Page 1

OptiCal

Humidity and Temperature Calibrator

User’s Manual

OPTI-CAL

integrated Humidity Calibrator

Data Acquisition

Max.

Min.

Desiccant Charge

Display Control

Auto On On Auto

495 206

Man. Off Off Man.

Chamber Set

Humidity

%rh

Humidity = Yellow

De-Humidify - Green

Chamber Set

Temperature

Heating = Yellow

Cooling = Green

°C

97079 Issue 9.2

March 2016

Page 2

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

OptiCal

For Michell Instruments' contact information please go to

www.michell.com

© 2016 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

OptiCal User’s Manual

Contents

Safety ................................................................................................................................vi

Electrical Safety ...........................................................................................................vi

Toxic Materials .............................................................................................................vi

Repair and Maintenance ...............................................................................................vi

Calibration ...................................................................................................................vi

Safety Conformity ........................................................................................................vi

Abbreviations .....................................................................................................................vii

Warnings ...........................................................................................................................vii

1 INTRODUCTION ................................................................................................1

1.1 Description ........................................................................................................ 1

1.2 System Components ........................................................................................... 2

1.2.1 Front Panel ................................................................................................... 2

2 INSTALLATION ..................................................................................................4

2.1 Installing the Relative Humidity and Temperature Control Probes ........................... 4

2.2 Filling the Water Reservoir .................................................................................. 6

2.3 Draining the Water Reservoir ............................................................................... 7

2.4 Desiccant .......................................................................................................... 8

2.5 Power Supply ..................................................................................................... 9

3 OPERATION ....................................................................................................10

3.1 Preparation ...................................................................................................... 10

3.1.1 Installing Relative Humidity Instruments for Calibration ................................. 10

3.2 Start-Up ........................................................................................................... 11

3.3 Local Control of Chamber Temperature and Humidity Set Points........................... 11

3.4 Remote Control of Chamber Temperature and Humidity Set Points ....................... 12

3.4.1 Digital Communications ............................................................................... 12

3.4.2 Putting the Optidew in Remote Mode............................................................ 13

3.4.3 Remote Control - Manual Set Point Control ................................................... 13

3.4.4 Remote Control - Automatic Set Point Control ............................................... 13

3.5 Typical Response Times for Various Step Changes ............................................... 14

3.6 Control Outputs ................................................................................................ 15

4 OPTIDEW REFERENCE INSTRUMENT ................................................................16

4.1 Optidew Display ............................................................................................... 16

4.1.1 Selecting Which ‘Screen’ to View on the Display ............................................ 16

4.1.2 Description of Screens 1- 8 .......................................................................... 17

4.2 Maintenance .................................................................................................... 19

4.2.1 Removing the Chilled Mirror Reference Sensor for Mirror Cleaning .................. 19

4.2.2 Sensor Mirror Cleaning ................................................................................ 20

4.2.3 Resetting the Mirror Condition ...................................................................... 21

4.2.4 Re-calibration of the Chilled Mirror Reference ................................................ 22

5 APPLICATION SOFTWARE ................................................................................23

5.1 Virtual Hygrometer ........................................................................................... 23

5.2 OptiCal Remote Chamber Control ...................................................................... 24

5.3 Parameter Setup .............................................................................................. 24

5.4 Charting and Logging ....................................................................................... 26

5.5 Statistics .......................................................................................................... 28

5.6 Control Parameters ........................................................................................... 28

5.7 Calibration Correction ....................................................................................... 29

5.8 Change of Password ......................................................................................... 31

6 TROUBLESHOOTING ........................................................................................32

iv 97079 Issue 9.2, March 2016

Page 5

OptiCal User’s Manual

Figures

Figure 1 OptiCal - Front View ...................................................................................2

Figure 2 OptiCal - Back Panel ...................................................................................3

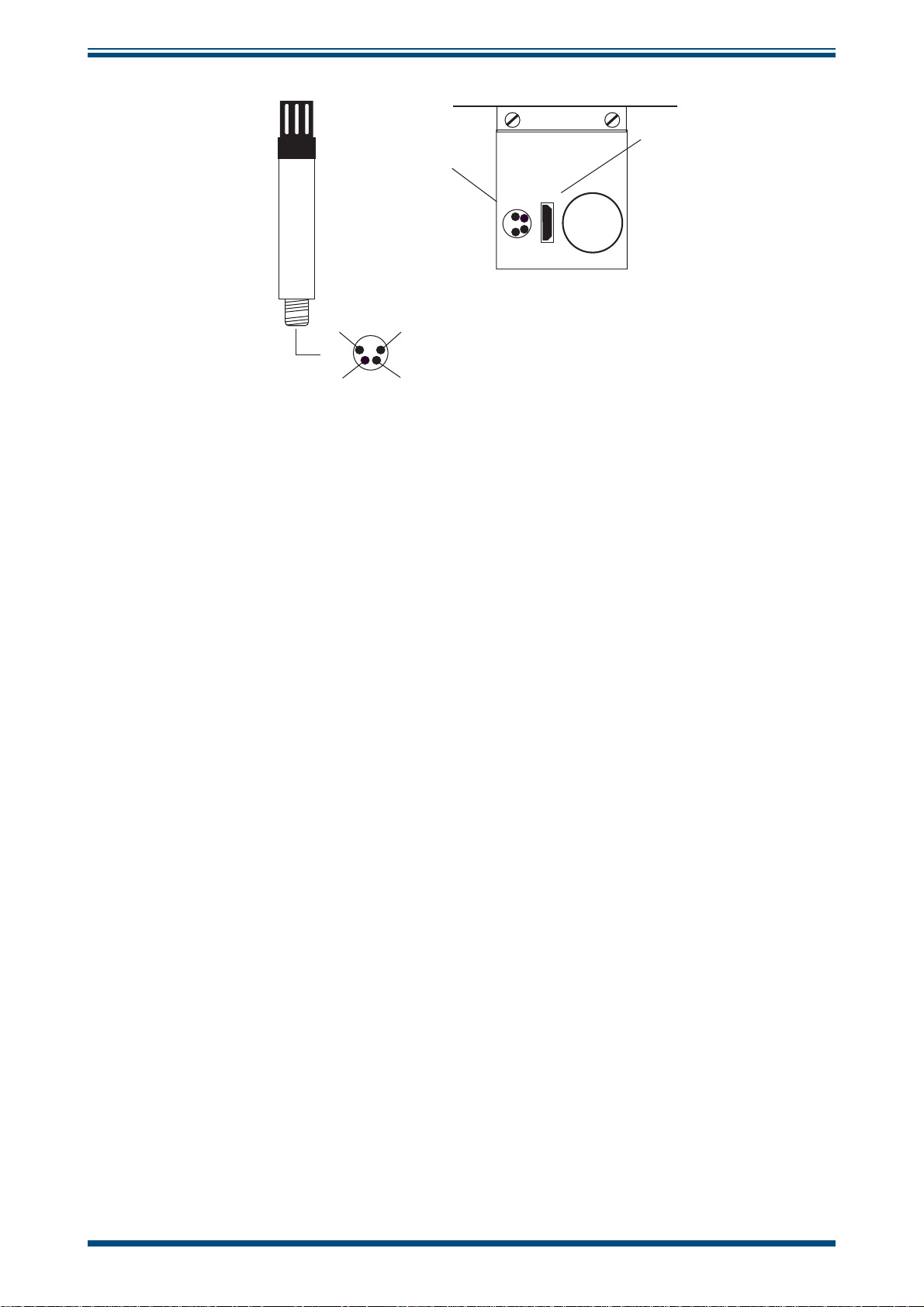

Figure 3 Probe Installation .......................................................................................4

Figure 4 Location of Probes Inside the Climate Chamber ............................................5

