

this is the case, contact Michell Instruments (www.michell.com) for guidance

on how adjustments can be made on site.

16 97090 Issue 16, April 2019

Page 25

Promet EExd User’s Manual

3 OPERATION

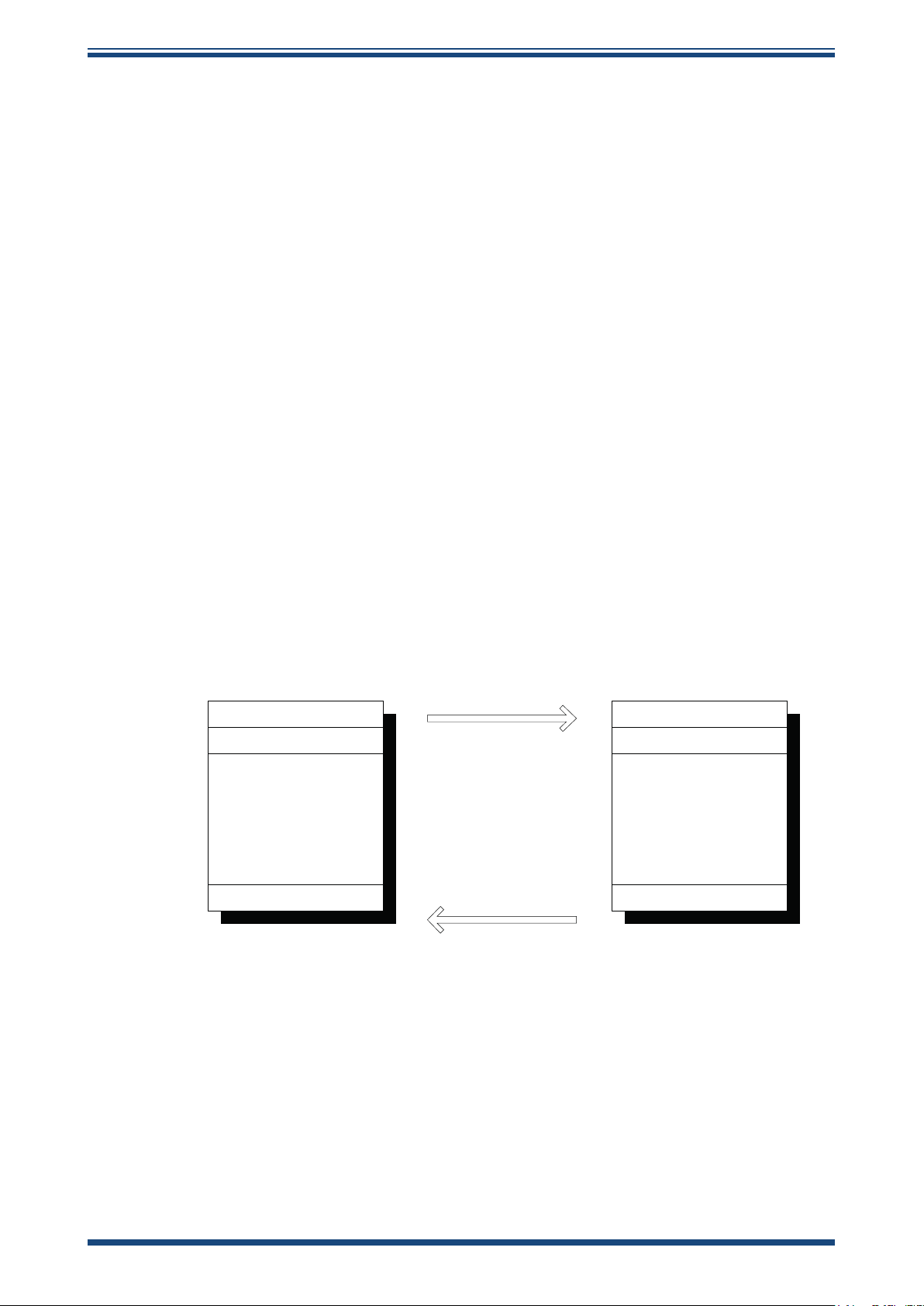

3.1 System Operation

At switch-on, the instrument will display the MAIN Page. It will synchronise itself to

the on-board real time clock, in order to begin logging data at the next minute that is

a multiple of 5 i.e. 5, 10, 15 etc. The MAIN Page will show the moisture and pressure

readings of either 1 or 2 sensors and a countdown to the time when it will take the

