Page 1

Chilled Mirror Instruments

Optidew

Chilled Mirror Hygrometer

The Optidew is a fast-responding chilled mirror hygrometer, equally at home in both industrial

humidity control and precision laboratory applications. It is available in bench top and wall mount

confi gurations, and features an intuitive touch screen interface for easy local operation. Using the

latest developments in chilled mirror technology, it has a response speed comparable to polymer

relative humidity sensors, combined with the reliability of drift-free measurements common to all

chilled mirror instruments.

Highlights

• New chilled mirror hybrid sensor gives fast

dynamic response to changes in humidity

• Accurate to ±0.15°C dew point, ±0.1°C

temperature

• Wide measurement range from -40 to +120°C

dew point

• Choice of communication methods, including

Modbus TCP over Ethernet communication for

easy networking

• Optional pressure transmitter for accurate

calculation of ppm

www.michell.com

& g/kg

V

Applications

• Reference humidity instrument for climatic and

environmental chambers

• Inlet air measurement for engine testing

• HVAC testing

• Environmental monitoring in clean rooms

• Coating process monitoring – for confectionary

and pharmaceuticals

• Control of humidity for metallurgical processes

Page 2

Chilled Mirror Instruments

Optidew

Chilled Mirror Hygrometer

The Optidew series is both robust and adaptable, designed

for dependable performance, whether it’s in a harsh industrial

environment or in a laboratory.

New design of chilled mirror sensor: fast

response speed with drift-free reliability

The Optidew uses a new design of cooled mirror sensor which

gives a fast response speed coupled with the accuracy and

reliability of the fundamental chilled mirror technique (see

opposite page).

Measuring in climatic chambers, the Optidew is able to

directly track changes in temperature and humidity without

experiencing time-consuming loss of control like traditional

chilled mirrors.

Touch-screen HMI for easy operation

Both the wall mounted and bench top models are available

with a 5.7” colour touch screen display to make local

operation and interrogation quick and simple to carry out.

Three housing confi gurations

Optidew 401:

A bench top instrument, the

Optidew 401 has a simple,

intuitive touch-screen HMI

which for easy confi guration and

operation. This version includes

a USB port and SD card slot for

easy data logging.