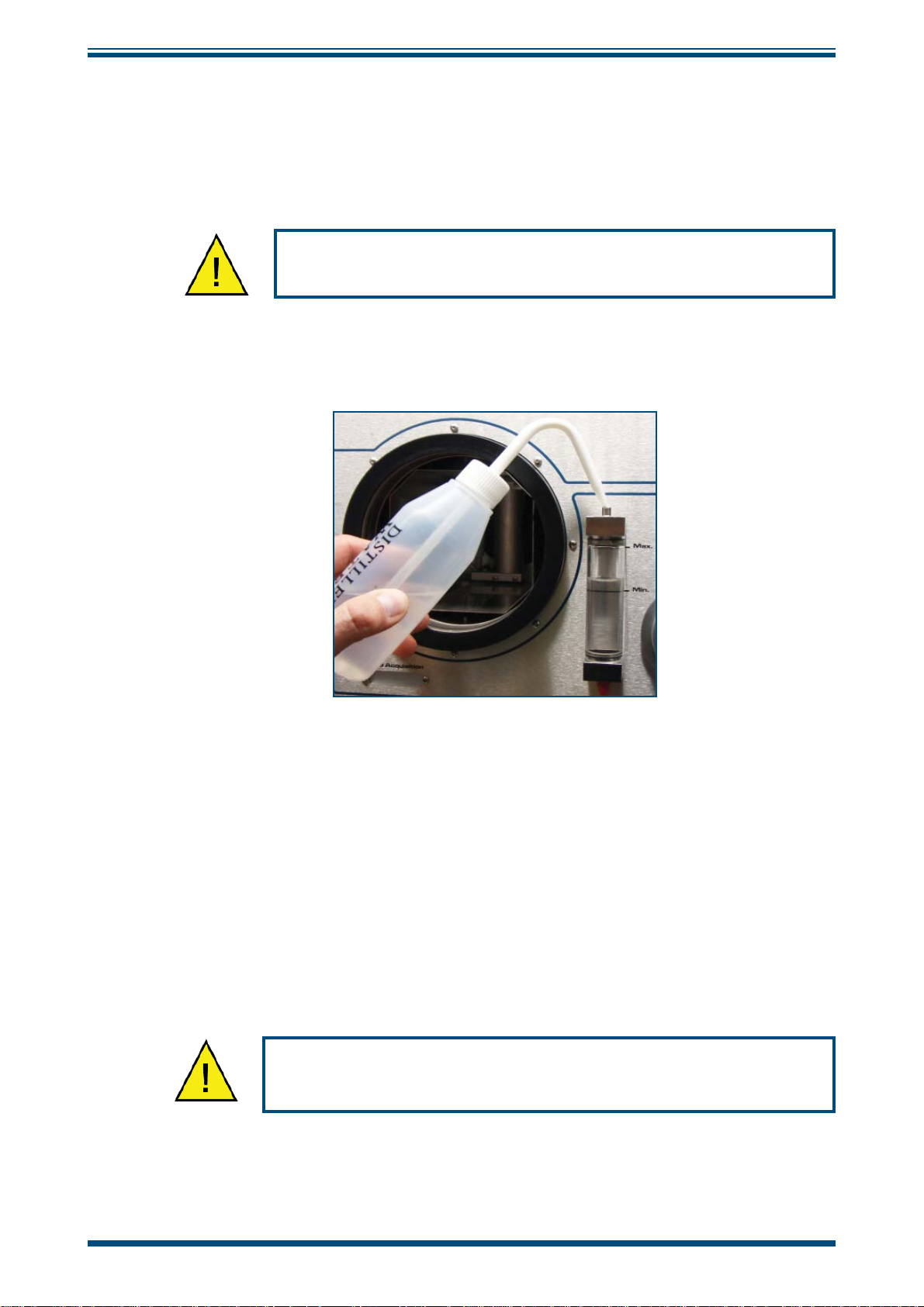

Figure 5 Filling the Water Reservoir ..........................................................................6

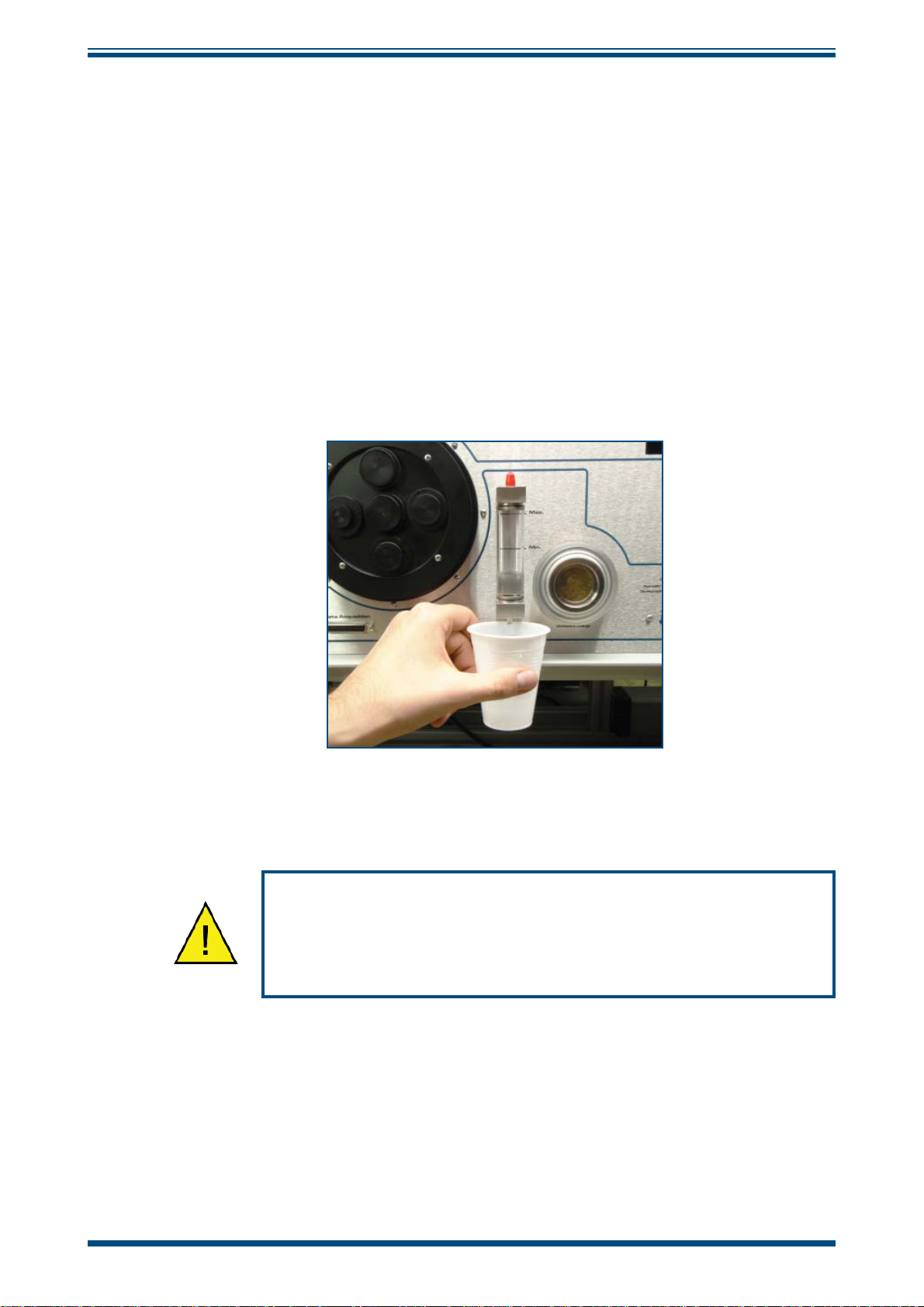

Figure 6 Emptying the Water Reservoir .....................................................................7

Figure 7 Desiccant Replacement ...............................................................................8

Figure 8 Level of Silica Gel Required .........................................................................8

Figure 9 Probe Ports ..............................................................................................10

Figure 10 Port Adapter Removal Tool ........................................................................10

Figure 11 Port Adapters and Removal Tool ................................................................10

Figure 12 Humidity and Temperature Setting Switches ...............................................11

Figure 13 Humidity and Temperature Setting Switches ...............................................12

Figure 14 OptiCal Manual Control .............................................................................13

Figure 15 OptiCal Programming ................................................................................13

Figure 16 Optidew Chilled Mirror Reference Display and Navigation ............................18

Figure 17 Lid Screw Locations ..................................................................................19

Figure 18 Sensor Mirror Cleaning .............................................................................. 20

Figure 19 Potentiometer Location .............................................................................21

Figure 20 Virtual Hygrometer Window ......................................................................23

Figure 21 Parameter Setup Window .......................................................................... 24

Figure 22 Chart/Log Control Panel Window ...............................................................26

Figure 23 Chart Window ..........................................................................................27

Figure 24 Basic Statistics Window .............................................................................28

Figure 25 Extracts From Calibration Certifi cates .........................................................29

Figure 26 Calibration Correction Window ................................................................... 31

Figure 27 Change Password Window ........................................................................31

Tables

Table 1 Typical Response Times for Step Changes ...................................................14

Appendices

Appendix A Technical Specifi cations ..............................................................................34

Appendix B EU Declaration of Conformity......................................................................36

Appendix C Quality, Recycling & Warranty Information ................................................... 38

C.1 Pressure Equipment Directive (PED) 97/23/EC ............................... 38

C.2 Recycling Policy .......................................................................... 38

C.3 WEEE Compliance ........................................................................ 38

C.4 RoHS2 Compliance ......................................................................39

C.5 Warranty ..................................................................................... 39

C.6 REACH Compliance ...................................................................... 40

C.7 Calibration Facilities ..................................................................... 40

C.8 Return Policy ............................................................................... 41

C.9 Manufacturing Quality .................................................................. 41

Appendix D Return Document & Decontamination Declaration ........................................ 43

Michell Instruments v

Page 6

OptiCal User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

qualifi ed personnel and good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument. The input power supply voltage is 85 to 264 V AC,

47/63 Hz.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide offi ces contact information.

Calibration

The OptiCal contains a high precision Optidew chilled mirror hygrometer. In order to maintain full

traceability the complete OptiCal instrument should be returned annually for a service and calibration

to the manufacturer, Michell Instruments, or one of their accredited service agents.

Safety Conformity

This product meets the essential protection requirements of the relevant EU directives. Further

details of applied standards may be found in Appendix A, Technical Specifi cations.

vi 97079 Issue 9.2, March 2016

Page 7

OptiCal User’s Manual

Abbreviations

The following abbreviations are used in this manual:

°C degrees Celsius

°F degrees Fahrenheit

AC alternating current

DC direct current

3

cubic centimeters

cm

-1

grams per kilogram

gkg

-3

grams per cubic meter

gm

Hz Hertz

in inch(es)

3

cubic inches

in

kg kilogram

lbs pounds

mA milli Ampere

max maximum

min minimum

mm millimeter

N/C normally closed

N/O normally open

% percentage

RH relative humidity

RS232 serial data transmission standard

T temperature

USB Universal Serial Bus

V Volts

Warnings

The following general warning listed below is applicable to this instrument. It is repeated

in the text in the appropriate locations.

Where this hazard warning symbol appears in the following

sections it is used to indicate areas where potentially hazardous

operations need to be carried out.

Michell Instruments vii

Page 8

OptiCal User’s Manual

1 INTRODUCTION

1.1 Description

The Michell OptiCal is a stable and accurate calibration solution for humidity sensors

over the 10 to 90%RH and +10 to +50°C (+50 to +122°F) range. The stand-alone,

transportable calibrator requires no external services other than mains power, and

features an integrated chilled mirror reference instrument to enable the operator to

perform calibrations that are traceable to national standards.

The calibration chamber features fi ve interchangeable ports to accommodate virtually

any brand, type or model of sensor. The environment within the insulated calibration

chamber is temperature controlled using a four-zone fan-assisted peltier arrangement

for maximum stability and minimum temperature gradient. The humidity of the

circulating air is precisely regulated using a closed-loop control system that functions

by proportionally mixing fl ows of dry and saturated air.

A bright and clear VFD (vacuum fl uorescent display) displays the parameters measured

by the reference instrument in various relative and absolute humidity units, alongside

the temperature within the chamber.