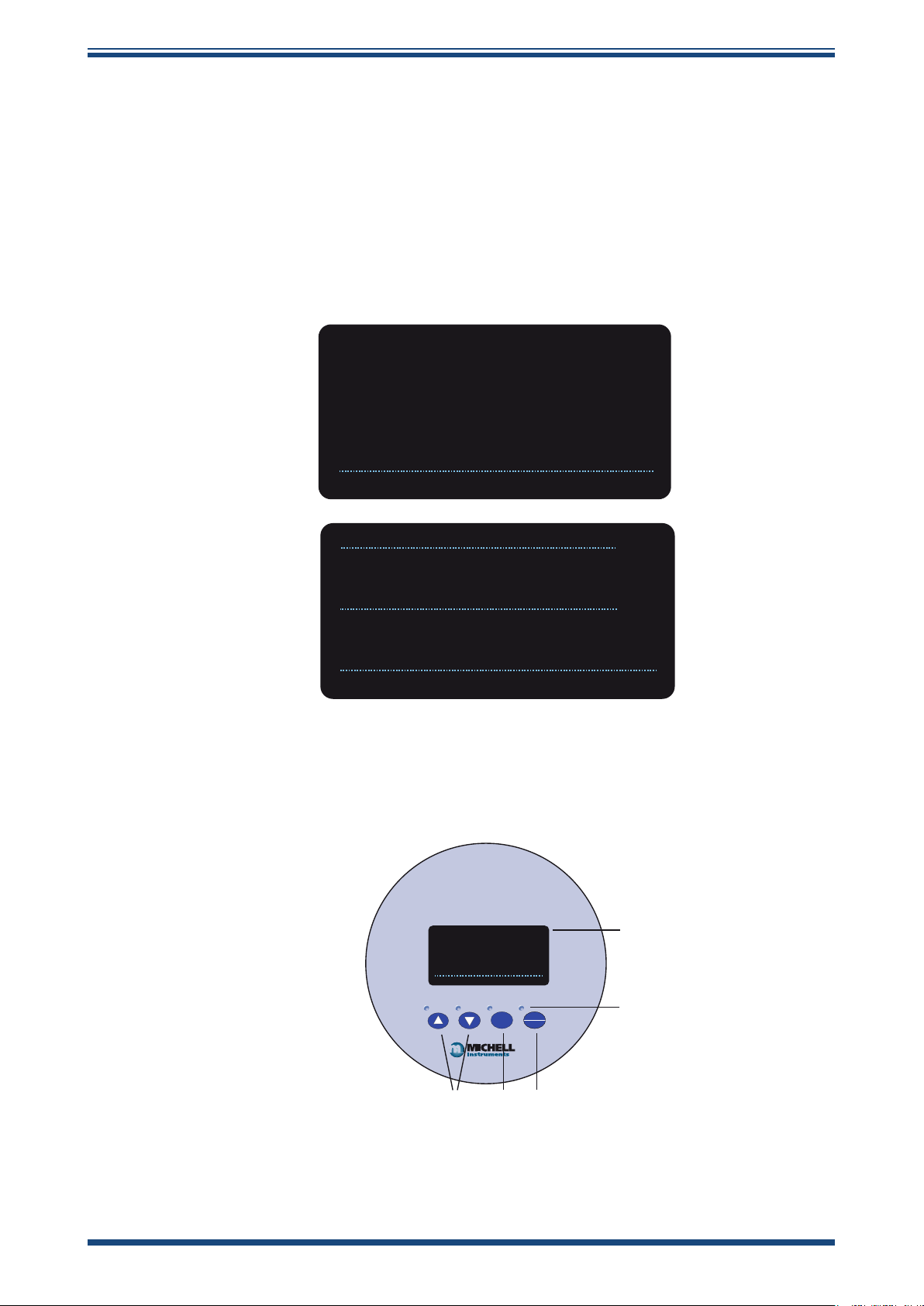

next data log. Figure 9 shows the MAIN Page for both 1 and 2 sensor configurations.

Pressing the MENU/MAIN button from this page will take you to the MAIN MENU Page

(see Section 3.4).

MOISTURE

OPERATION

Figure 8

3.2 User Interface

3.2.1 Interface Controls

16.2

0

Cdp

PRESSURE

0.4

TIME TO NEXT DATA LOG: 7m 45s

barg

CH 1

0.0 0Cdp

0 psig

CH 2

-80.0

0

Cdp

0 psig

TIME TO NEXT DATA LOG: 7m 45s

MAIN Page in Single Channel (top) and Dual Channel Modes

Promet EExd

Process Moisture Analyzer

MOISTURE

16.2

PRESSURE

0.4

TIME TO NEXT DATA LOG: 7m 45s

Up/Down

Buttons

Figure 9

Arrow

0

Cdp

barg

MENU

SELECT

MAIN

SELECT

MENU/

Button

MAIN

Button

User Interface

VFD Display

Blue LEDs

Figure 10 illustrates the user interface. It has a vacuum fluorescent display and four

touch sensitive pads that facilitate user interaction through the glass of the enclosure.

Michell Instruments 17

Page 26

OPERATION

3.2.2 ‘Up/Down Arrow’ Buttons

Promet EExd User’s Manual

The Up () and Down () buttons are used to change pages, scroll through lists and

adjust values.

