Page 1

Dew-Point Transmitters

Easidew Transmitters

Industrial Dew-Point Transmitters

Simple to install and maintain, the Easidew transmitter series measures dew point and moisture

content and is available with a range of process connections and electrical connectors. The Easidew

I.S. transmitter has global intrinsically safe certications and all Easidew models are available with

service exchange program which reduces the cost of maintenance.

Highlights

• Measurement ranges -110 up to +20°Cdp

• Dew point or ppmV moisture content output

• 2-wire loop power connection

• Accuracy ±2°Cdp

• Traceable calibration certicate

• Easidew I.S. IECEx, cCSAus, FM and ATEX approvals

• Low cost of ownership and easy maintenance with

sensor exchange program

• 316 Stainless steel sensor and sample blocks

• 5/8” UNF, 3/4” UNF, G 1/2” process connections

• KF40 Glove Box ange

• MiniDIN 43650, M12 electrical connectors

• Oxygen Service cleaned

www.michell.com

Applications

• Compressed air Class 1 to Class 6 dryers

• Breathing air

• Hydrogen coolant

• Inert and bulk gases

• Glove boxes

• Welding gases

• Hazardous areas

• Oxygen purity

Page 2

Dew-Point Transmitters

Easidew Transmitters

The Universal Moisture Transmitter

The Easidew transmitter has a wide measurement range

from -110 to +20°Cdp and one stocked product can be used

across all class 1 to class 6 industrial dryer applications.

The Easidew family of industrial transmitters incorporates

the latest Michell advanced ceramic technology providing

stable, reliable and repeatable moisture measurements for

all dew point applications.

Ease of Installation

Flexible product design ensures the unit can be quickly and

economically installed.

• Mini DIN 43650 form C or M12 5 pin electrical

connectors

• 5/8” UNF, 3/4” UNF, G1/2” BSP process connections

• KF40 Glove Box type ange process connection

• 316 stainless steel transmitter sample blocks

• On site conguration and diagnostic communication tool

Service Exchange/Recalibration

Program

Michell oers 2 services for customers who want minimum

downtime and sensor traceability, while maintaining the

reliability of their system:

• Sensor Exchange - Customers place an order for a

guaranteed, reconditioned sensor. When this arrives,

they exchange it for the installed sensor which is

returned to Michell, resulting in zero process downtime.

• Recalibration - Customers return their installed sensor

to Michell, where they are inspected, checked and recalibrated before being returned. This provides on-going

sensor traceability for the process.

Safety and Integrity

The mechanical design considers the health and safety quality

requirements of the end user, oering an ultra-high process

pressure barrier, along with meticulous levels of product

traceability and quality.

• High performance 450 bar process media barrier

• Optional gas wetted parts BS EN 10204 3.1 material

certied

• Optional cleaning for enriched oxygen service

• 13 point calibration certicate

Measurement Performance

The transmitter uses Michell’s market leading ceramic

measurement technology coupled with the latest generation,

sophisticated microcontroller electronics to provide accurate

and stable measurement across the transmitters product life.

• Accuracy ±2°Cdp

• Fast response to moisture changes

Flexibility of Ownership

The Easidew transmitter has a RS485 communication

system, which gives customers the opportunity to re-range

and re-scale with a communication kit for a wide variety of

moisture measurements.

• Re-ranging 4–20 mA within the –110 to +20°Cdp range

• Moisture scaling — dew point, ppm

V

Speed of Supply

The transmitter is manufactured within Michell’s worldleading high-volume moisture transmitter manufacturing

centre in the United Kingdom, which ensures reliability and

repeatability of delivery and eld supported by a network of

Michell’s global service centres.

Global Certications

The Easidew series has a broad range of certications to

ensure a single stocked unit can be used in any global

application.

• Easidew I.S. - ATEX & IECEx

• Easidew I.S. - cCSAus (US and Canada) & FM

• Easidew I.S. - EX-TC TR

• Easidew - UL approval

• All Easidews - Canadian pressure vessel approved (CRN)

Michell has a large team of experienced eld and factory

based application engineers who are available to assist with

any dew point sensor application.

• Calibration manufacturing system is traceable to

globally recognized NPL and NIST ISO 17025 standards

Installation Accessories

Transmitters are available with a range of practical accessories.

• 5/8” UNF, 3/4” UNF, G1/2” BSP Sample blocks

• Compact simple sample systems

• Process connection adaptors

Customization

If your application requires a customized sensor, we have

specialized design and manufacturing capability to cover your

requirements.

www.michell.com

Page 3

Dew-Point Transmitters

Technical Specications

Product Easidew, Easidew M12 and Easidew 34

Transmitter

Performance Specications

Measurement Range –110 to +20°C dew point; –100 to +20°C dew point; non standard ranges available on request

Accuracy ±2°C dew point*

Response Time 5 mins to T95 (dry to wet)

Repeatability 0.5°C dew point

Calibration Traceable 13 point calibration certicate

Electrical Specications

Output Signal

Output Dew point or moisture content

Analog Output Scaled Range Dew point: -110 up to +20°C; Moisture content in gas: 0– up to 3000 ppm