INTRODUCTION

The humidity and temperature set-points can be controlled either manually or

automatically as part of a calibration program. Manual control is achieved by the switches

on the front panel. Response time to a humidity or temperature step change is typically

quicker than ten minutes. The supplied application software allows calibration programs

to be created, enabling automatic time-based control of temperature and humidity set

points. The software also allows the user to monitor, chart and log calibration reference

data on a PC for later analysis.

The desiccant changes color to indicate when it needs to be recharged, and is visible

through a clear window on the front of the unit. Recharge the desiccant following the

instructions in Section 2.4. The water reservoir at the front of the unit shows the current

saturator fi ll level, and makes it easy to top up with distilled water when required (refer

to Section 2.2). Apart from periodic calibration of the chilled mirror reference, no other

maintenance is necessary. The only external service required is a single phase power

supply.

Michell Instruments 1

Page 9

INTRODUCTION

1.2 System Components

1.2.1 Front Panel

OPTI-CAL

integrated Humidity Calibrator

OptiCal User’s Manual

h

A A

Auto On On Auto

Man. Off Off Man.

h

B B

7

h

Chamber Set

Temperature

1 2 643 8

h

h

5

h

Display Control

495 206

Chamber Set

Humidity

%rh

h

h

°C

Max.

h

Min.

Data Acquisition Control Outputs

h

h

Desiccant Charge

Humidity = Yellow

De-Humidify - Green

h

Heating = Yellow

Cooling = Green

h

12

11

Figure 1

OptiCal - Front View

1. Chamber door

2. Water reservoir

3. Optidew chilled mirror reference VFD display

4. Desiccant cell and indicator window

5. Display control

6. Relative humidity set point (%RH)

A Manual/auto switches for relative humidity / temperature control

7.

9

10

MAN - Front panel switches control relative humidity / temperature set

points

AUTO - Remote RS232 / OptiSoft controls relative humidity / temperature

set points (see Section 3.4)

B ON/OFF switches for relative humidity / temperature control

8. Temperature set-point (°C)

9. Humidity control indication LED

Humidify (yellow)

De-humidify (green)

10. 4-Zone chamber temperature control indication LEDs

Heating (yellow)

Cooling (green)

11. Control outputs

12. RS232 digital communications connector

2 97079 Issue 9.2, March 2016

Page 10

OptiCal User’s Manual

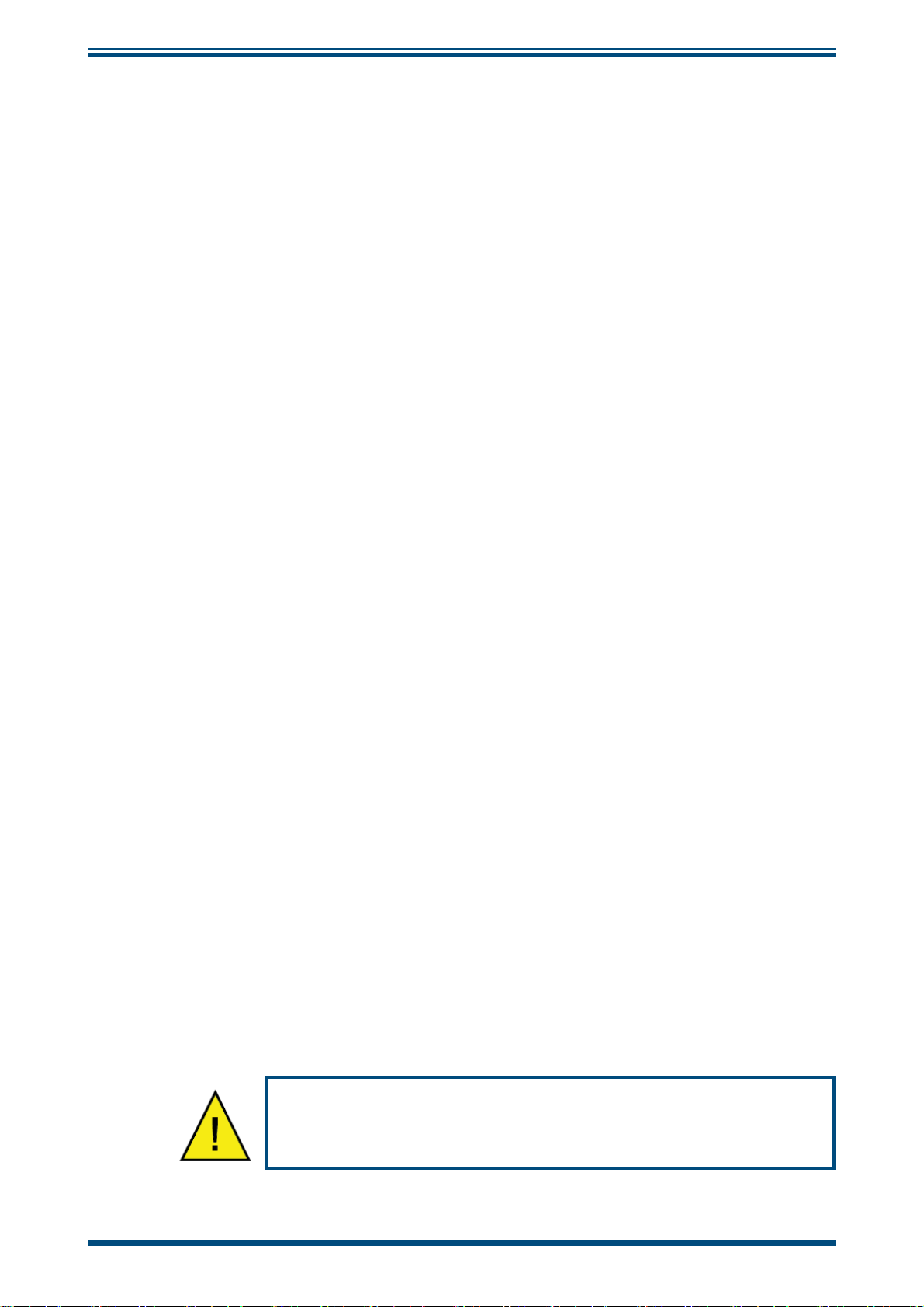

Back Panel

INTRODUCTION

1

h

On

Off

h

h

4

Remote Communications

Optics Adjustment

Figure 2

2

3

h

h

OptiCal - Back Panel

1. Remote Communications Switch to enable remote chamber control

2. Optidew chilled mirror reference optics adjustment potentiometer (refer

to Section 4.2)

3. Ventilation fans

4. Electrical mains connector, on/off switch and power input fuse

Accessories

The OptiCal humidity and temperature generator is delivered with the following standard

accessories:

• Bottle of distilled water

• Desiccant cell fi lled with indicating silica gel

• HT961T00 control probe + temperature probe

• Chamber door (according to customer specifi cation)

• IEC mains cord set

• Calibration certifi cate for internal reference probe

• Certifi cate of conformity (graph)

• User’s manual

• RS232 cable

• Application software

• Calibration certifi cate for Optidew chilled mirror reference instrument

Michell Instruments 3

Page 11

INSTALLATION

2 INSTALLATION

Before using the OptiCal make sure that Sections 2.1, 2.2 and

The OptiCal enclosure is designed for bench top mounting in a laboratory type

environment. It must be positioned in a clean and level location with suffi cient clearance

at the rear of the enclosure for adequate ventilation.

The OptiCal is not designed to be fully portable. However, it can

easily be moved to any suitable location for use. Before moving,

ensure that any water in the reservoir is drained and that the

RH control probe and the temperature probe in the chamber are

OptiCal User’s Manual

2.4 are read thoroughly.

removed.

The OptiCal should NOT be moved while in operation.