3.2.3 ‘SELECT’ Button

The SELECT button is used to select or de-select a highlighted item in a menu list.

Figure 10

Figure 11

Up/Down Arrow Buttons

SELECT

‘SELECT’ Button

3.2.4 ‘MENU/MAIN’ Button

The MENU/MAIN button is used to toggle between the MAIN Page and the MAIN MENU

Page, or return to the MAIN Page from any location within the menu structure.

Figure 12

MENU

MAIN

‘MENU/MAIN’ Button

18 97090 Issue 16, April 2019

Page 27

Promet EExd User’s Manual

3.3 Menu Structure

Figure 14 shows a map of the menu structure.

KEY

Choices

Menu Pages

Other Pages

NO

Main Menu

Status Page

SELECT

Error ?

YES

Error Report

Page

SELECT

SELECT

STATUS

View

Logged

Data

SELECT

LOGGING

MENU

View

Statistics

SELECT

Page

1

Page

2

SELECT

View

System

Faults

SELECT

Logged

Error Codes

Start-Up

Banner

Main Page

MENU

MAIN

VIEW/ADJ

VARIABLES

SELECT

Password

Page

NO

SELECT

Password

Correct?

YES

SENSOR

INFO

SELECT

WDP Sensor

OPERATION

MENU

MAIN

Press MENU/MAIN button to

get back to Main Page from

any location

MENU

MAIN

CONTACT

INFO

SELECT

Info

Contact/About

Logged Pages

Figure 13

Page

1

Page

2

Page

3

Variables Pages

Menu Structure

Use Up/Down arrow buttons

to scroll through

menu items and pages

Michell Instruments 19

Page 28

OPERATION

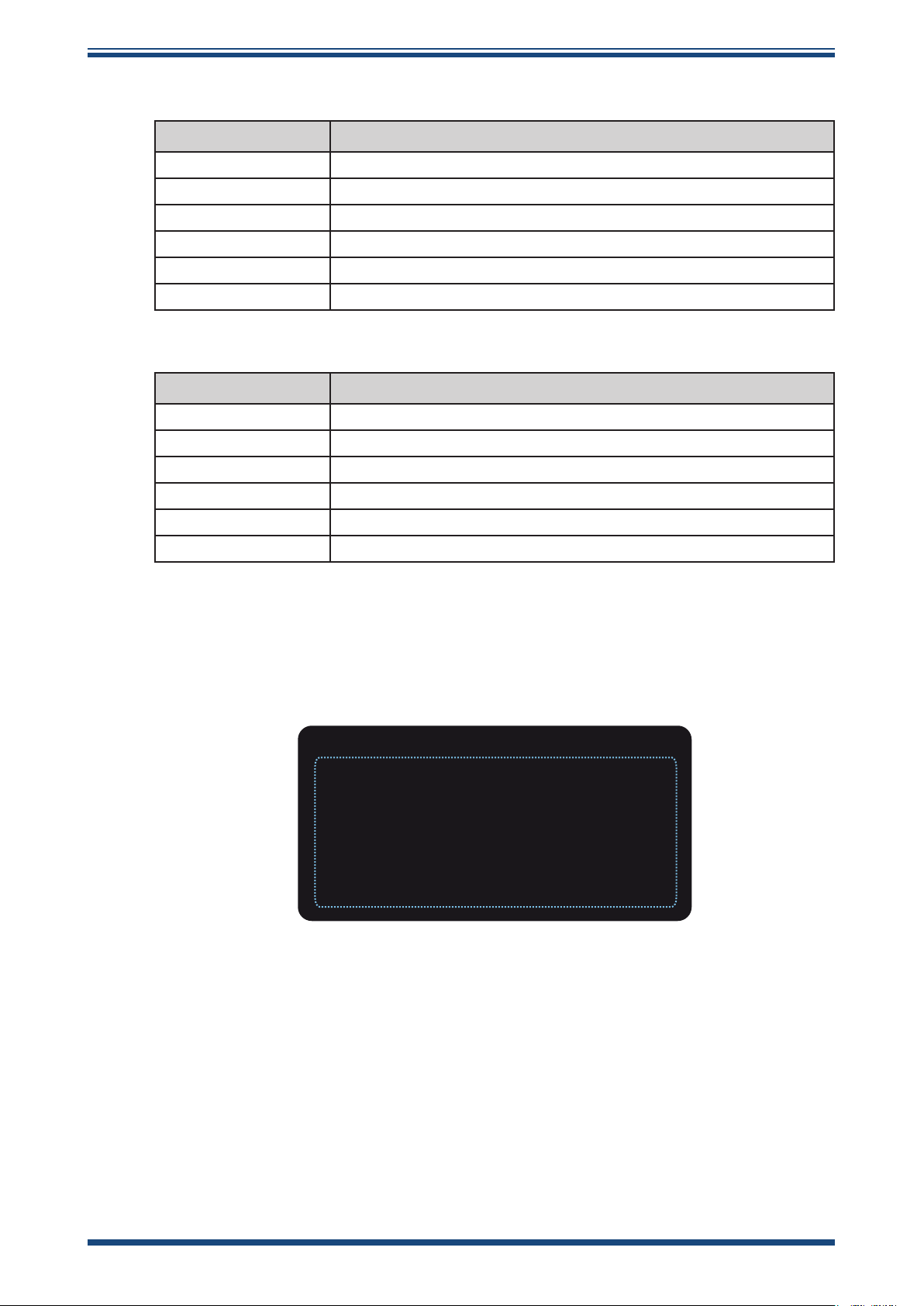

3.4 MAIN MENU Page

This page is accessed by pressing the MAIN/MENU button from the MAIN Page. The

instrument’s status, variables, logged data and system information are available through

this page. Use the Up () and Down () buttons to highlight the page of interest and

press the SELECT button to access.

Promet EExd User’s Manual

MENU

STATUS

LOGGING MENU

VIEW/ADJ VARIABLES

SENSOR INFO

CONTACT INFO

3.5 STATUS Page

This page shows the status of the process alarm and flow for one or both channels,

depending upon the configuration. When the measured moisture value rises above the

alarm set-point, the moisture alarm condition will be displayed as ON*ALERT*. No flow

is displayed as OFF*ALERT*.

Figure 14

MAIN MENU Page

STATUS PAGE

ALARM CONDITIONS

CHANNEL 1 MOI :ON

CHANNEL 1 FLOW :ON

TIME TO NEXT DATA LOG: 2m 11s

Figure 15

STATUS Page

XALERTX

Press the MAIN/MENU button to return to the MAIN Page.

20 97090 Issue 16, April 2019

Page 29

Promet EExd User’s Manual

3.6 LOGGING MENU Page

This page allows the viewing of data or statistical information on the logged data. Press

the SELECT button to see the following options:

View Logged Data

View Statistics

View System Faults

Press the Up () and Down () buttons and the SELECT button to enter these options

pages.

If there is no data available then No Data Available will be displayed and no access will

be given to the other two options.