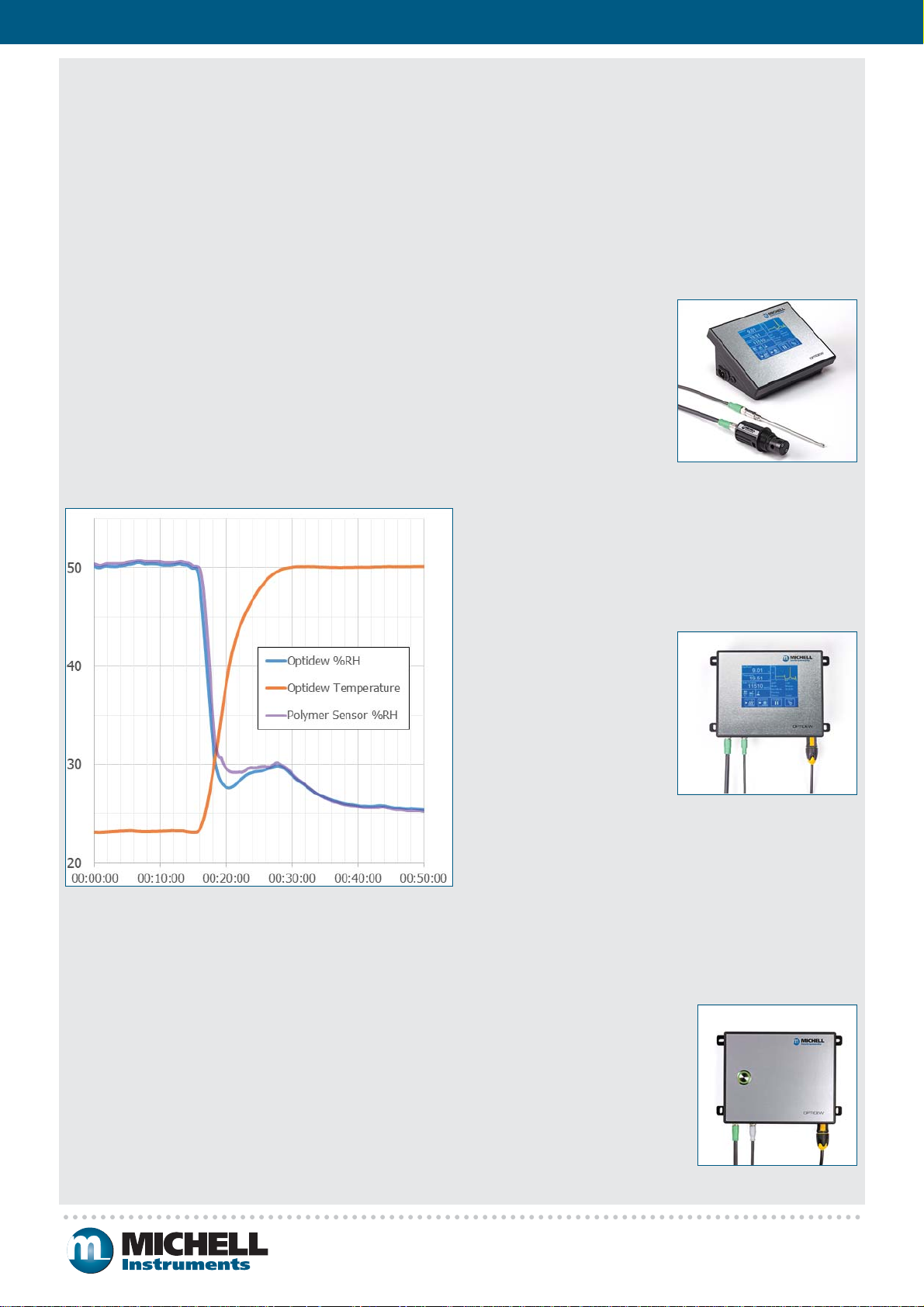

This chart shows a transition from a starting condition of

50%RH at 23°C to 25%RH at 50°C. The transition time shown

is purely that of the climatic chamber: no time is wasted

waiting for the Optidew to stabilise.

Ideal for use as an easily

transportable reference

hygrometer. Either as a transfer

standard to make fi eld calibrations of climatic chambers, or in

combination with a Michell HygroCal100 for validation of RH

probes.

The optional transport case allows use of the instrument

without even unpacking it – great for fi eld service work.

Optidew 501 – with display

The wall mounted Optidew

501 is designed for continuous

measurements of humidity

in industrial environments.

Modbus over RS485 is provided

as standard, with the option of

Modbus TCP over Ethernet for

simple networking of multiple

instruments.

A 316 Stainless steel sensor

block is available to connect the sensor to a fl owing sample. It

features an additional port so that a pressure transmitter can

be installed directly at the point of measurement.

Choice of sensors to suit different

applications

The dual-stage harsh environment sensor is designed for

tough industrial conditions and allows high temperature

measurements up to 120°C, for applications in metallurgy and

fuel cell testing.

The standard sensor is available with single- or dual-stage

cooling and is a reliable and cost-effective option for many

environmental control applications.

The optional pressure sensor gives additional detail about

the measurement. You can now clearly see whether changes

in dew point are related to moisture content or pressure. If

moisture content needs to be displayed in ppm

live pressure changes will be compensated for.

or g/kg, any

V

The Optidew 501 has the same touch screen interface as the

bench mount version. Operators can easily interrogate and

confi gure the instrument locally or remotely via the application

software.

Optidew 501 – transmitter

The most cost effective option

is the wall mounted Optidew

501 blind transmitter. All the

features of the other models are

available when connected to a

PC and operated via Michell’s

universal software. The multi-color

LED indicator also displays the

instrument’s status.

www.michell.com

Page 3

Chilled Mirror Instruments

119

1

4

688"

Fast responding chilled mirror

technology

All chilled mirror sensors measure the actual temperature

that moisture condenses to provide a reading of dew point.

This fundamental technique gives unparalleled accuracy and

reliability. Chilled mirror hygrometers are commonly used as

secondary or transfer calibration standards for humidity.

The new design uses a thin, fast responding hybrid mirror

that is highly resistant to corrosion from acids and other gas

contaminants, outlasting any traditional cooled mirror sensor

design.

Dynamic Contamination Control (DCC) Plus

DCC Plus is an improved version of our Dynamic

Contamination Control. This feature is designed to manage

the contamination on the mirror surface, extending operation

in harsh or dirty environments without the need to stop the

process to manually clean the mirror.

Improved frost assurance

Increased reliability at low dew points

It is possible for water to exist in liquid phase below 0°C as

super cooled water. When using a chilled mirror instrument,

liquid water may exist at temperatures down to –30°C in

certain conditions. The difference in vapor pressure between

condensed water and ice formed on a chilled mirror can

introduce dew-point errors of up to 10% of reading. The new

adaptive FAST system gives certainty about the state of the

mirror condensate, detecting when supercooled water could

form during measurement, and cooling the mirror suffi ciently

to freeze it, without the need for a DCC.