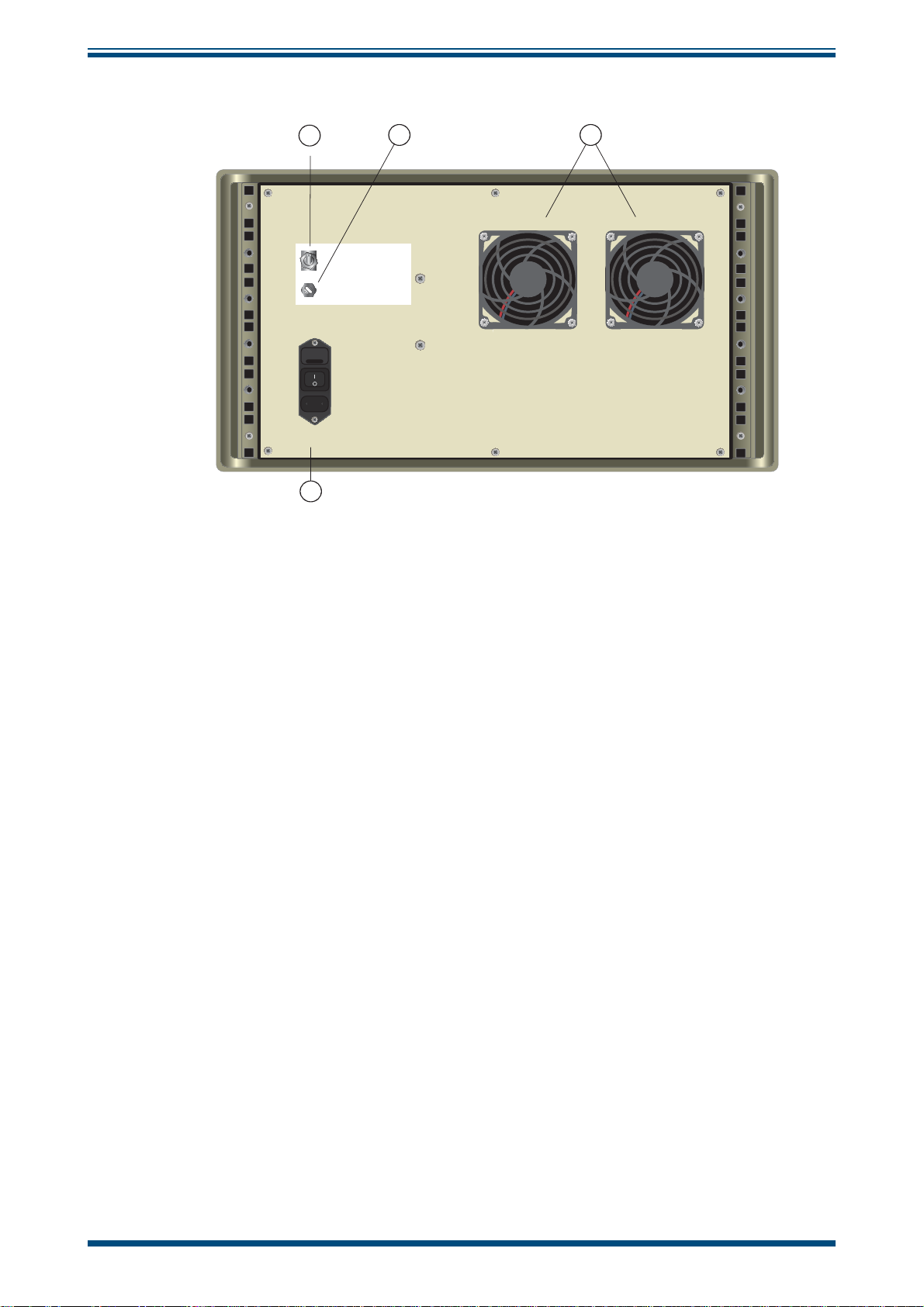

2.1 Installing the Relative Humidity and Temperature Control Probes

The relative humidity control probe and the Pt100 temperature probe are both supplied

as accessories with the OptiCal, and are removed during transportation.

To install the probes, remove the chamber door and plug in the probes as shown in

Figure 3.

This internal RH control probe is delivered with its own calibration certifi cate.

RH Control

Probe

Temperature Probe

Figure 3

The RH control probe and the temperature probe must always

Probe Installation

be removed during transportation.

4 97079 Issue 9.2, March 2016

Page 12

OptiCal User’s Manual

Control

Probe

Connector

INSTALLATION

Temperature

Probe

Connector

h

h

TOP VIEW

GND

OUTPUT TEMP

Figure 4

+ SUPPLY (8 - 35 VDC)

OUTPUT RH

BOTTOM VIEW

Location of Probes Inside the Climate Chamber

Michell Instruments 5

Page 13

INSTALLATION

2.2 Filling the Water Reservoir

Before operation the water reservoir located on the front panel must be fi lled with

distilled water (supplied with the instrument).

Do not use tap water or demineralized water!

OptiCal User’s Manual

Figure 5

Use the fi lter bottle supplied to fi ll the water reservoir.

1. Remove the red plastic cap from the top of the reservoir.

2. Carefully fi ll with clean distilled water to a level between the two indicator

lines.

3. Replace the red cap on the water reservoir after fi lling.

Do NOT fi ll above the MAX indicated line as this may cause liquid

to enter the humidity chamber and adversely affect the control

Filling the Water Reservoir

process.

6 97079 Issue 9.2, March 2016

Page 14

OptiCal User’s Manual

2.3 Draining the Water Reservoir

Drain the water reservoir before transporting, or if the system is accidentally overfi lled.

To empty the water reservoir:

1. Remove the red caps from the bottom and top of the water reservoir.

2. Drain the water into a suitable container.

3. Tilt the OptiCal to empty it completely.

4. Re-fi t the red cap after emptying.

INSTALLATION

Figure 6

It is essential to drain the water reservoir before transporting or

when the system is not going to be used for a few weeks.

Do not re-use any of the drained water within the system.

Emptying the Water Reservoir

Michell Instruments 7

Page 15

INSTALLATION

2.4 Desiccant

The OptiCal has a container fi lled with a desiccant which is used to dry the chamber air.

The desiccant container can be accessed by following these steps:

Figure 7

OptiCal User’s Manual

Desiccant Replacement

1. Remove the clear plastic screw cap on the front panel.

2. Pull out the desiccant container using fi nger tips.

3. Fill with desiccant up to the tapered thread as shown below.

Figure 8

The natural color of the desiccant (dry silica gel) should be orange. As moisture is

absorbed the color will gradually change to transparent.

When the desiccant has become transparent, this is an indication that the instrument’s

ability to generate low humidity is reduced. It is recommended that the silica gel is

replaced or regenerated at this time.

The silica gel can be regenerated by emptying it completely from the desiccant chamber

and drying it in an oven for approximately 3 hours at a temperature between 130°C

(266°F) and 160°C (320°F). After drying it in an oven, allow the silica gel to cool before

refi lling the desiccant chamber and refi tting the chamber into the generator. Ensure that

the screw lid is correctly fi tted.

Level of Silica Gel Required

Frequency of desiccant regeneration or replacement is dependant entirely upon the

length of time in operation. Typically, given a normal calibration profi le and operation

cycle, the OptiCal can continually generate accurate and stable chamber humidity for a

period of several weeks before regeneration or replacement of the silica gel is necessary.

8 97079 Issue 9.2, March 2016

Page 16

OptiCal User’s Manual

2.5 Power Supply

A single mains power supply between 85 to 264 V AC is required to operate the unit.

The power supply connection is a 3 pin IEC plug located on the rear panel of the

instrument. The

adjacent to the power socket.

A 3-core power cable is provided, the free end of which should be wired to a suitable

earthed plug or directly connected via a fused power spur. The power cable conductors

are color coded according to the international convention:

Brown L (Live)

Blue N (Neutral)

Green/Yellow E (Earth/GND)

ON/OFF switch and the power input fuse are in the same location,

INSTALLATION

The instrument must be connected to an electrical earth for

safety purposes.

Michell Instruments 9

Page 17

OPERATION

OptiCal User’s Manual

3 OPERATION

3.1 Preparation

3.1.1 Installing Relative Humidity Instruments for Calibration

Relative humidity probes can easily be installed into the humidity chamber through

the ports in the door. The amount and size of the ports are supplied per customer

specifi cation.

h

h

Port openings

available per

customer specification

Figure 9

NOTE: Ports which are not being used should be covered with a blind stop

to exclude temperature and relative humidity infl uences from outside the

chamber.

NOTE: If a door without ports (A000268) is used, the probes under calibration

must be placed inside the measurement chamber. To ensure good air fl ow, do

not overfi ll the chamber with probes.

The ports adapters can be changed using a port adapter removal tool (A000265)

available from Michell Instruments.

Probe Ports

Blind stop

Figure 10

Insert the two pegs on the adapter tool into the corresponding holes on the port

adapters and turn counter-clockwise to loosen, and clockwise to tighten.

Figure 11

Port Adapter Removal Tool

Port Adapters and Removal Tool

10 97079 Issue 9.2, March 2016

Page 18

OptiCal User’s Manual

OPERATION

3.2 Start-Up

After installing the calibration instruments, switch on the OptiCal by using the ON/OFF

switch on the rear panel of the instrument.

3.3 Local Control of Chamber Temperature and Humidity Set Points

The desired percentage of relative humidity and temperature (in °C) can be manually

set by using the humidity and temperature setting switches when the

switches are in the

disabled individually using the associated

NOTE: Suffi cient time must be allowed for the OptiCal to thermally stabilize

before monitoring the humidity and temperature readings.

MAN position. Humidity or temperature control can be enabled or

ON/OFF switch.

AUTO/MAN

Auto On On Auto

450

Chamber Set

Humidity

Figure 12

Man. Off Off Man.

Humidity and Temperature Setting Switches

245

Chamber Set

Temperature

1. Put the AUTO/MAN switches into the MAN position.

2. Put the

3. Set the

to the

ON/OFF switches into the ON position.

REMOTE COMMUNICATION switch on the back of the instrument

OFF position.

Michell Instruments 11

Page 19

OPERATION

OptiCal User’s Manual

3.4 Remote Control of Chamber Temperature and Humidity Set Points

To enable remote control of temperature and humidity set points follow the instructions

below:

Auto On On Auto

245

Chamber Set

Temperature

Display Control

450

Chamber Set

Humidity

Man. Off Off Man.

Figure 13

1. Put the AUTO/MAN switches into the AUTO position.

2. Put the

ON/OFF switches into the ON position.

3. Set the REMOTE COMMUNICATION switch on the back of the instrument

to the

ON position.

4. Put the Optidew in

5. The OptiCal temperature and humidity set points can now be controlled

from the OptiCal application software. Refer to Section 3.4.3 and Section

3.4.4.

NOTE: If the OptiCal is used with manual set-points, put the switches into

the MAN position (refer to Section 3.3).

3.4.1 Digital Communications

Humidity and Temperature Setting Switches

REMOTE Mode. Refer to Section 4.1.

Located on the front panel is a 9 way ‘D’ connector, which is used to communicate with

Opti-Soft application software or with an ASCII terminal program (see Section 5).

The communication interface is RS232.

Pin number RS232

2Tx

3Rx

5 GND

NOTE: To enable remote control of the chamber set points, both the front

panel

AUTO/MAN switches should be set to AUTO and the rear panel REMOTE

COMMUNICATIONS switch set to ON. The Optidew should also be in REMOTE

Mode. Refer to Section 3.4.2 and Section 4.1.

12 97079 Issue 9.2, March 2016

Page 20

OptiCal User’s Manual

3.4.2 Putting the Optidew in Remote Mode

On start-up, the Optidew reference is automatically in LOCAL Mode. Once the display

has stopped showing the start-up banner it is possible to change between the two modes

by simply holding down the DISPLAY CONTROL button for approximately 7 seconds. In

REMOTE Mode the display will show REMOTE MODE, indicating that communication

with a PC via the RS232 port is possible.

3.4.3 Remote Control - Manual Set Point Control

Opti-Soft has the facility to manually control the OptiCal via the manual control window.

To set the required %RH and temperature values, adjust the controls and press the

Apply button.

OPERATION

Figure 14

3.4.4 Remote Control - Automatic Set Point Control

Opti-Soft provides a programming facility for the OptiCal, where the user can design,

open and save programs with up to 10 dwell-points.