3.6.1 VIEW LOGGED DATA Page

OPERATION

This page allows access to the previous measurement results made by the instrument.

A rolling total of a maximum of 150 samples can be logged, which represents a

measurement history of 150 x (measurement time) in minutes. Sample 1 represents

the most recent measurement taken. After 150 measurements have been logged, the

oldest measurement will be deleted and replaced as each new measurement is logged.

Caution: Changing the moisture value, e.g. from dew point to ppm, will result

in the loss of all logged data.

Access to each measurement sample is via the Up () and Down () buttons, which

may be used to scroll through each page of information. If faster scrolling is required

(to quickly move to another sample) press the SELECT button and the sample number

will increase by 10. When the sample number selected is greater than that acquired, or

is greater than 150, Sample 1 will be selected and displayed.

Sample Number Time of Sample

Date (day/month)

LOGGED DATA

NO. 1 10:20 29/06

MOI 6.2 oCdp

PRES 0.2 barg

Figure 16

Michell Instruments 21

LOGGED DATA Page

Page 30

OPERATION

Each page of logged data contains:

• Sample number 1 to 150, 1 being the most recent

• Date of sample dd/mm

• Time of sample 24 hr format, hh:mm

• The values of Moisture content/Dew point and Pressure

• The units of measurement

Press the MAIN/MENU button to return to the MAIN Page.

3.6.2 VIEW STATISTICS Page

These pages display the maximum, minimum and average values for each measured

parameter for up to 150 previous measurement samples. RESET LOG on the MAIN

MENU Page re-sets the logging statistics.

Promet EExd User’s Manual

for 1 or 2 channels

STATISTICS PAGE 1/2

MOI MAX 0.6

o

C

at 08:00 on 02/03

o

MOI MIN 0.6

C

at 08:00 on 02/03

MOI AVR 0.6

Figure 17

Use the Up () and Down () buttons to scroll through the statistics.

Press the MAIN/MENU button to return to the MAIN Page.

STATISTICS Page

o

C

22 97090 Issue 16, April 2019

Page 31

Promet EExd User’s Manual

3.6.3 VIEW SYSTEM FAULTS Page

This page displays a record of the last six system faults that have occurred and have

subsequently been corrected. This assists in the diagnosis of any past anomaly in

measured values. Any present system faults will be displayed in the bottom message

line of the MAIN Page.

LOGGED ERROR CODES

CODE TIME & DATE

0008 11:10 02/08/12

OPERATION

Figure 18

Refer to Section 4.4 for descriptions of the error messages and codes.

Press the MAIN/MENU button to return to the MAIN Page.

3.7 VIEW/ADJ VARIABLES Page

For more information on each variable refer to Appendix B.

3.7.1 Password

To safeguard against unauthorized adjustment of set-up parameters and variables, an

entry lock is provided.