Supply Voltage 12 to 28 V DC

Load Resistance Max 250 Ω @ 14 V (500 Ω @ 24 V)

Current Consumption 23 mA max, depending on output signal

CE Conformity Approved

UL61010-1 & CAN/CSA C22.2 No. 61010-1

4–20 mA (2-wire connection, current source); User congurable over range

Easidew M12: Modbus RTU over RS485

Operating Specications

Operating Temperature -40 to +60°C

Compensated Temperature Range -20 to +50°C

Storage Temperature -40 to +60°C

Operating Pressure 45 MPa (450 barg) maximum

Flow Rate 1 to 5 Nl/min mounted in standard sampling block; 0 to 10 m/sec direct insertion

Mechanical Specications

Ingress Protection

Intrinsically Safe Area Certicates

Oxygen Service

Housing Material 316 stainless steel

Dimensions

Filter (Sensor Protection)

Easidew: 5/8” - 18 UNF

Process Connection

KF40 Flange Accessories Flange for 5/8” 18 UNF & 3/4” 16 UNF process connections

Weight 150g

Electrical Connections

Mating Electrical Connectors

Diagnostic Conditions

(factory programmed)

Approved Galvanic Isolators

NOTES * Over Compensated Temperature Range

Easidew 34: 3/4” - 16 UNF

Easidew M12: 5/8” - 18 UNF, 3/4” - 16 UNF, G1/2”

BSP

Easidew: MiniDIN 43650 form C

Easidew M12: M12 5 Pin (A coded)

IP66 in accordance with standard BS EN 60529:1992; NEMA 4 protection in accordance

MiniDIN 43650 form C L=132mm x ø45mm (with connector cable)

Easidew M12: M12 5 pin L = 155mm x ø45mm (with connector cable)

Optional: 316 stainless steel sintered guard <80µm

Easidew M12: optional 0.8, 2, 5 metre M12 A coded connector/cable available

with standard NEMA 250–2003

Easidew M12: IP65

ATEX: II 1 G Ex ia IIC T4 Ga (-20 to +70 °C)

IECEx: EX ia IIC T4 Ga (-20 to +70 °C)

TC TR@ 0Ex ia IICT4 Ga (-20 to +70 °C)

FM: Class I, Division 1, Groups A B C D, T4

CSAUS: Class I, Division 1, Groups A B C D, T4

C

Optional: Cleaned for enriched oxygen service

Standard: HDPE <10µm

5/8” - 18 UNF, 3/4” - 16 UNF, G1/2” BSP

MiniDin 43650 form C

Mating connector supplied as standard

Sensor fault: 23 mA

Under-range dew point: 4 mA

Over-range dew point: 20 mA

KFD2-CR-EX1.20200

KFD2-CR-EX1.30200

KFD0-CS-EX1.50P

KFD0-CS-EX2.50P

KFD2-STC4-EX1.H

MTL5041

MTL5040

Easidew I.S. Transmitter

V;