Figure 15

OptiCal Manual Control

OptiCal Programming

Program progress is shown by the color change in the program table and the dwell time

of the active dwell point is decremented every second to show the time remaining.

Michell Instruments 13

Page 21

OPERATION

OptiCal User’s Manual

3.5 Typical Response Times for Various Step Changes

Typical response times for various step changes are shown in Table 1 below. T100

represents the total time taken to reach stability at the new set-point.

T63 and T95 values represent the time taken to reach 63% and 95% respectively of

the step change in relative humidity and/or temperature. (Start temperature = 23°C /

Start RH = 50%)

Temperature °C RH % T63 T95 T100

Step 1 15 20 ≤12 ≤23 ≤26

Step 2 15 50 ≤2 ≤3 ≤5

Step 3 15 80 ≤3 ≤7 ≤9

Step 4 25 20 ≤3 ≤5 ≤14

Step 5 25 80 ≤3 ≤8 ≤10

The time taken depends on the quality of the desiccant and the overall temperature of the OptiCal calibration chamber

•

Time in minutes

Table 1 Typical Response Times for Step Changes

The OptiCal can also be used with relative humidity generation only or with temperature

generation only.

For example: If the calibration on the instruments is done and new instruments need

to be inserted, both switches can be set to

OFF. This will cause the pump to switch off

in order to save energy.

If only temperature calibration is needed, humidity generation can be switched off.

NOTE: In this instance, the pumps will also stop.

The minimum chamber temperature that can be reached is about 10°C (18°F) below

ambient temperature. The maximum chamber temperature is limited to about +52°C

(+125°F).

14 97079 Issue 9.2, March 2016

Page 22

OptiCal User’s Manual

3.6 Control Outputs

Pin Number Description

1 4-20 mA temperature output (chilled mirror)

20 V

3 4-20 mA %RH output (chilled mirror)

40 V

5 N/C

6 0-10 V temperature output (control probe)

70 V

8 0-10 V %RH output (control probe)

9 Chilled mirror, clean optics / alarm relay N/O

10 Chilled mirror, clean optics / alarm relay COM

11 Chilled mirror, clean optics / alarm relay N/C

12 Chilled mirror status relay N/O

13 Chilled mirror status relay COM

14 Chilled mirror status relay N/C

OPERATION

Warning:

Maximum 100 mA per channel

Maximum relay voltage 30 V

Michell Instruments 15

Page 23

OPTIDEW

4 OPTIDEW REFERENCE INSTRUMENT

The OptiCal is supplied with an integrated Optidew chilled mirror reference instrument

to provide a fundamental and traceable reference measurement of the humidity within

the chamber, while being totally independent from the controlling relative humidity

probe. The advantage of this technique is to isolate the control of the chamber from

the control system of the chilled mirror sensor to provide a fast responding and highly

stable system.

4.1 Optidew Display

The Optidew reference has an integral VFD (Vacuum Fluorescent Display) mounted on

the front panel of the OptiCal instrument. To the right of the display is a single multifunction button which enables the user to select between the Optidew’s two modes of

operation and scroll through the measured and calculated parameters such as ambient

temperature or relative humidity, and indications of system status. The mode can be

either LOCAL or REMOTE. In LOCAL Mode the integral display is active and data such

as temperature and relative humidity are displayed on the VFD screen. In

Mode the display is inactive and the RS232 output is enabled and available via the 9 pin

RS232 communication connector.

OptiCal User’s Manual

REMOTE

Start-up banner

When power is applied to the OptiCal, the Optidew reference display will initially show

test characters for approximately 0.5 seconds, after which the start-up banner will be

displayed for approximately 7 seconds. The instrument will start up in

which case the display is active and the RS232 output is not available.

Remote Mode for communication with a PC

On start-up, the Optidew reference is automatically in

has stopped showing the start-up banner it is possible to change between the two modes

by simply holding down the

REMOTE Mode the display will show REMOTE MODE, indicating that communication

In

with a PC via the RS232 port is possible.

LOCAL Mode

rh 49.9 %

t 10.0 °C

REMOTE Mode

DISPLAY CONTROL button for approximately 7 seconds.

* REMOTE MODE *

LOCAL Mode. Once the display

LOCAL Mode in

4.1.1 Selecting Which ‘Screen’ to View on the Display

After the start-up banner has ended, the display will show Screen 1. This displays

the status of the Optidew chilled mirror reference instrument, i.e. DCC and ambient

temperature. To scroll to Screen 2 - fi rmly but momentarily press the multifunction

button. It is not possible to view any other screens until the

complete. Note that there may be a small delay before the display changes to the next

screen - this is normal. After the

All eight screens can now be accessed by depressing the multi-function button.

DATA HOLD period has fi nished, Screen 3 will appear.

DATA HOLD period is

16 97079 Issue 9.2, March 2016

Page 24

OptiCal User’s Manual

4.1.2 Description of Screens 1- 8

Below is a description of the parameters and system status information shown on each

screen (see

Screen 1: Displays the status of the Optidew chilled mirror reference instrument

Figure 16).

OPTIDEW

It will show

DCC, DATA HOLD, OPTICS ALARM or MEASURE according to the current

status of the Optidew chilled mirror reference instrument.

Screen 2: Peltier power and the Mirror condition

Peltier power indicates how much the heat pump is depressing in order to measure

the dew point. When the peltier power has a value of 100% and does not reduce over

an extended period of time, it means that the heat pump is at maximum depression.

In normal operation this indicates that the dew point is lower than the present mirror

temperature and therefore cannot be measured.

Alongside the peltier power value is an indicator that shows the control stability. When

this indicator shows

on the dew point.

form dew on the mirror surface.

CNTRL, it indicates the system is controlling the mirror temperature

COOL indicates the system is depressing the heat pump in order to

HEAT indicates a rapid increase in dew-point level,

whereby the system needs to increase the temperature of the mirror surface to read

this new dew-point value.

The mirror condition indicates the amount of signal received back from the mirror which

includes both the level of moisture and contamination on the mirror surface. In

DCC

mode this display will only show the amount of mirror contamination and, if greater

than 80% after a

DCC, will initiate an optics alarm condition.

Screen 3: Humidity in %RH and ambient temperature

Screen 4: Humidity in dew-point and ambient temperature

Screen 5: Humidity in gkg

Screen 6: Humidity in gm

Screen 7: The fi rst line in this screen displays Δ (t – t

-1

and ambient temperature

-3

and ambient temperature

). This is the difference between

dp

ambient temperature and dew point. Note that this parameter will be equal to 0 if

the dew point is higher than the ambient temperature (e.g. during a

DCC cycle). The

second line displays the ambient temperature.

Screen 8: The fi rst line displays a

which is equivalent to %RH/100. The second line

W

displays ambient temperature.

Michell Instruments 17

Page 25

OPTIDEW

OptiCal User’s Manual

Apply

Power

h h h h h h h h h

h

h

During DCC, Hold

and Optics Alarm

Optidew Transmitter

Initialising

Status = MEASURE

Mirror: 50%

Peltier: 40% COOL

rh 49.9 %

t 10.0 °C

tdp 0.0 °C

t 10.0 °C

Start up

banner

Screen 1

Screen 2

Screen 3

Screen 4

Y 106.00 gkg-1

t 10.0 °C

dv 106.00 gm-3

t 10.0 °C

(t-tdp) 10.0 °C

t 10.0 °C

aw 0.5

t 10.0 °C

Screen 5

Screen 6

Screen 7

Screen 8

Figure 16

Optidew Chilled Mirror Reference Display and Navigation

18 97079 Issue 9.2, March 2016

Page 26

OptiCal User’s Manual

!