The user must first input the access code to enter the VIEW/ADJ VARIABLES Pages.

The password is: 7316

LOGGED ERROR Page

ENTER PASSWORD

USE ARROW KEYS AND

SELECT KEY

0 0 0 0

Figure 19

Use the Up () and Down () buttons to change the highlighted digit and press the

SELECT button to enter and move to the next digit. Inputting 4 correct digits will result

in access to the VARIABLES Pages as detailed in the following sections.

Michell Instruments 23

PASSWORD Page

Page 32

OPERATION

20

3.7.2 VARIABLES Pages

Three pages (four pages in the dual channel configuration) are used to display the

system variables. They can be adjusted by using the Up (), Down () and SELECT

buttons.

Use the Up () and Down () buttons to scroll through the list and from page to page.

To select a variable for adjustment, scroll to the desired variable and press the SELECT

button. A small box will appear beside the value to indicate that it can be adjusted. Use

the Up () and Down () buttons to change the value. NOTE: Numerical values

can be changed at a faster rate by extending the duration of the Up () and

Down () button press.

VARIABLES PAGE 1/3

UNITS

apply

alarm

OP1 MIN

Dew Point

n/a

0

-100

OP1 MAX

OP2 MIN

0 barg

Promet EExd User’s Manual

o

C

o

C

o

C

Figure 20

3.7.3 Single Channel Configuration VARIABLES Pages

For more information on each variable refer to Appendix B

VARIABLES Page 1

Variable Brief Description

UNITS

apply

alarm

OP1min

OP1max

OP2min

Moisture measurement

Used for calculating dew point at an applied pressure for ideal or

natural gas

Moisture value that trips the process alarm

Moisture value that gives 4 mA on mA1 output

Moisture value that gives 20 mA on mA1 output

Dew-point or Pressure value that gives 4 mA on mA2 output

VARIABLES Page

24 97090 Issue 16, April 2019

Page 33

Promet EExd User’s Manual

VARIABLES Page 2

Variable Brief Description

OPERATION

OP2max

°C/°F

Pressure

TIME

DATE

OP2/4 PARAM

VARIABLES Page 3

Variable Brief Description

LOG INT’VAL

RESET LOG

INST ADDR

INT TEMP SP

SET DEFAULT

3.7.4 Dual Channel Configuration VARIABLES Pages

Dew-point or Pressure value that gives 20 mA on mA2 output

Temperature units selection

Pressure units selection

System time

System date

Adjustable range/options: Measured Dew point, Pressure

Time interval between data logs

Clears the logged data

Sets the instrument address

Set-point temperature of the internal heater

Sets the system defaults

For more information on each variable refer to Appendix B

VARIABLES Page 1

Variable Brief Description

CHN1

apply

alarm

CHN2

apply

alarm

VARIABLES Page 2

Variable Brief Description

OP1min

OP1max

OP2min

OP2max

OP3min

OP3max

Moisture measurement for Channel 1

Used for calculating dew point at an applied pressure for ideal or

natural gas

Moisture value that trips the process alarm for Channel 1

Moisture measurement for Channel 2

Used for calculating dew point at an applied pressure for ideal or

natural gas

Moisture value that trips the process alarm for Channel 2

Moisture value that gives 4 mA on mA1 output

Moisture value that gives 20 mA on mA1 output

Dew-point or Pressure value that gives 4 mA on mA2 output

Dew-point or Pressure value that gives 20 mA on mA2 output

Moisture value that gives 4 mA on mA3 output

Moisture value that gives 20 mA on mA3 output

Michell Instruments 25

Page 34

OPERATION

VARIABLES Page 3

Promet EExd User’s Manual

Variable Brief Description

OP4min

OP4max

°C/°F

Pressure

TIME

DATE

VARIABLES Page 4

Variable Brief Description

OP2/4 PARAM

SET DEFAULT

LOG INT’VAL

RESET LOG

INST ADDR

INT TEMP SP

Dew-point or Pressure value that gives 4 mA on mA4 output

Dew-point or Pressure value that gives 20 mA on mA4 output

Temperature units selection

Pressure units selection

System time

System date

Adjustable range/options: Measured Dew point, Pressure

Set the system defaults

Time interval between data logs

Clears the logged data

Sets the instrument address

Set-point temperature of the internal heater

3.8 SENSOR INFO Page

This page contains the information relating to the water dew-point sensors.

Hours Used Duration that the sensor has been in active use

Next Cal Next recommended calibration date of sensor

Sensor S/N Serial number of sensor

SENSOR INFO

HOURS USED 00006

NEXT CAL 11/2012

SENSOR S/N FD79-0430

Figure 21

SENSOR INFO Page

26 97090 Issue 16, April 2019

Page 35

Promet EExd User’s Manual

3.9 CONTACT INFO Page

This page contains contact information for Michell Instruments.