Dimensions

145.0mm 5.709"

46.0mm 1.811"

240.0mm 9.449"

260.0mm 10.236"

220.0mm 8.661"

103.2mm 4.063"

46.2mm 1.819"

180.0mm 7.087"

69.5mm 2.736"

32.2mm 1.268"

172.0mm 6.772"

220.0mm 8.661"

.

mm

.

44.7mm 1.760"

Ø10.5mm [0.413”]

Ø3.7mm [0.146”]*

1mm [0.039”]

32.0mm 1.260"

M36 x 1.5

M30 x 1.5

28.0mm 1.102"

Weld burr may extend 1mm from colar to towards tip of probe

5.6mm [0.22”]

www.michell.com

Page 4

Chilled Mirror Instruments

Technical Specifi cations

Performance

Dew Point Measurement Accuracy ±0.15°C

Repeatability ±0.05°C

Sensitivity ±0.01°C

Response Stable measurement at +10°C dp within 1 minute

Dew-Point Sensor

Sensor Single Stage Dual Stage Harsh Environment

Dew Point Range (°C) -25 to +90°C -40 to +90°C -40 to +120°C

Temperature Range (°C) -40 to +90°C -40 to +90°C -40 to +120°C

% RH Range @ 23°C 2.25 to 100% RH 0.45 to 100% RH 0.45 to 100% RH

Material POM (head)

Corrosion & Saturation

Protection

Mirror Temperature Measurement Pt1000, Class A

Recommended Sample Flow Ambient (environmental measurements) to 2Nl/min (fl owing sample)

Pressure 2500 kPa max

Process Connection M36x1.5

Aluminium (body)

Active Component Isolation System

Remote PRT

Temperature Measurement Accuracy ±0.1°C

Temperature Measurement PT100, Class A

Cables

Cable Length 0.3, 3, 5, 10 and 20m lengths available (cables can be combined)

Maximum operating temperature Standard: 90°C max. High temperature: 120°C max.

Remote Pressure Sensor (Optional)

Pressure Measurement Accuracy ±0.25% FS

Pressure Measurement Range 0-160 kPa OR 0-2500 kPa

Process Connection 1/8” NPT-M

Control Unit

Resolution 1 or 2 decimal places selectable

Measurement Units °Cdp or °Fdp, Relative humidity - %, Absolute humidity - g/m

Enclosure Wall Mount - Optidew 501 Bench Top - Optidew 401

Material ABS ABS

Analog Outputs Two 0/4-20mA outputs (maximum load 500Ω) Two 0/4-20mA outputs (maximum load 500Ω)

Digital Communications Modbus RTU over RS485 (standard)

Alarms 1x Process Relay,

Inputs 4-20mA for pressure sensor 4-20mA for pressure sensor

Data Logging SD card slot (optional) SD card slot (standard)

Ingress Protection IP54 (standard), IP65 (optional) IP54

Dimensions 220x175x75mm 220x175x118mm

Weight Control unit: 1.5kg, Sensor: 200g Control unit: 1.5kg, Sensor: 200g

Display 5.7” color touch screen (optional) 5.7” color touch screen

Environmental Conditions -20 to +50°C, up to 100%RH non-condensing (optional) 100% RH condensing with IP65 connector version

Supply Voltage 100 to 240VAC, 50 to 60Hz

Power Consumption 30VA max

(Twb) - °C, °F, Water Vapor Pressure (wvp) - Pa, Ambient Temperature - °C, °F, Pressure converted DP - °C, °F,

Pressure - kPa, Bara, Barg, Psia, Psig

Modbus TCP over Ethernet (optional)

1x Alarm Relay,

Both Form C, 1A, 30Vdc.

POM (head)

Aluminium (body)

PEEK (head)

Aluminium (body)

3

, ppmV, Mixing Ratio - g/kg, Wet Bulb Temperature

Modbus RTU over:

USB (standard)

RS485 (standard)

Modbus TCP over Ethernet (optional)

1x Process Relay,

1x Alarm Relay,

Both Form C, 1A, 30Vdc

Rotronic Instruments Corp. 135 Engineers Road, Suite 150, Hauppauge NY 11788 Tel: 631 427 3898, Email: us.info@

michell.com, Web: www.michell.com/us

Michell Instruments adopts a continuous development programme which sometimes necessitates specifi cation changes without notice.

Issue no: Optidew_97552_V3_US_1018

© 2018 Michell Instruments

Loading...

Loading...