4.2 Maintenance

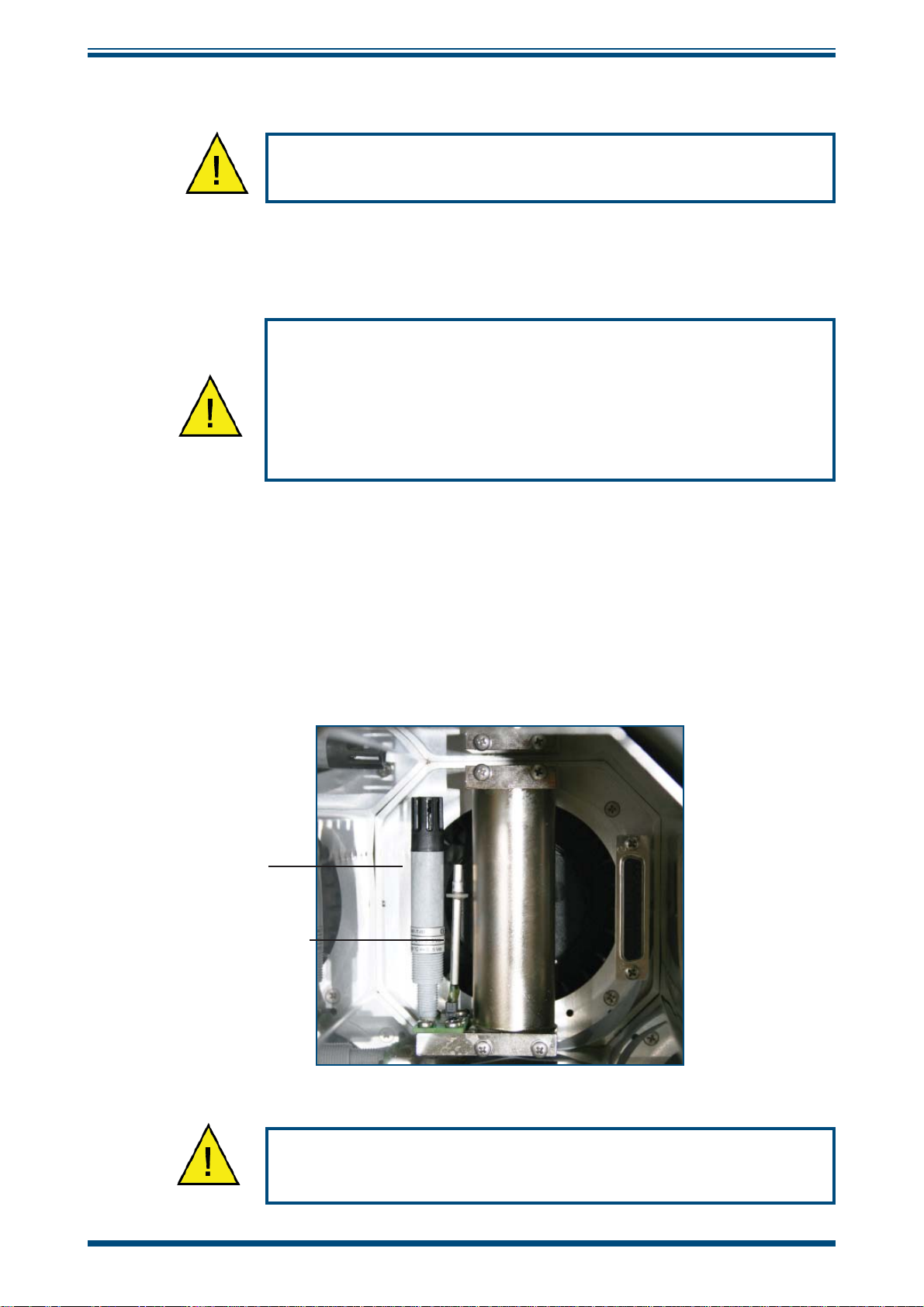

Failure to follow these maintenance procedures may result in

premature wear or damage to the heat pump.

4.2.1 Removing the Chilled Mirror Reference Sensor for Mirror Cleaning

1. Remove the 4 screws securing the top lid to the OptiCal.

Screws

OPTIDEW

Figure 17

2. Disconnect the sensor cable from the Optidew sensor.

3. Unscrew the Optidew sensor from the side of the chamber.

Lid Screw Locations

4. Clean the sensor mirror according to the instructions in the next section.

Michell Instruments 19

Page 27

OPTIDEW

4.2.2 Sensor Mirror Cleaning

Throughout the life of the instrument, periodic cleaning of the mirror surface and optics

window may be required. Sensor cleaning is mandatory if the instrument indicates an

optics fault.

The cleaning procedure is as follows:

1. Switch off the instrument and remove the sensor from its sample block.

2. Clean the mirror surface and optics window with a cotton bud/Q-Tip

soaked in distilled water. If the sensor has been exposed to oil based

contamination then use one of the following solvents: methanol, ethanol,

or isopropyl alcohol. To avoid damage to the mirror surface do not press

too fi rmly on the cotton bud/Q-Tip when cleaning. Allow the cleaning

solvent to fully evaporate.

3. Reset the mirror condition according to the instructions in Section 5.2.

OptiCal User’s Manual

Figure 18

Sensor Mirror Cleaning

20 97079 Issue 9.2, March 2016

Page 28

OptiCal User’s Manual

4.2.3 Resetting the Mirror Condition

This is an important part of the normal operation of the instrument. The mirror condition

should be reset:

• after the mirror has been cleaned.

OPTIDEW

• if the mirror condition shows

LOW or fl ashing 0% on the display or

application software during a DCC cycle.

• if the mirror condition is greater than 10% during a DCC cycle.

Potentiometer

On

Remote Communications

Off

h

Optics Adjustment

Figure 19

Potentiometer Location

Procedure (using display or application software)

NOTE: The instructions on the next page can be followed for adjustment using

RS232 serial commands, if more convenient.

1. Clean the mirror according to the instructions above.

2. Cycle power to the instrument to initiate a DCC cycle.

The instrument will now be in DCC for 4 minutes – it is important that the

adjustments are only made in this mode. If the instrument comes out of

DCC (the status LED will no longer be illuminated), just cycle power to the

instrument.

3. Observe the mirror condition on the display, or the application software.

4. Adjust the potentiometer until the mirror condition is 0 - 2%.

If the mirror condition shows

LOW (on the display) or fl ashing 0% (on the

application software) then it is under-range and a positive adjustment is

required.

NOTE: During adjustment there will be a delay of approximately

5 seconds before the mirror condition value updates to the actual

value.

5. Cycle power to the instrument.

Michell Instruments 21

Page 29

OPTIDEW

Procedure (using RS232 serial commands)

1. Connect to the instrument using the RS232 connection.

2. Send the following commands, one after the other:

OptiCal User’s Manual

Command Description

st Stops all continuous output to the serial port

gofth

abc Starts a DCC cycle

The instrument will now be in DCC for 4 minutes – it is important that

the adjustments are only made in this mode. During this time adjust the

potentiometer until the signal level is 150 ±10.

If the instrument comes out of DCC (the status LED will no longer be

illuminated) send the

Continuously outputs signal mirror level, between 0 and

1023

abc command again.

3. Once adjustment is complete, cycle power to the instrument.

4.2.4 Re-calibration of the Chilled Mirror Reference

As with all high quality measuring instruments, regular re-calibrations of the integral

chilled mirror reference against a standard is recommended. This can only be achieved

by exposure of the sensor to sample gases of known moisture content, while comparing

readings against a calibrated reference instrument traceable to national standards. It

is recommended that the entire instrument is returned to Michell Instruments on an

annual basis for calibration and routine maintenance and service.

The accuracy and integrity of the Optidew reference will highlight any drift in the

accuracy of the controlling %RH probe, which will be seen as a difference between

the set point for %RH and temperature and the values measured by the reference

instrument. When these differences become signifi cant, then a replacement %RH probe

will be required.

22 97079 Issue 9.2, March 2016

Page 30

OptiCal User’s Manual

5 APPLICATION SOFTWARE

The application software is an interface to the OptiCal. It provides a display of the

measured and calculated parameters, system status, charting and logging, statistical

information and a facility to view and change the system parameters. To set up the

Digital Communications refer to Section 3.4.1.

NOTE: Communication with the software is only possible when the unit is in

REMOTE Mode (see Section 4.1).

5.1 Virtual Hygrometer

The Virtual Hygrometer window provides a display for the instrument by showing the

measured parameters and status.

APPLICATION SOFTWARE

Figure 20

The Humidity display has the ability to show dew point (°C/°F), %RH, gm-3, gkg-1, ∆

(t – t

will show the measured or calculated value, but will not change the Channel 1 mA

output of the instrument, as this can only be done via the Parameter Setup window

(see Section 5.3). When the software is executed, it will default to the present setting

of Channel 1 mA output. The ambient temperature is constantly shown in the lower

display. NOTE: The

the temperature, e.g. during DCC. This is normal and not a fault.

) or aW by clicking on the Change Units button. Selecting one of these options

dp

humidity display will blink if the dew point is higher than

Virtual Hygrometer Window

Mirror Condition indicates the amount of signal received back from the mirror, which

includes both the level of moisture and contamination on the mirror surface. In

mode this display will only show the amount of mirror contamination and, if greater

than 80% after a

Instrument status is shown via the fi ve colored indicators. In

or by the

showing the

ends, the

system enters the measurement phase. The

if cleaning of the mirror surface is required. Refer to Section 4.2 for details of mirror

cleaning.

DCC Initiate button), both the DCC and Hold indicators will illuminate

DCC indicator will turn off leaving only the Hold indicator illuminated until the

DCC, an optics alarm condition will initiate.

DCC (initiated automatically

DCC status and the hold on Channel 1 mA output. When the DCC period

Fault indicator will illuminate after a DCC

DCC

Michell Instruments 23

Page 31

APPLICATION SOFTWARE

The Alarm indicator will illuminate when the measured variable exceeds the alarm set

point (if selected) (refer to Section 5.3).

Max Cool can be initiated by the Max Cool On button. Once initiated, the Max

Cool indicator will illuminate and the system will drive the heat pump into maximum

depression. This feature can be used to ascertain if the measured dew point is within

the measurement capability of the instrument.

OptiCal User’s Manual

Clicking on the

measured parameters to be viewed. See Section 5.5.

Charting and logging of the measured values can be initiated by clicking on the

Statistics button allows maximum, minimum and average values of the

log button. See Section 5.4.

Hold display in DCC mode check box stops the system from updating the display

The

during

until both

DCC, when enabled. The display is held when DCC is initiated and is not updated

DCC and Hold periods have expired.

5.2 OptiCal Remote Chamber Control

The OptiCal chamber relative humidity and temperature set points can be controlled

remotely from within OptiSoft. Refer to Section 3.4.

5.3 Parameter Setup

The Parameter Setup window allows the setting and ranging of Channel 1 and 2 mA

outputs, the duration for

pressure and alarm set points.

DCC, Measurement and Hold, and the values for atmospheric

Chart/

Figure 21

Parameter Setup Window

24 97079 Issue 9.2, March 2016

Page 32

OptiCal User’s Manual

The Display Units and Channel 1 mA output are selected by clicking the left hand mouse

button in the relevant box. This will change the settings of both the instrument and the

virtual hygrometer window. Changing the mA outputs from 4-20 mA to 0-20 mA & vice

versa will change both Channel 1 & Channel 2 mA outputs.

The maximum and minimum values of Channel 1 and Channel 2 are –200 to +1000

respectively, therefore allowing the range of the outputs to be anywhere between these

limits. The values for Max and Min must be integer values with a difference between

them of at least 1°C/F.

If Channel 1 is to be set for %RH, gm

of Channel 1 Min should be 0, as a negative value for these parameters is not possible.

The pressure value is used to correct gm-3 and gkg-1 for atmospheric pressure. By

entering the atmospheric pressure the display and Channel 1 mA output (if either gm-3

or gkg-1 is selected) will both be corrected accordingly.

APPLICATION SOFTWARE

-3

, gkg-1, or ∆ (t – tdp), then the minimum value

The Alarm can be set to

dew point, ambient temperature, temperature difference, %RH, gm-3 or gkg-1 as shown

above. The set point needs to be an integer value between –200 and +1000, although

negative set points are only valid for dew point and ambient temperature. If the process

variable exceeds the set point, the

illuminate and the Optics Fault/Alarm relay will change state.