MICHELL INSTRUMENTS

WEB:

WWW.MICHELL-INSTRUMENTS.COM

E-MAIL:

INFO@MICHELL-INSTRUMENTS.COM

OPERATION

CONTACT INFO

Figure 22

CONTACT INFO Page

Michell Instruments 27

Page 36

MAINTENANCE

4 MAINTENANCE

Promet EExd User’s Manual

The power to the enclosure must be

turned off before any work is carried out

in the measurement system enclosure.

Observe de-energize durations.

Gas line connections to the measurement

system must be isolated and de-pressurized

before any work commences.

Before powering up the instrument

the “Start-Up Purge Procedure” must

be carried out. See Section 2.6.

To ensure the full requirement of this product’s safety

certificate is maintained, any loosened or disturbed

tubework or couplings must be subject to a gas

pressure test and appropriate leak check at 1.5x the

max operating pressure before the full product is re-

energized.

The design of the Promet EExd sensor cell and measurement system is such that no

specific routine maintenance is required. If, however, a fault does occur with your

system that is not covered within this manual please contact Michell Instruments (www.

michell.com) or your local representative.

4.1 Enclosure Cover and User Interface

The enclosure cover is part of the flameproof protection for the enclosure and has an

IP66 rating. It should be firmly closed to ensure flameproof integrity and continued

environmental protection. For prolonged and easy operation ensure that the threads

are always lubricated with a light grease. A grub screw is used as a locking device. This

should be loosened before unscrewing the cover counter-clockwise.

The user interface assembly uses two ¼ turn bayonet style fasteners to secure it. These

are finger operated and should be turned clockwise to lock and counter-clockwise to

release. The user interface, once disconnected from the two ¼ turn fasteners, can

be temporarily re-positioned on the instrument by securing the right-hand fastener

in the left-hand mount. This will situate the interface assembly in an overhanging

position outside of the enclosure allowing greater access. If there is insufficient space

to accommodate the overhanging user interface assembly on the left-hand side, it may

be rotated 180° (upside down) and placed on the right-hand side.

28 97090 Issue 16, April 2019

Page 37

Promet EExd User’s Manual

Promet EExd

Process Moisture Analyzer

MAINTENANCE

Figure 23

Ribbon Cable Connection

Always keep the bayonet fittings lightly lubricated. If required, the user interface can

be fully disconnected from the instrument by disconnecting the ribbon cable connection

to the main processor PCB.

All of the procedures below can only be carried out by

first unscrewing the enclosure glass cover and removing

the user interface assembly.