www.michell.com

Page 4

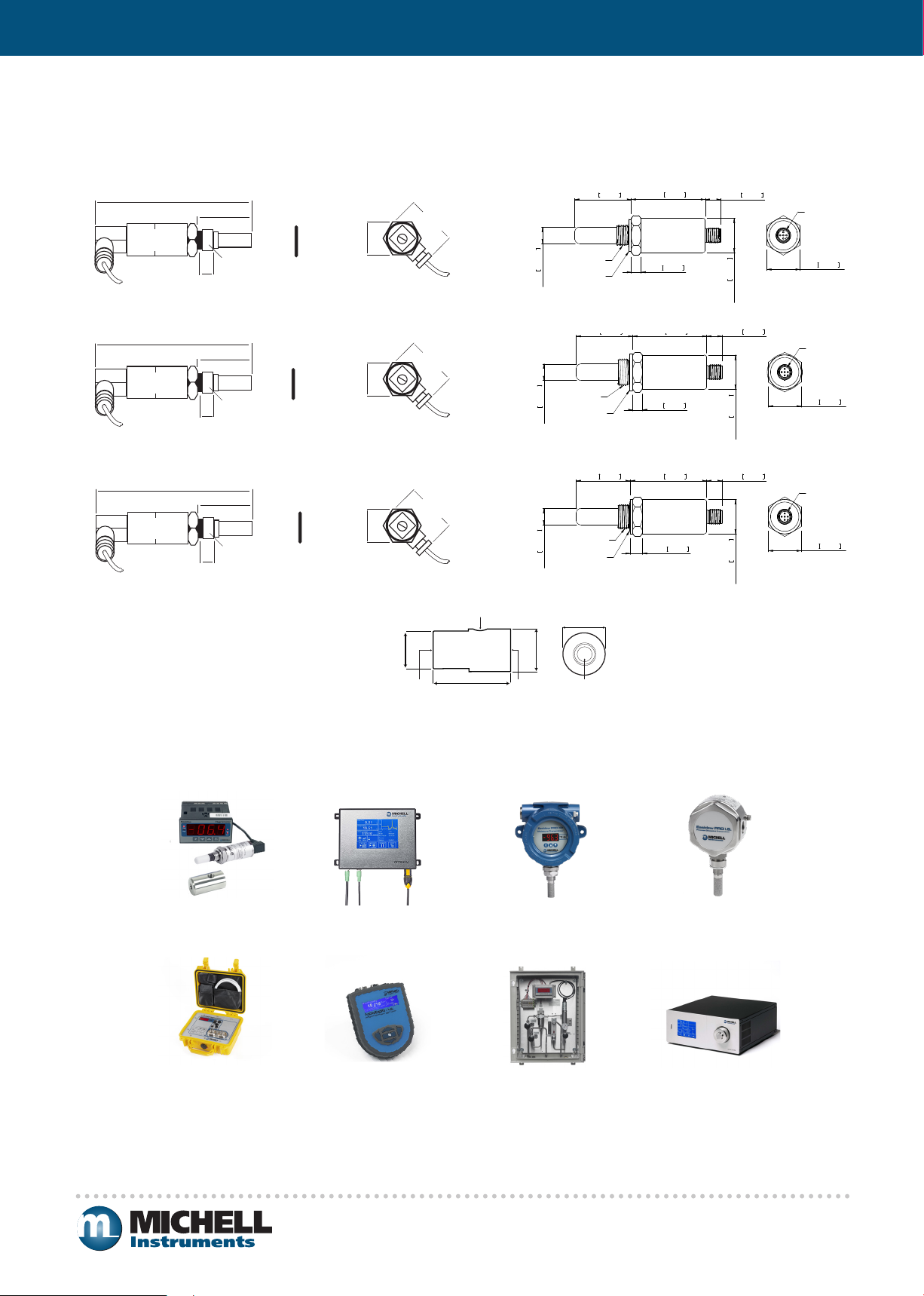

Dew-Point Transmitters

27 A/F

13.0 0.512

46.0 1.811

60.3 2.374

12.7 0.500

8.0 0.315

27.0 1.063

O

5/8" UNF THREAD

BONDED SEAL

M12 5-WAY

A CODED

27.0 1.063 A/F

DIMENSIONS IN mm [INCHES]

13.0 0.512

46.0 1.811 60.3 2.374 12.7 0.500

8.0 0.315

27.0 1.063

O

G1/2 THREAD

BONDED SEAL

M12 5-WAY

A CODED

27.0 1.063 A/F

DIMENSIONS IN mm [INCHES]

13.0 0.512

44.0 1.732 62.3 2.453 12.7 0.500

10.0 0.394

27.0 1.063

O

3/4" UNF THREAD

O-RING SEAL

M12 5-WAY

A CODED

27.0 1.063 A/F

DIMENSIONS IN mm [INCHES]

Easidew Transmitters

Product Dimensions

Easidew & Easidew I.S. Easidew M12

5/8” Bonded Seal

ø25.4 x 2mm

(ø1 x 0.07”)

27mm

(1.06”)

A/F

45mm

(1.77”)

10mm

(0.39”)

132mm

ø27mm

(1.06”)

(5.19”)

10mm

(0.39”)

46mm

(1.81”)

5/8” UNF

46mm

(1.81”)

G1/2” BSP

46mm

(1.81”)

3/4” UNF

G1/2” BSP Bonded Seal

ø28.65 x 2.61mm

(ø1.12 x 0.10”)

3/4” O-Ring

ø18.72 x 2.62mm

(ø0.75 x 0.09”)

10mm

(0.39”)

10mm

(0.39”)

132mm

ø27mm

(1.06”)

132mm

ø27mm

(1.06”)

(5.19”)

(5.19”)

10mm

(0.39”)

10mm

(0.39”)

Related Process Products

27mm

(1.06”)

A/F

27mm

(1.06”)

A/F

45mm

(1.77”)

45mm

(1.77”)

1/8” NPT

30mm

1/8” NPT

(see accessories and spare parts)

55.2mm

Optional Sample Block

5/8”-18 UNF

3/4” UNF

G1/2” BSP

ø30mm

5/8”-18 UNF

3/4” UNF

G1/2” BSP

Michell Instruments 48 Lancaster Way Business Park, Ely, Cambridgeshire, CB6 3NW

Tel: +44 (0) 1353 658000, Fax: +44 (0) 1353 658199, Email: info@michell.com, Web: www.michell.com/uk

Michell Instruments adopts a continuous development programme which sometimes necessitates specication changes without notice.

Issue no: Easidew Transmitters_ 97554_V3_UK_0220

Easidew Online

Dew-Point Hygrometer

MDM50

Portable Hygrometer

Chilled Mirror Hygrometer

MDM300 I.S.

Dew-Point Hygrometer

Optidew 501

Easidew PRO X.P.

Explosion Proof Moisture

Transmitter

ES20

Compact Sampling System

Easidew PRO I.S.

Intrincically Safe Moisture

Transmitter

S8000 RS

High Precision Chilled

Mirror Hygrometer

© 2020 Michell Instruments

Loading...

Loading...