To change any of the values, enter the required value and click on the return key. The

background of the text box will change to yellow to indicate that the change is taking

place. When confi rmation has been received that the instrument has accepted the

change, the background will change back to green.

NOTE: When the

Parameter Setup window is open, the values in the Virtual

OFF or set to be active on any of the process variables i.e.

Alarm indicator on the virtual hygrometer will

Hygrometer window are frozen. The Parameter Setup window needs to be

closed for the software to resume normal display mode.

Michell Instruments 25

Page 33

APPLICATION SOFTWARE

5.4 Charting and Logging

Clicking on the Chart/log button in the Virtual Hygrometer window brings up the

Chart / log control panel

OptiCal User’s Manual

window.

Figure 22

The chart, in its default confi guration, displays dew point, temperature and %RH.

However, gm-3, gkg-1 and ∆(t – tdp), can be added by clicking in the appropriate check

box.

Within the

minimum of 5 seconds to a maximum of 1 hour. It offers the facility to log the temperature

of the mirror while in

and chart the held data values accordingly.

To log the measured and calculated humidity values to a data fi le for further analysis,

click on the check box in the

Global section, you can select the charting and logging interval from a

DCC and Hold, or hold the measured value while in these modes

Chart/Log Control Panel Window

Logging section and specify a fi le name by clicking on the

Browse button. If a log fi le is not required simply uncheck the box.

Run, Pause and Stop the charting and logging facility, use the chart control buttons

To

accordingly.

26 97079 Issue 9.2, March 2016

Page 34

OptiCal User’s Manual

Clicking on the Run button will bring up the chart as shown below. The chart shows

the measured and calculated humidity values selected in the Chart section, with an

assigned identifi able color for each value. It is possible to scale, zoom and scroll both X

and Y axis of the chart by using the controls in the

be activated by clicking on the

APPLICATION SOFTWARE

Chart Settings window, which can

Chart Settings button.

Figure 23

The X & Y axes can be individually scaled. The X-axis can be scaled by using the ZoomX

feature in the

and max values, or selecting a parameter in the

to the actual values of the parameter.

There are a number of modes associated with the chart, which can be selected from

Chart mode list; Plot, Scroll (X, Y, & XY), Cursor, Zoom (X, Y, & XY) and Zoom Box.

the

In order to use the scrolling and zooming modes, make your selection and click the left

mouse button on the chart itself, moving the mouse across the chart accordingly with

the left mouse button held down. This will zoom or scroll the chart accordingly.

Individual data points can be selected from the chart by using the cursor mode. Select

the parameter in question by clicking on a legend on the right hand side of the chart (°C

dew point is shown as selected above) and moving the cursor to the point of interest the actual value with its time stamp will be displayed above the chart.

Chart mode section, while the Y-axis can be scaled by changing the min

Chart Window

Auto-scale list, which scales the Y-axis

Michell Instruments 27

Page 35

APPLICATION SOFTWARE

5.5 Statistics

Clicking on the Statistics button on the Virtual Hygrometer window will display the

Basic statistics window as shown below:

OptiCal User’s Manual

This window shows the maximum, minimum and average of each parameter since the

program began taking readings from the instrument, or since the re-set button was

pressed.

5.6 Control Parameters

The control parameters (protected by a password) should only

be amended by trained personnel in order to adjust the system

Contact a Michell Technical Representative for details.

Figure 24

for operation in extreme conditions.

Basic Statistics Window

(www.michell.com)

28 97079 Issue 9.2, March 2016

Page 36

OptiCal User’s Manual

5.7 Calibration Correction

The OptiCal will be delivered with a Calibration certifi cate for the Optidew chilled mirror

reference instrument detailing the deviation at each measurement point from a known

reference value. Data provided on the Calibration certifi cate is normally arranged as

shown in the following extracts:

Extract from a UKAS Calibration Certifi cate:

APPLICATION SOFTWARE

Generated

Dew point

°C

-39.89 -40.11 -20 +0.22 ±0.26

-20.10 -20.31 0 +0.21 ±0.22

0.39 0.20 21 +0.19 ±0.18

Extract from a Standard Calibration Certifi cate:

Dew-point

Temperature

°C

Generated

Dew point

-40.1 -40.2

-20.1 -20.1

Temperature

°C

0.2 0.1

Test Hygrometer

Sensor

°C

Correction

Required

°C

Instrument

Display

°C

Uncertainty

Expanded

°C

Figure 25

From time to time the Optidew reference instrument may be calibrated by an external

calibration agency, where similar data will be provided.

Extracts From Calibration Certifi cates

Michell Instruments 29

Page 37

APPLICATION SOFTWARE

The Calibration Correction window is a utility that allows an authorized user to input

calibration information in order to effect a real-time correction of the displayed, charted

and logged data within the Opti-Soft application software.

Data for dew-point temperature and ambient temperature, both in units of °C, may be

entered for correction purposes, along with the original Calibration certifi cate reference

number and date of calibration, providing full traceability of data. Once the correction

data has been applied, by clicking on the check box, the main

window will indicate that corrected data is being displayed and will show the Calibration

certifi cate number and date. This information is also saved to the

export.

OptiCal User’s Manual

Virtual Hygrometer

Log fi le for data

Figure 26

shows the Calibration Correction window. Four sets of data may be entered:

DP Ref Dew-point data for the reference hygrometer used to

calibrate the Optidew (sometimes called the actual

dew point or the standard)

DP Reading Measured dew-point value of the Optidew under test

Temp Ref Temperature data from the reference thermometer

Temp Reading Measured temperature value of the Optidew under

test

Data can be entered for between 3 and 11 different dew-point and temperature

calibration points. If no data is inserted, no calibration correction is possible. Data

should be entered with the highest dew-point and temperature values at the top of

the page, in descending value order to the bottom. If out-of-sequence data or spurious

characters are entered, the software will raise a warning message and bad data must

be re-entered.

Calibration Certificate Number fi eld is an optional entry fi eld and is alphanumeric.

The

Any information entered into this fi eld will be displayed on the main

window when calibration correction is enabled. In addition it will be saved to the Log

fi le. Similarly, the date of calibration may be entered for display and logging when

correction is enabled.

Virtual Hygrometer

30 97079 Issue 9.2, March 2016

Page 38

OptiCal User’s Manual

Once all necessary data has been entered in the Calibration Correction window, click

on the

Apply and Close to return to the main Virtual Hygrometer display. Upon the next

update, the corrections entered will be applied to all displayed and logged data, and a

legend above the display will indicate this fact. To remove

select the check box and click on Apply, then on Close.

Use Calibration Date to Correct Measure Values check box and then click on

APPLICATION SOFTWARE

Calibration Correction, de-

Figure 26

NOTE: Enter the calibration data in descending order so the highest values

are in row 1 as shown above.

5.8 Change of Password

The initial password is Michell. This can be changed after entering the Control and

Calibration Data

following window where you can enter a new password with up to 20 alphanumeric

characters. The password is not case sensitive.

windows. Selecting the Change Password menu item will display the

Calibration Correction Window

Figure 27

Change Password Window

Michell Instruments 31

Page 39

TROUBLESHOOTING

6 TROUBLESHOOTING

Problem Possible Solution

OptiCal User’s Manual

No drying

No humidifying Water level too low

No drying and humidifying Switch 2 is off

No heating or cooling Switch 3 is off

No display Fuse on back panel

No external control

Rear panel Remote Communication switch set to ON

Water in chamber; dry the chamber

Front panel switches set to AUTO

Change desiccant

32 97079 Issue 9.2, March 2016

Page 40

OptiCal User’s Manual

APPENDIX A

Appendix A

Technical Specifi cations

Michell Instruments 33

Page 41

APPENDIX A

Appendix A Technical Specifi cations

Humidity

Generated Range 10 - 90%RH

Control Element Accuracy

Stability ±0.2%RH (20 - 80%RH)

Temperature

≤ ±1%RH (10 - 70%RH)

≤ ±1.5%RH (70 - 90%RH)

OptiCal User’s Manual

Generated Range

+10 to +50°C (+50 to +122°F)

(lowest T set point = +10°C (+18°F) below ambient)

Accuracy ±0.1°C (±0.18°F)

Stability ±0.1°C (±0.18°F)

Chamber

Ramp Rate From

+20 to +40°C (+68 to +104°F)

+40 to +20°C (+104 to +68°F)

1.5°C/minute (2.7°F/minute)

0.7°C/minute (1.2°F/minute)

Control Element Removable relative humidity sensor

Reference

Accuracy

Measurement Units

Dew Point:

Temperature: ±0.1°C

Dew point (°C/°F), %RH, temperature (°C/°F), gm

water activity (aW)

±0.2°C

Analog: 4-20 mA or 0-20 mA over user-settable output

Accuracy: ±0.2°C (±3.6°F)

Outputs

500Ω Maximum Load Resistance

Digital: RS232 @ 9600 baud rate

Alarm: volt free contact, 30 V 100 mA max

General

-3

, gkg-1,

Probe Ports

Chamber Volume 2000cm

Up to 5 - sensor body diameters 5 - 25mm (0.2 - 0.98”)

accommodated by port adapters

3

(122.1in3 )

Chamber Dimensions 105 x 105 x 160mm (4.13 x 4.13 x 6.3”) (w x h x d)

Instrument Dimensions 520 x 290 x 420mm (20.5 x 11.4 x 16.5”) (w x h x d)

Set-point Resolution 0.1 for humidity and temperature

Displays 2 line vacuum fl uorescent display

Supply 85 to 264 V AC, 47/63 Hz, 150 VA

Weight 20kg (44lbs)

34 97079 Issue 9.2, March 2016

Page 42

OptiCal User’s Manual

APPENDIX B

Appendix B

EC Declaration of Conformity

Michell Instruments 35

Page 43

APPENDIX B

Appendix B EU Declaration of Conformity

OptiCal User’s Manual

36 97079 Issue 9.2, March 2016

Page 44

OptiCal User’s Manual

APPENDIX C

Appendix C

Quality, Recycling

& Warranty

Information

Michell Instruments 37

Page 45

APPENDIX C

OptiCal User’s Manual

Appendix C Quality, Recycling & Warranty Information

C.1 Pressure Equipment Directive (PED) 97/23/EC

The above Directive has been implemented in United Kingdom Law by the Pressure Equipment

Regulations 1999.