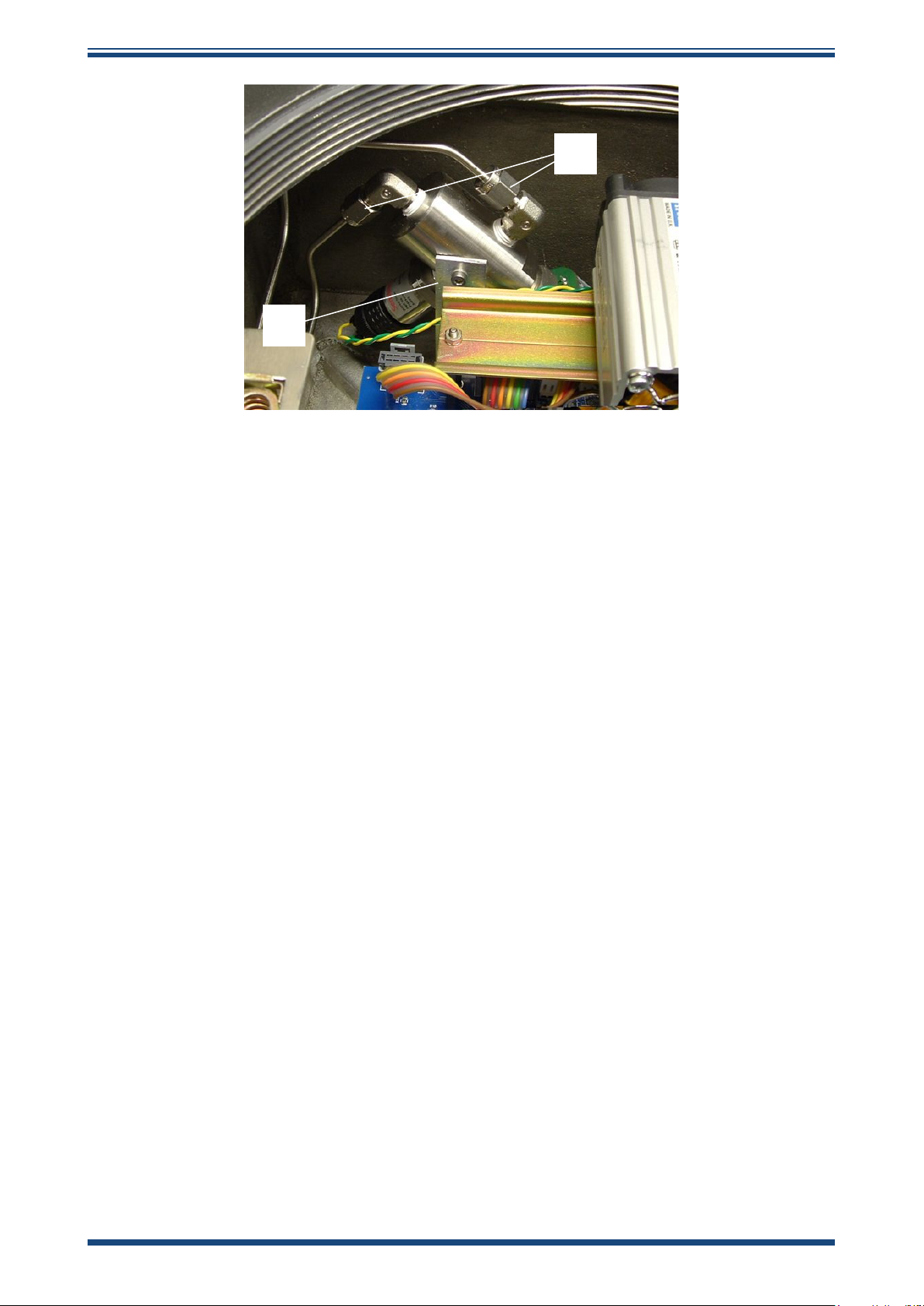

4.2 Replacement of the Moisture Sensor Assembly

The power to the enclosure must be turned off before

any work is carried out in the measurement system

enclosure. Observe de-energize durations.

1. Isolate the incoming sample gas line by CLOSING the sample inlet

isolation valve and allow the system to depressurize. Isolate the power

and observe the de-energize duration.

2. Remove the enclosure window and mount the user interface (see

Section 4.1).

3. Using a 2.5mm hex key remove the M3 cap head screw (1 in Figure 25)

securing the water sensor assembly to the stay bracket.

4. Restrain the sensor assembly. Use a 11mm spanner to loosen and

remove the 2 off 1/8” water dew-point sensor sample pipe connections

(2 in Figure 25).

Michell Instruments 29

Page 38

MAINTENANCE

Promet EExd User’s Manual

2

1

Figure 24

5. Carefully pull the sensor block assembly out of the enclosure. This will

allow access to the two sensor connections and the pressure transducer

connection.

6. Disconnect the ribbon cable connectors from the sensor pcb.

7. Unscrew the connector from the pressure transducer and fully remove

the moisture sensor assembly from the enclosure.

8. Reconnect the sensor and pressure transducer connections to the

replacement moisture sensor assembly. Reposition the assembly on the

stay bracket and secure with the M3 cap head screw.

9. Refit and fully tighten the 1/8” water dew-point sensor sample pipe

connections.

10. To ensure the full requirement of this product’s safety certificate is

maintained, any loosened or disturbed tubework or couplings must be

subject to a gas pressure test and appropriate leak check at 1.5x the

max operating pressure before the full product is re-energized.

Moisture Sensor Assembly Replacement

30 97090 Issue 16, April 2019

Page 39

Promet EExd User’s Manual

4.3 Replacement of the Flow Switch (if fitted)

The power to the enclosure must be turned off before any

work is carried out in the measurement system enclosure.

Observe de-energize durations.

1. Isolate the incoming sample gas line by CLOSING the sample inlet

isolation valve and allow the system to depressurize. NOTE: Always

refer to Appendix G.4 - Special Conditions of Safe Use.

2. Remove the enclosure window and mount the user interface as shown

in Section 4.1.

3. Restrain the flow switch assembly using an 11mm spanner to loosen

and remove the 2 off 1/8” sample pipe connections.

MAINTENANCE

4. Disconnect the 2-wire cable connector from the flow switch to the main

circuit board.

5. Carefully pull the flow switch assembly out of the enclosure.

6. Replacement of the flow switch is simply a reversal of the above

procedure.

7. To ensure the full requirement of this product’s safety certificate is

maintained, any loosened or disturbed tubework or couplings must be

subject to a gas pressure test and appropriate leak check at 1.5x the

max operating pressure before the full product is re-energized.

Michell Instruments 31

Page 40

MAINTENANCE

4.4 Troubleshooting

4.4.1 Error Messages

If a system errors occurs, an error message will appear at the bottom line of the MAIN

Page describing the problem. If more than one system error has occurred, the error

messages associated with those faults will continually scroll in turn.

Promet EExd User’s Manual

MOISTURE

0.5

PRESSURE

0

NO FLOW

Error Message Description and Possible Cause

oCdp

psig

Figure 25

MOISTURE UNDER RANGE

MOISTURE OVER RANGE

TEMPERATURE ERROR

NO FLOW

PRESSURE TRANSMITTER FAILURE

CAL TABLE ERROR

LBMMSCF OUT OF RANGE

INTERNAL HEATER FAULT

Error Message Line

Sensor tile failure

Sensor tile failure

Temperature sensing device of the moisture

sensor has failed

No gas ow through sensor measurement cell see Section 2.7

No pressure detected in the sensor measurement

cell

Fault with sensor calibration data

Calculation of moisture in natural gas cannot be

calculated due to invalid inputs

Fault with the internal temperature control

32 97090 Issue 16, April 2019

Page 41

Promet EExd User’s Manual

4.4.2 Logged Error Codes

This page displays a record of the last six system error codes that have occurred in

order to assist in the diagnosis of any past anomalies. Error codes are only logged at the

end of every measurement cycle and indicate a change in status of single or multiple

errors. For example, if an error code 0004 was logged this would indicate CHANNEL 1

TEMPERATURE ERROR. If an error code of 0000 was next logged this would indicate

that the error had now cleared.

LOGGED ERROR CODES

CODE TIME & DATE

0008 11:10 02/08/12

MAINTENANCE

Figure 26

Logged Error Codes and Error Indication (Modbus Register 35)

Also see Appendix G, Register Configuration C for more details

Error Code Error Message

0000 All previous errors now cleared

0001 Channel 1 moisture sensor under range

0002 Channel 1 moisture sensor over range

0004 Channel 1 temperature device fault

0008 Channel 1 no ow

0010 Channel 1 pressure transmitter failure

0020 Channel 1 LBMMSCF calculation error

0040 Not used

0080 Channel 2 moisture sensor under range

0100 Channel 2 moisture sensor over range

0200 Channel 2 temperature device fault

0400 Channel 2 no ow

0800 Channel 2 pressure transmitter failure

1000 Channel 2 LBMMSCF calculation error

2000 Not used

4000 Internal heater fault

The 4 digit error codes are hexadecimal numbers that are dependent upon the bits set

within the error indication register.

Logged Error Codes

Michell Instruments 33

Page 42

MAINTENANCE

If more than one error has occurred, then the error codes will be added together, e.g.

1) Error Code 0104 =

Error Code 0100 (Channel 2 sensor over range) plus

Error Code 0004 ( Channel 1 temperature device fault) (0100 + 0004 = 0104)

2) Error Code 0C00 =

Error Code 0800 (Channel 2 pressure transmitter fault) plus

Error Code 0040 (Channel 2 no flow ) (0800 + 0400 = 0C00)

Note : In hexadecimal

A = 10

B = 11

C = 12

D = 13

E = 14

F = 15

Promet EExd User’s Manual

4.4.3 Analyzer Status Alarm Relay

Each alarm relay features Normally Open (N/O), Normally Closed (N/C) and Common

(C) contacts.

The process alarm contacts change state when the moisture value is greater than the

alarm set point.

The fault alarm contacts change state when an error associated with the channel occurs,

or when there is a supply failure.

34 97090 Issue 16, April 2019

Page 43

Promet EExd User’s Manual

APPENDIX A

Appendix A

Technical Specifications

Michell Instruments 35

Page 44

APPENDIX A

Appendix A Technical Specications

Main Unit – Measurement Parameters

Channel Conguration Single and dual channel

Moisture Parameters Dew point °C and °F / Pressure

Automatic pressure compensated conversions:

ppmV for natural gas and ideal gas

Moisture Content

Analysis Pressure barg, MPa and psig

Sensor Technology

Sensor Technology Michell Ceramic Moisture Sensor

Measurement Range

Calibration Range

Accuracy

Measured Resolution

Displayed Resolution

Temperature Coecient Algorithm compensation

lb/MMscf and mg/m3 for natural gas

dew point at a pressure input by the user for natural gas & ideal gas

Calculations for natural gas moisture content based on either IS0

18453 or IGT#8 to customer order preference

-120 to +30°Cdp (-184 to +86°Fdp)

1 ppbV to 30,000 ppm

0 to 250 barg (0 to 3625 psig)

-100 to +20°Cdp (-148 to +68°Fdp)

10 ppbV to 23,000 ppm

Dew point: ±1°C between –59.9 & +20°Cdp

(±1.8°F between -75.9 to +68°Fdp)

Moisture content: ±10% of reading

Dew point: ±2°C between –60 & -100°Cdp

(±3.6°F between -76 to -148°Fdp)

Moisture content: ±20% of reading

Analysis Pressure: ±0.25% FS

0.1°C: -80 to +20°Cdp (0.2°F: -112 to +68°Fdp)

1°C: -100 to -80°Cdp (2°F: -148 to -112°Fdp)

Dew point: 0.1°C (0.2°F)

Moisture content: autoscale, 5 digits

MPa and barg: 0.1 (1 psig)

V

V

Promet EExd User’s Manual

HMI

Keyboard/Interface Capacitive touch-screen through glass