The Regulations require that all pressure equipment and assemblies within the scope of the Pressure

Equipment Directive must be safe when placed on the market or put into service.

Michell Instruments’ products have been assessed and, as referenced against the Classifi cation Charts

detailed in Annex II of the Directive, do not fall into the requirements for CE marking compliance

with the Pressure Equipment Directive.

Article 3, paragraph 3 states that any product containing a pressurized fl uid that does not qualify for

compliance should, nevertheless, be constructed with Sound Engineering Practice (SEP).

Michell Instruments attests here that its products have been designed, manufactured & tested to

assure safe operation, and in accordance with Sound Engineering Practices.

C.2 Recycling Policy

Michell Instruments is concerned with the protection of the environment. It is our commitment to

reduce and eliminate from our operations, wherever possible, the use of substances which may be

harmful to the environment. Similarly, we are increasingly using recyclable and/or recycled material

in our business and products wherever it is practical to do so.

To protect natural resources and to promote material reuse, please separate batteries from other

types of waste and recycle responsibly. If batteries are not properly disposed of, these substances

can cause harm to human health and the environment.

The product that you have purchased may contain recyclable and/or recycled parts and we will be

happy to provide you with information on these components if required. For further information

please see the following sections.

C.3 WEEE Compliance

Directive 2012/19/EU 4 July 2012 on Waste Electronic and Electrical Equipment (WEEE)

The Waste Electronic and Electrical Equipment (WEEE) Directive places rules upon European

manufacturers of electrical and electronic equipment. The directives’ aim is to reduce the impact

that electronic devices have on the environment.

Michell Instruments is in full compliance with the WEEE Directive and is registered with an approved

recycler (Registration No. WEE/JB0235YW) and treats the requirement of the directive and the

protection of the environment with the utmost importance. All Michell Instruments’ products are

appropriately marked indicating their requirement for recycling.

It may be required to return certain instruments for treatment at the end of their working life.

Feb 2013

38 97079 Issue 9.2, March 2016

Page 46

OptiCal User’s Manual

C.4 RoHS2 Compliance

Directive 2011/65/EU of the European Parliament and of the Council of 8 June 2011

The Restriction of Hazardous Substances (RoHS) Directive places rules upon European manufacturers

of electrical and electronic equipment. The directives’ aim is to reduce the impact that electronic

devices have on the environment.

According to the EC Directive 2002/95/EC, Michell Instruments’ products qualify as Category 9,

Control and Monitoring Equipment. Under the 2002/95/EC Directive, Category 9 products are exempt

from compliance with the Directive.

However, the careful design of all Michell Instruments’ products takes into consideration the

requirements of the Directive and, wherever possible, compliance is achieved. All future products

will be developed entirely using compliant materials. Furthermore, Michell Instruments is taking

active steps to remove non-compliant materials and components from existing products wherever

these may occur. Presently, none of the non-compliant materials are known to occur in Michell

Instruments’ products.

The new Directive 2011/65/EU (RoHS2) entered into force on 21 July 2011 and required all Member

States to transpose the provisions into their respective national laws by 2 January 2013.

APPENDIX C

Under the provisions of the RoHS2 EU Directive 2011/65/EU (Article 3, [24]) defi nes ‘Control and

Monitoring Equipment’ specifi cally as ‘monitoring and control instruments designed exclusively for

industrial or professional use’.

RoHS2 EU Directive 2011/65/EU states the closing date for compliance of any Control and Monitoring

Equipment product sold into the EU market place as 22nd July 2017.

However, the careful design policy of all Michell Instruments’ products continues to attain compliance

in the shortest practical timescales and strives to ensure that less than 0.1% of total mass per

product, of all non-compliant materials, appear within them. Michell Instruments continues to

monitor suppliers and material sources to ensure that compliance of goods provided is maintained.

January 2013

C.5 Warranty

Unless otherwise agreed, the Supplier warrants that, as from the date of delivery for a period of 12

months, the goods and all their component parts, where applicable, are free from any defects in

design, workmanship, construction or materials.

The Supplier warrants that the services undertaken shall be performed using reasonable skill and

care, and be of a quality conforming to generally accepted industry standards and practices.

Except as expressly stated, all warranties whether express or implied, by operation of law or

otherwise, are hereby excluded in relation to the goods and services to be provided by the Supplier.

All warranty services are provided on a return to base basis. Any transportation costs for the return

of a warranty claim shall reside with the Customer.

Michell Instruments 39

Page 47

APPENDIX C

C.6 REACH Compliance

Regulation (EC) No. 1907/2006

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH)

Michell Instruments is a manufacturer of moisture measurement and gas analysis instrumentation

and is a ‘downstream’ user of chemicals, as described by the EU Council Directive 76/769/EEC. The

products we supply are not raw chemical products (goods).

Under normal and reasonably foreseeable circumstances of application, the goods supplied to you

shall not contain or release any prohibited chemicals. No listed SVHC (Substances of Very High

Concern) appear within products manufactured by Michell Instruments. Therefore the 0.1% mass

per product, or total usage of 1 tonne/year, will never be exceeded. For these reasons we are neither

required by obligation for registration nor for the creation of material safety data sheets (MSDS) for

our products.

OptiCal User’s Manual

Our continued review of the SVHC Candidate List and

compliant.

Michell Instruments maintains a hazardous material register in which MSDS data sheets are collated,

and we will check that our suppliers will comply to REACH requirements for all materials and

substances we use in the processes of our manufacturing.

In the unlikely event that any chemicals of concern appear in our products in quantities greater than

0.1% of total mass per product we will immediately inform you by correspondence according to the

REACH Article 33 requirements. Our current appraisal is, however, that we do not expect or foresee

such an incidence.

January 2013

C.7 Calibration Facilities

Michell Instruments’ calibration facilities are among the most sophisticated in the world and have

been recognized for their excellence.

Traceability to the National Physical Laboratory (NPL) UK is achieved through our UKAS Accreditation

(Number 0179). This covers dew point over the range -90 to +90°C (-130 to +194°F) and also

Relative Humidity.

latest additions is to ensure we remain

Dew-point calibrations are also traceable to the National Institute for Standards & Technology (NIST)

USA over the range -75 to +20°C (-103 to +68°F).

NOTE: Standard traceable calibration certifi cates for instruments and sensors are not

issued under our UKAS accreditation. UKAS certifi cates are usually to special order and

are clearly identifi ed.

40 97079 Issue 9.2, March 2016

Page 48

OptiCal User’s Manual

C.8 Return Policy

If a Michell Instruments’ product malfunctions within the warranty period, the following procedure

must be completed:

1. Notify a Michell Instruments’ distributor, giving full details of the problem, the

model variant and the serial number of the product.

2. If the nature of the problem indicates the need for factory service then the

instrument should be returned to Michell Instruments, carriage prepaid, preferably

in the original packaging, with a full description of the fault and the customer

contact information.

3. Upon receipt, Michell Instruments will evaluate the product to determine the cause

of the malfunction. Then, one of the following courses of action will be taken:

• If the fault is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If Michell Instruments determines that the fault is not covered

under the terms of the warranty, or if the warranty has expired,

an estimate for the cost of the repairs, at standard rates, will be

provided. Upon receipt of the owner’s approval to proceed, the

product will be repaired and returned.

APPENDIX C

C.9 Manufacturing Quality

Michell Instruments is registered with the British Standards Institute for Quality Assurance to:

BS EN ISO 9001: 2008

Rigorous procedures are performed at every stage of production to ensure that the materials of

construction, manufacturing, calibration and fi nal test procedures meet the requirements laid down

by our BSI approved Quality System.

Please contact Michell Instruments (www.michell.com) if the product does not arrive in perfect

working order.

Michell Instruments 41

Page 49

APPENDIX D

OptiCal User’s Manual

Appendix D

Return Document &

Decontamination Declaration

42 97079 Issue 9.2, March 2016

Page 50

OptiCal User’s Manual

Appendix D Return Document & Decontamination Declaration

'HFRQWDPLQDWLRQ&HUWL¿FDWH

IMPORTANT NOTE: Please complete this form prior to this instrument, or any components, leaving your

site and being returned to us, or, where applicable, prior to any work being carried out by a Michell

engineer at your site.

Instrument Serial Number

Warranty Repair? YES NO Original PO #

Company Name Contact Name

Address

Telephone # E-mail address

Reason for Return /Description of Fault:

APPENDIX D

Has this equipment been exposed (internally or externally) to any of the following?

Please circle (YES/NO) as applicable and provide details below

Biohazards YES NO

Biological agents YES NO

Hazardous chemicals YES NO

Radioactive substances YES NO

Other hazards YES NO

Please provide details of any hazardous materials used with this equipment as indicated above (use continuation sheet

if necessary)

Your method of cleaning/decontamination

Has the equipment been cleaned and decontaminated? YES NOT NECESSARY

Michell Instruments will not accept instruments that have been exposed to toxins, radio-activity or bio-hazardous

PDWHULDOV)RUPRVWDSSOLFDWLRQVLQYROYLQJVROYHQWVDFLGLFEDVLFÀDPPDEOH RUWR[LFJDVHVDVLPSOHSXUJHZLWKGU\

JDVGHZSRLQW&RYHUKRXUVVKRXOGEHVXI¿FLHQWWRGHFRQWDPLQDWHWKHXQLWSULRUWRUHWXUQ

Work will not be carried out on any unit that does not have a completed decontamination declaration.

Decontamination Declaration

I declare that the information above is true and complete to the best of my knowledge, and it is safe for Michell

personnel to service or repair the returned instrument.

Name (Print) Position

Signature Date

F0121, Issue 2, December 2011

Michell Instruments 43

Page 51

NOTES:

Page 52

http://www.michell.com

Loading...

Loading...